lock DAEWOO LACETTI 2004 Service Owner's Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 81 of 2643

1C1 – 38I1.4L/1.6L DOHC ENGINE MECHANICAL

DAEWOO V–121 BL4

OIL PAN

Removal Procedure

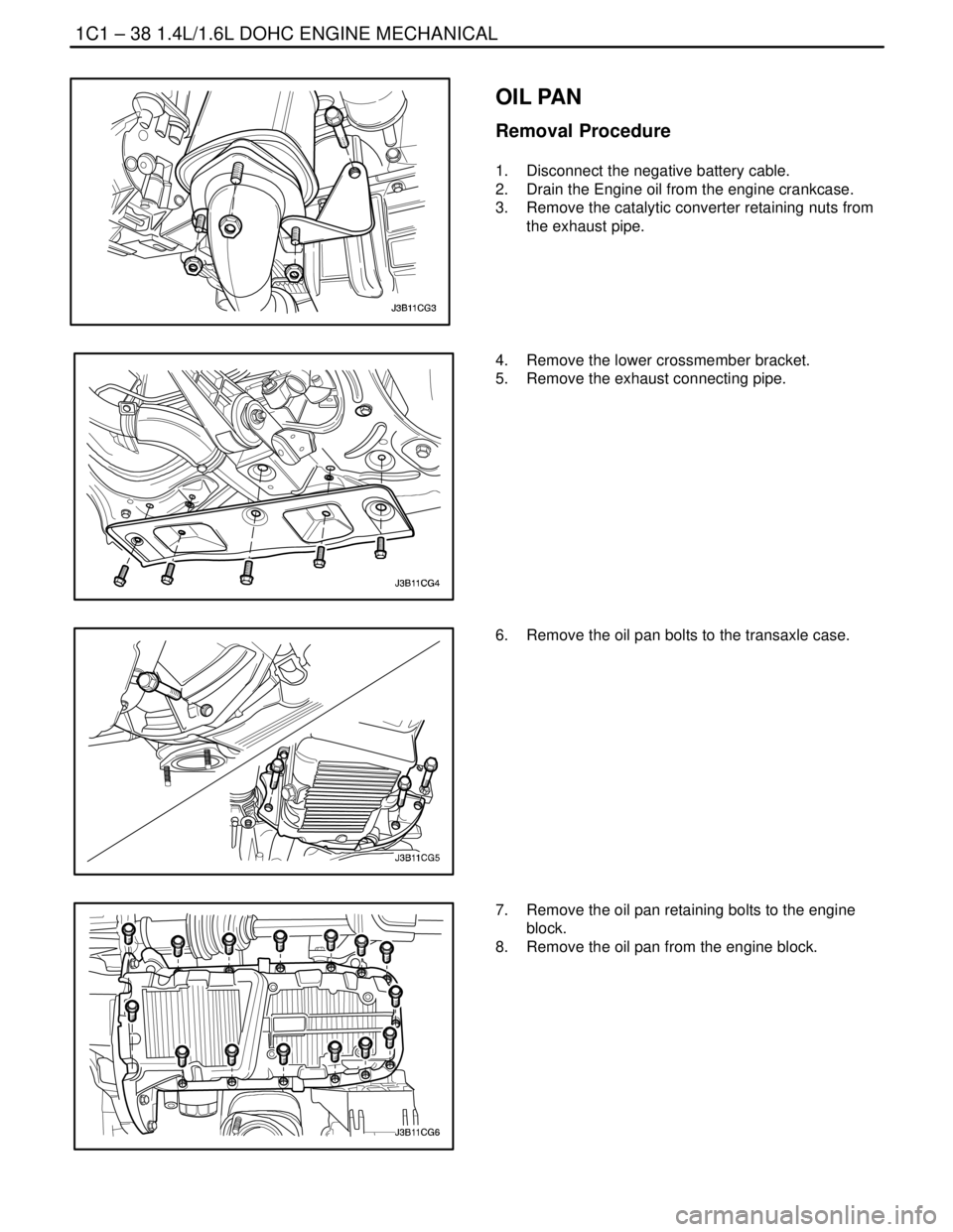

1. Disconnect the negative battery cable.

2. Drain the Engine oil from the engine crankcase.

3. Remove the catalytic converter retaining nuts from

the exhaust pipe.

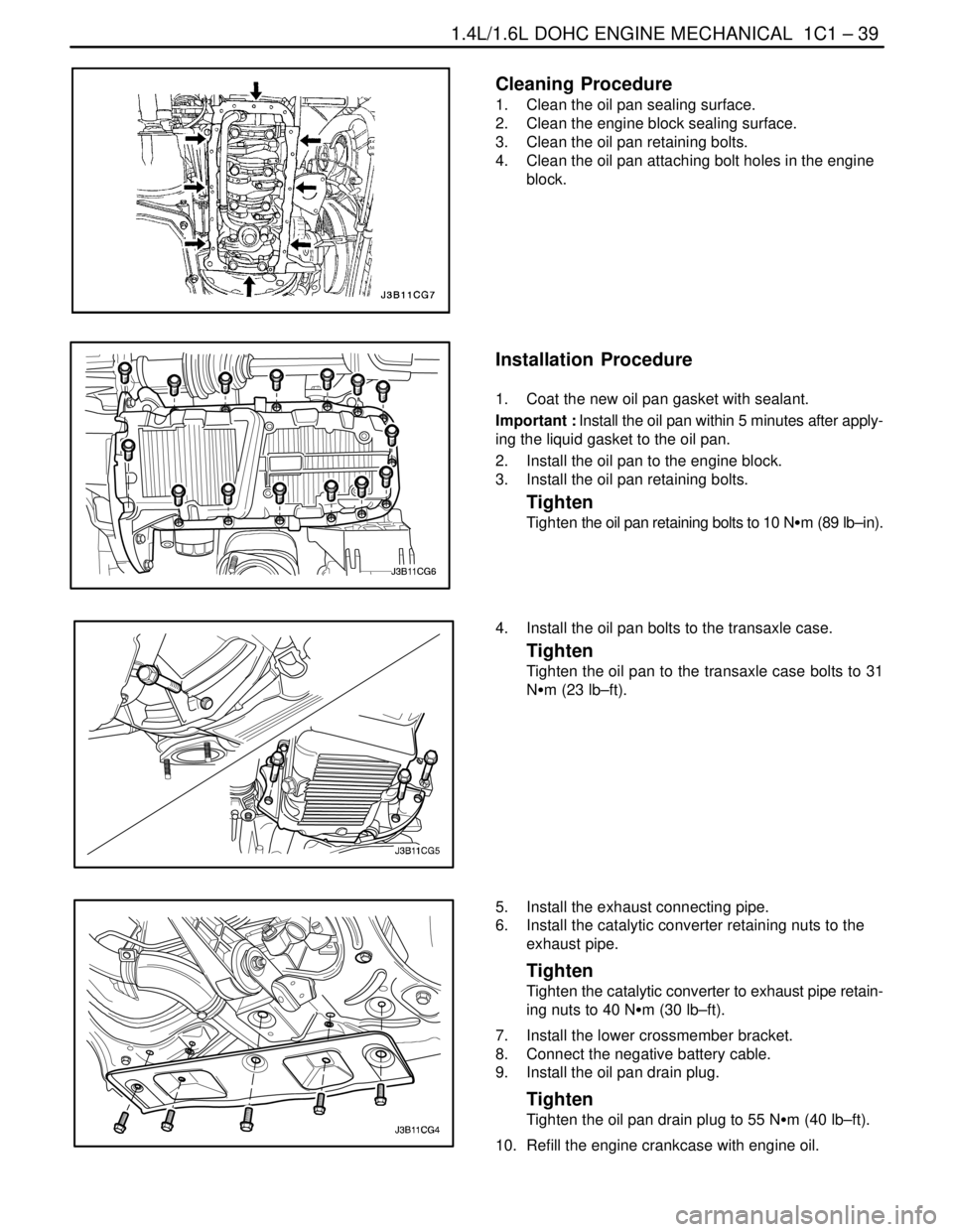

4. Remove the lower crossmember bracket.

5. Remove the exhaust connecting pipe.

6. Remove the oil pan bolts to the transaxle case.

7. Remove the oil pan retaining bolts to the engine

block.

8. Remove the oil pan from the engine block.

Page 82 of 2643

1.4L/1.6L DOHC ENGINE MECHANICAL 1C1 – 39

DAEWOO V–121 BL4

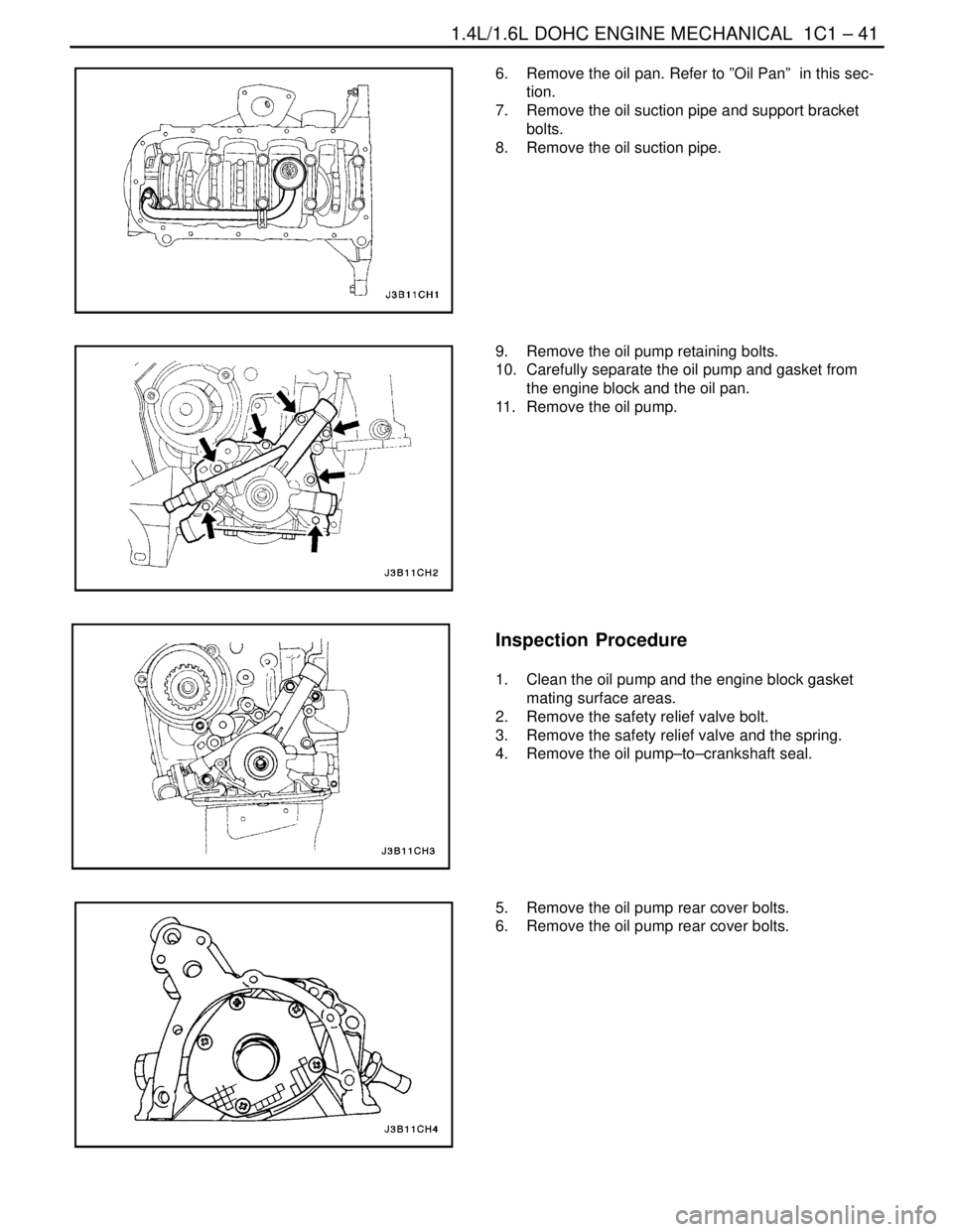

Cleaning Procedure

1. Clean the oil pan sealing surface.

2. Clean the engine block sealing surface.

3. Clean the oil pan retaining bolts.

4. Clean the oil pan attaching bolt holes in the engine

block.

Installation Procedure

1. Coat the new oil pan gasket with sealant.

Important : Install the oil pan within 5 minutes after apply-

ing the liquid gasket to the oil pan.

2. Install the oil pan to the engine block.

3. Install the oil pan retaining bolts.

Tighten

Tighten the oil pan retaining bolts to 10 NSm (89 lb–in).

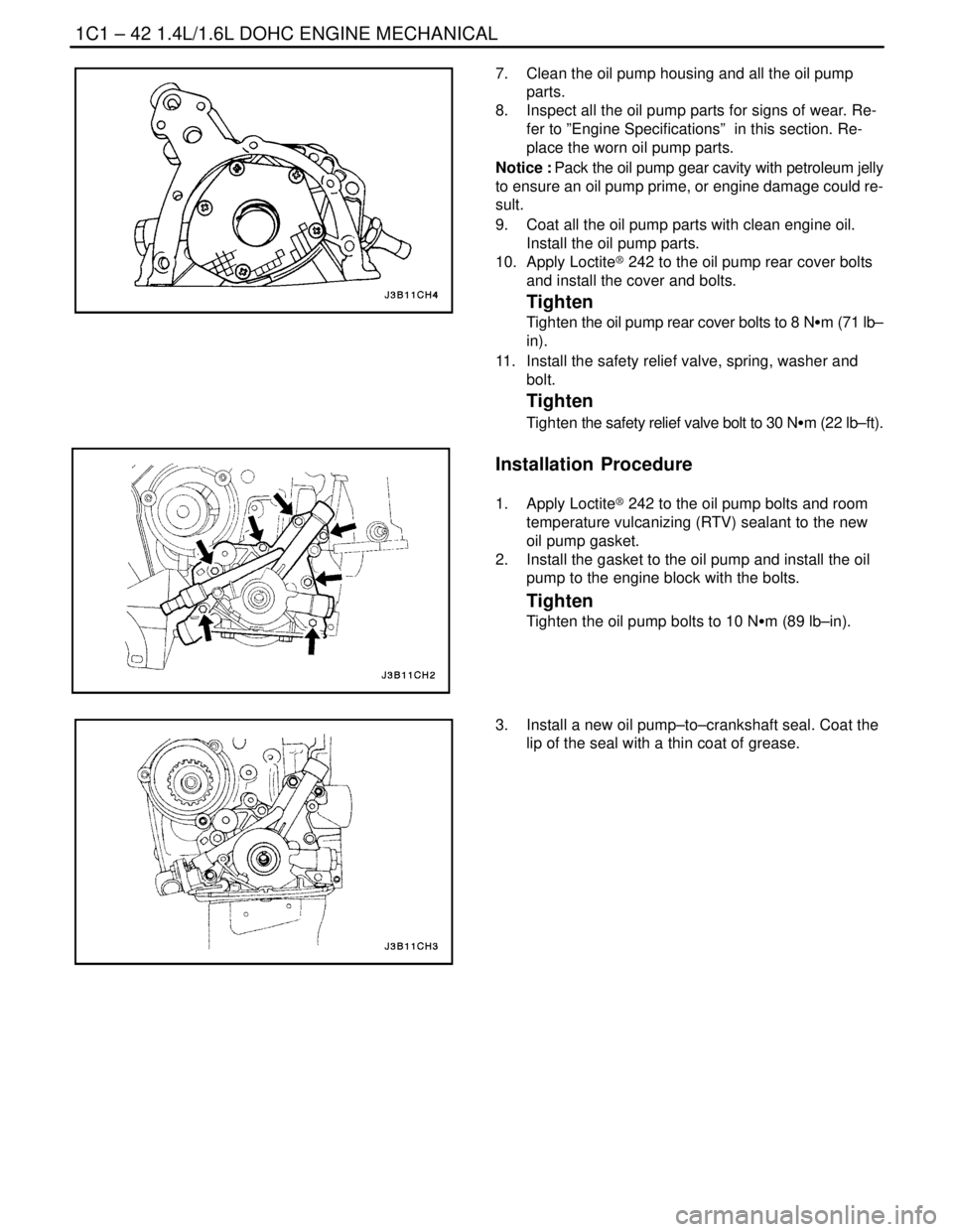

4. Install the oil pan bolts to the transaxle case.

Tighten

Tighten the oil pan to the transaxle case bolts to 31

NSm (23 lb–ft).

5. Install the exhaust connecting pipe.

6. Install the catalytic converter retaining nuts to the

exhaust pipe.

Tighten

Tighten the catalytic converter to exhaust pipe retain-

ing nuts to 40 NSm (30 lb–ft).

7. Install the lower crossmember bracket.

8. Connect the negative battery cable.

9. Install the oil pan drain plug.

Tighten

Tighten the oil pan drain plug to 55 NSm (40 lb–ft).

10. Refill the engine crankcase with engine oil.

Page 84 of 2643

1.4L/1.6L DOHC ENGINE MECHANICAL 1C1 – 41

DAEWOO V–121 BL4

6. Remove the oil pan. Refer to ”Oil Pan” in this sec-

tion.

7. Remove the oil suction pipe and support bracket

bolts.

8. Remove the oil suction pipe.

9. Remove the oil pump retaining bolts.

10. Carefully separate the oil pump and gasket from

the engine block and the oil pan.

11. Remove the oil pump.

Inspection Procedure

1. Clean the oil pump and the engine block gasket

mating surface areas.

2. Remove the safety relief valve bolt.

3. Remove the safety relief valve and the spring.

4. Remove the oil pump–to–crankshaft seal.

5. Remove the oil pump rear cover bolts.

6. Remove the oil pump rear cover bolts.

Page 85 of 2643

1C1 – 42I1.4L/1.6L DOHC ENGINE MECHANICAL

DAEWOO V–121 BL4

7. Clean the oil pump housing and all the oil pump

parts.

8. Inspect all the oil pump parts for signs of wear. Re-

fer to ”Engine Specifications” in this section. Re-

place the worn oil pump parts.

Notice : Pack the oil pump gear cavity with petroleum jelly

to ensure an oil pump prime, or engine damage could re-

sult.

9. Coat all the oil pump parts with clean engine oil.

Install the oil pump parts.

10. Apply Loctite® 242 to the oil pump rear cover bolts

and install the cover and bolts.

Tighten

Tighten the oil pump rear cover bolts to 8 NSm (71 lb–

in).

11. Install the safety relief valve, spring, washer and

bolt.

Tighten

Tighten the safety relief valve bolt to 30 NSm (22 lb–ft).

Installation Procedure

1. Apply Loctite® 242 to the oil pump bolts and room

temperature vulcanizing (RTV) sealant to the new

oil pump gasket.

2. Install the gasket to the oil pump and install the oil

pump to the engine block with the bolts.

Tighten

Tighten the oil pump bolts to 10 NSm (89 lb–in).

3. Install a new oil pump–to–crankshaft seal. Coat the

lip of the seal with a thin coat of grease.

Page 93 of 2643

1C1 – 50I1.4L/1.6L DOHC ENGINE MECHANICAL

DAEWOO V–121 BL4

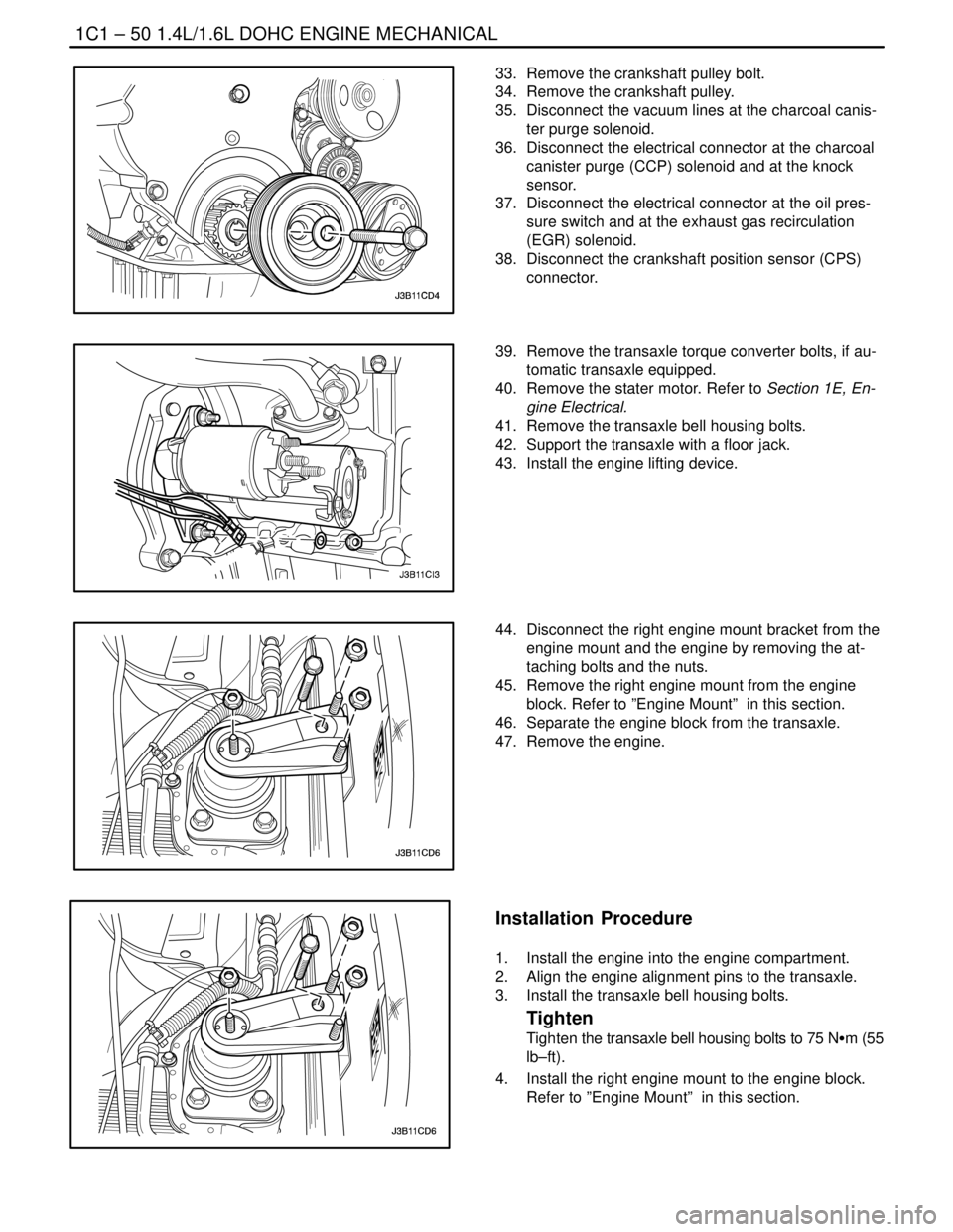

33. Remove the crankshaft pulley bolt.

34. Remove the crankshaft pulley.

35. Disconnect the vacuum lines at the charcoal canis-

ter purge solenoid.

36. Disconnect the electrical connector at the charcoal

canister purge (CCP) solenoid and at the knock

sensor.

37. Disconnect the electrical connector at the oil pres-

sure switch and at the exhaust gas recirculation

(EGR) solenoid.

38. Disconnect the crankshaft position sensor (CPS)

connector.

39. Remove the transaxle torque converter bolts, if au-

tomatic transaxle equipped.

40. Remove the stater motor. Refer to Section 1E, En-

gine Electrical.

41. Remove the transaxle bell housing bolts.

42. Support the transaxle with a floor jack.

43. Install the engine lifting device.

44. Disconnect the right engine mount bracket from the

engine mount and the engine by removing the at-

taching bolts and the nuts.

45. Remove the right engine mount from the engine

block. Refer to ”Engine Mount” in this section.

46. Separate the engine block from the transaxle.

47. Remove the engine.

Installation Procedure

1. Install the engine into the engine compartment.

2. Align the engine alignment pins to the transaxle.

3. Install the transaxle bell housing bolts.

Tighten

Tighten the transaxle bell housing bolts to 75 NSm (55

lb–ft).

4. Install the right engine mount to the engine block.

Refer to ”Engine Mount” in this section.

Page 98 of 2643

1.4L/1.6L DOHC ENGINE MECHANICAL 1C1 – 55

DAEWOO V–121 BL4

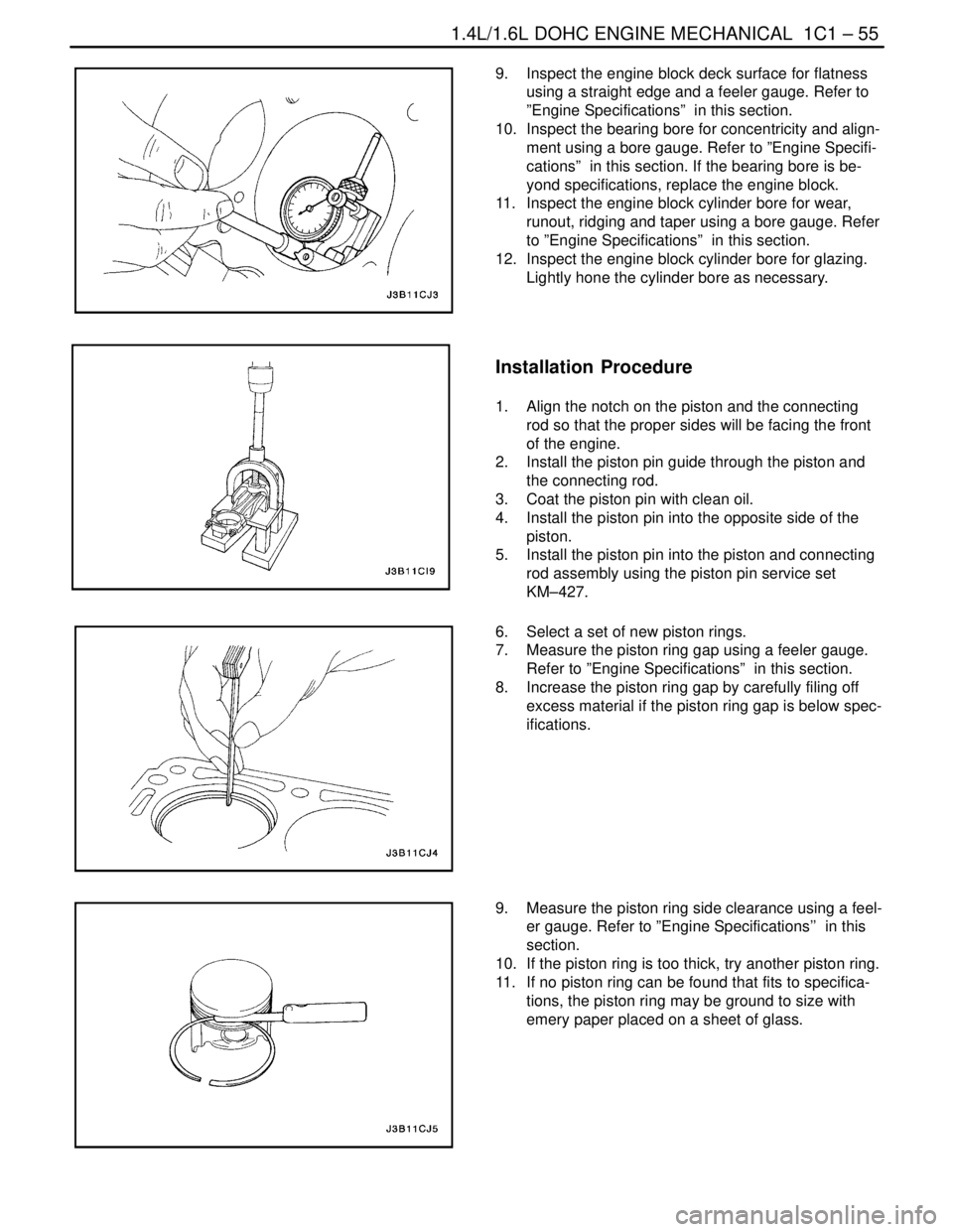

9. Inspect the engine block deck surface for flatness

using a straight edge and a feeler gauge. Refer to

”Engine Specifications” in this section.

10. Inspect the bearing bore for concentricity and align-

ment using a bore gauge. Refer to ”Engine Specifi-

cations” in this section. If the bearing bore is be-

yond specifications, replace the engine block.

11. Inspect the engine block cylinder bore for wear,

runout, ridging and taper using a bore gauge. Refer

to ”Engine Specifications” in this section.

12. Inspect the engine block cylinder bore for glazing.

Lightly hone the cylinder bore as necessary.

Installation Procedure

1. Align the notch on the piston and the connecting

rod so that the proper sides will be facing the front

of the engine.

2. Install the piston pin guide through the piston and

the connecting rod.

3. Coat the piston pin with clean oil.

4. Install the piston pin into the opposite side of the

piston.

5. Install the piston pin into the piston and connecting

rod assembly using the piston pin service set

KM–427.

6. Select a set of new piston rings.

7. Measure the piston ring gap using a feeler gauge.

Refer to ”Engine Specifications” in this section.

8. Increase the piston ring gap by carefully filing off

excess material if the piston ring gap is below spec-

ifications.

9. Measure the piston ring side clearance using a feel-

er gauge. Refer to ”Engine Specifications’’ in this

section.

10. If the piston ring is too thick, try another piston ring.

11. If no piston ring can be found that fits to specifica-

tions, the piston ring may be ground to size with

emery paper placed on a sheet of glass.

Page 105 of 2643

1C1 – 62I1.4L/1.6L DOHC ENGINE MECHANICAL

DAEWOO V–121 BL4

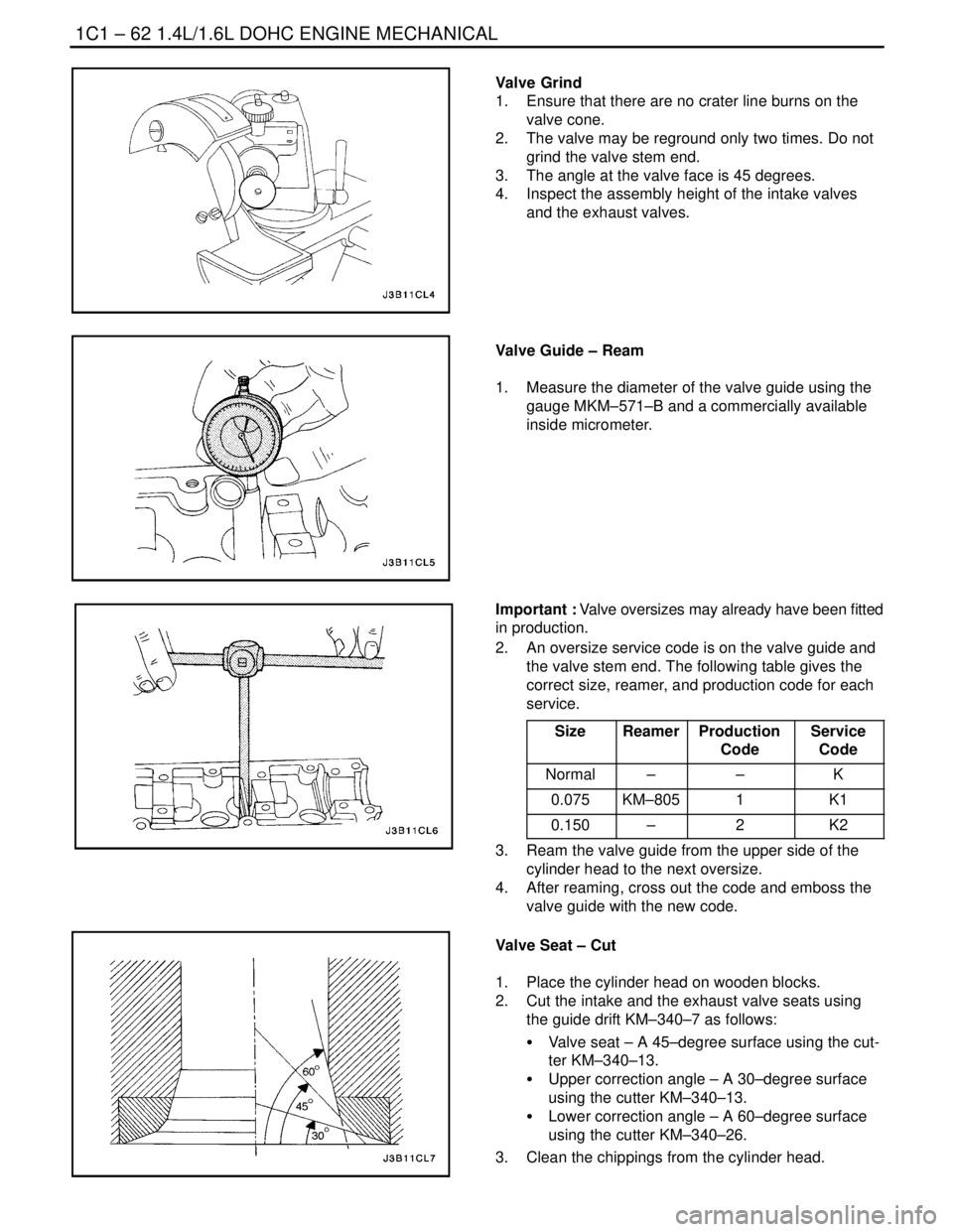

Valve Grind

1. Ensure that there are no crater line burns on the

valve cone.

2. The valve may be reground only two times. Do not

grind the valve stem end.

3. The angle at the valve face is 45 degrees.

4. Inspect the assembly height of the intake valves

and the exhaust valves.

Valve Guide – Ream

1. Measure the diameter of the valve guide using the

gauge MKM–571–B and a commercially available

inside micrometer.

Important : Valve oversizes may already have been fitted

in production.

2. An oversize service code is on the valve guide and

the valve stem end. The following table gives the

correct size, reamer, and production code for each

service.

Size

ReamerProduction

CodeService

Code

Normal––K

0.075KM–8051K1

0.150–2K2

3. Ream the valve guide from the upper side of the

cylinder head to the next oversize.

4. After reaming, cross out the code and emboss the

valve guide with the new code.

Valve Seat – Cut

1. Place the cylinder head on wooden blocks.

2. Cut the intake and the exhaust valve seats using

the guide drift KM–340–7 as follows:

S Valve seat – A 45–degree surface using the cut-

ter KM–340–13.

S Upper correction angle – A 30–degree surface

using the cutter KM–340–13.

S Lower correction angle – A 60–degree surface

using the cutter KM–340–26.

3. Clean the chippings from the cylinder head.

Page 112 of 2643

1.4L/1.6L DOHC ENGINE MECHANICAL 1C1 – 69

DAEWOO V–121 BL4

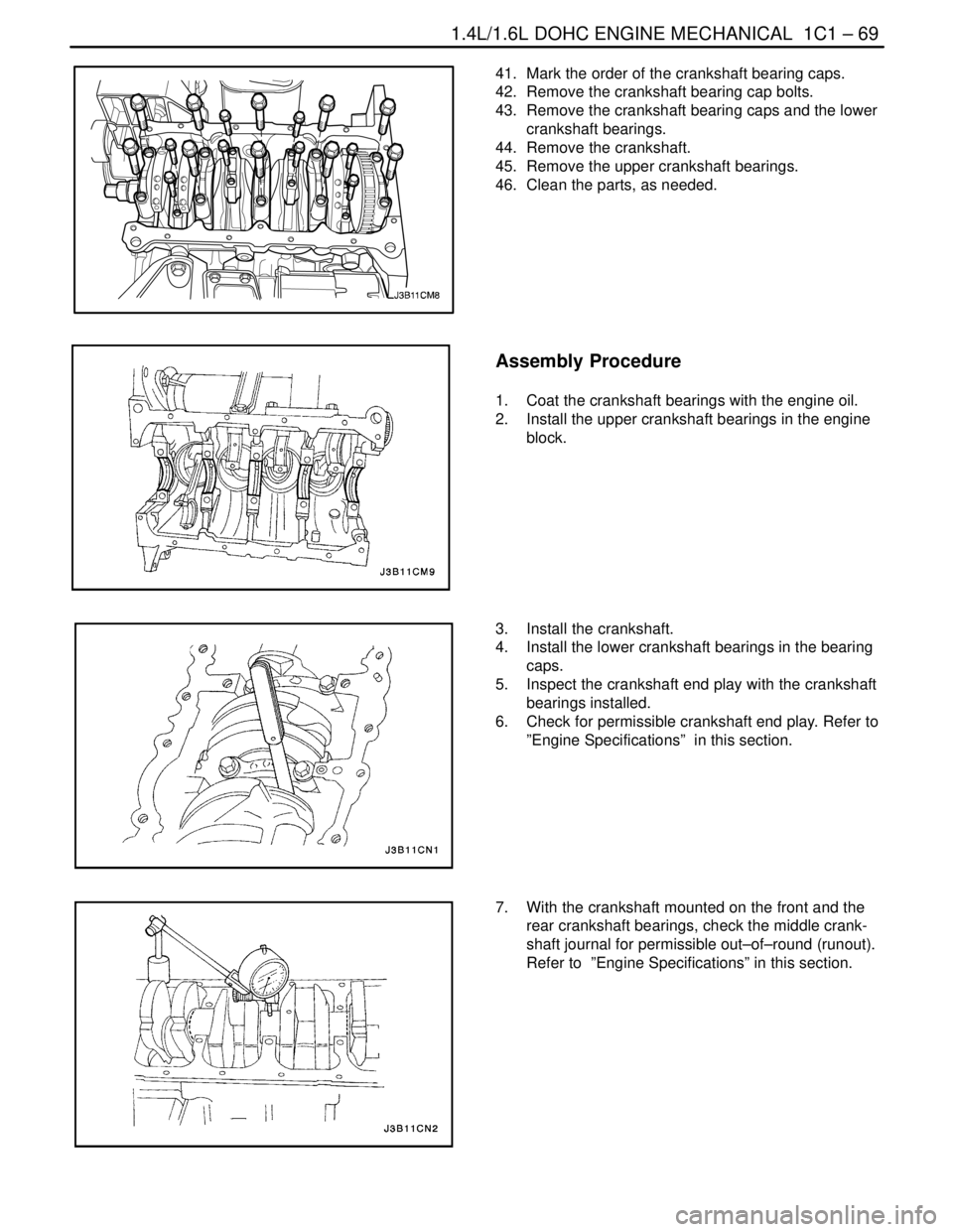

41. Mark the order of the crankshaft bearing caps.

42. Remove the crankshaft bearing cap bolts.

43. Remove the crankshaft bearing caps and the lower

crankshaft bearings.

44. Remove the crankshaft.

45. Remove the upper crankshaft bearings.

46. Clean the parts, as needed.

Assembly Procedure

1. Coat the crankshaft bearings with the engine oil.

2. Install the upper crankshaft bearings in the engine

block.

3. Install the crankshaft.

4. Install the lower crankshaft bearings in the bearing

caps.

5. Inspect the crankshaft end play with the crankshaft

bearings installed.

6. Check for permissible crankshaft end play. Refer to

”Engine Specifications” in this section.

7. With the crankshaft mounted on the front and the

rear crankshaft bearings, check the middle crank-

shaft journal for permissible out–of–round (runout).

Refer to ”Engine Specifications” in this section.

Page 113 of 2643

1C1 – 70I1.4L/1.6L DOHC ENGINE MECHANICAL

DAEWOO V–121 BL4

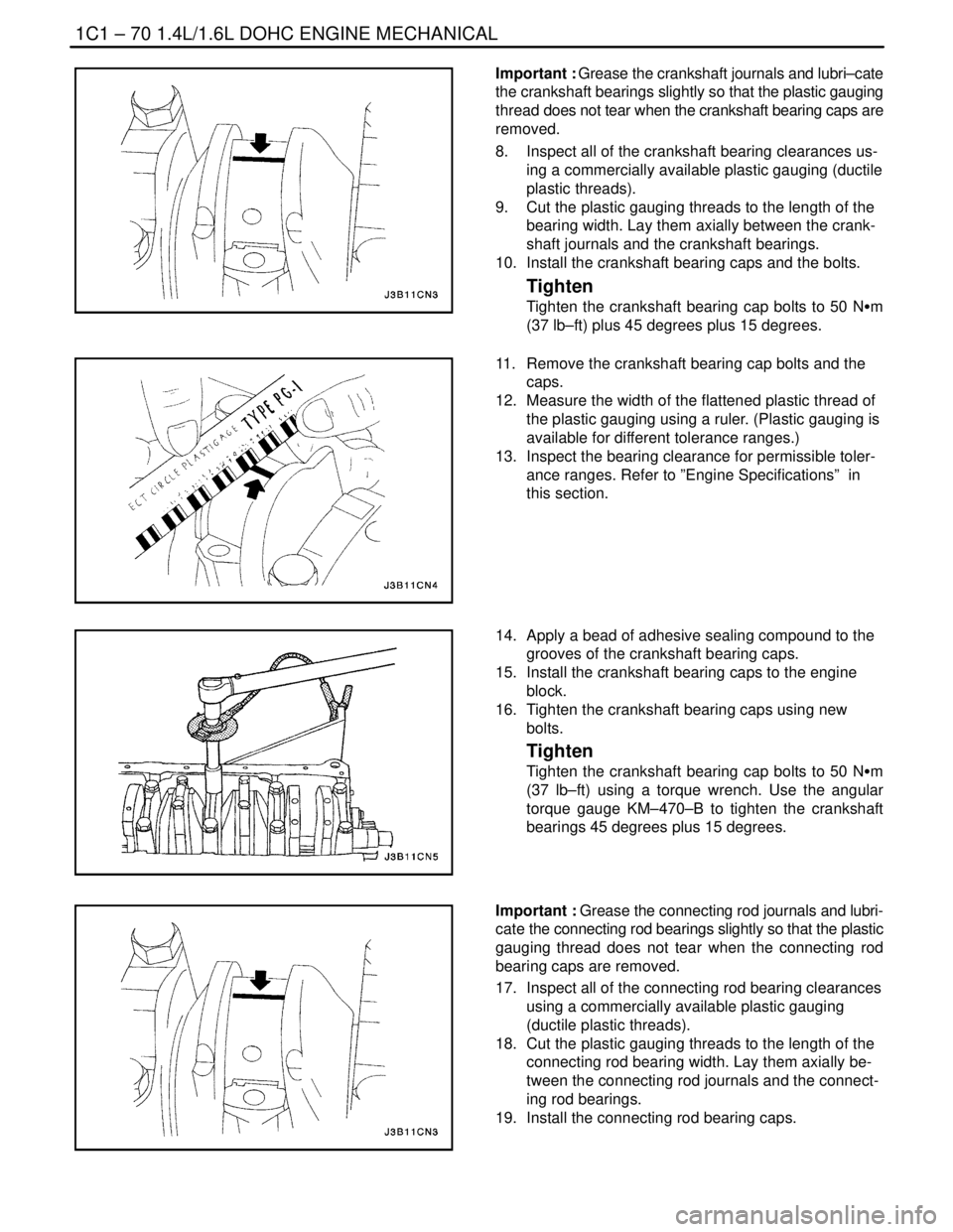

Important : Grease the crankshaft journals and lubri–cate

the crankshaft bearings slightly so that the plastic gauging

thread does not tear when the crankshaft bearing caps are

removed.

8. Inspect all of the crankshaft bearing clearances us-

ing a commercially available plastic gauging (ductile

plastic threads).

9. Cut the plastic gauging threads to the length of the

bearing width. Lay them axially between the crank-

shaft journals and the crankshaft bearings.

10. Install the crankshaft bearing caps and the bolts.

Tighten

Tighten the crankshaft bearing cap bolts to 50 NSm

(37 lb–ft) plus 45 degrees plus 15 degrees.

11. Remove the crankshaft bearing cap bolts and the

caps.

12. Measure the width of the flattened plastic thread of

the plastic gauging using a ruler. (Plastic gauging is

available for different tolerance ranges.)

13. Inspect the bearing clearance for permissible toler-

ance ranges. Refer to ”Engine Specifications” in

this section.

14. Apply a bead of adhesive sealing compound to the

grooves of the crankshaft bearing caps.

15. Install the crankshaft bearing caps to the engine

block.

16. Tighten the crankshaft bearing caps using new

bolts.

Tighten

Tighten the crankshaft bearing cap bolts to 50 NSm

(37 lb–ft) using a torque wrench. Use the angular

torque gauge KM–470–B to tighten the crankshaft

bearings 45 degrees plus 15 degrees.

Important : Grease the connecting rod journals and lubri-

cate the connecting rod bearings slightly so that the plastic

gauging thread does not tear when the connecting rod

bearing caps are removed.

17. Inspect all of the connecting rod bearing clearances

using a commercially available plastic gauging

(ductile plastic threads).

18. Cut the plastic gauging threads to the length of the

connecting rod bearing width. Lay them axially be-

tween the connecting rod journals and the connect-

ing rod bearings.

19. Install the connecting rod bearing caps.

Page 117 of 2643

1C1 – 74I1.4L/1.6L DOHC ENGINE MECHANICAL

DAEWOO V–121 BL4

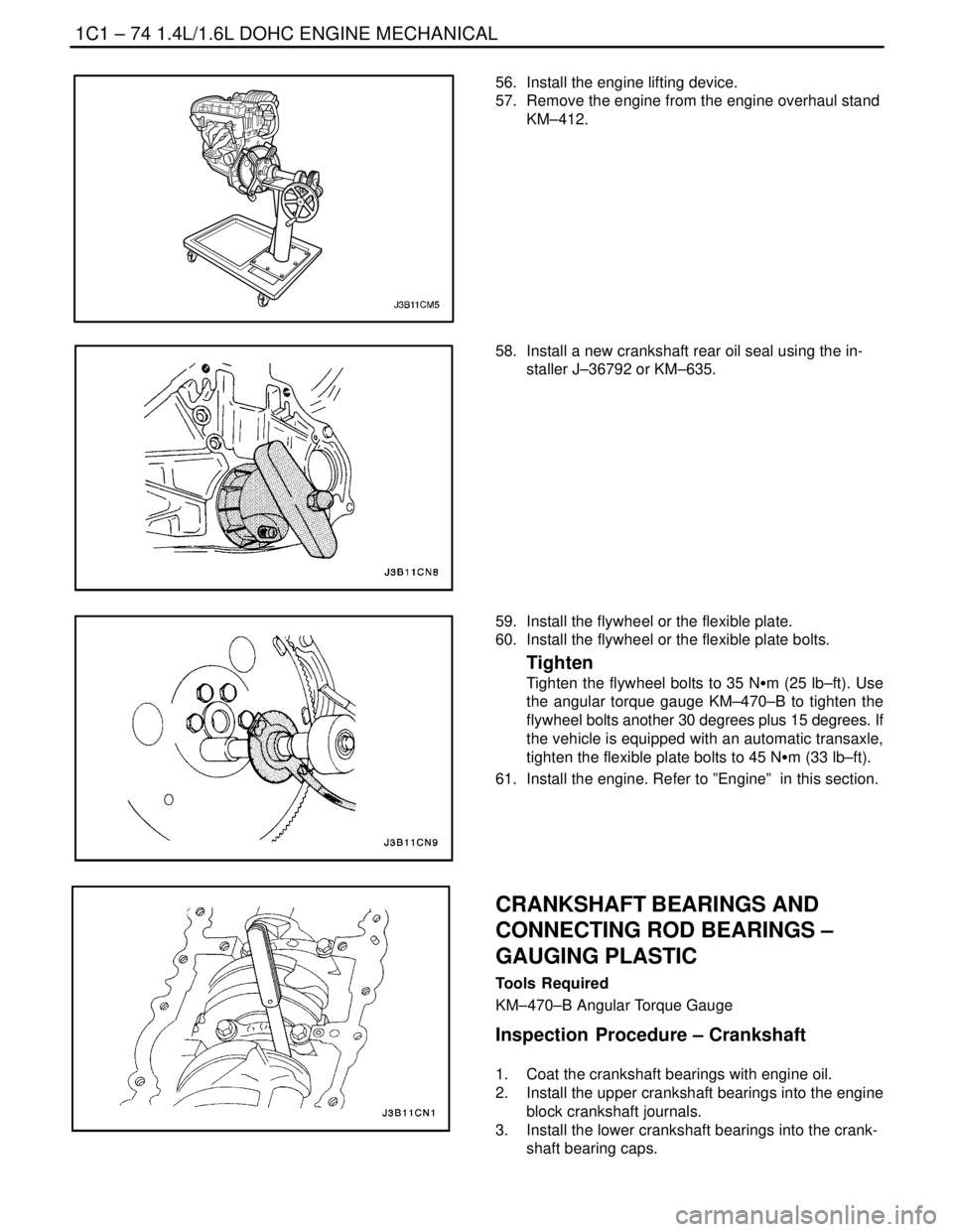

56. Install the engine lifting device.

57. Remove the engine from the engine overhaul stand

KM–412.

58. Install a new crankshaft rear oil seal using the in-

staller J–36792 or KM–635.

59. Install the flywheel or the flexible plate.

60. Install the flywheel or the flexible plate bolts.

Tighten

Tighten the flywheel bolts to 35 NSm (25 lb–ft). Use

the angular torque gauge KM–470–B to tighten the

flywheel bolts another 30 degrees plus 15 degrees. If

the vehicle is equipped with an automatic transaxle,

tighten the flexible plate bolts to 45 NSm (33 lb–ft).

61. Install the engine. Refer to ”Engine” in this section.

CRANKSHAFT BEARINGS AND

CONNECTING ROD BEARINGS –

GAUGING PLASTIC

Tools Required

KM–470–B Angular Torque Gauge

Inspection Procedure – Crankshaft

1. Coat the crankshaft bearings with engine oil.

2. Install the upper crankshaft bearings into the engine

block crankshaft journals.

3. Install the lower crankshaft bearings into the crank-

shaft bearing caps.