Section 5 DAEWOO LACETTI 2004 Service Repair Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 2091 of 2643

7D – 36IAUTOMATIC TEMPERATURE CONTROL HEATING, VENTILATION, AND AIR CONDITIONING SYSTEM

DAEWOO V–121 BL4

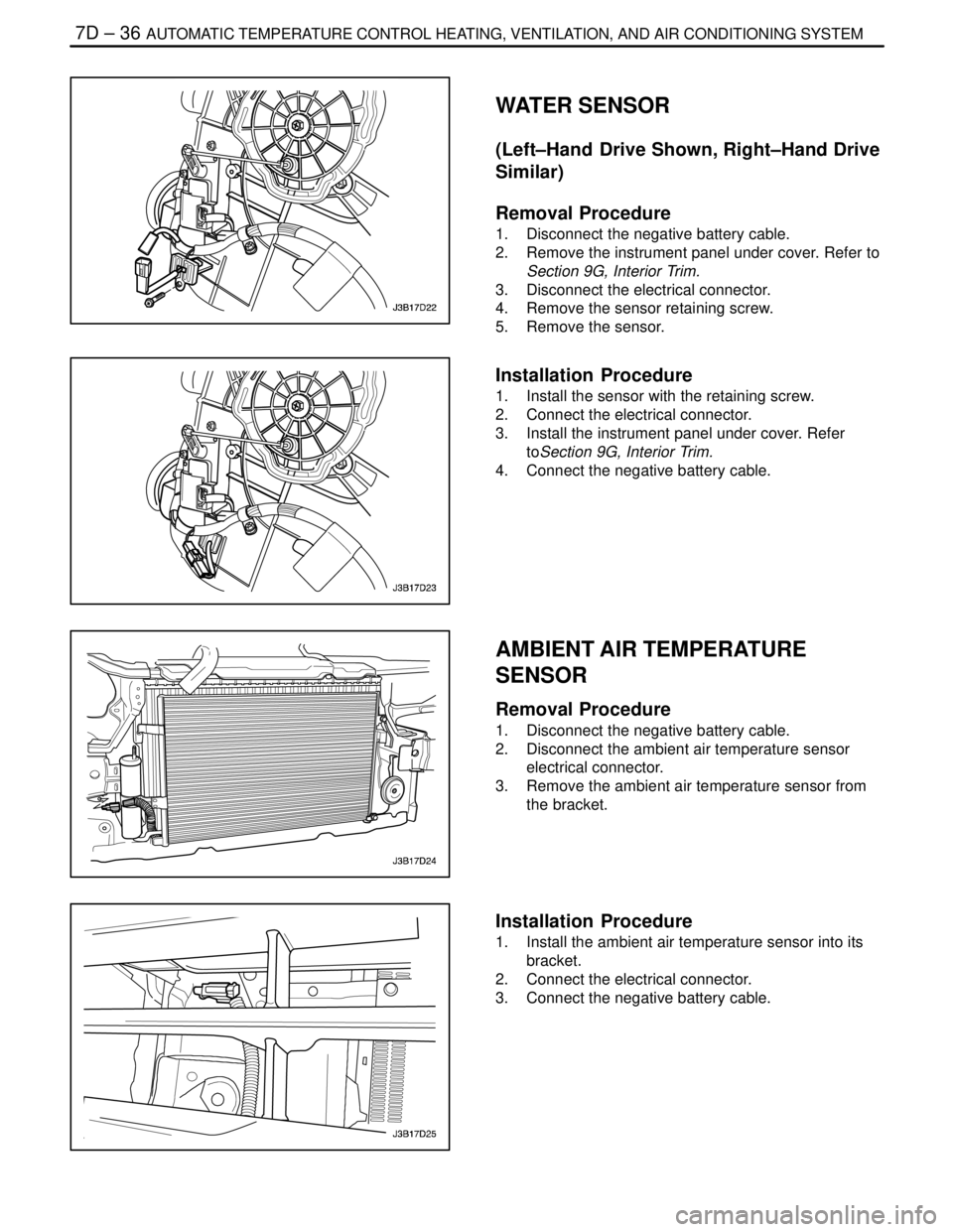

WATER SENSOR

(Left–Hand Drive Shown, Right–Hand Drive

Similar)

Removal Procedure

1. Disconnect the negative battery cable.

2. Remove the instrument panel under cover. Refer to

Section 9G, Interior Trim.

3. Disconnect the electrical connector.

4. Remove the sensor retaining screw.

5. Remove the sensor.

Installation Procedure

1. Install the sensor with the retaining screw.

2. Connect the electrical connector.

3. Install the instrument panel under cover. Refer

toSection 9G, Interior Trim.

4. Connect the negative battery cable.

AMBIENT AIR TEMPERATURE

SENSOR

Removal Procedure

1. Disconnect the negative battery cable.

2. Disconnect the ambient air temperature sensor

electrical connector.

3. Remove the ambient air temperature sensor from

the bracket.

Installation Procedure

1. Install the ambient air temperature sensor into its

bracket.

2. Connect the electrical connector.

3. Connect the negative battery cable.

Page 2092 of 2643

IAUTOMATIC TEMPERATURE CONTROL HEATING, VENTILATION, AND AIR CONDITIONING SYSTEM 7D – 37

DAEWOO V–121 BL4

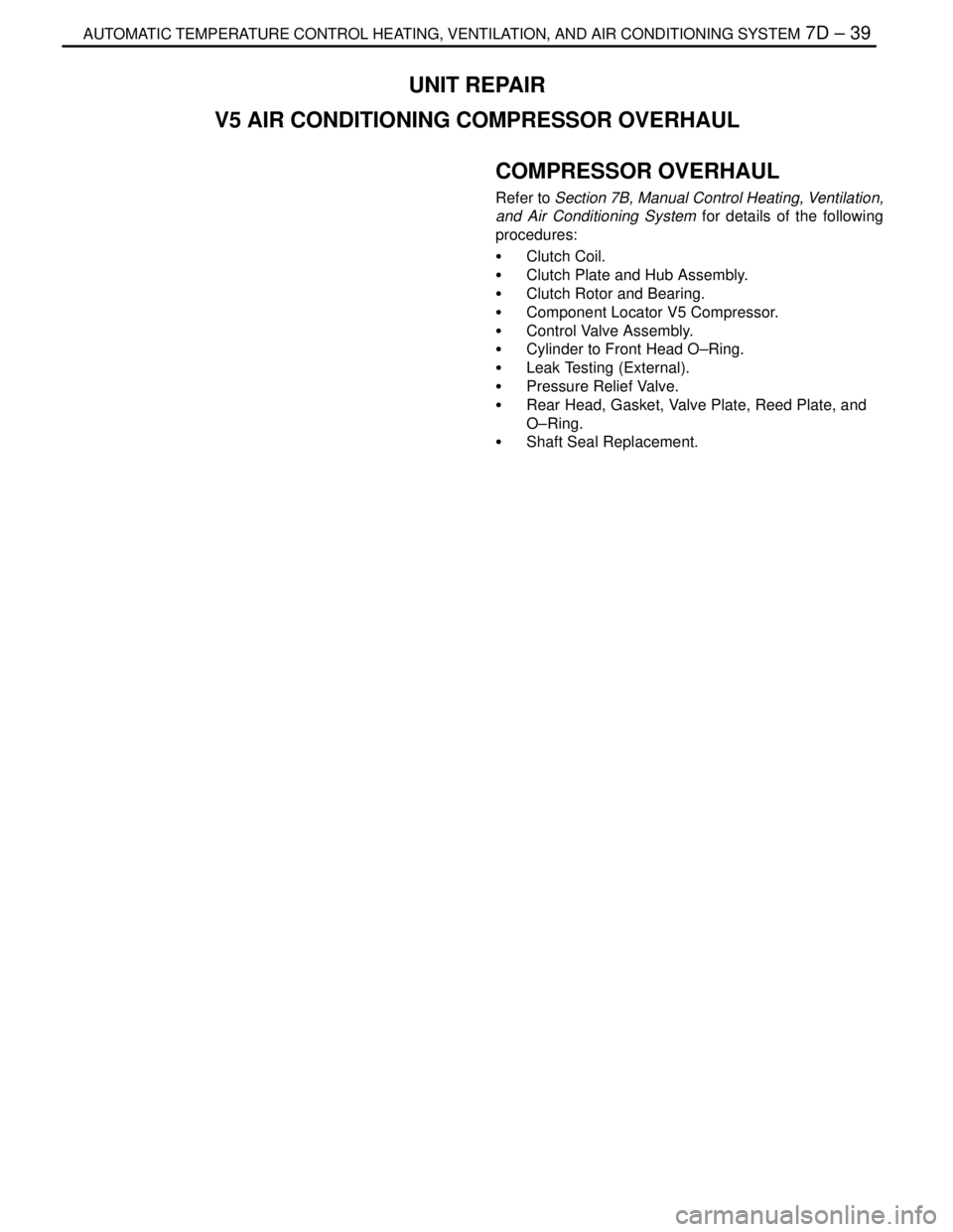

IN–CAR TEMPERATURE SENSOR

Removal Procedure

1. Disconnect the negative battery cable.

2. Remove the instrument panel under cover. Refer to

Section 9G, Interior Trim.

3. Disconnect the electrical connector.

4. Remove the tube by turning it clockwise.

5. Remove the screws.

6. Remove the in–car sensor with the tube.

Installation Procedure

1. Install the in–car sensor.

2. Install the in–car sensor retaining screws and tight-

en.

3. Install the air inlet tube and connect the electrical

connector.

4. Install the instrument panel under cover. Refer to

Section 9G, Interior Trim.

5. Connect the battery negative cable.

SUN SENSOR

Removal Procedure

1. Disconnect the negative battery cable.

2. Gently pry up on the sun sensor to remove it.

3. Secure the electrical connector to prevent it from

falling beneath the dash.

4. Disconnect the electrical connector and remove the

sun sensor.

Page 2094 of 2643

IAUTOMATIC TEMPERATURE CONTROL HEATING, VENTILATION, AND AIR CONDITIONING SYSTEM 7D – 39

DAEWOO V–121 BL4

UNIT REPAIR

V5 AIR CONDITIONING COMPRESSOR OVERHAUL

COMPRESSOR OVERHAUL

Refer to Section 7B, Manual Control Heating, Ventilation,

and Air Conditioning System for details of the following

procedures:

S Clutch Coil.

S Clutch Plate and Hub Assembly.

S Clutch Rotor and Bearing.

S Component Locator V5 Compressor.

S Control Valve Assembly.

S Cylinder to Front Head O–Ring.

S Leak Testing (External).

S Pressure Relief Valve.

S Rear Head, Gasket, Valve Plate, Reed Plate, and

O–Ring.

S Shaft Seal Replacement.

Page 2095 of 2643

7D – 40IAUTOMATIC TEMPERATURE CONTROL HEATING, VENTILATION, AND AIR CONDITIONING SYSTEM

DAEWOO V–121 BL4

GENERAL DESCRIPTION

AND SYSTEM OPERATION

GENERAL INFORMATION

THE V5 SYSTEM

Refer to Section 7B, Manual Control Heating, Ventilation,

and Air Conditioning System,for general information de-

tails for the following:

S System Components – Functional.

S The V5 A/C System.

S V5 Compressor – Description of Operation.

S V5 Compressor – General Description.

SYSTEM COMPONENTS–CONTROL

Controller

The operation of the A/C system is controlled by the

switches on the control head. This console–mounted

heating and ventilation system contains the following

knobs and display:

Temperature Control Push Knobs

1. Raise the temperature of the air entering the ve-

hicle by pressing the top switch, with the red arrow

pointing upward.

2. Lower the temperature by pressing the bottom

switch, with the blue arrow pointing downward.

3. Actuate the air mix door by an electric motor.

4. Vary the mix of the air passing through the heater

core with the air bypassing the core.

Each press of a switch changes the set temperature by in-

crements of 0.5°C (1°F). This is shown in the temperature

window on the function display.

The Function Display

This is an LCD display indicating the status of the control

settings selected. Starting from the left end of the display,

the sections are as follows:

1. Temperature setting – Indicates the temperature set

with the temperature control knob.

2. Auto status – Indicates whether the system is oper-

ating in the full auto mode or the manual mode.

3. Defroster icon – Indicates manual selection of full

defrost mode.

4. Mode – Indicated by icon, the mode chosen by the

system in auto (or by the operator in manual) is

shown by an illumination arrow indicating the air

path.

5. A/C – A snowflake icon indicating whether the A/C

is ON or OFF.

6. Fan speed – Indicates the fan speed by illuminating

a bar based on the segment at the front, for low

speed, and adding additional segments in order up

to the fifth, for high speed.Eight Additional Push Knobs

1. Full defrost – Causes the mode motors to direct all

air to the windshield and aide window outlets for

maximum defrosting.

2. Air intake – Switches between fresh air intake, the

default, and recirculating air. Airflow arrows on the

display indicate the mode in effect.

3. Full Auto Switch – Maintains the set temperature

automatically. In this mode, the fully automatic tem-

perature control (FATC) system controls the follow-

ing:

S The air mix door motor.

S The mode door motor.

S The blower motor speed.

S The inlet air door motor.

S A/C ON/OFF.

4. OFF Switch – Turns the automatic air conditioning

and fan control off.

5. Mode Switch – Allows manual selection of the air-

flow direction.

S Selection is shown on the function display.

S Each time the mode switch is pressed, the next

function is displayed.

6. A/C Switch – Allows manual selection and control

of the air conditioning function.

7. Fan Control Switch – Allows manual selection

among five fan speeds.

8. Defogger Switch – Turns on the electric defogging

heater in the rear window and the outside rearview

mirrors, if the vehicle is equipped with heated mir-

rors.

Pressure Transducer

Pressure transducer switching incorporates the functions

of the high–pressure and the low–pressure cutout

switches along with the fan cycling switch. The pressure

transducer is located in the high–side liquid refrigerant line

behind the right strut tower, between the right strut tower

and the fire wall. The output from this pressure transducer

goes to the electronic control module (ECM), which con-

trols the compressor function based on the pressure sig-

nal.

Wide–Open Throttle (WOT) Compressor

Cutoff

During full–throttle acceleration, the throttle position sen-

sor (TPS) sends a signal to the ECM, which then controls

the compressor clutch.

High RPM Cutoff

As engine rpm approaches the maximum limit, the ECM

will disengage the compressor clutch until the engine

slows to a lower rpm.

Page 2096 of 2643

SECTION : 8A

SEAT BELTS

CAUTION : Disconnect the negative battery cable before removing or installing any electrical unit or when a tool

or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help

prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise noted.

TABLE OF CONTENTS

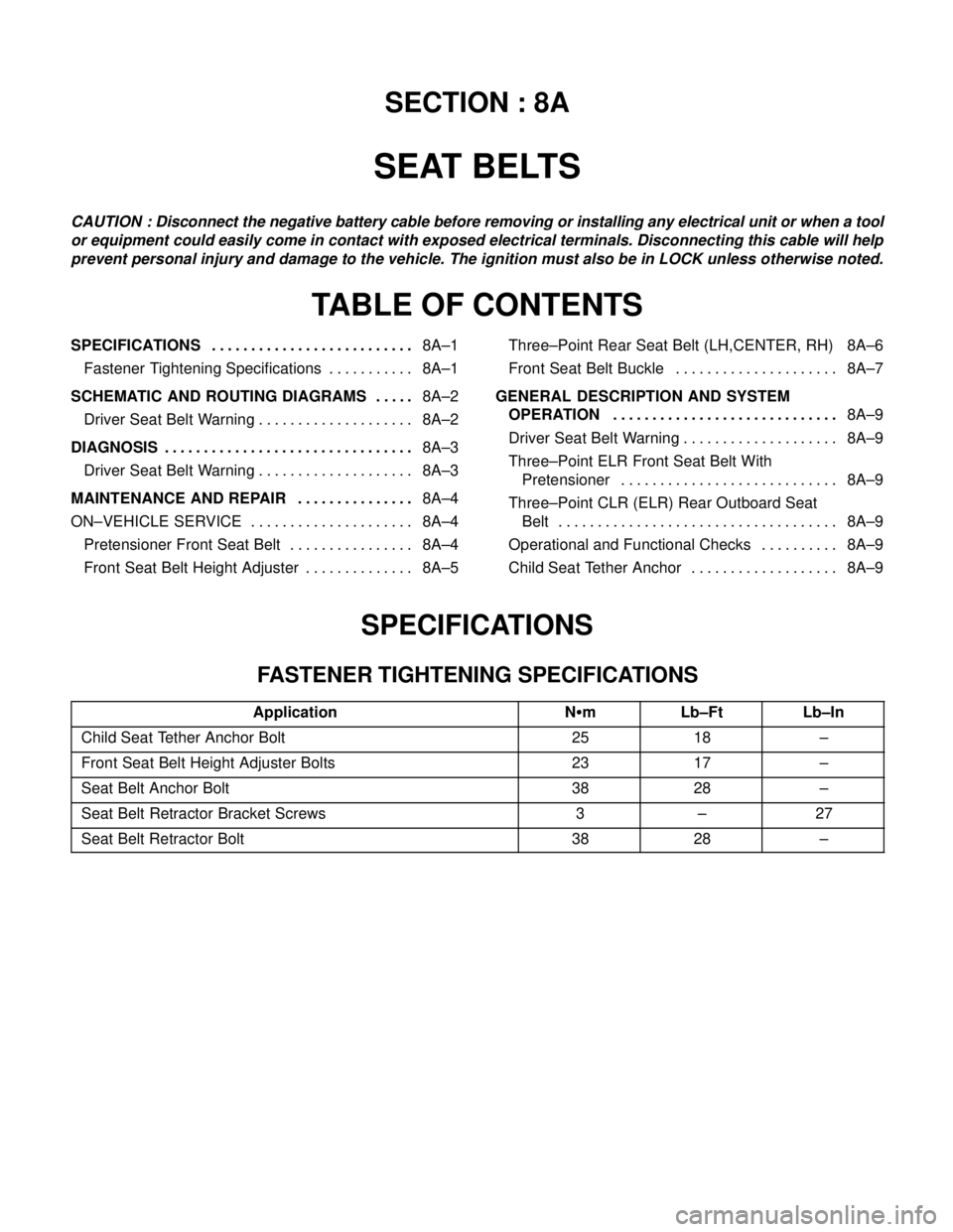

SPECIFICATIONS8A–1 . . . . . . . . . . . . . . . . . . . . . . . . . .

Fastener Tightening Specifications 8A–1. . . . . . . . . . .

SCHEMATIC AND ROUTING DIAGRAMS8A–2 . . . . .

Driver Seat Belt Warning 8A–2. . . . . . . . . . . . . . . . . . . .

DIAGNOSIS8A–3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Driver Seat Belt Warning 8A–3. . . . . . . . . . . . . . . . . . . .

MAINTENANCE AND REPAIR8A–4 . . . . . . . . . . . . . . .

ON–VEHICLE SERVICE 8A–4. . . . . . . . . . . . . . . . . . . . .

Pretensioner Front Seat Belt 8A–4. . . . . . . . . . . . . . . .

Front Seat Belt Height Adjuster 8A–5. . . . . . . . . . . . . . Three–Point Rear Seat Belt (LH,CENTER, RH) 8A–6

Front Seat Belt Buckle 8A–7. . . . . . . . . . . . . . . . . . . . .

GENERAL DESCRIPTION AND SYSTEM

OPERATION 8A–9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Driver Seat Belt Warning 8A–9. . . . . . . . . . . . . . . . . . . .

Three–Point ELR Front Seat Belt With

Pretensioner 8A–9. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Three–Point CLR (ELR) Rear Outboard Seat

Belt 8A–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operational and Functional Checks 8A–9. . . . . . . . . .

Child Seat Tether Anchor 8A–9. . . . . . . . . . . . . . . . . . .

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

ApplicationNSmLb–FtLb–In

Child Seat Tether Anchor Bolt2518–

Front Seat Belt Height Adjuster Bolts2317–

Seat Belt Anchor Bolt3828–

Seat Belt Retractor Bracket Screws3–27

Seat Belt Retractor Bolt3828–

Page 2100 of 2643

SEAT BELTS 8A – 5

DAEWOO V–121 BL4

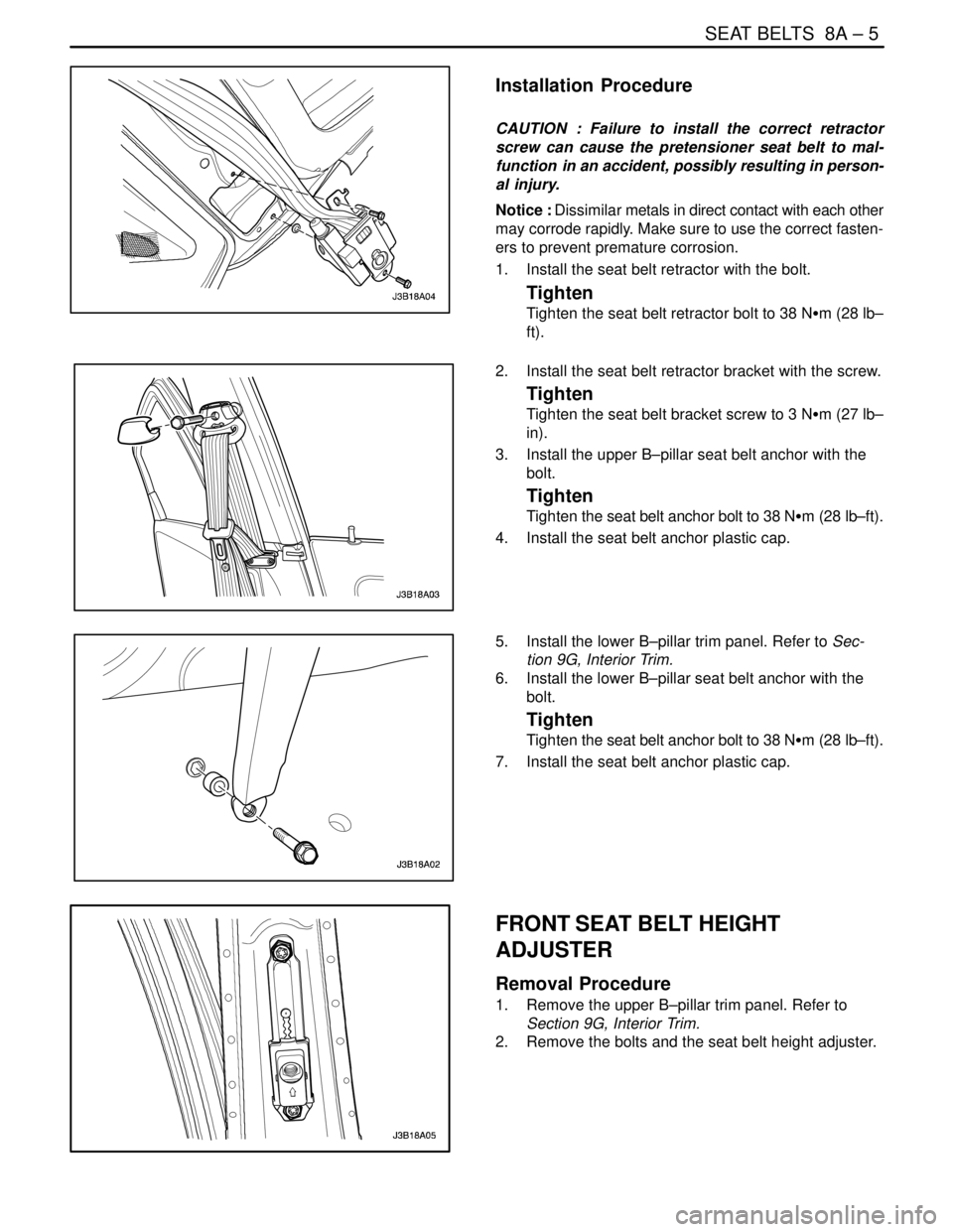

Installation Procedure

CAUTION : Failure to install the correct retractor

screw can cause the pretensioner seat belt to mal-

function in an accident, possibly resulting in person-

al injury.

Notice : Dissimilar metals in direct contact with each other

may corrode rapidly. Make sure to use the correct fasten-

ers to prevent premature corrosion.

1. Install the seat belt retractor with the bolt.

Tighten

Tighten the seat belt retractor bolt to 38 NSm (28 lb–

ft).

2. Install the seat belt retractor bracket with the screw.

Tighten

Tighten the seat belt bracket screw to 3 NSm (27 lb–

in).

3. Install the upper B–pillar seat belt anchor with the

bolt.

Tighten

Tighten the seat belt anchor bolt to 38 NSm (28 lb–ft).

4. Install the seat belt anchor plastic cap.

5. Install the lower B–pillar trim panel. Refer to Sec-

tion 9G, Interior Trim.

6. Install the lower B–pillar seat belt anchor with the

bolt.

Tighten

Tighten the seat belt anchor bolt to 38 NSm (28 lb–ft).

7. Install the seat belt anchor plastic cap.

FRONT SEAT BELT HEIGHT

ADJUSTER

Removal Procedure

1. Remove the upper B–pillar trim panel. Refer to

Section 9G, Interior Trim.

2. Remove the bolts and the seat belt height adjuster.

Page 2101 of 2643

8A – 6ISEAT BELTS

DAEWOO V–121 BL4

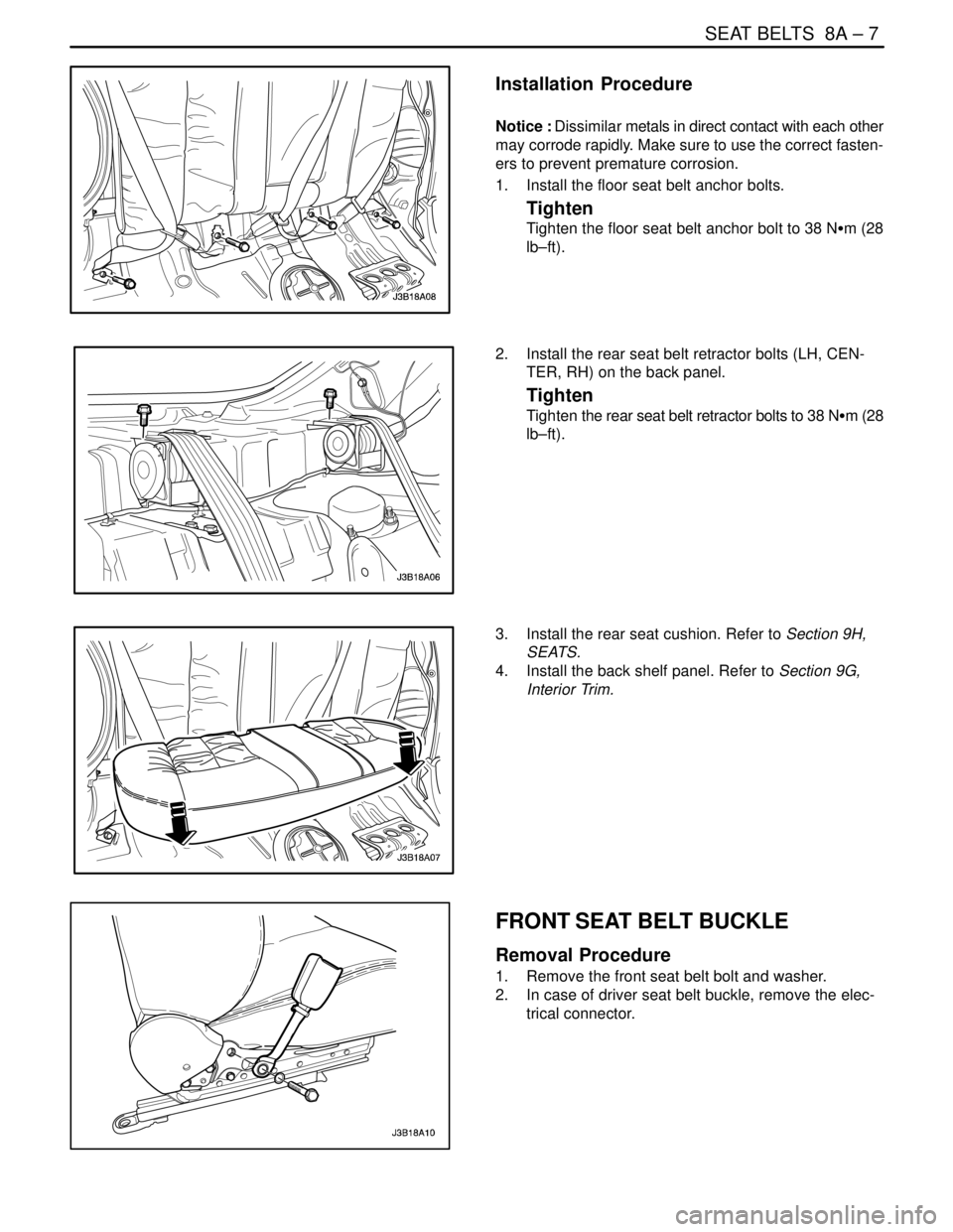

Installation Procedure

Notice : Dissimilar metals in direct contact with each other

may corrode rapidly. Make sure to use the correct fasten-

ers to prevent premature corrosion.

1. Install the seat belt height adjuster with the bolts.

Tighten

Tighten the front seat belt height adjuster bolts to 23

NSm (17 lb–ft).

2. Install the upper B–pillar trim panel. Refer to Sec-

tion 9G, Interior Trim.

THREE–POINT REAR SEAT BELT

(LH,CENTER, RH)

Removal Procedure

1. Remove the back shelf panel. Refer to Section 9G,

Interior Trim.

2. Remove the rear seat belt retractor securing bolts

(LH, CENTER, RH) from the back panel.

3. Remove the rear seat cushion. Refer to Section 9H,

SEATS.

4. Remove the floor seat belt anchor bolts.

5. Remove the seat belt.

Page 2102 of 2643

SEAT BELTS 8A – 7

DAEWOO V–121 BL4

Installation Procedure

Notice : Dissimilar metals in direct contact with each other

may corrode rapidly. Make sure to use the correct fasten-

ers to prevent premature corrosion.

1. Install the floor seat belt anchor bolts.

Tighten

Tighten the floor seat belt anchor bolt to 38 NSm (28

lb–ft).

2. Install the rear seat belt retractor bolts (LH, CEN-

TER, RH) on the back panel.

Tighten

Tighten the rear seat belt retractor bolts to 38 NSm (28

lb–ft).

3. Install the rear seat cushion. Refer to Section 9H,

SEATS.

4. Install the back shelf panel. Refer to Section 9G,

Interior Trim.

FRONT SEAT BELT BUCKLE

Removal Procedure

1. Remove the front seat belt bolt and washer.

2. In case of driver seat belt buckle, remove the elec-

trical connector.

Page 2105 of 2643

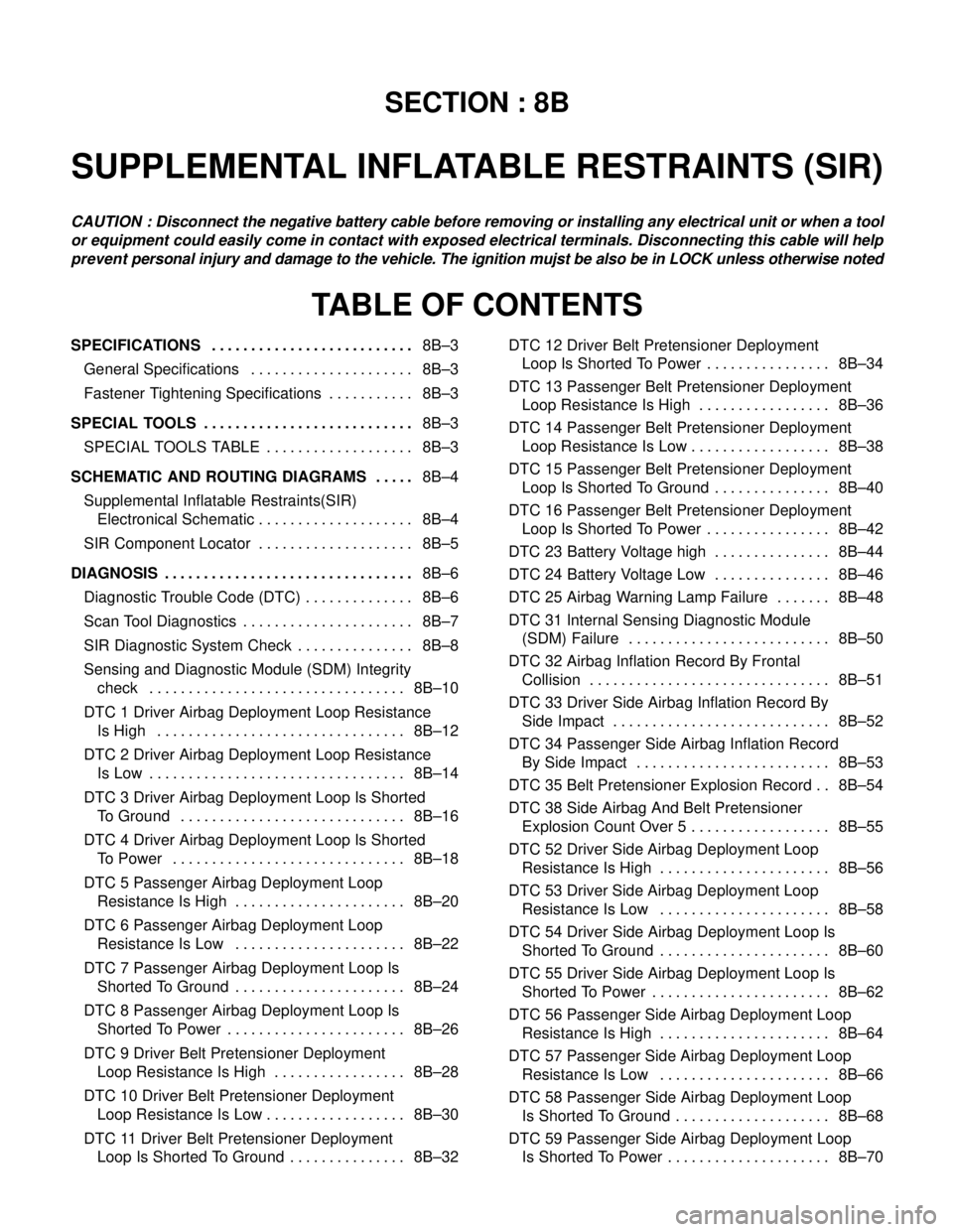

SECTION : 8B

SUPPLEMENTAL INFLATABLE RESTRAINTS (SIR)

CAUTION : Disconnect the negative battery cable before removing or installing any electrical unit or when a tool

or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help

prevent personal injury and damage to the vehicle. The ignition mujst be also be in LOCK unless otherwise noted

TABLE OF CONTENTS

SPECIFICATIONS8B–3 . . . . . . . . . . . . . . . . . . . . . . . . . .

General Specifications 8B–3. . . . . . . . . . . . . . . . . . . . .

Fastener Tightening Specifications 8B–3. . . . . . . . . . .

SPECIAL TOOLS8B–3 . . . . . . . . . . . . . . . . . . . . . . . . . . .

SPECIAL TOOLS TABLE 8B–3. . . . . . . . . . . . . . . . . . .

SCHEMATIC AND ROUTING DIAGRAMS8B–4 . . . . .

Supplemental Inflatable Restraints(SIR)

Electronical Schematic 8B–4. . . . . . . . . . . . . . . . . . . .

SIR Component Locator 8B–5. . . . . . . . . . . . . . . . . . . .

DIAGNOSIS8B–6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) 8B–6. . . . . . . . . . . . . .

Scan Tool Diagnostics 8B–7. . . . . . . . . . . . . . . . . . . . . .

SIR Diagnostic System Check 8B–8. . . . . . . . . . . . . . .

Sensing and Diagnostic Module (SDM) Integrity

check 8B–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC 1 Driver Airbag Deployment Loop Resistance

Is High 8B–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC 2 Driver Airbag Deployment Loop Resistance

Is Low 8B–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC 3 Driver Airbag Deployment Loop Is Shorted

To Ground 8B–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC 4 Driver Airbag Deployment Loop Is Shorted

To Power 8B–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC 5 Passenger Airbag Deployment Loop

Resistance Is High 8B–20. . . . . . . . . . . . . . . . . . . . . .

DTC 6 Passenger Airbag Deployment Loop

Resistance Is Low 8B–22. . . . . . . . . . . . . . . . . . . . . .

DTC 7 Passenger Airbag Deployment Loop Is

Shorted To Ground 8B–24. . . . . . . . . . . . . . . . . . . . . .

DTC 8 Passenger Airbag Deployment Loop Is

Shorted To Power 8B–26. . . . . . . . . . . . . . . . . . . . . . .

DTC 9 Driver Belt Pretensioner Deployment

Loop Resistance Is High 8B–28. . . . . . . . . . . . . . . . .

DTC 10 Driver Belt Pretensioner Deployment

Loop Resistance Is Low 8B–30. . . . . . . . . . . . . . . . . .

DTC 11 Driver Belt Pretensioner Deployment

Loop Is Shorted To Ground 8B–32. . . . . . . . . . . . . . . DTC 12 Driver Belt Pretensioner Deployment

Loop Is Shorted To Power 8B–34. . . . . . . . . . . . . . . .

DTC 13 Passenger Belt Pretensioner Deployment

Loop Resistance Is High 8B–36. . . . . . . . . . . . . . . . .

DTC 14 Passenger Belt Pretensioner Deployment

Loop Resistance Is Low 8B–38. . . . . . . . . . . . . . . . . .

DTC 15 Passenger Belt Pretensioner Deployment

Loop Is Shorted To Ground 8B–40. . . . . . . . . . . . . . .

DTC 16 Passenger Belt Pretensioner Deployment

Loop Is Shorted To Power 8B–42. . . . . . . . . . . . . . . .

DTC 23 Battery Voltage high 8B–44. . . . . . . . . . . . . . .

DTC 24 Battery Voltage Low 8B–46. . . . . . . . . . . . . . .

DTC 25 Airbag Warning Lamp Failure 8B–48. . . . . . .

DTC 31 Internal Sensing Diagnostic Module

(SDM) Failure 8B–50. . . . . . . . . . . . . . . . . . . . . . . . . .

DTC 32 Airbag Inflation Record By Frontal

Collision 8B–51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC 33 Driver Side Airbag Inflation Record By

Side Impact 8B–52. . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC 34 Passenger Side Airbag Inflation Record

By Side Impact 8B–53. . . . . . . . . . . . . . . . . . . . . . . . .

DTC 35 Belt Pretensioner Explosion Record 8B–54. .

DTC 38 Side Airbag And Belt Pretensioner

Explosion Count Over 5 8B–55. . . . . . . . . . . . . . . . . .

DTC 52 Driver Side Airbag Deployment Loop

Resistance Is High 8B–56. . . . . . . . . . . . . . . . . . . . . .

DTC 53 Driver Side Airbag Deployment Loop

Resistance Is Low 8B–58. . . . . . . . . . . . . . . . . . . . . .

DTC 54 Driver Side Airbag Deployment Loop Is

Shorted To Ground 8B–60. . . . . . . . . . . . . . . . . . . . . .

DTC 55 Driver Side Airbag Deployment Loop Is

Shorted To Power 8B–62. . . . . . . . . . . . . . . . . . . . . . .

DTC 56 Passenger Side Airbag Deployment Loop

Resistance Is High 8B–64. . . . . . . . . . . . . . . . . . . . . .

DTC 57 Passenger Side Airbag Deployment Loop

Resistance Is Low 8B–66. . . . . . . . . . . . . . . . . . . . . .

DTC 58 Passenger Side Airbag Deployment Loop

Is Shorted To Ground 8B–68. . . . . . . . . . . . . . . . . . . .

DTC 59 Passenger Side Airbag Deployment Loop

Is Shorted To Power 8B–70. . . . . . . . . . . . . . . . . . . . .

Page 2112 of 2643

8B – 8ISUPPLEMENTAL INFLATABLE RESTRAINTS (SIR)

DAEWOO V–121 BL4

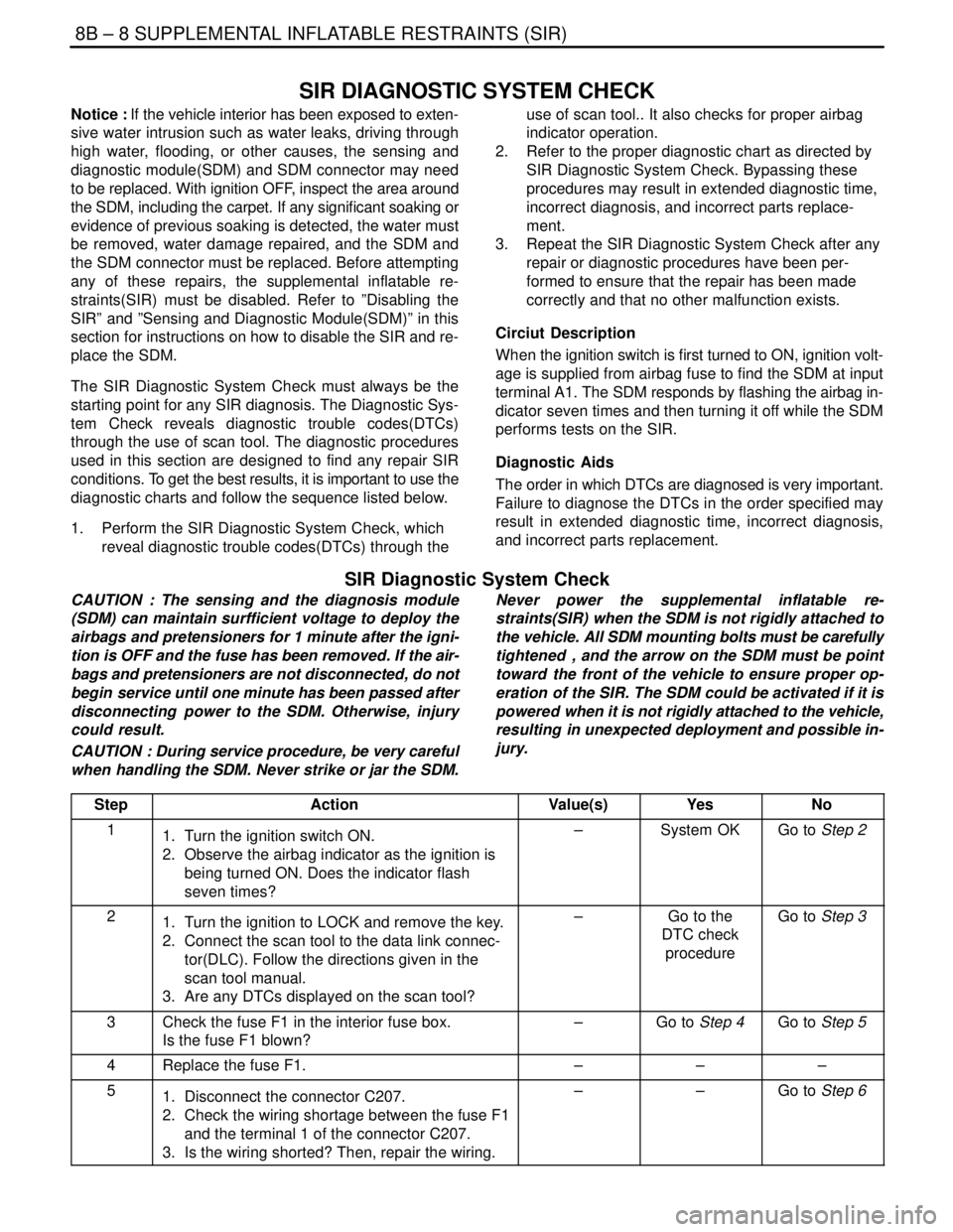

SIR DIAGNOSTIC SYSTEM CHECK

Notice : If the vehicle interior has been exposed to exten-

sive water intrusion such as water leaks, driving through

high water, flooding, or other causes, the sensing and

diagnostic module(SDM) and SDM connector may need

to be replaced. With ignition OFF, inspect the area around

the SDM, including the carpet. If any significant soaking or

evidence of previous soaking is detected, the water must

be removed, water damage repaired, and the SDM and

the SDM connector must be replaced. Before attempting

any of these repairs, the supplemental inflatable re-

straints(SIR) must be disabled. Refer to ”Disabling the

SIR” and ”Sensing and Diagnostic Module(SDM)” in this

section for instructions on how to disable the SIR and re-

place the SDM.

The SIR Diagnostic System Check must always be the

starting point for any SIR diagnosis. The Diagnostic Sys-

tem Check reveals diagnostic trouble codes(DTCs)

through the use of scan tool. The diagnostic procedures

used in this section are designed to find any repair SIR

conditions. To get the best results, it is important to use the

diagnostic charts and follow the sequence listed below.

1. Perform the SIR Diagnostic System Check, which

reveal diagnostic trouble codes(DTCs) through theuse of scan tool.. It also checks for proper airbag

indicator operation.

2. Refer to the proper diagnostic chart as directed by

SIR Diagnostic System Check. Bypassing these

procedures may result in extended diagnostic time,

incorrect diagnosis, and incorrect parts replace-

ment.

3. Repeat the SIR Diagnostic System Check after any

repair or diagnostic procedures have been per-

formed to ensure that the repair has been made

correctly and that no other malfunction exists.

Circiut Description

When the ignition switch is first turned to ON, ignition volt-

age is supplied from airbag fuse to find the SDM at input

terminal A1. The SDM responds by flashing the airbag in-

dicator seven times and then turning it off while the SDM

performs tests on the SIR.

Diagnostic Aids

The order in which DTCs are diagnosed is very important.

Failure to diagnose the DTCs in the order specified may

result in extended diagnostic time, incorrect diagnosis,

and incorrect parts replacement.

SIR Diagnostic System Check

CAUTION : The sensing and the diagnosis module

(SDM) can maintain surfficient voltage to deploy the

airbags and pretensioners for 1 minute after the igni-

tion is OFF and the fuse has been removed. If the air-

bags and pretensioners are not disconnected, do not

begin service until one minute has been passed after

disconnecting power to the SDM. Otherwise, injury

could result.

CAUTION : During service procedure, be very careful

when handling the SDM. Never strike or jar the SDM.Never power the supplemental inflatable re-

straints(SIR) when the SDM is not rigidly attached to

the vehicle. All SDM mounting bolts must be carefully

tightened , and the arrow on the SDM must be point

toward the front of the vehicle to ensure proper op-

eration of the SIR. The SDM could be activated if it is

powered when it is not rigidly attached to the vehicle,

resulting in unexpected deployment and possible in-

jury.

Step

ActionValue(s)YesNo

11. Turn the ignition switch ON.

2. Observe the airbag indicator as the ignition is

being turned ON. Does the indicator flash

seven times?–System OKGo to Step 2

21. Turn the ignition to LOCK and remove the key.

2. Connect the scan tool to the data link connec-

tor(DLC). Follow the directions given in the

scan tool manual.

3. Are any DTCs displayed on the scan tool?–Go to the

DTC check

procedureGo to Step 3

3Check the fuse F1 in the interior fuse box.

Is the fuse F1 blown?–Go to Step 4Go to Step 5

4Replace the fuse F1.–––

51. Disconnect the connector C207.

2. Check the wiring shortage between the fuse F1

and the terminal 1 of the connector C207.

3. Is the wiring shorted? Then, repair the wiring.––Go to Step 6