Rod DAEWOO LACETTI 2004 Service Owner's Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 117 of 2643

1C1 – 74I1.4L/1.6L DOHC ENGINE MECHANICAL

DAEWOO V–121 BL4

56. Install the engine lifting device.

57. Remove the engine from the engine overhaul stand

KM–412.

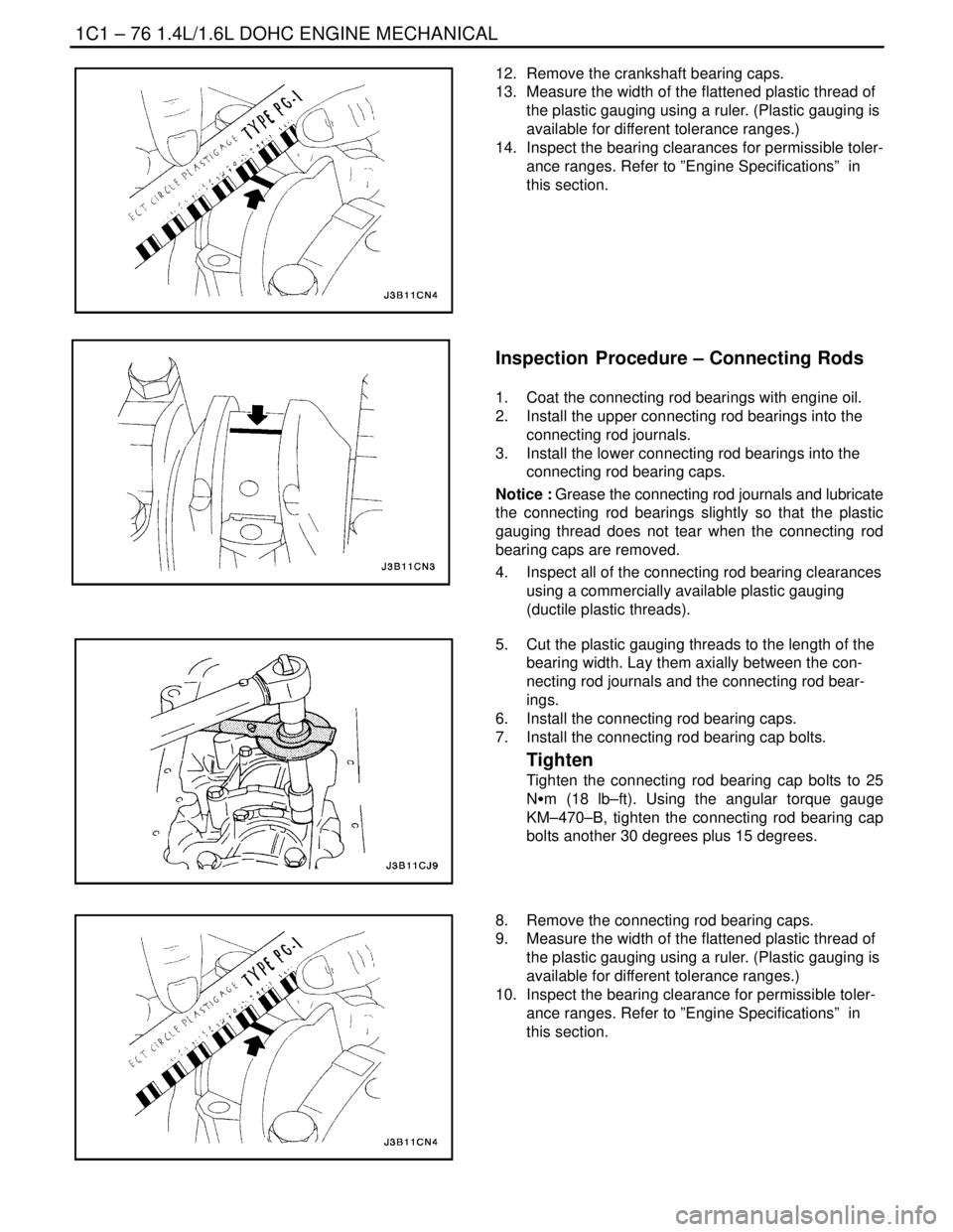

58. Install a new crankshaft rear oil seal using the in-

staller J–36792 or KM–635.

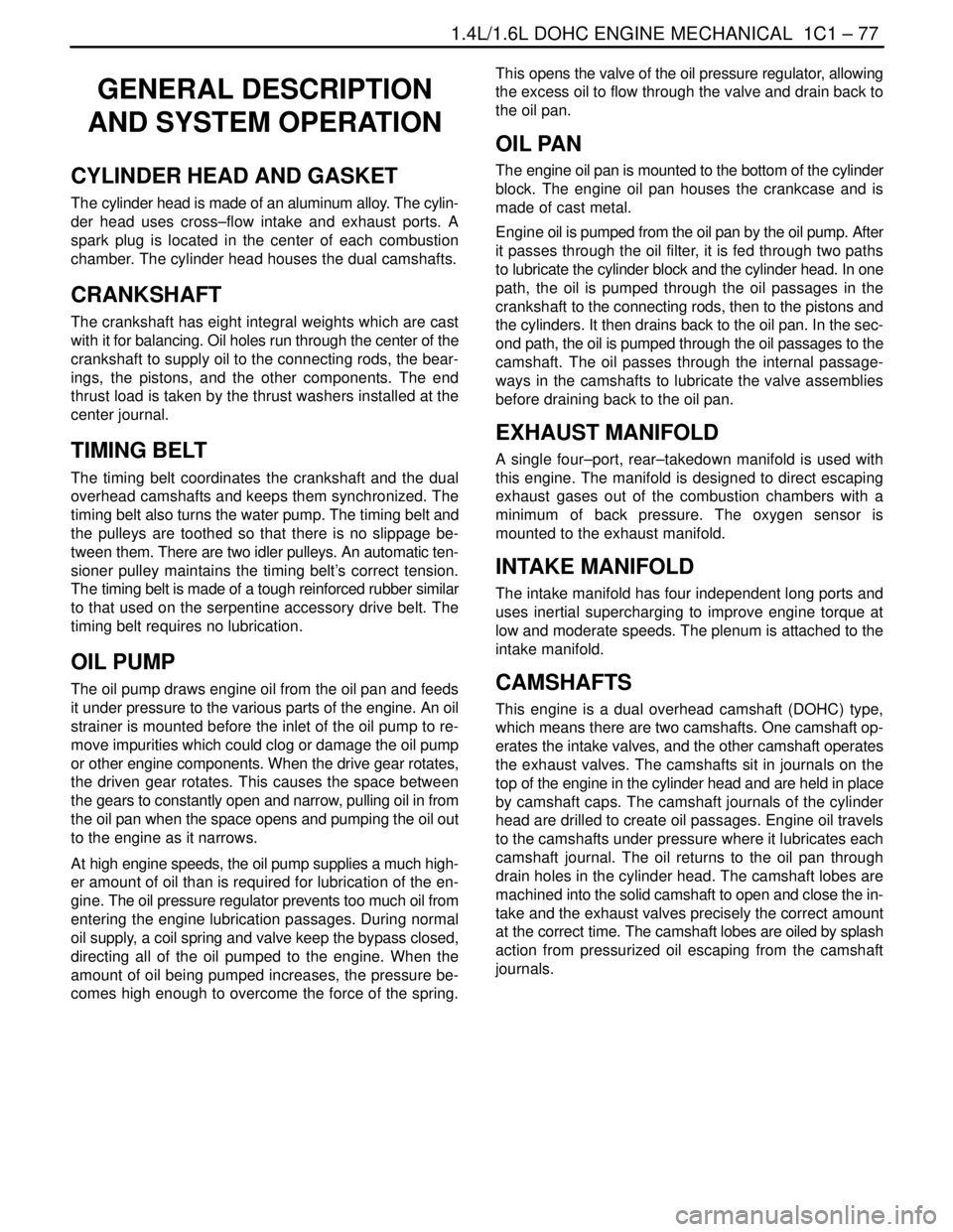

59. Install the flywheel or the flexible plate.

60. Install the flywheel or the flexible plate bolts.

Tighten

Tighten the flywheel bolts to 35 NSm (25 lb–ft). Use

the angular torque gauge KM–470–B to tighten the

flywheel bolts another 30 degrees plus 15 degrees. If

the vehicle is equipped with an automatic transaxle,

tighten the flexible plate bolts to 45 NSm (33 lb–ft).

61. Install the engine. Refer to ”Engine” in this section.

CRANKSHAFT BEARINGS AND

CONNECTING ROD BEARINGS –

GAUGING PLASTIC

Tools Required

KM–470–B Angular Torque Gauge

Inspection Procedure – Crankshaft

1. Coat the crankshaft bearings with engine oil.

2. Install the upper crankshaft bearings into the engine

block crankshaft journals.

3. Install the lower crankshaft bearings into the crank-

shaft bearing caps.

Page 119 of 2643

1C1 – 76I1.4L/1.6L DOHC ENGINE MECHANICAL

DAEWOO V–121 BL4

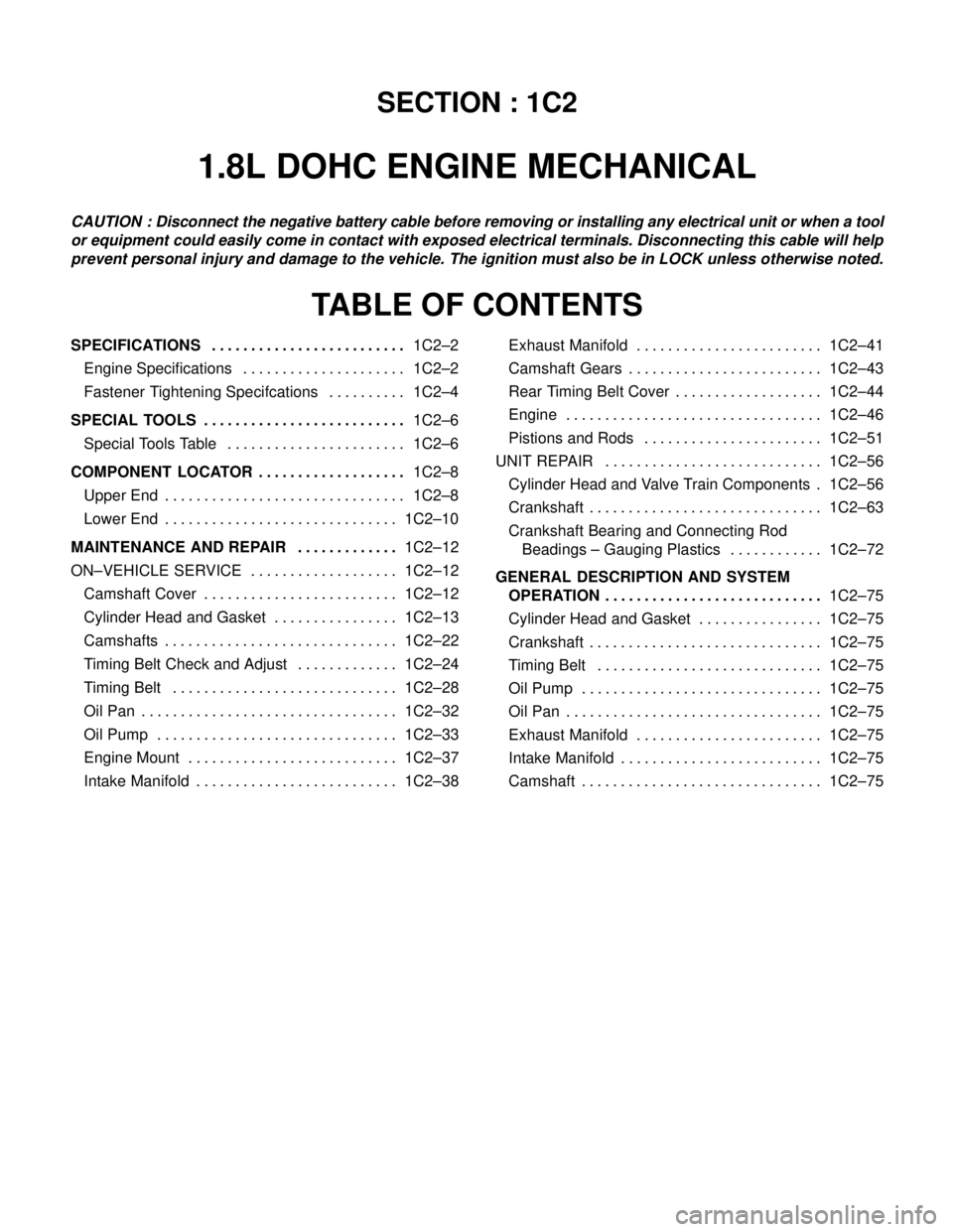

12. Remove the crankshaft bearing caps.

13. Measure the width of the flattened plastic thread of

the plastic gauging using a ruler. (Plastic gauging is

available for different tolerance ranges.)

14. Inspect the bearing clearances for permissible toler-

ance ranges. Refer to ”Engine Specifications” in

this section.

Inspection Procedure – Connecting Rods

1. Coat the connecting rod bearings with engine oil.

2. Install the upper connecting rod bearings into the

connecting rod journals.

3. Install the lower connecting rod bearings into the

connecting rod bearing caps.

Notice : Grease the connecting rod journals and lubricate

the connecting rod bearings slightly so that the plastic

gauging thread does not tear when the connecting rod

bearing caps are removed.

4. Inspect all of the connecting rod bearing clearances

using a commercially available plastic gauging

(ductile plastic threads).

5. Cut the plastic gauging threads to the length of the

bearing width. Lay them axially between the con-

necting rod journals and the connecting rod bear-

ings.

6. Install the connecting rod bearing caps.

7. Install the connecting rod bearing cap bolts.

Tighten

Tighten the connecting rod bearing cap bolts to 25

NSm (18 lb–ft). Using the angular torque gauge

KM–470–B, tighten the connecting rod bearing cap

bolts another 30 degrees plus 15 degrees.

8. Remove the connecting rod bearing caps.

9. Measure the width of the flattened plastic thread of

the plastic gauging using a ruler. (Plastic gauging is

available for different tolerance ranges.)

10. Inspect the bearing clearance for permissible toler-

ance ranges. Refer to ”Engine Specifications” in

this section.

Page 120 of 2643

1.4L/1.6L DOHC ENGINE MECHANICAL 1C1 – 77

DAEWOO V–121 BL4

GENERAL DESCRIPTION

AND SYSTEM OPERATION

CYLINDER HEAD AND GASKET

The cylinder head is made of an aluminum alloy. The cylin-

der head uses cross–flow intake and exhaust ports. A

spark plug is located in the center of each combustion

chamber. The cylinder head houses the dual camshafts.

CRANKSHAFT

The crankshaft has eight integral weights which are cast

with it for balancing. Oil holes run through the center of the

crankshaft to supply oil to the connecting rods, the bear-

ings, the pistons, and the other components. The end

thrust load is taken by the thrust washers installed at the

center journal.

TIMING BELT

The timing belt coordinates the crankshaft and the dual

overhead camshafts and keeps them synchronized. The

timing belt also turns the water pump. The timing belt and

the pulleys are toothed so that there is no slippage be-

tween them. There are two idler pulleys. An automatic ten-

sioner pulley maintains the timing belt’s correct tension.

The timing belt is made of a tough reinforced rubber similar

to that used on the serpentine accessory drive belt. The

timing belt requires no lubrication.

OIL PUMP

The oil pump draws engine oil from the oil pan and feeds

it under pressure to the various parts of the engine. An oil

strainer is mounted before the inlet of the oil pump to re-

move impurities which could clog or damage the oil pump

or other engine components. When the drive gear rotates,

the driven gear rotates. This causes the space between

the gears to constantly open and narrow, pulling oil in from

the oil pan when the space opens and pumping the oil out

to the engine as it narrows.

At high engine speeds, the oil pump supplies a much high-

er amount of oil than is required for lubrication of the en-

gine. The oil pressure regulator prevents too much oil from

entering the engine lubrication passages. During normal

oil supply, a coil spring and valve keep the bypass closed,

directing all of the oil pumped to the engine. When the

amount of oil being pumped increases, the pressure be-

comes high enough to overcome the force of the spring.This opens the valve of the oil pressure regulator, allowing

the excess oil to flow through the valve and drain back to

the oil pan.

OIL PAN

The engine oil pan is mounted to the bottom of the cylinder

block. The engine oil pan houses the crankcase and is

made of cast metal.

Engine oil is pumped from the oil pan by the oil pump. After

it passes through the oil filter, it is fed through two paths

to lubricate the cylinder block and the cylinder head. In one

path, the oil is pumped through the oil passages in the

crankshaft to the connecting rods, then to the pistons and

the cylinders. It then drains back to the oil pan. In the sec-

ond path, the oil is pumped through the oil passages to the

camshaft. The oil passes through the internal passage-

ways in the camshafts to lubricate the valve assemblies

before draining back to the oil pan.

EXHAUST MANIFOLD

A single four–port, rear–takedown manifold is used with

this engine. The manifold is designed to direct escaping

exhaust gases out of the combustion chambers with a

minimum of back pressure. The oxygen sensor is

mounted to the exhaust manifold.

INTAKE MANIFOLD

The intake manifold has four independent long ports and

uses inertial supercharging to improve engine torque at

low and moderate speeds. The plenum is attached to the

intake manifold.

CAMSHAFTS

This engine is a dual overhead camshaft (DOHC) type,

which means there are two camshafts. One camshaft op-

erates the intake valves, and the other camshaft operates

the exhaust valves. The camshafts sit in journals on the

top of the engine in the cylinder head and are held in place

by camshaft caps. The camshaft journals of the cylinder

head are drilled to create oil passages. Engine oil travels

to the camshafts under pressure where it lubricates each

camshaft journal. The oil returns to the oil pan through

drain holes in the cylinder head. The camshaft lobes are

machined into the solid camshaft to open and close the in-

take and the exhaust valves precisely the correct amount

at the correct time. The camshaft lobes are oiled by splash

action from pressurized oil escaping from the camshaft

journals.

Page 121 of 2643

SECTION : 1C2

1.8L DOHC ENGINE MECHANICAL

CAUTION : Disconnect the negative battery cable before removing or installing any electrical unit or when a tool

or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help

prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise noted.

TABLE OF CONTENTS

SPECIFICATIONS1C2–2 . . . . . . . . . . . . . . . . . . . . . . . . .

Engine Specifications 1C2–2. . . . . . . . . . . . . . . . . . . . .

Fastener Tightening Specifcations 1C2–4. . . . . . . . . .

SPECIAL TOOLS1C2–6 . . . . . . . . . . . . . . . . . . . . . . . . . .

Special Tools Table 1C2–6. . . . . . . . . . . . . . . . . . . . . . .

COMPONENT LOCATOR1C2–8 . . . . . . . . . . . . . . . . . . .

Upper End 1C2–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lower End 1C2–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MAINTENANCE AND REPAIR1C2–12 . . . . . . . . . . . . .

ON–VEHICLE SERVICE 1C2–12. . . . . . . . . . . . . . . . . . .

Camshaft Cover 1C2–12. . . . . . . . . . . . . . . . . . . . . . . . .

Cylinder Head and Gasket 1C2–13. . . . . . . . . . . . . . . .

Camshafts 1C2–22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Timing Belt Check and Adjust 1C2–24. . . . . . . . . . . . .

Timing Belt 1C2–28. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Oil Pan 1C2–32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Oil Pump 1C2–33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine Mount 1C2–37. . . . . . . . . . . . . . . . . . . . . . . . . . .

Intake Manifold 1C2–38. . . . . . . . . . . . . . . . . . . . . . . . . . Exhaust Manifold 1C2–41. . . . . . . . . . . . . . . . . . . . . . . .

Camshaft Gears 1C2–43. . . . . . . . . . . . . . . . . . . . . . . . .

Rear Timing Belt Cover 1C2–44. . . . . . . . . . . . . . . . . . .

Engine 1C2–46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pistions and Rods 1C2–51. . . . . . . . . . . . . . . . . . . . . . .

UNIT REPAIR 1C2–56. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cylinder Head and Valve Train Components 1C2–56.

Crankshaft 1C2–63. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Crankshaft Bearing and Connecting Rod

Beadings – Gauging Plastics 1C2–72. . . . . . . . . . . .

GENERAL DESCRIPTION AND SYSTEM

OPERATION1C2–75 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cylinder Head and Gasket 1C2–75. . . . . . . . . . . . . . . .

Crankshaft 1C2–75. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Timing Belt 1C2–75. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Oil Pump 1C2–75. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Oil Pan 1C2–75. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Exhaust Manifold 1C2–75. . . . . . . . . . . . . . . . . . . . . . . .

Intake Manifold 1C2–75. . . . . . . . . . . . . . . . . . . . . . . . . .

Camshaft 1C2–75. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 122 of 2643

1C2 – 2I1.8L DOHC ENGINE MECHANICAL

DAEWOO V–121 BL4

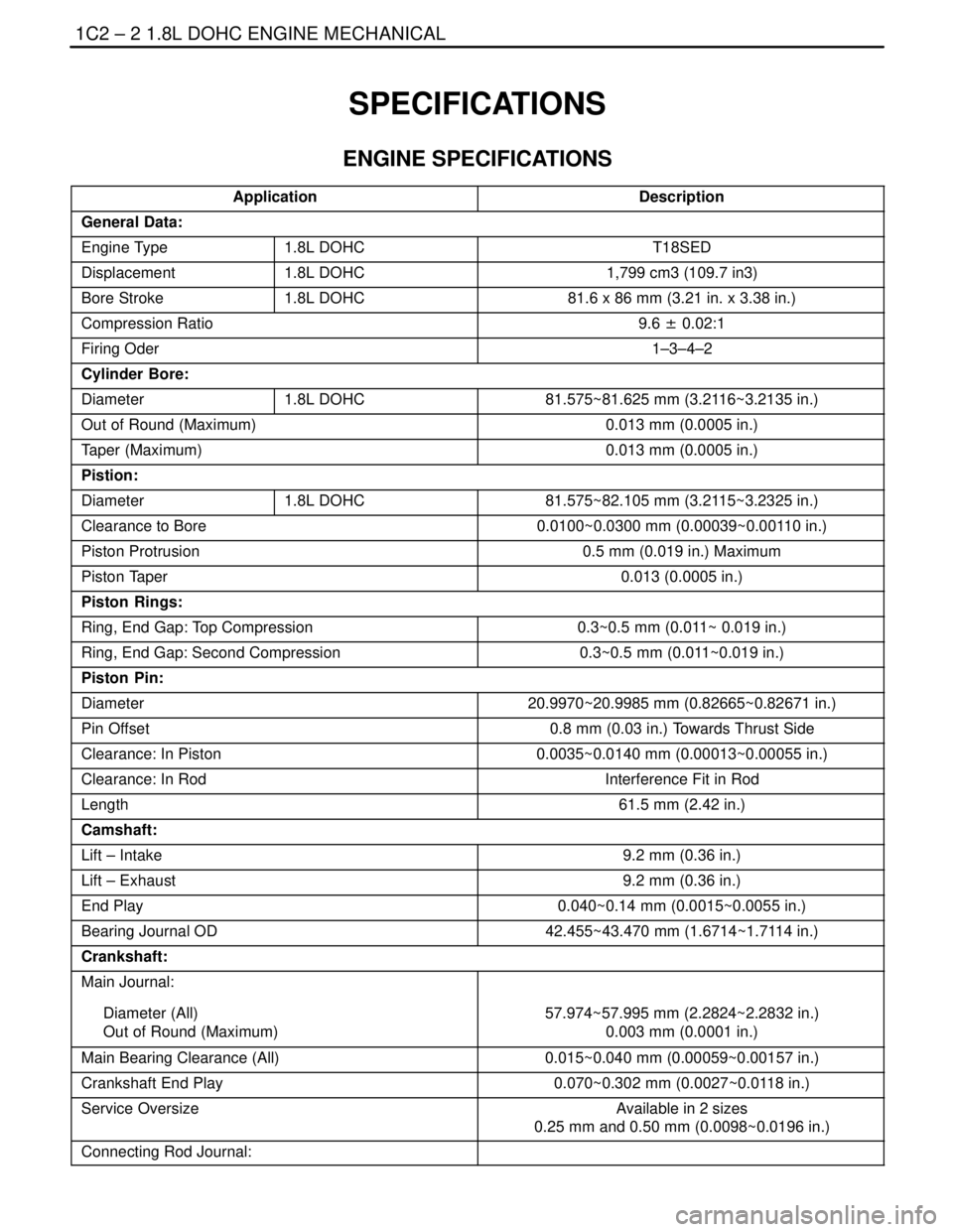

SPECIFICATIONS

ENGINE SPECIFICATIONS

ApplicationDescription

General Data:

Engine Type1.8L DOHCT18SED

Displacement1.8L DOHC1,799 cm3 (109.7 in3)

Bore Stroke1.8L DOHC81.6 x 86 mm (3.21 in. x 3.38 in.)

Compression Ratio9.6 ± 0.02:1

Firing Oder1–3–4–2

Cylinder Bore:

Diameter1.8L DOHC81.575~81.625 mm (3.2116~3.2135 in.)

Out of Round (Maximum)0.013 mm (0.0005 in.)

Taper (Maximum)0.013 mm (0.0005 in.)

Pistion:

Diameter1.8L DOHC81.575~82.105 mm (3.2115~3.2325 in.)

Clearance to Bore0.0100~0.0300 mm (0.00039~0.00110 in.)

Piston Protrusion0.5 mm (0.019 in.) Maximum

Piston Taper0.013 (0.0005 in.)

Piston Rings:

Ring, End Gap: Top Compression0.3~0.5 mm (0.011~ 0.019 in.)

Ring, End Gap: Second Compression0.3~0.5 mm (0.011~0.019 in.)

Piston Pin:

Diameter20.9970~20.9985 mm (0.82665~0.82671 in.)

Pin Offset0.8 mm (0.03 in.) Towards Thrust Side

Clearance: In Piston0.0035~0.0140 mm (0.00013~0.00055 in.)

Clearance: In RodInterference Fit in Rod

Length61.5 mm (2.42 in.)

Camshaft:

Lift – Intake9.2 mm (0.36 in.)

Lift – Exhaust9.2 mm (0.36 in.)

End Play0.040~0.14 mm (0.0015~0.0055 in.)

Bearing Journal OD42.455~43.470 mm (1.6714~1.7114 in.)

Crankshaft:

Main Journal:

Diameter (All)

Out of Round (Maximum)57.974~57.995 mm (2.2824~2.2832 in.)

0.003 mm (0.0001 in.)

Main Bearing Clearance (All)0.015~0.040 mm (0.00059~0.00157 in.)

Crankshaft End Play0.070~0.302 mm (0.0027~0.0118 in.)

Service OversizeAvailable in 2 sizes

0.25 mm and 0.50 mm (0.0098~0.0196 in.)

Connecting Rod Journal:

Page 124 of 2643

1C2 – 4I1.8L DOHC ENGINE MECHANICAL

DAEWOO V–121 BL4

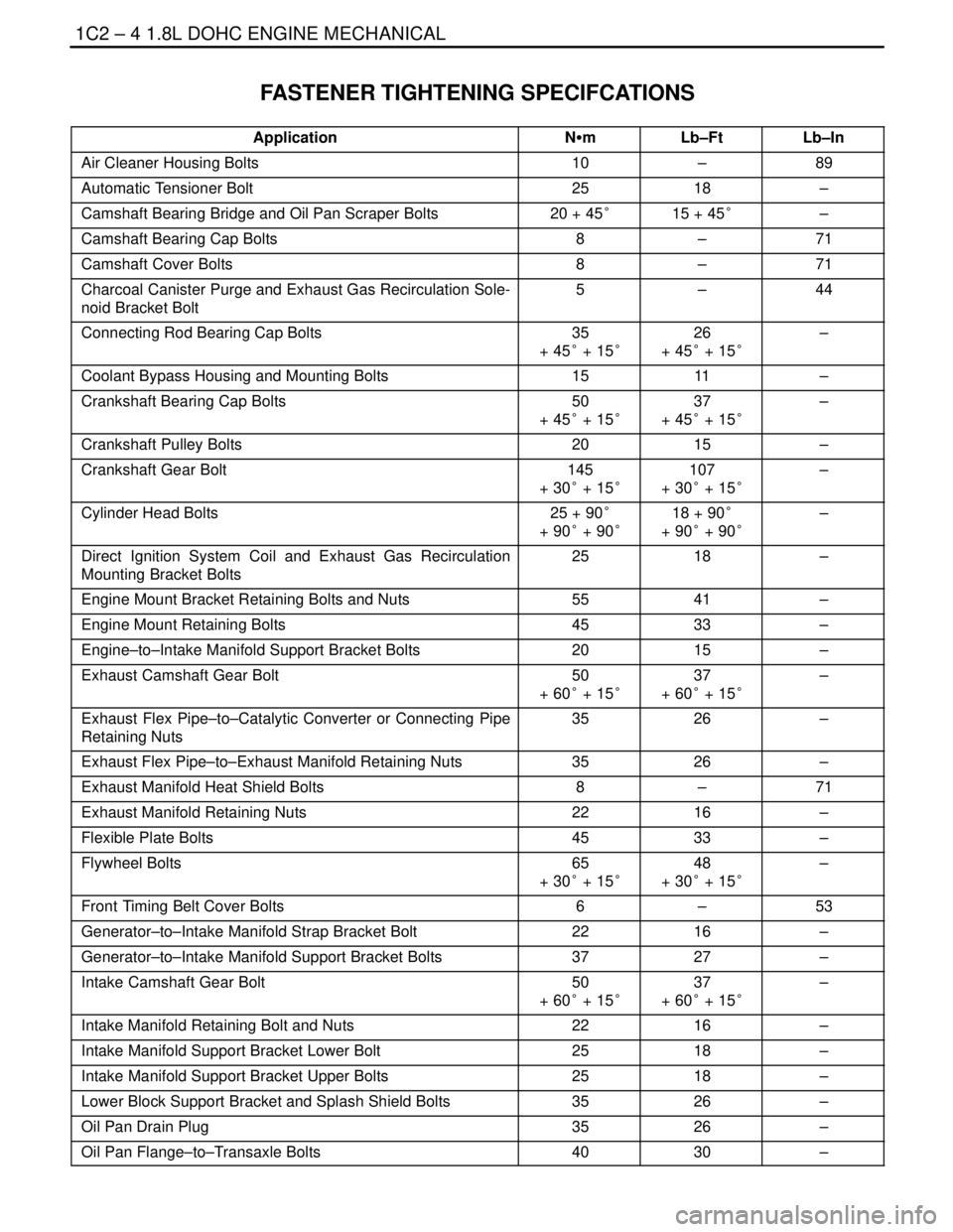

FASTENER TIGHTENING SPECIFCATIONS

ApplicationNSmLb–FtLb–In

Air Cleaner Housing Bolts10–89

Automatic Tensioner Bolt2518–

Camshaft Bearing Bridge and Oil Pan Scraper Bolts20 + 45°15 + 45°–

Camshaft Bearing Cap Bolts8–71

Camshaft Cover Bolts8–71

Charcoal Canister Purge and Exhaust Gas Recirculation Sole-

noid Bracket Bolt5–44

Connecting Rod Bearing Cap Bolts35

+ 45° + 15°26

+ 45° + 15°–

Coolant Bypass Housing and Mounting Bolts1511–

Crankshaft Bearing Cap Bolts50

+ 45° + 15°37

+ 45° + 15°–

Crankshaft Pulley Bolts2015–

Crankshaft Gear Bolt145

+ 30° + 15°107

+ 30° + 15°–

Cylinder Head Bolts25 + 90°

+ 90° + 90°18 + 90°

+ 90° + 90°–

Direct Ignition System Coil and Exhaust Gas Recirculation

Mounting Bracket Bolts2518–

Engine Mount Bracket Retaining Bolts and Nuts5541–

Engine Mount Retaining Bolts4533–

Engine–to–Intake Manifold Support Bracket Bolts2015–

Exhaust Camshaft Gear Bolt50

+ 60° + 15°37

+ 60° + 15°–

Exhaust Flex Pipe–to–Catalytic Converter or Connecting Pipe

Retaining Nuts3526–

Exhaust Flex Pipe–to–Exhaust Manifold Retaining Nuts3526–

Exhaust Manifold Heat Shield Bolts8–71

Exhaust Manifold Retaining Nuts2216–

Flexible Plate Bolts4533–

Flywheel Bolts65

+ 30° + 15°48

+ 30° + 15°–

Front Timing Belt Cover Bolts6–53

Generator–to–Intake Manifold Strap Bracket Bolt2216–

Generator–to–Intake Manifold Support Bracket Bolts3727–

Intake Camshaft Gear Bolt50

+ 60° + 15°37

+ 60° + 15°–

Intake Manifold Retaining Bolt and Nuts2216–

Intake Manifold Support Bracket Lower Bolt2518–

Intake Manifold Support Bracket Upper Bolts2518–

Lower Block Support Bracket and Splash Shield Bolts3526–

Oil Pan Drain Plug3526–

Oil Pan Flange–to–Transaxle Bolts4030–

Page 131 of 2643

1.8L DOHC ENGINE MECHANICAL 1C2 – 11

DAEWOO V–121 BL4

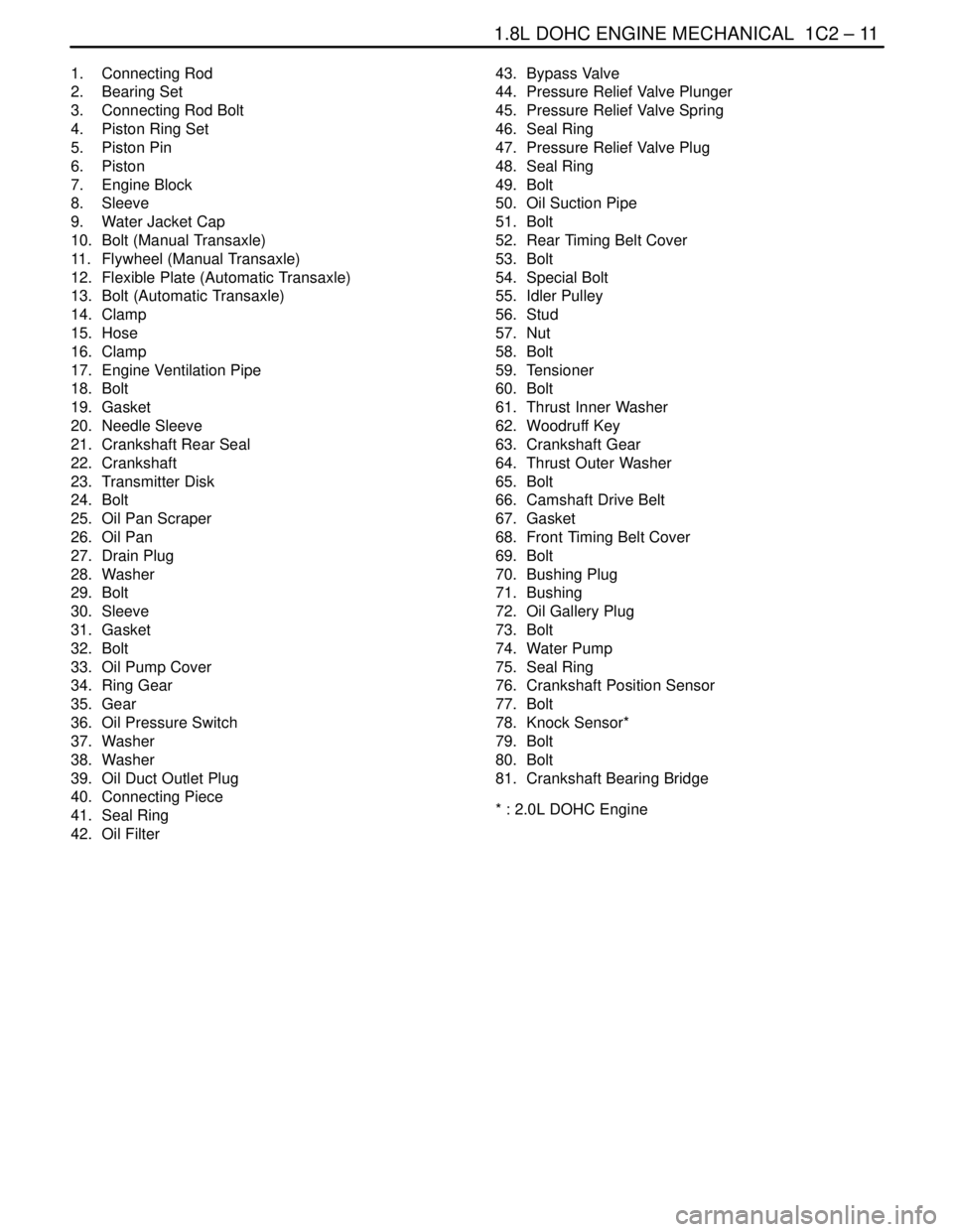

1. Connecting Rod

2. Bearing Set

3. Connecting Rod Bolt

4. Piston Ring Set

5. Piston Pin

6. Piston

7. Engine Block

8. Sleeve

9. Water Jacket Cap

10. Bolt (Manual Transaxle)

11. Flywheel (Manual Transaxle)

12. Flexible Plate (Automatic Transaxle)

13. Bolt (Automatic Transaxle)

14. Clamp

15. Hose

16. Clamp

17. Engine Ventilation Pipe

18. Bolt

19. Gasket

20. Needle Sleeve

21. Crankshaft Rear Seal

22. Crankshaft

23. Transmitter Disk

24. Bolt

25. Oil Pan Scraper

26. Oil Pan

27. Drain Plug

28. Washer

29. Bolt

30. Sleeve

31. Gasket

32. Bolt

33. Oil Pump Cover

34. Ring Gear

35. Gear

36. Oil Pressure Switch

37. Washer

38. Washer

39. Oil Duct Outlet Plug

40. Connecting Piece

41. Seal Ring

42. Oil Filter43. Bypass Valve

44. Pressure Relief Valve Plunger

45. Pressure Relief Valve Spring

46. Seal Ring

47. Pressure Relief Valve Plug

48. Seal Ring

49. Bolt

50. Oil Suction Pipe

51. Bolt

52. Rear Timing Belt Cover

53. Bolt

54. Special Bolt

55. Idler Pulley

56. Stud

57. Nut

58. Bolt

59. Tensioner

60. Bolt

61. Thrust Inner Washer

62. Woodruff Key

63. Crankshaft Gear

64. Thrust Outer Washer

65. Bolt

66. Camshaft Drive Belt

67. Gasket

68. Front Timing Belt Cover

69. Bolt

70. Bushing Plug

71. Bushing

72. Oil Gallery Plug

73. Bolt

74. Water Pump

75. Seal Ring

76. Crankshaft Position Sensor

77. Bolt

78. Knock Sensor*

79. Bolt

80. Bolt

81. Crankshaft Bearing Bridge

* : 2.0L DOHC Engine

Page 171 of 2643

1.8L DOHC ENGINE MECHANICAL 1C2 – 51

DAEWOO V–121 BL4

43. Connect the lower radiator hose to the coolant pipe.

44. Connect the upper radiator hose to the thermostat

housing.

45. Connect the heater inlet hose to the cylinder head.

46. Connect the heater outlet hose to the coolant pipe.

47. Connect the coolant surge tank hose to the coolant

pipe.

48. Connect the coolant hose to the throttle body.

49. Connect the throttle cable to the throttle body and

the intake manifold bracket.

50. Install the fuel pump fuse.

51. Connect the negative battery cable.

52. Refill the engine crankcase with engine oil.

53. Refill the engine coolant system. Refer to Section

1D, Engine Cooling.

54. Bleed the power steering system. Refer to Section

6A, Power Steering.

55. Refill the A/C refrigerant system, if equipped. Refer

to Section 7B, Manual Control Heating, Ventilation,

and Air Conditioning System.

56. Install the hood. Refer to Section 9R, Body Front

End.

PISTONS AND RODS

Tools Required

J–8037 Universal Piston Ring Compressor

J–8087 Cylinder Bore Check Gauge

KM–427 Piston Pin Service Set

KM–470–B Angular Torque Gauge

Removal Procedure

1. Remove the cylinder head with the intake manifold

and exhaust manifold attached. Refer to ”Cylinder

Head and Gasket” in this section.

2. Remove the oil pan. Refer to ”Oil Pan” in this sec-

tion.

3. Remove the oil suction pipe bolts and support

bracket bolts.

4. Remove the oil suction pipe.

5. Remove the crankshaft bearing bridge and the oil

pan scraper bolts.

6. Remove the crankshaft bearing bridge and the oil

pan scraper.

Page 172 of 2643

1C2 – 52I1.8L DOHC ENGINE MECHANICAL

DAEWOO V–121 BL4

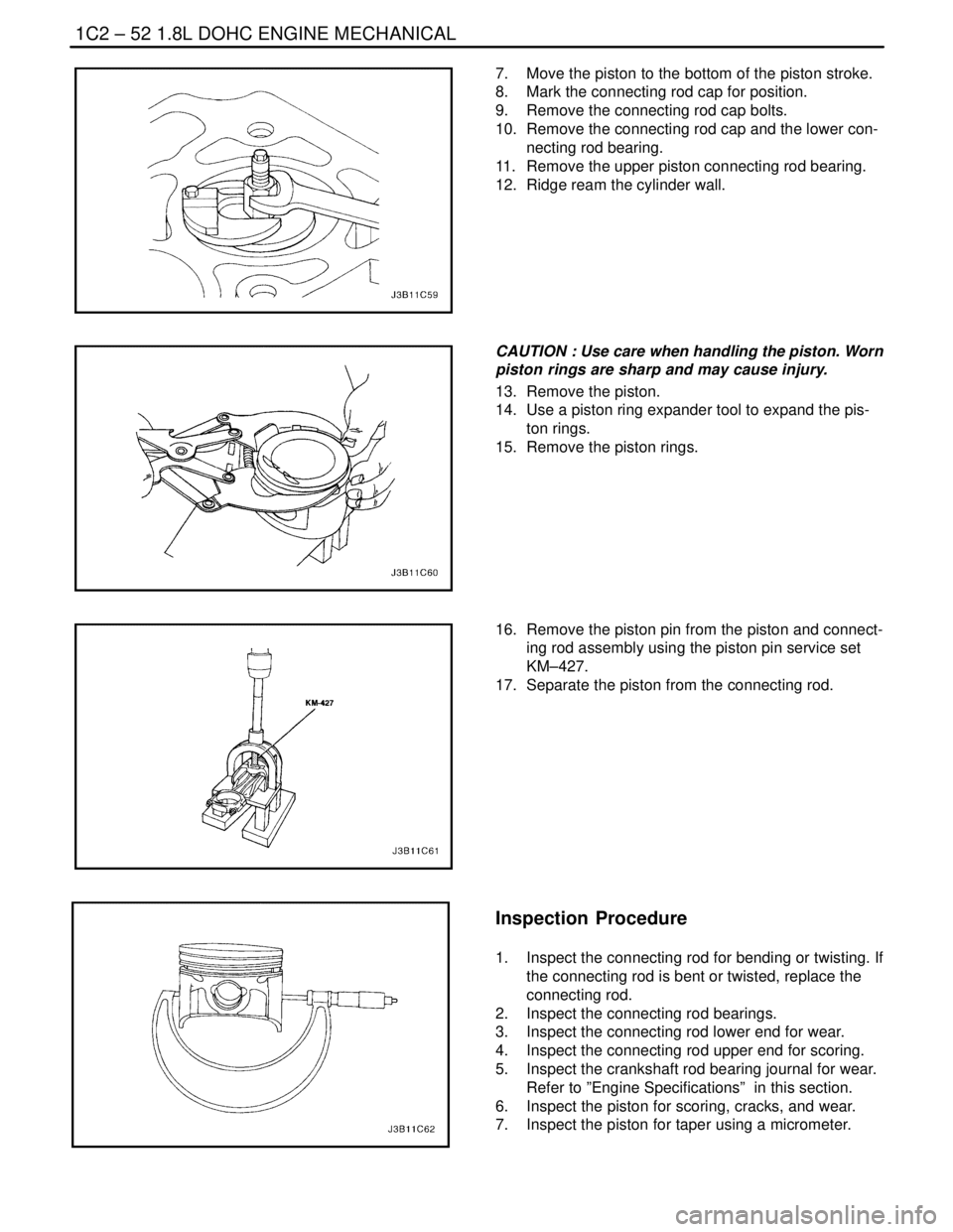

7. Move the piston to the bottom of the piston stroke.

8. Mark the connecting rod cap for position.

9. Remove the connecting rod cap bolts.

10. Remove the connecting rod cap and the lower con-

necting rod bearing.

11. Remove the upper piston connecting rod bearing.

12. Ridge ream the cylinder wall.

CAUTION : Use care when handling the piston. Worn

piston rings are sharp and may cause injury.

13. Remove the piston.

14. Use a piston ring expander tool to expand the pis-

ton rings.

15. Remove the piston rings.

16. Remove the piston pin from the piston and connect-

ing rod assembly using the piston pin service set

KM–427.

17. Separate the piston from the connecting rod.

Inspection Procedure

1. Inspect the connecting rod for bending or twisting. If

the connecting rod is bent or twisted, replace the

connecting rod.

2. Inspect the connecting rod bearings.

3. Inspect the connecting rod lower end for wear.

4. Inspect the connecting rod upper end for scoring.

5. Inspect the crankshaft rod bearing journal for wear.

Refer to ”Engine Specifications” in this section.

6. Inspect the piston for scoring, cracks, and wear.

7. Inspect the piston for taper using a micrometer.

Page 173 of 2643

1.8L DOHC ENGINE MECHANICAL 1C2 – 53

DAEWOO V–121 BL4

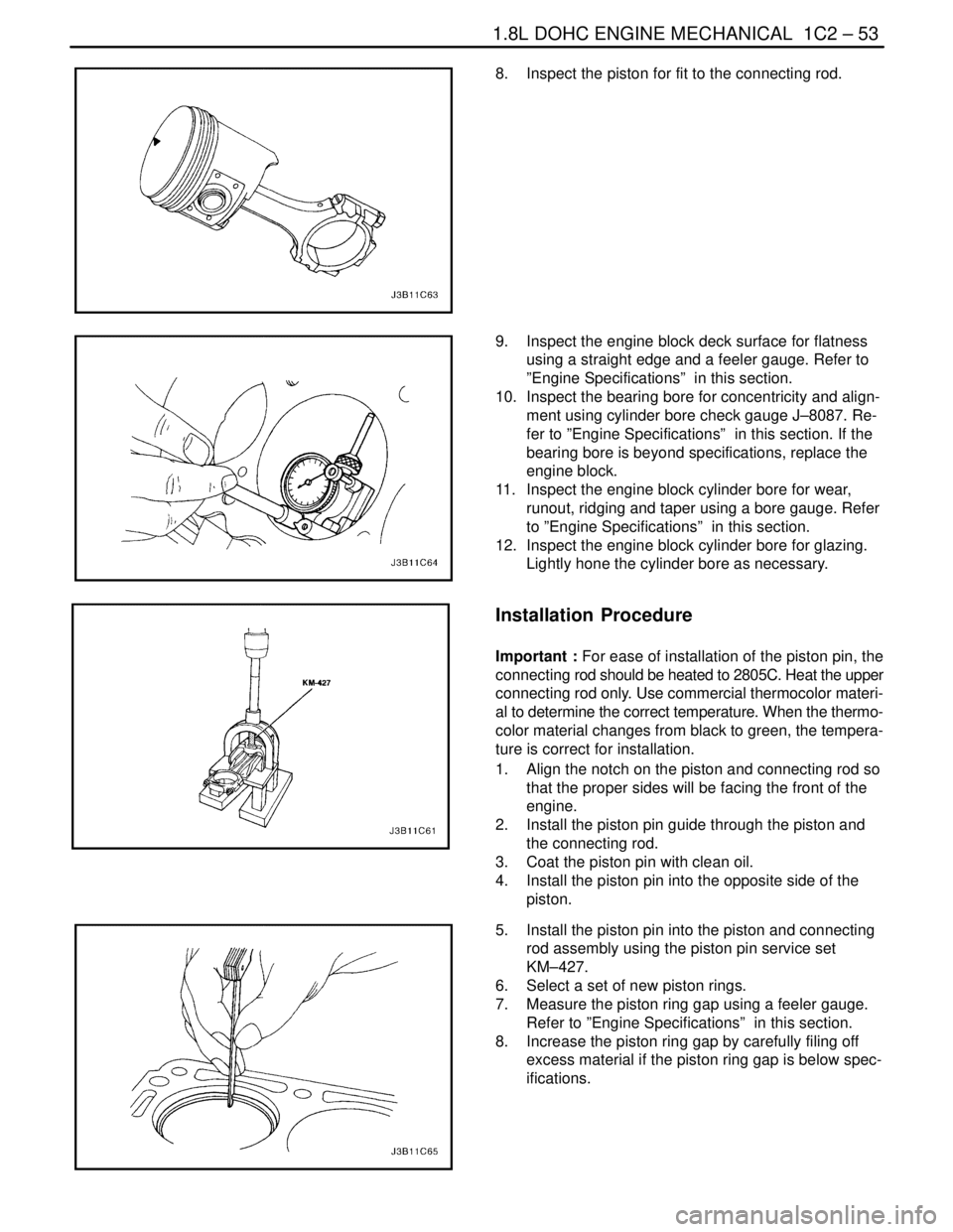

8. Inspect the piston for fit to the connecting rod.

9. Inspect the engine block deck surface for flatness

using a straight edge and a feeler gauge. Refer to

”Engine Specifications” in this section.

10. Inspect the bearing bore for concentricity and align-

ment using cylinder bore check gauge J–8087. Re-

fer to ”Engine Specifications” in this section. If the

bearing bore is beyond specifications, replace the

engine block.

11. Inspect the engine block cylinder bore for wear,

runout, ridging and taper using a bore gauge. Refer

to ”Engine Specifications” in this section.

12. Inspect the engine block cylinder bore for glazing.

Lightly hone the cylinder bore as necessary.

Installation Procedure

Important : For ease of installation of the piston pin, the

connecting rod should be heated to 2805C. Heat the upper

connecting rod only. Use commercial thermocolor materi-

al to determine the correct temperature. When the thermo-

color material changes from black to green, the tempera-

ture is correct for installation.

1. Align the notch on the piston and connecting rod so

that the proper sides will be facing the front of the

engine.

2. Install the piston pin guide through the piston and

the connecting rod.

3. Coat the piston pin with clean oil.

4. Install the piston pin into the opposite side of the

piston.

5. Install the piston pin into the piston and connecting

rod assembly using the piston pin service set

KM–427.

6. Select a set of new piston rings.

7. Measure the piston ring gap using a feeler gauge.

Refer to ”Engine Specifications” in this section.

8. Increase the piston ring gap by carefully filing off

excess material if the piston ring gap is below spec-

ifications.