NUBIRA/LACETTI ROOF, BACK PANEL AND REAR FLOOR PANEL 5–11

3–2. REPAIR PROCEDURE

1. Remove the related parts.

S Parts to be removed when removing the back panel.

S Rear seat belt and rear seat.

S Muffler, fuel tank and related parts.

S Chassis parts.

S Other related parts.

CAUTION : Do not smoke while working near the

fuel system. Keep open flame away from the fuel

system. If necessary, remove the fuel tank and off

lines.

2. Roughly pull out and straighten the damaged area.

S Check the damage and roughly pull out and re pair the

related back panel, side panel, wheel house inner, rear

longitudinal and other damaged parts with the frame

straightener before remov ing the extension rear floor

panel, rear floor pane and back panel.

S Attach the car to the frame straightener by tightening the

underbody clamps located at the jack up designated

points on the bottom of the frame door opening.

Note : Measure in reference to the dimensions on the

body repair chart.

3. Cut and pry off the back panel.

S The back panel to be cut and pried off when removing

the back panel.

4. Cut and pry off the rear floor and extension rear floor

panel.

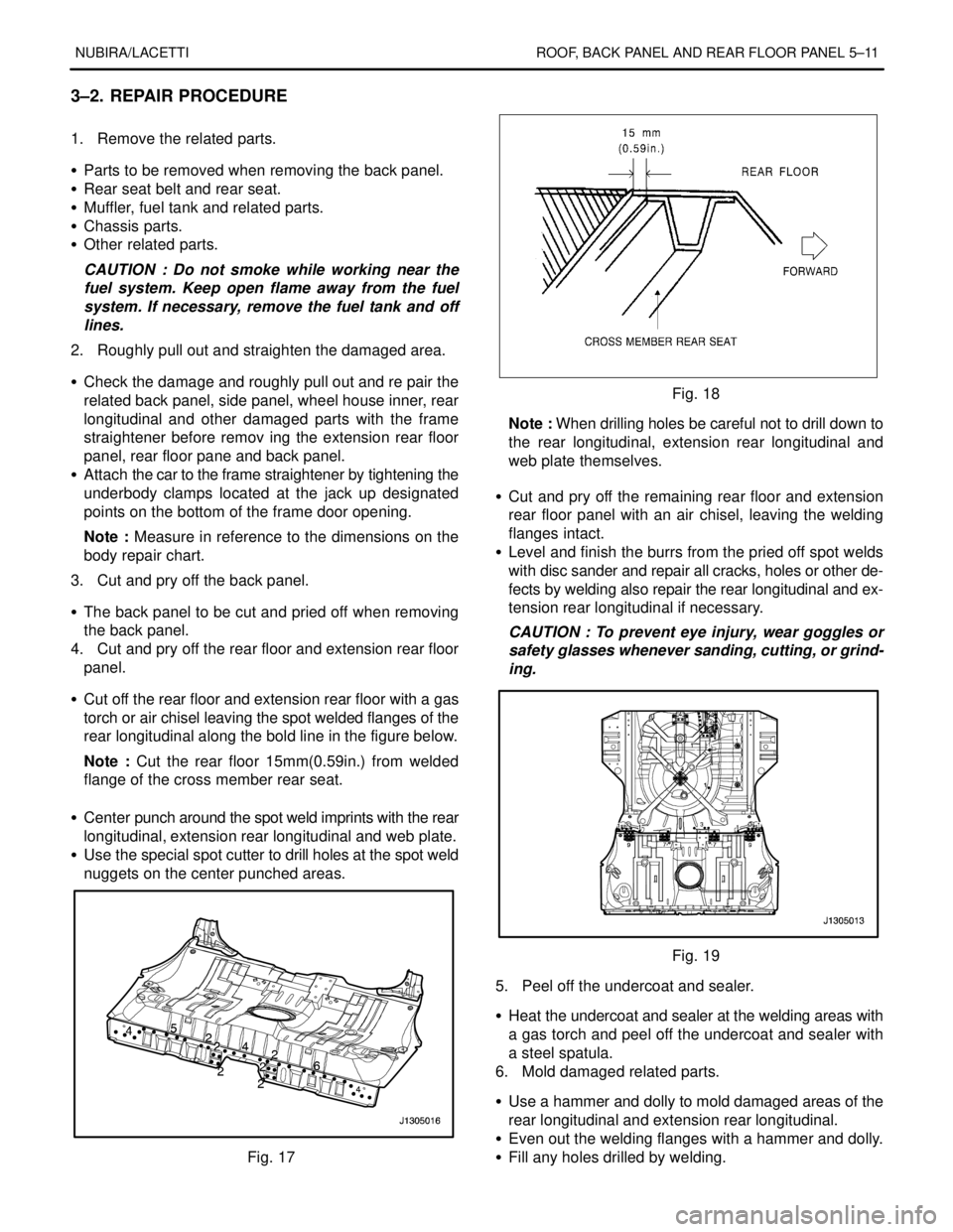

S Cut off the rear floor and extension rear floor with a gas

torch or air chisel leaving the spot welded flanges of the

rear longitudinal along the bold line in the figure below.

Note : Cut the rear floor 15mm(0.59in.) from welded

flange of the cross member rear seat.

S Center punch around the spot weld imprints with the rear

longitudinal, extension rear longitudinal and web plate.

S Use the special spot cutter to drill holes at the spot weld

nuggets on the center punched areas.

Fig. 17

Fig. 18

Note : When drilling holes be careful not to drill down to

the rear longitudinal, extension rear longitudinal and

web plate themselves.

S Cut and pry off the remaining rear floor and extension

rear floor panel with an air chisel, leaving the welding

flanges intact.

S Level and finish the burrs from the pried off spot welds

with disc sander and repair all cracks, holes or other de-

fects by welding also repair the rear longitudinal and ex-

tension rear longitudinal if necessary.

CAUTION : To prevent eye injury, wear goggles or

safety glasses whenever sanding, cutting, or grind-

ing.

Fig. 19

5. Peel off the undercoat and sealer.

S Heat the undercoat and sealer at the welding areas with

a gas torch and peel off the undercoat and sealer with

a steel spatula.

6. Mold damaged related parts.

S Use a hammer and dolly to mold damaged areas of the

rear longitudinal and extension rear longitudinal.

S Even out the welding flanges with a hammer and dolly.

S Fill any holes drilled by welding.