Iat DAEWOO LACETTI 2004 Service Repair Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 1950 of 2643

POWER STEERING GEAR 6C – 33

DAEWOO V–121 BL4

GENERAL DESCRIPTION

AND SYSTEM OPERATION

POWER RACK AND PINION

The power rack and pinion steering system has a rotary

control valve that directs hydraulic fluid coming from the

hydraulic pump to one side or the other side of the rack pis-

ton. The integral rack piston is attached to the rack. The

rack piston converts hydraulic pressure to a linear force

that moves the rack left or right. That force is then trans-

mitted through the tie rods to the steering knuckles, which

turn the wheels.

If power rack and pinion steering is not available, manual

rack and pinion control is used; however, with this system,

more steering effort is required. The movement of the

steering wheel is transferred to the pinion. The rotary

movement of the pinion is then transferred through the pin-

ion threads, which mesh with teeth on the rack, thereby

causing the rack to move in a linear direction.

A vane–type of hydraulic pump provides hydraulic pres-

sure for both steering systems.

SPEED SENSITIVE POWER

STEERING SYSTEM

The speed sensitive power steering (SSPS) system varies

the driver effort required to steer as the vehicle speed

changes. At low speeds, the system provides maximum

power assist for easy turning and parking maneuvers. At

higher speeds, the steering power is reduced to provide

the driver with firmer steering and directional stability. The

SSPS system accomplishes this by reducing the amount

of power steering fluid flow from the power steering pump

to the power steering gear as the vehicle speed increases.

When the vehicle is stationary, the SSPS system provides

maximum fluid flow to the steering gear. As the vehicle

speed increases, the fluid flow to the steering gear is de-

creased.

Control Module

The SSPS control module processes the vehicle speed in-

formation from the engine control module (ECM) and uses

the steering wheel rotation sensor to provide a control sig-

nal to the electronic variable orifice (EVO) actuator located

on the power steering pump.

Electronic Variable Orifice (EVO) Actuator

The electronic variable orifice (EVO) actuator is located on

the power steering pump and contains a solenoid– oper-

ated pintle valve. Fluid leaving the pump passes through

an orifice in the actuator tip. When the EVO actuator is

powered by the SSPS control module, the pintle moves

into the orifice and reduces the power steering fluid flow.As the vehicle speed increases, current from the SSPS

control module increases, and the pintle blocks more and

more of the orifice.

Steering Wheel Rotation Sensor

The steering wheel rotation sensor is located at the end of

the steering column housing and is used to send a signal

to the controller when abrupt or evasive steering maneu-

vers are needed.

Power Steering Pressure Hose

SSPS vehicles have a specific pressure hose assembly

which includes an in–line check valve in the rack and pin-

ion assembly. This reduces the amount of steering wheel

”kick” when driving over irregular road surfaces while oper-

ating at speeds with reduced flow rate and pressure.

Power Rack and Pinion

Except for differences in valve machining, the design of

the SSPS power rack and pinion assembly is the same as

for the a non–SSPS system. The steering wheel move-

ment is transferred to the pinion via the intermediate shaft.

The pinion moves the rack left or right through meshing the

pinion and the rack teeth. The force is then transmitted

through the tie rods and steering knuckle to steer the

wheels.

The power rack and pinion steering system has a rotary

control valve which directs the hydraulic fluid from the

power steering pump to one side or the other side of the

rack piston. The piston is attached to the rack and uses hy-

draulic pressure to move the rack left or right. The rotary

control valve regulates the degree of assist by responding

to the driver’s torque input.

If hydraulic assist is not available, manual control is main-

tained. However, under this condition, more steering effort

is required.

Power Steering Pump

The standard vane–type pump, which provides hydraulic

pressure for the system, incorporates a special discharge

fitting to hold the EVO actuator.

System Operation

System operation originates with input from the vehicle

speed sensor via the engine control module to the SSPS

control module. The SSPS control module sends a signal

to the SSPS actuator to vary the rate of fluid flow output

by the power steering pump.

Circuit Operation

The SSPS system uses inputs from the speed sensor and

steering wheel rotation sensor to the SSPS controller to

determine the desired amount of power steering assist.

The SSPS control module constantly compares the

amount of current flowing through the EVO actuator to the

desired current it has calculated. The EVO actuator has a

pintle that moves in and out of an orifice, regulating power

Page 1964 of 2643

6E – 10ISTEERING WHEEL AND COLUMN

DAEWOO V–121 BL4

3. Install the upper and the lower steering column cov-

er panels. Install the upper and the lower steering

column cover panel screws.

Tighten

Tighten the upper and the lower steering column cov-

er panel screws to 2.5 NSm (22 lb–in).

4. Connect the negative battery cable.

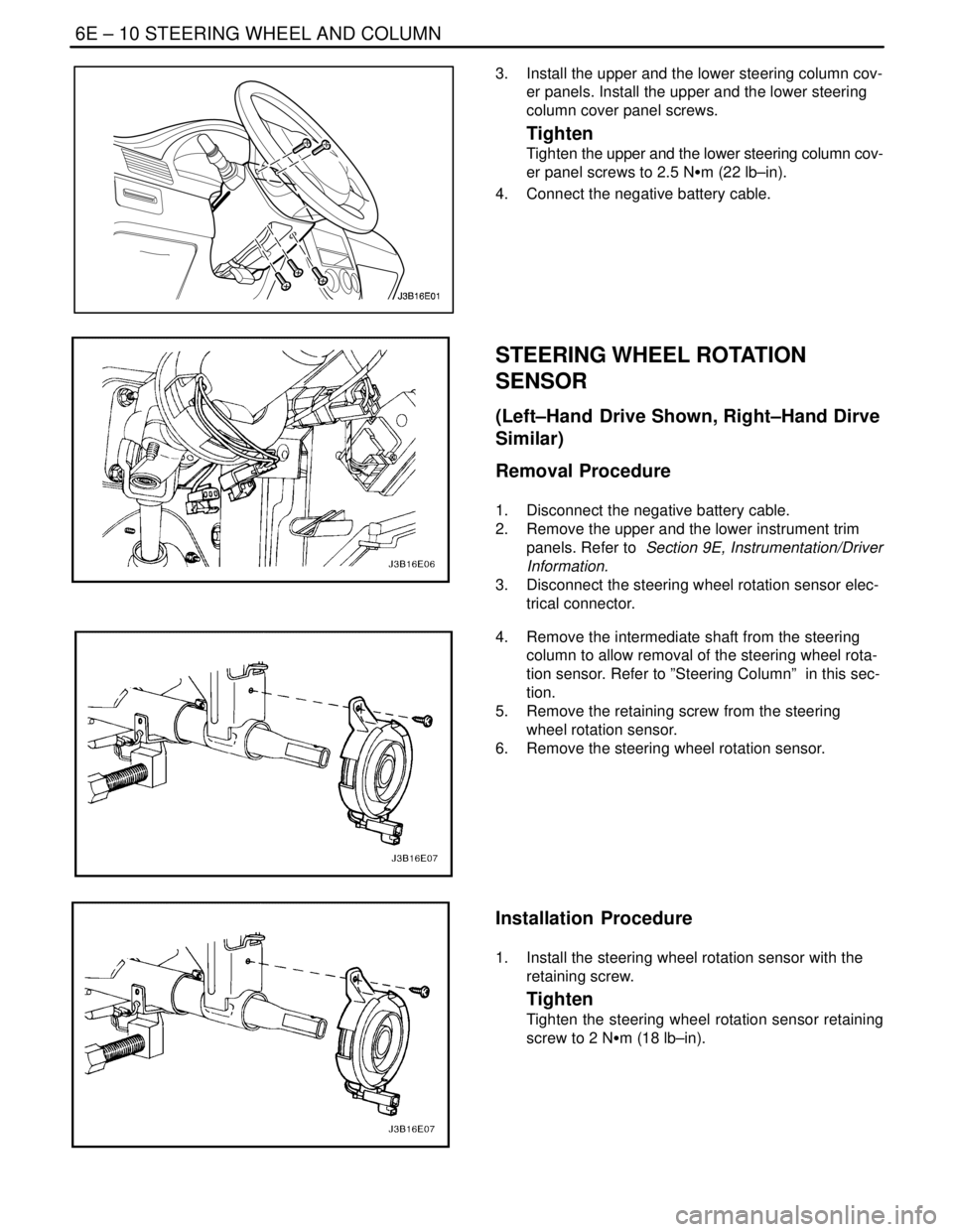

STEERING WHEEL ROTATION

SENSOR

(Left–Hand Drive Shown, Right–Hand Dirve

Similar)

Removal Procedure

1. Disconnect the negative battery cable.

2. Remove the upper and the lower instrument trim

panels. Refer to Section 9E, Instrumentation/Driver

Information.

3. Disconnect the steering wheel rotation sensor elec-

trical connector.

4. Remove the intermediate shaft from the steering

column to allow removal of the steering wheel rota-

tion sensor. Refer to ”Steering Column” in this sec-

tion.

5. Remove the retaining screw from the steering

wheel rotation sensor.

6. Remove the steering wheel rotation sensor.

Installation Procedure

1. Install the steering wheel rotation sensor with the

retaining screw.

Tighten

Tighten the steering wheel rotation sensor retaining

screw to 2 NSm (18 lb–in).

Page 1965 of 2643

STEERING WHEEL AND COLUMN 6E – 11

DAEWOO V–121 BL4

2. Install the intermediate shaft onto the steering col-

umn. Refer to ”Steering Column” in this section.

3. Connect the steering wheel rotation sensor electri-

cal connector.

4. Install the upper and the lower instrument trim pan-

els. Refer to Section 9E, Instrumentation/Driver

Information.

5. Connect the negative battery cable.

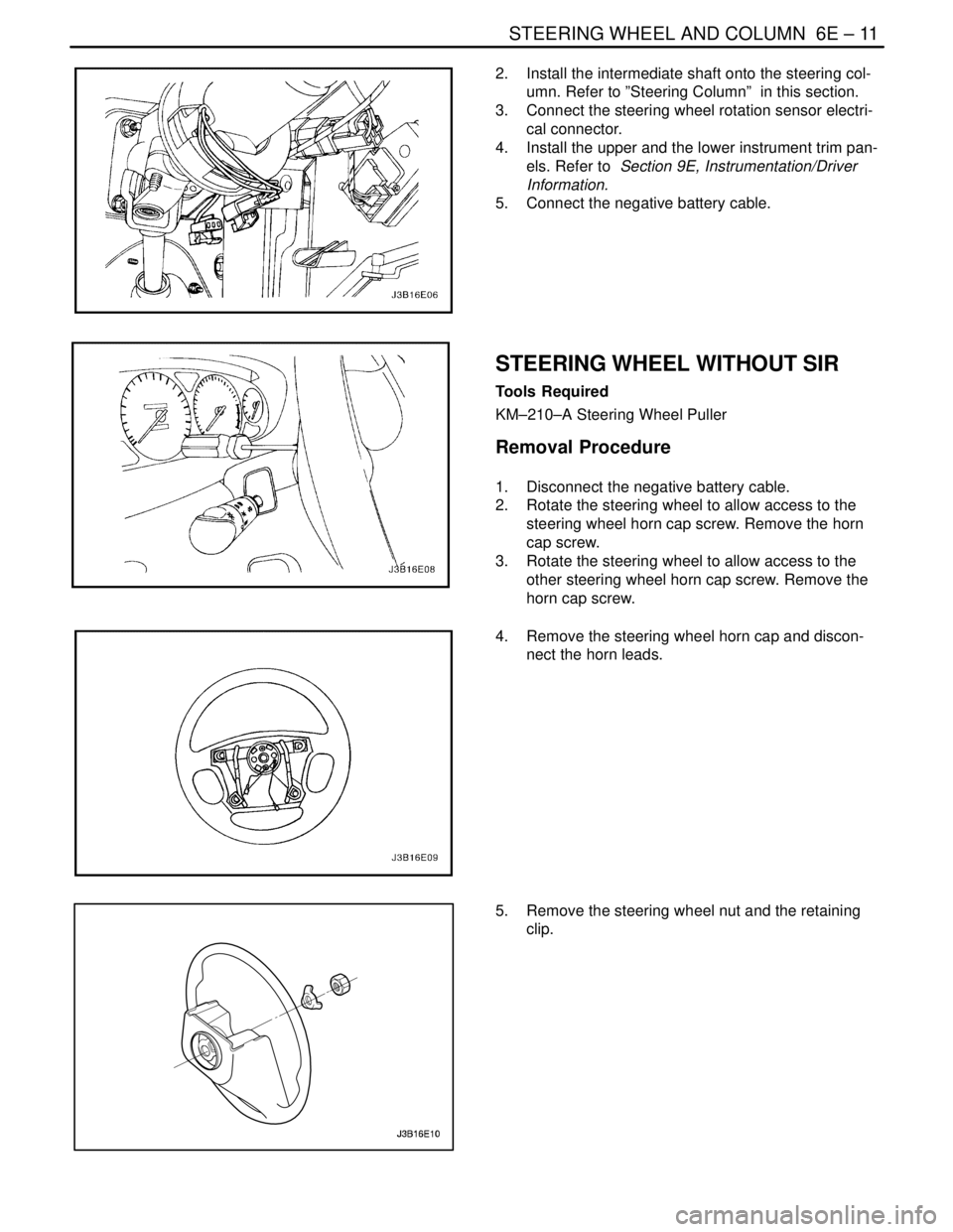

STEERING WHEEL WITHOUT SIR

Tools Required

KM–210–A Steering Wheel Puller

Removal Procedure

1. Disconnect the negative battery cable.

2. Rotate the steering wheel to allow access to the

steering wheel horn cap screw. Remove the horn

cap screw.

3. Rotate the steering wheel to allow access to the

other steering wheel horn cap screw. Remove the

horn cap screw.

4. Remove the steering wheel horn cap and discon-

nect the horn leads.

5. Remove the steering wheel nut and the retaining

clip.

Page 1970 of 2643

6E – 16ISTEERING WHEEL AND COLUMN

DAEWOO V–121 BL4

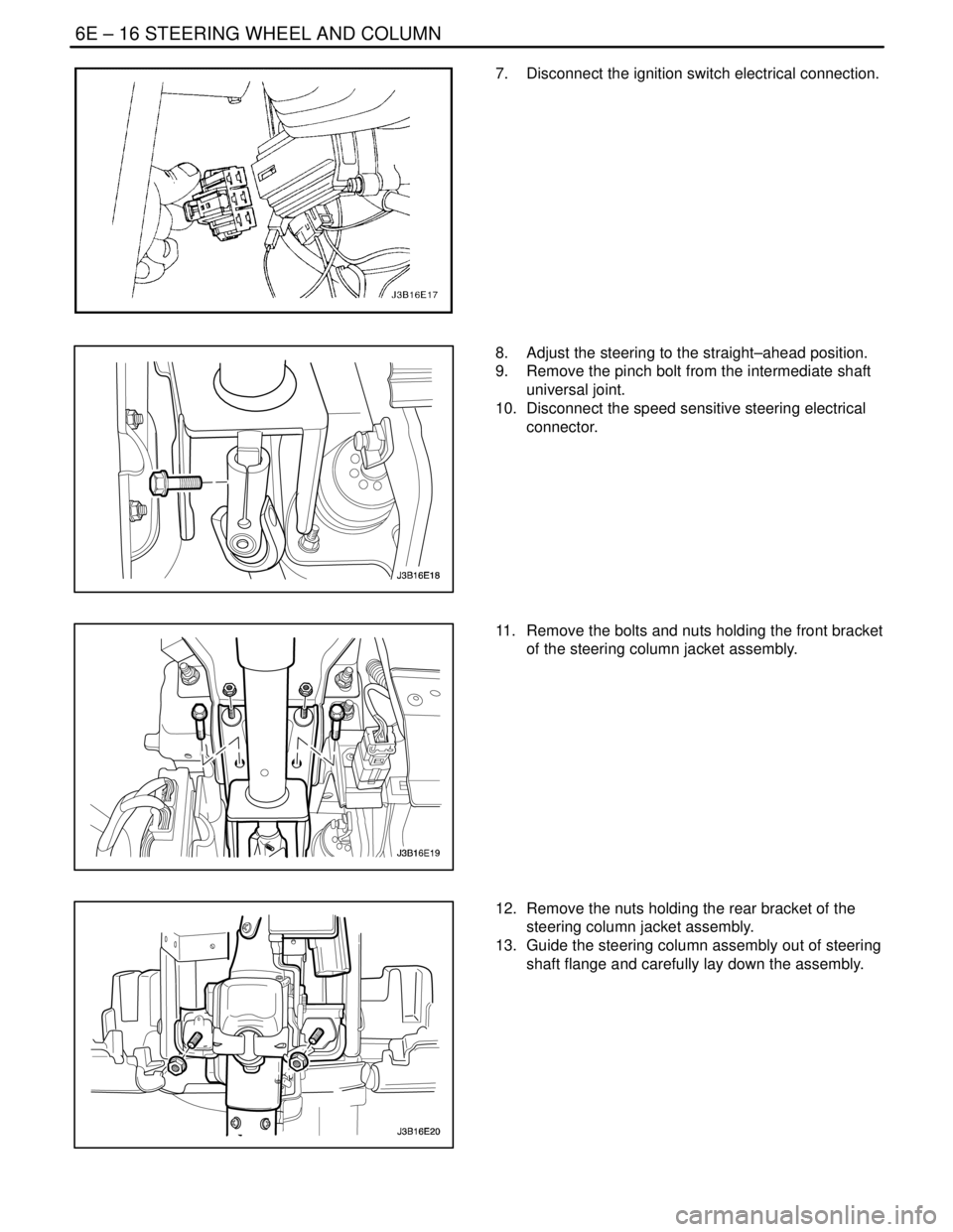

7. Disconnect the ignition switch electrical connection.

8. Adjust the steering to the straight–ahead position.

9. Remove the pinch bolt from the intermediate shaft

universal joint.

10. Disconnect the speed sensitive steering electrical

connector.

11. Remove the bolts and nuts holding the front bracket

of the steering column jacket assembly.

12. Remove the nuts holding the rear bracket of the

steering column jacket assembly.

13. Guide the steering column assembly out of steering

shaft flange and carefully lay down the assembly.

Page 2010 of 2643

7B – 8IMANUAL CONTROL HEATING, VENTILATION AND AIR CONDITIONING SYSTEM

DAEWOO V–121 BL4

DIAGNOSIS

GENERAL DIAGNOSIS

TESTING THE REFRIGERANT

SYSTEM

If you suspect a problem in the refrigerant system, check

for the following conditions:

1. Check the outer surfaces of the radiator and the

condenser cores to be sure that the airflow is not

blocked by dirt, leaves, or other foreign material.

Check between the condenser and the radiator, as

well as all outer surfaces.

2. Check for restrictions or kinks in the condenser

core, the hoses, and the tubes.

3. Check the operation of the blower fan.

4. Check all the air ducts for leaks or restrictions. Low

airflow rate may indicate a restricted evaporator

core.

5. Check for slippage of the compressor clutch.

6. Check the drive belt tension.

INSUFFICIENT COOLING ”QUICK

CHECK” PROCEDURE

Perform the following ”hand–feel” procedure to get a quick

idea of whether the A/C system has the proper charge of

Refrigerant–134a. The air temperature must be above

21°C (70°F) for most models.

1. Warm up engine. Run the engine at idle.

2. Open the hood and all the doors.

3. Turn the A/C switch ON.

4. Set the temperature control to the full cold position.

5. Set the blower speed switch on the maximum

speed setting.

6. ”Hand–feel” the temperature of the evaporator out-

let pipe. The pipe should be cold.

7. Check for other problems. Refer to ”Testing the Re-

frigerant System” in this section.

8. Leak check the system. Refer to ”Leak Testing the

Refrigerant System” in this section. If you find a

leak, discharge the system and repair the leak as

required. After completing the repair, evacuate the

system and charge it.

9. If there is no leak, refer to ”Insufficient Cooling

Diagnosis” in this section.

Page 2018 of 2643

7B – 16IMANUAL CONTROL HEATING, VENTILATION AND AIR CONDITIONING SYSTEM

DAEWOO V–121 BL4

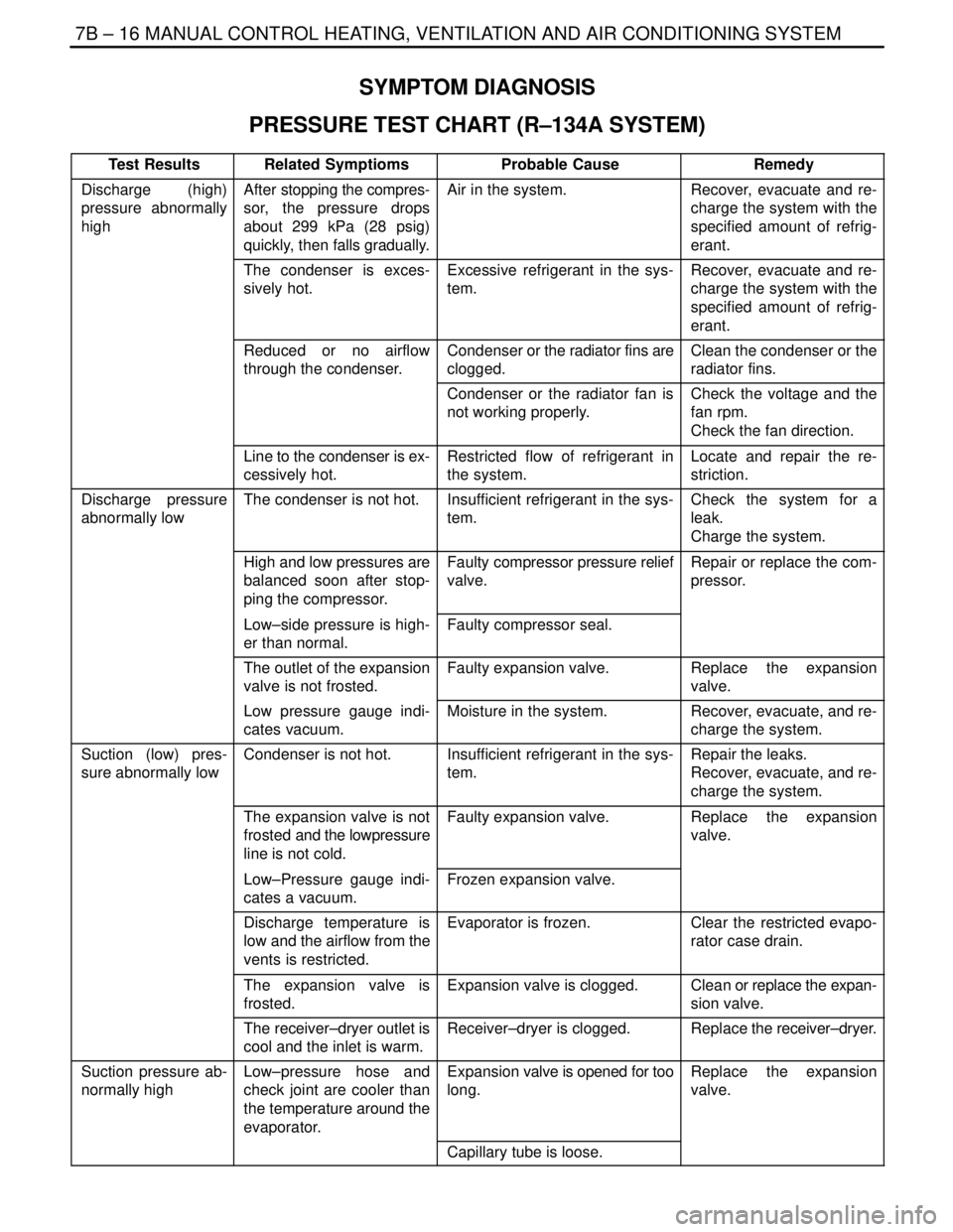

SYMPTOM DIAGNOSIS

PRESSURE TEST CHART (R–134A SYSTEM)

Test ResultsRelated SymptiomsProbable CauseRemedy

Discharge (high)

pressure abnormally

highAfter stopping the compres-

sor, the pressure drops

about 299 kPa (28 psig)

quickly, then falls gradually.Air in the system.Recover, evacuate and re-

charge the system with the

specified amount of refrig-

erant.

The condenser is exces-

sively hot.Excessive refrigerant in the sys-

tem.Recover, evacuate and re-

charge the system with the

specified amount of refrig-

erant.

Reduced or no airflow

through the condenser.Condenser or the radiator fins are

clogged.Clean the condenser or the

radiator fins.

Condenser or the radiator fan is

not working properly.Check the voltage and the

fan rpm.

Check the fan direction.

Line to the condenser is ex-

cessively hot.Restricted flow of refrigerant in

the system.Locate and repair the re-

striction.

Discharge pressure

abnormally lowThe condenser is not hot.Insufficient refrigerant in the sys-

tem.Check the system for a

leak.

Charge the system.

High and low pressures are

balanced soon after stop-

ping the compressor.Faulty compressor pressure relief

valve.Repair or replace the com-

pressor.

Low–side pressure is high-

er than normal.Faulty compressor seal.

The outlet of the expansion

valve is not frosted.Faulty expansion valve.Replace the expansion

valve.

Low pressure gauge indi-

cates vacuum.Moisture in the system.Recover, evacuate, and re-

charge the system.

Suction (low) pres-

sure abnormally lowCondenser is not hot.Insufficient refrigerant in the sys-

tem.Repair the leaks.

Recover, evacuate, and re-

charge the system.

The expansion valve is not

frosted and the lowpressure

line is not cold.Faulty expansion valve.Replace the expansion

valve.

Low–Pressure gauge indi-

cates a vacuum.Frozen expansion valve.

Discharge temperature is

low and the airflow from the

vents is restricted.Evaporator is frozen.Clear the restricted evapo-

rator case drain.

The expansion valve is

frosted.Expansion valve is clogged.Clean or replace the expan-

sion valve.

The receiver–dryer outlet is

cool and the inlet is warm.Receiver–dryer is clogged.Replace the receiver–dryer.

Suction pressure ab-

normally highLow–pressure hose and

check joint are cooler than

the temperature around the

evaporator.Expansion valve is opened for too

long.Replace the expansion

valve.

Capillary tube is loose.

Page 2019 of 2643

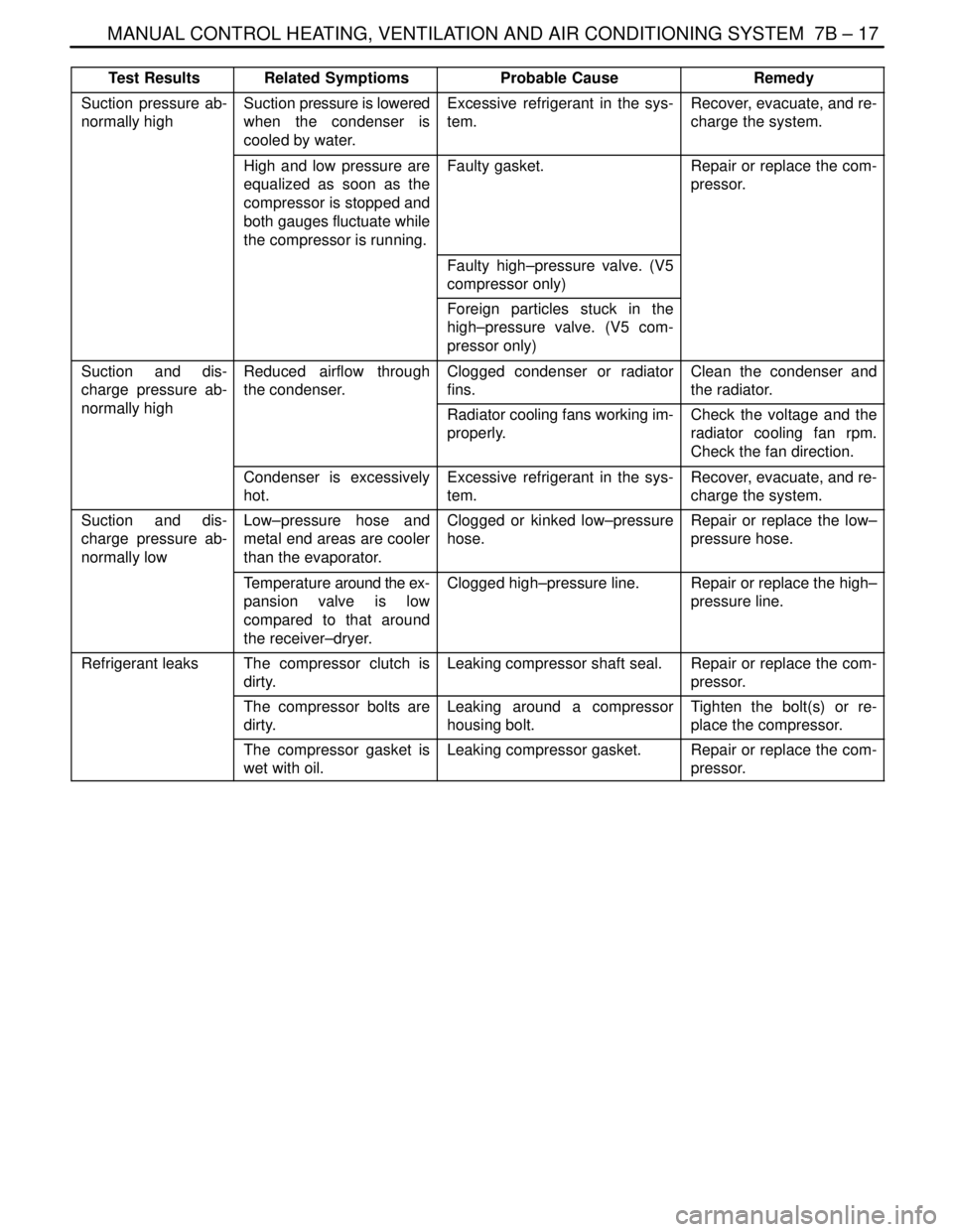

MANUAL CONTROL HEATING, VENTILATION AND AIR CONDITIONING SYSTEM 7B – 17

DAEWOO V–121 BL4

Test ResultsRemedy Probable Cause Related Symptioms

Suction pressure ab-

normally highSuction pressure is lowered

when the condenser is

cooled by water.Excessive refrigerant in the sys-

tem.Recover, evacuate, and re-

charge the system.

High and low pressure are

equalized as soon as the

compressor is stopped and

both gauges fluctuate while

the compressor is running.Faulty gasket.Repair or replace the com-

pressor.

Faulty high–pressure valve. (V5

compressor only)

Foreign particles stuck in the

high–pressure valve. (V5 com-

pressor only)

Suction and dis-

charge pressure ab-

ll hi h

Reduced airflow through

the condenser.Clogged condenser or radiator

fins.Clean the condenser and

the radiator.

g

normally highRadiator cooling fans working im-

properly.Check the voltage and the

radiator cooling fan rpm.

Check the fan direction.

Condenser is excessively

hot.Excessive refrigerant in the sys-

tem.Recover, evacuate, and re-

charge the system.

Suction and dis-

charge pressure ab-

normally lowLow–pressure hose and

metal end areas are cooler

than the evaporator.Clogged or kinked low–pressure

hose.Repair or replace the low–

pressure hose.

Temperature around the ex-

pansion valve is low

compared to that around

the receiver–dryer.Clogged high–pressure line.Repair or replace the high–

pressure line.

Refrigerant leaksThe compressor clutch is

dirty.Leaking compressor shaft seal.Repair or replace the com-

pressor.

The compressor bolts are

dirty.Leaking around a compressor

housing bolt.Tighten the bolt(s) or re-

place the compressor.

The compressor gasket is

wet with oil.Leaking compressor gasket.Repair or replace the com-

pressor.

Page 2021 of 2643

MANUAL CONTROL HEATING, VENTILATION AND AIR CONDITIONING SYSTEM 7B – 19

DAEWOO V–121 BL4

MAINTENANCE AND REPAIR

ON–VEHICLE SERVICE

GENERAL A/C SYSTEM SERVICE PROCEDURES

O–RING REPLACEMENT

Important : Even though O–rings may look identical, it is

extremely important that only recommended service re-

placement air conditioning O–rings be used or excessive

leakage of refrigerant may occur.

Important : Always slip the O–ring onto the flange tube to

ensure proper locating and sealing.

Install new Daewoo–approved service replacement air

conditioning (A/C) O–rings whenever a joint or a fitting is

disassembled, except when the O–rings are provided on

new components.

When replacing O–rings on an A/C component or a joint

connection, the fitting design should be identified to en-

sure installation of the correct air conditioning service re-

placement O–ring. Some joint connections and compo-

nents will implement a ”captured” O–ring design fitting that

uses a groove to retain the O–ring. Others do not have a

groove and use a ”non–captured” or ”standard” O–ring.

Assembly and tightening procedures are the same for

both designs, but the O–rings are different.

Notice : Before installation, verify that both O–rings and

fittings have not been nicked or deformed. Deformed or

nicked parts must be replaced. Failure to use the proper

service replacement parts and procedures may result in

excessive refrigerant leakage.

HANDLING REFRIGERANT

CAUTION : Always work in a well–ventilated area and

avoid breathing any refrigerant fumes. If you have dif-

ficulty with breathing, seek medical attention immedi-

ately. If refrigerant comes in contact with any part of

your body, flush the exposed area with water. If a rash

or pain develops, seek medical attention.

Air conditioning systems contain refrigerant. This is a

chemical mixture which requires special handling proce-

dures to avoid personal injury.

Always wear goggles and wrap a clean cloth around the

fittings, the valves and the connections when performing

work that involves opening the refrigerant system. Do not

weld or steam clean on or near any vehicle–installed air

conditioning lines or components.

All refrigerant drums are shipped with a heavy metal screw

cap. The purpose of the cap is to protect the valve and the

safety plug from damage. It is good practice to replace the

cap after each use of the drum.If it is necessary to transport or carry any container of re-

frigerant in a vehicle, do not carry it in the passenger

compartment.

HANDLING OF REFRIGERANT LINES

AND FITTINGS

Notice : Using too low or too high torque when tightening

a fitting can result in loose joints or deformed joint parts.

Both conditions can result in refrigerant leakage.

S Keep all metal tubing lines free of dents or kinks.

Any line restrictions will cause the loss of system

capacity.

S Never bend a flexible hose line to a radius of less

than four times the diameter of the hose.

S Never allow a flexible hose line to come within 65

mm (2–1/2 inches) of the exhaust manifold.

S Inspect flexible hose lines regularly for leaks or

brittleness.

S Replace flexible hose lines with new lines if you find

signs of deterioration or leaking.

S Discharge all refrigerant of the refrigeration system

before disconnecting any fitting in the refrigeration

system.

S Proceed very cautiously regardless of the gauge

readings.

CAUTION : Keep your face and your hands away from

the fitting so that you will not be injured if there hap-

pens to be liquid refrigerant in the line.

S Open the fittings very slowly.

S If you notice pressure when you loosen a fitting,

allow the pressure to bleed off as described under

”Discharging, Adding Oil, Evacuating, and Charging

Procedures for A/C System” in this section.

S Cap or tape any refrigerant line immediately after it

is opened. This will prevent the entrance of mois-

ture and dirt, which can cause internal compressor

wear or plugged lines in the condenser, the evapo-

rator core, the expansion valve, or the compressor

inlet screens.

Important : Use two proper wrenches to connect the O–

ring fittings.

S Back up the opposing fitting to prevent distortion of

the connecting lines or the components.

S Back up both the swagged fitting on the flexible

hose connections and the coupling to which it is

attached with two wrenches to prevent turning the

fitting and damaging the ground seat.

S Keep the O–rings and the seats in perfect condi-

tion. A burr or a piece of dirt may cause a refriger-

ant leak.

Page 2053 of 2643

MANUAL CONTROL HEATING, VENTILATION AND AIR CONDITIONING SYSTEM 7B – 51

DAEWOO V–121 BL4

GENERAL DESCRIPTION

AND SYSTEM OPERATION

GENERAL INFORMATION

THE V5 A/C SYSTEM

The V5 variable displacement compressor along with the

thermal expansion valve on the evaporator, constitutes a

largely self–regulating system. There is no pressure cycl-

ing switch, no high–pressure cut–off switch and no low–

pressure cut–off switch. The compressor clutch is con-

trolled by the electronic control module (ECM), which

receives data from various engine systems and from a

pressure transducer located in the high–pressure refriger-

ant pipe. In normal operation, the clutch is engaged contin-

uously. Should one of the monitored conditions become

abnormal, the ECM will disengage the compressor clutch

until normal operation is restored. These conditions in-

clude the following:

S Wide–open throttle.

S High engine coolant temperature.

S High engine RPM.

S Refrigerant low pressure.

S Refrigerant high pressure.

The compressor clutch will remain disengaged until nor-

mal operation is established.

SYSTEM

COMPONENTS–FUNCTIONAL

Compressor

All compressors are belt–driven from the engine crank-

shaft through the compressor clutch pulley. The compres-

sor pulley rotates without driving the compressor shaft un-

til an electromagnetic clutch coil is energized. When

voltage is applied to energize the clutch coil, the clutch

plate and hub assembly is drawn rearward toward the

pulley. The magnetic force locks the clutch plate and

pulley together as one unit to drive the compressor shaft.

As the compressor shaft is driven, it compresses the low–

pressure refrigerant vapor from the evaporator into a

high–pressure, high–temperature vapor. The refrigerant

oil which is used to lubricate the compressor is carried with

the refrigerant. Refer to ”V5 Air Conditioning Compressor

Overhaul” in this section.

Condenser Core

The condenser assembly in front of the radiator consists

of coils which carry the refrigerant, and cooling fins that

provide the rapid transfer of heat. The air passing through

the condenser cools the high–pressure refrigerant vapor

and causes it to condense into a liquid.

Expansion Valve

The expansion valve is located with the evaporator core,

on the front passenger side fire wall.

The expansion valve can fail in three different positions:

open, closed, or restricted.

An expansion valve that fails in the open position will result

in a noisy A/C compressor or no cooling. The cause can

be a broken spring, a broken ball, or excessive moisture

in the A/C system. If the spring or the ball are found to be

defective, replace the expansion valve. If excessive mois-

ture is found in the A/C system, recycle the refrigerant.

An expansion valve that fails in the closed position will re-

sult in low suction pressure and no cooling. This may be

caused by a failed power dome or excessive moisture in

the A/C system. If the power dome on the expansion valve

is found to be defective, replace the expansion valve. If ex-

cessive moisture is found in the A/C system, recycle the

refrigerant.

A restricted expansion valve will result in low suction pres-

sure and no cooling. This may be caused by debris in the

refrigerant system. If debris is believed to be the cause, re-

cycle the refrigerant, replace the expansion valve, and re-

place the receiver–dryer.

Evaporator Core

The evaporator is a device which cools and dehumidifies

the air before it enters the vehicle. High–pressure liquid re-

frigerant flows through the expansion tube orifice and be-

comes a low–pressure gas in the evaporator. The heat in

the air passing through the evaporator core is transferred

to the cooler surface of the core, which cools the air. As the

process of heat transfer from the air to the evaporator core

surface is taking place, any moisture or humidity in the air

condenses on the outside surface of the evaporator core

and is drained off as water.

Receiver–Dryer

The sealed receiver–dryer assembly is connected to the

condenser outlet pipe. It acts as a refrigerant storing con-

tainer, receiving liquid, vapor, and refrigerant oil from the

evaporator.

At the bottom of the receiver–dryer is the desiccant, which

acts as a drying agent for the moisture that may have en-

tered the system. An oil bleed hole is located near the bot-

tom of the receiver–dryer outlet pipe to provide an oil re-

turn path to the compressor. The receiver–dryer is

serviceable only as an assembly.

Heater Core

The heater core heats the air before it enters the vehicle.

Engine coolant is circulated through the core to heat the

outside air passing over the fins of the core. The core is

functional at all times and may be used to temper condi-

tioned air in the A/C mode as well as in the heat or the vent

modes.

Page 2073 of 2643

7D – 18IAUTOMATIC TEMPERATURE CONTROL HEATING, VENTILATION, AND AIR CONDITIONING SYSTEM

DAEWOO V–121 BL4

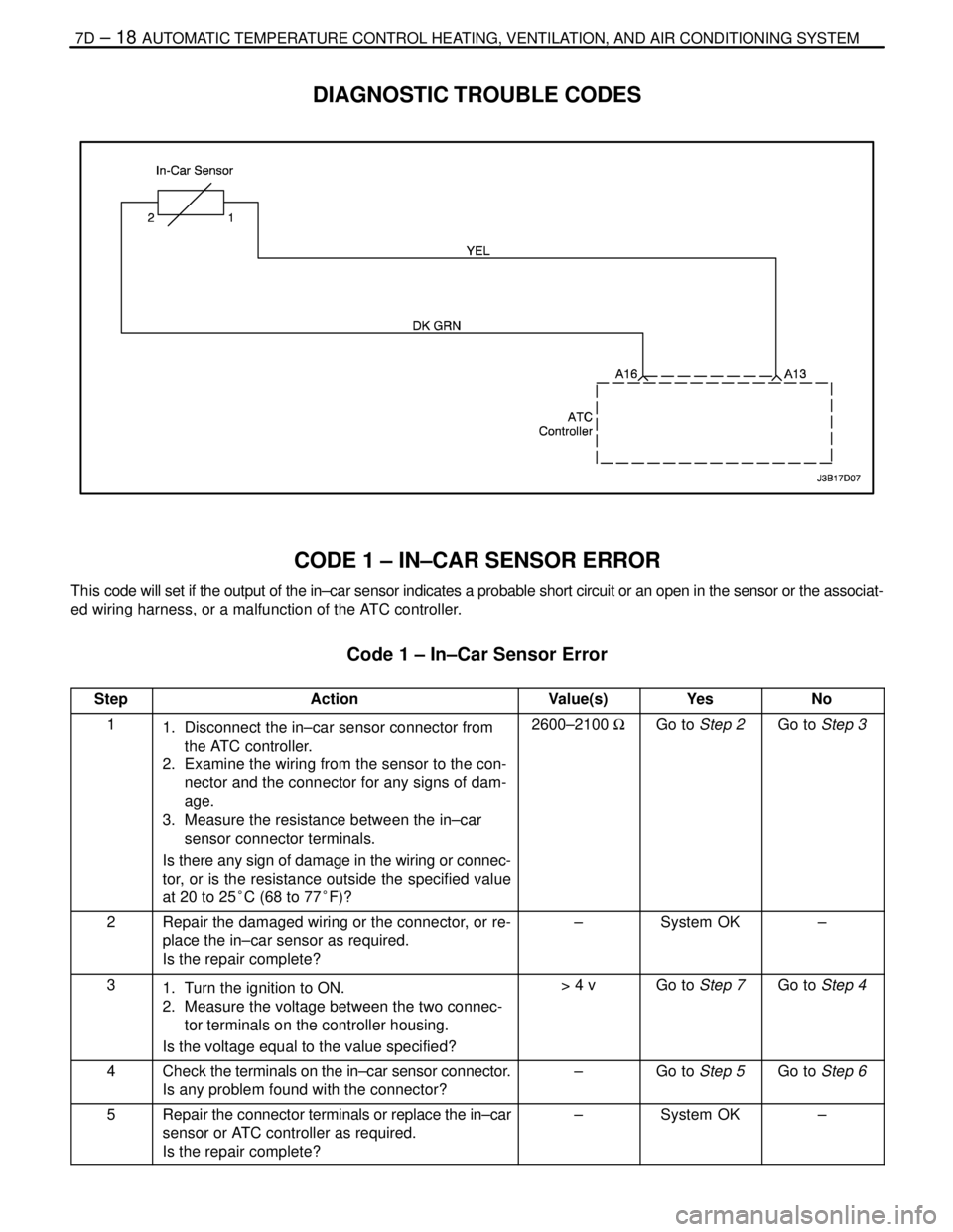

DIAGNOSTIC TROUBLE CODES

CODE 1 – IN–CAR SENSOR ERROR

This code will set if the output of the in–car sensor indicates a probable short circuit or an open in the sensor or the associat-

ed wiring harness, or a malfunction of the ATC controller.

Code 1 – In–Car Sensor Error

StepActionValue(s)YesNo

11. Disconnect the in–car sensor connector from

the ATC controller.

2. Examine the wiring from the sensor to the con-

nector and the connector for any signs of dam-

age.

3. Measure the resistance between the in–car

sensor connector terminals.

Is there any sign of damage in the wiring or connec-

tor, or is the resistance outside the specified value

at 20 to 25°C (68 to 77°F)?2600–2100 ΩGo to Step 2Go to Step 3

2Repair the damaged wiring or the connector, or re-

place the in–car sensor as required.

Is the repair complete?–System OK–

31. Turn the ignition to ON.

2. Measure the voltage between the two connec-

tor terminals on the controller housing.

Is the voltage equal to the value specified?> 4 vGo to Step 7Go to Step 4

4Check the terminals on the in–car sensor connector.

Is any problem found with the connector?–Go to Step 5Go to Step 6

5Repair the connector terminals or replace the in–car

sensor or ATC controller as required.

Is the repair complete?–System OK–