Section 5 DAEWOO LACETTI 2004 Service Repair Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 1072 of 2643

REAR DRUM BRAKES 4E2 – 3

DAEWOO V–121 BL4

MAINTENANCE AND REPAIR

ON–VEHICLE SERVICE

BRAKE ADJUSTMENT

Removal Procedure

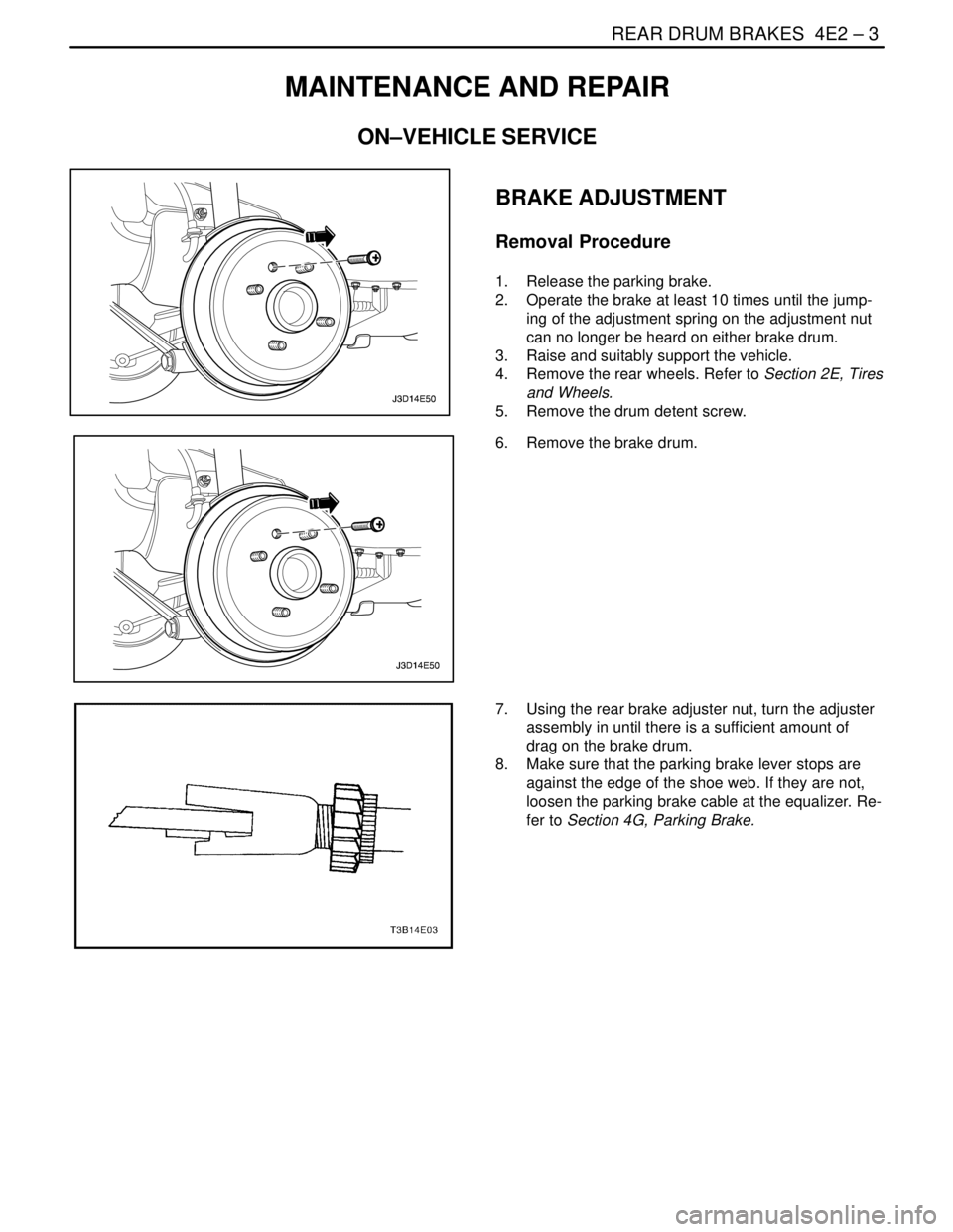

1. Release the parking brake.

2. Operate the brake at least 10 times until the jump-

ing of the adjustment spring on the adjustment nut

can no longer be heard on either brake drum.

3. Raise and suitably support the vehicle.

4. Remove the rear wheels. Refer to Section 2E, Tires

and Wheels.

5. Remove the drum detent screw.

6. Remove the brake drum.

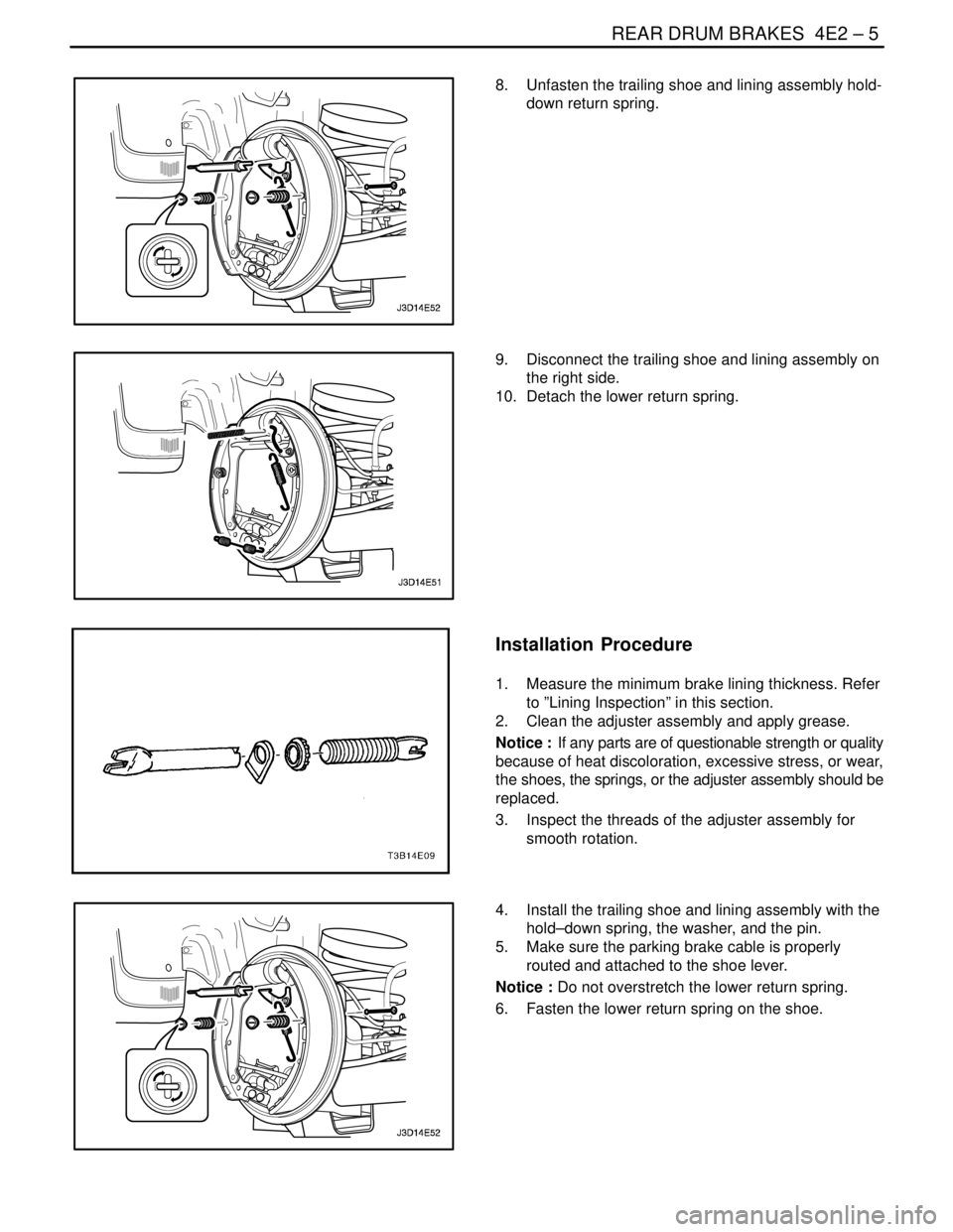

7. Using the rear brake adjuster nut, turn the adjuster

assembly in until there is a sufficient amount of

drag on the brake drum.

8. Make sure that the parking brake lever stops are

against the edge of the shoe web. If they are not,

loosen the parking brake cable at the equalizer. Re-

fer to Section 4G, Parking Brake.

Page 1073 of 2643

4E2 – 4IREAR DRUM BRAKES

DAEWOO V–121 BL4

Installation Procedure

1. Position the rear brake drum. Fasten the drum det-

ent screw.

Tighten

Tighten the drum detent screw to 4 NSm (35 lb–in).

2. Install the rear wheels. Refer to Section 2E, Tires

and Wheels.

Important : The brake pedal must be operated more than

10 times. When the clicking can no longer be heard, the

clearance between the brake shoe and drum is adjusted.

3. Apply the foot brake several times until the clicking

of the adjustment actuator can no longer be heard.

4. Adjust the parking brake. Refer to Section 4G,

Parking Brake.

SHOE AND LINING

Removal Procedure

1. Raise and suitably support the vehicle.

2. Remove the rear wheels. Refer to Section 2E, Tires

and Wheels.

3. Loosen the parking brake cable. Refer to Section

4G, Parking Brake.

4. Remove the brake drum.

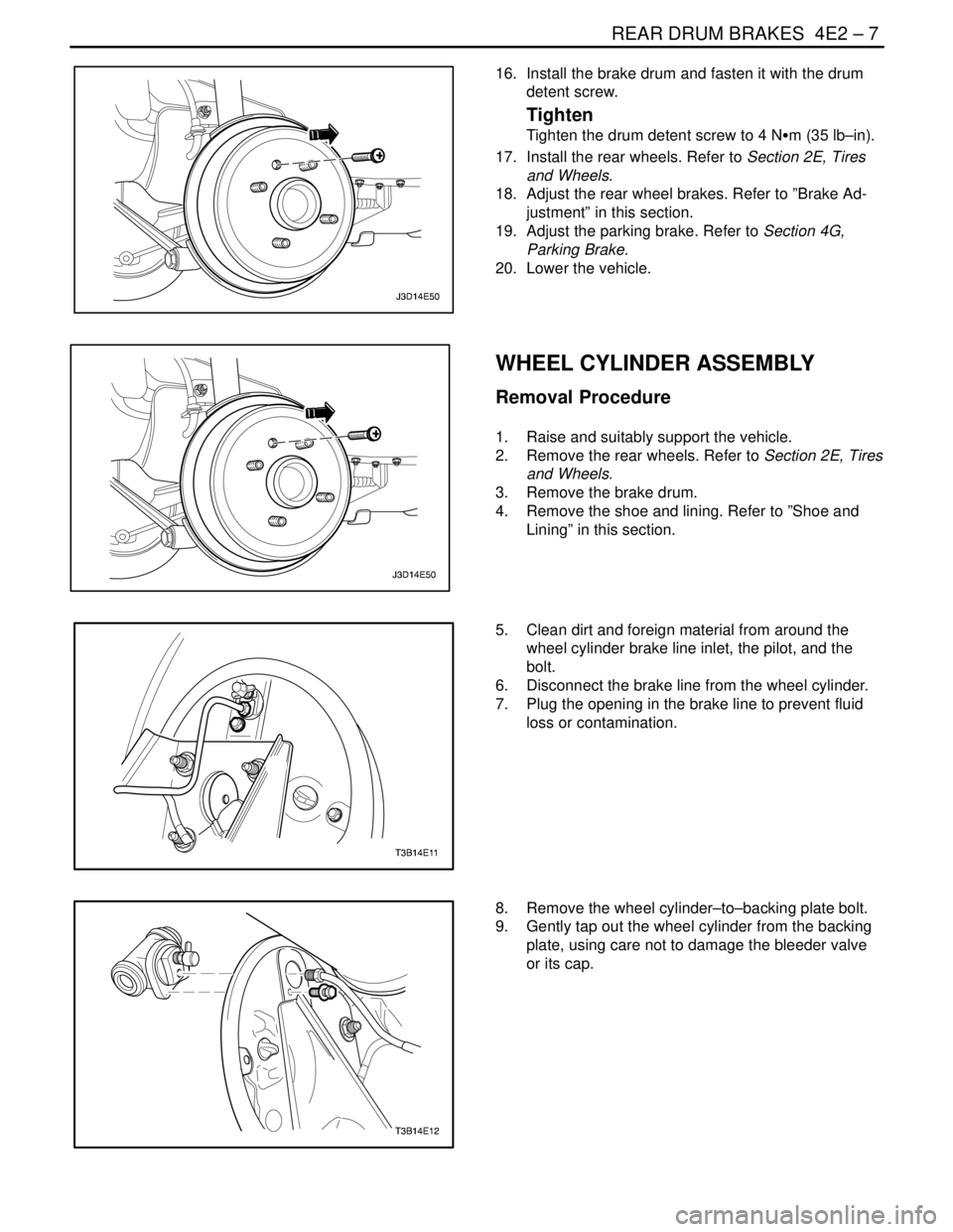

5. Loosen the leading shoe hold–down return spring.

6. Disconnect the upper link of the connecting link

spring of the leading shoe to relieve tension on the

upper return spring.

7. Remove the upper return spring and the adjuster.

Page 1074 of 2643

REAR DRUM BRAKES 4E2 – 5

DAEWOO V–121 BL4

8. Unfasten the trailing shoe and lining assembly hold-

down return spring.

9. Disconnect the trailing shoe and lining assembly on

the right side.

10. Detach the lower return spring.

Installation Procedure

1. Measure the minimum brake lining thickness. Refer

to ”Lining Inspection” in this section.

2. Clean the adjuster assembly and apply grease.

Notice : If any parts are of questionable strength or quality

because of heat discoloration, excessive stress, or wear,

the shoes, the springs, or the adjuster assembly should be

replaced.

3. Inspect the threads of the adjuster assembly for

smooth rotation.

4. Install the trailing shoe and lining assembly with the

hold–down spring, the washer, and the pin.

5. Make sure the parking brake cable is properly

routed and attached to the shoe lever.

Notice : Do not overstretch the lower return spring.

6. Fasten the lower return spring on the shoe.

Page 1076 of 2643

REAR DRUM BRAKES 4E2 – 7

DAEWOO V–121 BL4

16. Install the brake drum and fasten it with the drum

detent screw.

Tighten

Tighten the drum detent screw to 4 NSm (35 lb–in).

17. Install the rear wheels. Refer to Section 2E, Tires

and Wheels.

18. Adjust the rear wheel brakes. Refer to ”Brake Ad-

justment” in this section.

19. Adjust the parking brake. Refer to Section 4G,

Parking Brake.

20. Lower the vehicle.

WHEEL CYLINDER ASSEMBLY

Removal Procedure

1. Raise and suitably support the vehicle.

2. Remove the rear wheels. Refer to Section 2E, Tires

and Wheels.

3. Remove the brake drum.

4. Remove the shoe and lining. Refer to ”Shoe and

Lining” in this section.

5. Clean dirt and foreign material from around the

wheel cylinder brake line inlet, the pilot, and the

bolt.

6. Disconnect the brake line from the wheel cylinder.

7. Plug the opening in the brake line to prevent fluid

loss or contamination.

8. Remove the wheel cylinder–to–backing plate bolt.

9. Gently tap out the wheel cylinder from the backing

plate, using care not to damage the bleeder valve

or its cap.

Page 1077 of 2643

4E2 – 8IREAR DRUM BRAKES

DAEWOO V–121 BL4

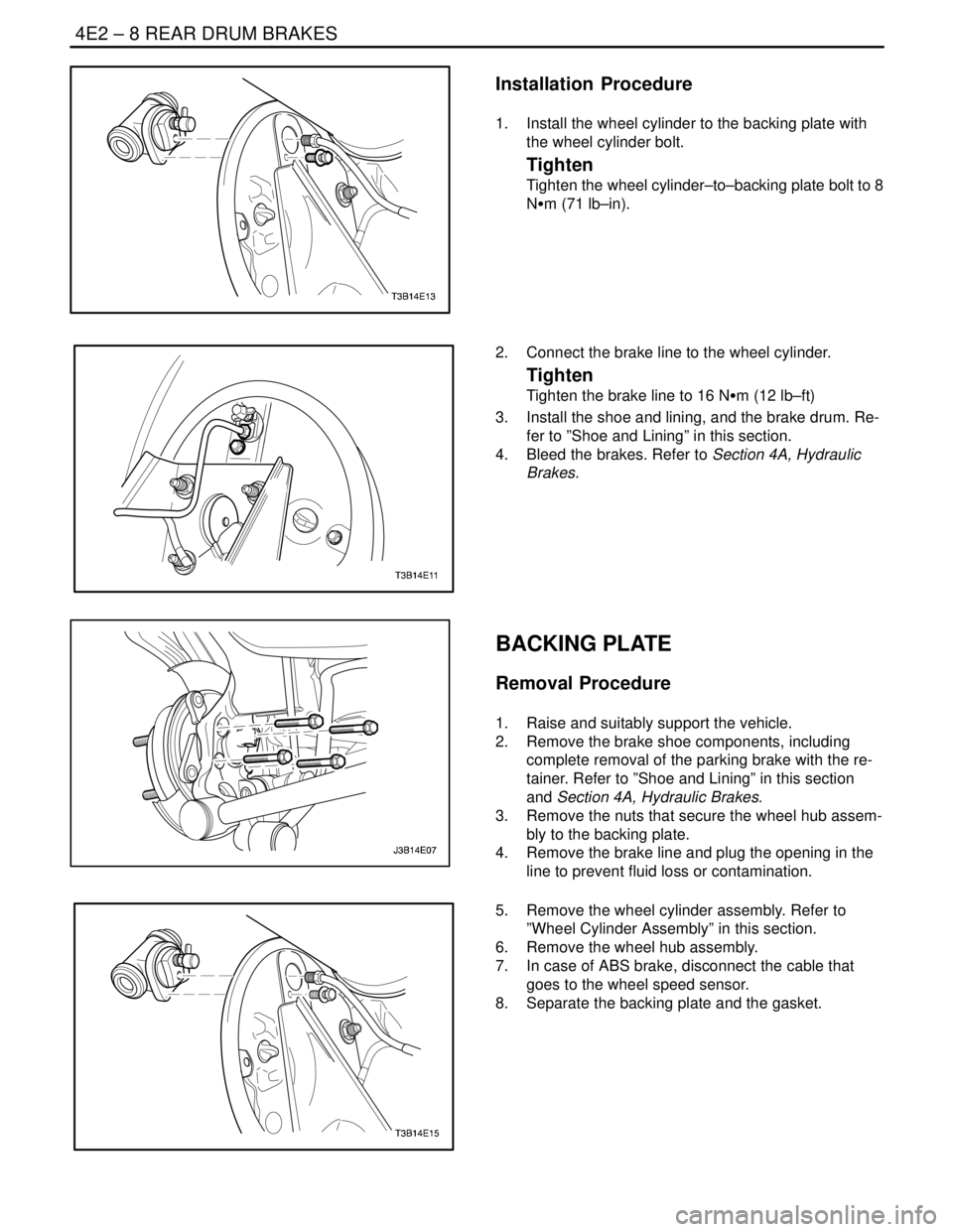

Installation Procedure

1. Install the wheel cylinder to the backing plate with

the wheel cylinder bolt.

Tighten

Tighten the wheel cylinder–to–backing plate bolt to 8

NSm (71 lb–in).

2. Connect the brake line to the wheel cylinder.

Tighten

Tighten the brake line to 16 NSm (12 lb–ft)

3. Install the shoe and lining, and the brake drum. Re-

fer to ”Shoe and Lining” in this section.

4. Bleed the brakes. Refer to Section 4A, Hydraulic

Brakes.

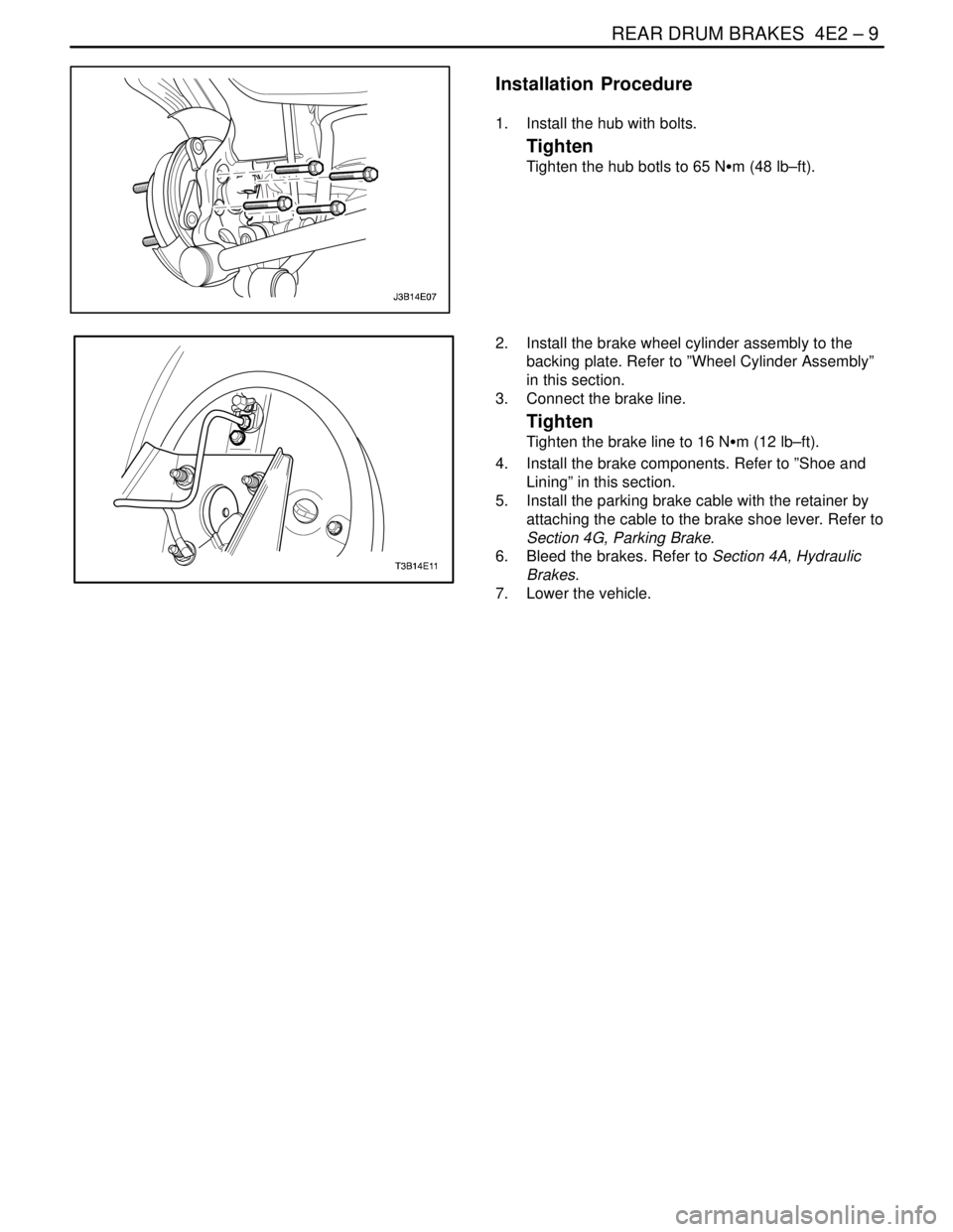

BACKING PLATE

Removal Procedure

1. Raise and suitably support the vehicle.

2. Remove the brake shoe components, including

complete removal of the parking brake with the re-

tainer. Refer to ”Shoe and Lining” in this section

and Section 4A, Hydraulic Brakes.

3. Remove the nuts that secure the wheel hub assem-

bly to the backing plate.

4. Remove the brake line and plug the opening in the

line to prevent fluid loss or contamination.

5. Remove the wheel cylinder assembly. Refer to

”Wheel Cylinder Assembly” in this section.

6. Remove the wheel hub assembly.

7. In case of ABS brake, disconnect the cable that

goes to the wheel speed sensor.

8. Separate the backing plate and the gasket.

Page 1078 of 2643

REAR DRUM BRAKES 4E2 – 9

DAEWOO V–121 BL4

Installation Procedure

1. Install the hub with bolts.

Tighten

Tighten the hub botls to 65 NSm (48 lb–ft).

2. Install the brake wheel cylinder assembly to the

backing plate. Refer to ”Wheel Cylinder Assembly”

in this section.

3. Connect the brake line.

Tighten

Tighten the brake line to 16 NSm (12 lb–ft).

4. Install the brake components. Refer to ”Shoe and

Lining” in this section.

5. Install the parking brake cable with the retainer by

attaching the cable to the brake shoe lever. Refer to

Section 4G, Parking Brake.

6. Bleed the brakes. Refer to Section 4A, Hydraulic

Brakes.

7. Lower the vehicle.

Page 1079 of 2643

4E2 – 10IREAR DRUM BRAKES

DAEWOO V–121 BL4

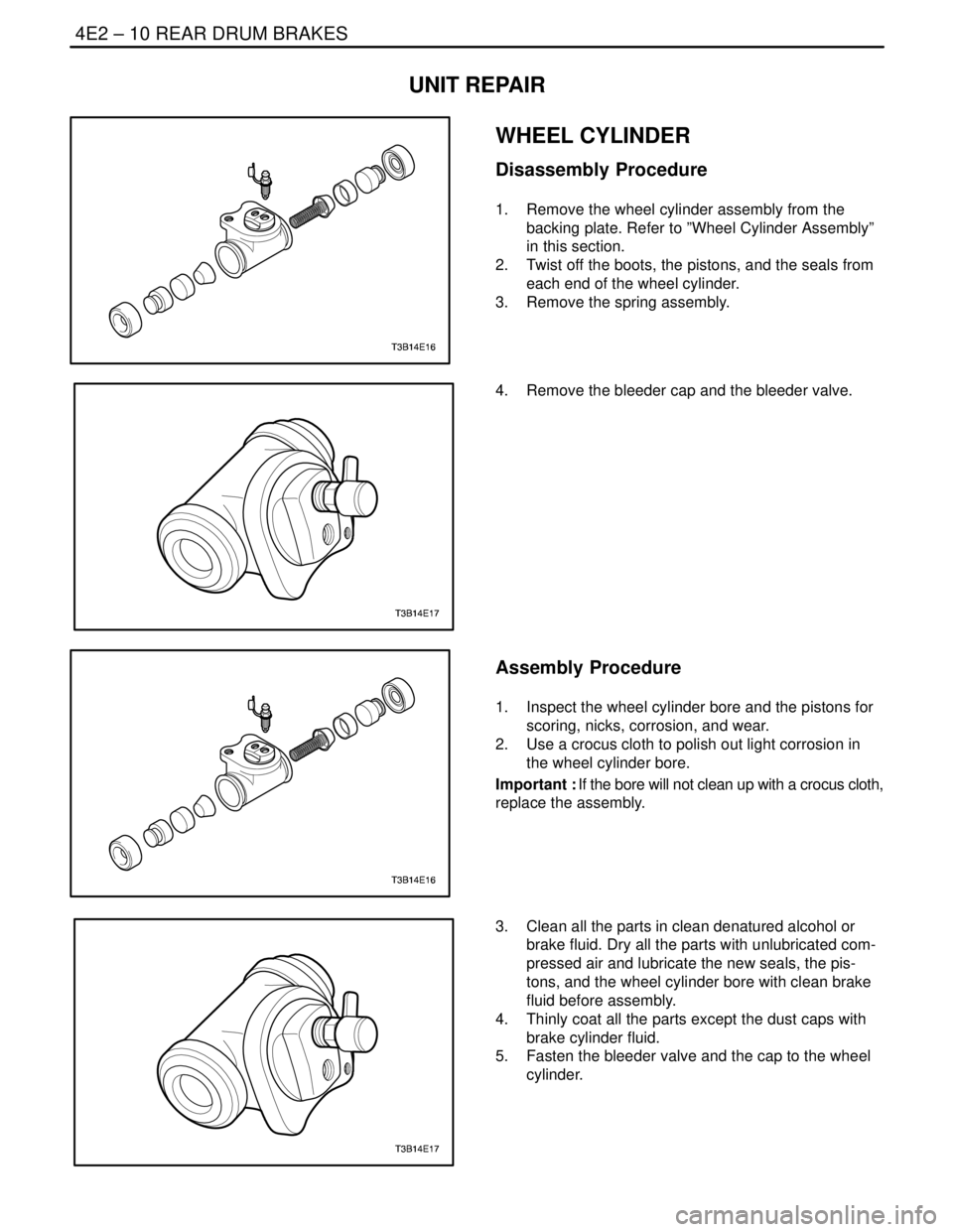

UNIT REPAIR

WHEEL CYLINDER

Disassembly Procedure

1. Remove the wheel cylinder assembly from the

backing plate. Refer to ”Wheel Cylinder Assembly”

in this section.

2. Twist off the boots, the pistons, and the seals from

each end of the wheel cylinder.

3. Remove the spring assembly.

4. Remove the bleeder cap and the bleeder valve.

Assembly Procedure

1. Inspect the wheel cylinder bore and the pistons for

scoring, nicks, corrosion, and wear.

2. Use a crocus cloth to polish out light corrosion in

the wheel cylinder bore.

Important : If the bore will not clean up with a crocus cloth,

replace the assembly.

3. Clean all the parts in clean denatured alcohol or

brake fluid. Dry all the parts with unlubricated com-

pressed air and lubricate the new seals, the pis-

tons, and the wheel cylinder bore with clean brake

fluid before assembly.

4. Thinly coat all the parts except the dust caps with

brake cylinder fluid.

5. Fasten the bleeder valve and the cap to the wheel

cylinder.

Page 1080 of 2643

REAR DRUM BRAKES 4E2 – 11

DAEWOO V–121 BL4

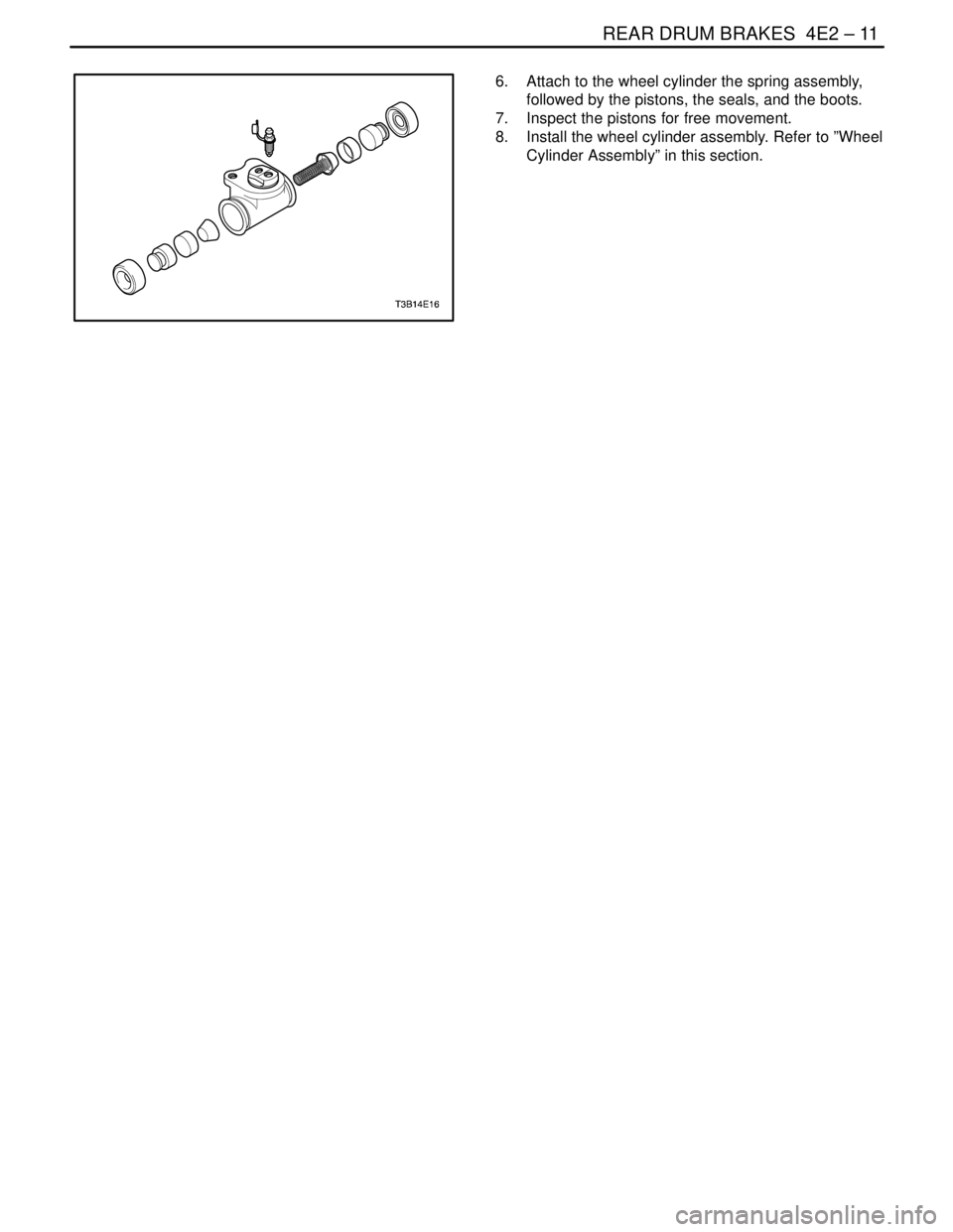

6. Attach to the wheel cylinder the spring assembly,

followed by the pistons, the seals, and the boots.

7. Inspect the pistons for free movement.

8. Install the wheel cylinder assembly. Refer to ”Wheel

Cylinder Assembly” in this section.

Page 1082 of 2643

SECTION : 4F

ANTILOCK BRAKE SYSTEM

CAUTION : Disconnect the negative battery cable before removing or installing any electrical unit or when a tool

or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help

prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise noted.

TABLE OF CONTENTS

SPECIFICATIONS4F–2 . . . . . . . . . . . . . . . . . . . . . . . . . .

Fastener Tightening Specifications 4F–2. . . . . . . . . .

SPECIAL TOOLS4F–2 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Special Tools Table 4F–2. . . . . . . . . . . . . . . . . . . . . . . .

SCHEMATIC AND ROUTING DIAGRAMS4F–3 . . . . .

Abs System Circuit (I) 4F–3. . . . . . . . . . . . . . . . . . . . . .

Abs System Circuit (II) 4F–4. . . . . . . . . . . . . . . . . . . . .

Ebcm Connector Face View 4F–5. . . . . . . . . . . . . . . . .

COMPONENT LOCATOR4F–6 . . . . . . . . . . . . . . . . . . . .

ABS/EBD System Drive 4F–6. . . . . . . . . . . . . . . . . . . .

DIAGNOSIS4F–7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Circuit Check 4F–7. . . . . . . . . . . . . . . . . . .

ABS Indicator Lamp Inoperative 4F–9. . . . . . . . . . . . .

Power Supply to Control Module,

No DTCs Stored 4F–12. . . . . . . . . . . . . . . . . . . . . . . .

ABS Indicator Lamp Illuminated Continuously,

No DTCs Stored 4F–16. . . . . . . . . . . . . . . . . . . . . . . .

Electronic Brake–Force Distribution (EBD)

System Indicator Lamp Inoperative 4F–18. . . . . . . .

SELF–DIAGNOSTICS 4F–22. . . . . . . . . . . . . . . . . . . .

DISPLAYING DTCs 4F–22. . . . . . . . . . . . . . . . . . . . . . .

CLEARING DTCs 4F–22. . . . . . . . . . . . . . . . . . . . . . . .

INTERMITTENTS AND POOR

CONNECTIONS 4F–22. . . . . . . . . . . . . . . . . . . . . . . .

DTC C0035 Left Front Wheel Speed Sensor

Circuit Malfunction 4F–23. . . . . . . . . . . . . . . . . . . . . .

DTC C0040 Right Front Wheel Speed Sensor

Circuit Malfunction 4F–26. . . . . . . . . . . . . . . . . . . . . .

DTC C0045 Left Rear Wheel Speed Sensor

Circuit Malfunction 4F–29. . . . . . . . . . . . . . . . . . . . . .

DTC C0050 Right Rear Wheel Speed Sensor

Circuit Malfunction 4F–32. . . . . . . . . . . . . . . . . . . . . .

DTC C0060/C0065 Left Front Inlet and

Outlet Valve Solenoid Fault 4F–35. . . . . . . . . . . . . . .

DTC C0070/C0075 Right Front Inlet and

Outlet Valve Solenoid Fault 4F–37. . . . . . . . . . . . . . . DTC C0080/C0085 Left Rear Inlet and

Outlet Valve Solenoid Fault 4F–39. . . . . . . . . . . . . . .

DTC C0090/C0095 Right Rear Inlet and

Outlet Valve Solenoid Fault 4F–41. . . . . . . . . . . . . . .

DTC C0110 Pump Motor Circuit Malfunction 4F–43. .

DTC C0121 Valve Relay Circuit Malfunction 4F–45. .

DTC C0161 ABS Brake Switch Circuit

Malfunction 4F–47. . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC C0245 Wheel Speed Sensor Frequency

Error 4F–50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC C0550 ABS Control Module Internal

Fault 4F–54. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC C0800 Low Voltage Fault 4F–56. . . . . . . . . . . . .

DTC C0931 Overheated 4F–59. . . . . . . . . . . . . . . . . . .

MAINTENANCE AND REPAIR4F–60 . . . . . . . . . . . . . .

ON–VEHICLE SERVICE 4F–60. . . . . . . . . . . . . . . . . . . .

Service Precautions 4F–60. . . . . . . . . . . . . . . . . . . . . . .

Bleeding System 4F–61. . . . . . . . . . . . . . . . . . . . . . . . .

ABS 5.3 Assembly 4F–61. . . . . . . . . . . . . . . . . . . . . . . .

Front Wheel Speed Sensor 4F–62. . . . . . . . . . . . . . . .

Front Wheel Speed Sensor Jumper Harness 4F–63.

Rear Wheel Speed Sensor 4F–64. . . . . . . . . . . . . . . . .

GENERAL DESCRIPTION AND SYSTEM

OPERATION4F–65 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Basic Knowledge Required 4F–65. . . . . . . . . . . . . . . . .

ABS System Components 4F–65. . . . . . . . . . . . . . . . .

Base Braking Mode 4F–65. . . . . . . . . . . . . . . . . . . . . . .

Antilock Braking Mode 4F–66. . . . . . . . . . . . . . . . . . . . .

EBD System 4F–69. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electronic Brake–Force Distribution (EBD) Failure

Matrix 4F–70. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tires and ABS/EBD 4F–71. . . . . . . . . . . . . . . . . . . . . . .

Electronic Brake Control Module (EBCM) 4F–71. . . .

Front Wheel Speed Sensors 4F–71. . . . . . . . . . . . . . .

Front Wheel Speed Sensor Rings 4F–71. . . . . . . . . . .

Rear Wheel Speed Sensors and Rings 4F–71. . . . . .

Valve Relay and Pump Motor Relay 4F–71. . . . . . . . .

Page 1104 of 2643

ANTILOCK BRAKE SYSTEM 4F – 23

DAEWOO V–121 BL4

J3B14F05

Left Front

Wheel Speed

Sensor

EBCM

LH BLU BRN1

2

76

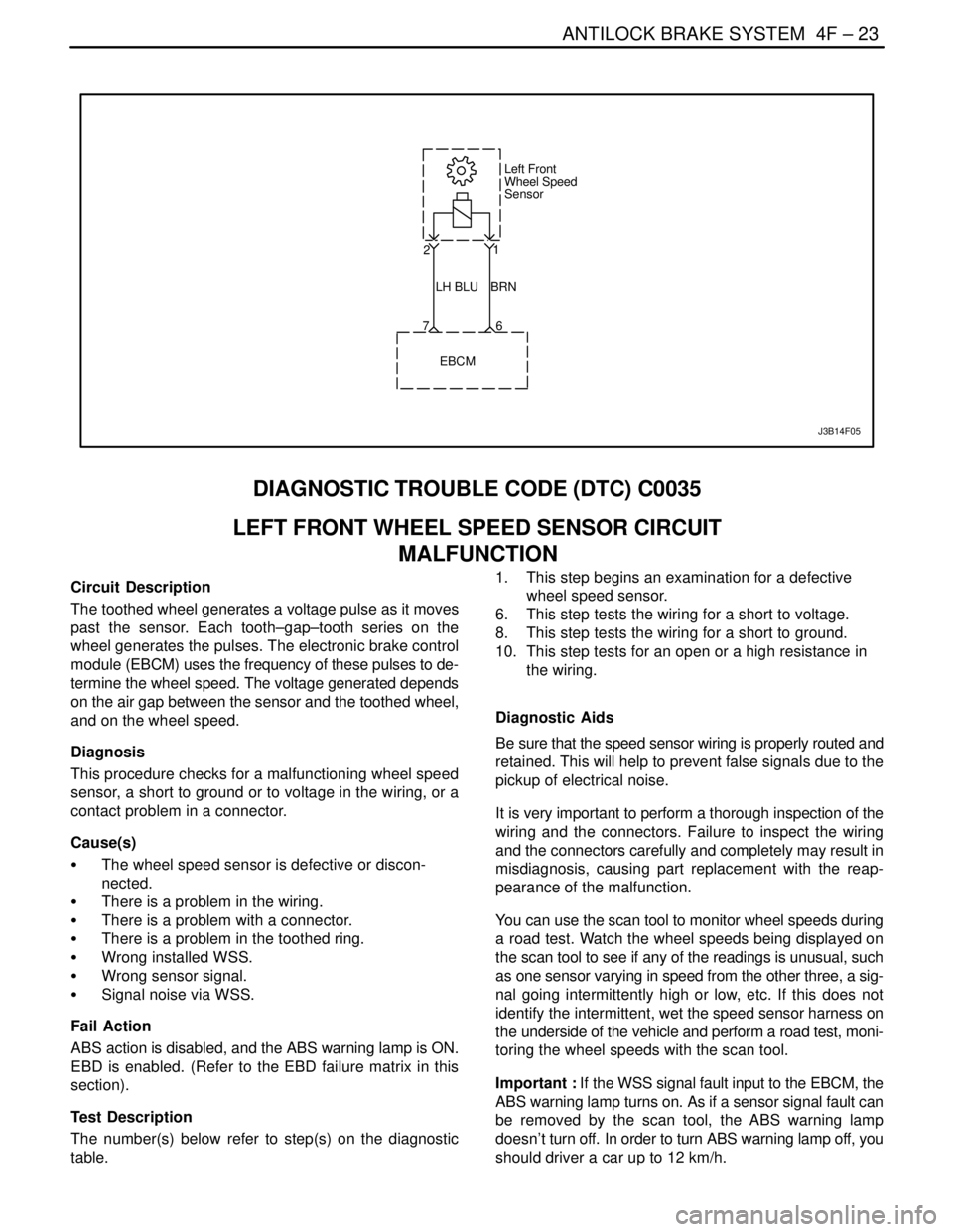

DIAGNOSTIC TROUBLE CODE (DTC) C0035

LEFT FRONT WHEEL SPEED SENSOR CIRCUIT

MALFUNCTION

Circuit Description

The toothed wheel generates a voltage pulse as it moves

past the sensor. Each tooth–gap–tooth series on the

wheel generates the pulses. The electronic brake control

module (EBCM) uses the frequency of these pulses to de-

termine the wheel speed. The voltage generated depends

on the air gap between the sensor and the toothed wheel,

and on the wheel speed.

Diagnosis

This procedure checks for a malfunctioning wheel speed

sensor, a short to ground or to voltage in the wiring, or a

contact problem in a connector.

Cause(s)

S The wheel speed sensor is defective or discon-

nected.

S There is a problem in the wiring.

S There is a problem with a connector.

S There is a problem in the toothed ring.

S Wrong installed WSS.

S Wrong sensor signal.

S Signal noise via WSS.

Fail Action

ABS action is disabled, and the ABS warning lamp is ON.

EBD is enabled. (Refer to the EBD failure matrix in this

section).

Test Description

The number(s) below refer to step(s) on the diagnostic

table.1. This step begins an examination for a defective

wheel speed sensor.

6. This step tests the wiring for a short to voltage.

8. This step tests the wiring for a short to ground.

10. This step tests for an open or a high resistance in

the wiring.

Diagnostic Aids

Be sure that the speed sensor wiring is properly routed and

retained. This will help to prevent false signals due to the

pickup of electrical noise.

It is very important to perform a thorough inspection of the

wiring and the connectors. Failure to inspect the wiring

and the connectors carefully and completely may result in

misdiagnosis, causing part replacement with the reap-

pearance of the malfunction.

You can use the scan tool to monitor wheel speeds during

a road test. Watch the wheel speeds being displayed on

the scan tool to see if any of the readings is unusual, such

as one sensor varying in speed from the other three, a sig-

nal going intermittently high or low, etc. If this does not

identify the intermittent, wet the speed sensor harness on

the underside of the vehicle and perform a road test, moni-

toring the wheel speeds with the scan tool.

Important : If the WSS signal fault input to the EBCM, the

ABS warning lamp turns on. As if a sensor signal fault can

be removed by the scan tool, the ABS warning lamp

doesn’t turn off. In order to turn ABS warning lamp off, you

should driver a car up to 12 km/h.