speed DAEWOO LACETTI 2004 Service Repair Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 1655 of 2643

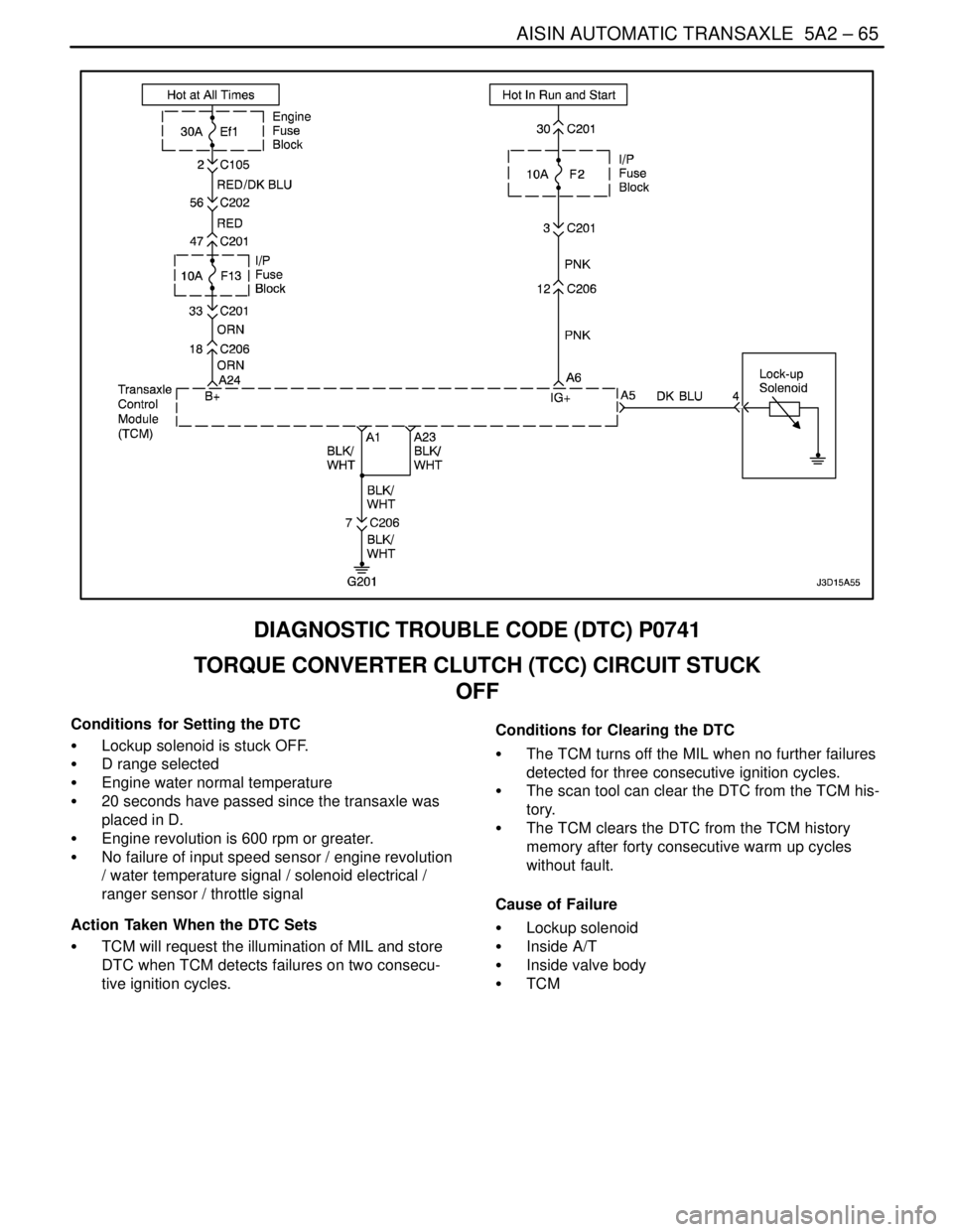

AISIN AUTOMATIC TRANSAXLE 5A2 – 65

DAEWOO V–121 BL4

DIAGNOSTIC TROUBLE CODE (DTC) P0741

TORQUE CONVERTER CLUTCH (TCC) CIRCUIT STUCK

OFF

Conditions for Setting the DTC

S Lockup solenoid is stuck OFF.

S D range selected

S Engine water normal temperature

S 20 seconds have passed since the transaxle was

placed in D.

S Engine revolution is 600 rpm or greater.

S No failure of input speed sensor / engine revolution

/ water temperature signal / solenoid electrical /

ranger sensor / throttle signal

Action Taken When the DTC Sets

S TCM will request the illumination of MIL and store

DTC when TCM detects failures on two consecu-

tive ignition cycles.Conditions for Clearing the DTC

S The TCM turns off the MIL when no further failures

detected for three consecutive ignition cycles.

S The scan tool can clear the DTC from the TCM his-

tory.

S The TCM clears the DTC from the TCM history

memory after forty consecutive warm up cycles

without fault.

Cause of Failure

S Lockup solenoid

S Inside A/T

S Inside valve body

S TCM

Page 1657 of 2643

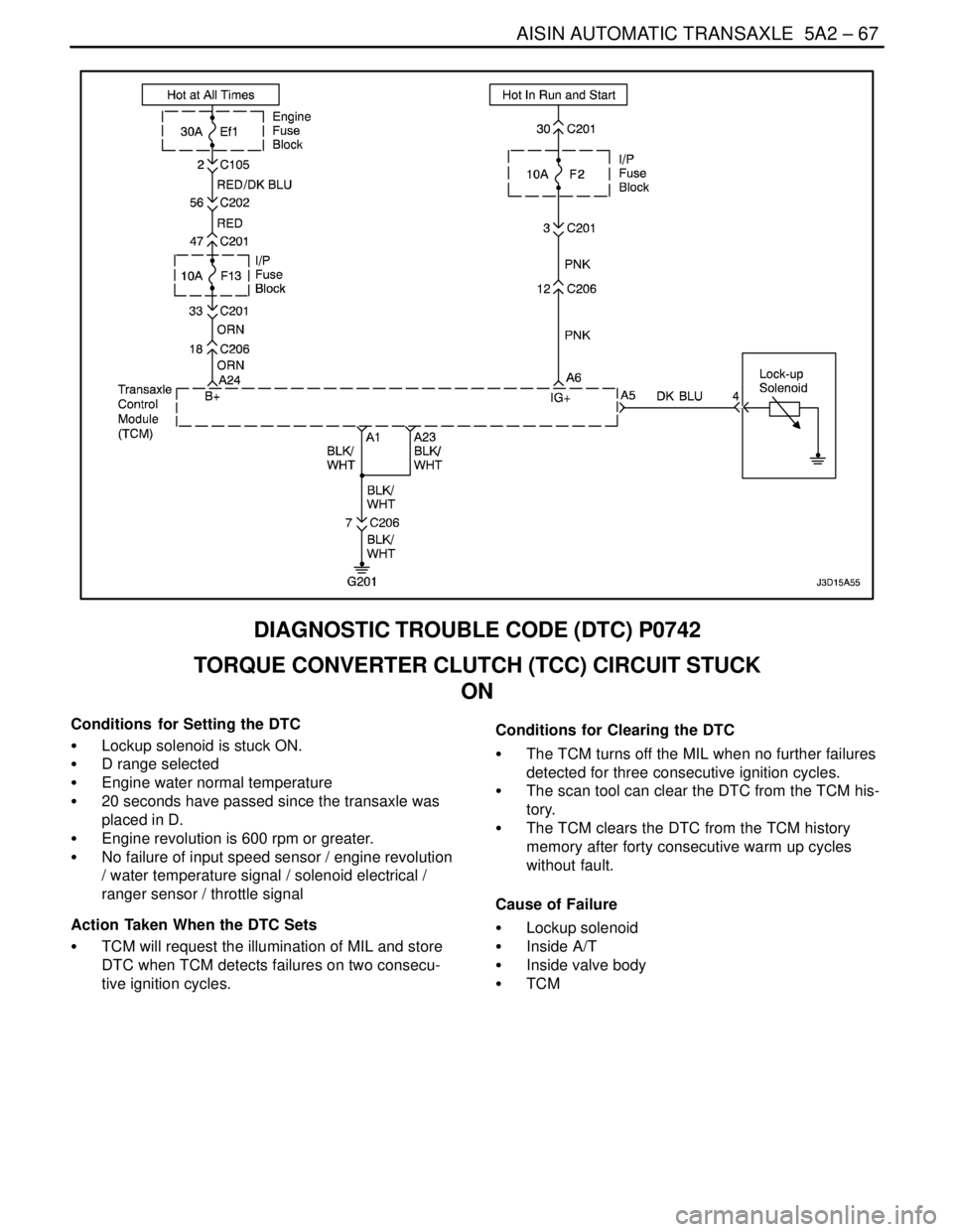

AISIN AUTOMATIC TRANSAXLE 5A2 – 67

DAEWOO V–121 BL4

DIAGNOSTIC TROUBLE CODE (DTC) P0742

TORQUE CONVERTER CLUTCH (TCC) CIRCUIT STUCK

ON

Conditions for Setting the DTC

S Lockup solenoid is stuck ON.

S D range selected

S Engine water normal temperature

S 20 seconds have passed since the transaxle was

placed in D.

S Engine revolution is 600 rpm or greater.

S No failure of input speed sensor / engine revolution

/ water temperature signal / solenoid electrical /

ranger sensor / throttle signal

Action Taken When the DTC Sets

S TCM will request the illumination of MIL and store

DTC when TCM detects failures on two consecu-

tive ignition cycles.Conditions for Clearing the DTC

S The TCM turns off the MIL when no further failures

detected for three consecutive ignition cycles.

S The scan tool can clear the DTC from the TCM his-

tory.

S The TCM clears the DTC from the TCM history

memory after forty consecutive warm up cycles

without fault.

Cause of Failure

S Lockup solenoid

S Inside A/T

S Inside valve body

S TCM

Page 1665 of 2643

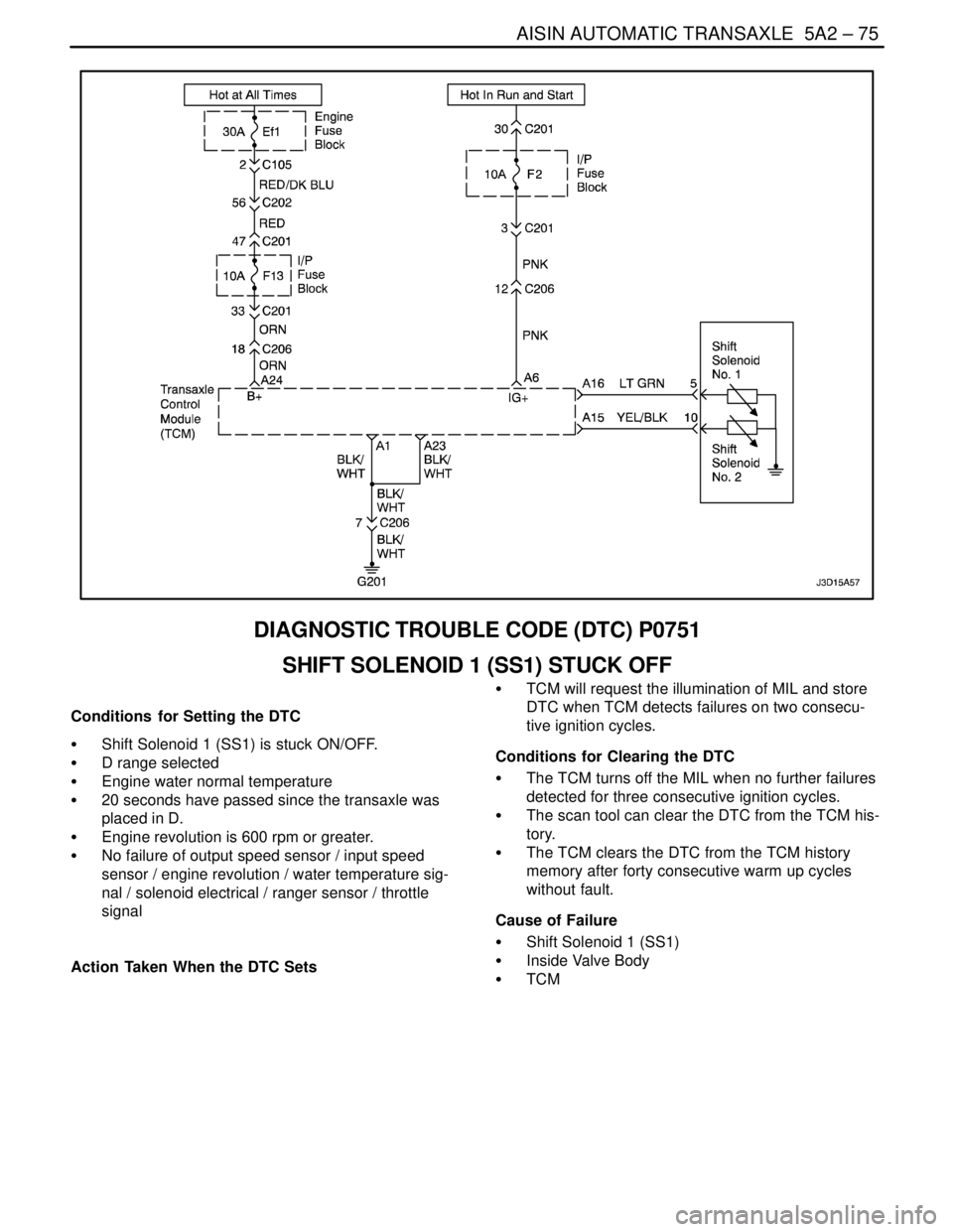

AISIN AUTOMATIC TRANSAXLE 5A2 – 75

DAEWOO V–121 BL4

DIAGNOSTIC TROUBLE CODE (DTC) P0751

SHIFT SOLENOID 1 (SS1) STUCK OFF

Conditions for Setting the DTC

S Shift Solenoid 1 (SS1) is stuck ON/OFF.

S D range selected

S Engine water normal temperature

S 20 seconds have passed since the transaxle was

placed in D.

S Engine revolution is 600 rpm or greater.

S No failure of output speed sensor / input speed

sensor / engine revolution / water temperature sig-

nal / solenoid electrical / ranger sensor / throttle

signal

Action Taken When the DTC SetsS TCM will request the illumination of MIL and store

DTC when TCM detects failures on two consecu-

tive ignition cycles.

Conditions for Clearing the DTC

S The TCM turns off the MIL when no further failures

detected for three consecutive ignition cycles.

S The scan tool can clear the DTC from the TCM his-

tory.

S The TCM clears the DTC from the TCM history

memory after forty consecutive warm up cycles

without fault.

Cause of Failure

S Shift Solenoid 1 (SS1)

S Inside Valve Body

S TCM

Page 1670 of 2643

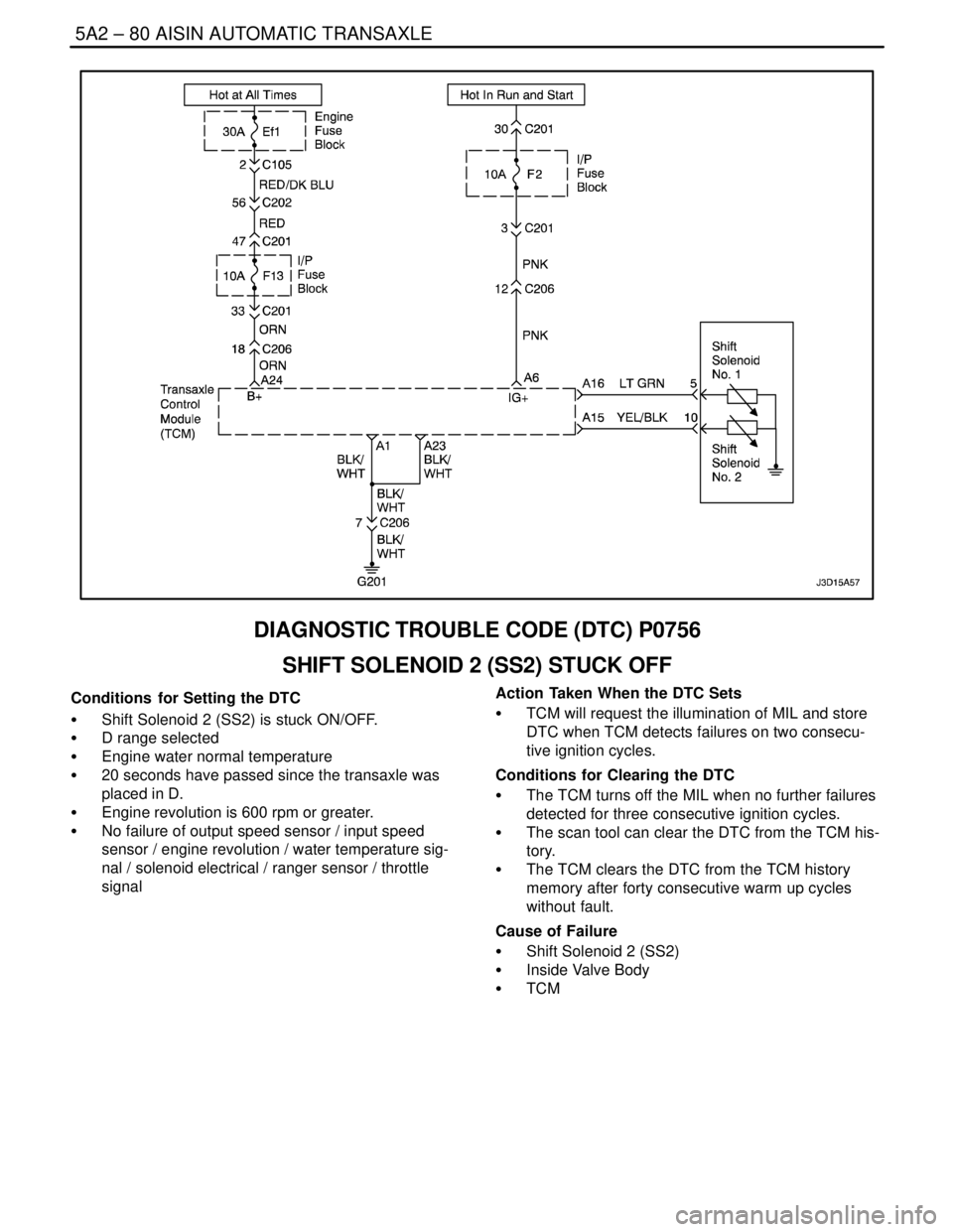

5A2 – 80IAISIN AUTOMATIC TRANSAXLE

DAEWOO V–121 BL4

DIAGNOSTIC TROUBLE CODE (DTC) P0756

SHIFT SOLENOID 2 (SS2) STUCK OFF

Conditions for Setting the DTC

S Shift Solenoid 2 (SS2) is stuck ON/OFF.

S D range selected

S Engine water normal temperature

S 20 seconds have passed since the transaxle was

placed in D.

S Engine revolution is 600 rpm or greater.

S No failure of output speed sensor / input speed

sensor / engine revolution / water temperature sig-

nal / solenoid electrical / ranger sensor / throttle

signalAction Taken When the DTC Sets

S TCM will request the illumination of MIL and store

DTC when TCM detects failures on two consecu-

tive ignition cycles.

Conditions for Clearing the DTC

S The TCM turns off the MIL when no further failures

detected for three consecutive ignition cycles.

S The scan tool can clear the DTC from the TCM his-

tory.

S The TCM clears the DTC from the TCM history

memory after forty consecutive warm up cycles

without fault.

Cause of Failure

S Shift Solenoid 2 (SS2)

S Inside Valve Body

S TCM

Page 1678 of 2643

5A2 – 88IAISIN AUTOMATIC TRANSAXLE

DAEWOO V–121 BL4

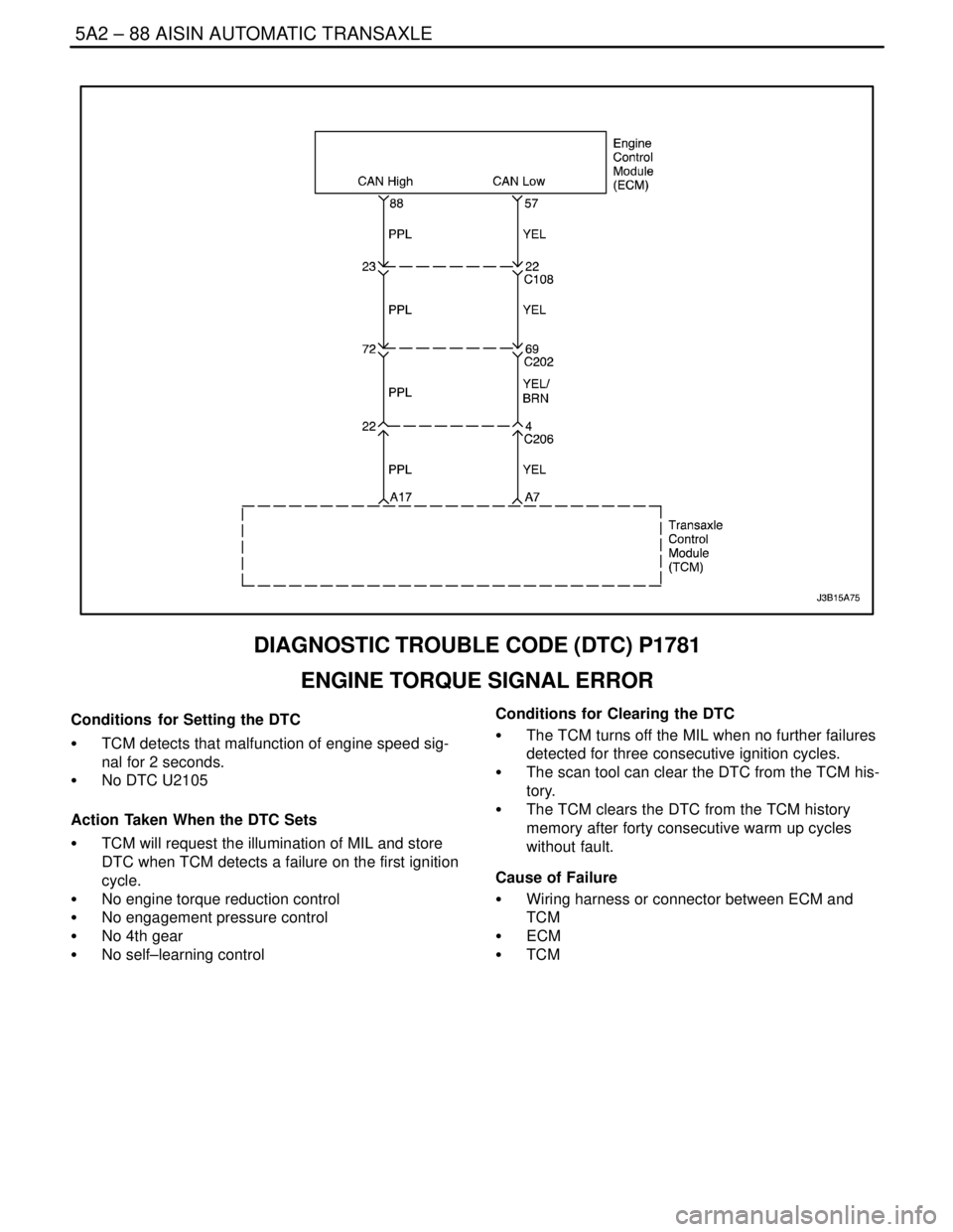

DIAGNOSTIC TROUBLE CODE (DTC) P1781

ENGINE TORQUE SIGNAL ERROR

Conditions for Setting the DTC

S TCM detects that malfunction of engine speed sig-

nal for 2 seconds.

S No DTC U2105

Action Taken When the DTC Sets

S TCM will request the illumination of MIL and store

DTC when TCM detects a failure on the first ignition

cycle.

S No engine torque reduction control

S No engagement pressure control

S No 4th gear

S No self–learning controlConditions for Clearing the DTC

S The TCM turns off the MIL when no further failures

detected for three consecutive ignition cycles.

S The scan tool can clear the DTC from the TCM his-

tory.

S The TCM clears the DTC from the TCM history

memory after forty consecutive warm up cycles

without fault.

Cause of Failure

S Wiring harness or connector between ECM and

TCM

S ECM

S TCM

Page 1679 of 2643

AISIN AUTOMATIC TRANSAXLE 5A2 – 89

DAEWOO V–121 BL4

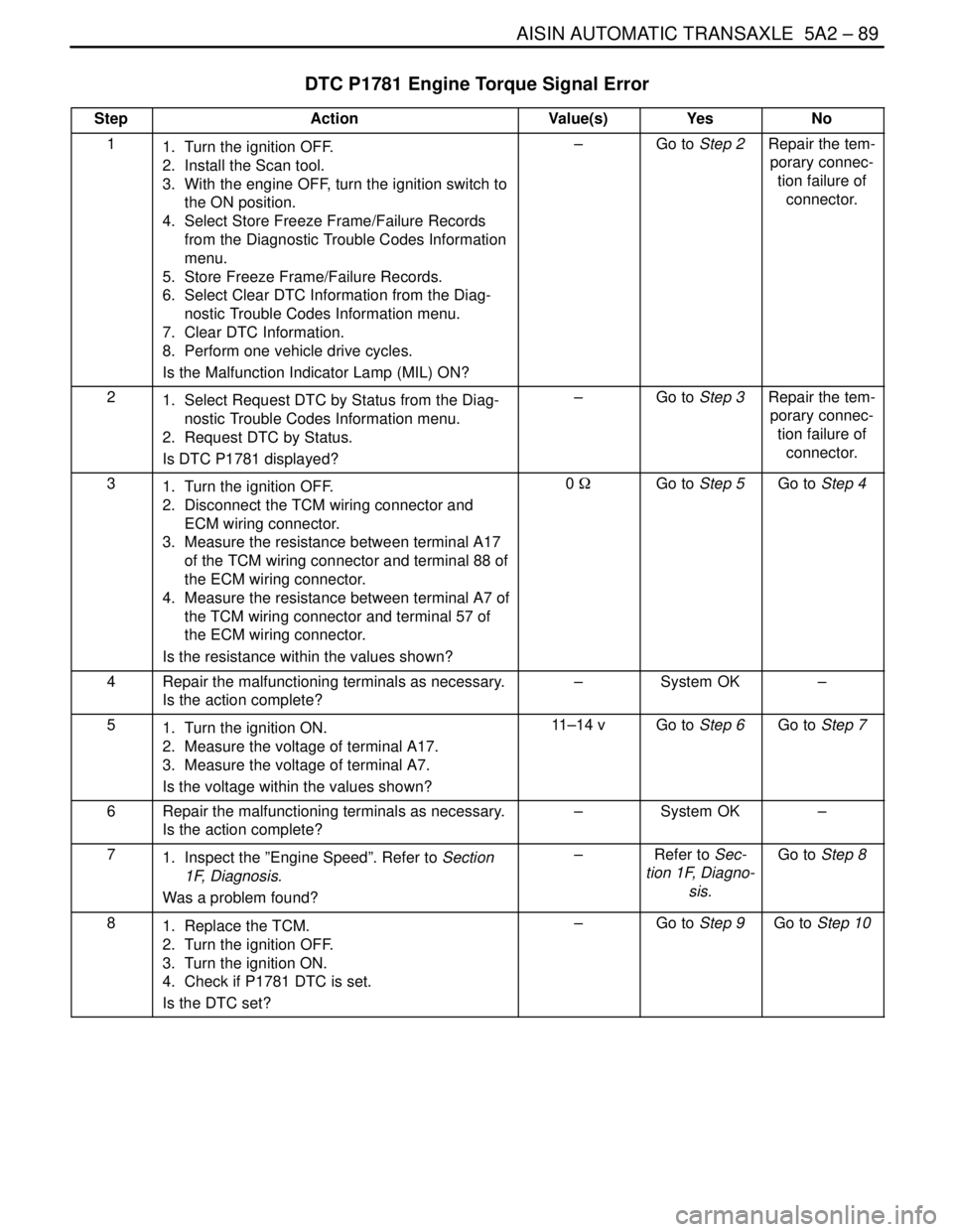

DTC P1781 Engine Torque Signal Error

StepActionValue(s)YesNo

11. Turn the ignition OFF.

2. Install the Scan tool.

3. With the engine OFF, turn the ignition switch to

the ON position.

4. Select Store Freeze Frame/Failure Records

from the Diagnostic Trouble Codes Information

menu.

5. Store Freeze Frame/Failure Records.

6. Select Clear DTC Information from the Diag-

nostic Trouble Codes Information menu.

7. Clear DTC Information.

8. Perform one vehicle drive cycles.

Is the Malfunction Indicator Lamp (MIL) ON?–Go to Step 2Repair the tem-

porary connec-

tion failure of

connector.

21. Select Request DTC by Status from the Diag-

nostic Trouble Codes Information menu.

2. Request DTC by Status.

Is DTC P1781 displayed?–Go to Step 3Repair the tem-

porary connec-

tion failure of

connector.

31. Turn the ignition OFF.

2. Disconnect the TCM wiring connector and

ECM wiring connector.

3. Measure the resistance between terminal A17

of the TCM wiring connector and terminal 88 of

the ECM wiring connector.

4. Measure the resistance between terminal A7 of

the TCM wiring connector and terminal 57 of

the ECM wiring connector.

Is the resistance within the values shown?0 WGo to Step 5Go to Step 4

4Repair the malfunctioning terminals as necessary.

Is the action complete?–System OK–

51. Turn the ignition ON.

2. Measure the voltage of terminal A17.

3. Measure the voltage of terminal A7.

Is the voltage within the values shown?11–14 vGo to Step 6Go to Step 7

6Repair the malfunctioning terminals as necessary.

Is the action complete?–System OK–

71. Inspect the ”Engine Speed”. Refer to Section

1F, Diagnosis.

Was a problem found?–Refer to Sec-

tion 1F, Diagno-

sis.Go to Step 8

81. Replace the TCM.

2. Turn the ignition OFF.

3. Turn the ignition ON.

4. Check if P1781 DTC is set.

Is the DTC set?–Go to Step 9Go to Step 10

Page 1696 of 2643

5A2 – 106IAISIN AUTOMATIC TRANSAXLE

DAEWOO V–121 BL4

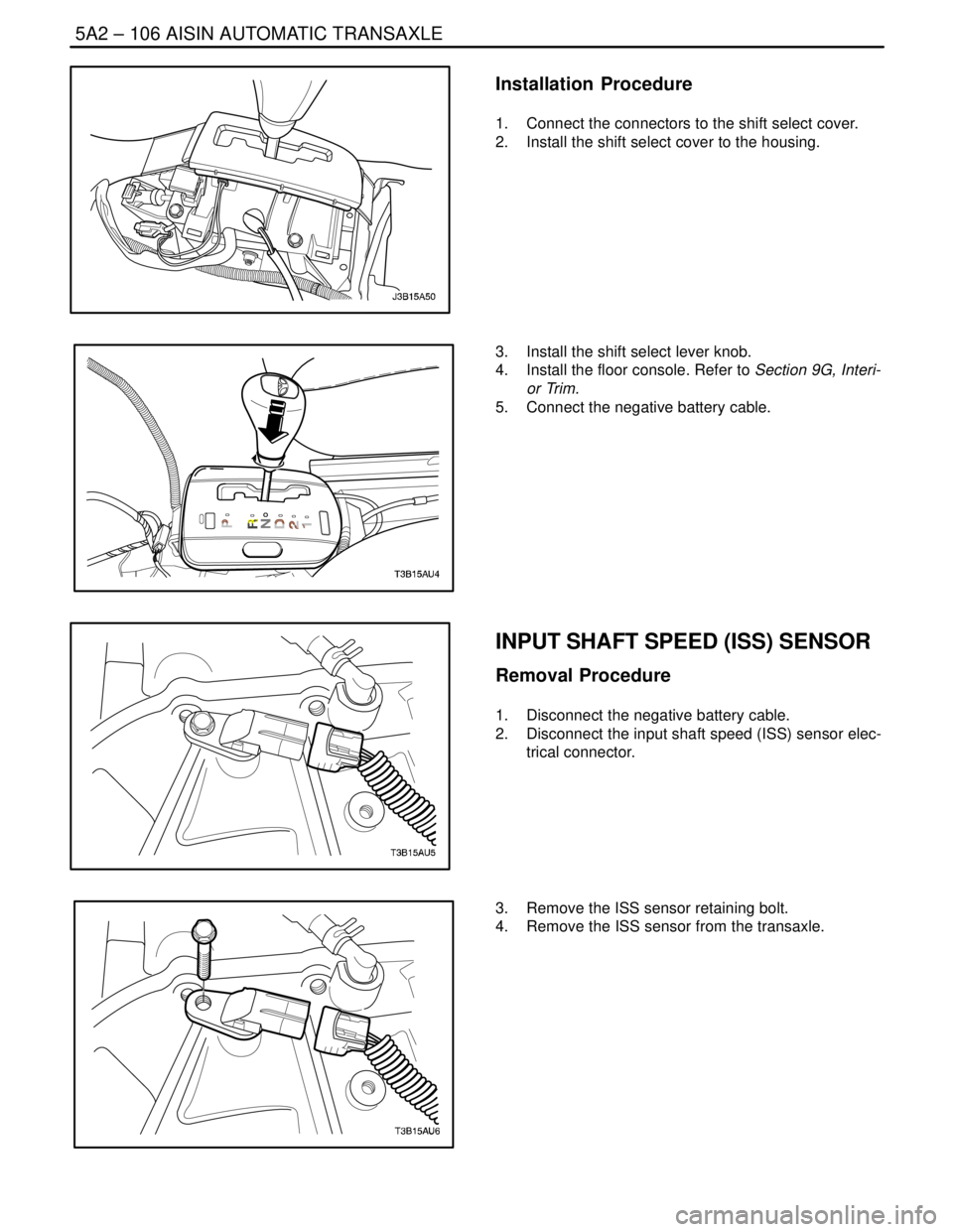

Installation Procedure

1. Connect the connectors to the shift select cover.

2. Install the shift select cover to the housing.

3. Install the shift select lever knob.

4. Install the floor console. Refer to Section 9G, Interi-

or Trim.

5. Connect the negative battery cable.

INPUT SHAFT SPEED (ISS) SENSOR

Removal Procedure

1. Disconnect the negative battery cable.

2. Disconnect the input shaft speed (ISS) sensor elec-

trical connector.

3. Remove the ISS sensor retaining bolt.

4. Remove the ISS sensor from the transaxle.

Page 1697 of 2643

AISIN AUTOMATIC TRANSAXLE 5A2 – 107

DAEWOO V–121 BL4

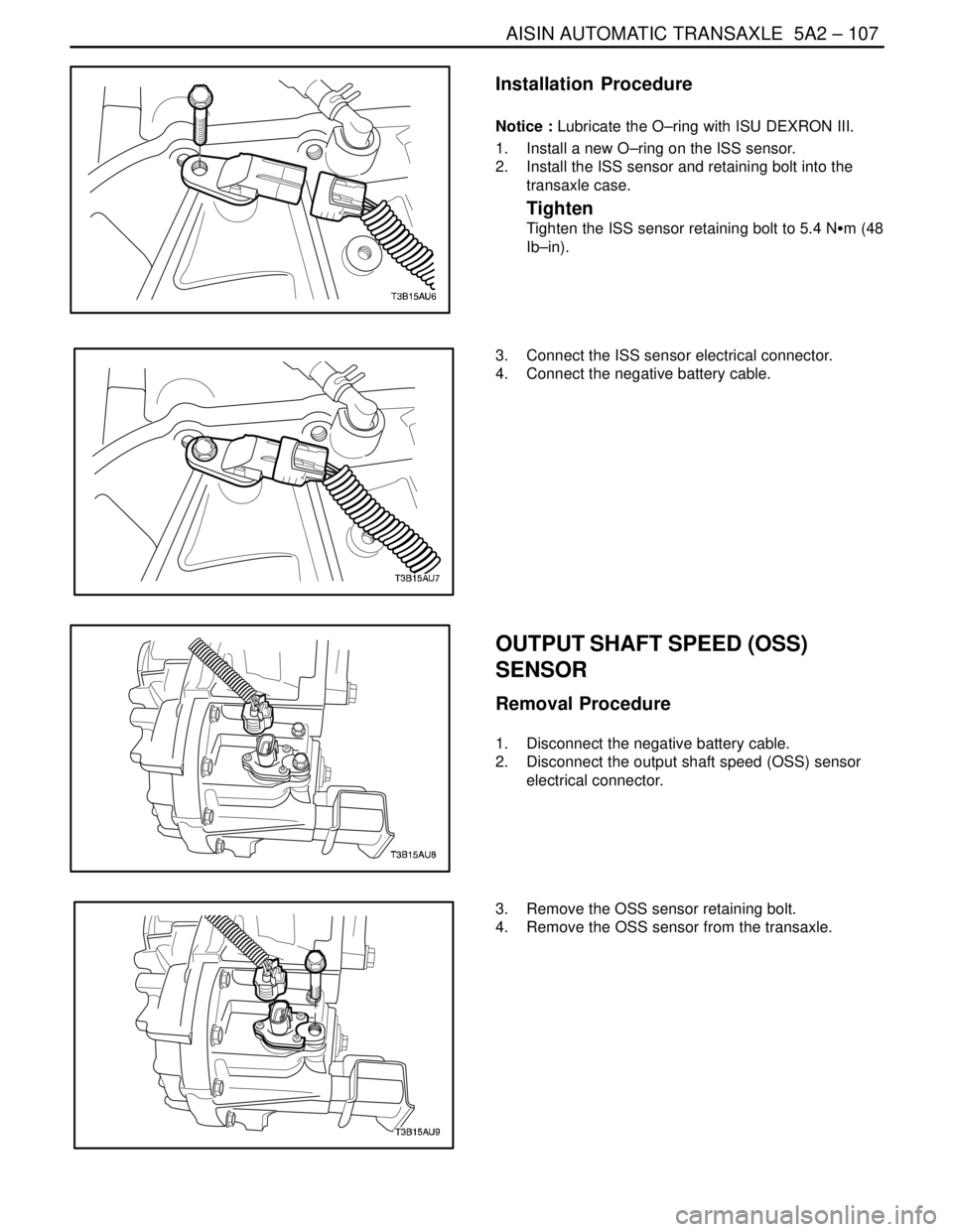

Installation Procedure

Notice : Lubricate the O–ring with ISU DEXRON III.

1. Install a new O–ring on the ISS sensor.

2. Install the ISS sensor and retaining bolt into the

transaxle case.

Tighten

Tighten the ISS sensor retaining bolt to 5.4 NSm (48

Ib–in).

3. Connect the ISS sensor electrical connector.

4. Connect the negative battery cable.

OUTPUT SHAFT SPEED (OSS)

SENSOR

Removal Procedure

1. Disconnect the negative battery cable.

2. Disconnect the output shaft speed (OSS) sensor

electrical connector.

3. Remove the OSS sensor retaining bolt.

4. Remove the OSS sensor from the transaxle.

Page 1698 of 2643

5A2 – 108IAISIN AUTOMATIC TRANSAXLE

DAEWOO V–121 BL4

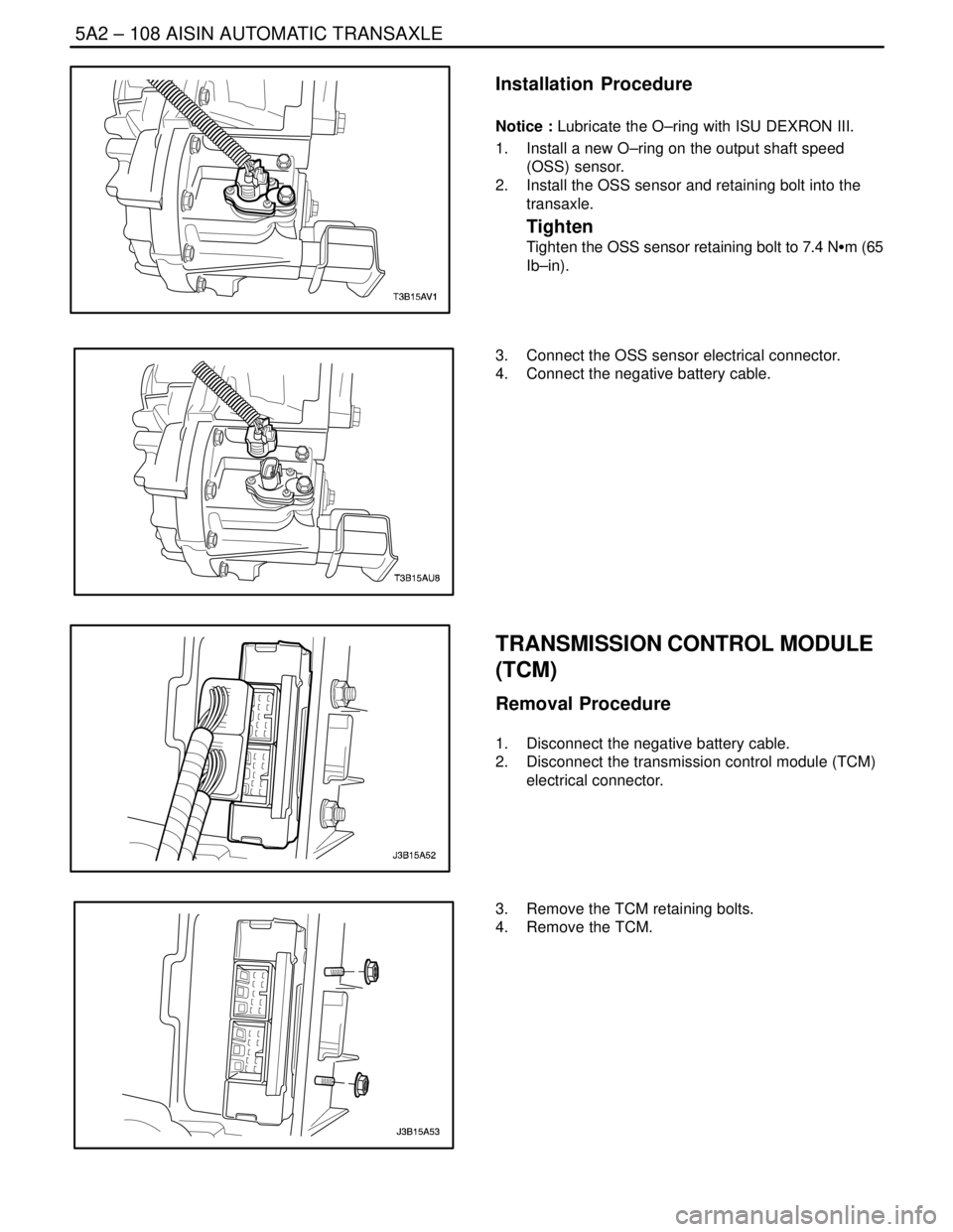

Installation Procedure

Notice : Lubricate the O–ring with ISU DEXRON III.

1. Install a new O–ring on the output shaft speed

(OSS) sensor.

2. Install the OSS sensor and retaining bolt into the

transaxle.

Tighten

Tighten the OSS sensor retaining bolt to 7.4 NSm (65

Ib–in).

3. Connect the OSS sensor electrical connector.

4. Connect the negative battery cable.

TRANSMISSION CONTROL MODULE

(TCM)

Removal Procedure

1. Disconnect the negative battery cable.

2. Disconnect the transmission control module (TCM)

electrical connector.

3. Remove the TCM retaining bolts.

4. Remove the TCM.

Page 1702 of 2643

5A2 – 112IAISIN AUTOMATIC TRANSAXLE

DAEWOO V–121 BL4

7. Disconnect the input shaft speed (ISS) sensor elec-

trical connector.

8. Disconnect the output shaft speed (OSS) sensor

electrical connector.

9. Disconnect the Transmission Range (TR) Switch

electrical connector.

10. Disconnect the transaxle electrical connector.

11. Remove the service hall cover.

12. Remove the three torque converter bolts.

13. Remove the damping block connection nut and

bolt.

14. Remove the rear mounting bracket bolts and rear

mounting bracket.

15. Remove the three upper transaxle mounting brack-

et bolts.