speed DAEWOO LACETTI 2004 Service Repair Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 1708 of 2643

5A2 – 118IAISIN AUTOMATIC TRANSAXLE

DAEWOO V–121 BL4

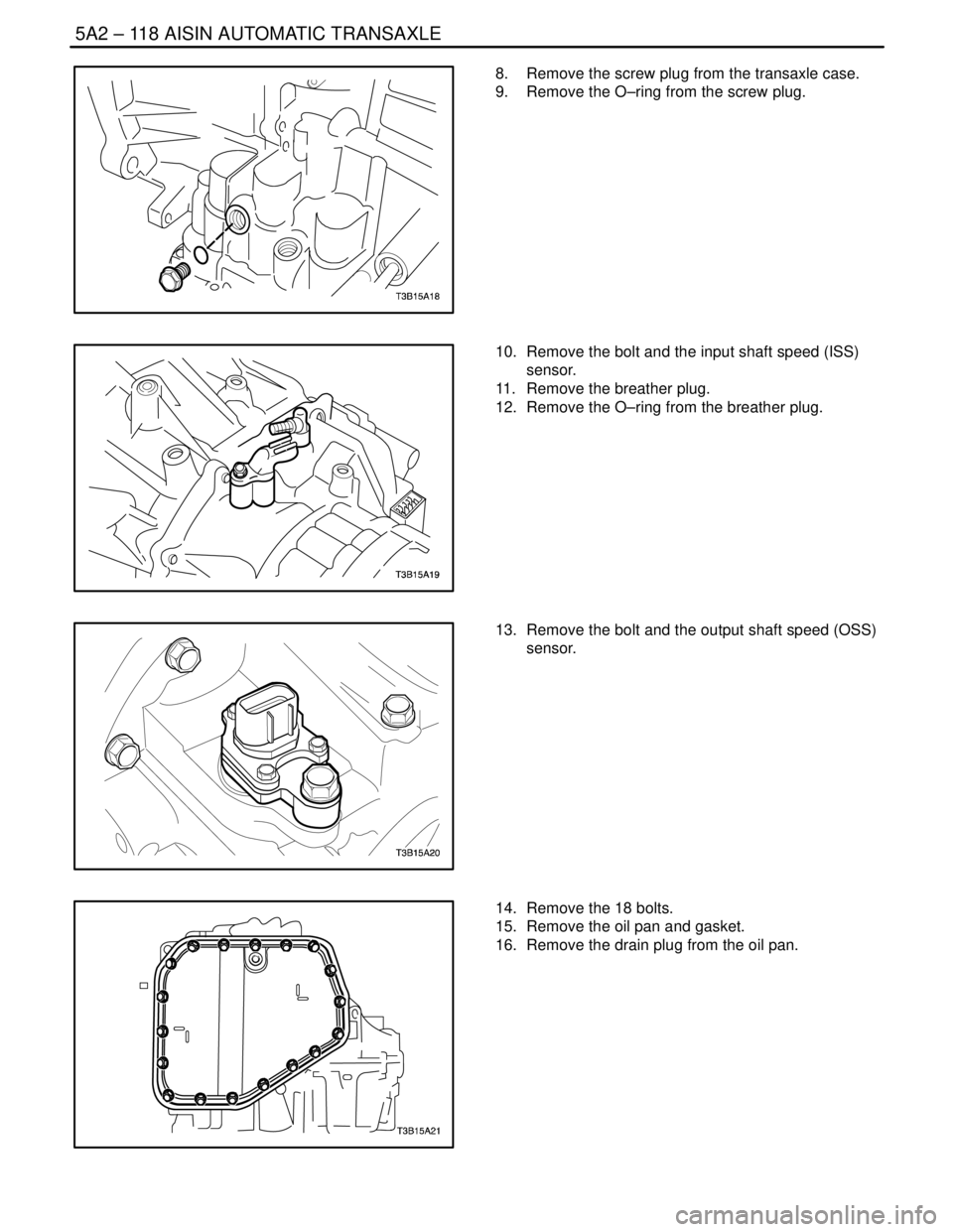

8. Remove the screw plug from the transaxle case.

9. Remove the O–ring from the screw plug.

10. Remove the bolt and the input shaft speed (ISS)

sensor.

11. Remove the breather plug.

12. Remove the O–ring from the breather plug.

13. Remove the bolt and the output shaft speed (OSS)

sensor.

14. Remove the 18 bolts.

15. Remove the oil pan and gasket.

16. Remove the drain plug from the oil pan.

Page 1753 of 2643

AISIN AUTOMATIC TRANSAXLE 5A2 – 163

DAEWOO V–121 BL4

120. Install the oil strainer to the valve body with the

3 bolts.

Tighten

Tighten the bolts to 9.8 NSm (87 lb–in).

121. Install the 2 magnets in the oil pan.

122. Install a new gasket to the oil pan and install

them to the transaxle case with the 18 bolts.

Tighten

Tighten the bolts to 7 NSm (62 lb–in).

123. Install the output shaft speed (OSS) sensor.

Tighten

Tighten the bolt to 7.4 NSm (65 lb–in).

Page 1754 of 2643

5A2 – 164IAISIN AUTOMATIC TRANSAXLE

DAEWOO V–121 BL4

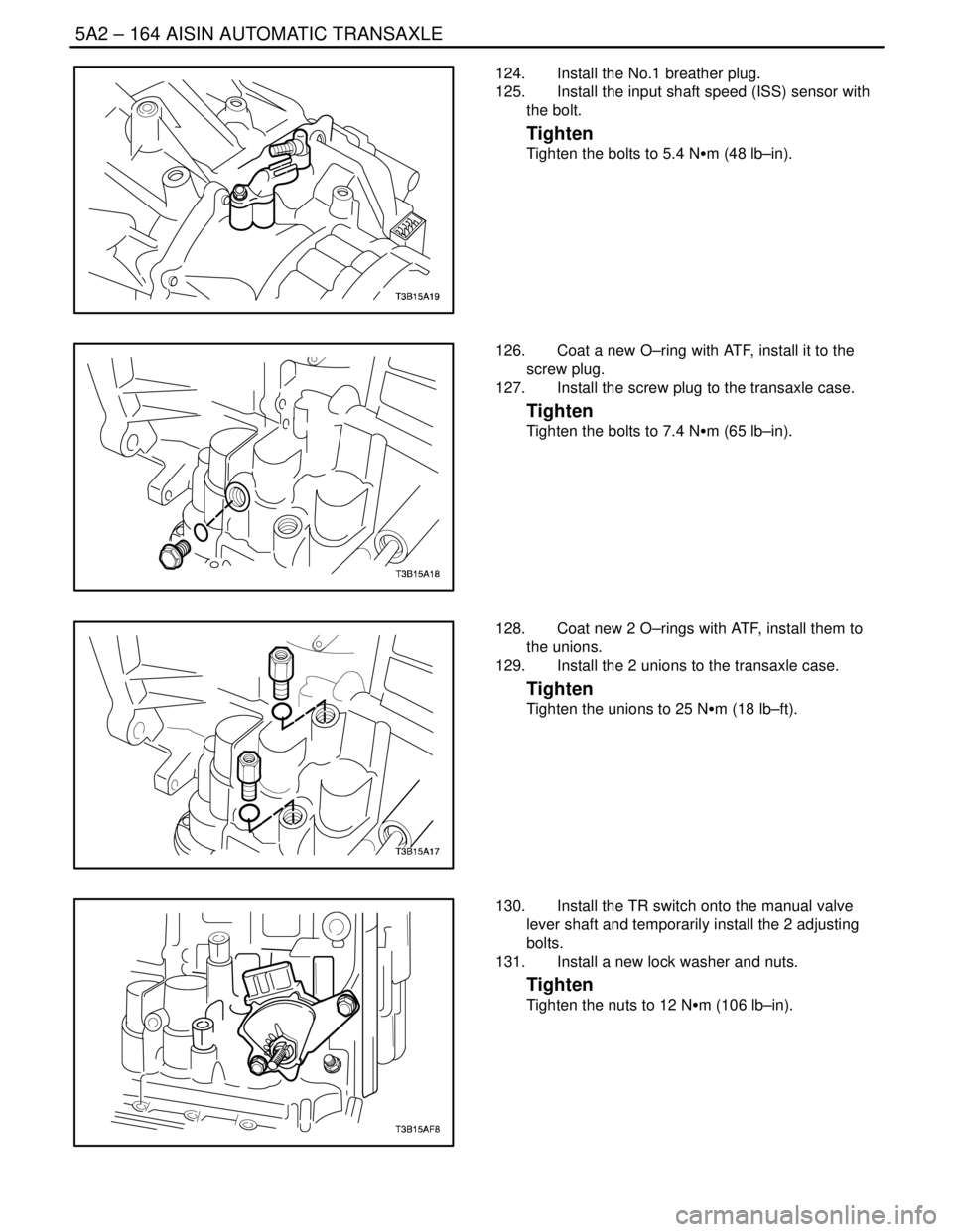

124. Install the No.1 breather plug.

125. Install the input shaft speed (ISS) sensor with

the bolt.

Tighten

Tighten the bolts to 5.4 NSm (48 lb–in).

126. Coat a new O–ring with ATF, install it to the

screw plug.

127. Install the screw plug to the transaxle case.

Tighten

Tighten the bolts to 7.4 NSm (65 lb–in).

128. Coat new 2 O–rings with ATF, install them to

the unions.

129. Install the 2 unions to the transaxle case.

Tighten

Tighten the unions to 25 NSm (18 lb–ft).

130. Install the TR switch onto the manual valve

lever shaft and temporarily install the 2 adjusting

bolts.

131. Install a new lock washer and nuts.

Tighten

Tighten the nuts to 12 NSm (106 lb–in).

Page 1808 of 2643

5A2 – 218IAISIN AUTOMATIC TRANSAXLE

DAEWOO V–121 BL4

GENERAL DESCRIPTION

AND SYSTEM OPERATION

TRANSAXLE DESCRIPTION

The new automatic transmission is an electronically con-

trolled 4–speed automatic transmission with Lock–up

mechanism.

The transmission is mainly composed of the torque con-

verter with lock up clutch, newly developed 4–speed plan-

etary gear unit, the hydraulic control system and the elec-

tric control system.

ELECTRONICAL COMPONENTS

Transmission Control Module (TCM)

The TCM primarily controls shift points and lockup en-

gagement. It is located on the driver side under the instru-

ment panel.

The transmission is controlled by an electronic shift sys-

tem. The Transmission Control Module (TCM) processes

input signals. From the information received, the TCM

controls the transmission hydraulic system.

The electronic shift system consists of the following :

S Transmission control module (TCM)

S Shift solenoids (SS1 and SS2)

S Pressure control solenoid (PCS)

S Lockup solenoid

S Input shaft speed (ISS) sensor

S Output shaft speed (OSS) sensor

S Transmission Fluid Temperature (TFT) sensor

S Transmission Range (TR) Switch

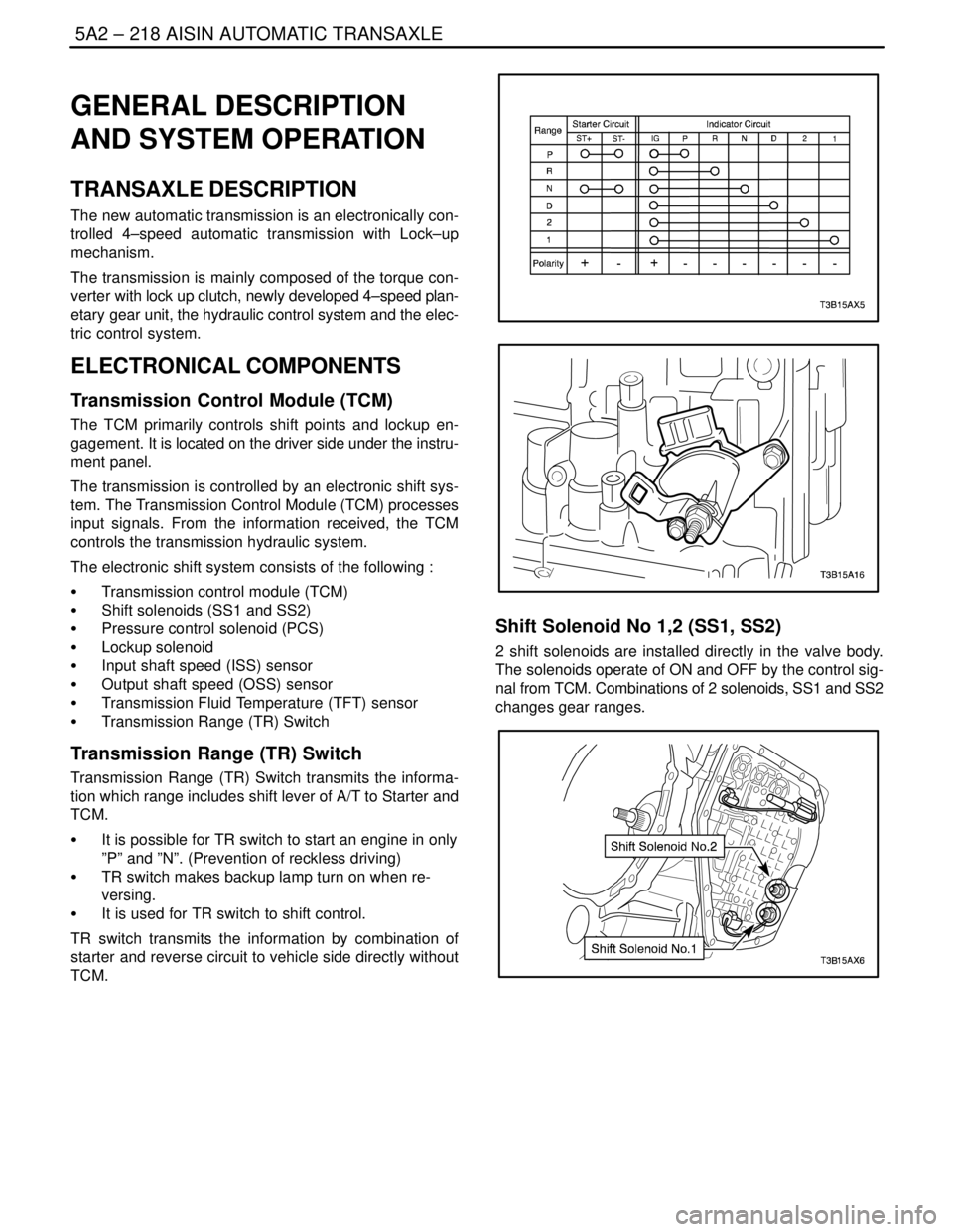

Transmission Range (TR) Switch

Transmission Range (TR) Switch transmits the informa-

tion which range includes shift lever of A/T to Starter and

TCM.

S It is possible for TR switch to start an engine in only

”P” and ”N”. (Prevention of reckless driving)

S TR switch makes backup lamp turn on when re-

versing.

S It is used for TR switch to shift control.

TR switch transmits the information by combination of

starter and reverse circuit to vehicle side directly without

TCM.

Shift Solenoid No 1,2 (SS1, SS2)

2 shift solenoids are installed directly in the valve body.

The solenoids operate of ON and OFF by the control sig-

nal from TCM. Combinations of 2 solenoids, SS1 and SS2

changes gear ranges.

Page 1809 of 2643

AISIN AUTOMATIC TRANSAXLE 5A2 – 219

DAEWOO V–121 BL4

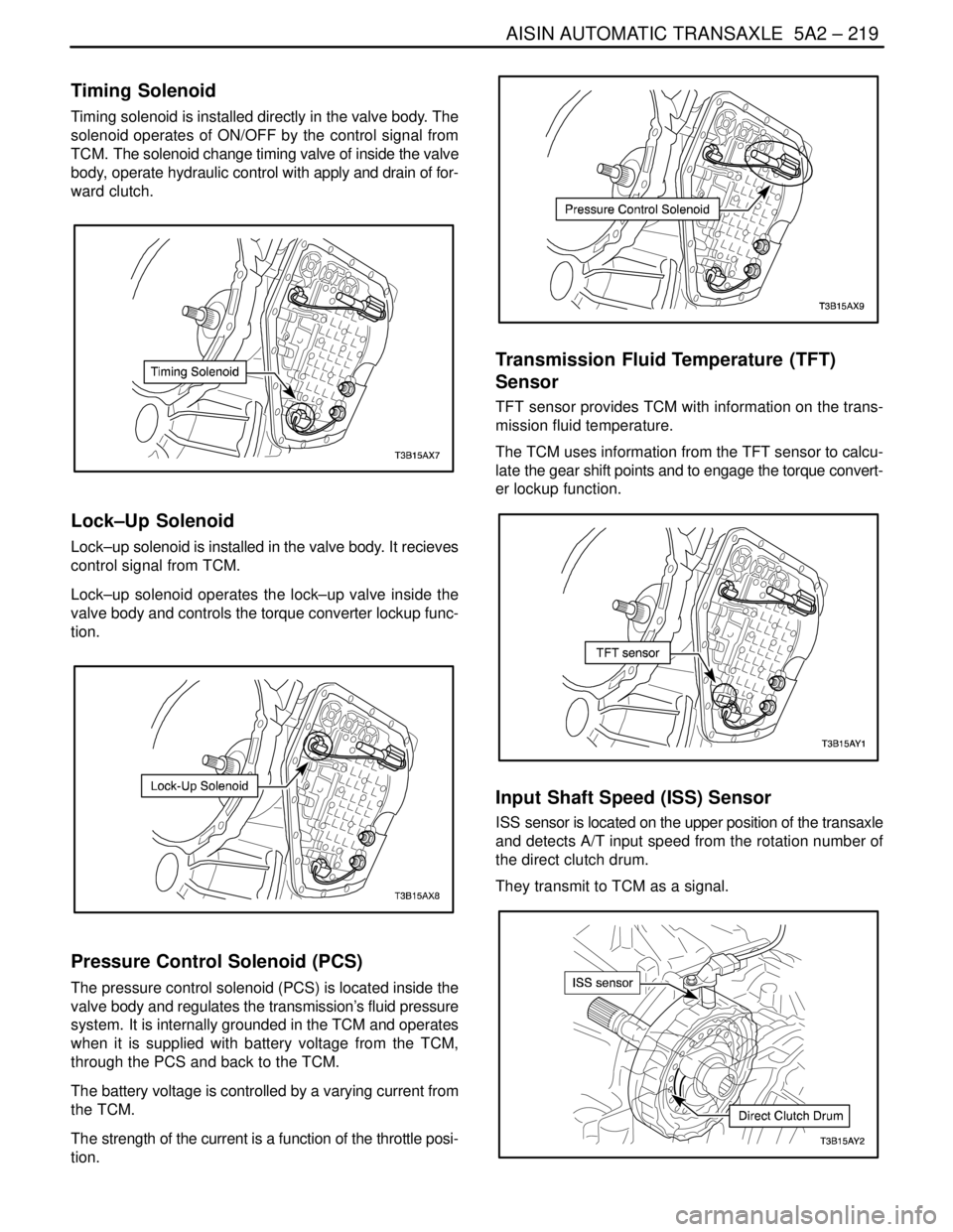

Timing Solenoid

Timing solenoid is installed directly in the valve body. The

solenoid operates of ON/OFF by the control signal from

TCM. The solenoid change timing valve of inside the valve

body, operate hydraulic control with apply and drain of for-

ward clutch.

Lock–Up Solenoid

Lock–up solenoid is installed in the valve body. It recieves

control signal from TCM.

Lock–up solenoid operates the lock–up valve inside the

valve body and controls the torque converter lockup func-

tion.

Pressure Control Solenoid (PCS)

The pressure control solenoid (PCS) is located inside the

valve body and regulates the transmission’s fluid pressure

system. It is internally grounded in the TCM and operates

when it is supplied with battery voltage from the TCM,

through the PCS and back to the TCM.

The battery voltage is controlled by a varying current from

the TCM.

The strength of the current is a function of the throttle posi-

tion.

Transmission Fluid Temperature (TFT)

Sensor

TFT sensor provides TCM with information on the trans-

mission fluid temperature.

The TCM uses information from the TFT sensor to calcu-

late the gear shift points and to engage the torque convert-

er lockup function.

Input Shaft Speed (ISS) Sensor

ISS sensor is located on the upper position of the transaxle

and detects A/T input speed from the rotation number of

the direct clutch drum.

They transmit to TCM as a signal.

Page 1810 of 2643

5A2 – 220IAISIN AUTOMATIC TRANSAXLE

DAEWOO V–121 BL4

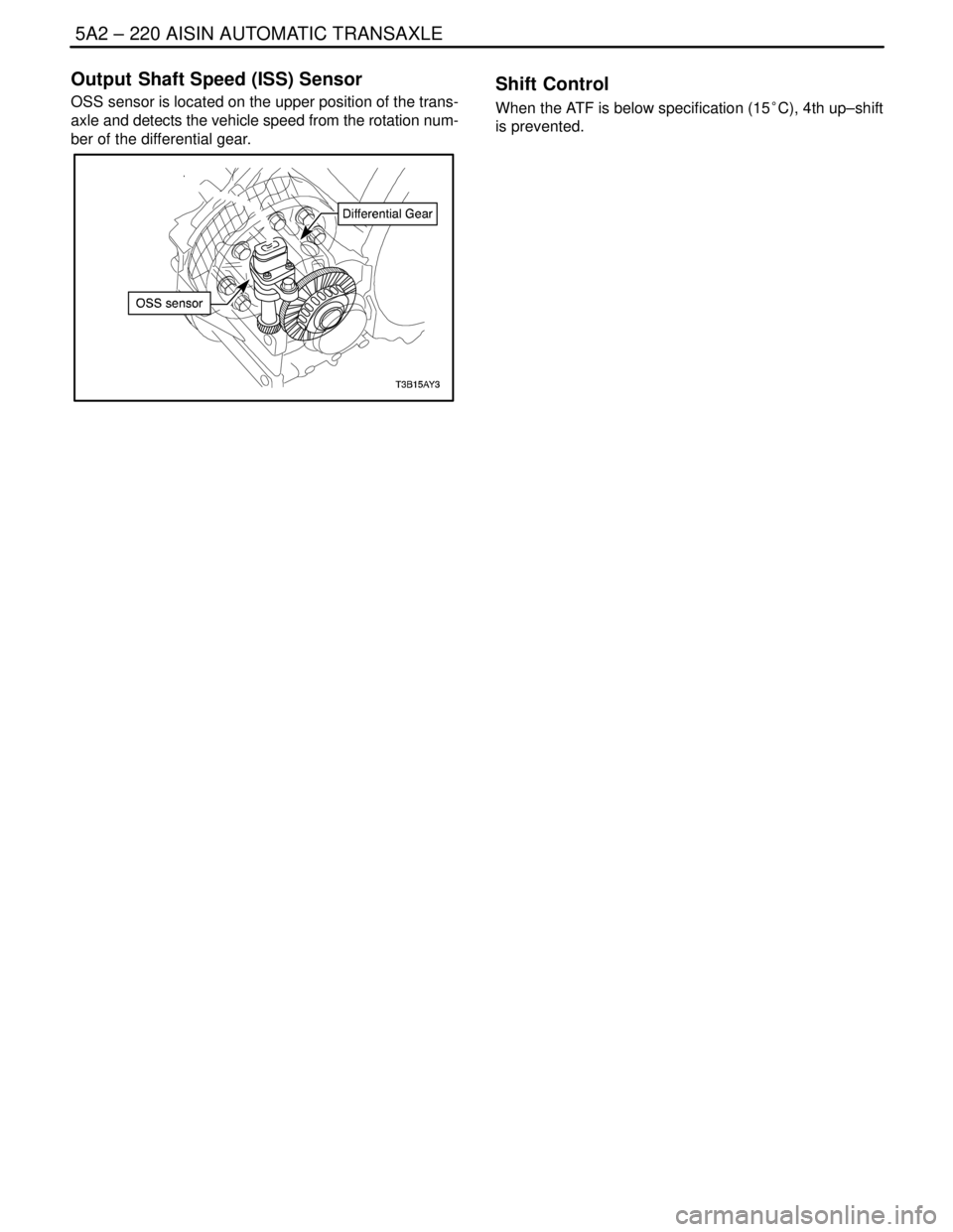

Output Shaft Speed (ISS) Sensor

OSS sensor is located on the upper position of the trans-

axle and detects the vehicle speed from the rotation num-

ber of the differential gear.

Shift Control

When the ATF is below specification (15°C), 4th up–shift

is prevented.

Page 1812 of 2643

5A2 – 222IAISIN AUTOMATIC TRANSAXLE

DAEWOO V–121 BL4

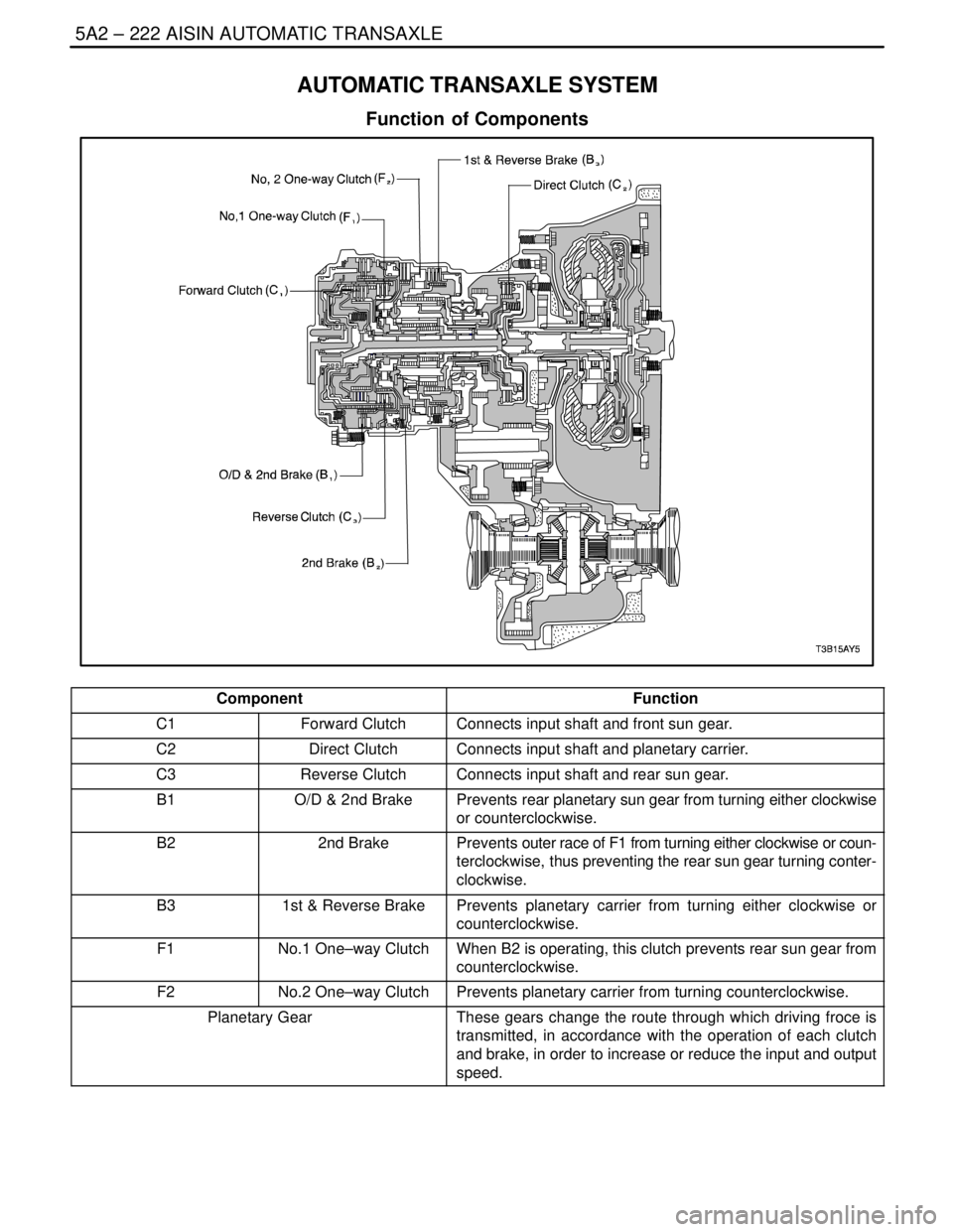

AUTOMATIC TRANSAXLE SYSTEM

Function of Components

ComponentFunction

C1Forward ClutchConnects input shaft and front sun gear.

C2Direct ClutchConnects input shaft and planetary carrier.

C3Reverse ClutchConnects input shaft and rear sun gear.

B1O/D & 2nd BrakePrevents rear planetary sun gear from turning either clockwise

or counterclockwise.

B22nd BrakePrevents outer race of F1 from turning either clockwise or coun-

terclockwise, thus preventing the rear sun gear turning conter-

clockwise.

B31st & Reverse BrakePrevents planetary carrier from turning either clockwise or

counterclockwise.

F1No.1 One–way ClutchWhen B2 is operating, this clutch prevents rear sun gear from

counterclockwise.

F2No.2 One–way ClutchPrevents planetary carrier from turning counterclockwise.

Planetary GearThese gears change the route through which driving froce is

transmitted, in accordance with the operation of each clutch

and brake, in order to increase or reduce the input and output

speed.

Page 1825 of 2643

SECTION : 5B

FIVE–SPEED MANUAL TRANSAXLE

CAUTION : Disconnect the negative battery cable before removing or installing any electrical unit or when a tool

or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help

prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise noted.

TABLE OF CONTENTS

SPECIFICATIONS5B–2 . . . . . . . . . . . . . . . . . . . . . . . . . .

Fastener Tightening Specifications 5B–2. . . . . . . . . . .

SPECIAL TOOLS5B–3 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Special Tools Table 5B–3. . . . . . . . . . . . . . . . . . . . . . . .

DIAGNOSIS5B–5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Isolate Noise 5B–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Symptom Diagnosis 5B–6. . . . . . . . . . . . . . . . . . . . . . . .

COMPONENT LOCATORS5B–9 . . . . . . . . . . . . . . . . . .

Gears and Case 5B–9. . . . . . . . . . . . . . . . . . . . . . . . . . .

Bearing Plate 5B–11. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Differential Gear 5B–12. . . . . . . . . . . . . . . . . . . . . . . . . .

Shift Linkage 5B–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MAINTENANCE AND REPAIR5B–15 . . . . . . . . . . . . . .

ON–VEHICLE SERVICE 5B–15. . . . . . . . . . . . . . . . . . . .

Checking Fluid Level 5B–15. . . . . . . . . . . . . . . . . . . . . .

Shift Linkage Adjustment 5B–15. . . . . . . . . . . . . . . . . . Gearshift Lever 5B–17. . . . . . . . . . . . . . . . . . . . . . . . . . .

Gearshift Lever Housing 5B–18. . . . . . . . . . . . . . . . . . .

Speedometer Driven Gear 5B–18. . . . . . . . . . . . . . . . .

Shift Linkage Assembly 5B–19. . . . . . . . . . . . . . . . . . . .

Drive Axle Seal 5B–20. . . . . . . . . . . . . . . . . . . . . . . . . . .

Transaxle Assembly 5B–21. . . . . . . . . . . . . . . . . . . . . . .

UNIT REPAIR 5B–26. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Major Component Disassembly 5B–26. . . . . . . . . . . . .

Input Shaft and Cluster Gear 5B–35. . . . . . . . . . . . . . .

Mainshaft 5B–37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Housing Case 5B–48. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Differential 5B–50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Major Component Assembly 5B–56. . . . . . . . . . . . . . .

GENERAL DESCRIPTION AND SYSTEM

OPERATION5B–63 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Five–Speed Manual Transaxle 5B–63. . . . . . . . . . . . . .

Page 1826 of 2643

5B – 2IFIVE–SPEED MANUAL TRANSAXLE

DAEWOO V–121 BL4

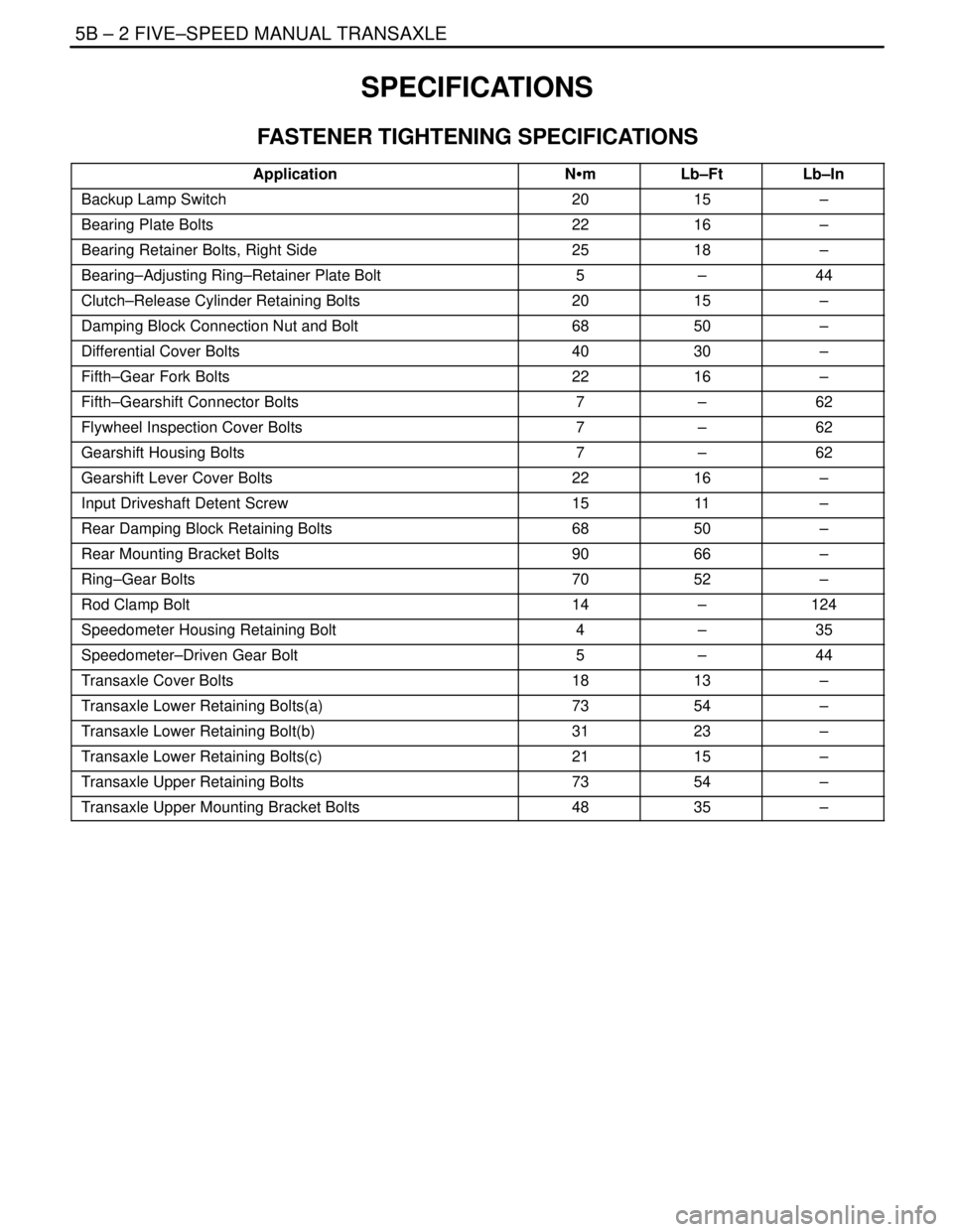

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

ApplicationNSmLb–FtLb–In

Backup Lamp Switch2015–

Bearing Plate Bolts2216–

Bearing Retainer Bolts, Right Side2518–

Bearing–Adjusting Ring–Retainer Plate Bolt5–44

Clutch–Release Cylinder Retaining Bolts2015–

Damping Block Connection Nut and Bolt6850–

Differential Cover Bolts4030–

Fifth–Gear Fork Bolts2216–

Fifth–Gearshift Connector Bolts7–62

Flywheel Inspection Cover Bolts7–62

Gearshift Housing Bolts7–62

Gearshift Lever Cover Bolts2216–

Input Driveshaft Detent Screw1511–

Rear Damping Block Retaining Bolts6850–

Rear Mounting Bracket Bolts9066–

Ring–Gear Bolts7052–

Rod Clamp Bolt14–124

Speedometer Housing Retaining Bolt4–35

Speedometer–Driven Gear Bolt5–44

Transaxle Cover Bolts1813–

Transaxle Lower Retaining Bolts(a)7354–

Transaxle Lower Retaining Bolt(b)3123–

Transaxle Lower Retaining Bolts(c)2115–

Transaxle Upper Retaining Bolts7354–

Transaxle Upper Mounting Bracket Bolts4835–

Page 1827 of 2643

FIVE–SPEED MANUAL TRANSAXLE 5B – 3

DAEWOO V–121 BL4

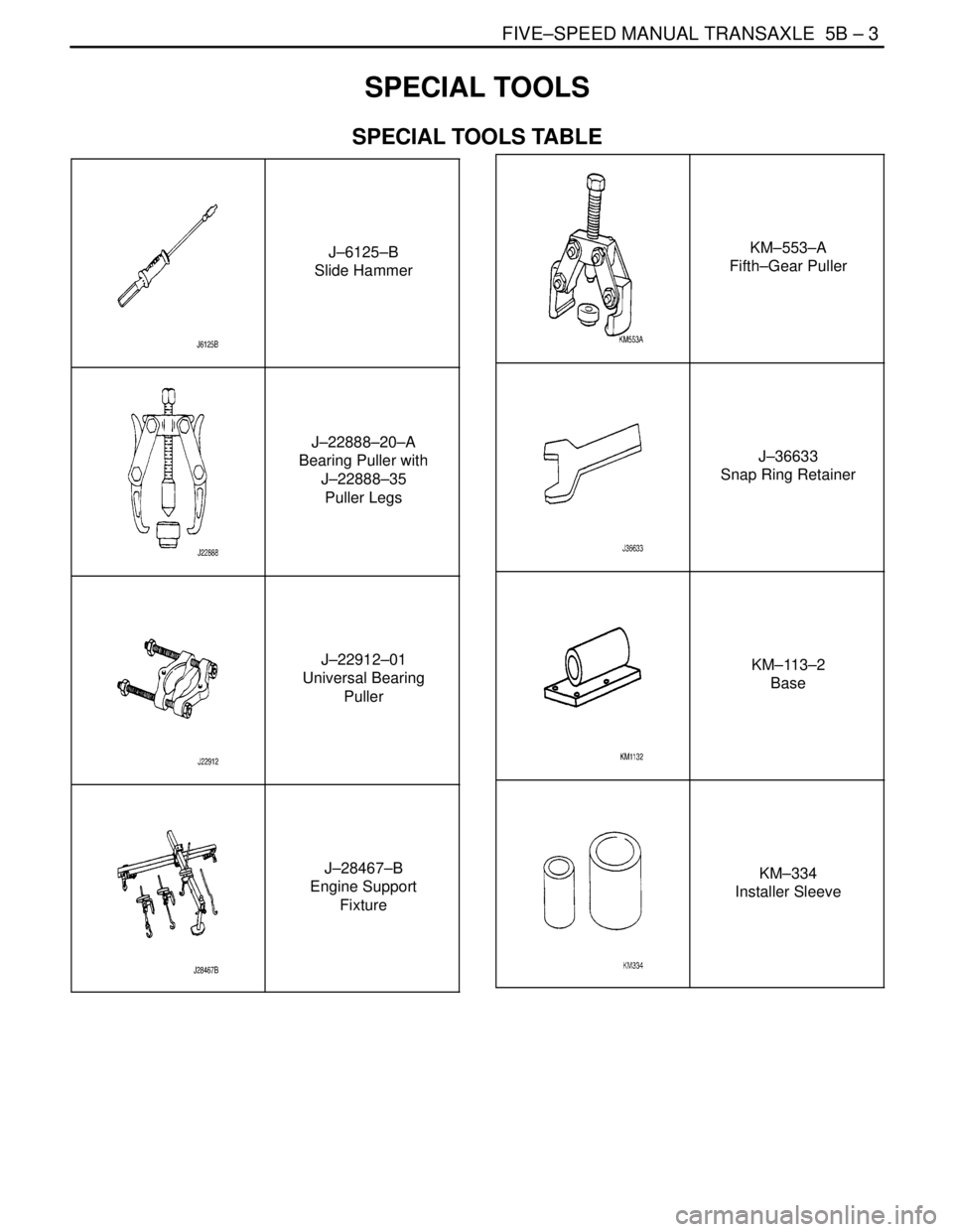

SPECIAL TOOLS

SPECIAL TOOLS TABLE

J–6125–B

Slide Hammer

J–22888–20–A

Bearing Puller with

J–22888–35

Puller Legs

J–22912–01

Universal Bearing

Puller

J–28467–B

Engine Support

Fixture

KM–553–A

Fifth–Gear Puller

J–36633

Snap Ring Retainer

KM–113–2

Base

KM–334

Installer Sleeve