air filter DAEWOO LACETTI 2004 Service Owner's Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 715 of 2643

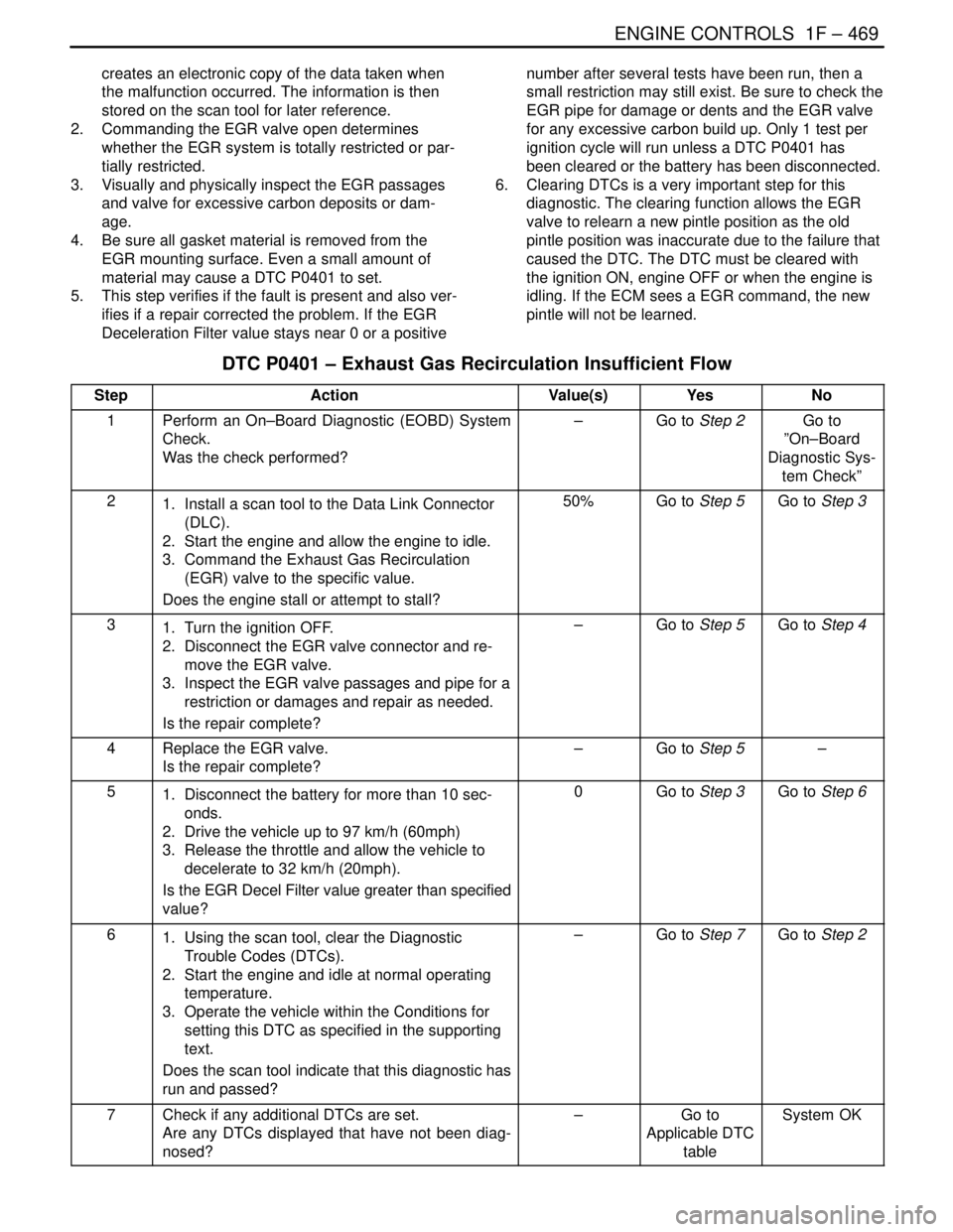

ENGINE CONTROLS 1F – 469

DAEWOO V–121 BL4

creates an electronic copy of the data taken when

the malfunction occurred. The information is then

stored on the scan tool for later reference.

2. Commanding the EGR valve open determines

whether the EGR system is totally restricted or par-

tially restricted.

3. Visually and physically inspect the EGR passages

and valve for excessive carbon deposits or dam-

age.

4. Be sure all gasket material is removed from the

EGR mounting surface. Even a small amount of

material may cause a DTC P0401 to set.

5. This step verifies if the fault is present and also ver-

ifies if a repair corrected the problem. If the EGR

Deceleration Filter value stays near 0 or a positivenumber after several tests have been run, then a

small restriction may still exist. Be sure to check the

EGR pipe for damage or dents and the EGR valve

for any excessive carbon build up. Only 1 test per

ignition cycle will run unless a DTC P0401 has

been cleared or the battery has been disconnected.

6. Clearing DTCs is a very important step for this

diagnostic. The clearing function allows the EGR

valve to relearn a new pintle position as the old

pintle position was inaccurate due to the failure that

caused the DTC. The DTC must be cleared with

the ignition ON, engine OFF or when the engine is

idling. If the ECM sees a EGR command, the new

pintle will not be learned.

DTC P0401 – Exhaust Gas Recirculation Insufficient Flow

StepActionValue(s)YesNo

1Perform an On–Board Diagnostic (EOBD) System

Check.

Was the check performed?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Install a scan tool to the Data Link Connector

(DLC).

2. Start the engine and allow the engine to idle.

3. Command the Exhaust Gas Recirculation

(EGR) valve to the specific value.

Does the engine stall or attempt to stall?50%Go to Step 5Go to Step 3

31. Turn the ignition OFF.

2. Disconnect the EGR valve connector and re-

move the EGR valve.

3. Inspect the EGR valve passages and pipe for a

restriction or damages and repair as needed.

Is the repair complete?–Go to Step 5Go to Step 4

4Replace the EGR valve.

Is the repair complete?–Go to Step 5–

51. Disconnect the battery for more than 10 sec-

onds.

2. Drive the vehicle up to 97 km/h (60mph)

3. Release the throttle and allow the vehicle to

decelerate to 32 km/h (20mph).

Is the EGR Decel Filter value greater than specified

value?0Go to Step 3Go to Step 6

61. Using the scan tool, clear the Diagnostic

Trouble Codes (DTCs).

2. Start the engine and idle at normal operating

temperature.

3. Operate the vehicle within the Conditions for

setting this DTC as specified in the supporting

text.

Does the scan tool indicate that this diagnostic has

run and passed?–Go to Step 7Go to Step 2

7Check if any additional DTCs are set.

Are any DTCs displayed that have not been diag-

nosed?–Go to

Applicable DTC

tableSystem OK

Page 794 of 2643

1F – 548IENGINE CONTROLS

DAEWOO V–121 BL4

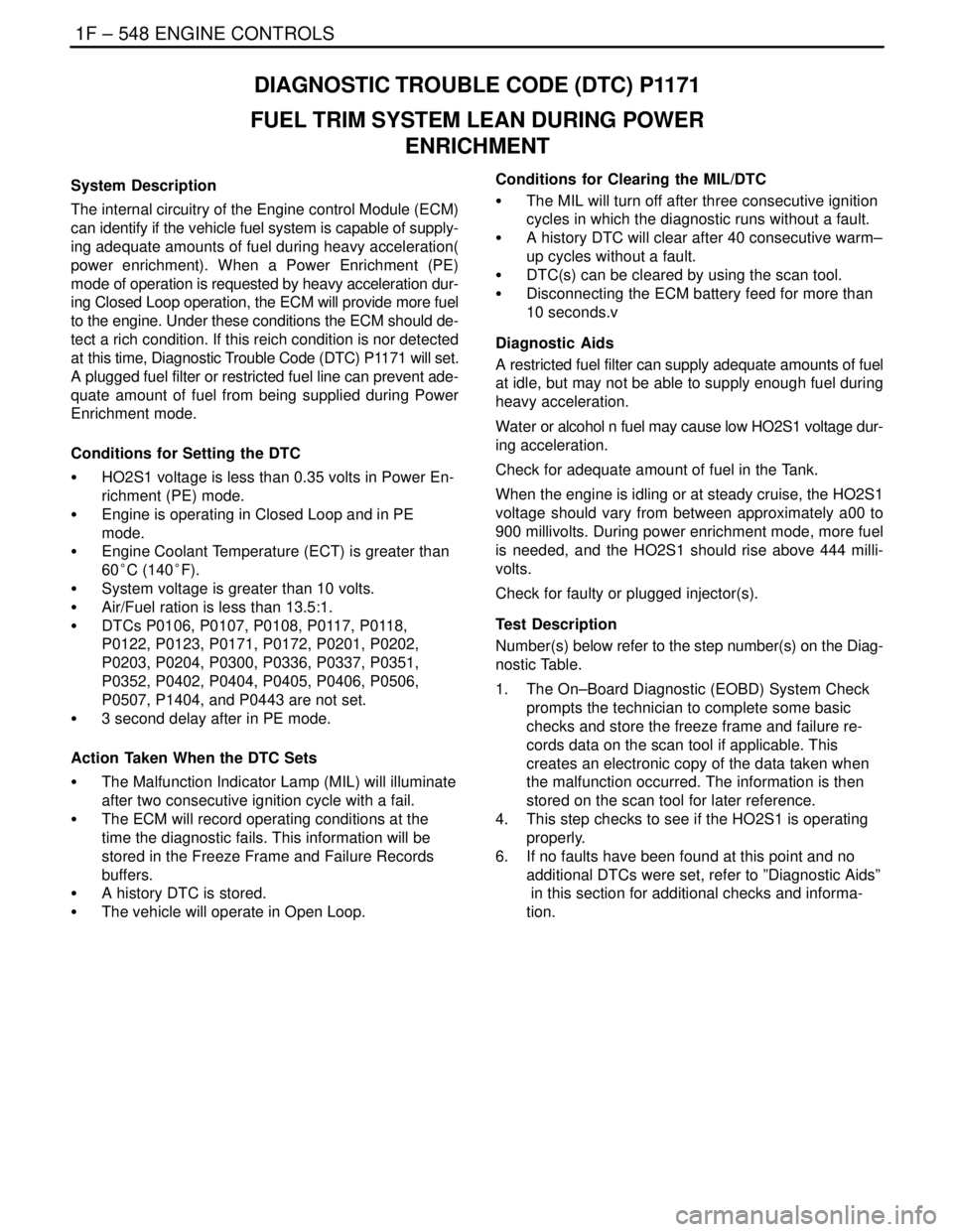

DIAGNOSTIC TROUBLE CODE (DTC) P1171

FUEL TRIM SYSTEM LEAN DURING POWER

ENRICHMENT

System Description

The internal circuitry of the Engine control Module (ECM)

can identify if the vehicle fuel system is capable of supply-

ing adequate amounts of fuel during heavy acceleration(

power enrichment). When a Power Enrichment (PE)

mode of operation is requested by heavy acceleration dur-

ing Closed Loop operation, the ECM will provide more fuel

to the engine. Under these conditions the ECM should de-

tect a rich condition. If this reich condition is nor detected

at this time, Diagnostic Trouble Code (DTC) P1171 will set.

A plugged fuel filter or restricted fuel line can prevent ade-

quate amount of fuel from being supplied during Power

Enrichment mode.

Conditions for Setting the DTC

S HO2S1 voltage is less than 0.35 volts in Power En-

richment (PE) mode.

S Engine is operating in Closed Loop and in PE

mode.

S Engine Coolant Temperature (ECT) is greater than

60°C (140°F).

S System voltage is greater than 10 volts.

S Air/Fuel ration is less than 13.5:1.

S DTCs P0106, P0107, P0108, P0117, P0118,

P0122, P0123, P0171, P0172, P0201, P0202,

P0203, P0204, P0300, P0336, P0337, P0351,

P0352, P0402, P0404, P0405, P0406, P0506,

P0507, P1404, and P0443 are not set.

S 3 second delay after in PE mode.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will illuminate

after two consecutive ignition cycle with a fail.

S The ECM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Freeze Frame and Failure Records

buffers.

S A history DTC is stored.

S The vehicle will operate in Open Loop.Conditions for Clearing the MIL/DTC

S The MIL will turn off after three consecutive ignition

cycles in which the diagnostic runs without a fault.

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.v

Diagnostic Aids

A restricted fuel filter can supply adequate amounts of fuel

at idle, but may not be able to supply enough fuel during

heavy acceleration.

Water or alcohol n fuel may cause low HO2S1 voltage dur-

ing acceleration.

Check for adequate amount of fuel in the Tank.

When the engine is idling or at steady cruise, the HO2S1

voltage should vary from between approximately a00 to

900 millivolts. During power enrichment mode, more fuel

is needed, and the HO2S1 should rise above 444 milli-

volts.

Check for faulty or plugged injector(s).

Test Description

Number(s) below refer to the step number(s) on the Diag-

nostic Table.

1. The On–Board Diagnostic (EOBD) System Check

prompts the technician to complete some basic

checks and store the freeze frame and failure re-

cords data on the scan tool if applicable. This

creates an electronic copy of the data taken when

the malfunction occurred. The information is then

stored on the scan tool for later reference.

4. This step checks to see if the HO2S1 is operating

properly.

6. If no faults have been found at this point and no

additional DTCs were set, refer to ”Diagnostic Aids”

in this section for additional checks and informa-

tion.

Page 825 of 2643

ENGINE CONTROLS 1F – 579

DAEWOO V–121 BL4

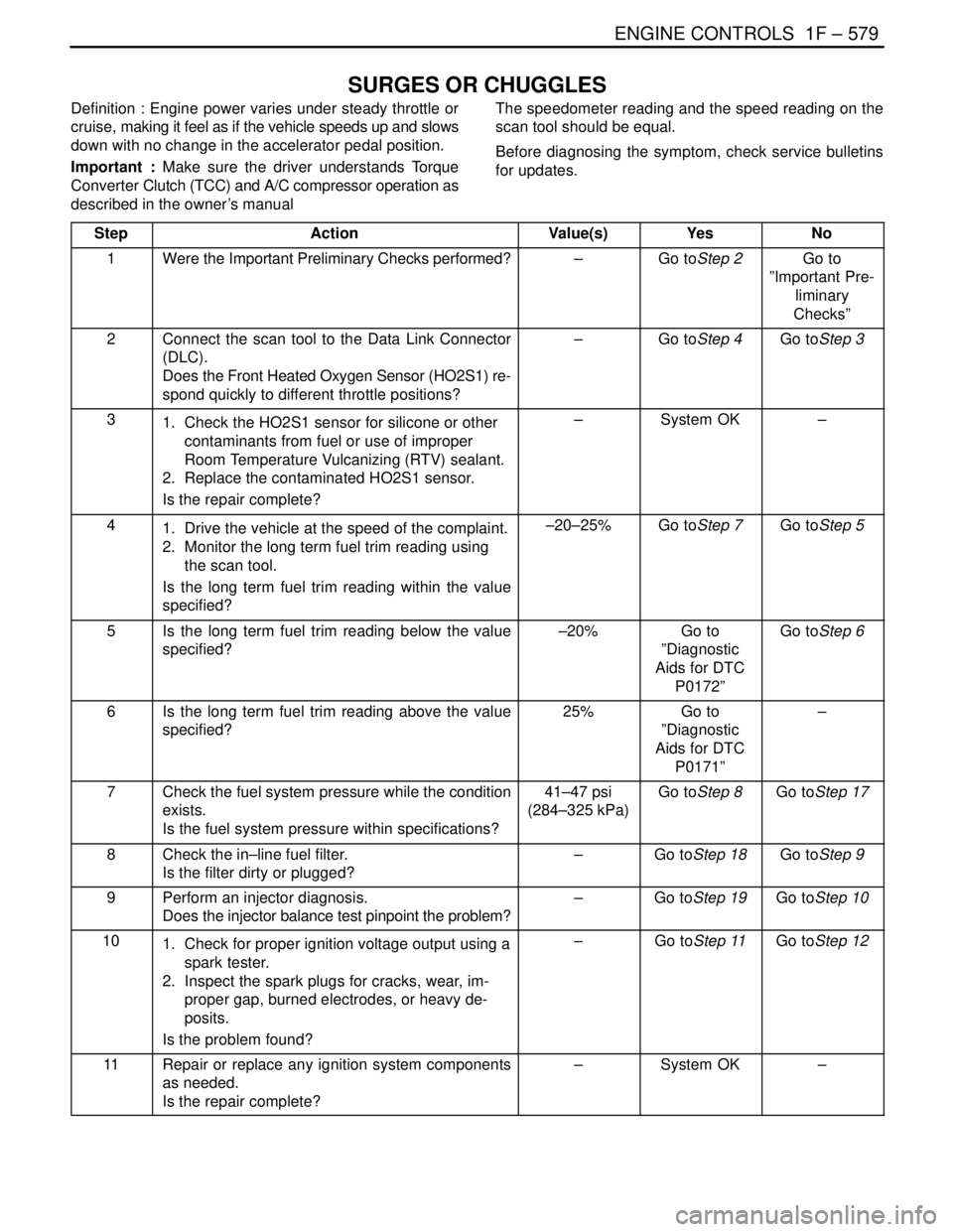

SURGES OR CHUGGLES

Definition : Engine power varies under steady throttle or

cruise, making it feel as if the vehicle speeds up and slows

down with no change in the accelerator pedal position.

Important : Make sure the driver understands Torque

Converter Clutch (TCC) and A/C compressor operation as

described in the owner’s manualThe speedometer reading and the speed reading on the

scan tool should be equal.

Before diagnosing the symptom, check service bulletins

for updates.

Step

ActionValue(s)YesNo

1Were the Important Preliminary Checks performed?–Go toStep 2Go to

”Important Pre-

liminary

Checks”

2Connect the scan tool to the Data Link Connector

(DLC).

Does the Front Heated Oxygen Sensor (HO2S1) re-

spond quickly to different throttle positions?–Go toStep 4Go toStep 3

31. Check the HO2S1 sensor for silicone or other

contaminants from fuel or use of improper

Room Temperature Vulcanizing (RTV) sealant.

2. Replace the contaminated HO2S1 sensor.

Is the repair complete?–System OK–

41. Drive the vehicle at the speed of the complaint.

2. Monitor the long term fuel trim reading using

the scan tool.

Is the long term fuel trim reading within the value

specified?–20–25%Go toStep 7Go toStep 5

5Is the long term fuel trim reading below the value

specified?–20%Go to

”Diagnostic

Aids for DTC

P0172”Go toStep 6

6Is the long term fuel trim reading above the value

specified?25%Go to

”Diagnostic

Aids for DTC

P0171”–

7Check the fuel system pressure while the condition

exists.

Is the fuel system pressure within specifications?41–47 psi

(284–325 kPa)Go toStep 8Go toStep 17

8Check the in–line fuel filter.

Is the filter dirty or plugged?–Go toStep 18Go toStep 9

9Perform an injector diagnosis.

Does the injector balance test pinpoint the problem?–Go toStep 19Go toStep 10

101. Check for proper ignition voltage output using a

spark tester.

2. Inspect the spark plugs for cracks, wear, im-

proper gap, burned electrodes, or heavy de-

posits.

Is the problem found?–Go toStep 11Go toStep 12

11Repair or replace any ignition system components

as needed.

Is the repair complete?–System OK–

Page 826 of 2643

1F – 580IENGINE CONTROLS

DAEWOO V–121 BL4

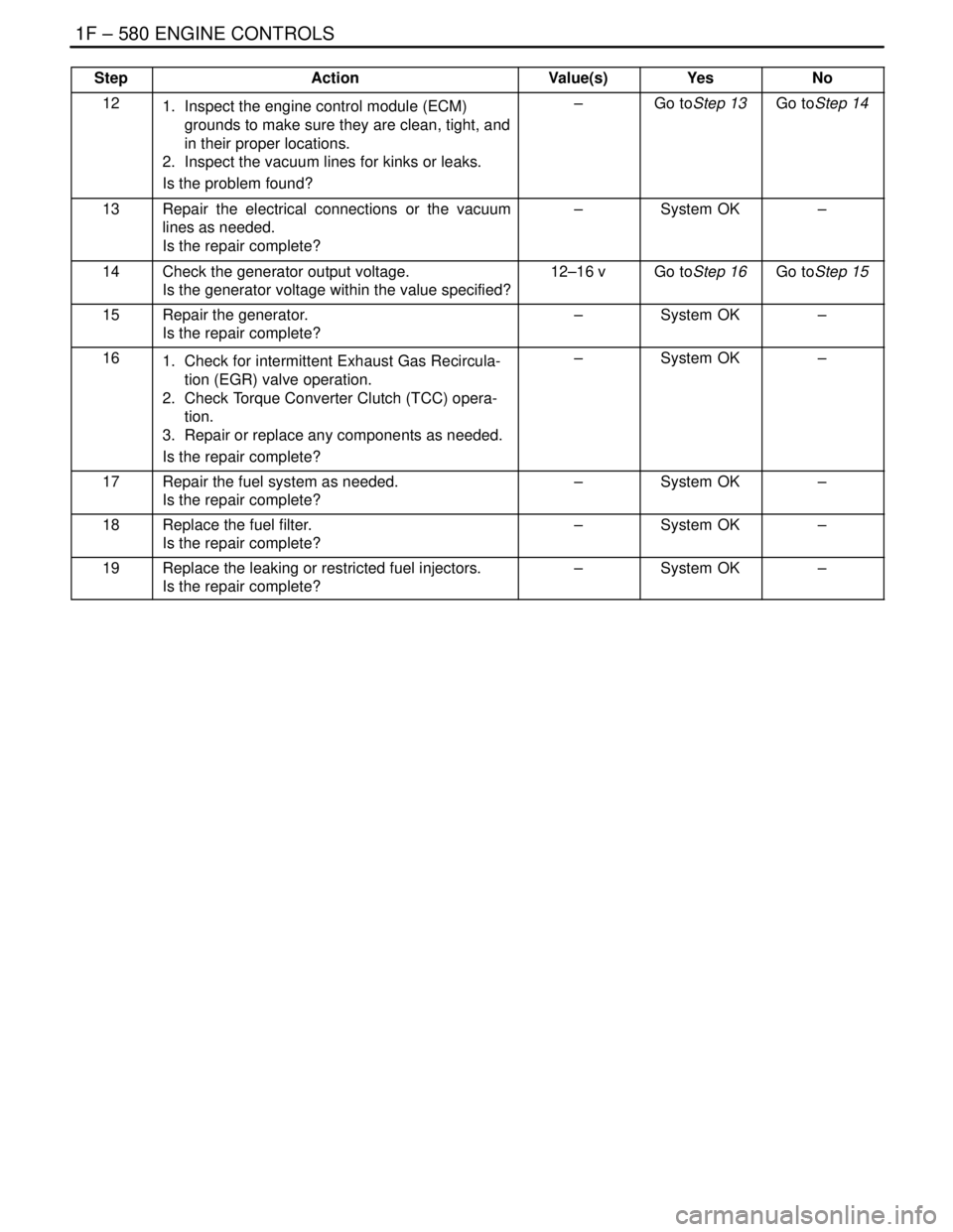

StepNo Yes Value(s) Action

121. Inspect the engine control module (ECM)

grounds to make sure they are clean, tight, and

in their proper locations.

2. Inspect the vacuum lines for kinks or leaks.

Is the problem found?–Go toStep 13Go toStep 14

13Repair the electrical connections or the vacuum

lines as needed.

Is the repair complete?–System OK–

14Check the generator output voltage.

Is the generator voltage within the value specified?12–16 vGo toStep 16Go toStep 15

15Repair the generator.

Is the repair complete?–System OK–

161. Check for intermittent Exhaust Gas Recircula-

tion (EGR) valve operation.

2. Check Torque Converter Clutch (TCC) opera-

tion.

3. Repair or replace any components as needed.

Is the repair complete?–System OK–

17Repair the fuel system as needed.

Is the repair complete?–System OK–

18Replace the fuel filter.

Is the repair complete?–System OK–

19Replace the leaking or restricted fuel injectors.

Is the repair complete?–System OK–

Page 827 of 2643

ENGINE CONTROLS 1F – 581

DAEWOO V–121 BL4

LACK OF POWER, SLUGGISHNESS, OR SPONGINESS

Definition : The engine delivers less than expected power. There is little or no increase in speed when the accelerator pedal

is partially applied.

Step

ActionValue(s)YesNo

1Were the Important Preliminary Checks performed?–Go toStep 2Go to

”Important Pre-

liminary

Checks”

21. Verify the customer’s complaint.

2. Compare the performance of the customer’s

vehicle with a similar unit.

Does the problem exist?–Go toStep 3System OK

31. Inspect the air filter for excessive contamina-

tion.

2. Replace the air filter as needed.

3. Check the transaxle shift pattern and downshift

operation.

Does the transaxle operate properly?–Go toStep 4Go toStep 5

4Check the fuel system pressure.

Is the fuel system pressure within specifications?41–47 psi

(284–325 kPa)Go toStep 7Go toStep 6

5Repair the transaxle as needed.

Is the repair complete?–System OK–

6Repair the fuel system as needed.

Is the repair complete?–System OK–

7Check for a restricted fuel filter or contaminated fuel.

Is the problem found?–Go toStep 8Go toStep 9

8Repair or replace any components as needed.

Is the repair complete?–System OK–

91. Check the ignition system output for all of the

cylinders using a spark tester.

2. Check for proper ignition control operation.

Is the ignition system operating properly?–Go toStep 10Go toStep 11

101. With the engine at normal operating tempera-

ture, connect a vacuum gauge to a vacuum

port on the intake manifold.

2. Operate the engine at 1,000 rpm.

3. Record the vacuum reading.

4. Increase the engine speed to 2,500 rpm.

5. Note the vacuum reading at a steady 2,500

rpm.

Does the vacuum decrease more than the value

specified?10 kPa

(3 in. Hg)Go toStep 12Go toStep 15

11Repair or replace any ignition system components

as needed.

Is the repair complete?–System OK–

12Inspect the exhaust system for restrictions and dam-

aged or collapsed pipes.

Is the problem found?–Go toStep 13Go toStep 15

13Repair or replace any components as needed.

Is the repair complete?–System OK–

Page 831 of 2643

ENGINE CONTROLS 1F – 585

DAEWOO V–121 BL4

StepNo Yes Value(s) Action

71. Perform a cylinder compression test.

2. If the compression is low, repair the engine as

needed.

3. Inspect for proper valve timing, bent pushrods,

worn rocker arms, broken or weak valve

springs, and worn camshaft lobes.

4. Inspect the intake manifold and the exhaust

manifold passages for casting flash.

Is the problem found?–Go toStep 8Go toStep 9

8Repair or replace any components as needed.

Is the repair complete?–System OK–

91. Check the fuel system for a plugged in–line fuel

filter.

2. Check the fuel system for low fuel pressure. If

the fuel pressure is below the value specified,

service the fuel system as needed.

3. Inspect for contaminated fuel.

Is the problem found?41–47 psi

(284–325 kPa)Go toStep 10Go toStep 11

10Repair or replace any components as needed.

Is the repair complete?–System OK–

111. Disconnect all of the fuel injector harness con-

nectors at the fuel injectors.

2. Connect an injector test light to the harness

terminals of each fuel injector connector.

3. Note the test light while cranking the engine for

each fuel injector.

Does the test light blink for all of the fuel injectors?–Go toStep 13Go toStep 12

121. Repair or replace the faulty injector drive circuit

harness, the connector, or the connector termi-

nal.

2. If the harness, the connectors, and the termi-

nals are OK, replace the engine control module

(ECM).

Is the repair complete?–System OK–

13Measure the resistance of each fuel injector. The re-

sistance will increase slightly at higher tempera-

tures.

Is the injector resistance within the value specified?11.6–12.4 ΩGo toStep 15Go toStep 14

14Replace any fuel injectors with a resistance that is

out of specifications.

Is the repair complete?–System OK–

15Perform an injector balance test.

Is the problem found?–Go toStep 16Go toStep 17

16Replace any restricted or leaking fuel injectors.

Is the repair complete?–System OK–

Page 833 of 2643

ENGINE CONTROLS 1F – 587

DAEWOO V–121 BL4

POOR FUEL ECONOMY

Definition : Fuel economy, as measured by an actual road

test, is noticeably lower than expected. Also, fuel econo-

my is noticeably lower than it was on this vehicle at one

time, as previously shown by an actual road test.

Important : Driving habits affect fuel economy. Check the

owner’s driving habits by asking the following questions:1. Is the A/C system (i.e. defroster mode) turned on

all the time?

2. Are the tires at the correct air pressure?

3. Have excessively heavy loads been carried?

4. Does the driver accelerate too much and too often?

Suggest the driver read the section in the owner’s

manual about fuel economy.

Step

ActionValue(s)YesNo

1Were the Important Preliminary Checks performed?–Go toStep 2Go to

”Important Pre-

liminary

Checks”

21. Inspect the air filter for excessive contamina-

tion.

2. Inspect for fuel system leaks.

Are all needed checks complete?–Go toStep 3–

31. Inspect the spark plugs for excessive wear,

insulation cracks, improper gap, or heavy de-

posits.

2. Replace any faulty spark plugs.

3. Inspect the ignition wires for cracking, hard-

ness, and proper connections.

Are all needed checks and repairs complete?–Go toStep 4–

41. Inspect the engine coolant level.

2. Check the thermostat for being always open or

for an incorrect heat range.

3. Replace the thermostat as needed.

Are all needed checks and repairs complete?–Go toStep 5–

51. Check the transaxle shift pattern. Ensure all

transaxle gears are functioning.

2. Check the Torque Converter Clutch (TCC) op-

eration with a scan tool. The scan tool should

indicate rpm drop when the TCC is command-

ed on.

3. Check for proper calibration of the speedome-

ter.

4. Check the brakes for dragging.

5. Check the cylinder compression.

6. Repair, replace, or adjust any components as

needed.

Are all checks and needed repairs complete?–System OK–

Page 865 of 2643

ENGINE CONTROLS 1F – 619

DAEWOO V–121 BL4

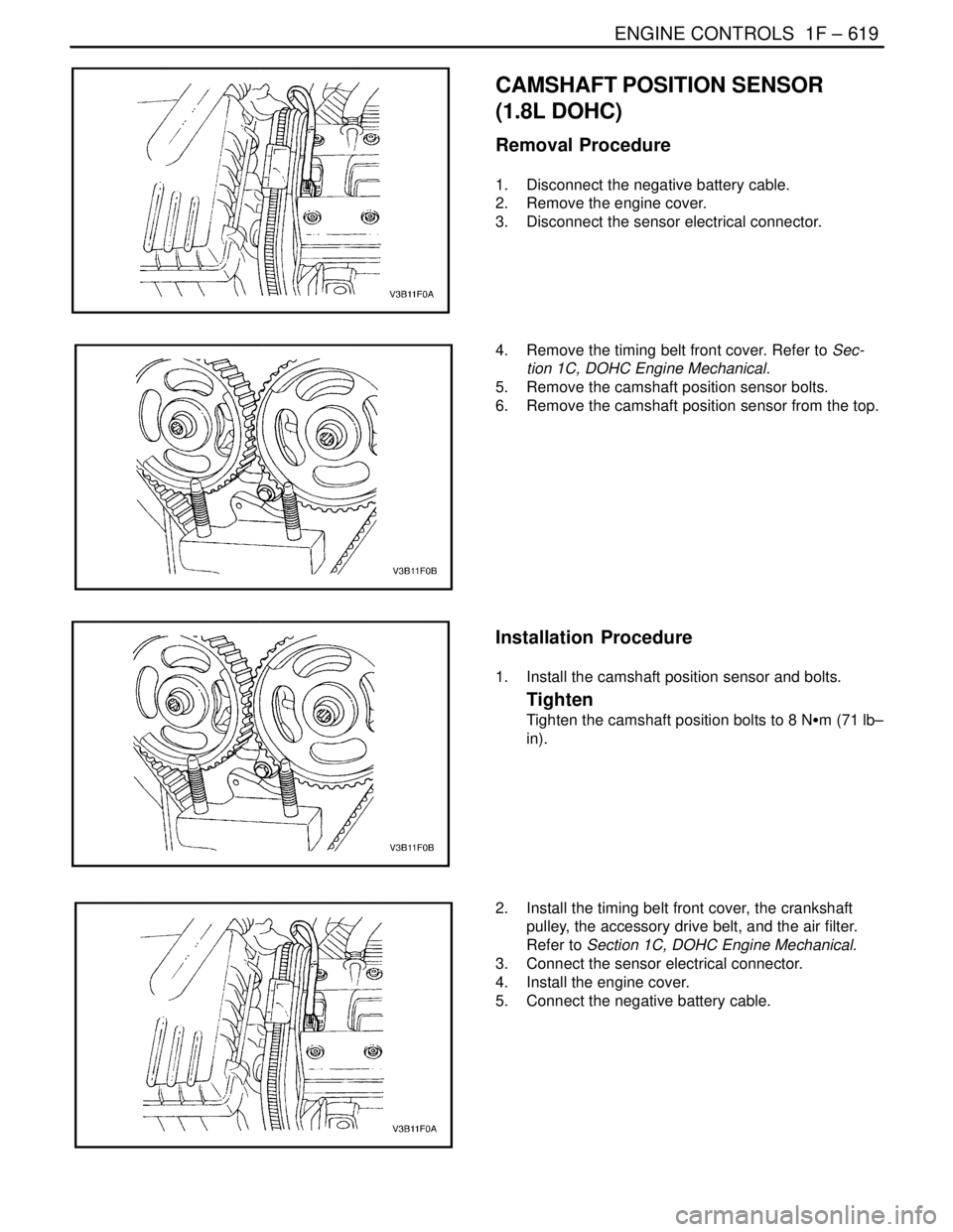

CAMSHAFT POSITION SENSOR

(1.8L DOHC)

Removal Procedure

1. Disconnect the negative battery cable.

2. Remove the engine cover.

3. Disconnect the sensor electrical connector.

4. Remove the timing belt front cover. Refer to Sec-

tion 1C, DOHC Engine Mechanical.

5. Remove the camshaft position sensor bolts.

6. Remove the camshaft position sensor from the top.

Installation Procedure

1. Install the camshaft position sensor and bolts.

Tighten

Tighten the camshaft position bolts to 8 NSm (71 lb–

in).

2. Install the timing belt front cover, the crankshaft

pulley, the accessory drive belt, and the air filter.

Refer to Section 1C, DOHC Engine Mechanical.

3. Connect the sensor electrical connector.

4. Install the engine cover.

5. Connect the negative battery cable.

Page 875 of 2643

ENGINE CONTROLS 1F – 629

DAEWOO V–121 BL4

tentially interfere with the operation of the Exhaust Gas

Recirculation (EGR) valve and thereby turn on the MIL.

Small leaks in the exhaust system near the post catalyst

oxygen sensor can also cause the MIL to turn on.

Aftermarket electronics, such as cellular phones, stereos,

and anti–theft devices, may radiate electromagnetic inter-

ference (EMI) into the control system if they are improperly

installed. This may cause a false sensor reading and turn

on the MIL.

Environment

Temporary environmental conditions, such as localized

flooding, will have an effect on the vehicle ignition system.

If the ignition system is rain–soaked, it can temporarily

cause engine misfire and turn on the MIL.

Refueling

A new EOBD diagnostic checks the integrity of the entire

Evaporative (EVAP) Emission system. If the vehicle is re-

started after refueling and the fuel cap is not secured cor-

rectly, the on–board diagnostic system will sense this as

a system fault, turn on the MIL, and set DTC P0440.

Vehicle Marshaling

The transportation of new vehicles from the assembly

plant to the dealership can involve as many as 60 key

cycles within 2 to 3 miles of driving. This type of operation

contributes to the fuel fouling of the spark plugs and will

turn on the MIL with a set DTC P0300.

Poor Vehicle Maintenance

The sensitivity of EOBD diagnostics will cause the MIL to

turn on if the vehicle is not maintained properly. Restricted

air filters, fuel filters, and crankcase deposits due to lack

of oil changes or improper oil viscosity can trigger actual

vehicle faults that were not previously monitored prior to

EOBD. Poor vehicle maintenance can not be classified as

a ”non–vehicle fault,” but with the sensitivity of EOBD

diagnostics, vehicle maintenance schedules must be

more closely followed.

Severe Vibration

The Misfire diagnostic measures small changes in the

rotational speed of the crankshaft. Severe driveline vibra-

tions in the vehicle, such as caused by an excessive

amount of mud on the wheels, can have the same effect

on crankshaft speed as misfire and, therefore, may set

DTC P0300.

Related System Faults

Many of the EOBD system diagnostics will not run if the

engine controlmodule (ECM) detects a fault on a related

system or component. One example would be that if the

ECM detected a Misfire fault, the diagnostics on the cata-

lytic converter would be suspended until the Misfire fault

was repaired. If the Misfire fault is severe enough, the cat-

alytic converter can be damaged due to overheating andwill never set a Catalyst DTC until the Misfire fault is re-

paired and the Catalyst diagnostic is allowed to run to

completion. If this happens, the customer may have to

make two trips to the dealership in order to repair the ve-

hicle.

SERIAL DATA COMMUNICATIONS

Class II Serial Data Communications

Government regulations require that all vehicle manufac-

turers establish a common communication system. This

vehicle utilizes the ”Class II” communication system. Each

bit of information can have one of two lengths: long or

short. This allows vehicle wiring to be reduced by transmit-

ting and receiving multiple signals over a single wire. The

messages carried on Class II data streams are also priori-

tized. If two messages attempt to establish communica-

tions on the data line at the same time, only the message

with higher priority will continue. The device with the lower

priority message must wait. Themost significant result of

this regulation is that it provides scan tool manufacturers

with the capability to access data from any make or model

vehicle that is sold.

The data displayed on the other scan tool will appear the

same, with some exceptions. Some scan tools will only be

able to display certain vehicle parameters as values that

are a coded representation of the true or actual value. On

this vehicle the scan tool displays the actual values for ve-

hicle parameters. It will not be necessary to perform any

conversions from coded values to actual values.

ON–BOARD DIAGNOSTIC (EOBD)

On–Board Diagnostic Tests

A diagnostic test is a series of steps, the result of which is

a pass or fail reported to the diagnostic executive. When

a diagnostic test reports a pass result, the diagnostic

executive records the following data:

S The diagnostic test has been completed since the

last ignition cycle.

S The diagnostic test has passed during the current

ignition cycle.

S The fault identified by the diagnostic test is not cur-

rently active.

When a diagnostic test reports a fail result, the diagnostic

executive records the following data:

S The diagnostic test has been completed since the

last ignition cycle.

S The fault identified by the diagnostic test is current-

ly active.

S The fault has been active during this ignition cycle.

S The operating conditions at the time of the failure.

Remember, a fuel trim Diagnostic Trouble Code (DTC)

may be triggered by a list of vehicle faults. Make use of all

information available (other DTCs stored, rich or lean con-

dition, etc.) when diagnosing a fuel trim fault.

Page 1394 of 2643

ZF 4 HP 16 AUTOMATIC TRANSAXLE 5A1 – 45

DAEWOO V–121 BL4

CLUTCH PLATE DIAGNOSIS

Composition Plates

Dry the plate and inspect the plates for the following condi-

tions :

S Pitting

S Flaking

S Wear

S Glazing

S Cracking

S Charring

Chips or metal particles embedded in the lining

Replace a composition plate which shows any of these

conditions.

Steel Plates

Wipe the plates dry and check the plates for heat discolor-

ation. If the surfaces are smooth, even if colorsmear is in-

dicated, you can reuse the plate. If the plate is discolored

with hot spots or if the surface is scuffed, replace the plate.

Important : If the clutch shows evidence or extreme heat

or burning, replace the springs.

Causes of Burned Clutch Plates

The following conditions can result in a burned clutch

plate:

S Incorrect usage of clutch plates.

S Engine coolant in the transaxle fluid.

S A cracked clutch piston.

S Damaged or missing seals.

S Low line pressure.

S Valve problems.

– The valve body face is not flat

– Porosity between channels

– The valve bushing clips are improperly installed.

– The check balls are misplaced.

S The seal rings are worn or damaged

Engine Coolant in Transaxle

Notice : Antifreeze will deteriorate the O–ring seals and

the glue used to bond the clutch material to the pressure

plate. Both conditions may cause transaxle damage.

Perform the following steps if the transaxle oil cooler has

developed a leak, allowing engine coolant to enter the

transaxle:

1. Because the coolant will attach to the seal material

causing leakage, disassemble the transaxle and

replace all rubber type seals.

2. Because the facing material may become sepa-

rated from the steel center portion, replace the

composition faced clutch plate assemblies.

3. Replace all nylon parts including washers.

4. Replace the torque converter.

5. Thoroughly clean and rebuild the transaxle, using

new gaskets and oil filter.6. Flush the cooler lines after you have properly re-

paired or replaced the transaxle.

COOLER FLUSHING AND FLOW

TEST

Notice : You must flush the cooler whenever you receive

a transaxle for service. Cooler flushing is essential for

SRTA installation, major overhaul, whenever you replace

a pump or torque converter, or whenever you suspect that

the fluid has been contaminated.

After filling the transaxle with fluid, start the engine and run

for 30 seconds. This will remove any residual moisture

from the oil cooler. Disconnect the return line at the trans-

axle and observe the flow with the engine running. If the

fluid flow is insufficient, check the fluid flow by disconnect-

ing the feed line at the cooler. Observe the flow with the

engine running.

S If the flow from the cooler return line at the trans-

axle is insufficient, check the flow rate from the feed

line to the cooler. BLockage exists in the transaxle

or the cooler.

S If the flow from the transaxle feed line to the cooler

is insufficient, the transaxle is the cause of the fluid

flow problem.

S If the flow the transaxle feed line to the cooler is

insufficient, but flow from the cooler return line to

the transaxle is insufficient, inspect the cooler pipes

and fittings. Then repeat the cooler flushing proce-

dure. If the flow is still insufficient, replace the cool-

er.

TRANSAXLE FLUID LEVEL SERVICE

PROCEDURE

This procedure is to be used when checking a concern

with the fluid level in a vehicle. A low fluid level will result

in slipping and loss of drive/ reverse or delay on engage-

ment of drive/ reverse when the vehicle is cold.

The vehicle is first checked for transaxle diagnostic mes-

sages on the scan tool. If the oil level is low, it is possible

to register a vehicle speed signal fault.

The vehicle is to be test driven to determine if there is an

abnormal delay when selecting drive or reverse, or loss of

drive. One symptom of low fluid level is a momentary loss

of drive when driving the vehicle around a corner. Also

when the transaxle fluid level is low, a loss of drive may oc-

cur when the transaxle fluid temperature is low.

When adding or changing transaxle fluid use only ESSO

LT 71141 automatic transaxle fluid or other approved

fluids. The use of incorrect fluid will cause the performance

and durability of the transaxle to be severely degraded.

Fluid Level Diagnosis Procedure

1. If the vehicle is at operating temperature allow the

vehicle to cool down for two hours, but no greater

than four hours. Or if the vehicle is at cool status,

start the engine and allow the engine to idle for

approximately 5 minutes (825~875 rpm), if pos-