Section 5 DAEWOO LACETTI 2004 Service Repair Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 1027 of 2643

HYDRAULIC BRAKES 4A – 11

DAEWOO V–121 BL4

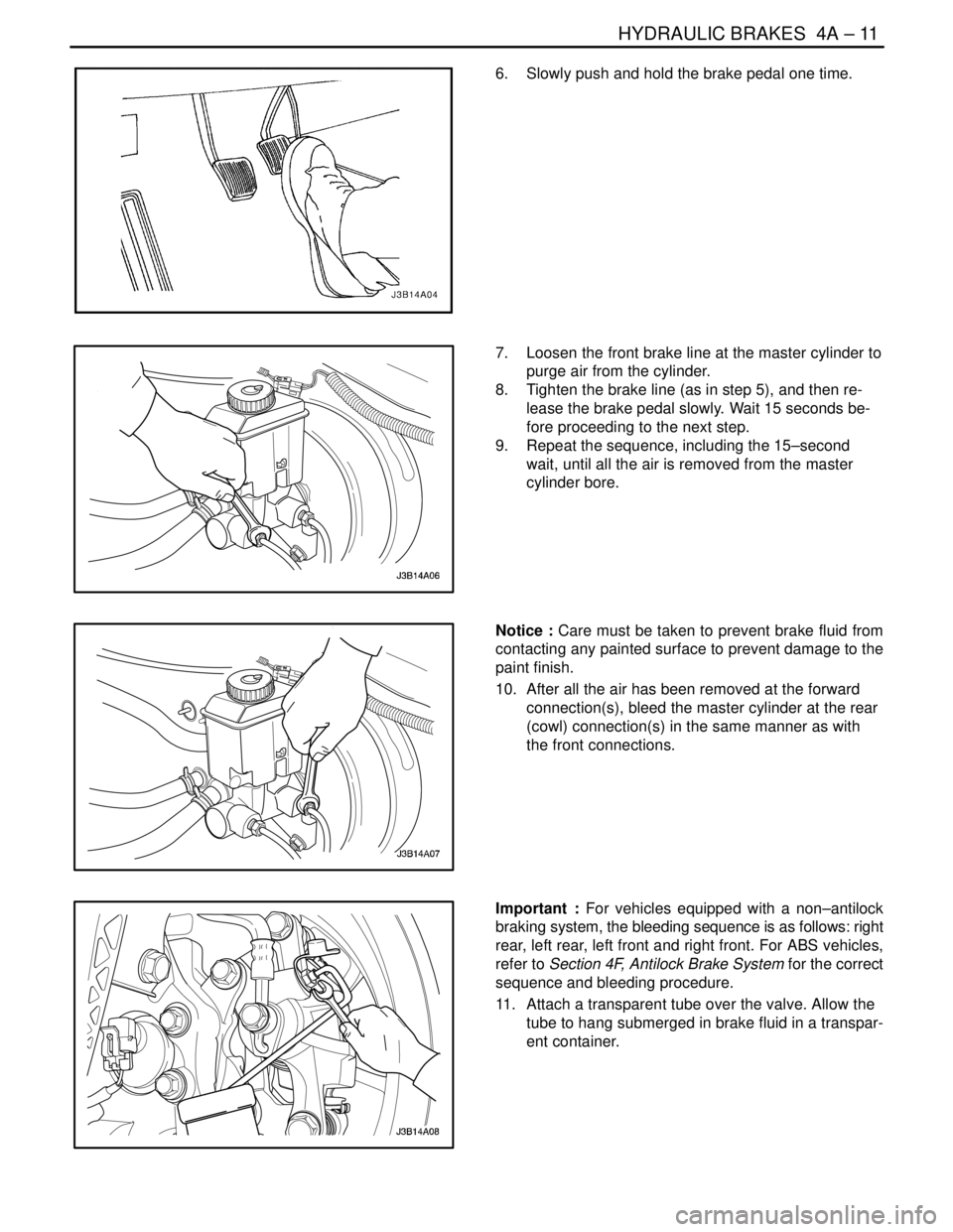

6. Slowly push and hold the brake pedal one time.

7. Loosen the front brake line at the master cylinder to

purge air from the cylinder.

8. Tighten the brake line (as in step 5), and then re-

lease the brake pedal slowly. Wait 15 seconds be-

fore proceeding to the next step.

9. Repeat the sequence, including the 15–second

wait, until all the air is removed from the master

cylinder bore.

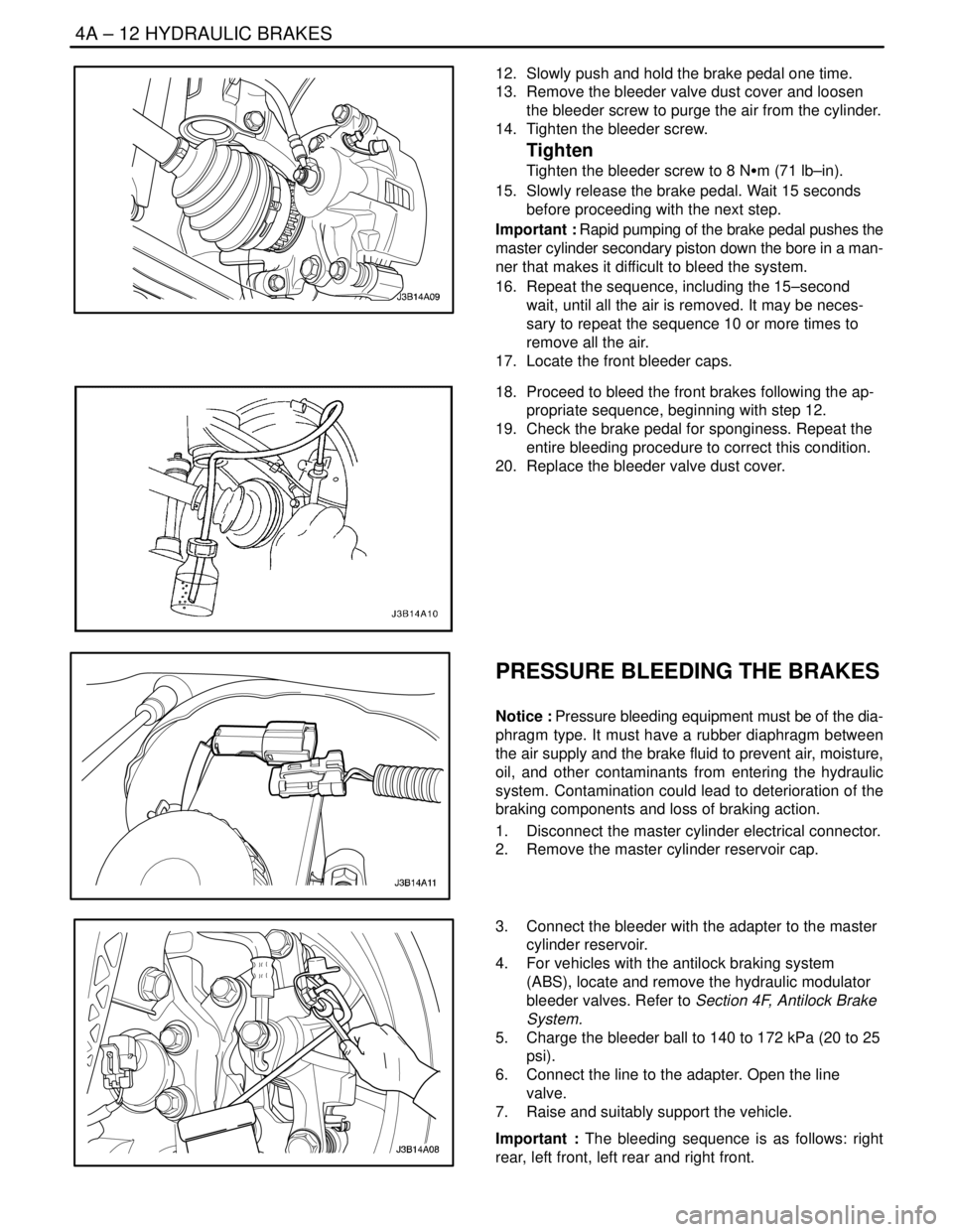

Notice : Care must be taken to prevent brake fluid from

contacting any painted surface to prevent damage to the

paint finish.

10. After all the air has been removed at the forward

connection(s), bleed the master cylinder at the rear

(cowl) connection(s) in the same manner as with

the front connections.

Important : For vehicles equipped with a non–antilock

braking system, the bleeding sequence is as follows: right

rear, left rear, left front and right front. For ABS vehicles,

refer to Section 4F, Antilock Brake System for the correct

sequence and bleeding procedure.

11. Attach a transparent tube over the valve. Allow the

tube to hang submerged in brake fluid in a transpar-

ent container.

Page 1028 of 2643

4A – 12IHYDRAULIC BRAKES

DAEWOO V–121 BL4

12. Slowly push and hold the brake pedal one time.

13. Remove the bleeder valve dust cover and loosen

the bleeder screw to purge the air from the cylinder.

14. Tighten the bleeder screw.

Tighten

Tighten the bleeder screw to 8 NSm (71 lb–in).

15. Slowly release the brake pedal. Wait 15 seconds

before proceeding with the next step.

Important : Rapid pumping of the brake pedal pushes the

master cylinder secondary piston down the bore in a man-

ner that makes it difficult to bleed the system.

16. Repeat the sequence, including the 15–second

wait, until all the air is removed. It may be neces-

sary to repeat the sequence 10 or more times to

remove all the air.

17. Locate the front bleeder caps.

18. Proceed to bleed the front brakes following the ap-

propriate sequence, beginning with step 12.

19. Check the brake pedal for sponginess. Repeat the

entire bleeding procedure to correct this condition.

20. Replace the bleeder valve dust cover.

PRESSURE BLEEDING THE BRAKES

Notice : Pressure bleeding equipment must be of the dia-

phragm type. It must have a rubber diaphragm between

the air supply and the brake fluid to prevent air, moisture,

oil, and other contaminants from entering the hydraulic

system. Contamination could lead to deterioration of the

braking components and loss of braking action.

1. Disconnect the master cylinder electrical connector.

2. Remove the master cylinder reservoir cap.

3. Connect the bleeder with the adapter to the master

cylinder reservoir.

4. For vehicles with the antilock braking system

(ABS), locate and remove the hydraulic modulator

bleeder valves. Refer to Section 4F, Antilock Brake

System.

5. Charge the bleeder ball to 140 to 172 kPa (20 to 25

psi).

6. Connect the line to the adapter. Open the line

valve.

7. Raise and suitably support the vehicle.

Important : The bleeding sequence is as follows: right

rear, left front, left rear and right front.

Page 1030 of 2643

4A – 14IHYDRAULIC BRAKES

DAEWOO V–121 BL4

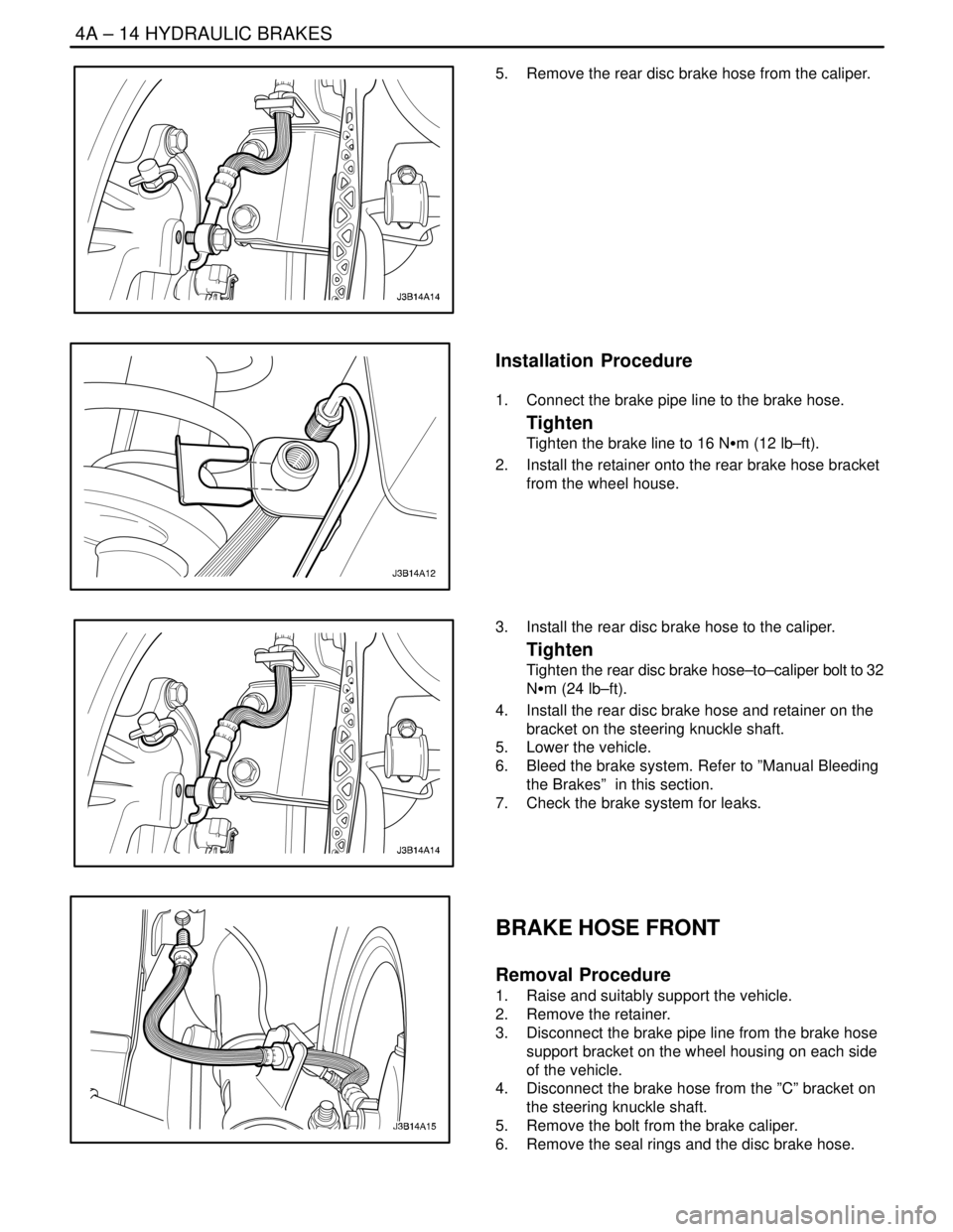

5. Remove the rear disc brake hose from the caliper.

Installation Procedure

1. Connect the brake pipe line to the brake hose.

Tighten

Tighten the brake line to 16 NSm (12 lb–ft).

2. Install the retainer onto the rear brake hose bracket

from the wheel house.

3. Install the rear disc brake hose to the caliper.

Tighten

Tighten the rear disc brake hose–to–caliper bolt to 32

NSm (24 lb–ft).

4. Install the rear disc brake hose and retainer on the

bracket on the steering knuckle shaft.

5. Lower the vehicle.

6. Bleed the brake system. Refer to ”Manual Bleeding

the Brakes” in this section.

7. Check the brake system for leaks.

BRAKE HOSE FRONT

Removal Procedure

1. Raise and suitably support the vehicle.

2. Remove the retainer.

3. Disconnect the brake pipe line from the brake hose

support bracket on the wheel housing on each side

of the vehicle.

4. Disconnect the brake hose from the ”C” bracket on

the steering knuckle shaft.

5. Remove the bolt from the brake caliper.

6. Remove the seal rings and the disc brake hose.

Page 1031 of 2643

HYDRAULIC BRAKES 4A – 15

DAEWOO V–121 BL4

Installation Procedure

1. Install the new disc brake hose to the caliper with

new seal rings and the bolt.

Tighten

Tighten the front disc brake hose–to–caliper bolt to 40

NSm (30 lb–ft).

2. Slide the brake hose on the steering knuckle shaft

”C” bracket.

3. Connect the brake pipe line to the brake hose on

the wheel housing bracket on each side of the ve-

hicle.

Tighten

Tighten the brake line to 16 NSm (12 lb–ft).

4. Lower the vehicle.

5. Bleed the brake system. Refer to ”Manual Bleeding

the Brakes” in this section.

6. Check the brake system for leaks.

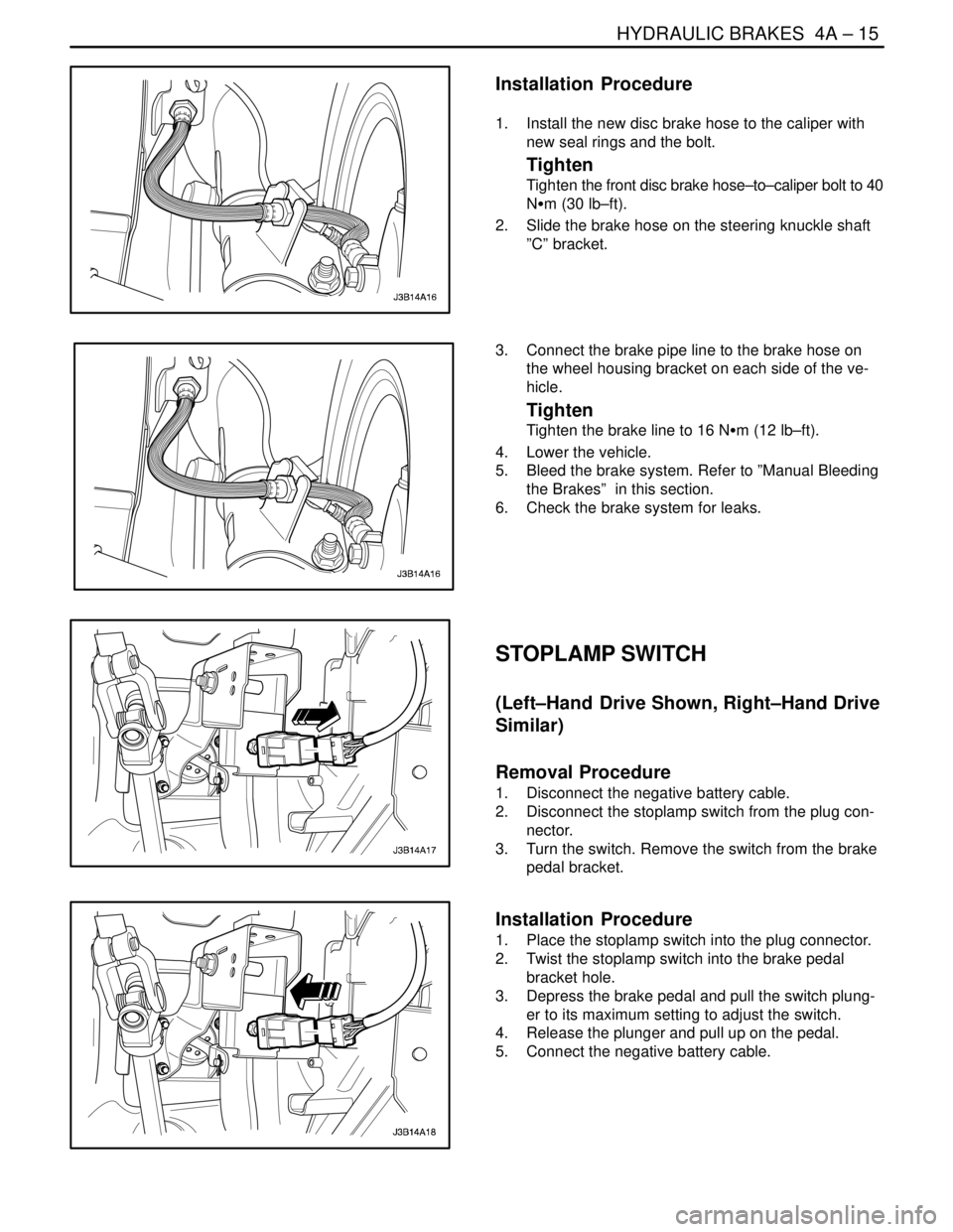

STOPLAMP SWITCH

(Left–Hand Drive Shown, Right–Hand Drive

Similar)

Removal Procedure

1. Disconnect the negative battery cable.

2. Disconnect the stoplamp switch from the plug con-

nector.

3. Turn the switch. Remove the switch from the brake

pedal bracket.

Installation Procedure

1. Place the stoplamp switch into the plug connector.

2. Twist the stoplamp switch into the brake pedal

bracket hole.

3. Depress the brake pedal and pull the switch plung-

er to its maximum setting to adjust the switch.

4. Release the plunger and pull up on the pedal.

5. Connect the negative battery cable.

Page 1032 of 2643

4A – 16IHYDRAULIC BRAKES

DAEWOO V–121 BL4

BRAKE PEDAL

(Left–Hand Drive Shown, Right–Hand Drive

Similar)

Removal Procedure

1. Remove the instrument panel. Refer to Section 9E,

Instrumentation/Driver Information.

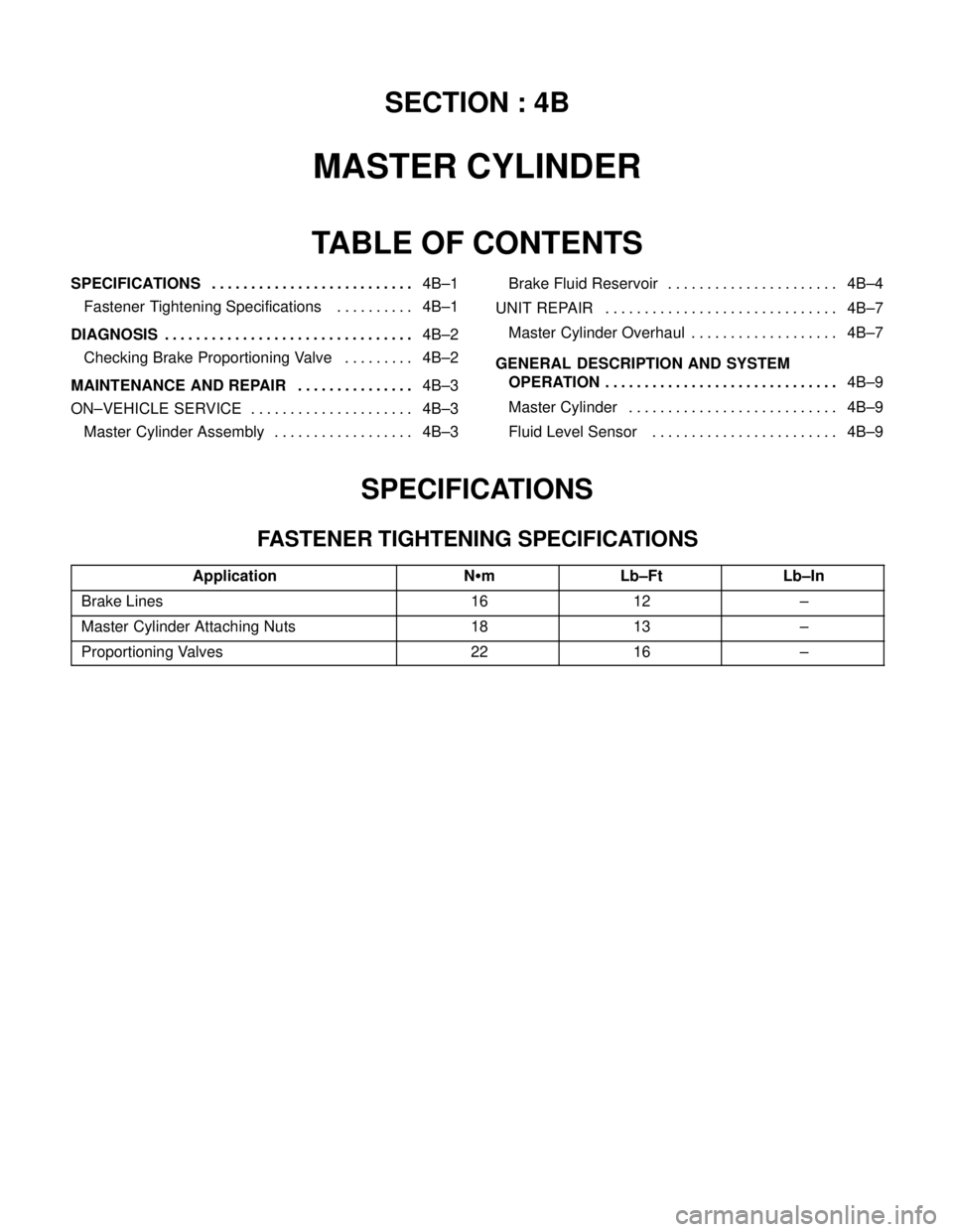

2. Remove the nuts from the brace.

3. Remove the brake pedal.

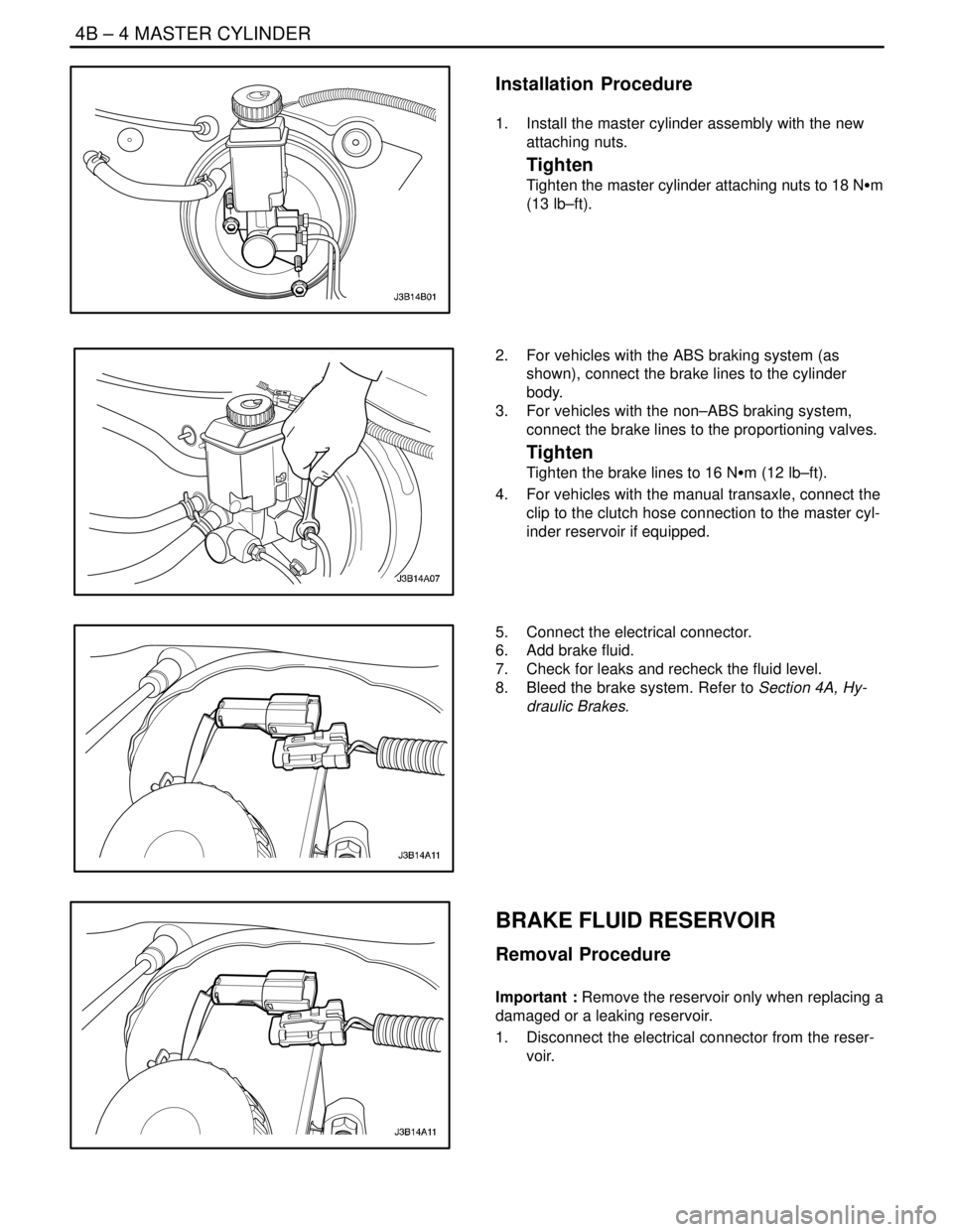

Installation Procedure

1. Install the brace with nuts.

Tighten

Tighten the brace with nuts to 22 NSm (16 lb–ft).

2. Install the brake pedal.

3. Install the instrument panel. Refer to Section 9E,

Instrumentation/Driver Information.

Page 1034 of 2643

SECTION : 4B

MASTER CYLINDER

TABLE OF CONTENTS

SPECIFICATIONS4B–1 . . . . . . . . . . . . . . . . . . . . . . . . . .

Fastener Tightening Specifications 4B–1. . . . . . . . . .

DIAGNOSIS4B–2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Checking Brake Proportioning Valve 4B–2. . . . . . . . .

MAINTENANCE AND REPAIR4B–3 . . . . . . . . . . . . . . .

ON–VEHICLE SERVICE 4B–3. . . . . . . . . . . . . . . . . . . . .

Master Cylinder Assembly 4B–3. . . . . . . . . . . . . . . . . . Brake Fluid Reservoir 4B–4. . . . . . . . . . . . . . . . . . . . . .

UNIT REPAIR 4B–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Master Cylinder Overhaul 4B–7. . . . . . . . . . . . . . . . . . .

GENERAL DESCRIPTION AND SYSTEM

OPERATION4B–9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Master Cylinder 4B–9. . . . . . . . . . . . . . . . . . . . . . . . . . .

Fluid Level Sensor 4B–9. . . . . . . . . . . . . . . . . . . . . . . .

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

ApplicationNSmLb–FtLb–In

Brake Lines1612–

Master Cylinder Attaching Nuts1813–

Proportioning Valves2216–

Page 1037 of 2643

4B – 4IMASTER CYLINDER

DAEWOO V–121 BL4

Installation Procedure

1. Install the master cylinder assembly with the new

attaching nuts.

Tighten

Tighten the master cylinder attaching nuts to 18 NSm

(13 lb–ft).

2. For vehicles with the ABS braking system (as

shown), connect the brake lines to the cylinder

body.

3. For vehicles with the non–ABS braking system,

connect the brake lines to the proportioning valves.

Tighten

Tighten the brake lines to 16 NSm (12 lb–ft).

4. For vehicles with the manual transaxle, connect the

clip to the clutch hose connection to the master cyl-

inder reservoir if equipped.

5. Connect the electrical connector.

6. Add brake fluid.

7. Check for leaks and recheck the fluid level.

8. Bleed the brake system. Refer to Section 4A, Hy-

draulic Brakes.

BRAKE FLUID RESERVOIR

Removal Procedure

Important : Remove the reservoir only when replacing a

damaged or a leaking reservoir.

1. Disconnect the electrical connector from the reser-

voir.

Page 1039 of 2643

4B – 6IMASTER CYLINDER

DAEWOO V–121 BL4

4. Add brake fluid.

5. Raise and suitably support the vehicle.

6. Bleed the braking system. Refer to Section 4A, Hy-

draulic Brakes orSection 4F, Antilock Brake Sys-

tem.Bleed the clutch master cylinder. Refer to Sec-

tion 5C, Clutch.

7. Lower the vehicle.

8. Connect the reservoir electrical connector.

Page 1040 of 2643

MASTER CYLINDER 4B – 7

DAEWOO V–121 BL4

UNIT REPAIR

MASTER CYLINDER OVERHAUL

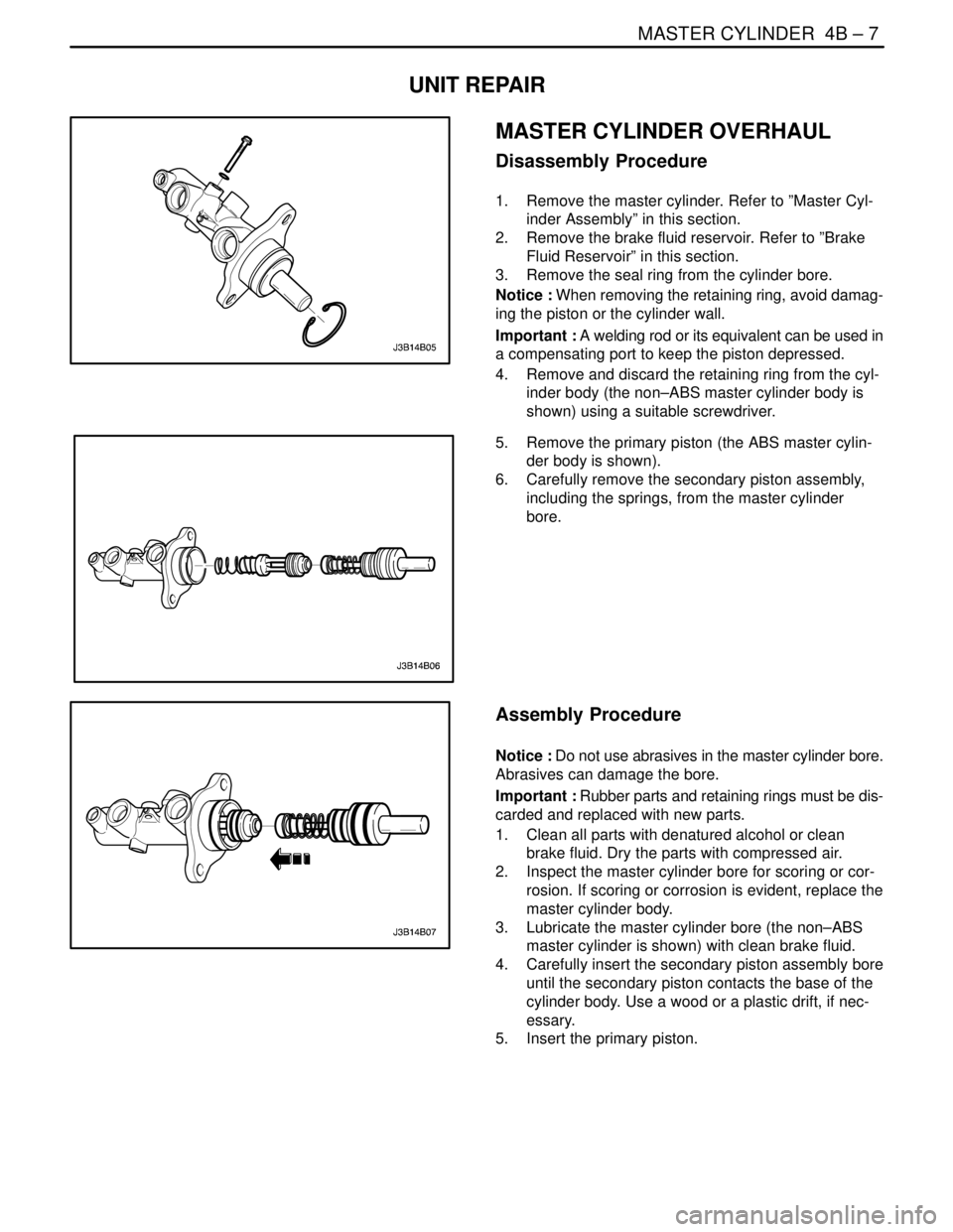

Disassembly Procedure

1. Remove the master cylinder. Refer to ”Master Cyl-

inder Assembly” in this section.

2. Remove the brake fluid reservoir. Refer to ”Brake

Fluid Reservoir” in this section.

3. Remove the seal ring from the cylinder bore.

Notice : When removing the retaining ring, avoid damag-

ing the piston or the cylinder wall.

Important : A welding rod or its equivalent can be used in

a compensating port to keep the piston depressed.

4. Remove and discard the retaining ring from the cyl-

inder body (the non–ABS master cylinder body is

shown) using a suitable screwdriver.

5. Remove the primary piston (the ABS master cylin-

der body is shown).

6. Carefully remove the secondary piston assembly,

including the springs, from the master cylinder

bore.

Assembly Procedure

Notice : Do not use abrasives in the master cylinder bore.

Abrasives can damage the bore.

Important : Rubber parts and retaining rings must be dis-

carded and replaced with new parts.

1. Clean all parts with denatured alcohol or clean

brake fluid. Dry the parts with compressed air.

2. Inspect the master cylinder bore for scoring or cor-

rosion. If scoring or corrosion is evident, replace the

master cylinder body.

3. Lubricate the master cylinder bore (the non–ABS

master cylinder is shown) with clean brake fluid.

4. Carefully insert the secondary piston assembly bore

until the secondary piston contacts the base of the

cylinder body. Use a wood or a plastic drift, if nec-

essary.

5. Insert the primary piston.

Page 1041 of 2643

4B – 8IMASTER CYLINDER

DAEWOO V–121 BL4

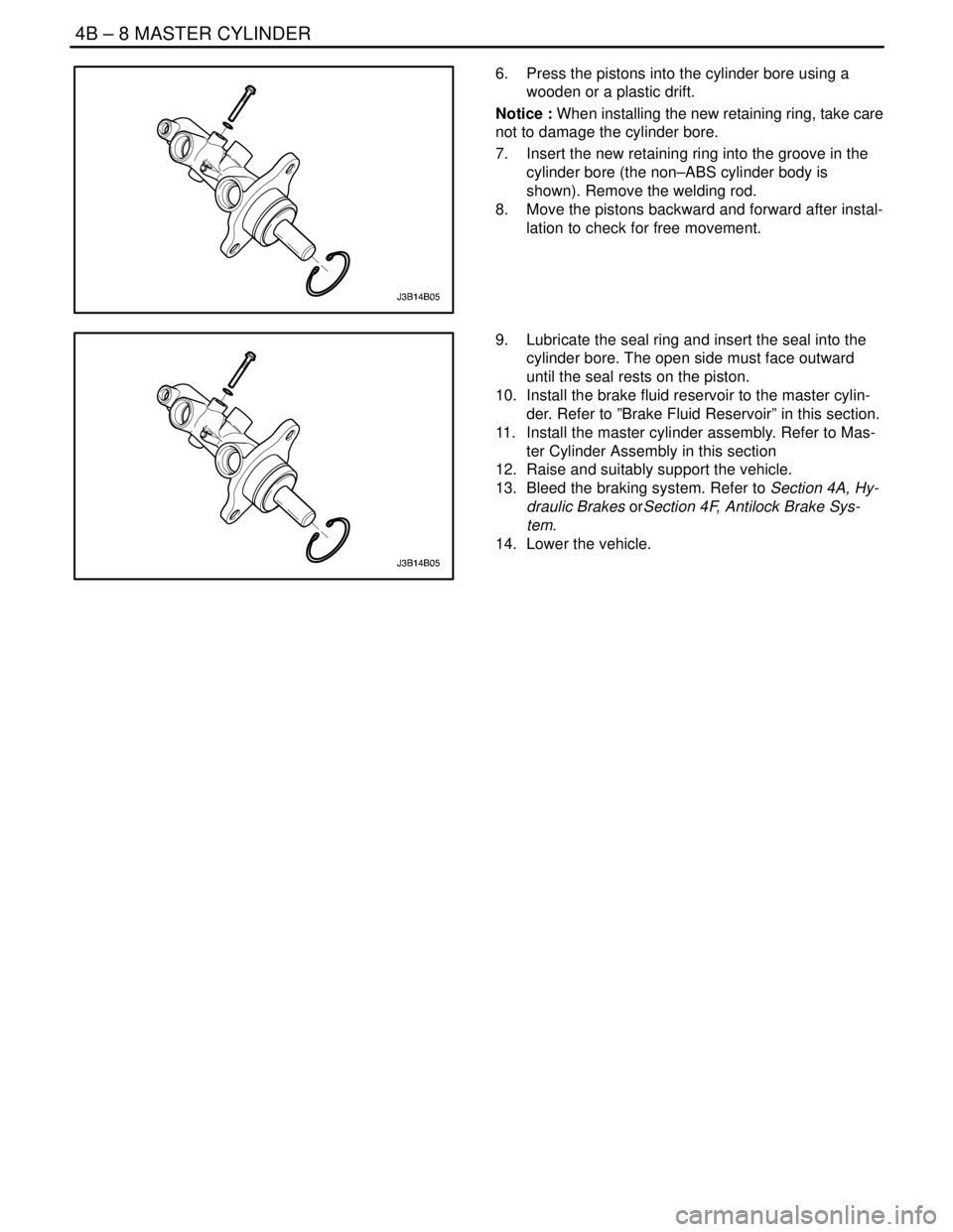

6. Press the pistons into the cylinder bore using a

wooden or a plastic drift.

Notice : When installing the new retaining ring, take care

not to damage the cylinder bore.

7. Insert the new retaining ring into the groove in the

cylinder bore (the non–ABS cylinder body is

shown). Remove the welding rod.

8. Move the pistons backward and forward after instal-

lation to check for free movement.

9. Lubricate the seal ring and insert the seal into the

cylinder bore. The open side must face outward

until the seal rests on the piston.

10. Install the brake fluid reservoir to the master cylin-

der. Refer to ”Brake Fluid Reservoir” in this section.

11. Install the master cylinder assembly. Refer to Mas-

ter Cylinder Assembly in this section

12. Raise and suitably support the vehicle.

13. Bleed the braking system. Refer to Section 4A, Hy-

draulic Brakes orSection 4F, Antilock Brake Sys-

tem.

14. Lower the vehicle.