Iat DAEWOO LACETTI 2004 Service Owner's Guide

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 213 of 2643

1D – 18IENGINE COOLING

DAEWOO V–121 BL4

GENERAL DESCRIPTION

AND SYSTEM OPERATION

GENERAL DESCRIPTION

The cooling system maintains the engine temperature at

an efficient level during all engine operating conditions.

When the engine is cold, the cooling system cools the en-

gine slowly or not at all. This slow cooling of the engine al-

lows the engine to warm up quickly.

The cooling system includes a radiator and recovery sub-

system, cooling fans, a thermostat and housing, a coolant

pump, and a coolant pump drive belt. The timing belt

drives the coolant pump.

All components must function properly in order for the

cooling system to operate. The coolant pump draws the

coolant from the radiator. The coolant then circulates

through water jackets in the engine block, the intake man-

ifold, and the cylinder head. When the coolant reaches the

operating temperature of the thermostat, the thermostat

opens. The coolant then goes back to the radiator where

it cools.

This system directs some coolant through the hoses to the

heater core. This provides for heating and defrosting. The

surge tank is connected to the radiator to recover the cool-

ant displaced by expansion from the high temperatures.

The surge tank maintains the correct coolant level.

The cooling system for this vehicle has no radiator cap or

filler neck. The coolant is added to the cooling system

through the surge tank.

RADIATOR

This vehicle has a lightweight tube–and–fin aluminum ra-

diator. Plastic tanks are mounted on the right and the left

sides of the radiator core.

On vehicles equipped with automatic transaxles, the

transaxle fluid cooler lines run through the left radiator

tank. A radiator drain cock is on this radiator.

To drain the cooling system, open the drain cock.

SURGE TANK

The surge tank is a transparent plastic reservoir, similar to

the windshield washer reservoir.

The surge tank is connected to the radiator by a hose and

to the engine cooling system by another hose. As the ve-

hicle is driven, the engine coolant heats and expands. The

portion of the engine coolant displaced by this expansion

flows from the radiator and the engine into the surge tank.

The air trapped in the radiator and the engine is degassed

into the surge tank.When the engine stops, the engine coolant cools and con-

tracts. The displaced engine coolant is then drawn back

into the radiator and the engine. This keeps the radiator

filled with the coolant to the desired level at all times and

increases the cooling efficiency.

Maintain the coolant level between the MIN and the MAX

marks on the surge tank when the system is cold.

WATER PUMP

The belt–driven centrifugal water pump consists of an im-

peller, a drive shaft, and a belt pulley. The water pump is

mounted on the front of the transverse–mounted engine,

and is driven by the timing belt.

The impeller is supported by a completely sealed bearing.

The water pump is serviced as an assembly and, there-

fore, cannot be disassembled.

THERMOSTAT

A wax pellet–type thermostat controls the flow of the en-

gine coolant through the engine cooling system. The ther-

mostat is mounted in the thermostat housing to the front

of the cylinder head.

The thermostat stops the flow of the engine coolant from

the engine to the radiator in order to provide faster warm–

up, and to regulate the coolant temperature. The thermo-

stat remains closed while the engine coolant is cold, pre-

venting circulation of the engine coolant through the

radiator. At this point, the engine coolant is allowed to cir-

culate only throughout the heater core to warm it quickly

and evenly.

As the engine warms, the thermostat opens. This allows

the engine coolant to flow through the radiator, where the

heat is dissipated through the radiator. This opening and

closing of the thermostat permits enough engine coolant

to enter the radiator to keep the engine within proper en-

gine temperature operating limits.

The wax pellet in the thermostat is hermetically sealed in

a metal case. The wax element of the thermostat expands

when it is heated and contracts when it is cooled.

As the vehicle is driven and the engine warms, the engine

coolant temperature increases. When the engine coolant

reaches a specified temperature, the wax pellet element

in the thermostat expands and exerts pressure against the

metal case, forcing the valve open. This allows the engine

coolant to flow through the engine cooling system and cool

the engine.

As the wax pellet cools, the contraction allows a spring to

close the valve.

The thermostat begins to open at 87°C (189°F) and is fully

open at 102°C (216°F). The thermostat closes at 86°C

(187°F).

Page 214 of 2643

ENGINE COOLING 1D – 19

DAEWOO V–121 BL4

ELECTRIC COOLING FAN

CAUTION : Keep hands, tools, and clothing away

from the engine cooling fans to help prevent personal

injury. This fan is electric and can turn ON whether or

not the engine is running.

CAUTION : If a fan blade is bent or damaged in any

way, no attempt should be made to repair or reuse the

damaged part. A bent or damaged fan assembly

should always be replaced with a new one. Failure to

do so can result in personal injury.

The cooling fans are mounted behind the radiator in the

engine compartment. The electric cooling fans increase

the flow of air across the radiator fins and across the con-

denser on air condition (A/C)–equipped vehicles. This

helps to speed cooling when the vehicle is at idle or moving

at low speeds.

1.4L DOHC engine fan size is 340mm (13.4 in.) and

1.6L/1.8L DOHC engine main fan size is 300 mm (11.8

inches) in diameter with five blades to aid the air flow

through the radiator and the condenser. An electric motor

attached to the radiator support drives the fan.

A/C models have two fans – the main fan and the auxiliary

fan. The auxiliary fan is 300 mm (11.8 inches) in diameter.

Non–A/C models have only the main fan.

A/C OFF or Non–A/C Model (1.4L/1.6L)

S The cooling fans are actuated by the electronic

control module (ECM) using a low–speed cooling

fan relay and a high–speed cooling fan relay. On

A/C–equipped vehicles, a series/parallel cooling fan

relay is also used.

S The ECM will turn the cooling fans on at low speed

when the coolant temperature reaches 97.5°C

(207.5°F) and the cooling fans off at 95.25°C

(203.4°F).

A/C OFF or Non–A/C Model (1.8L)

S The cooling fans are actuated by the electronic

control module (ECM) using a low–speed cooling

fan relay and a high–speed cooling fan relay. On

A/C–equipped vehicles, a series/parallel cooling fan

relay is also used.

S The ECM will turn the cooling fans on at low speed

when the coolant temperature reaches 93°C

(199°F) and the cooling fans off at 90°C (194°F).

A/C ON (1.4L/1.6L)

S The ECM will turn the cooling fans on at low speed

when the A/C system is on. The ECM will change

to high speed when the coolant temperature reach-

es 101.25°C (214°F) or the high side A/C pressure

reaches 1859 kPa (270 psi).

S The cooling fans will return to low speed when the

coolant temperature reaches 99°C (210°F) and the

high side A/C pressure reaches 1449 kPa (210 psi).

A/C ON (1.8L)

S The ECM will turn the cooling fans on at low speed

when the A/C system is on. The ECM will change

to high speed when the coolant temperature reach-

es 97°C (207°F) or the high side A/C pressure

reaches 1859 kPa (270 psi).

S The cooling fans will return to low speed when the

coolant temperature reaches 94°C (201°F) and the

high side A/C pressure reaches 1449 kPa (210 psi).

ENGINE BLOCK HEATER

The vehicle is designed to accept an engine block heater

that helps to warm the engine and to improve starting in

cold weather. It also can help to reduce fuel consumption

while a cold engine warms up.

The engine block heater is located under the intake man-

ifold and uses an existing expansion plug for installation.

Page 231 of 2643

ENGINE ELECTRICAL 1E – 17

DAEWOO V–121 BL4

UNIT REPAIR

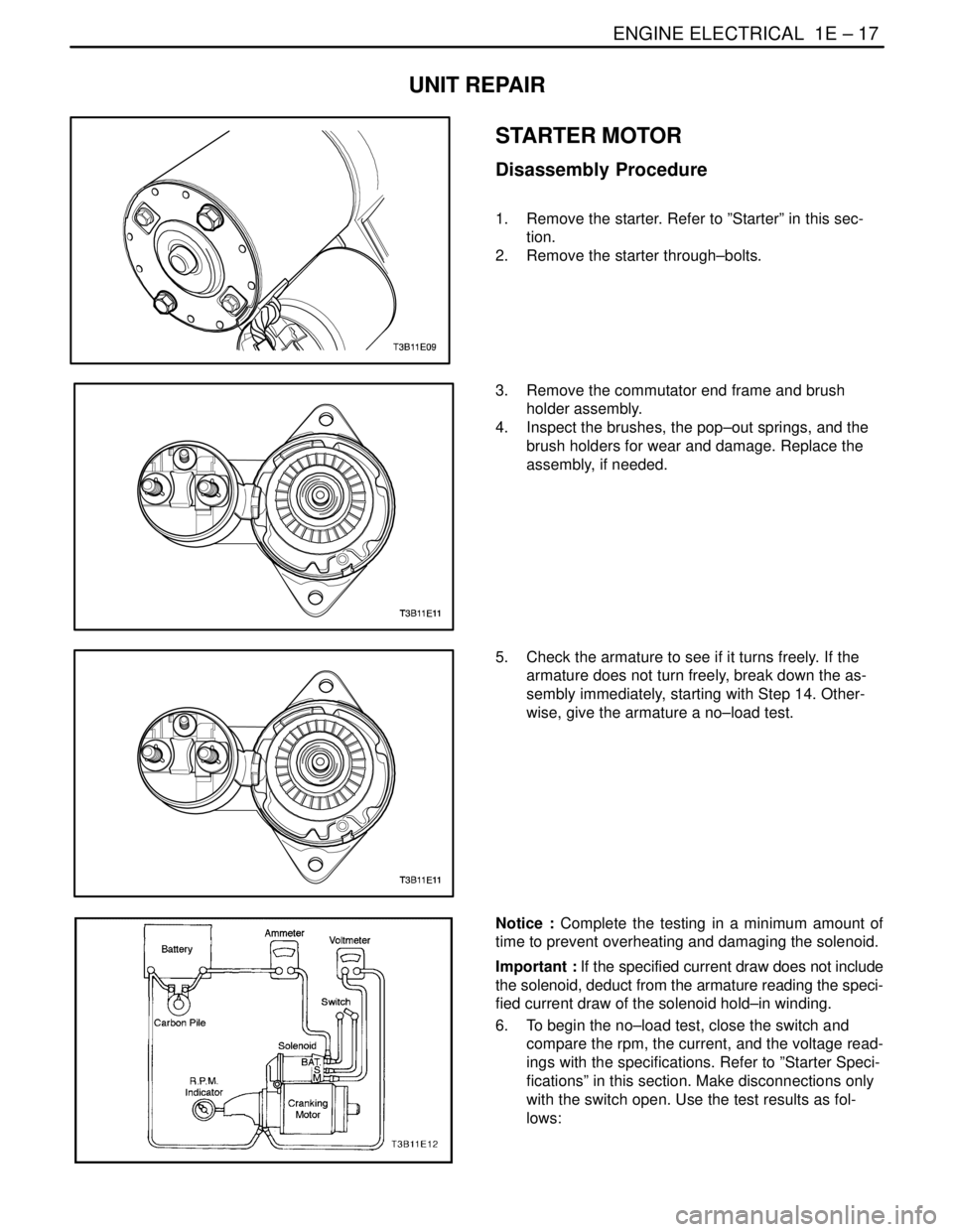

STARTER MOTOR

Disassembly Procedure

1. Remove the starter. Refer to ”Starter” in this sec-

tion.

2. Remove the starter through–bolts.

3. Remove the commutator end frame and brush

holder assembly.

4. Inspect the brushes, the pop–out springs, and the

brush holders for wear and damage. Replace the

assembly, if needed.

5. Check the armature to see if it turns freely. If the

armature does not turn freely, break down the as-

sembly immediately, starting with Step 14. Other-

wise, give the armature a no–load test.

Notice : Complete the testing in a minimum amount of

time to prevent overheating and damaging the solenoid.

Important : If the specified current draw does not include

the solenoid, deduct from the armature reading the speci-

fied current draw of the solenoid hold–in winding.

6. To begin the no–load test, close the switch and

compare the rpm, the current, and the voltage read-

ings with the specifications. Refer to ”Starter Speci-

fications” in this section. Make disconnections only

with the switch open. Use the test results as fol-

lows:

Page 243 of 2643

ENGINE ELECTRICAL 1E – 29

DAEWOO V–121 BL4

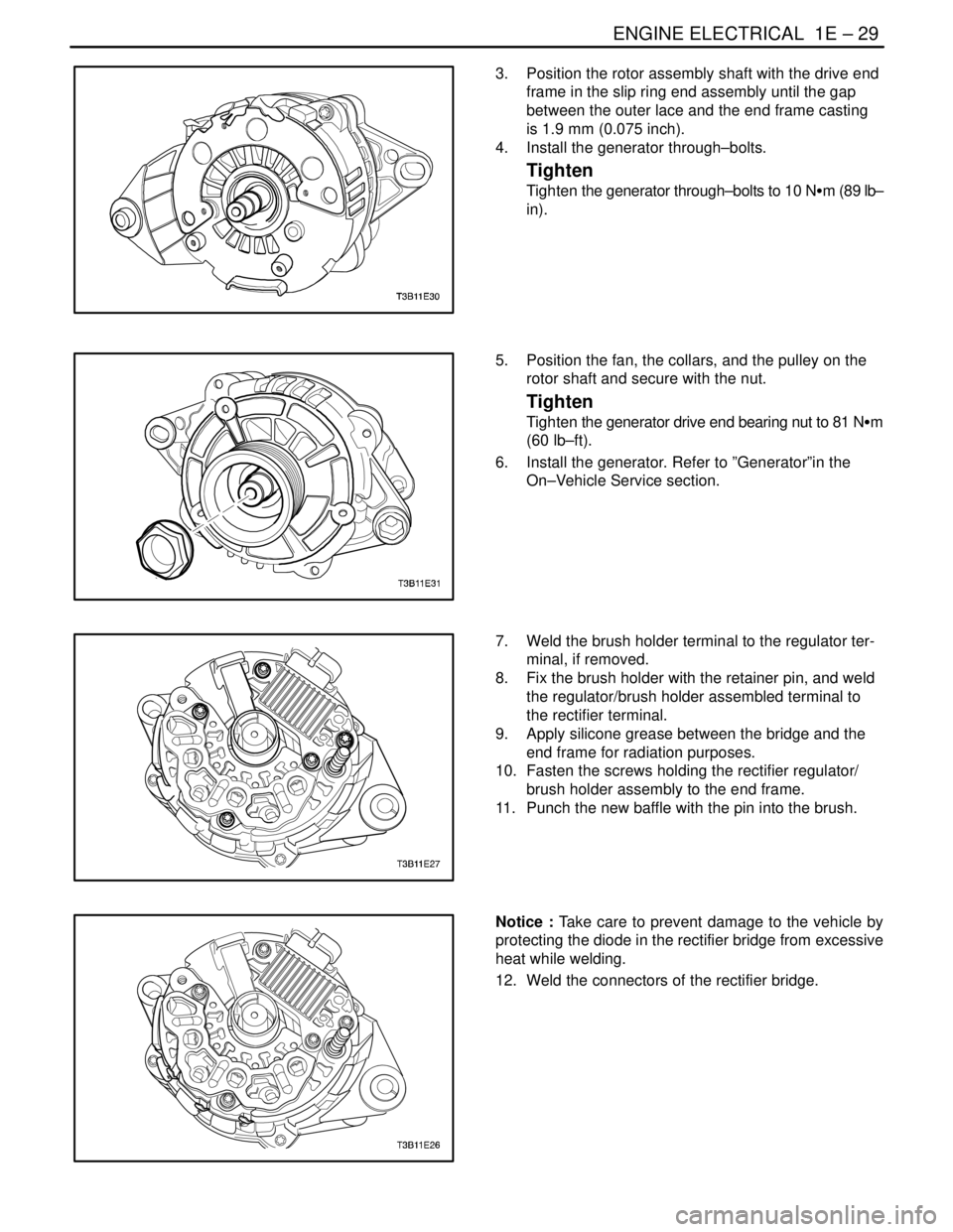

3. Position the rotor assembly shaft with the drive end

frame in the slip ring end assembly until the gap

between the outer lace and the end frame casting

is 1.9 mm (0.075 inch).

4. Install the generator through–bolts.

Tighten

Tighten the generator through–bolts to 10 NSm (89 lb–

in).

5. Position the fan, the collars, and the pulley on the

rotor shaft and secure with the nut.

Tighten

Tighten the generator drive end bearing nut to 81 NSm

(60 lb–ft).

6. Install the generator. Refer to ”Generator”in the

On–Vehicle Service section.

7. Weld the brush holder terminal to the regulator ter-

minal, if removed.

8. Fix the brush holder with the retainer pin, and weld

the regulator/brush holder assembled terminal to

the rectifier terminal.

9. Apply silicone grease between the bridge and the

end frame for radiation purposes.

10. Fasten the screws holding the rectifier regulator/

brush holder assembly to the end frame.

11. Punch the new baffle with the pin into the brush.

Notice : Take care to prevent damage to the vehicle by

protecting the diode in the rectifier bridge from excessive

heat while welding.

12. Weld the connectors of the rectifier bridge.

Page 246 of 2643

1E – 32IENGINE ELECTRICAL

DAEWOO V–121 BL4

the same cable to the positive terminal on the other

battery. Never connect the other end to the nega-

tive terminal of the discharged battery.

CAUTION : To avoid injury do not attach the cable di-

rectly to the negative terminal of the discharged bat-

tery. Doing so could cause sparks and a possible bat-

tery explosion.

6. Clamp one end of the second cable to the negative

terminal of the booster battery. Make the final con-

nection to a solid engine ground (such as the en-

gine lift bracket) at least 450 millimeters (18 inches)

from the discharged battery.

7. Start the engine of the vehicle with the good bat-

tery. Run the engine at a moderate speed for sever-

al minutes. Then start the engine of the vehicle

which has the discharged battery.

8. Remove the jumper cables by reversing the above

sequence exactly. Remove the negative cable from

the vehicle with the discharged battery first. While

removing each clamp, take care that it does not

touch any other metal while the other end remains

attached.

GENERATOR

The Delco–Remy CS charging system has several mod-

els available, including the CS. The number denotes the

outer diameter in millimeters of the stator lamination.

CS generators are equipped with internal regulators. A

Delta stator, a rectifier bridge, and a rotor with slip rings

and brushes are electrically similar to earlier generators.

A conventional pulley and fan are used. There is no test

hole.

Unlike three–wire generators, the CS may be used with

only two connections: battery positive and an ”L’’ terminal

to the charge indicator lamp.

As with other charging systems, the charge indicator lamp

lights when the ignition switch is turned to RUN, and goes

out when the engine is running. If the charge indicator is

on with the engine running, a charging system defect is in-

dicated. This indicator light will glow at full brilliance for

several kinds of defects as well as when the system volt-

age is too high or too low.The regulator voltage setting varies with temperature and

limits the system voltage by controlling rotor field current.

At high speeds, the on–time may be 10 percent and the

off–time 90 percent. At low speeds, with high electrical

loads, on–time may be 90 percent and the off–time 10 per-

cent.

CHARGING SYSTEM

CS generators use a new type of regulator that incorpo-

rates a diode trio. A Delta stator, a rectifier bridge, and a

rotor with slip rings and brushes are electrically similar to

earlier generators. A conventional pulley and fan are used.

There is no test hole.

STARTER

Wound field starter motors have pole pieces, arranged

around the armature, which are energized by wound field

coils.

Enclosed shift lever cranking motors have the shift lever

mechanism and the solenoid plunger enclosed in the drive

housing, protecting them from exposure to dirt, icy condi-

tions, and splashes.

In the basic circuit, solenoid windings are energized when

the switch is closed. The resulting plunger and shift lever

movement causes the pinion to engage the engine fly-

wheel ring gear. The solenoid main contacts close. Crank-

ing then takes place.

When the engine starts, pinion overrun protects the arma-

ture from excessive speed until the switch is opened, at

which time the return spring causes the pinion to disen-

gage. To prevent excessive overrun, the switch should be

released immediately after the engine starts.

STARTING SYSTEM

The engine electrical system includes the battery, the igni-

tion, the starter, the generator, and all the related wiring.

Diagnostic tables will aid in troubleshooting system faults.

When a fault is traced to a particular component, refer to

that component section of the service manual.

The starting system circuit consists of the battery, the

starter motor, the ignition switch, and all the related electri-

cal wiring. All of these components are connected electri-

cally.

Page 250 of 2643

1F – 4IENGINE CONTROLS

DAEWOO V–121 BL4

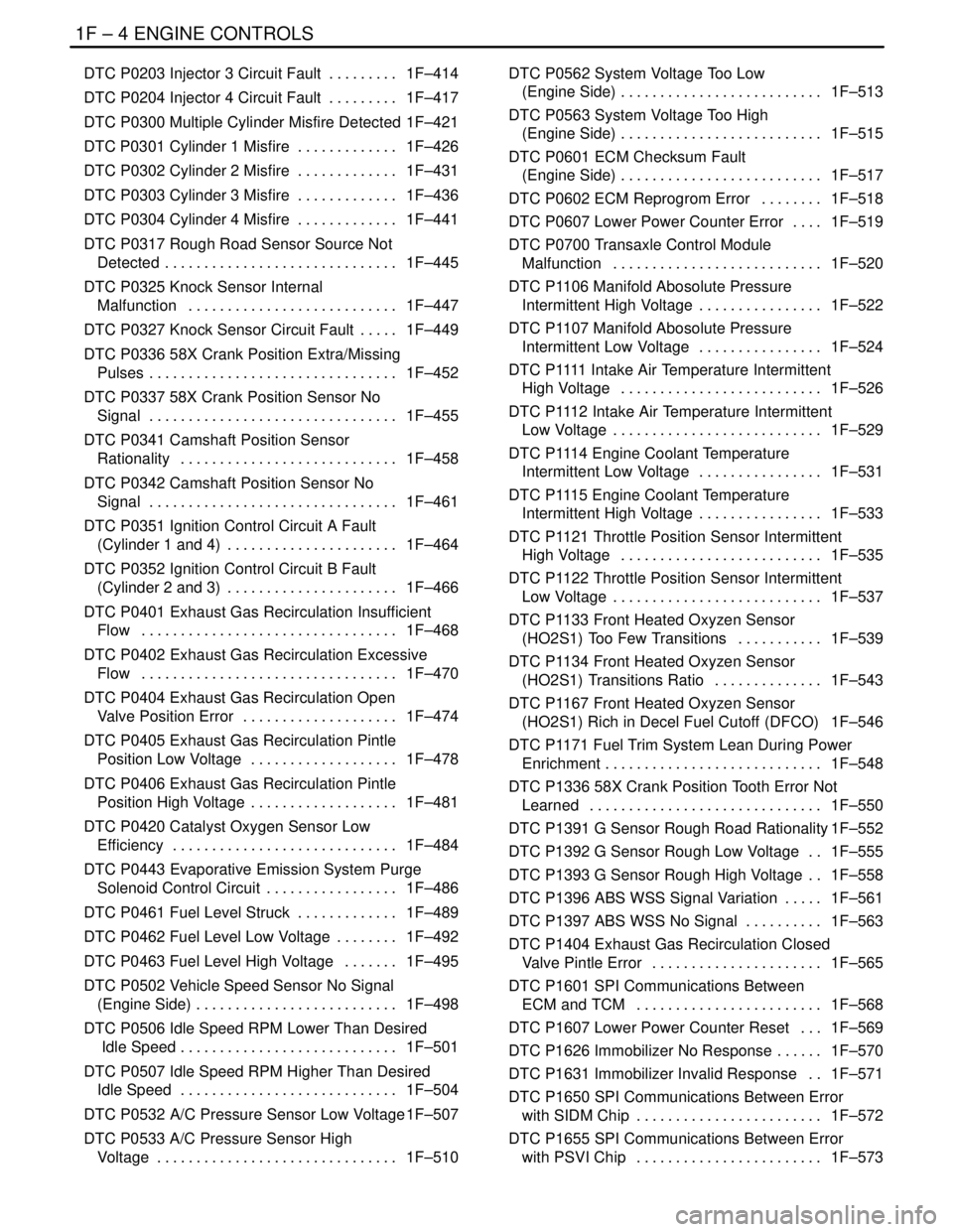

DTC P0203 Injector 3 Circuit Fault 1F–414. . . . . . . . .

DTC P0204 Injector 4 Circuit Fault 1F–417. . . . . . . . .

DTC P0300 Multiple Cylinder Misfire Detected 1F–421

DTC P0301 Cylinder 1 Misfire 1F–426. . . . . . . . . . . . .

DTC P0302 Cylinder 2 Misfire 1F–431. . . . . . . . . . . . .

DTC P0303 Cylinder 3 Misfire 1F–436. . . . . . . . . . . . .

DTC P0304 Cylinder 4 Misfire 1F–441. . . . . . . . . . . . .

DTC P0317 Rough Road Sensor Source Not

Detected 1F–445. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0325 Knock Sensor Internal

Malfunction 1F–447. . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0327 Knock Sensor Circuit Fault 1F–449. . . . .

DTC P0336 58X Crank Position Extra/Missing

Pulses 1F–452. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0337 58X Crank Position Sensor No

Signal 1F–455. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0341 Camshaft Position Sensor

Rationality 1F–458. . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0342 Camshaft Position Sensor No

Signal 1F–461. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0351 Ignition Control Circuit A Fault

(Cylinder 1 and 4) 1F–464. . . . . . . . . . . . . . . . . . . . . .

DTC P0352 Ignition Control Circuit B Fault

(Cylinder 2 and 3) 1F–466. . . . . . . . . . . . . . . . . . . . . .

DTC P0401 Exhaust Gas Recirculation Insufficient

Flow 1F–468. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0402 Exhaust Gas Recirculation Excessive

Flow 1F–470. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0404 Exhaust Gas Recirculation Open

Valve Position Error 1F–474. . . . . . . . . . . . . . . . . . . .

DTC P0405 Exhaust Gas Recirculation Pintle

Position Low Voltage 1F–478. . . . . . . . . . . . . . . . . . .

DTC P0406 Exhaust Gas Recirculation Pintle

Position High Voltage 1F–481. . . . . . . . . . . . . . . . . . .

DTC P0420 Catalyst Oxygen Sensor Low

Efficiency 1F–484. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0443 Evaporative Emission System Purge

Solenoid Control Circuit 1F–486. . . . . . . . . . . . . . . . .

DTC P0461 Fuel Level Struck 1F–489. . . . . . . . . . . . .

DTC P0462 Fuel Level Low Voltage 1F–492. . . . . . . .

DTC P0463 Fuel Level High Voltage 1F–495. . . . . . .

DTC P0502 Vehicle Speed Sensor No Signal

(Engine Side) 1F–498. . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0506 Idle Speed RPM Lower Than Desired

Idle Speed 1F–501. . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0507 Idle Speed RPM Higher Than Desired

Idle Speed 1F–504. . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0532 A/C Pressure Sensor Low Voltage 1F–507

DTC P0533 A/C Pressure Sensor High

Voltage 1F–510. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . DTC P0562 System Voltage Too Low

(Engine Side) 1F–513. . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0563 System Voltage Too High

(Engine Side) 1F–515. . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0601 ECM Checksum Fault

(Engine Side) 1F–517. . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0602 ECM Reprogrom Error 1F–518. . . . . . . .

DTC P0607 Lower Power Counter Error 1F–519. . . .

DTC P0700 Transaxle Control Module

Malfunction 1F–520. . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P1106 Manifold Abosolute Pressure

Intermittent High Voltage 1F–522. . . . . . . . . . . . . . . .

DTC P1107 Manifold Abosolute Pressure

Intermittent Low Voltage 1F–524. . . . . . . . . . . . . . . .

DTC P1111 Intake Air Temperature Intermittent

High Voltage 1F–526. . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P1112 Intake Air Temperature Intermittent

Low Voltage 1F–529. . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P1114 Engine Coolant Temperature

Intermittent Low Voltage 1F–531. . . . . . . . . . . . . . . .

DTC P1115 Engine Coolant Temperature

Intermittent High Voltage 1F–533. . . . . . . . . . . . . . . .

DTC P1121 Throttle Position Sensor Intermittent

High Voltage 1F–535. . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P1122 Throttle Position Sensor Intermittent

Low Voltage 1F–537. . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P1133 Front Heated Oxyzen Sensor

(HO2S1) Too Few Transitions 1F–539. . . . . . . . . . .

DTC P1134 Front Heated Oxyzen Sensor

(HO2S1) Transitions Ratio 1F–543. . . . . . . . . . . . . .

DTC P1167 Front Heated Oxyzen Sensor

(HO2S1) Rich in Decel Fuel Cutoff (DFCO) 1F–546

DTC P1171 Fuel Trim System Lean During Power

Enrichment 1F–548. . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P1336 58X Crank Position Tooth Error Not

Learned 1F–550. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P1391 G Sensor Rough Road Rationality 1F–552

DTC P1392 G Sensor Rough Low Voltage 1F–555. .

DTC P1393 G Sensor Rough High Voltage 1F–558. .

DTC P1396 ABS WSS Signal Variation 1F–561. . . . .

DTC P1397 ABS WSS No Signal 1F–563. . . . . . . . . .

DTC P1404 Exhaust Gas Recirculation Closed

Valve Pintle Error 1F–565. . . . . . . . . . . . . . . . . . . . . .

DTC P1601 SPI Communications Between

ECM and TCM 1F–568. . . . . . . . . . . . . . . . . . . . . . . .

DTC P1607 Lower Power Counter Reset 1F–569. . .

DTC P1626 Immobilizer No Response 1F–570. . . . . .

DTC P1631 Immobilizer Invalid Response 1F–571. .

DTC P1650 SPI Communications Between Error

with SIDM Chip 1F–572. . . . . . . . . . . . . . . . . . . . . . . .

DTC P1655 SPI Communications Between Error

with PSVI Chip 1F–573. . . . . . . . . . . . . . . . . . . . . . . .

Page 252 of 2643

1F – 6IENGINE CONTROLS

DAEWOO V–121 BL4

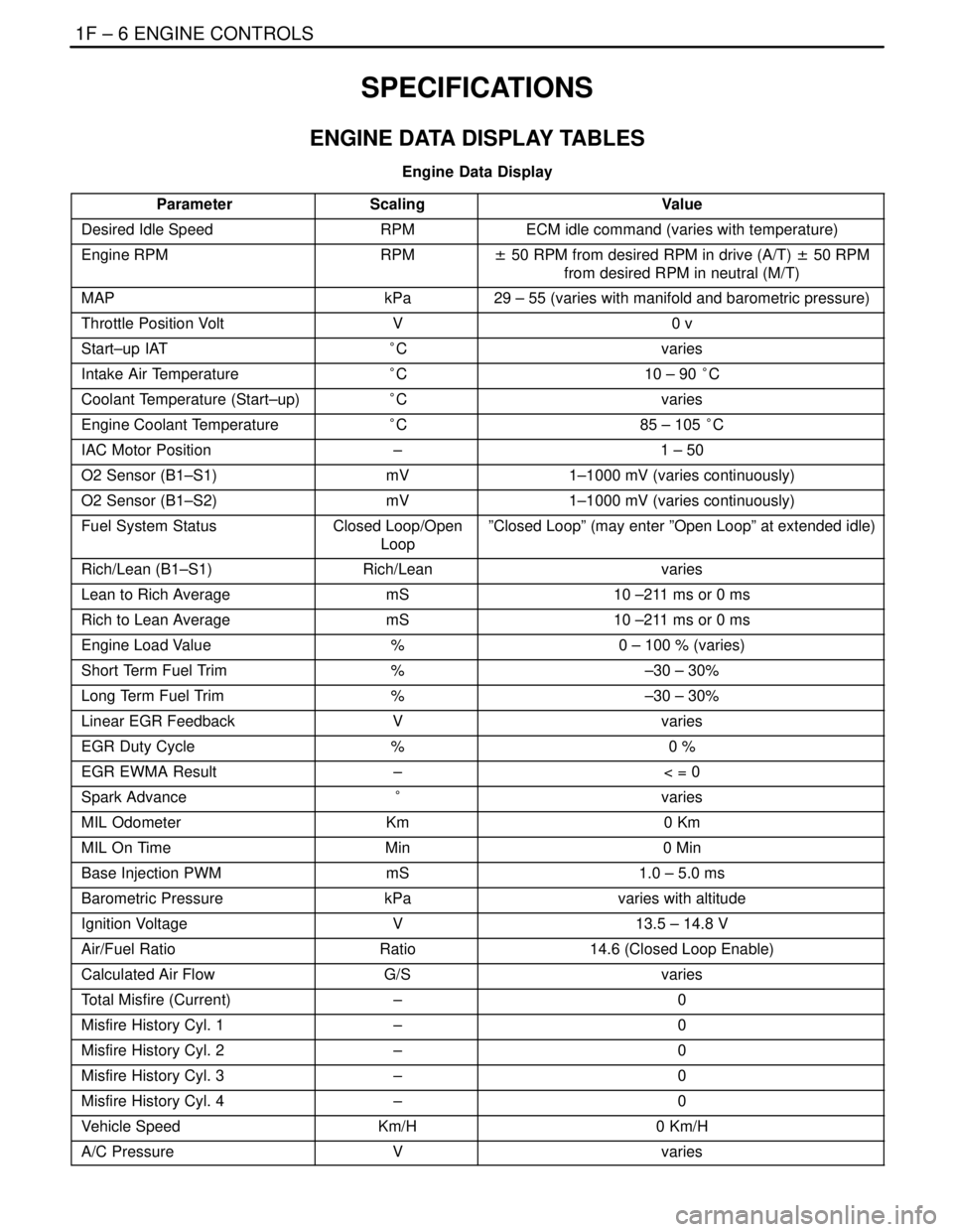

SPECIFICATIONS

ENGINE DATA DISPLAY TABLES

Engine Data Display

Parameter

ScalingValue

Desired Idle SpeedRPMECM idle command (varies with temperature)

Engine RPMRPM± 50 RPM from desired RPM in drive (A/T) ± 50 RPM

from desired RPM in neutral (M/T)

MAPkPa29 – 55 (varies with manifold and barometric pressure)

Throttle Position VoltV0 v

Start–up IAT°Cvaries

Intake Air Temperature°C10 – 90 °C

Coolant Temperature (Start–up)°Cvaries

Engine Coolant Temperature°C85 – 105 °C

IAC Motor Position–1 – 50

O2 Sensor (B1–S1)mV1–1000 mV (varies continuously)

O2 Sensor (B1–S2)mV1–1000 mV (varies continuously)

Fuel System StatusClosed Loop/Open

Loop”Closed Loop” (may enter ”Open Loop” at extended idle)

Rich/Lean (B1–S1)Rich/Leanvaries

Lean to Rich AveragemS10 –211 ms or 0 ms

Rich to Lean AveragemS10 –211 ms or 0 ms

Engine Load Value%0 – 100 % (varies)

Short Term Fuel Trim%–30 – 30%

Long Term Fuel Trim%–30 – 30%

Linear EGR FeedbackVvaries

EGR Duty Cycle%0 %

EGR EWMA Result–< = 0

Spark Advance°varies

MIL OdometerKm0 Km

MIL On TimeMin0 Min

Base Injection PWMmS1.0 – 5.0 ms

Barometric PressurekPavaries with altitude

Ignition VoltageV13.5 – 14.8 V

Air/Fuel RatioRatio14.6 (Closed Loop Enable)

Calculated Air FlowG/Svaries

Total Misfire (Current)–0

Misfire History Cyl. 1–0

Misfire History Cyl. 2–0

Misfire History Cyl. 3–0

Misfire History Cyl. 4–0

Vehicle SpeedKm/H0 Km/H

A/C PressureVvaries

Page 254 of 2643

1F – 8IENGINE CONTROLS

DAEWOO V–121 BL4

EGR Desired Position

The desired exhaust gas recirculation (EGR) position is

the commanded EGR position. The ECM calculates the

desired EGR position. The higher the percentage, the lon-

ger the ECM is commanding the EGR valve ON.

Engine Load

Indicates engine load based on manifold absolute pres-

sure. The higher the percentage, the more load the engine

is under.

Engine Run Time

The engine run time is a measure of how long the engine

has been running. When the engine stops running, the tim-

er resets to zero.

Engine Speed

Engine Speed is computed by the ECM from the fuel con-

trol reference input. It should remain close to desired idle

under the various engine loads with the engine idling.

Fan

The Fan Control (FC) Relay is commanded by the ECM.

The FC Relay displays the command as ON or OFF.

Fuel Level Sensor

The Fuel Level Sensor monitors the fuel level in the tank.

The Fuel Level Sensor monitors the rate of change of the

air pressure in the EVAP system. Several of the Enhanced

EVAP System diagnostics are dependent upon the correct

fuel level.

Fuel System Status

The Closed Loop is displayed indicating that the ECM is

controlling the fuel delivery according to the Front Heated

Oxygen Sensor (HO2S1) voltage as close to an air/fuel ra-

tio of 14.7 to 1 as possible.

IAC Position

The scan tool displays the ECM command for the Idle Air

Control (IAC) pintle position in counts. The higher the

number of counts, the greater the commanded idle speed

reads. The Idle Air Control responds to changes in the en-

gine load in order to maintain the desired idle rpm.

Ignition 1 (Voltage)

The ignition volts represent the system voltage measured

by the ECM at the ignition feed circuit.

Intake Air Temperature

The ECM converts the resistance of the Intake Air Tem-

perature (IAT) sensor to degrees in the same manner as

the engine coolant temperature (ECT) sensor. In take air

temperature is used by the ECM to adjust fuel delivery and

spark timing according to incoming air density.Knock Present

The KS Noise Channel indicates when the ECM detects

the KS signal. The ECM should display NO at idle.

Long Term FT

The Long Term Fuel Trim (FT) is derived from the short

term fuel trim value. The Long Term FT is used for the long

term correction of the fuel delivery. A value of 128 counts

(0%) indicates that the fuel delivery requires no com-

pensation in order to maintain a 14.7:1 air to fuel ratio. A

value below 128 counts means that the fuel system is too

rich and the fuel delivery is being reduced. The ECM is de-

creasing the injector pulse width. A value above 128

counts indicates that a lean condition exists for which the

ECM is compensating.

MAP

The Manifold Absolute Pressure (MAP) sensor measures

the change in the intake manifold pressure which results

from engine load and speed changes. As the intake man-

ifold pressure increases, the air density in the intake also

increases and the additional fuel is required.

Misfire History #1–4

Indicates the number of misfires that have occurred after

195 current misfires have been counted. The current mis-

fire counter will add its misfires to the history misfire count-

er after 195 total misfires have taken place. If 1 cylinder is

misfiring, the misfiring current counter will have 195 mis-

fires counted before adding to its history counter. If 2 cylin-

ders are misfiring, the misfiring current counter will add to

their history counters after 97 misfires. The counter incre-

ments only after a misfire diagnostic trouble code (DTC)

has been set.

Front Heated Oxygen Sensor

The pre–converter Front Heated Oxygen Sensor

(HO2S1) reading represents the exhaust oxygen sensor

output voltage. This voltage will fluctuate constantly be-

tween 100 mv (lean exhaust) and 900 mv (rich exhaust)

when the system is operating in a Closed Loop.

Rear Heated Oxygen Sensor

The post–converter Rear Heated Oxygen Sensor

(HO2S2) represents the exhaust oxygen output voltage

past the catalytic converter. This voltage remains inactive,

or the voltage will appear lazy within a range of 100 mv

(lean exhaust) and 900 mv (rich exhaust) when operating

in a Closed Loop.

Short Term FT

The Short Term FT represents a short term correction to

fuel delivery by the ECM in response to the amount of time

the oxygen sensor voltage spends above or below the 450

mv threshold. If the oxygen sensor has mainly been below

450 mv, indicating a lean air/fuel mixture, short term fuel

trim will increase to tell the ECM to add fuel. If the oxygen

sensor voltage stays mainly above the threshold, the ECM

will reduce fuel delivery to compensate for the indicated

rich condition.

Page 257 of 2643

ENGINE CONTROLS 1F – 11

DAEWOO V–121 BL4

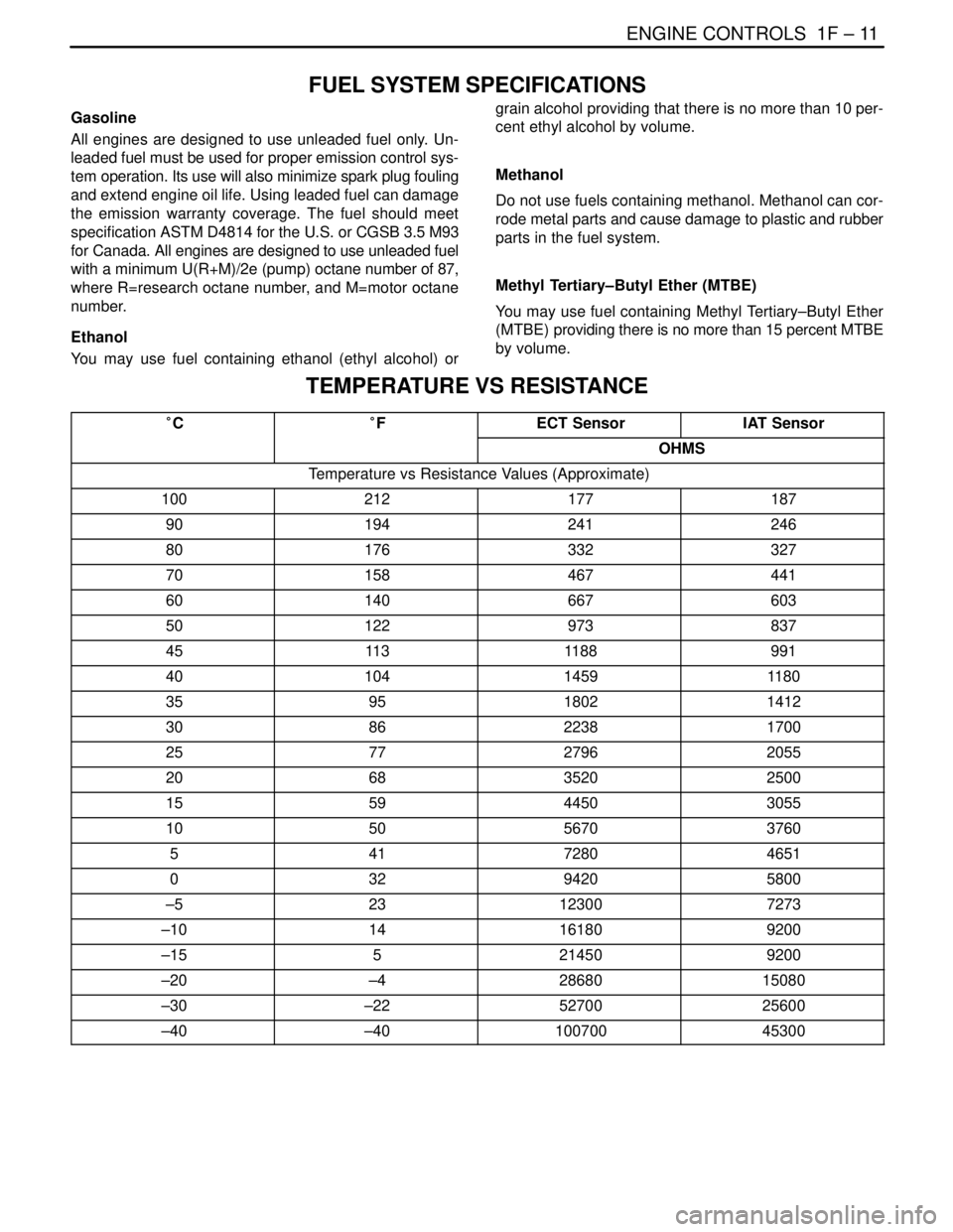

FUEL SYSTEM SPECIFICATIONS

Gasoline

All engines are designed to use unleaded fuel only. Un-

leaded fuel must be used for proper emission control sys-

tem operation. Its use will also minimize spark plug fouling

and extend engine oil life. Using leaded fuel can damage

the emission warranty coverage. The fuel should meet

specification ASTM D4814 for the U.S. or CGSB 3.5 M93

for Canada. All engines are designed to use unleaded fuel

with a minimum U(R+M)/2e (pump) octane number of 87,

where R=research octane number, and M=motor octane

number.

Ethanol

You may use fuel containing ethanol (ethyl alcohol) orgrain alcohol providing that there is no more than 10 per-

cent ethyl alcohol by volume.

Methanol

Do not use fuels containing methanol. Methanol can cor-

rode metal parts and cause damage to plastic and rubber

parts in the fuel system.

Methyl Tertiary–Butyl Ether (MTBE)

You may use fuel containing Methyl Tertiary–Butyl Ether

(MTBE) providing there is no more than 15 percent MTBE

by volume.

TEMPERATURE VS RESISTANCE

°C°FECT SensorIAT Sensor

OHMS

Temperature vs Resistance Values (Approximate)

100212177187

90194241246

80176332327

70158467441

60140667603

50122973837

4511 31188991

4010414591180

359518021412

308622381700

257727962055

206835202500

155944503055

105056703760

54172804651

03294205800

–523123007273

–1014161809200

–155214509200

–20–42868015080

–30–225270025600

–40–4010070045300

Page 274 of 2643

1F – 28IENGINE CONTROLS

DAEWOO V–121 BL4

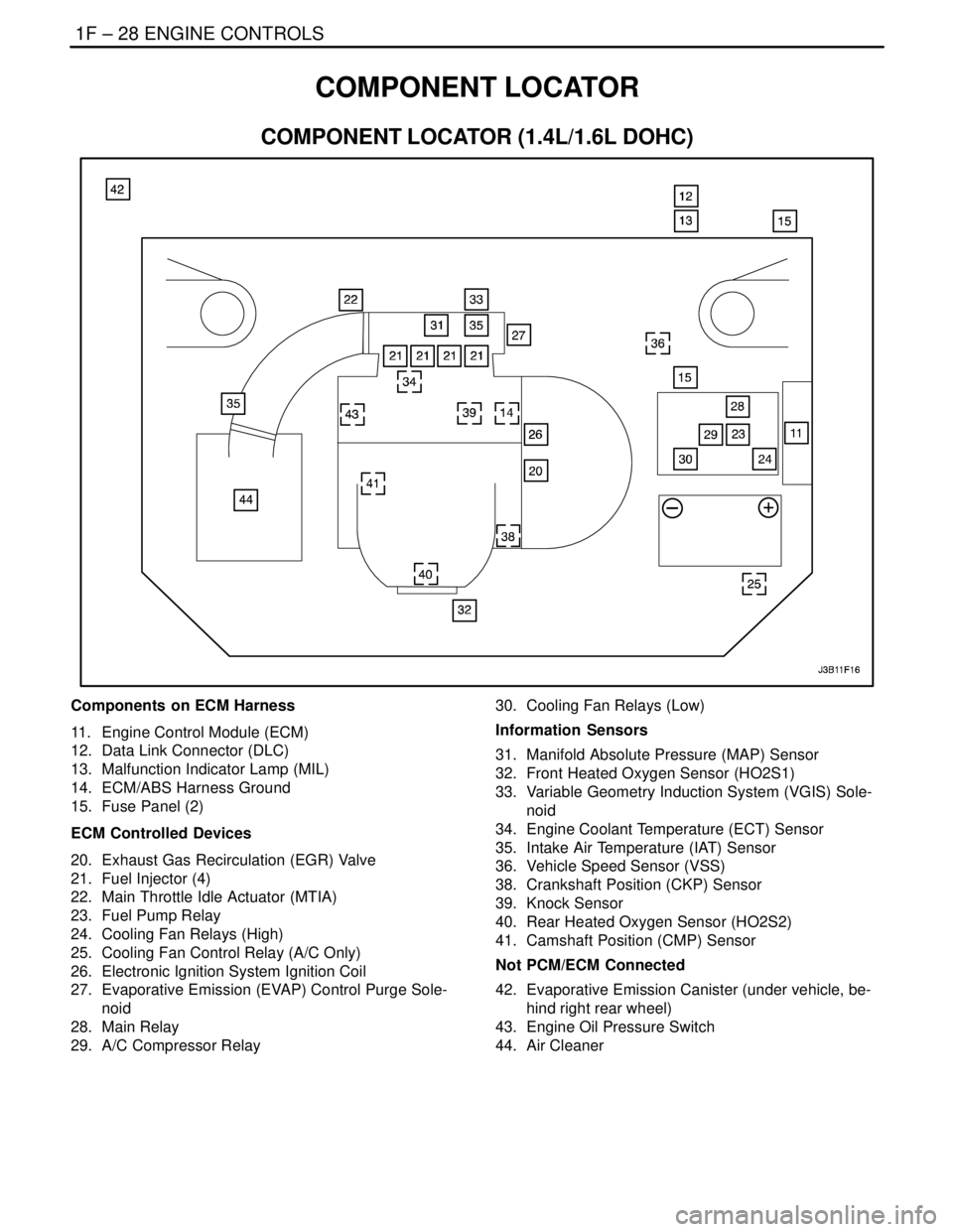

COMPONENT LOCATOR

COMPONENT LOCATOR (1.4L/1.6L DOHC)

Components on ECM Harness

11. Engine Control Module (ECM)

12. Data Link Connector (DLC)

13. Malfunction Indicator Lamp (MIL)

14. ECM/ABS Harness Ground

15. Fuse Panel (2)

ECM Controlled Devices

20. Exhaust Gas Recirculation (EGR) Valve

21. Fuel Injector (4)

22. Main Throttle Idle Actuator (MTIA)

23. Fuel Pump Relay

24. Cooling Fan Relays (High)

25. Cooling Fan Control Relay (A/C Only)

26. Electronic Ignition System Ignition Coil

27. Evaporative Emission (EVAP) Control Purge Sole-

noid

28. Main Relay

29. A/C Compressor Relay30. Cooling Fan Relays (Low)

Information Sensors

31. Manifold Absolute Pressure (MAP) Sensor

32. Front Heated Oxygen Sensor (HO2S1)

33. Variable Geometry Induction System (VGIS) Sole-

noid

34. Engine Coolant Temperature (ECT) Sensor

35. Intake Air Temperature (IAT) Sensor

36. Vehicle Speed Sensor (VSS)

38. Crankshaft Position (CKP) Sensor

39. Knock Sensor

40. Rear Heated Oxygen Sensor (HO2S2)

41. Camshaft Position (CMP) Sensor

Not PCM/ECM Connected

42. Evaporative Emission Canister (under vehicle, be-

hind right rear wheel)

43. Engine Oil Pressure Switch

44. Air Cleaner