Section 5 DAEWOO LACETTI 2004 Service Repair Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 1054 of 2643

4D – 6IFRONT DISC BRAKES

DAEWOO V–121 BL4

UNIT REPAIR

CALIPER OVERHAUL

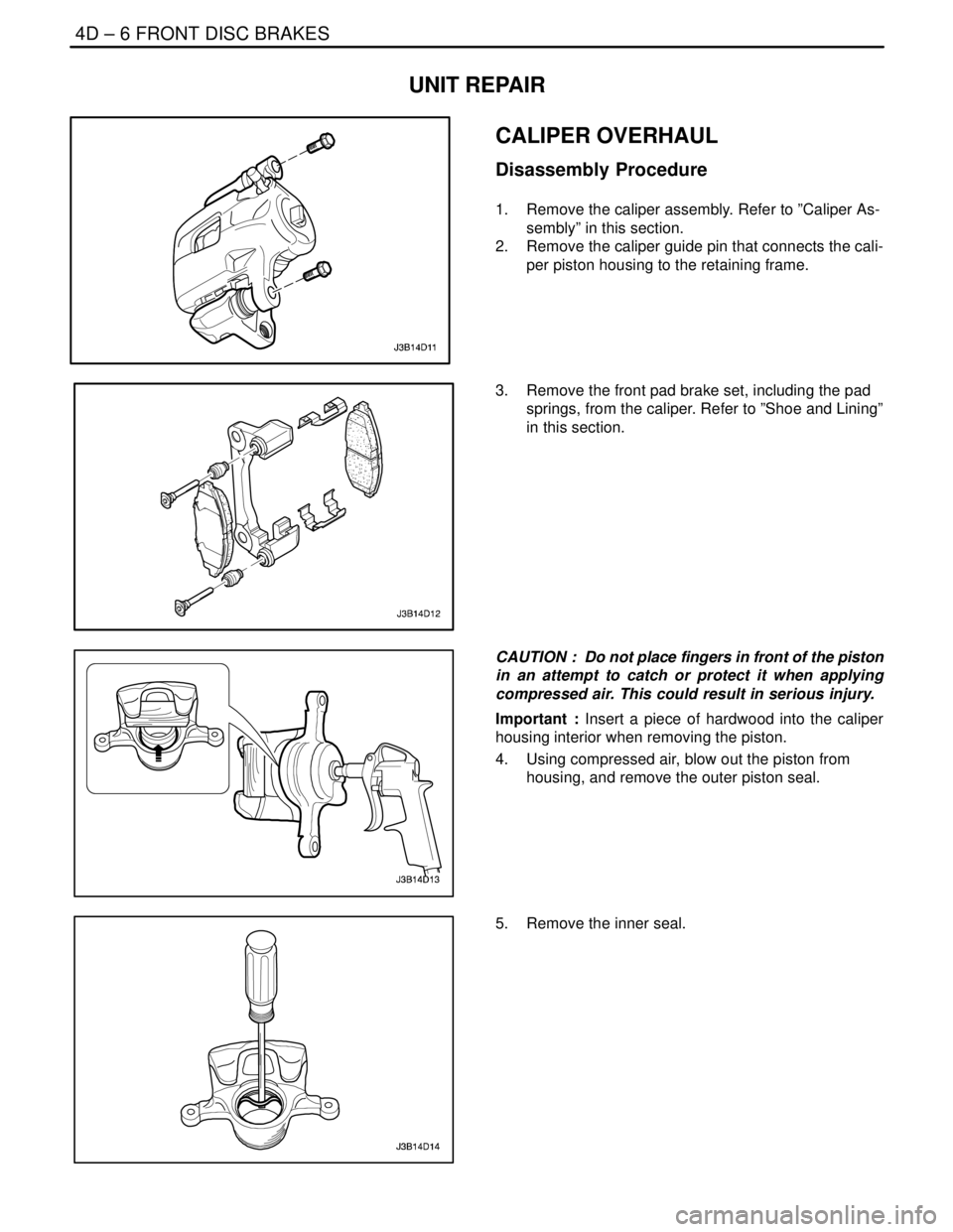

Disassembly Procedure

1. Remove the caliper assembly. Refer to ”Caliper As-

sembly” in this section.

2. Remove the caliper guide pin that connects the cali-

per piston housing to the retaining frame.

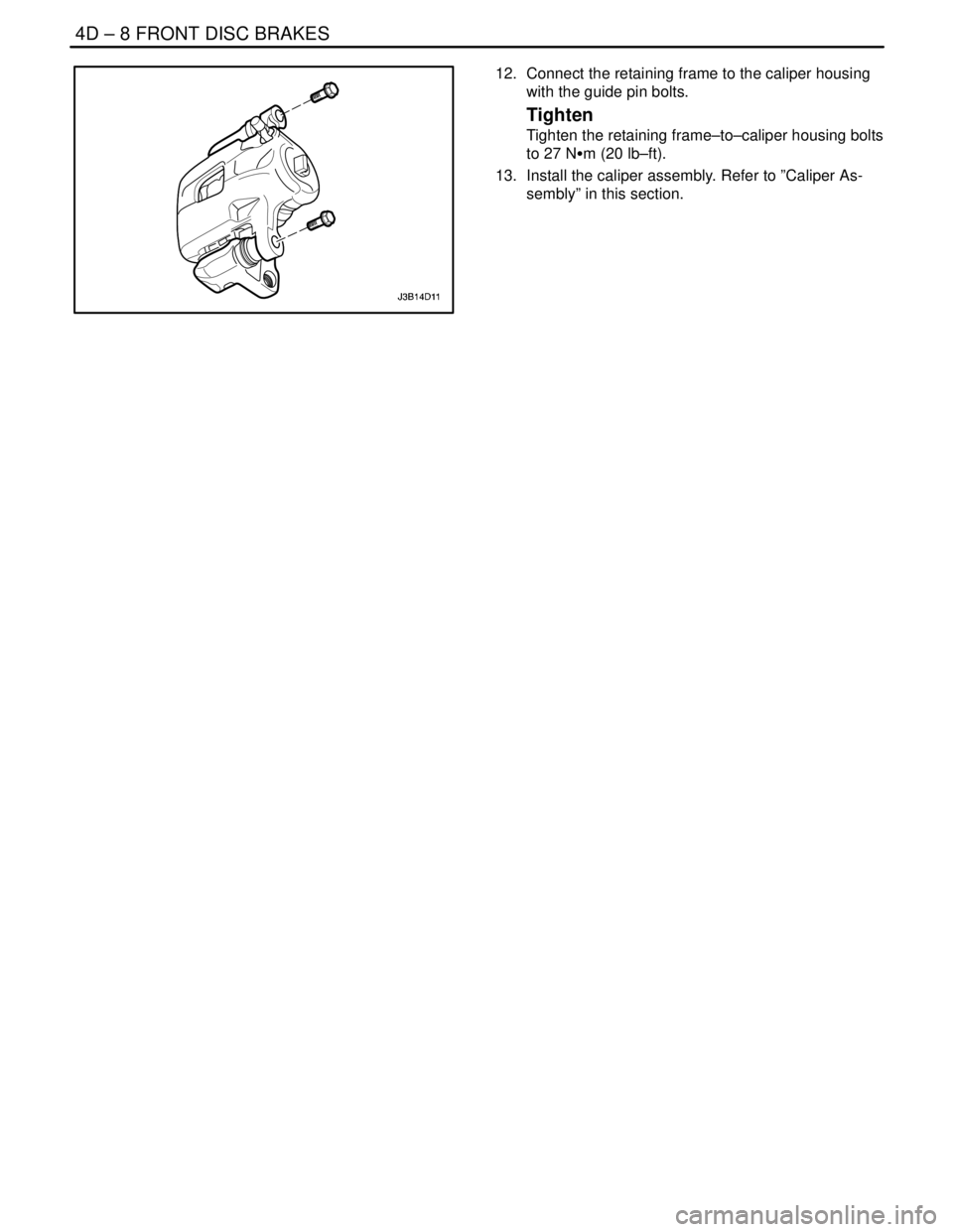

3. Remove the front pad brake set, including the pad

springs, from the caliper. Refer to ”Shoe and Lining”

in this section.

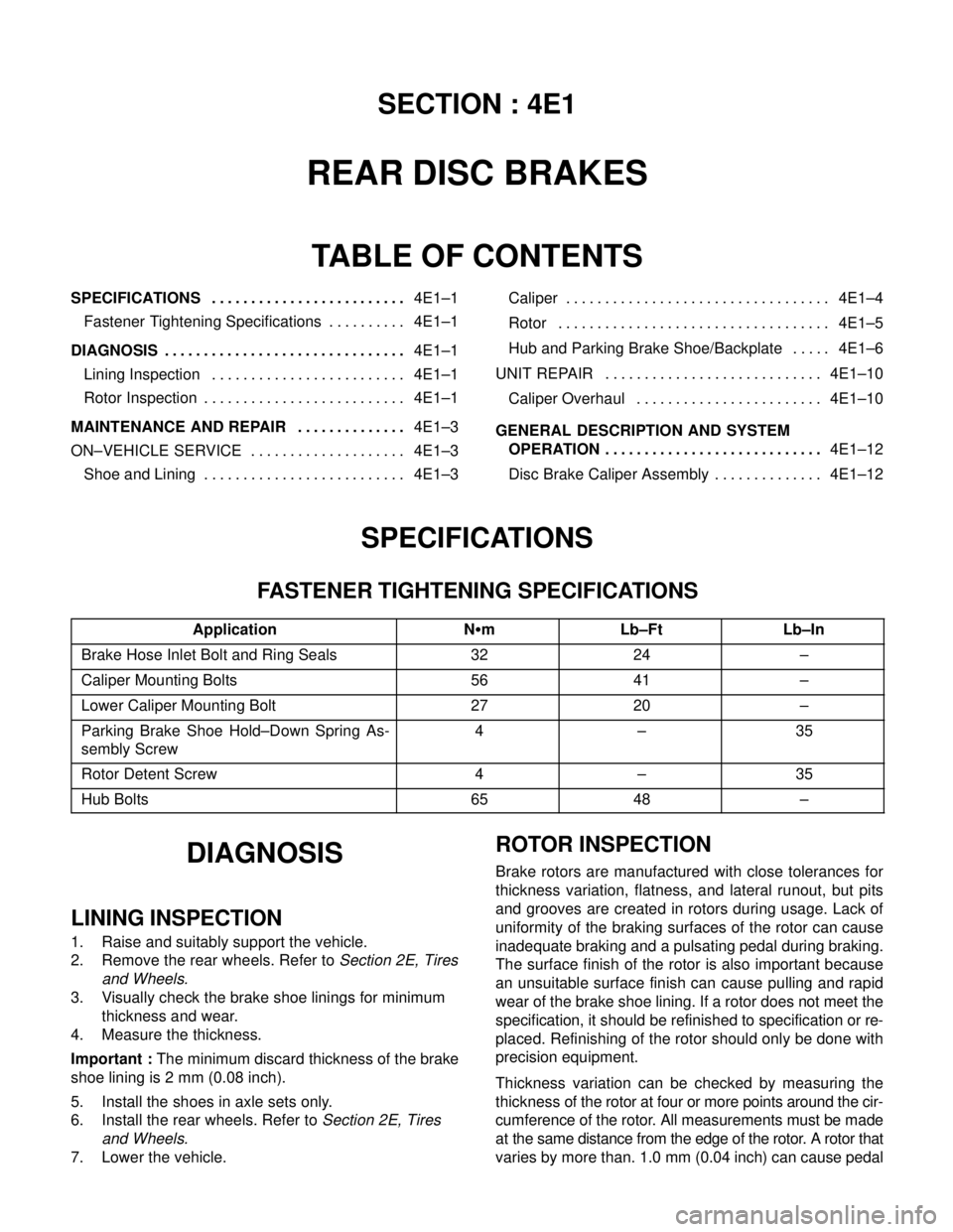

CAUTION : Do not place fingers in front of the piston

in an attempt to catch or protect it when applying

compressed air. This could result in serious injury.

Important : Insert a piece of hardwood into the caliper

housing interior when removing the piston.

4. Using compressed air, blow out the piston from

housing, and remove the outer piston seal.

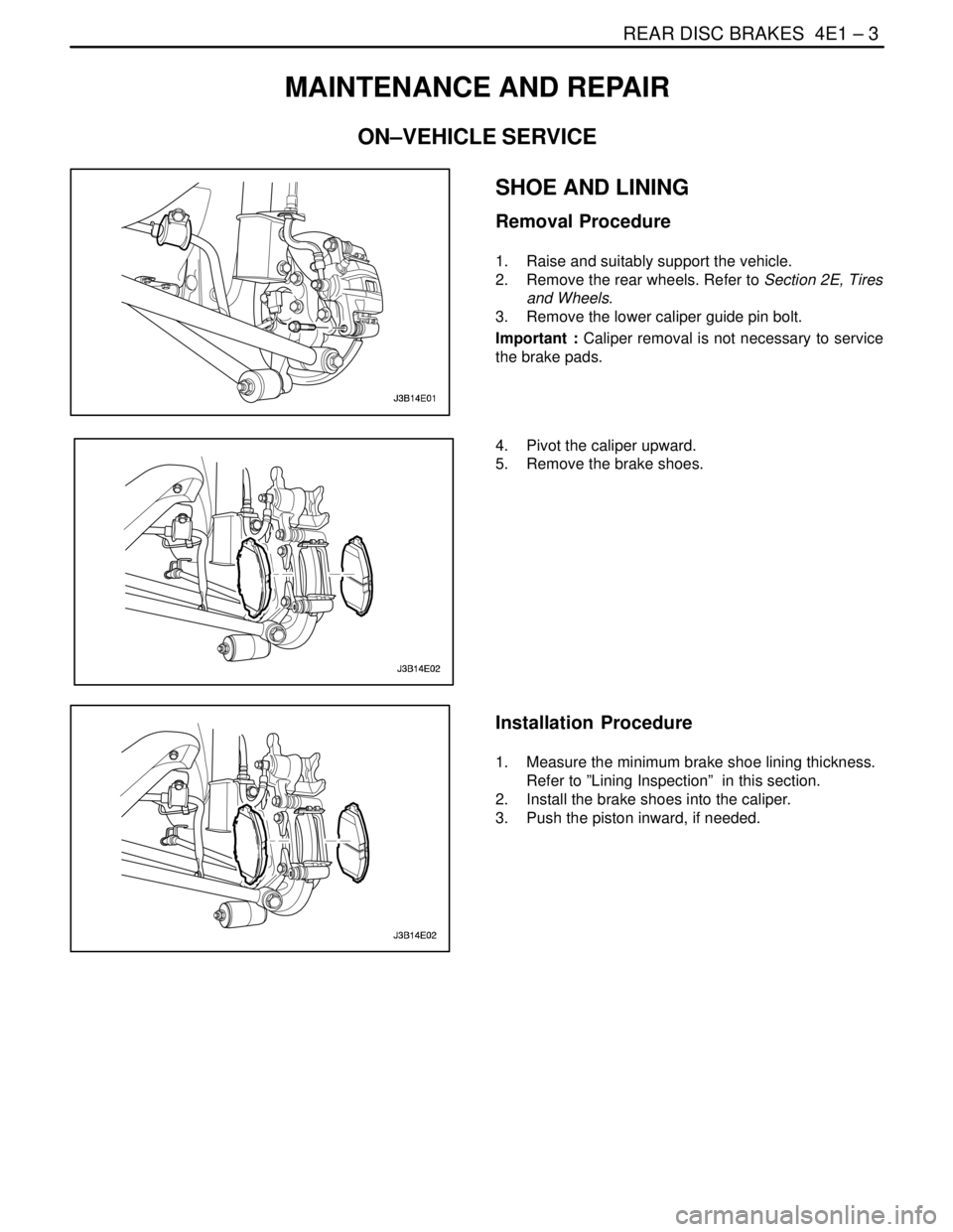

5. Remove the inner seal.

Page 1056 of 2643

4D – 8IFRONT DISC BRAKES

DAEWOO V–121 BL4

12. Connect the retaining frame to the caliper housing

with the guide pin bolts.

Tighten

Tighten the retaining frame–to–caliper housing bolts

to 27 NSm (20 lb–ft).

13. Install the caliper assembly. Refer to ”Caliper As-

sembly” in this section.

Page 1058 of 2643

SECTION : 4E1

REAR DISC BRAKES

TABLE OF CONTENTS

SPECIFICATIONS4E1–1 . . . . . . . . . . . . . . . . . . . . . . . . .

Fastener Tightening Specifications 4E1–1. . . . . . . . . .

DIAGNOSIS4E1–1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lining Inspection 4E1–1. . . . . . . . . . . . . . . . . . . . . . . . .

Rotor Inspection 4E1–1. . . . . . . . . . . . . . . . . . . . . . . . . .

MAINTENANCE AND REPAIR4E1–3 . . . . . . . . . . . . . .

ON–VEHICLE SERVICE 4E1–3. . . . . . . . . . . . . . . . . . . .

Shoe and Lining 4E1–3. . . . . . . . . . . . . . . . . . . . . . . . . . Caliper 4E1–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rotor 4E1–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hub and Parking Brake Shoe/Backplate 4E1–6. . . . .

UNIT REPAIR 4E1–10. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Caliper Overhaul 4E1–10. . . . . . . . . . . . . . . . . . . . . . . .

GENERAL DESCRIPTION AND SYSTEM

OPERATION4E1–12 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disc Brake Caliper Assembly 4E1–12. . . . . . . . . . . . . .

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

ApplicationNSmLb–FtLb–In

Brake Hose Inlet Bolt and Ring Seals3224–

Caliper Mounting Bolts5641–

Lower Caliper Mounting Bolt2720–

Parking Brake Shoe Hold–Down Spring As-

sembly Screw4–35

Rotor Detent Screw4–35

Hub Bolts6548–

DIAGNOSIS

LINING INSPECTION

1. Raise and suitably support the vehicle.

2. Remove the rear wheels. Refer to Section 2E, Tires

and Wheels.

3. Visually check the brake shoe linings for minimum

thickness and wear.

4. Measure the thickness.

Important : The minimum discard thickness of the brake

shoe lining is 2 mm (0.08 inch).

5. Install the shoes in axle sets only.

6. Install the rear wheels. Refer to Section 2E, Tires

and Wheels.

7. Lower the vehicle.

ROTOR INSPECTION

Brake rotors are manufactured with close tolerances for

thickness variation, flatness, and lateral runout, but pits

and grooves are created in rotors during usage. Lack of

uniformity of the braking surfaces of the rotor can cause

inadequate braking and a pulsating pedal during braking.

The surface finish of the rotor is also important because

an unsuitable surface finish can cause pulling and rapid

wear of the brake shoe lining. If a rotor does not meet the

specification, it should be refinished to specification or re-

placed. Refinishing of the rotor should only be done with

precision equipment.

Thickness variation can be checked by measuring the

thickness of the rotor at four or more points around the cir-

cumference of the rotor. All measurements must be made

at the same distance from the edge of the rotor. A rotor that

varies by more than. 1.0 mm (0.04 inch) can cause pedal

Page 1060 of 2643

REAR DISC BRAKES 4E1 – 3

DAEWOO V–121 BL4

MAINTENANCE AND REPAIR

ON–VEHICLE SERVICE

SHOE AND LINING

Removal Procedure

1. Raise and suitably support the vehicle.

2. Remove the rear wheels. Refer to Section 2E, Tires

and Wheels.

3. Remove the lower caliper guide pin bolt.

Important : Caliper removal is not necessary to service

the brake pads.

4. Pivot the caliper upward.

5. Remove the brake shoes.

Installation Procedure

1. Measure the minimum brake shoe lining thickness.

Refer to ”Lining Inspection” in this section.

2. Install the brake shoes into the caliper.

3. Push the piston inward, if needed.

Page 1061 of 2643

4E1 – 4IREAR DISC BRAKES

DAEWOO V–121 BL4

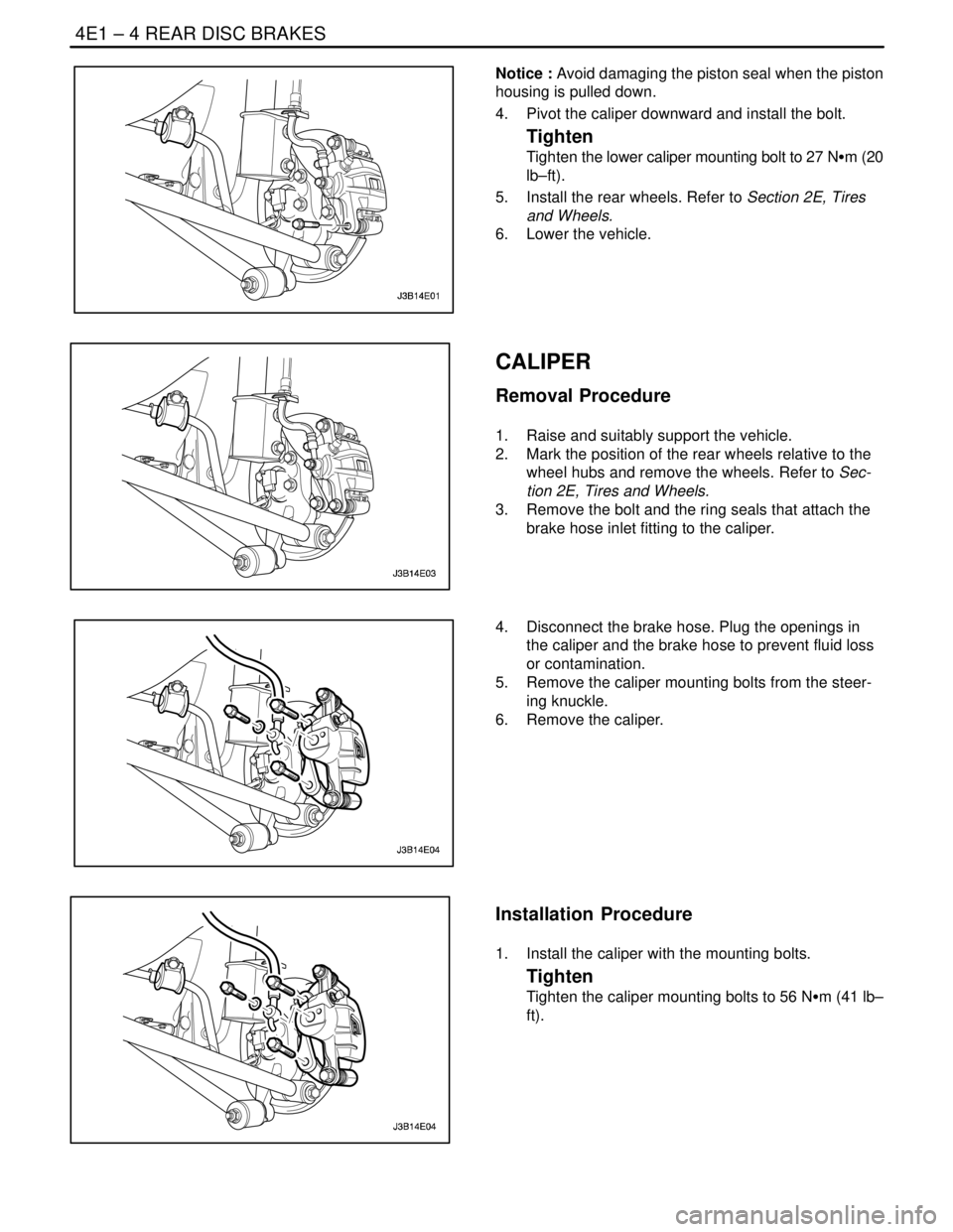

Notice : Avoid damaging the piston seal when the piston

housing is pulled down.

4. Pivot the caliper downward and install the bolt.

Tighten

Tighten the lower caliper mounting bolt to 27 NSm (20

lb–ft).

5. Install the rear wheels. Refer to Section 2E, Tires

and Wheels.

6. Lower the vehicle.

CALIPER

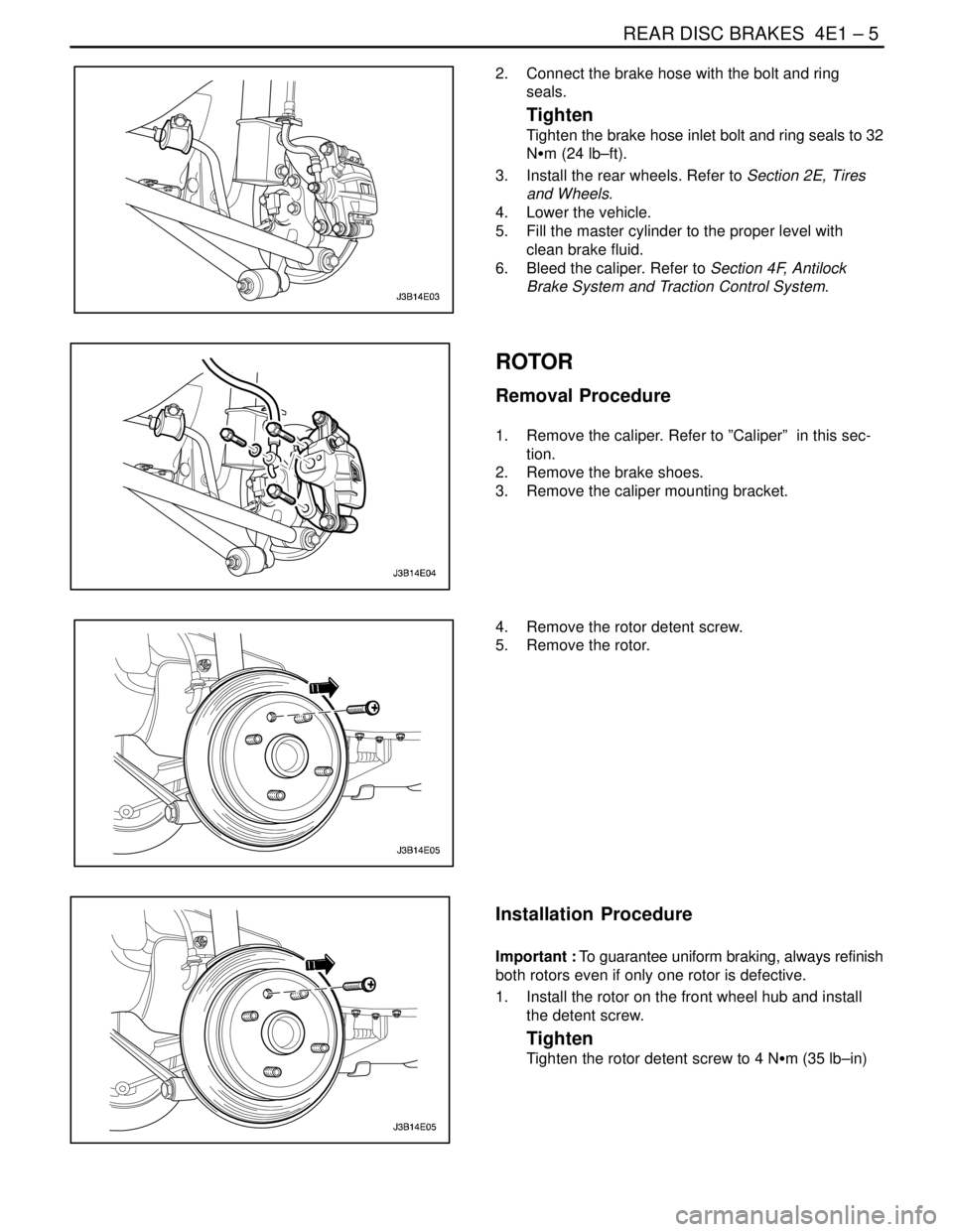

Removal Procedure

1. Raise and suitably support the vehicle.

2. Mark the position of the rear wheels relative to the

wheel hubs and remove the wheels. Refer to Sec-

tion 2E, Tires and Wheels.

3. Remove the bolt and the ring seals that attach the

brake hose inlet fitting to the caliper.

4. Disconnect the brake hose. Plug the openings in

the caliper and the brake hose to prevent fluid loss

or contamination.

5. Remove the caliper mounting bolts from the steer-

ing knuckle.

6. Remove the caliper.

Installation Procedure

1. Install the caliper with the mounting bolts.

Tighten

Tighten the caliper mounting bolts to 56 NSm (41 lb–

ft).

Page 1062 of 2643

REAR DISC BRAKES 4E1 – 5

DAEWOO V–121 BL4

2. Connect the brake hose with the bolt and ring

seals.

Tighten

Tighten the brake hose inlet bolt and ring seals to 32

NSm (24 lb–ft).

3. Install the rear wheels. Refer to Section 2E, Tires

and Wheels.

4. Lower the vehicle.

5. Fill the master cylinder to the proper level with

clean brake fluid.

6. Bleed the caliper. Refer to Section 4F, Antilock

Brake System and Traction Control System.

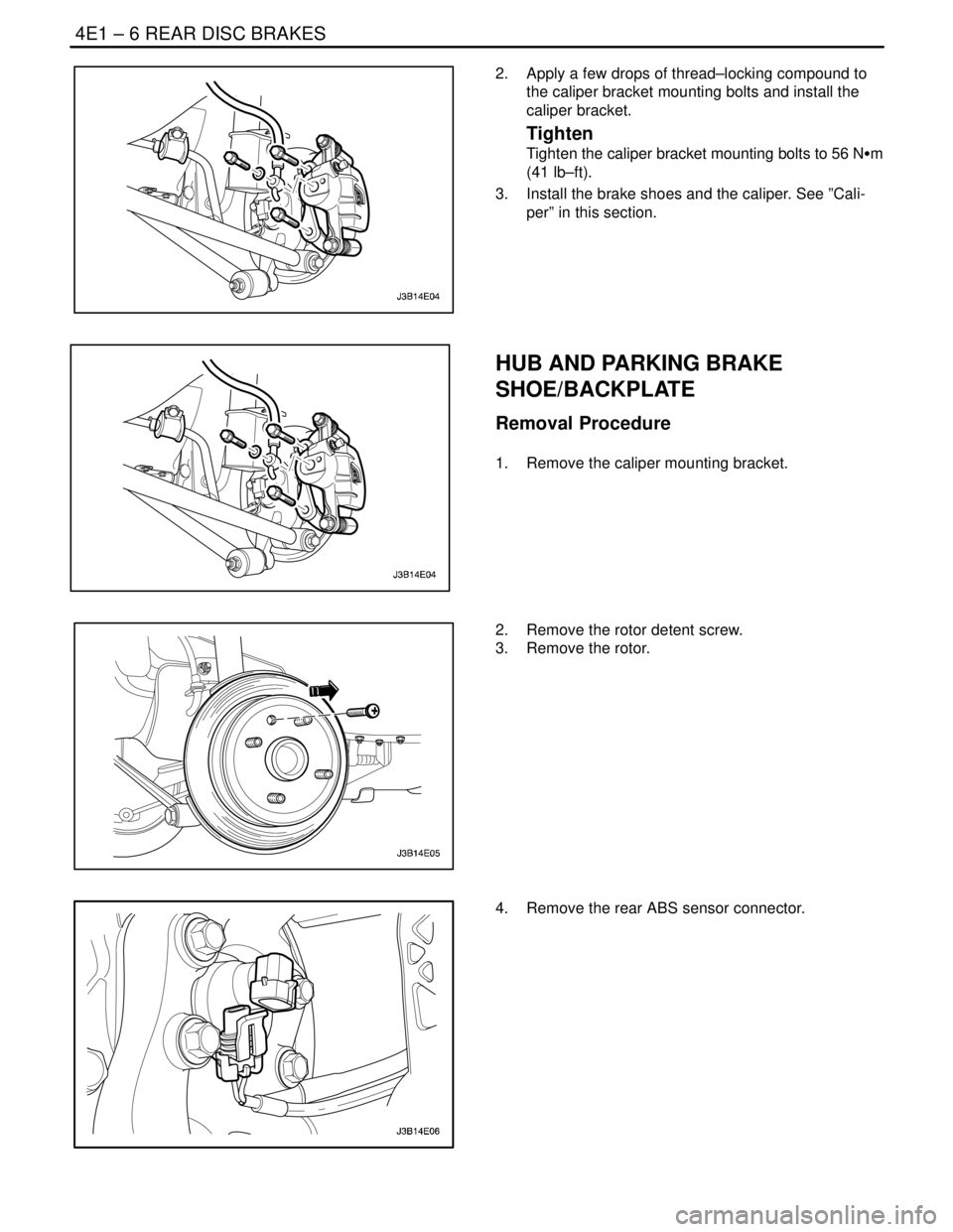

ROTOR

Removal Procedure

1. Remove the caliper. Refer to ”Caliper” in this sec-

tion.

2. Remove the brake shoes.

3. Remove the caliper mounting bracket.

4. Remove the rotor detent screw.

5. Remove the rotor.

Installation Procedure

Important : To guarantee uniform braking, always refinish

both rotors even if only one rotor is defective.

1. Install the rotor on the front wheel hub and install

the detent screw.

Tighten

Tighten the rotor detent screw to 4 NSm (35 lb–in)

Page 1063 of 2643

4E1 – 6IREAR DISC BRAKES

DAEWOO V–121 BL4

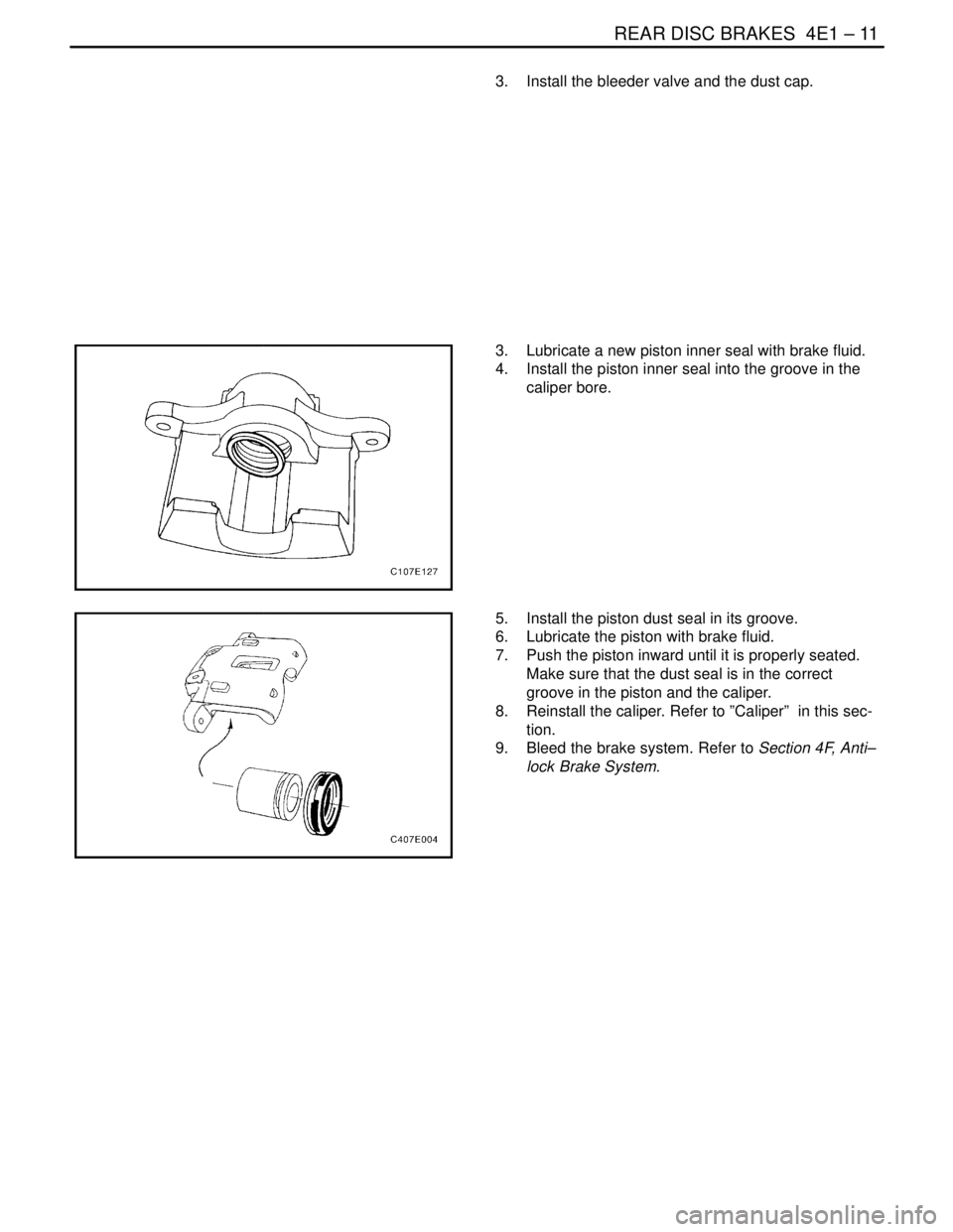

2. Apply a few drops of thread–locking compound to

the caliper bracket mounting bolts and install the

caliper bracket.

Tighten

Tighten the caliper bracket mounting bolts to 56 NSm

(41 lb–ft).

3. Install the brake shoes and the caliper. See ”Cali-

per” in this section.

HUB AND PARKING BRAKE

SHOE/BACKPLATE

Removal Procedure

1. Remove the caliper mounting bracket.

2. Remove the rotor detent screw.

3. Remove the rotor.

4. Remove the rear ABS sensor connector.

Page 1068 of 2643

REAR DISC BRAKES 4E1 – 11

DAEWOO V–121 BL4

3. Install the bleeder valve and the dust cap.

3. Lubricate a new piston inner seal with brake fluid.

4. Install the piston inner seal into the groove in the

caliper bore.

5. Install the piston dust seal in its groove.

6. Lubricate the piston with brake fluid.

7. Push the piston inward until it is properly seated.

Make sure that the dust seal is in the correct

groove in the piston and the caliper.

8. Reinstall the caliper. Refer to ”Caliper” in this sec-

tion.

9. Bleed the brake system. Refer to Section 4F, Anti–

lock Brake System.

Page 1069 of 2643

4E1 – 12IREAR DISC BRAKES

DAEWOO V–121 BL4

GENERAL DESCRIPTION

AND SYSTEM OPERATION

DISC BRAKE CALIPER ASSEMBLY

The caliper has a single bore and is mounted to the steer-

ing knuckle with two mounting bolts. Hydraulic pressure,

created by applying the brake pedal, is converted by the

caliper to a stopping force. This force acts equally against

the piston and the bottom of the caliper bore to move the

piston outward and to slide the caliper inward, resulting in

a clamping action on the rotor. This clamping action forces

the linings against the rotor, creating friction to stop the ve-

hicle.S Replace all components included in the repair kits

used to service the caliper.

S Lubricate the rubber parts with clean brake fluid to

ease assembly.

S Do not use lubricated shop air on brake parts, as

damage to the rubber components may result.

S If any hydraulic component is removed or discon-

nected, it may be necessary to bleed all or part of

the brake system. Refer to Section 4F, Anti–lock

Brake System.

S Replace the shoes in axle sets only.

S The torque values specified are for dry, unlubri-

cated fasteners.

S Perform the service operations on a clean bench,

free from oily material.

Page 1070 of 2643

SECTION : 4E2

REAR DRUM BRAKES

TABLE OF CONTENTS

SPECIFICATIONS4E2–1 . . . . . . . . . . . . . . . . . . . . . . . . .

Fastener Tightening Specifications 4E2–1. . . . . . . . .

DIAGNOSIS4E2–1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lining Inspection 4E2–1. . . . . . . . . . . . . . . . . . . . . . . . .

Drums 4E2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MAINTENANCE AND REPAIR4E2–3 . . . . . . . . . . . . . .

ON–VEHICLE SERVICE 4E2–3. . . . . . . . . . . . . . . . . . . .

Brake Adjustment 4E2–3. . . . . . . . . . . . . . . . . . . . . . . . Shoe and Lining 4E2–4. . . . . . . . . . . . . . . . . . . . . . . . .

Wheel Cylinder Assembly 4E2–7. . . . . . . . . . . . . . . . .

Backing Plate 4E2–8. . . . . . . . . . . . . . . . . . . . . . . . . . . .

UNIT REPAIR 4E2–10. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wheel Cylinder 4E2–10. . . . . . . . . . . . . . . . . . . . . . . . .

GENERAL DESCRIPTION AND SYSTEM

OPERATION4E2–12 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Drum Brakes 4E2–12. . . . . . . . . . . . . . . . . . . . . . . . . . .

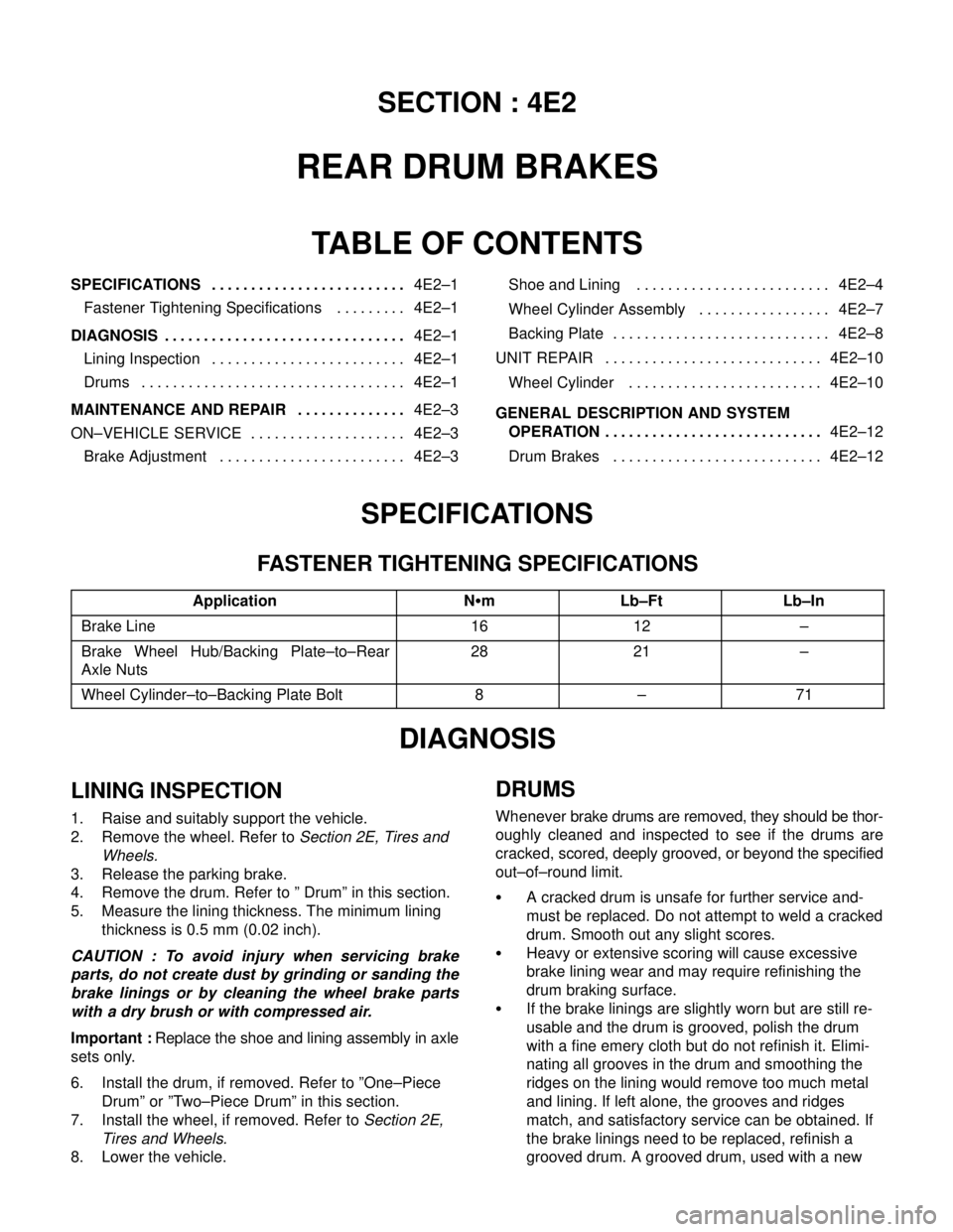

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

ApplicationNSmLb–FtLb–In

Brake Line1612–

Brake Wheel Hub/Backing Plate–to–Rear

Axle Nuts2821–

Wheel Cylinder–to–Backing Plate Bolt8–71

DIAGNOSIS

LINING INSPECTION

1. Raise and suitably support the vehicle.

2. Remove the wheel. Refer to Section 2E, Tires and

Wheels.

3. Release the parking brake.

4. Remove the drum. Refer to ” Drum” in this section.

5. Measure the lining thickness. The minimum lining

thickness is 0.5 mm (0.02 inch).

CAUTION : To avoid injury when servicing brake

parts, do not create dust by grinding or sanding the

brake linings or by cleaning the wheel brake parts

with a dry brush or with compressed air.

Important : Replace the shoe and lining assembly in axle

sets only.

6. Install the drum, if removed. Refer to ”One–Piece

Drum” or ”Two–Piece Drum” in this section.

7. Install the wheel, if removed. Refer to Section 2E,

Tires and Wheels.

8. Lower the vehicle.

DRUMS

Whenever brake drums are removed, they should be thor-

oughly cleaned and inspected to see if the drums are

cracked, scored, deeply grooved, or beyond the specified

out–of–round limit.

S A cracked drum is unsafe for further service and-

must be replaced. Do not attempt to weld a cracked

drum. Smooth out any slight scores.

S Heavy or extensive scoring will cause excessive

brake lining wear and may require refinishing the

drum braking surface.

S If the brake linings are slightly worn but are still re-

usable and the drum is grooved, polish the drum

with a fine emery cloth but do not refinish it. Elimi-

nating all grooves in the drum and smoothing the

ridges on the lining would remove too much metal

and lining. If left alone, the grooves and ridges

match, and satisfactory service can be obtained. If

the brake linings need to be replaced, refinish a

grooved drum. A grooved drum, used with a new