9–14 SEALING, CAULKING AND DEADNER NUBIRA/LACETTI

2. DEADNER

2–1. GENERAL DESCRIPTION

.

Deadner is properly designed and applied for reduce the

vibration and noise. Also, it plays in maintaining the

structural rigidity of the panel.

.

2–2. REPAIR PROCEDURE

.

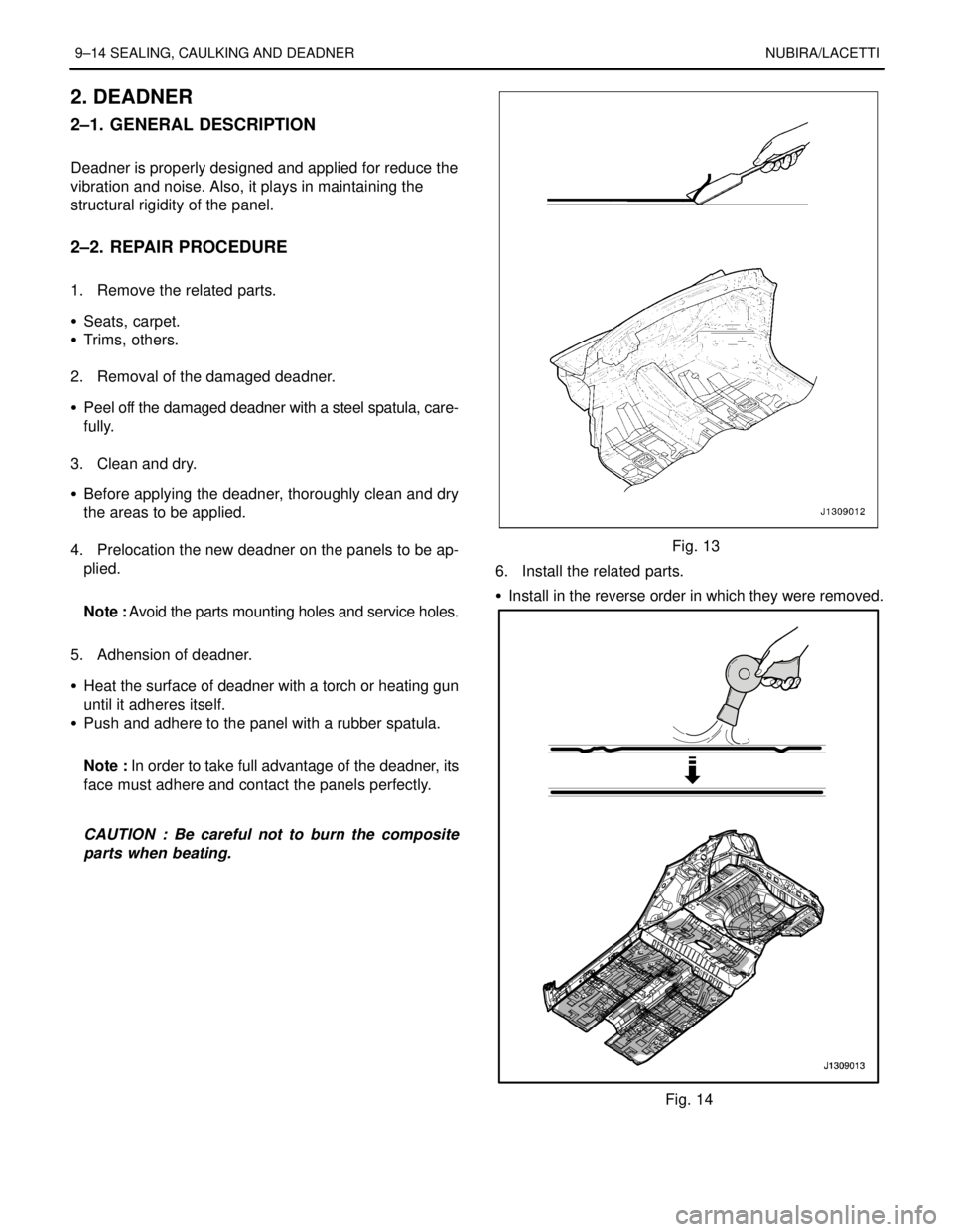

1. Remove the related parts.

S Seats, carpet.

S Trims, others.

.

2. Removal of the damaged deadner.

S Peel off the damaged deadner with a steel spatula, care-

fully.

.

3. Clean and dry.

S Before applying the deadner, thoroughly clean and dry

the areas to be applied.

.

4. Prelocation the new deadner on the panels to be ap-

plied.

.

Note : Avoid the parts mounting holes and service holes.

.

5. Adhension of deadner.

S Heat the surface of deadner with a torch or heating gun

until it adheres itself.

S Push and adhere to the panel with a rubber spatula.

.

Note : In order to take full advantage of the deadner, its

face must adhere and contact the panels perfectly.

.

CAUTION : Be careful not to burn the composite

parts when beating.

Fig. 13

6. Install the related parts.

S Install in the reverse order in which they were removed.

Fig. 14

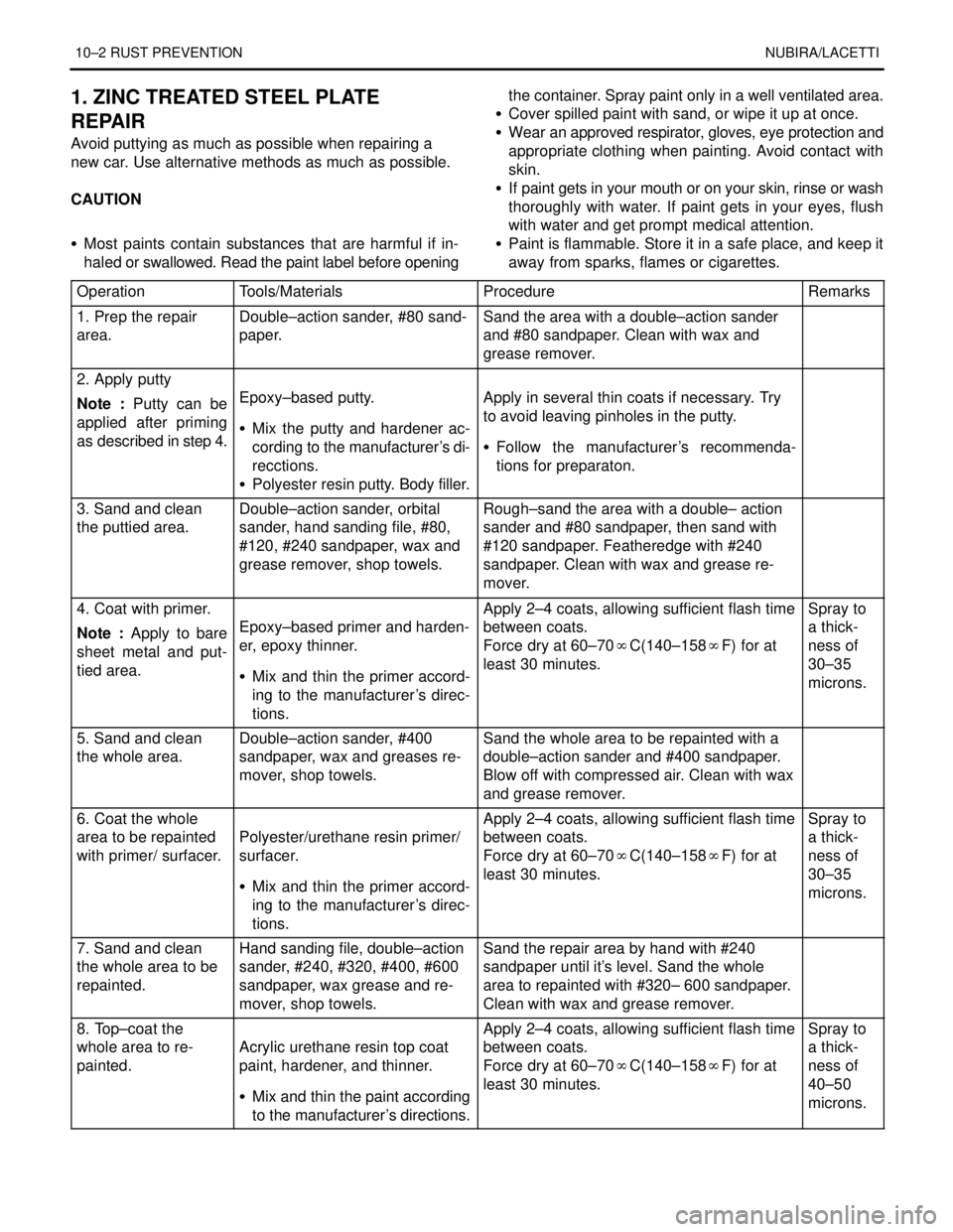

NUBIRA/LACETTIRUST PREVENTION 10–1

SECTION 10

RUST PREVENTION

CONTENTS

1. ZINC TREATED STEEL PLATE REPAIR 10 – 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. RUST PREVENTIVE PROCEDURE 10 – 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.GENERAL INFORMATION10–3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.AREA COVERED BY ANTI–RUST AGENTS 10–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.UNDERCOATING DIAGRAM10–6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10–2 RUST PREVENTIONNUBIRA/LACETTI

1. ZINC TREATED STEEL PLATE

REPAIR

Avoid puttying as much as possible when repairing a

new car. Use alternative methods as much as possible.

.

CAUTION

S Most paints contain substances that are harmful if in-

haled or swallowed. Read the paint label before openingthe container. Spray paint only in a well ventilated area.

S Cover spilled paint with sand, or wipe it up at once.

S Wear an approved respirator, gloves, eye protection and

appropriate clothing when painting. Avoid contact with

skin.

S If paint gets in your mouth or on your skin, rinse or wash

thoroughly with water. If paint gets in your eyes, flush

with water and get prompt medical attention.

S Paint is flammable. Store it in a safe place, and keep it

away from sparks, flames or cigarettes.

Operation

Tools/MaterialsProcedureRemarks

1. Prep the repair

area.Double–action sander, #80 sand-

paper.Sand the area with a double–action sander

and #80 sandpaper. Clean with wax and

grease remover..

2. Apply putty

Note : Putty can be

applied after priming

as described in step 4.

Epoxy–based putty.

S Mix the putty and hardener ac-

cording to the manufacturer’s di-

recctions.

S Polyester resin putty. Body filler.Apply in several thin coats if necessary. Try

to avoid leaving pinholes in the putty.

S Follow the manufacturer’s recommenda-

tions for preparaton.

.

3. Sand and clean

the puttied area.Double–action sander, orbital

sander, hand sanding file, #80,

#120, #240 sandpaper, wax and

grease remover, shop towels.Rough–sand the area with a double– action

sander and #80 sandpaper, then sand with

#120 sandpaper. Featheredge with #240

sandpaper. Clean with wax and grease re-

mover..

4. Coat with primer.

Note : Apply to bare

sheet metal and put-

tied area.

Epoxy–based primer and harden-

er, epoxy thinner.

S Mix and thin the primer accord-

ing to the manufacturer’s direc-

tions.

Apply 2–4 coats, allowing sufficient flash time

between coats.

Force dry at 60–70�C(140–158�F) for at

least 30 minutes.Spray to

a thick-

ness of

30–35

microns.

5. Sand and clean

the whole area.Double–action sander, #400

sandpaper, wax and greases re-

mover, shop towels.Sand the whole area to be repainted with a

double–action sander and #400 sandpaper.

Blow off with compressed air. Clean with wax

and grease remover..

6. Coat the whole

area to be repainted

with primer/ surfacer.

Polyester/urethane resin primer/

surfacer.

S Mix and thin the primer accord-

ing to the manufacturer’s direc-

tions.

Apply 2–4 coats, allowing sufficient flash time

between coats.

Force dry at 60–70�C(140–158�F) for at

least 30 minutes.Spray to

a thick-

ness of

30–35

microns.

7. Sand and clean

the whole area to be

repainted.Hand sanding file, double–action

sander, #240, #320, #400, #600

sandpaper, wax grease and re-

mover, shop towels.Sand the repair area by hand with #240

sandpaper until it’s level. Sand the whole

area to repainted with #320– 600 sandpaper.

Clean with wax and grease remover..

8. Top–coat the

whole area to re-

painted.

Acrylic urethane resin top coat

paint, hardener, and thinner.

S Mix and thin the paint according

to the manufacturer’s directions.

Apply 2–4 coats, allowing sufficient flash time

between coats.

Force dry at 60–70�C(140–158�F) for at

least 30 minutes.Spray to

a thick-

ness of

40–50

microns.