light DAEWOO LACETTI 2004 Service Service Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 312 of 2643

1F – 66IENGINE CONTROLS

DAEWOO V–121 BL4

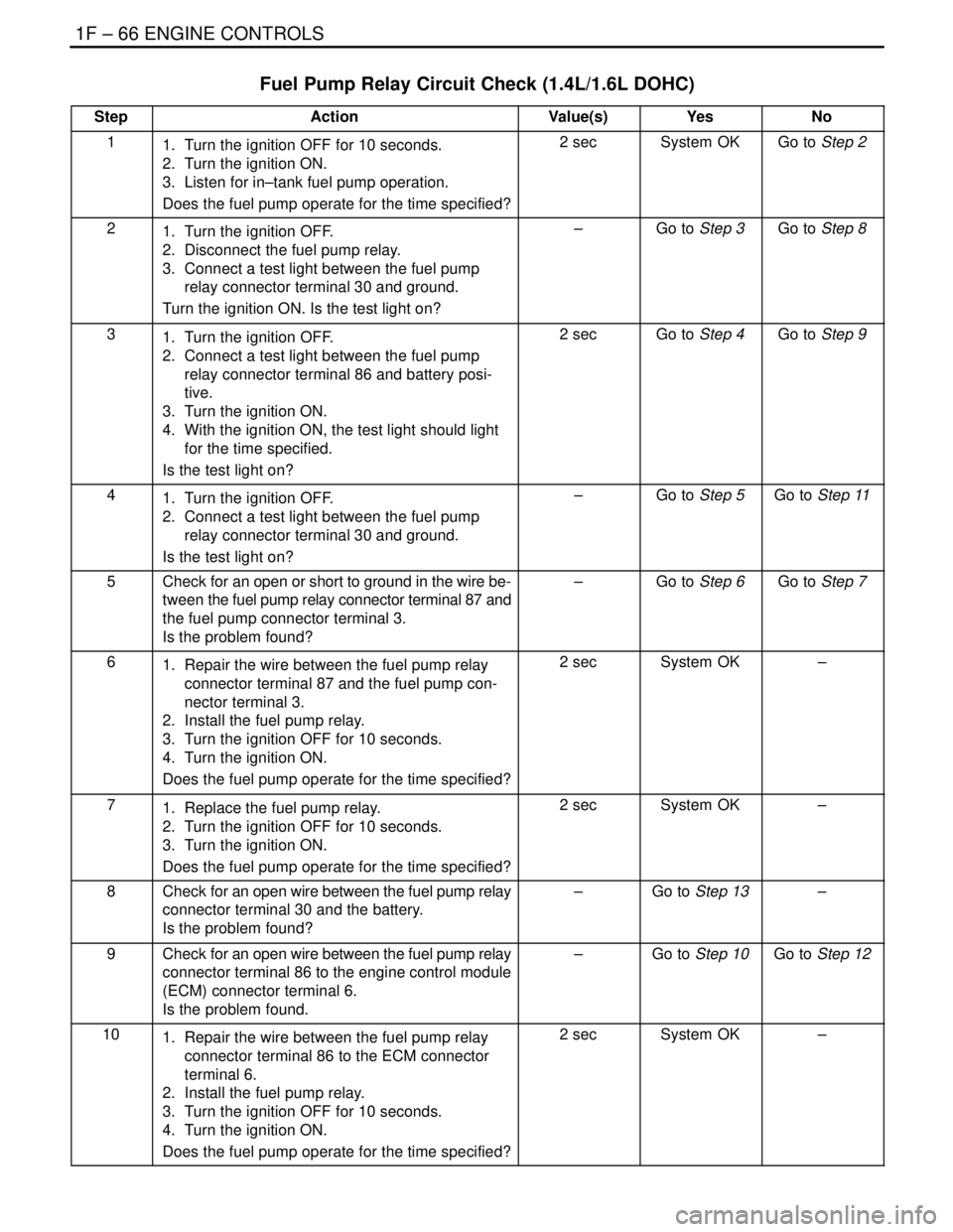

Fuel Pump Relay Circuit Check (1.4L/1.6L DOHC)

StepActionValue(s)YesNo

11. Turn the ignition OFF for 10 seconds.

2. Turn the ignition ON.

3. Listen for in–tank fuel pump operation.

Does the fuel pump operate for the time specified?2 secSystem OKGo to Step 2

21. Turn the ignition OFF.

2. Disconnect the fuel pump relay.

3. Connect a test light between the fuel pump

relay connector terminal 30 and ground.

Turn the ignition ON. Is the test light on?–Go to Step 3Go to Step 8

31. Turn the ignition OFF.

2. Connect a test light between the fuel pump

relay connector terminal 86 and battery posi-

tive.

3. Turn the ignition ON.

4. With the ignition ON, the test light should light

for the time specified.

Is the test light on?2 secGo to Step 4Go to Step 9

41. Turn the ignition OFF.

2. Connect a test light between the fuel pump

relay connector terminal 30 and ground.

Is the test light on?–Go to Step 5Go to Step 11

5Check for an open or short to ground in the wire be-

tween the fuel pump relay connector terminal 87 and

the fuel pump connector terminal 3.

Is the problem found?–Go to Step 6Go to Step 7

61. Repair the wire between the fuel pump relay

connector terminal 87 and the fuel pump con-

nector terminal 3.

2. Install the fuel pump relay.

3. Turn the ignition OFF for 10 seconds.

4. Turn the ignition ON.

Does the fuel pump operate for the time specified?2 secSystem OK–

71. Replace the fuel pump relay.

2. Turn the ignition OFF for 10 seconds.

3. Turn the ignition ON.

Does the fuel pump operate for the time specified?2 secSystem OK–

8Check for an open wire between the fuel pump relay

connector terminal 30 and the battery.

Is the problem found?–Go to Step 13–

9Check for an open wire between the fuel pump relay

connector terminal 86 to the engine control module

(ECM) connector terminal 6.

Is the problem found.–Go to Step 10Go to Step 12

101. Repair the wire between the fuel pump relay

connector terminal 86 to the ECM connector

terminal 6.

2. Install the fuel pump relay.

3. Turn the ignition OFF for 10 seconds.

4. Turn the ignition ON.

Does the fuel pump operate for the time specified?2 secSystem OK–

Page 315 of 2643

ENGINE CONTROLS 1F – 69

DAEWOO V–121 BL4

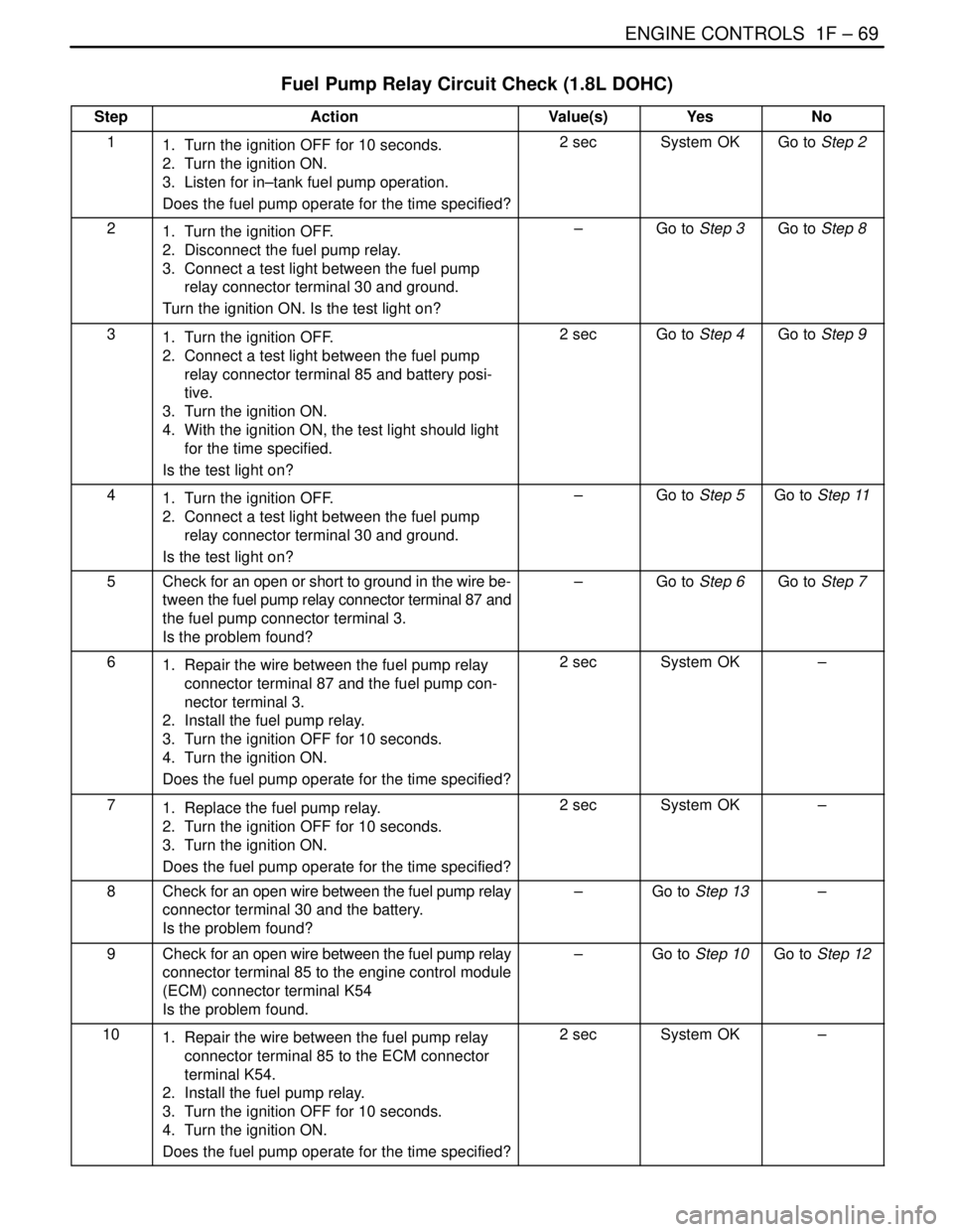

Fuel Pump Relay Circuit Check (1.8L DOHC)

StepActionValue(s)YesNo

11. Turn the ignition OFF for 10 seconds.

2. Turn the ignition ON.

3. Listen for in–tank fuel pump operation.

Does the fuel pump operate for the time specified?2 secSystem OKGo to Step 2

21. Turn the ignition OFF.

2. Disconnect the fuel pump relay.

3. Connect a test light between the fuel pump

relay connector terminal 30 and ground.

Turn the ignition ON. Is the test light on?–Go to Step 3Go to Step 8

31. Turn the ignition OFF.

2. Connect a test light between the fuel pump

relay connector terminal 85 and battery posi-

tive.

3. Turn the ignition ON.

4. With the ignition ON, the test light should light

for the time specified.

Is the test light on?2 secGo to Step 4Go to Step 9

41. Turn the ignition OFF.

2. Connect a test light between the fuel pump

relay connector terminal 30 and ground.

Is the test light on?–Go to Step 5Go to Step 11

5Check for an open or short to ground in the wire be-

tween the fuel pump relay connector terminal 87 and

the fuel pump connector terminal 3.

Is the problem found?–Go to Step 6Go to Step 7

61. Repair the wire between the fuel pump relay

connector terminal 87 and the fuel pump con-

nector terminal 3.

2. Install the fuel pump relay.

3. Turn the ignition OFF for 10 seconds.

4. Turn the ignition ON.

Does the fuel pump operate for the time specified?2 secSystem OK–

71. Replace the fuel pump relay.

2. Turn the ignition OFF for 10 seconds.

3. Turn the ignition ON.

Does the fuel pump operate for the time specified?2 secSystem OK–

8Check for an open wire between the fuel pump relay

connector terminal 30 and the battery.

Is the problem found?–Go to Step 13–

9Check for an open wire between the fuel pump relay

connector terminal 85 to the engine control module

(ECM) connector terminal K54

Is the problem found.–Go to Step 10Go to Step 12

101. Repair the wire between the fuel pump relay

connector terminal 85 to the ECM connector

terminal K54.

2. Install the fuel pump relay.

3. Turn the ignition OFF for 10 seconds.

4. Turn the ignition ON.

Does the fuel pump operate for the time specified?2 secSystem OK–

Page 317 of 2643

ENGINE CONTROLS 1F – 71

DAEWOO V–121 BL4

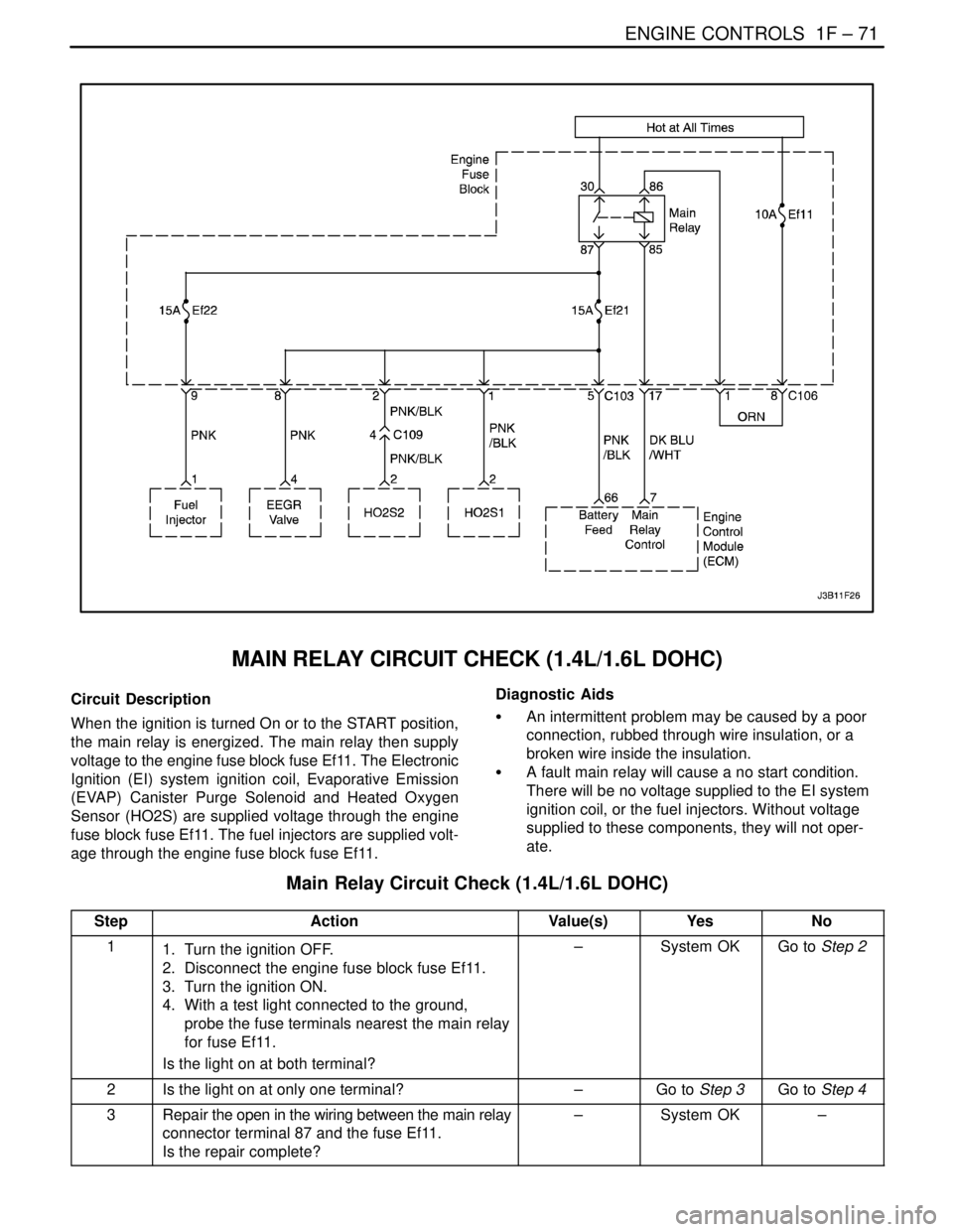

MAIN RELAY CIRCUIT CHECK (1.4L/1.6L DOHC)

Circuit Description

When the ignition is turned On or to the START position,

the main relay is energized. The main relay then supply

voltage to the engine fuse block fuse Ef11. The Electronic

Ignition (EI) system ignition coil, Evaporative Emission

(EVAP) Canister Purge Solenoid and Heated Oxygen

Sensor (HO2S) are supplied voltage through the engine

fuse block fuse Ef11. The fuel injectors are supplied volt-

age through the engine fuse block fuse Ef11.Diagnostic Aids

S An intermittent problem may be caused by a poor

connection, rubbed through wire insulation, or a

broken wire inside the insulation.

S A fault main relay will cause a no start condition.

There will be no voltage supplied to the EI system

ignition coil, or the fuel injectors. Without voltage

supplied to these components, they will not oper-

ate.

Main Relay Circuit Check (1.4L/1.6L DOHC)

StepActionValue(s)YesNo

11. Turn the ignition OFF.

2. Disconnect the engine fuse block fuse Ef11.

3. Turn the ignition ON.

4. With a test light connected to the ground,

probe the fuse terminals nearest the main relay

for fuse Ef11.

Is the light on at both terminal?–System OKGo to Step 2

2Is the light on at only one terminal?–Go to Step 3Go to Step 4

3Repair the open in the wiring between the main relay

connector terminal 87 and the fuse Ef11.

Is the repair complete?–System OK–

Page 318 of 2643

1F – 72IENGINE CONTROLS

DAEWOO V–121 BL4

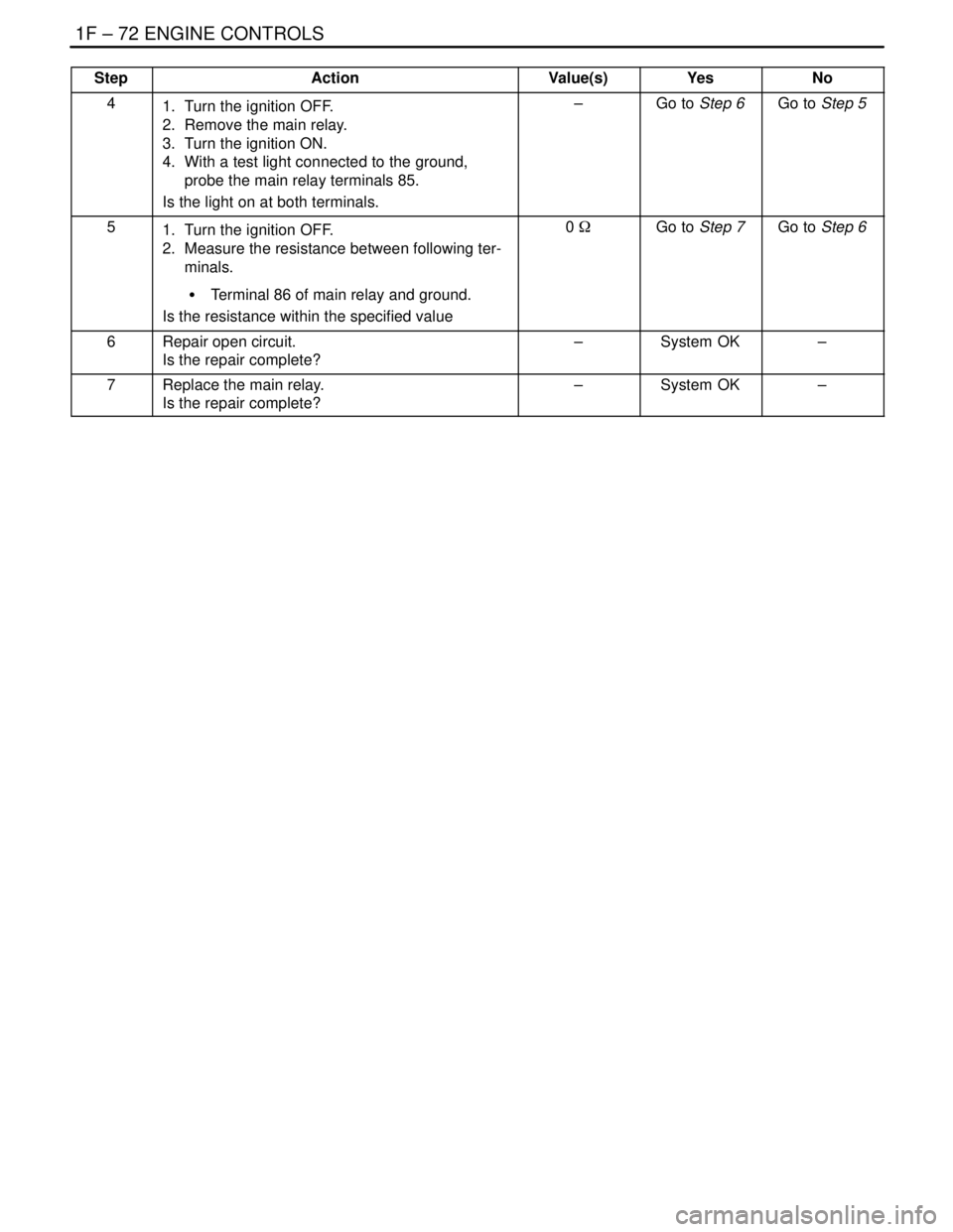

StepNo Yes Value(s) Action

41. Turn the ignition OFF.

2. Remove the main relay.

3. Turn the ignition ON.

4. With a test light connected to the ground,

probe the main relay terminals 85.

Is the light on at both terminals.–Go to Step 6Go to Step 5

51. Turn the ignition OFF.

2. Measure the resistance between following ter-

minals.

S Terminal 86 of main relay and ground.

Is the resistance within the specified value0 WGo to Step 7Go to Step 6

6Repair open circuit.

Is the repair complete?–System OK–

7Replace the main relay.

Is the repair complete?–System OK–

Page 319 of 2643

ENGINE CONTROLS 1F – 73

DAEWOO V–121 BL4

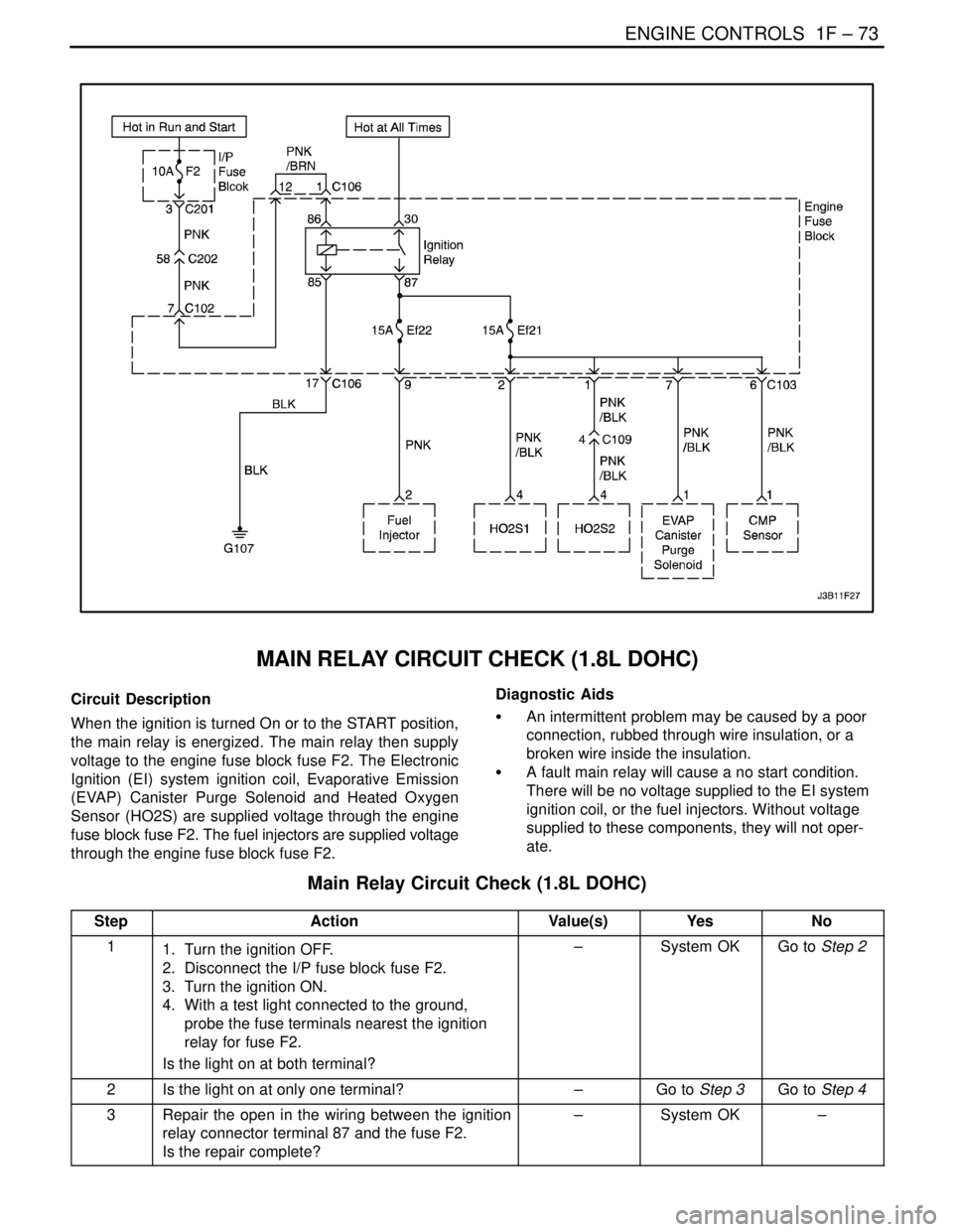

MAIN RELAY CIRCUIT CHECK (1.8L DOHC)

Circuit Description

When the ignition is turned On or to the START position,

the main relay is energized. The main relay then supply

voltage to the engine fuse block fuse F2. The Electronic

Ignition (EI) system ignition coil, Evaporative Emission

(EVAP) Canister Purge Solenoid and Heated Oxygen

Sensor (HO2S) are supplied voltage through the engine

fuse block fuse F2. The fuel injectors are supplied voltage

through the engine fuse block fuse F2.Diagnostic Aids

S An intermittent problem may be caused by a poor

connection, rubbed through wire insulation, or a

broken wire inside the insulation.

S A fault main relay will cause a no start condition.

There will be no voltage supplied to the EI system

ignition coil, or the fuel injectors. Without voltage

supplied to these components, they will not oper-

ate.

Main Relay Circuit Check (1.8L DOHC)

StepActionValue(s)YesNo

11. Turn the ignition OFF.

2. Disconnect the I/P fuse block fuse F2.

3. Turn the ignition ON.

4. With a test light connected to the ground,

probe the fuse terminals nearest the ignition

relay for fuse F2.

Is the light on at both terminal?–System OKGo to Step 2

2Is the light on at only one terminal?–Go to Step 3Go to Step 4

3Repair the open in the wiring between the ignition

relay connector terminal 87 and the fuse F2.

Is the repair complete?–System OK–

Page 320 of 2643

1F – 74IENGINE CONTROLS

DAEWOO V–121 BL4

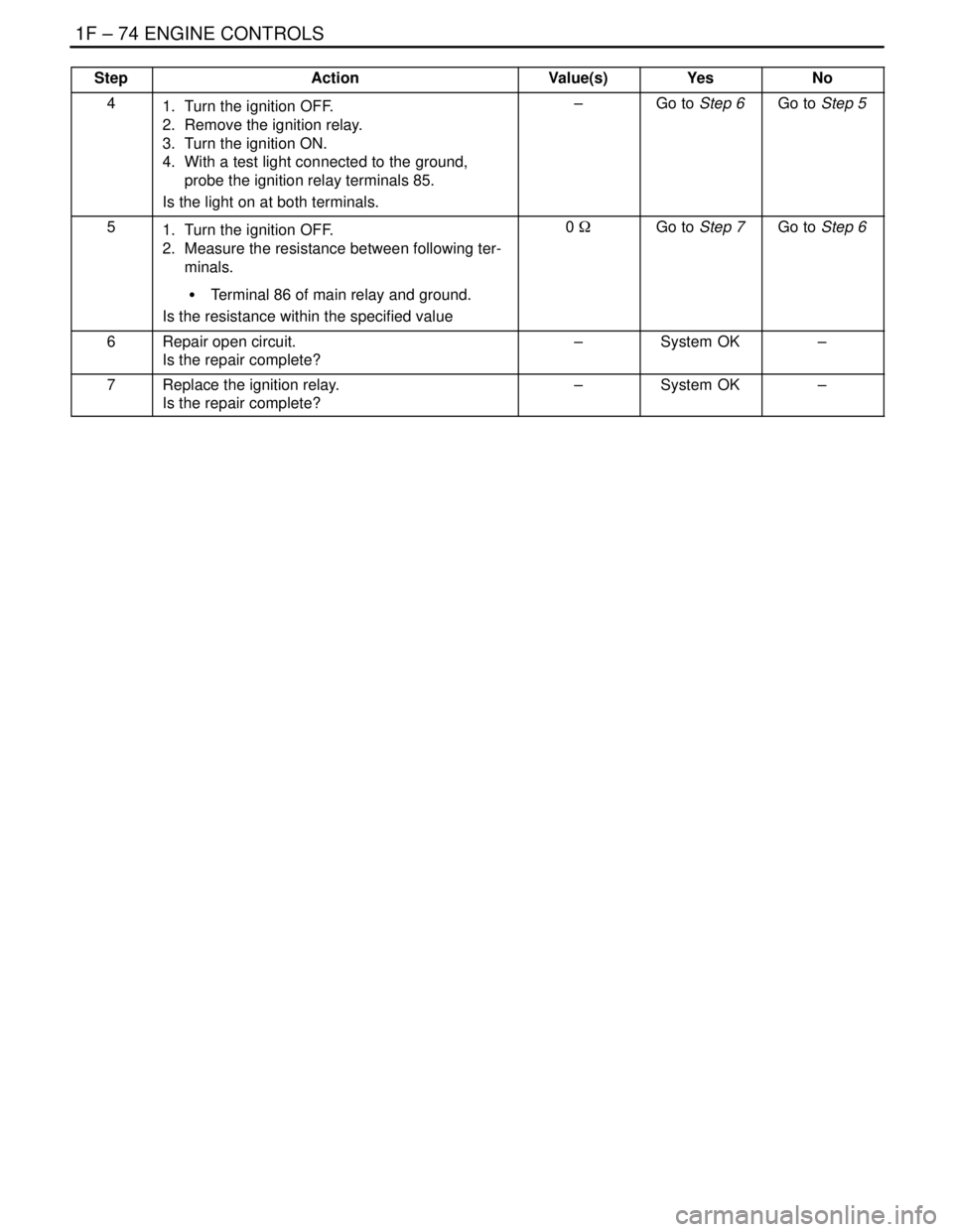

StepNo Yes Value(s) Action

41. Turn the ignition OFF.

2. Remove the ignition relay.

3. Turn the ignition ON.

4. With a test light connected to the ground,

probe the ignition relay terminals 85.

Is the light on at both terminals.–Go to Step 6Go to Step 5

51. Turn the ignition OFF.

2. Measure the resistance between following ter-

minals.

S Terminal 86 of main relay and ground.

Is the resistance within the specified value0 WGo to Step 7Go to Step 6

6Repair open circuit.

Is the repair complete?–System OK–

7Replace the ignition relay.

Is the repair complete?–System OK–

Page 333 of 2643

ENGINE CONTROLS 1F – 87

DAEWOO V–121 BL4

StepNo Yes Value(s) Action

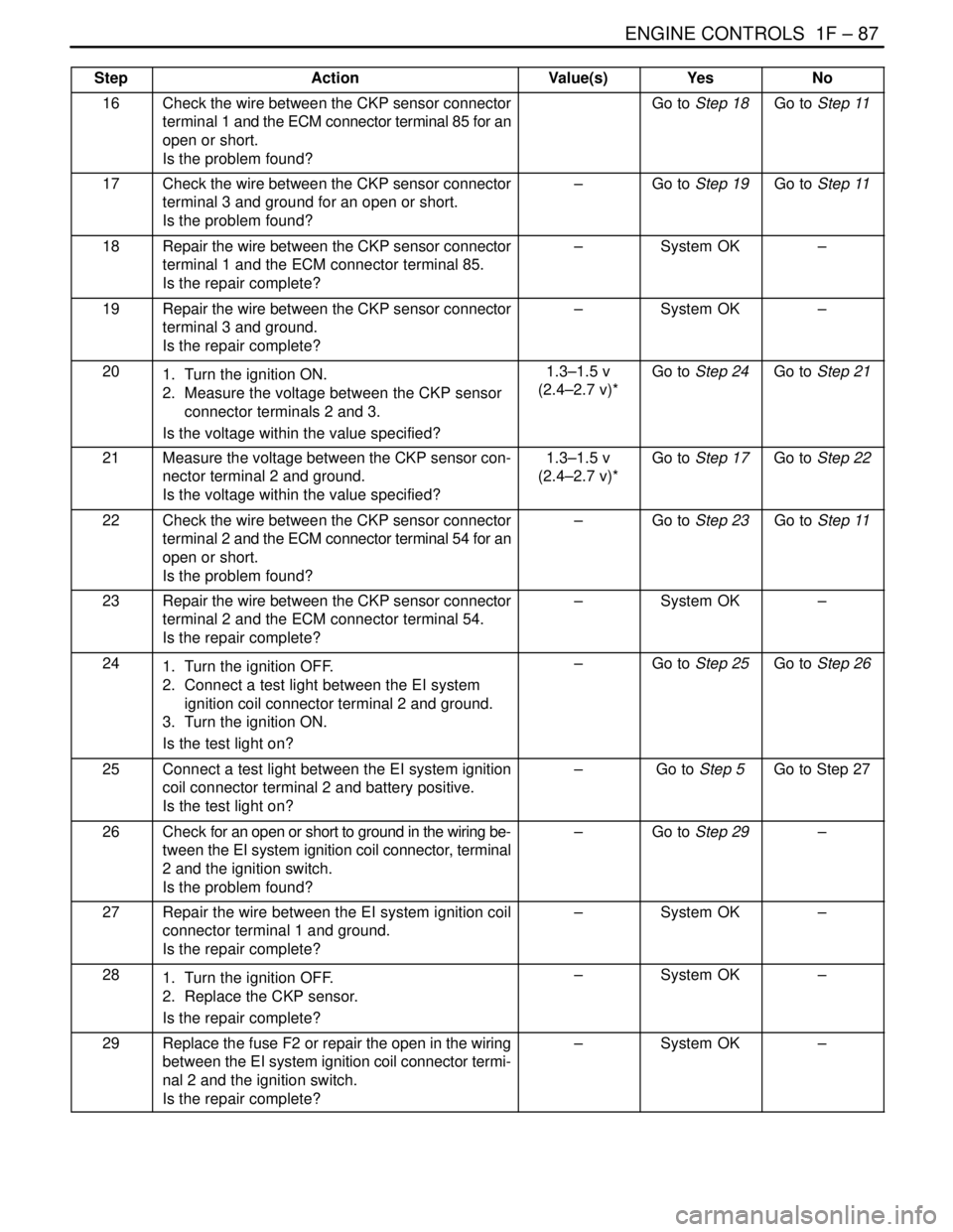

16Check the wire between the CKP sensor connector

terminal 1 and the ECM connector terminal 85 for an

open or short.

Is the problem found?Go to Step 18Go to Step 11

17Check the wire between the CKP sensor connector

terminal 3 and ground for an open or short.

Is the problem found?–Go to Step 19Go to Step 11

18Repair the wire between the CKP sensor connector

terminal 1 and the ECM connector terminal 85.

Is the repair complete?–System OK–

19Repair the wire between the CKP sensor connector

terminal 3 and ground.

Is the repair complete?–System OK–

201. Turn the ignition ON.

2. Measure the voltage between the CKP sensor

connector terminals 2 and 3.

Is the voltage within the value specified?1.3–1.5 v

(2.4–2.7 v)*Go to Step 24Go to Step 21

21Measure the voltage between the CKP sensor con-

nector terminal 2 and ground.

Is the voltage within the value specified?1.3–1.5 v

(2.4–2.7 v)*Go to Step 17Go to Step 22

22Check the wire between the CKP sensor connector

terminal 2 and the ECM connector terminal 54 for an

open or short.

Is the problem found?–Go to Step 23Go to Step 11

23Repair the wire between the CKP sensor connector

terminal 2 and the ECM connector terminal 54.

Is the repair complete?–System OK–

241. Turn the ignition OFF.

2. Connect a test light between the EI system

ignition coil connector terminal 2 and ground.

3. Turn the ignition ON.

Is the test light on?–Go to Step 25Go to Step 26

25Connect a test light between the EI system ignition

coil connector terminal 2 and battery positive.

Is the test light on?–Go to Step 5Go to Step 27

26Check for an open or short to ground in the wiring be-

tween the EI system ignition coil connector, terminal

2 and the ignition switch.

Is the problem found?–Go to Step 29–

27Repair the wire between the EI system ignition coil

connector terminal 1 and ground.

Is the repair complete?–System OK–

281. Turn the ignition OFF.

2. Replace the CKP sensor.

Is the repair complete?–System OK–

29Replace the fuse F2 or repair the open in the wiring

between the EI system ignition coil connector termi-

nal 2 and the ignition switch.

Is the repair complete?–System OK–

Page 337 of 2643

ENGINE CONTROLS 1F – 91

DAEWOO V–121 BL4

StepNo Yes Value(s) Action

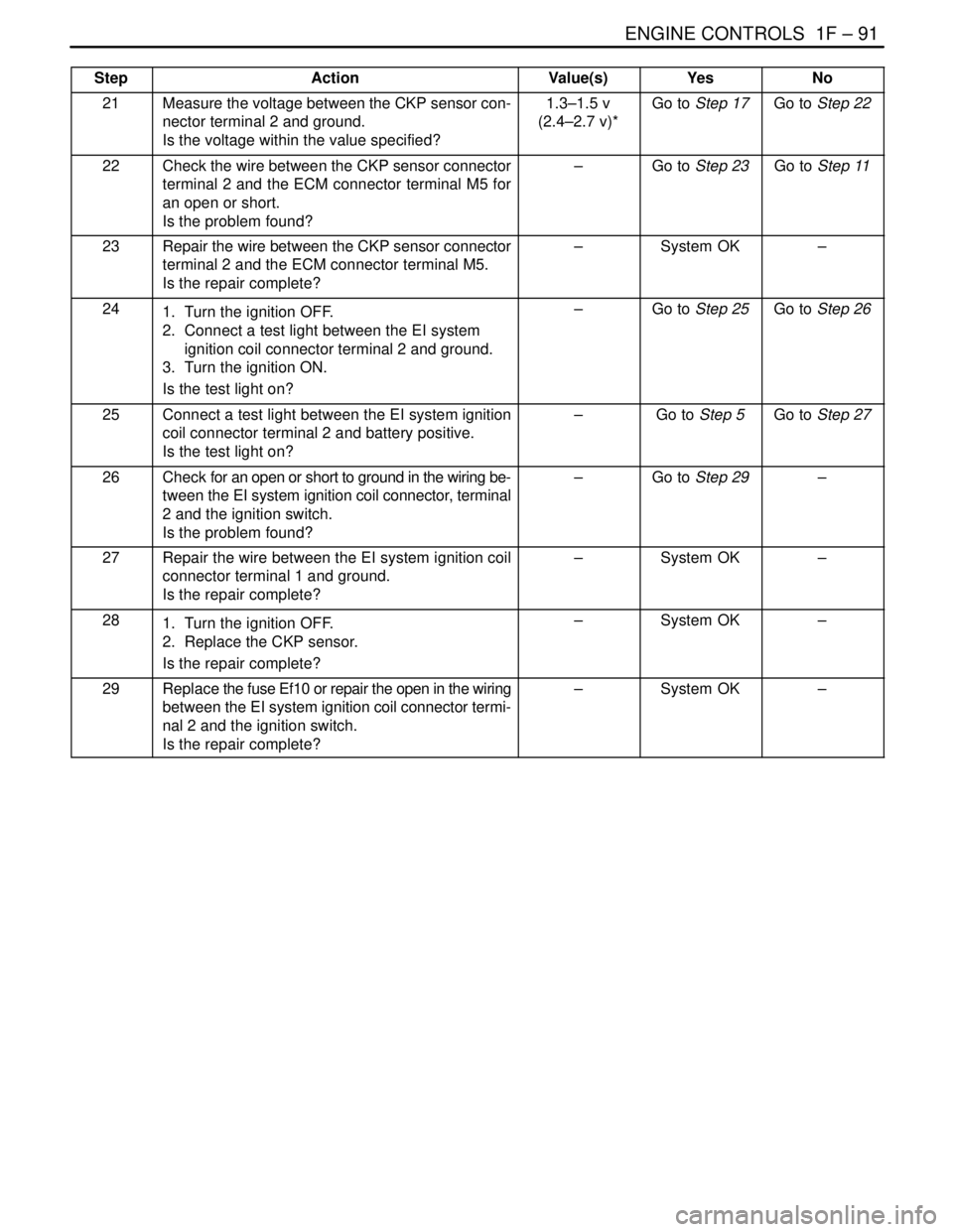

21Measure the voltage between the CKP sensor con-

nector terminal 2 and ground.

Is the voltage within the value specified?1.3–1.5 v

(2.4–2.7 v)*Go to Step 17Go to Step 22

22Check the wire between the CKP sensor connector

terminal 2 and the ECM connector terminal M5 for

an open or short.

Is the problem found?–Go to Step 23Go to Step 11

23Repair the wire between the CKP sensor connector

terminal 2 and the ECM connector terminal M5.

Is the repair complete?–System OK–

241. Turn the ignition OFF.

2. Connect a test light between the EI system

ignition coil connector terminal 2 and ground.

3. Turn the ignition ON.

Is the test light on?–Go to Step 25Go to Step 26

25Connect a test light between the EI system ignition

coil connector terminal 2 and battery positive.

Is the test light on?–Go to Step 5Go to Step 27

26Check for an open or short to ground in the wiring be-

tween the EI system ignition coil connector, terminal

2 and the ignition switch.

Is the problem found?–Go to Step 29–

27Repair the wire between the EI system ignition coil

connector terminal 1 and ground.

Is the repair complete?–System OK–

281. Turn the ignition OFF.

2. Replace the CKP sensor.

Is the repair complete?–System OK–

29Replace the fuse Ef10 or repair the open in the wiring

between the EI system ignition coil connector termi-

nal 2 and the ignition switch.

Is the repair complete?–System OK–

Page 340 of 2643

1F – 94IENGINE CONTROLS

DAEWOO V–121 BL4

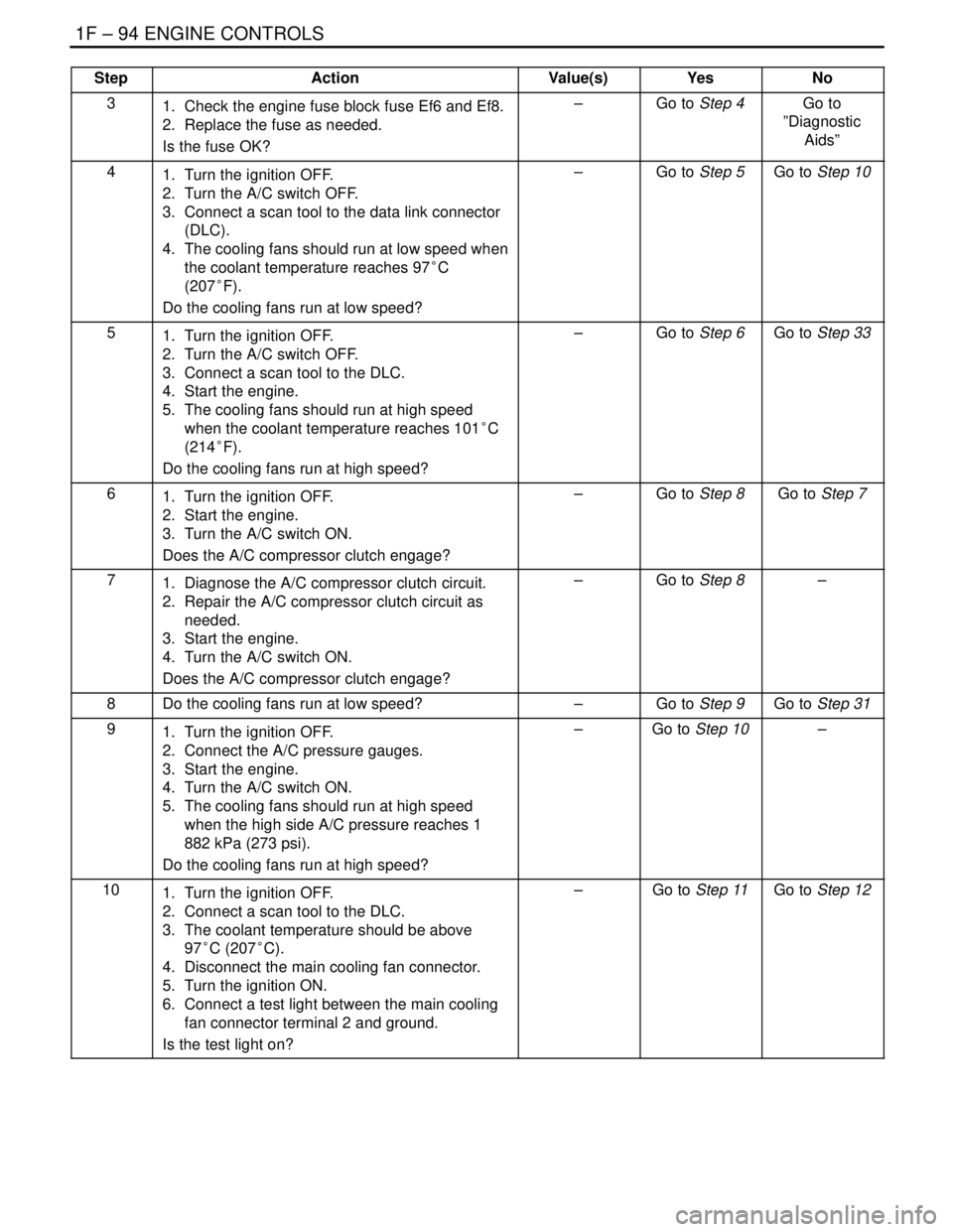

StepNo Yes Value(s) Action

31. Check the engine fuse block fuse Ef6 and Ef8.

2. Replace the fuse as needed.

Is the fuse OK?–Go to Step 4Go to

”Diagnostic

Aids”

41. Turn the ignition OFF.

2. Turn the A/C switch OFF.

3. Connect a scan tool to the data link connector

(DLC).

4. The cooling fans should run at low speed when

the coolant temperature reaches 97°C

(207°F).

Do the cooling fans run at low speed?–Go to Step 5Go to Step 10

51. Turn the ignition OFF.

2. Turn the A/C switch OFF.

3. Connect a scan tool to the DLC.

4. Start the engine.

5. The cooling fans should run at high speed

when the coolant temperature reaches 101°C

(214°F).

Do the cooling fans run at high speed?–Go to Step 6Go to Step 33

61. Turn the ignition OFF.

2. Start the engine.

3. Turn the A/C switch ON.

Does the A/C compressor clutch engage?–Go to Step 8Go to Step 7

71. Diagnose the A/C compressor clutch circuit.

2. Repair the A/C compressor clutch circuit as

needed.

3. Start the engine.

4. Turn the A/C switch ON.

Does the A/C compressor clutch engage?–Go to Step 8–

8Do the cooling fans run at low speed?–Go to Step 9Go to Step 31

91. Turn the ignition OFF.

2. Connect the A/C pressure gauges.

3. Start the engine.

4. Turn the A/C switch ON.

5. The cooling fans should run at high speed

when the high side A/C pressure reaches 1

882 kPa (273 psi).

Do the cooling fans run at high speed?–Go to Step 10–

101. Turn the ignition OFF.

2. Connect a scan tool to the DLC.

3. The coolant temperature should be above

97°C (207°C).

4. Disconnect the main cooling fan connector.

5. Turn the ignition ON.

6. Connect a test light between the main cooling

fan connector terminal 2 and ground.

Is the test light on?–Go to Step 11Go to Step 12

Page 341 of 2643

ENGINE CONTROLS 1F – 95

DAEWOO V–121 BL4

StepNo Yes Value(s) Action

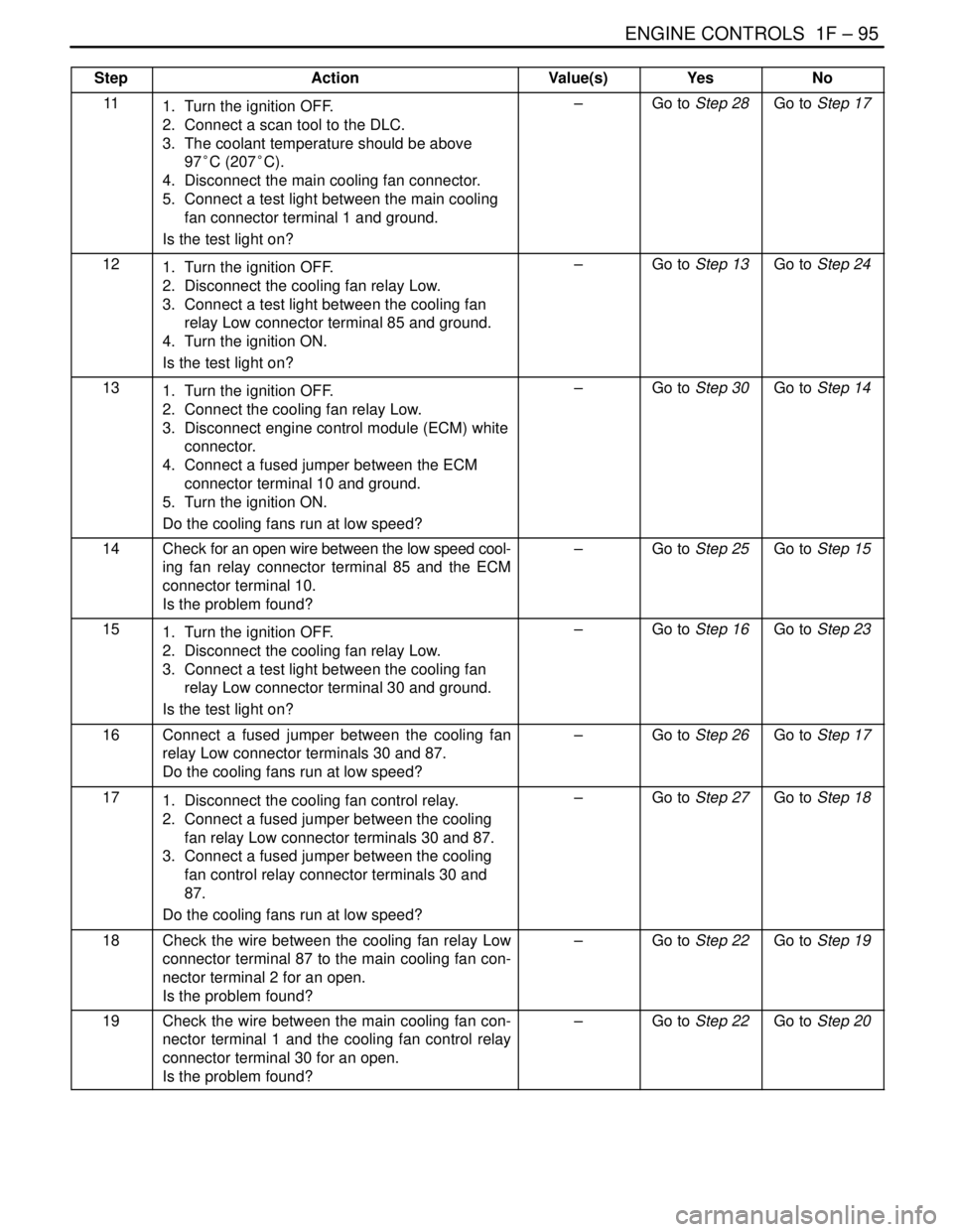

111. Turn the ignition OFF.

2. Connect a scan tool to the DLC.

3. The coolant temperature should be above

97°C (207°C).

4. Disconnect the main cooling fan connector.

5. Connect a test light between the main cooling

fan connector terminal 1 and ground.

Is the test light on?–Go to Step 28Go to Step 17

121. Turn the ignition OFF.

2. Disconnect the cooling fan relay Low.

3. Connect a test light between the cooling fan

relay Low connector terminal 85 and ground.

4. Turn the ignition ON.

Is the test light on?–Go to Step 13Go to Step 24

131. Turn the ignition OFF.

2. Connect the cooling fan relay Low.

3. Disconnect engine control module (ECM) white

connector.

4. Connect a fused jumper between the ECM

connector terminal 10 and ground.

5. Turn the ignition ON.

Do the cooling fans run at low speed?–Go to Step 30Go to Step 14

14Check for an open wire between the low speed cool-

ing fan relay connector terminal 85 and the ECM

connector terminal 10.

Is the problem found?–Go to Step 25Go to Step 15

151. Turn the ignition OFF.

2. Disconnect the cooling fan relay Low.

3. Connect a test light between the cooling fan

relay Low connector terminal 30 and ground.

Is the test light on?–Go to Step 16Go to Step 23

16Connect a fused jumper between the cooling fan

relay Low connector terminals 30 and 87.

Do the cooling fans run at low speed?–Go to Step 26Go to Step 17

171. Disconnect the cooling fan control relay.

2. Connect a fused jumper between the cooling

fan relay Low connector terminals 30 and 87.

3. Connect a fused jumper between the cooling

fan control relay connector terminals 30 and

87.

Do the cooling fans run at low speed?–Go to Step 27Go to Step 18

18Check the wire between the cooling fan relay Low

connector terminal 87 to the main cooling fan con-

nector terminal 2 for an open.

Is the problem found?–Go to Step 22Go to Step 19

19Check the wire between the main cooling fan con-

nector terminal 1 and the cooling fan control relay

connector terminal 30 for an open.

Is the problem found?–Go to Step 22Go to Step 20