speed DAEWOO LACETTI 2004 Service Owner's Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 248 of 2643

1F – 2IENGINE CONTROLS

DAEWOO V–121 BL4

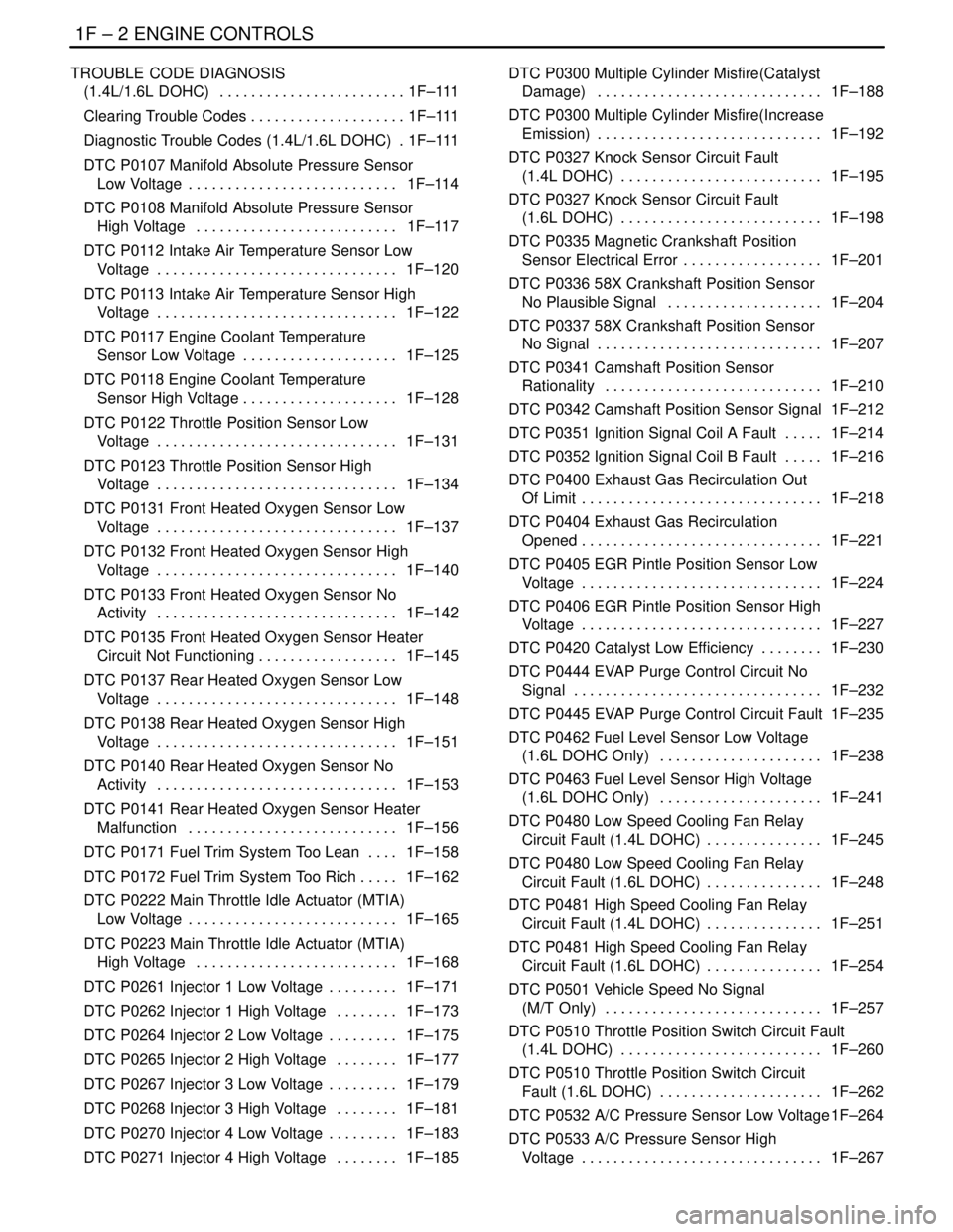

TROUBLE CODE DIAGNOSIS

(1.4L/1.6L DOHC) 1F–111. . . . . . . . . . . . . . . . . . . . . . . .

Clearing Trouble Codes 1F–111. . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Codes (1.4L/1.6L DOHC) 1F–111.

DTC P0107 Manifold Absolute Pressure Sensor

Low Voltage 1F–114. . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0108 Manifold Absolute Pressure Sensor

High Voltage 1F–117. . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0112 Intake Air Temperature Sensor Low

Voltage 1F–120. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0113 Intake Air Temperature Sensor High

Voltage 1F–122. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0117 Engine Coolant Temperature

Sensor Low Voltage 1F–125. . . . . . . . . . . . . . . . . . . .

DTC P0118 Engine Coolant Temperature

Sensor High Voltage 1F–128. . . . . . . . . . . . . . . . . . . .

DTC P0122 Throttle Position Sensor Low

Voltage 1F–131. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0123 Throttle Position Sensor High

Voltage 1F–134. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0131 Front Heated Oxygen Sensor Low

Voltage 1F–137. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0132 Front Heated Oxygen Sensor High

Voltage 1F–140. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0133 Front Heated Oxygen Sensor No

Activity 1F–142. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0135 Front Heated Oxygen Sensor Heater

Circuit Not Functioning 1F–145. . . . . . . . . . . . . . . . . .

DTC P0137 Rear Heated Oxygen Sensor Low

Voltage 1F–148. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0138 Rear Heated Oxygen Sensor High

Voltage 1F–151. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0140 Rear Heated Oxygen Sensor No

Activity 1F–153. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0141 Rear Heated Oxygen Sensor Heater

Malfunction 1F–156. . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0171 Fuel Trim System Too Lean 1F–158. . . .

DTC P0172 Fuel Trim System Too Rich 1F–162. . . . .

DTC P0222 Main Throttle Idle Actuator (MTIA)

Low Voltage 1F–165. . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0223 Main Throttle Idle Actuator (MTIA)

High Voltage 1F–168. . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0261 Injector 1 Low Voltage 1F–171. . . . . . . . .

DTC P0262 Injector 1 High Voltage 1F–173. . . . . . . .

DTC P0264 Injector 2 Low Voltage 1F–175. . . . . . . . .

DTC P0265 Injector 2 High Voltage 1F–177. . . . . . . .

DTC P0267 Injector 3 Low Voltage 1F–179. . . . . . . . .

DTC P0268 Injector 3 High Voltage 1F–181. . . . . . . .

DTC P0270 Injector 4 Low Voltage 1F–183. . . . . . . . .

DTC P0271 Injector 4 High Voltage 1F–185. . . . . . . . DTC P0300 Multiple Cylinder Misfire(Catalyst

Damage) 1F–188. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0300 Multiple Cylinder Misfire(Increase

Emission) 1F–192. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0327 Knock Sensor Circuit Fault

(1.4L DOHC) 1F–195. . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0327 Knock Sensor Circuit Fault

(1.6L DOHC) 1F–198. . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0335 Magnetic Crankshaft Position

Sensor Electrical Error 1F–201. . . . . . . . . . . . . . . . . .

DTC P0336 58X Crankshaft Position Sensor

No Plausible Signal 1F–204. . . . . . . . . . . . . . . . . . . .

DTC P0337 58X Crankshaft Position Sensor

No Signal 1F–207. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0341 Camshaft Position Sensor

Rationality 1F–210. . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0342 Camshaft Position Sensor Signal 1F–212

DTC P0351 Ignition Signal Coil A Fault 1F–214. . . . .

DTC P0352 Ignition Signal Coil B Fault 1F–216. . . . .

DTC P0400 Exhaust Gas Recirculation Out

Of Limit 1F–218. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0404 Exhaust Gas Recirculation

Opened 1F–221. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0405 EGR Pintle Position Sensor Low

Voltage 1F–224. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0406 EGR Pintle Position Sensor High

Voltage 1F–227. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0420 Catalyst Low Efficiency 1F–230. . . . . . . .

DTC P0444 EVAP Purge Control Circuit No

Signal 1F–232. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0445 EVAP Purge Control Circuit Fault 1F–235

DTC P0462 Fuel Level Sensor Low Voltage

(1.6L DOHC Only) 1F–238. . . . . . . . . . . . . . . . . . . . .

DTC P0463 Fuel Level Sensor High Voltage

(1.6L DOHC Only) 1F–241. . . . . . . . . . . . . . . . . . . . .

DTC P0480 Low Speed Cooling Fan Relay

Circuit Fault (1.4L DOHC) 1F–245. . . . . . . . . . . . . . .

DTC P0480 Low Speed Cooling Fan Relay

Circuit Fault (1.6L DOHC) 1F–248. . . . . . . . . . . . . . .

DTC P0481 High Speed Cooling Fan Relay

Circuit Fault (1.4L DOHC) 1F–251. . . . . . . . . . . . . . .

DTC P0481 High Speed Cooling Fan Relay

Circuit Fault (1.6L DOHC) 1F–254. . . . . . . . . . . . . . .

DTC P0501 Vehicle Speed No Signal

(M/T Only) 1F–257. . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0510 Throttle Position Switch Circuit Fault

(1.4L DOHC) 1F–260. . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0510 Throttle Position Switch Circuit

Fault (1.6L DOHC) 1F–262. . . . . . . . . . . . . . . . . . . . .

DTC P0532 A/C Pressure Sensor Low Voltage 1F–264

DTC P0533 A/C Pressure Sensor High

Voltage 1F–267. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 250 of 2643

1F – 4IENGINE CONTROLS

DAEWOO V–121 BL4

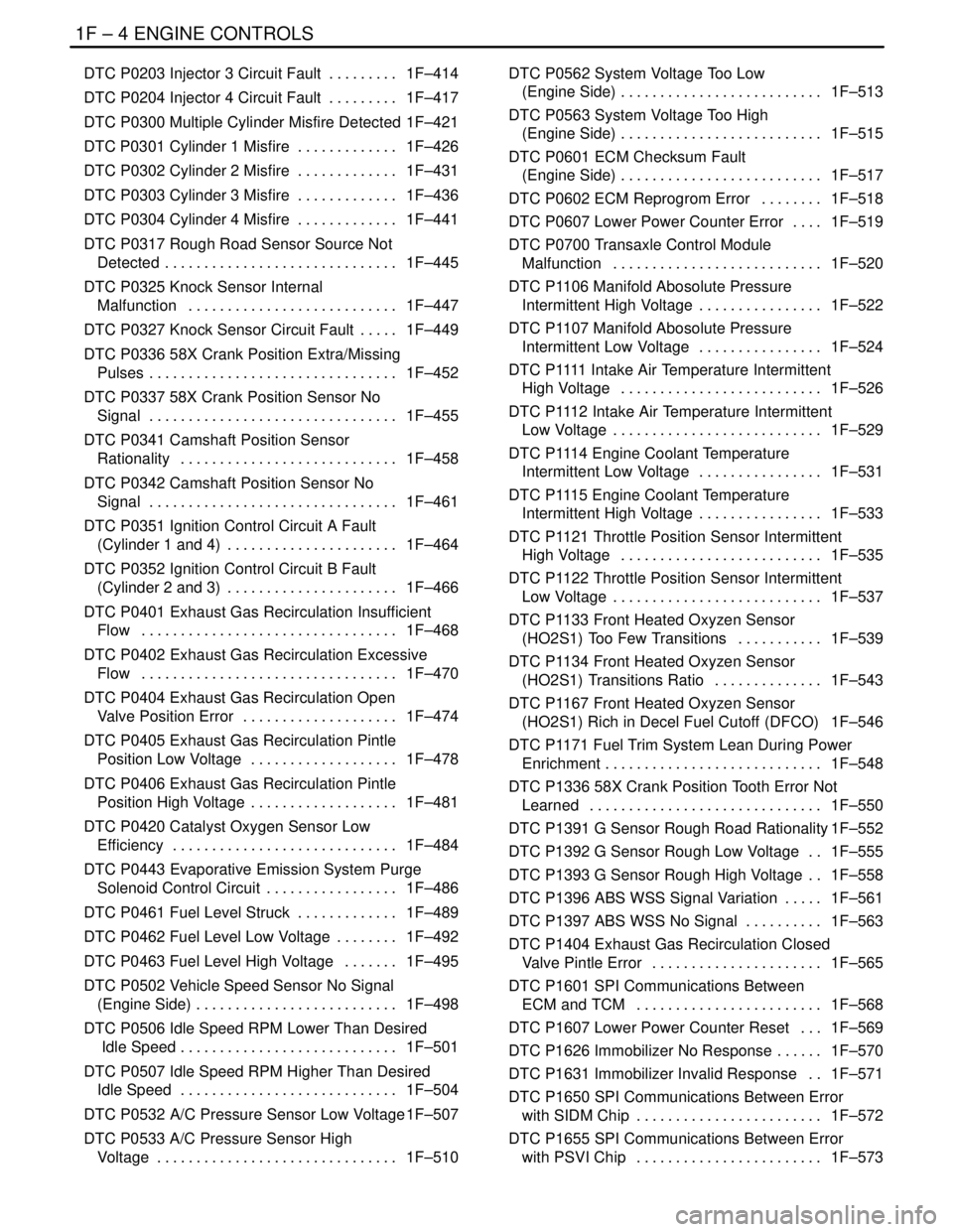

DTC P0203 Injector 3 Circuit Fault 1F–414. . . . . . . . .

DTC P0204 Injector 4 Circuit Fault 1F–417. . . . . . . . .

DTC P0300 Multiple Cylinder Misfire Detected 1F–421

DTC P0301 Cylinder 1 Misfire 1F–426. . . . . . . . . . . . .

DTC P0302 Cylinder 2 Misfire 1F–431. . . . . . . . . . . . .

DTC P0303 Cylinder 3 Misfire 1F–436. . . . . . . . . . . . .

DTC P0304 Cylinder 4 Misfire 1F–441. . . . . . . . . . . . .

DTC P0317 Rough Road Sensor Source Not

Detected 1F–445. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0325 Knock Sensor Internal

Malfunction 1F–447. . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0327 Knock Sensor Circuit Fault 1F–449. . . . .

DTC P0336 58X Crank Position Extra/Missing

Pulses 1F–452. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0337 58X Crank Position Sensor No

Signal 1F–455. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0341 Camshaft Position Sensor

Rationality 1F–458. . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0342 Camshaft Position Sensor No

Signal 1F–461. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0351 Ignition Control Circuit A Fault

(Cylinder 1 and 4) 1F–464. . . . . . . . . . . . . . . . . . . . . .

DTC P0352 Ignition Control Circuit B Fault

(Cylinder 2 and 3) 1F–466. . . . . . . . . . . . . . . . . . . . . .

DTC P0401 Exhaust Gas Recirculation Insufficient

Flow 1F–468. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0402 Exhaust Gas Recirculation Excessive

Flow 1F–470. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0404 Exhaust Gas Recirculation Open

Valve Position Error 1F–474. . . . . . . . . . . . . . . . . . . .

DTC P0405 Exhaust Gas Recirculation Pintle

Position Low Voltage 1F–478. . . . . . . . . . . . . . . . . . .

DTC P0406 Exhaust Gas Recirculation Pintle

Position High Voltage 1F–481. . . . . . . . . . . . . . . . . . .

DTC P0420 Catalyst Oxygen Sensor Low

Efficiency 1F–484. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0443 Evaporative Emission System Purge

Solenoid Control Circuit 1F–486. . . . . . . . . . . . . . . . .

DTC P0461 Fuel Level Struck 1F–489. . . . . . . . . . . . .

DTC P0462 Fuel Level Low Voltage 1F–492. . . . . . . .

DTC P0463 Fuel Level High Voltage 1F–495. . . . . . .

DTC P0502 Vehicle Speed Sensor No Signal

(Engine Side) 1F–498. . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0506 Idle Speed RPM Lower Than Desired

Idle Speed 1F–501. . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0507 Idle Speed RPM Higher Than Desired

Idle Speed 1F–504. . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0532 A/C Pressure Sensor Low Voltage 1F–507

DTC P0533 A/C Pressure Sensor High

Voltage 1F–510. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . DTC P0562 System Voltage Too Low

(Engine Side) 1F–513. . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0563 System Voltage Too High

(Engine Side) 1F–515. . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0601 ECM Checksum Fault

(Engine Side) 1F–517. . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0602 ECM Reprogrom Error 1F–518. . . . . . . .

DTC P0607 Lower Power Counter Error 1F–519. . . .

DTC P0700 Transaxle Control Module

Malfunction 1F–520. . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P1106 Manifold Abosolute Pressure

Intermittent High Voltage 1F–522. . . . . . . . . . . . . . . .

DTC P1107 Manifold Abosolute Pressure

Intermittent Low Voltage 1F–524. . . . . . . . . . . . . . . .

DTC P1111 Intake Air Temperature Intermittent

High Voltage 1F–526. . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P1112 Intake Air Temperature Intermittent

Low Voltage 1F–529. . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P1114 Engine Coolant Temperature

Intermittent Low Voltage 1F–531. . . . . . . . . . . . . . . .

DTC P1115 Engine Coolant Temperature

Intermittent High Voltage 1F–533. . . . . . . . . . . . . . . .

DTC P1121 Throttle Position Sensor Intermittent

High Voltage 1F–535. . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P1122 Throttle Position Sensor Intermittent

Low Voltage 1F–537. . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P1133 Front Heated Oxyzen Sensor

(HO2S1) Too Few Transitions 1F–539. . . . . . . . . . .

DTC P1134 Front Heated Oxyzen Sensor

(HO2S1) Transitions Ratio 1F–543. . . . . . . . . . . . . .

DTC P1167 Front Heated Oxyzen Sensor

(HO2S1) Rich in Decel Fuel Cutoff (DFCO) 1F–546

DTC P1171 Fuel Trim System Lean During Power

Enrichment 1F–548. . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P1336 58X Crank Position Tooth Error Not

Learned 1F–550. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P1391 G Sensor Rough Road Rationality 1F–552

DTC P1392 G Sensor Rough Low Voltage 1F–555. .

DTC P1393 G Sensor Rough High Voltage 1F–558. .

DTC P1396 ABS WSS Signal Variation 1F–561. . . . .

DTC P1397 ABS WSS No Signal 1F–563. . . . . . . . . .

DTC P1404 Exhaust Gas Recirculation Closed

Valve Pintle Error 1F–565. . . . . . . . . . . . . . . . . . . . . .

DTC P1601 SPI Communications Between

ECM and TCM 1F–568. . . . . . . . . . . . . . . . . . . . . . . .

DTC P1607 Lower Power Counter Reset 1F–569. . .

DTC P1626 Immobilizer No Response 1F–570. . . . . .

DTC P1631 Immobilizer Invalid Response 1F–571. .

DTC P1650 SPI Communications Between Error

with SIDM Chip 1F–572. . . . . . . . . . . . . . . . . . . . . . . .

DTC P1655 SPI Communications Between Error

with PSVI Chip 1F–573. . . . . . . . . . . . . . . . . . . . . . . .

Page 252 of 2643

1F – 6IENGINE CONTROLS

DAEWOO V–121 BL4

SPECIFICATIONS

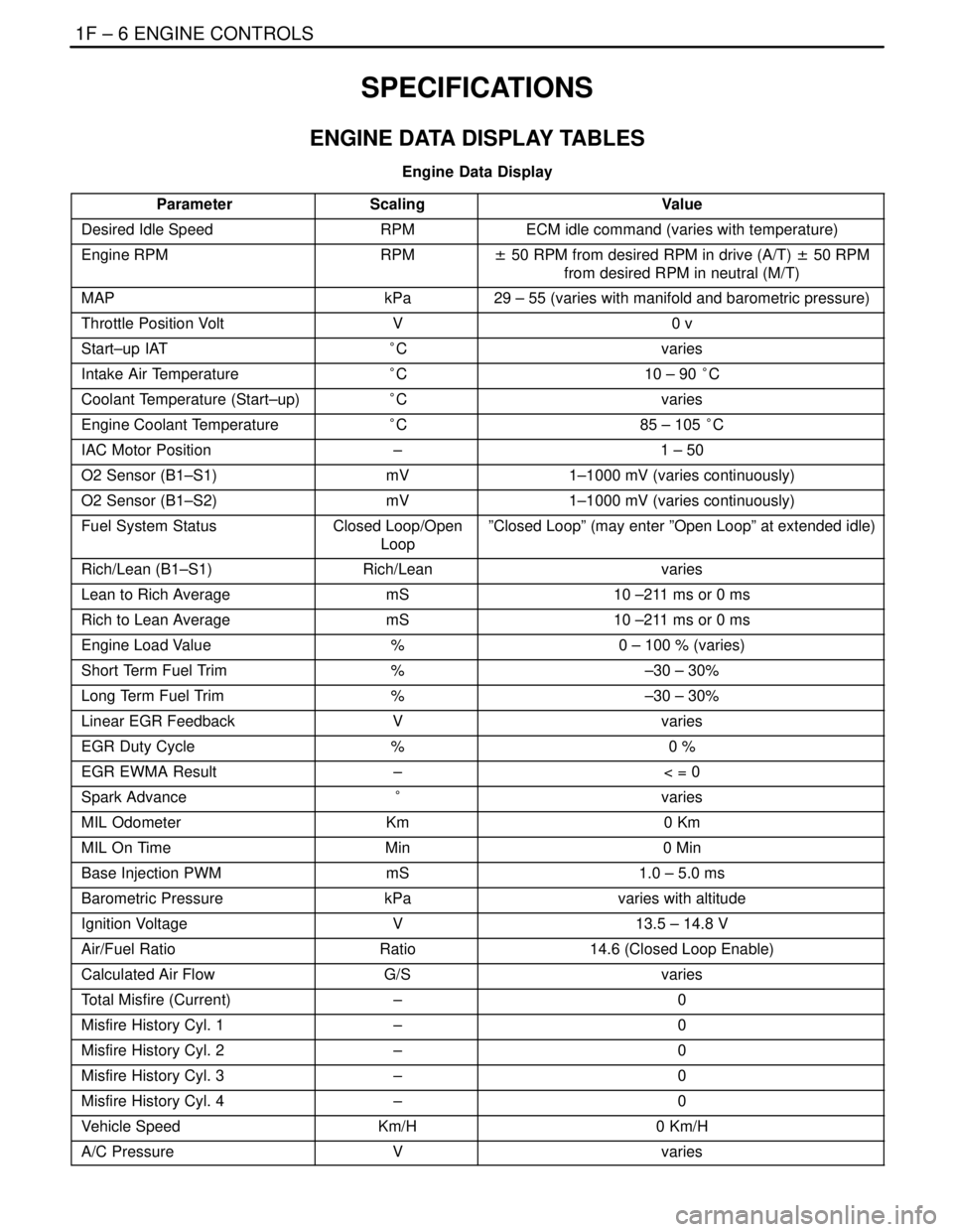

ENGINE DATA DISPLAY TABLES

Engine Data Display

Parameter

ScalingValue

Desired Idle SpeedRPMECM idle command (varies with temperature)

Engine RPMRPM± 50 RPM from desired RPM in drive (A/T) ± 50 RPM

from desired RPM in neutral (M/T)

MAPkPa29 – 55 (varies with manifold and barometric pressure)

Throttle Position VoltV0 v

Start–up IAT°Cvaries

Intake Air Temperature°C10 – 90 °C

Coolant Temperature (Start–up)°Cvaries

Engine Coolant Temperature°C85 – 105 °C

IAC Motor Position–1 – 50

O2 Sensor (B1–S1)mV1–1000 mV (varies continuously)

O2 Sensor (B1–S2)mV1–1000 mV (varies continuously)

Fuel System StatusClosed Loop/Open

Loop”Closed Loop” (may enter ”Open Loop” at extended idle)

Rich/Lean (B1–S1)Rich/Leanvaries

Lean to Rich AveragemS10 –211 ms or 0 ms

Rich to Lean AveragemS10 –211 ms or 0 ms

Engine Load Value%0 – 100 % (varies)

Short Term Fuel Trim%–30 – 30%

Long Term Fuel Trim%–30 – 30%

Linear EGR FeedbackVvaries

EGR Duty Cycle%0 %

EGR EWMA Result–< = 0

Spark Advance°varies

MIL OdometerKm0 Km

MIL On TimeMin0 Min

Base Injection PWMmS1.0 – 5.0 ms

Barometric PressurekPavaries with altitude

Ignition VoltageV13.5 – 14.8 V

Air/Fuel RatioRatio14.6 (Closed Loop Enable)

Calculated Air FlowG/Svaries

Total Misfire (Current)–0

Misfire History Cyl. 1–0

Misfire History Cyl. 2–0

Misfire History Cyl. 3–0

Misfire History Cyl. 4–0

Vehicle SpeedKm/H0 Km/H

A/C PressureVvaries

Page 253 of 2643

ENGINE CONTROLS 1F – 7

DAEWOO V–121 BL4

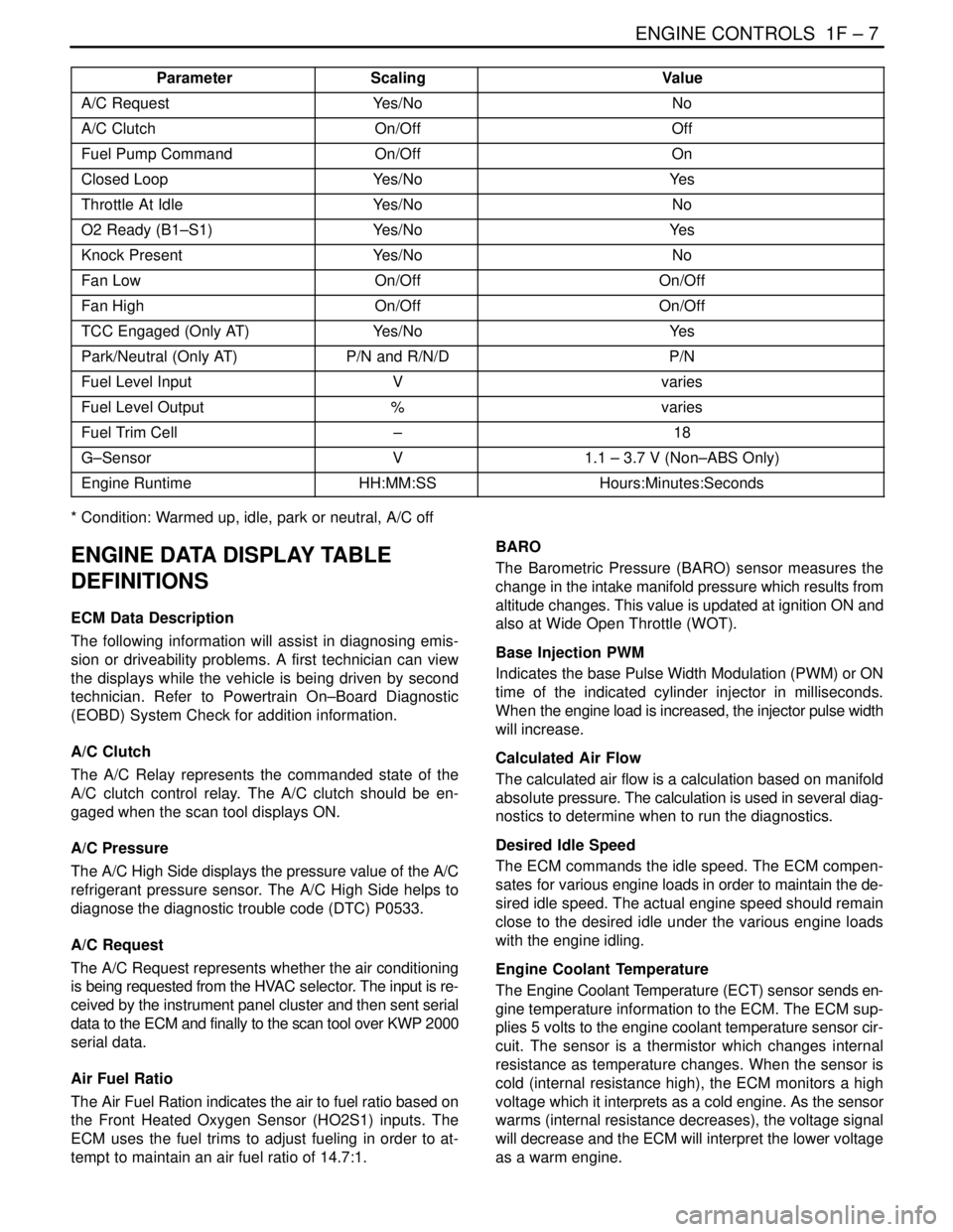

Parameter ValueScaling

A/C RequestYes/NoNo

A/C ClutchOn/OffOff

Fuel Pump CommandOn/OffOn

Closed LoopYes/NoYe s

Throttle At IdleYes/NoNo

O2 Ready (B1–S1)Yes/NoYe s

Knock PresentYes/NoNo

Fan LowOn/OffOn/Off

Fan HighOn/OffOn/Off

TCC Engaged (Only AT)Yes/NoYe s

Park/Neutral (Only AT)P/N and R/N/DP/N

Fuel Level InputVvaries

Fuel Level Output%varies

Fuel Trim Cell–18

G–SensorV1.1 – 3.7 V (Non–ABS Only)

Engine RuntimeHH:MM:SSHours:Minutes:Seconds

* Condition: Warmed up, idle, park or neutral, A/C off

ENGINE DATA DISPLAY TABLE

DEFINITIONS

ECM Data Description

The following information will assist in diagnosing emis-

sion or driveability problems. A first technician can view

the displays while the vehicle is being driven by second

technician. Refer to Powertrain On–Board Diagnostic

(EOBD) System Check for addition information.

A/C Clutch

The A/C Relay represents the commanded state of the

A/C clutch control relay. The A/C clutch should be en-

gaged when the scan tool displays ON.

A/C Pressure

The A/C High Side displays the pressure value of the A/C

refrigerant pressure sensor. The A/C High Side helps to

diagnose the diagnostic trouble code (DTC) P0533.

A/C Request

The A/C Request represents whether the air conditioning

is being requested from the HVAC selector. The input is re-

ceived by the instrument panel cluster and then sent serial

data to the ECM and finally to the scan tool over KWP 2000

serial data.

Air Fuel Ratio

The Air Fuel Ration indicates the air to fuel ratio based on

the Front Heated Oxygen Sensor (HO2S1) inputs. The

ECM uses the fuel trims to adjust fueling in order to at-

tempt to maintain an air fuel ratio of 14.7:1.BARO

The Barometric Pressure (BARO) sensor measures the

change in the intake manifold pressure which results from

altitude changes. This value is updated at ignition ON and

also at Wide Open Throttle (WOT).

Base Injection PWM

Indicates the base Pulse Width Modulation (PWM) or ON

time of the indicated cylinder injector in milliseconds.

When the engine load is increased, the injector pulse width

will increase.

Calculated Air Flow

The calculated air flow is a calculation based on manifold

absolute pressure. The calculation is used in several diag-

nostics to determine when to run the diagnostics.

Desired Idle Speed

The ECM commands the idle speed. The ECM compen-

sates for various engine loads in order to maintain the de-

sired idle speed. The actual engine speed should remain

close to the desired idle under the various engine loads

with the engine idling.

Engine Coolant Temperature

The Engine Coolant Temperature (ECT) sensor sends en-

gine temperature information to the ECM. The ECM sup-

plies 5 volts to the engine coolant temperature sensor cir-

cuit. The sensor is a thermistor which changes internal

resistance as temperature changes. When the sensor is

cold (internal resistance high), the ECM monitors a high

voltage which it interprets as a cold engine. As the sensor

warms (internal resistance decreases), the voltage signal

will decrease and the ECM will interpret the lower voltage

as a warm engine.

Page 254 of 2643

1F – 8IENGINE CONTROLS

DAEWOO V–121 BL4

EGR Desired Position

The desired exhaust gas recirculation (EGR) position is

the commanded EGR position. The ECM calculates the

desired EGR position. The higher the percentage, the lon-

ger the ECM is commanding the EGR valve ON.

Engine Load

Indicates engine load based on manifold absolute pres-

sure. The higher the percentage, the more load the engine

is under.

Engine Run Time

The engine run time is a measure of how long the engine

has been running. When the engine stops running, the tim-

er resets to zero.

Engine Speed

Engine Speed is computed by the ECM from the fuel con-

trol reference input. It should remain close to desired idle

under the various engine loads with the engine idling.

Fan

The Fan Control (FC) Relay is commanded by the ECM.

The FC Relay displays the command as ON or OFF.

Fuel Level Sensor

The Fuel Level Sensor monitors the fuel level in the tank.

The Fuel Level Sensor monitors the rate of change of the

air pressure in the EVAP system. Several of the Enhanced

EVAP System diagnostics are dependent upon the correct

fuel level.

Fuel System Status

The Closed Loop is displayed indicating that the ECM is

controlling the fuel delivery according to the Front Heated

Oxygen Sensor (HO2S1) voltage as close to an air/fuel ra-

tio of 14.7 to 1 as possible.

IAC Position

The scan tool displays the ECM command for the Idle Air

Control (IAC) pintle position in counts. The higher the

number of counts, the greater the commanded idle speed

reads. The Idle Air Control responds to changes in the en-

gine load in order to maintain the desired idle rpm.

Ignition 1 (Voltage)

The ignition volts represent the system voltage measured

by the ECM at the ignition feed circuit.

Intake Air Temperature

The ECM converts the resistance of the Intake Air Tem-

perature (IAT) sensor to degrees in the same manner as

the engine coolant temperature (ECT) sensor. In take air

temperature is used by the ECM to adjust fuel delivery and

spark timing according to incoming air density.Knock Present

The KS Noise Channel indicates when the ECM detects

the KS signal. The ECM should display NO at idle.

Long Term FT

The Long Term Fuel Trim (FT) is derived from the short

term fuel trim value. The Long Term FT is used for the long

term correction of the fuel delivery. A value of 128 counts

(0%) indicates that the fuel delivery requires no com-

pensation in order to maintain a 14.7:1 air to fuel ratio. A

value below 128 counts means that the fuel system is too

rich and the fuel delivery is being reduced. The ECM is de-

creasing the injector pulse width. A value above 128

counts indicates that a lean condition exists for which the

ECM is compensating.

MAP

The Manifold Absolute Pressure (MAP) sensor measures

the change in the intake manifold pressure which results

from engine load and speed changes. As the intake man-

ifold pressure increases, the air density in the intake also

increases and the additional fuel is required.

Misfire History #1–4

Indicates the number of misfires that have occurred after

195 current misfires have been counted. The current mis-

fire counter will add its misfires to the history misfire count-

er after 195 total misfires have taken place. If 1 cylinder is

misfiring, the misfiring current counter will have 195 mis-

fires counted before adding to its history counter. If 2 cylin-

ders are misfiring, the misfiring current counter will add to

their history counters after 97 misfires. The counter incre-

ments only after a misfire diagnostic trouble code (DTC)

has been set.

Front Heated Oxygen Sensor

The pre–converter Front Heated Oxygen Sensor

(HO2S1) reading represents the exhaust oxygen sensor

output voltage. This voltage will fluctuate constantly be-

tween 100 mv (lean exhaust) and 900 mv (rich exhaust)

when the system is operating in a Closed Loop.

Rear Heated Oxygen Sensor

The post–converter Rear Heated Oxygen Sensor

(HO2S2) represents the exhaust oxygen output voltage

past the catalytic converter. This voltage remains inactive,

or the voltage will appear lazy within a range of 100 mv

(lean exhaust) and 900 mv (rich exhaust) when operating

in a Closed Loop.

Short Term FT

The Short Term FT represents a short term correction to

fuel delivery by the ECM in response to the amount of time

the oxygen sensor voltage spends above or below the 450

mv threshold. If the oxygen sensor has mainly been below

450 mv, indicating a lean air/fuel mixture, short term fuel

trim will increase to tell the ECM to add fuel. If the oxygen

sensor voltage stays mainly above the threshold, the ECM

will reduce fuel delivery to compensate for the indicated

rich condition.

Page 255 of 2643

ENGINE CONTROLS 1F – 9

DAEWOO V–121 BL4

Spark Advance

This is a display of the spark advance Ignition Coil (IC) cal-

culation which the ECM is programming in the ignition sys-

tem. It computes the desired spark advance using data

such as engine temperature, rpm, engine load, vehicle

speed and operating mode.

TCC Engaged

When the brake pedal is applied, the Torque Converter

Clutch (TCC) brake switch sends a signal to the ECM to

disengage the TCC and disable the cruise control.

Total Misfire Current Counter

Indicates the total number of misfires that have been de-tected in all the cylinders after 100 engine cycles. One

cycle equals one complete 4 stroke cycle. The total misfire

only increments during the steady state cruise conditions.

TP Sensor

The ECM uses the TP Sensor in order to determine the

amount of the throttle demanded by the vehicle’s operator.

The TP Sensor reads between 0.36–0.96 volts at idle to

above 4 volts at WOT.

Vehicle Speed

The vehicle speed sensor signal is converted into mph or

km/h for display. The vehicle speed output from the ECM

is 4000 pulses per mile. The scan tool uses the KWP 2000

serial data from the ECM to obtain vehicle speed, while the

Instrument Panel Cluster (IPC), cruise control module and

the chime alarm module use the 4000 ppm output.

Page 274 of 2643

1F – 28IENGINE CONTROLS

DAEWOO V–121 BL4

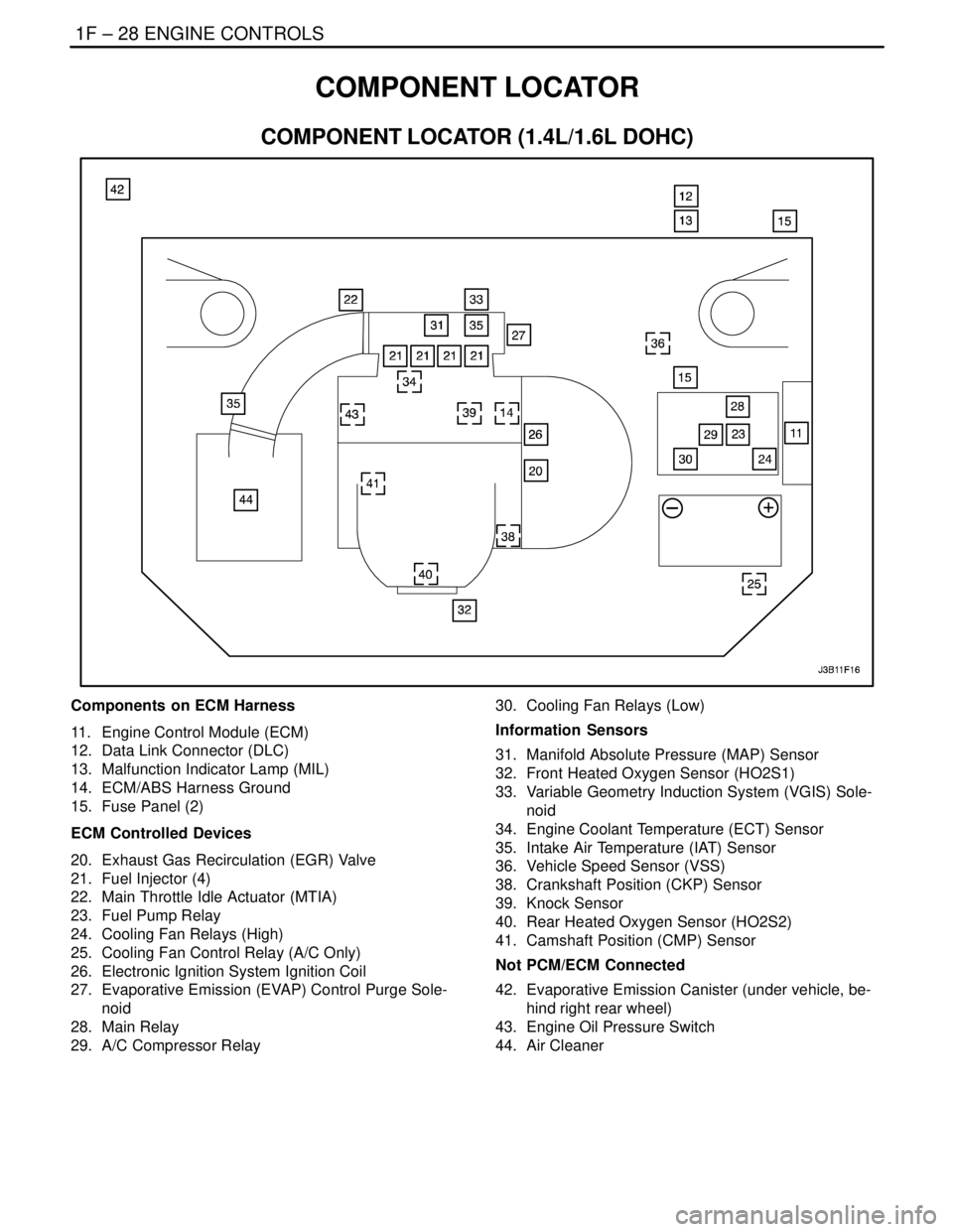

COMPONENT LOCATOR

COMPONENT LOCATOR (1.4L/1.6L DOHC)

Components on ECM Harness

11. Engine Control Module (ECM)

12. Data Link Connector (DLC)

13. Malfunction Indicator Lamp (MIL)

14. ECM/ABS Harness Ground

15. Fuse Panel (2)

ECM Controlled Devices

20. Exhaust Gas Recirculation (EGR) Valve

21. Fuel Injector (4)

22. Main Throttle Idle Actuator (MTIA)

23. Fuel Pump Relay

24. Cooling Fan Relays (High)

25. Cooling Fan Control Relay (A/C Only)

26. Electronic Ignition System Ignition Coil

27. Evaporative Emission (EVAP) Control Purge Sole-

noid

28. Main Relay

29. A/C Compressor Relay30. Cooling Fan Relays (Low)

Information Sensors

31. Manifold Absolute Pressure (MAP) Sensor

32. Front Heated Oxygen Sensor (HO2S1)

33. Variable Geometry Induction System (VGIS) Sole-

noid

34. Engine Coolant Temperature (ECT) Sensor

35. Intake Air Temperature (IAT) Sensor

36. Vehicle Speed Sensor (VSS)

38. Crankshaft Position (CKP) Sensor

39. Knock Sensor

40. Rear Heated Oxygen Sensor (HO2S2)

41. Camshaft Position (CMP) Sensor

Not PCM/ECM Connected

42. Evaporative Emission Canister (under vehicle, be-

hind right rear wheel)

43. Engine Oil Pressure Switch

44. Air Cleaner

Page 275 of 2643

ENGINE CONTROLS 1F – 29

DAEWOO V–121 BL4

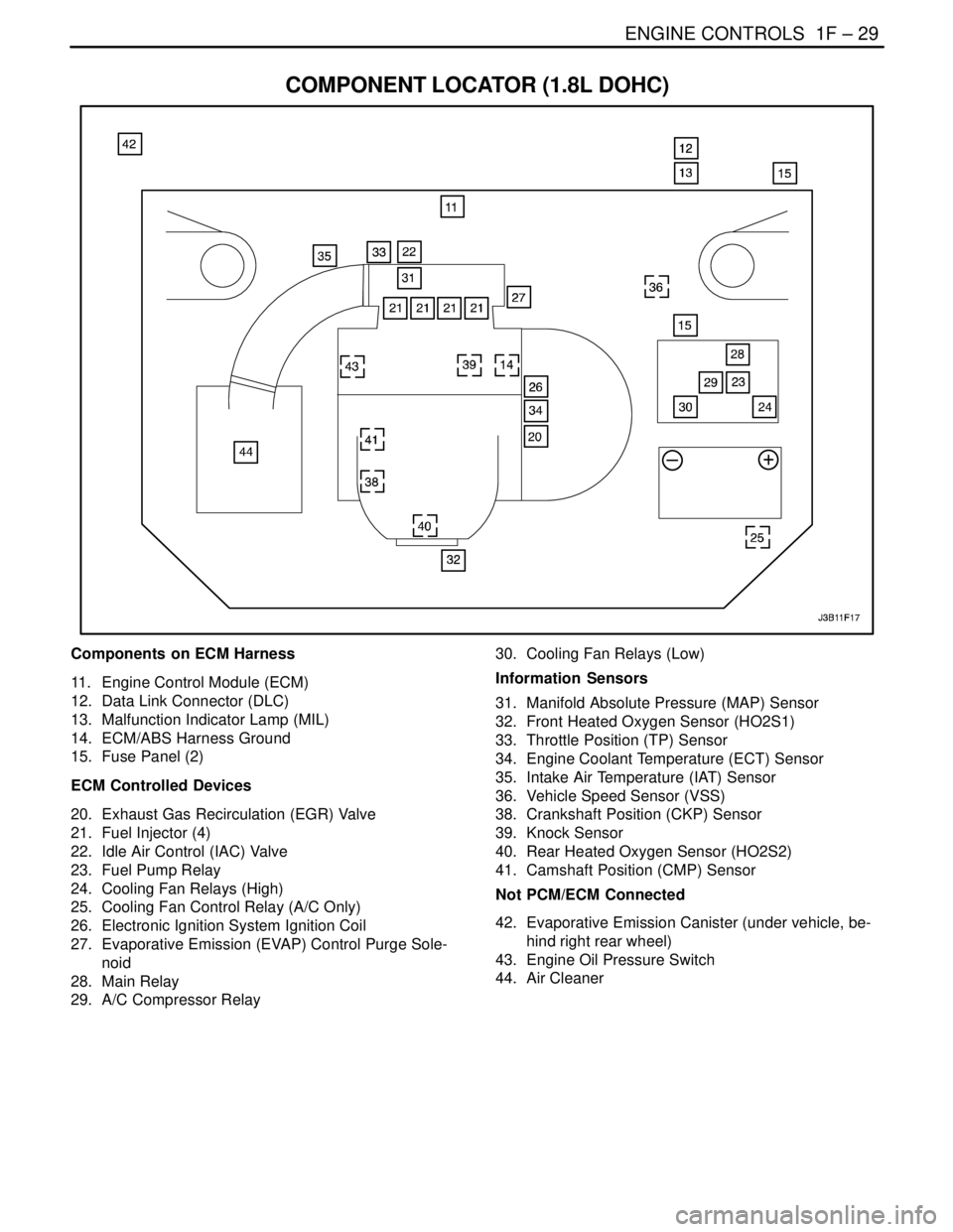

COMPONENT LOCATOR (1.8L DOHC)

Components on ECM Harness

11. Engine Control Module (ECM)

12. Data Link Connector (DLC)

13. Malfunction Indicator Lamp (MIL)

14. ECM/ABS Harness Ground

15. Fuse Panel (2)

ECM Controlled Devices

20. Exhaust Gas Recirculation (EGR) Valve

21. Fuel Injector (4)

22. Idle Air Control (IAC) Valve

23. Fuel Pump Relay

24. Cooling Fan Relays (High)

25. Cooling Fan Control Relay (A/C Only)

26. Electronic Ignition System Ignition Coil

27. Evaporative Emission (EVAP) Control Purge Sole-

noid

28. Main Relay

29. A/C Compressor Relay30. Cooling Fan Relays (Low)

Information Sensors

31. Manifold Absolute Pressure (MAP) Sensor

32. Front Heated Oxygen Sensor (HO2S1)

33. Throttle Position (TP) Sensor

34. Engine Coolant Temperature (ECT) Sensor

35. Intake Air Temperature (IAT) Sensor

36. Vehicle Speed Sensor (VSS)

38. Crankshaft Position (CKP) Sensor

39. Knock Sensor

40. Rear Heated Oxygen Sensor (HO2S2)

41. Camshaft Position (CMP) Sensor

Not PCM/ECM Connected

42. Evaporative Emission Canister (under vehicle, be-

hind right rear wheel)

43. Engine Oil Pressure Switch

44. Air Cleaner

Page 325 of 2643

ENGINE CONTROLS 1F – 79

DAEWOO V–121 BL4

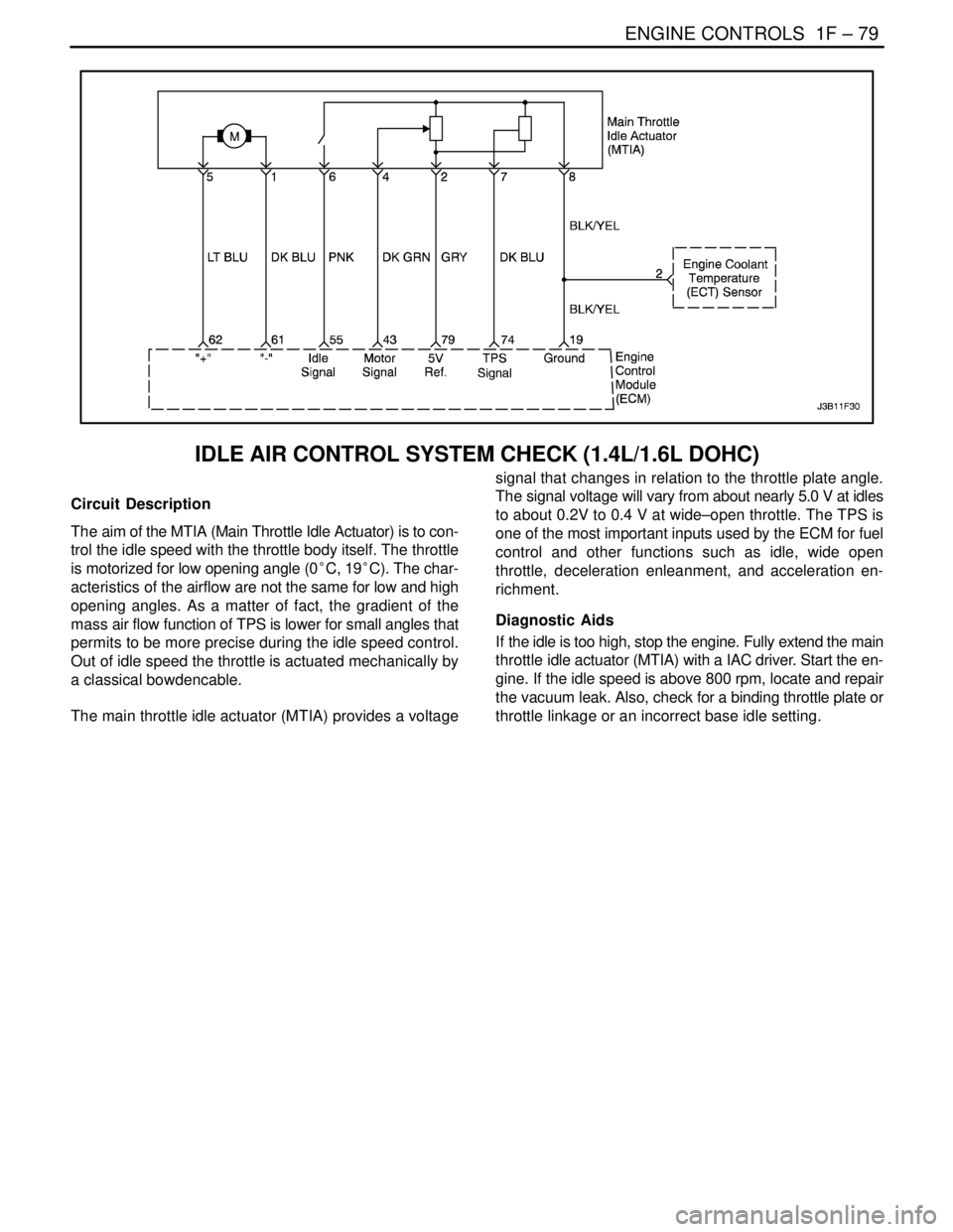

IDLE AIR CONTROL SYSTEM CHECK (1.4L/1.6L DOHC)

Circuit Description

The aim of the MTIA (Main Throttle Idle Actuator) is to con-

trol the idle speed with the throttle body itself. The throttle

is motorized for low opening angle (0°C, 19°C). The char-

acteristics of the airflow are not the same for low and high

opening angles. As a matter of fact, the gradient of the

mass air flow function of TPS is lower for small angles that

permits to be more precise during the idle speed control.

Out of idle speed the throttle is actuated mechanically by

a classical bowdencable.

The main throttle idle actuator (MTIA) provides a voltagesignal that changes in relation to the throttle plate angle.

The signal voltage will vary from about nearly 5.0 V at idles

to about 0.2V to 0.4 V at wide–open throttle. The TPS is

one of the most important inputs used by the ECM for fuel

control and other functions such as idle, wide open

throttle, deceleration enleanment, and acceleration en-

richment.

Diagnostic Aids

If the idle is too high, stop the engine. Fully extend the main

throttle idle actuator (MTIA) with a IAC driver. Start the en-

gine. If the idle speed is above 800 rpm, locate and repair

the vacuum leak. Also, check for a binding throttle plate or

throttle linkage or an incorrect base idle setting.

Page 328 of 2643

1F – 82IENGINE CONTROLS

DAEWOO V–121 BL4

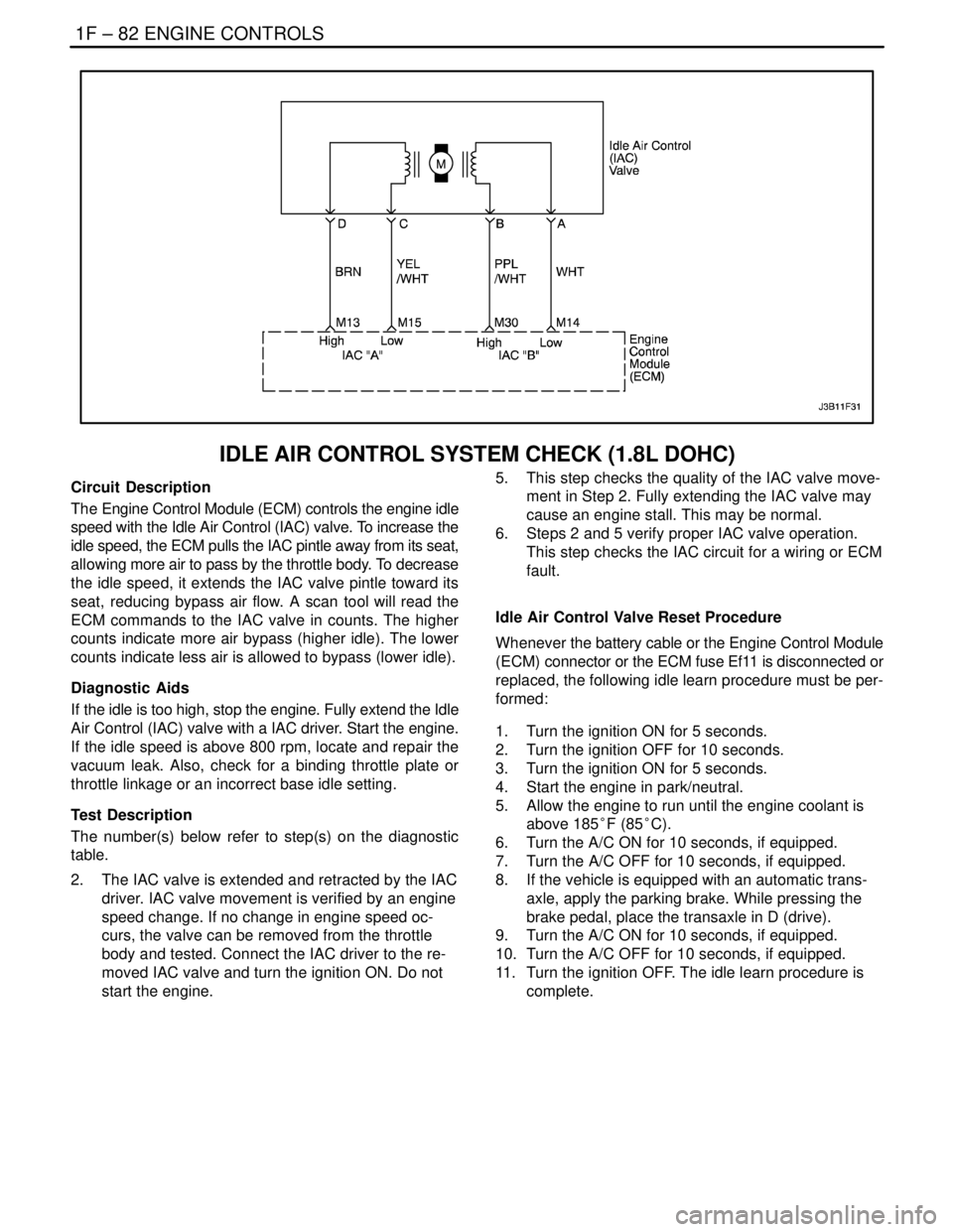

IDLE AIR CONTROL SYSTEM CHECK (1.8L DOHC)

Circuit Description

The Engine Control Module (ECM) controls the engine idle

speed with the Idle Air Control (IAC) valve. To increase the

idle speed, the ECM pulls the IAC pintle away from its seat,

allowing more air to pass by the throttle body. To decrease

the idle speed, it extends the IAC valve pintle toward its

seat, reducing bypass air flow. A scan tool will read the

ECM commands to the IAC valve in counts. The higher

counts indicate more air bypass (higher idle). The lower

counts indicate less air is allowed to bypass (lower idle).

Diagnostic Aids

If the idle is too high, stop the engine. Fully extend the Idle

Air Control (IAC) valve with a IAC driver. Start the engine.

If the idle speed is above 800 rpm, locate and repair the

vacuum leak. Also, check for a binding throttle plate or

throttle linkage or an incorrect base idle setting.

Test Description

The number(s) below refer to step(s) on the diagnostic

table.

2. The IAC valve is extended and retracted by the IAC

driver. IAC valve movement is verified by an engine

speed change. If no change in engine speed oc-

curs, the valve can be removed from the throttle

body and tested. Connect the IAC driver to the re-

moved IAC valve and turn the ignition ON. Do not

start the engine.5. This step checks the quality of the IAC valve move-

ment in Step 2. Fully extending the IAC valve may

cause an engine stall. This may be normal.

6. Steps 2 and 5 verify proper IAC valve operation.

This step checks the IAC circuit for a wiring or ECM

fault.

Idle Air Control Valve Reset Procedure

Whenever the battery cable or the Engine Control Module

(ECM) connector or the ECM fuse Ef11 is disconnected or

replaced, the following idle learn procedure must be per-

formed:

1. Turn the ignition ON for 5 seconds.

2. Turn the ignition OFF for 10 seconds.

3. Turn the ignition ON for 5 seconds.

4. Start the engine in park/neutral.

5. Allow the engine to run until the engine coolant is

above 185°F (85°C).

6. Turn the A/C ON for 10 seconds, if equipped.

7. Turn the A/C OFF for 10 seconds, if equipped.

8. If the vehicle is equipped with an automatic trans-

axle, apply the parking brake. While pressing the

brake pedal, place the transaxle in D (drive).

9. Turn the A/C ON for 10 seconds, if equipped.

10. Turn the A/C OFF for 10 seconds, if equipped.

11. Turn the ignition OFF. The idle learn procedure is

complete.