Section 5 DAEWOO LACETTI 2004 Service Repair Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 2384 of 2643

GLASS AND MIRRORS 9L – 5

DAEWOO V–121 BL4

DIAGNOSIS

TESTING REAR WINDOW

DEFOGGER GRID LINE

If it has been observed during use that a grid line is inop-

erative, the following procedure can be used to find the

break. If none of the grid lines is operating, a full system

diagnosis should be completed before attempting to repair

the grid lines.

1. Turn the ignition ON.

2. Turn the rear window defogger on.

3. From the inside of the vehicle, connect a voltmeter

to each end of a grid line. The voltmeter will indi-

cate battery voltage if the grid line is open.

Notice : Use care when touching the voltmeter leads to a

grid line. If the leads are roughly applied, the grid line may

be scratched, resulting in an open circuit.4. If a grid line is found to be open, move a voltmeter

lead from one side of the grid line and retest at a

point nearer to the other side of the window. Contin-

ue to retest, each time bringing one of the voltmeter

leads closer to the opposite side of the window

from where it was originally placed. The break in

the grid line is at the point where the voltmeter be-

gins reading 0 volts instead of battery voltage.

5. Use a marking crayon to lightly mark the break

point on the rear window. Mark the glass instead of

marking directly on the grid line, and make the

mark far enough from the grid line so that it can

easily be removed without disturbing the repair.

6. Use a grid line repair kit to fix the break in the grid

line. Refer to ”Rear Window Defogger Grid Line

Repair” in this section.

OUTSIDE REARVIEW MIRROR DEFOGGERS

StepActionValue(s)YesNo

1Check the rear window defogger.

Does the rear window defogger work?–Go to Step 4 Go to Step 2

2Repair the rear window defogger before proceeding

with the outside rearview mirror diagnosis.

Is the repair complete?–Go to Step 3–

3Test the outside rearview mirror defoggers.

Does the repair of the rear window defogger system

also fix the problem with the outside rearview mirror

defoggers?–System OKGo to Step 4

4Check fuse Ef25.

Is fuse Ef25 blown?–Go to Step 5 Go to Step 6

51. Check for a short circuit and repair it, if neces-

sary.

2. Replace the fuse.

Is the repair complete?–System OK–

61. On the side of the vehicle which has the mal-

functioning outside rearview mirror defogger,

remove the black plastic escutcheon from the

trim panel side of the door.

2. Disconnect the outside rearview mirror electri-

cal connector.

3. Turn the ignition ON.

4. Turn on the defogger.

5. Use a voltmeter to backprobe terminal 3 (ORN)

at the outside rearview mirror electrical connec-

tor.

Does the voltmeter indicate the specified value?11–14 v Go to Step 8 Go to Step 7

7Repair the open circuit between fuse Ef25 and the

outside rearview mirror connector.

Is the repair complete?–System OK–

Page 2389 of 2643

9L – 10IGLASS AND MIRRORS

DAEWOO V–121 BL4

MAINTENANCE AND REPAIR

ON–VEHICLE SERVICE

WINDSHIELD

Tools Required

J–24402 Glass Sealant Remover

Removal Procedure

1. Remove the cowl vent grille. Refer to Section 9R,

Body Front End.

2. Remove the inside rearview mirror. Refer to ”Rear-

view Mirror” in this section.

3. Remove the weatherstrip around the windshield.

4. Using the glass sealant remover J–24402, cut the

adhesive around the windshield.

5. Remove the windshield from the vehicle.

6. Using a knife, remove the adhesive from the wind-

shield.

7. Using a knife, remove the adhesive from the wind-

shield frame.

Page 2390 of 2643

GLASS AND MIRRORS 9L – 11

DAEWOO V–121 BL4

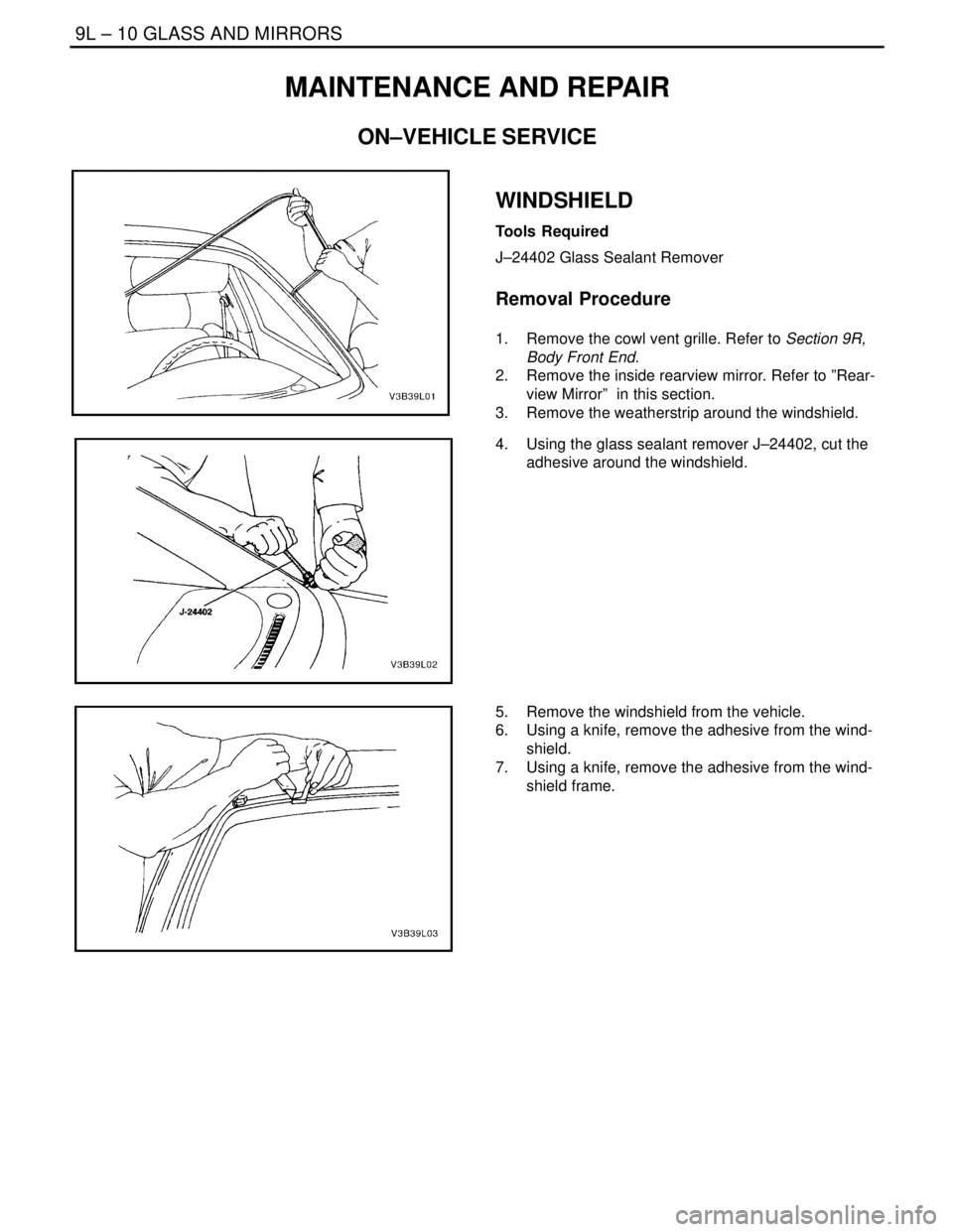

Installation Procedure

1. Install the new weatherstrip to the windshield.

2. Apply tape to the new weatherstrip and the wind-

shield to hold the weatherstrip in place.

3. Apply adhesive primer to the windshield frame and

the perimeter of the windshield.

4. Apply glass adhesive to the windshield frame.

5. Install the windshield into the windshield frame.

6. Reposition the tape over the weatherstrip, the wind-

shield, and the windshield frame to hold the wind-

shield in place.

7. Let the adhesive dry for 24 hours.

8. Remove the tape.

9. Check for waterleaks by pouring water on the wind-

shield. If a leak is found, dry the windshield and fill

the area that leaks with adhesive. If the leak per-

sists, remove the windshield and repeat the entire

procedure.

10. Install the inside rearview mirror. Refer to ”Rear-

view Mirror” in this section.

11. Install the cowl vent grille. Refer to Section 9R,

Body Front End.

REAR WINDOW GLASS

Tools Required

J–24402 Glass Sealant Remover

Removal Procedure

1. Disconnect the negative battery cable.

2. Remove the C–pillar trim panel. Refer to Section

9E, Interior Trim.

3. Disconnect the rear window defogger electrical con-

nector.

Page 2392 of 2643

GLASS AND MIRRORS 9L – 13

DAEWOO V–121 BL4

2. Apply tape to the new weatherstrip and the rear

window to hold the weatherstrip in place.

3. Apply adhesive primer to the rear window frame

and the perimeter of the rear window.

4. Apply glass adhesive to the rear window frame.

5. Install the rear window into the rear window frame.

6. Reposition the tape over the weatherstrip, the rear

window, and the rear window frame to hold the rear

window in place.

7. Let the adhesive dry for 24 hours.

8. Remove the tape.

9. Check for waterleaks by pouring water on the rear

window. If a leak is found, dry the window and fill

the area that leaks with adhesive. If the leak per-

sists, remove the rear window and repeat the entire

procedure.

10. Connect the rear window defogger electrical con-

nector.

11. Install the C–pillar trim panel. Refer to Section 9E,

Interior Trim.

12. Connect the negative battery cable.

REAR WINDOW DEFOGGER GRID

LINE REPAIR

1. Disconnect the negative battery cable.

2. Disconnect the rear window defogger electrical con-

nector.

3. Inspect the rear window defogger grid lines.

4. Mark the grid line break on the outside of the glass

with a wax pencil or a crayon.

Page 2394 of 2643

GLASS AND MIRRORS 9L – 15

DAEWOO V–121 BL4

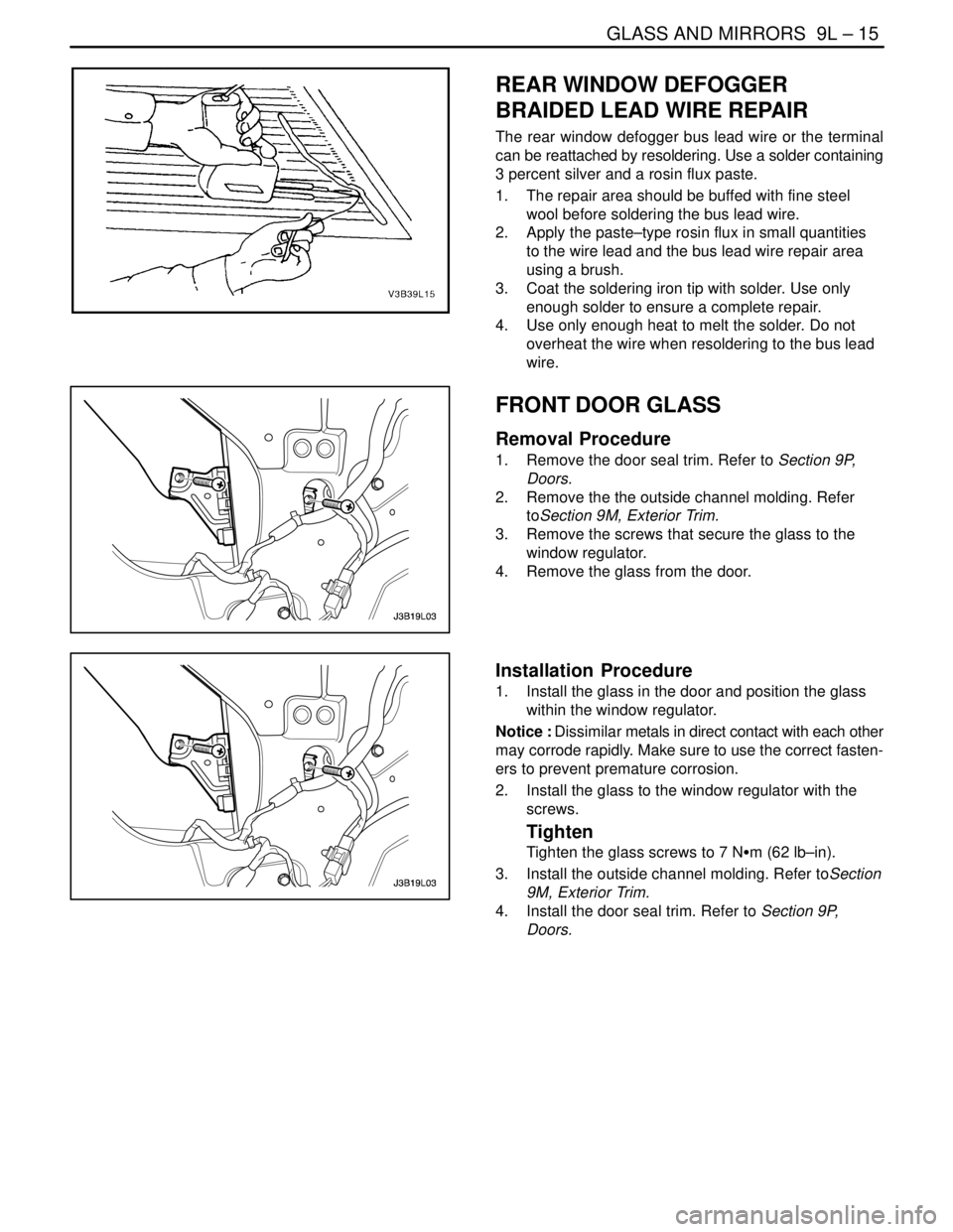

REAR WINDOW DEFOGGER

BRAIDED LEAD WIRE REPAIR

The rear window defogger bus lead wire or the terminal

can be reattached by resoldering. Use a solder containing

3 percent silver and a rosin flux paste.

1. The repair area should be buffed with fine steel

wool before soldering the bus lead wire.

2. Apply the paste–type rosin flux in small quantities

to the wire lead and the bus lead wire repair area

using a brush.

3. Coat the soldering iron tip with solder. Use only

enough solder to ensure a complete repair.

4. Use only enough heat to melt the solder. Do not

overheat the wire when resoldering to the bus lead

wire.

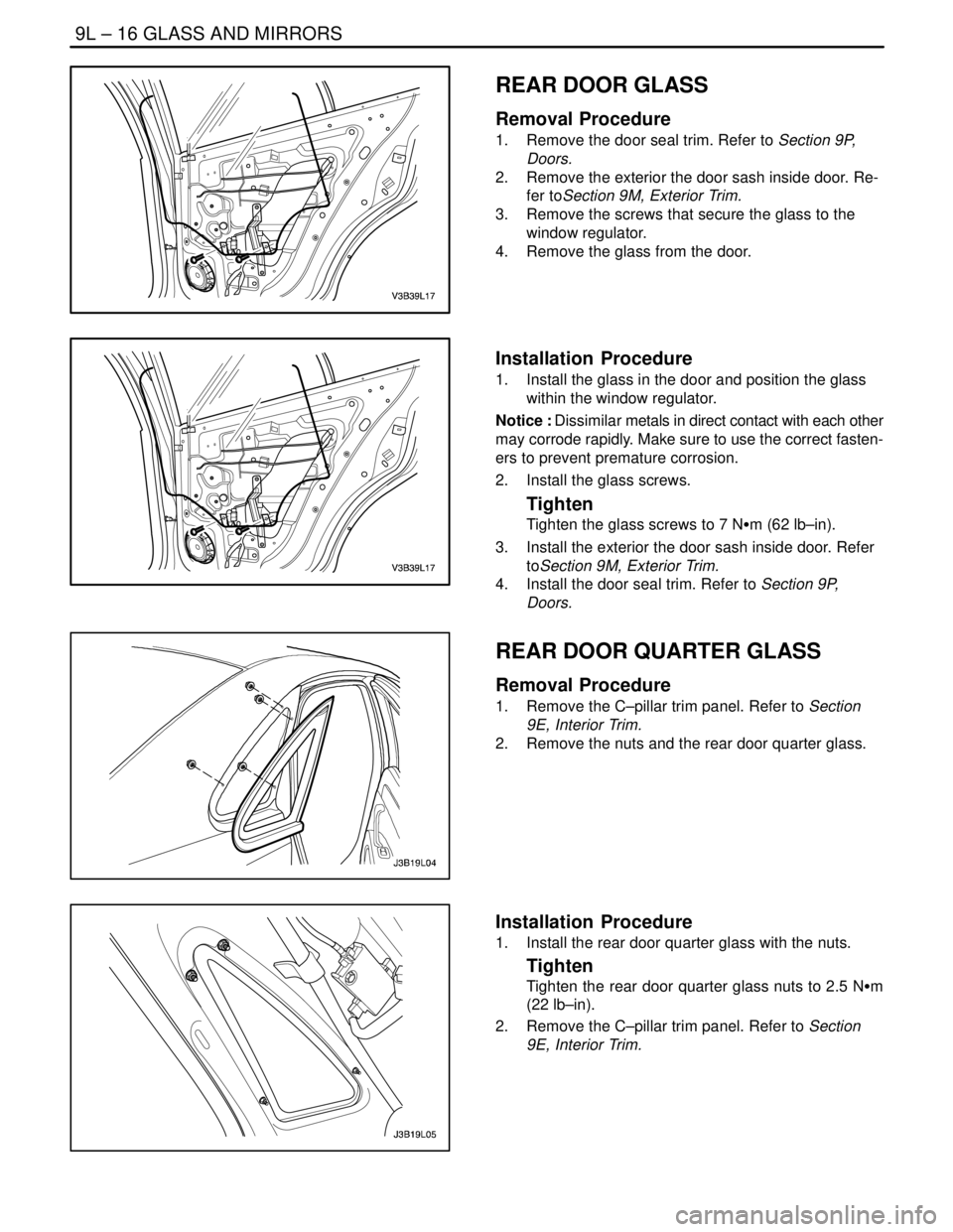

FRONT DOOR GLASS

Removal Procedure

1. Remove the door seal trim. Refer to Section 9P,

Doors.

2. Remove the the outside channel molding. Refer

toSection 9M, Exterior Trim.

3. Remove the screws that secure the glass to the

window regulator.

4. Remove the glass from the door.

Installation Procedure

1. Install the glass in the door and position the glass

within the window regulator.

Notice : Dissimilar metals in direct contact with each other

may corrode rapidly. Make sure to use the correct fasten-

ers to prevent premature corrosion.

2. Install the glass to the window regulator with the

screws.

Tighten

Tighten the glass screws to 7 NSm (62 lb–in).

3. Install the outside channel molding. Refer toSection

9M, Exterior Trim.

4. Install the door seal trim. Refer to Section 9P,

Doors.

Page 2395 of 2643

9L – 16IGLASS AND MIRRORS

DAEWOO V–121 BL4

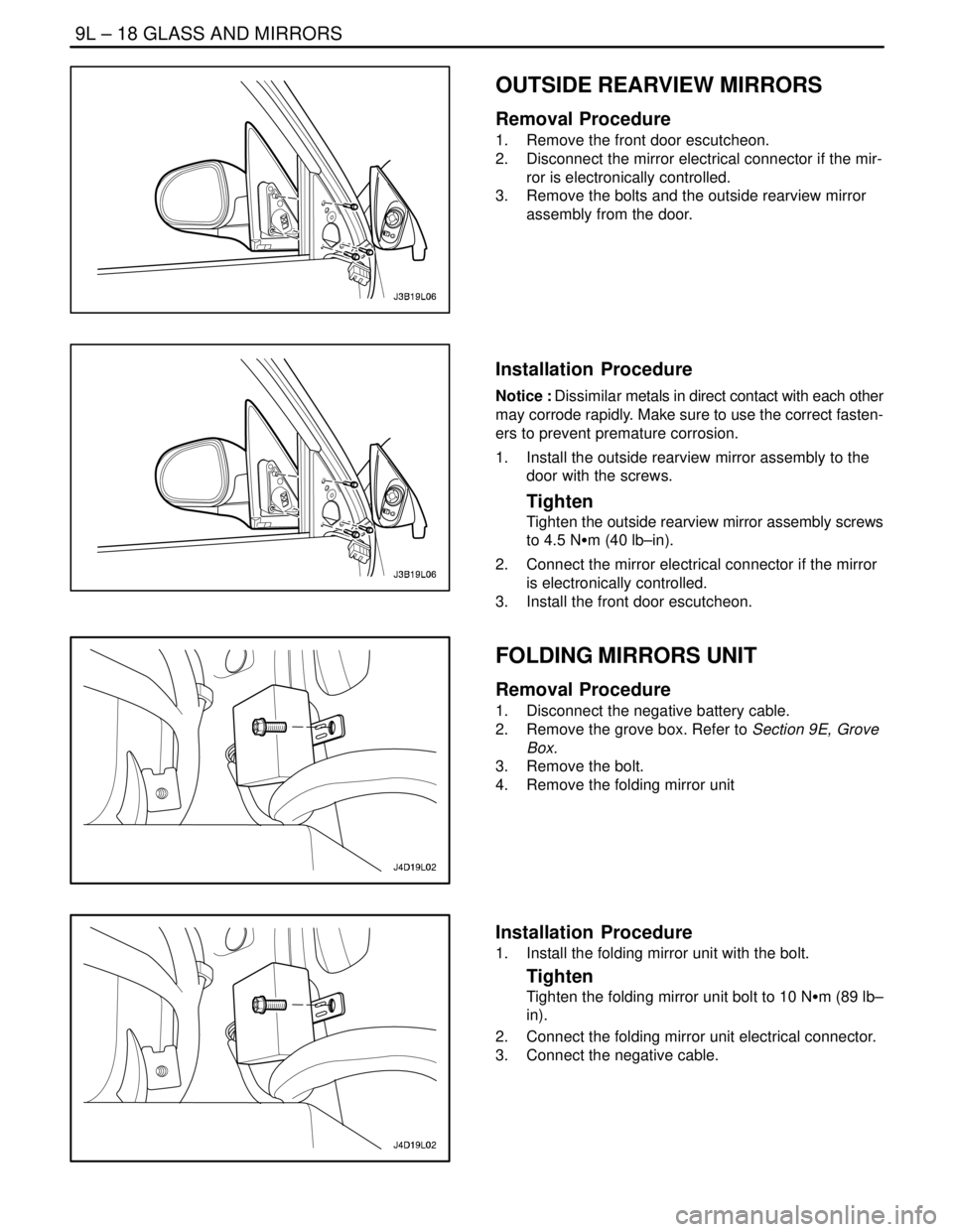

REAR DOOR GLASS

Removal Procedure

1. Remove the door seal trim. Refer to Section 9P,

Doors.

2. Remove the exterior the door sash inside door. Re-

fer toSection 9M, Exterior Trim.

3. Remove the screws that secure the glass to the

window regulator.

4. Remove the glass from the door.

Installation Procedure

1. Install the glass in the door and position the glass

within the window regulator.

Notice : Dissimilar metals in direct contact with each other

may corrode rapidly. Make sure to use the correct fasten-

ers to prevent premature corrosion.

2. Install the glass screws.

Tighten

Tighten the glass screws to 7 NSm (62 lb–in).

3. Install the exterior the door sash inside door. Refer

toSection 9M, Exterior Trim.

4. Install the door seal trim. Refer to Section 9P,

Doors.

REAR DOOR QUARTER GLASS

Removal Procedure

1. Remove the C–pillar trim panel. Refer to Section

9E, Interior Trim.

2. Remove the nuts and the rear door quarter glass.

Installation Procedure

1. Install the rear door quarter glass with the nuts.

Tighten

Tighten the rear door quarter glass nuts to 2.5 NSm

(22 lb–in).

2. Remove the C–pillar trim panel. Refer to Section

9E, Interior Trim.

Page 2397 of 2643

9L – 18IGLASS AND MIRRORS

DAEWOO V–121 BL4

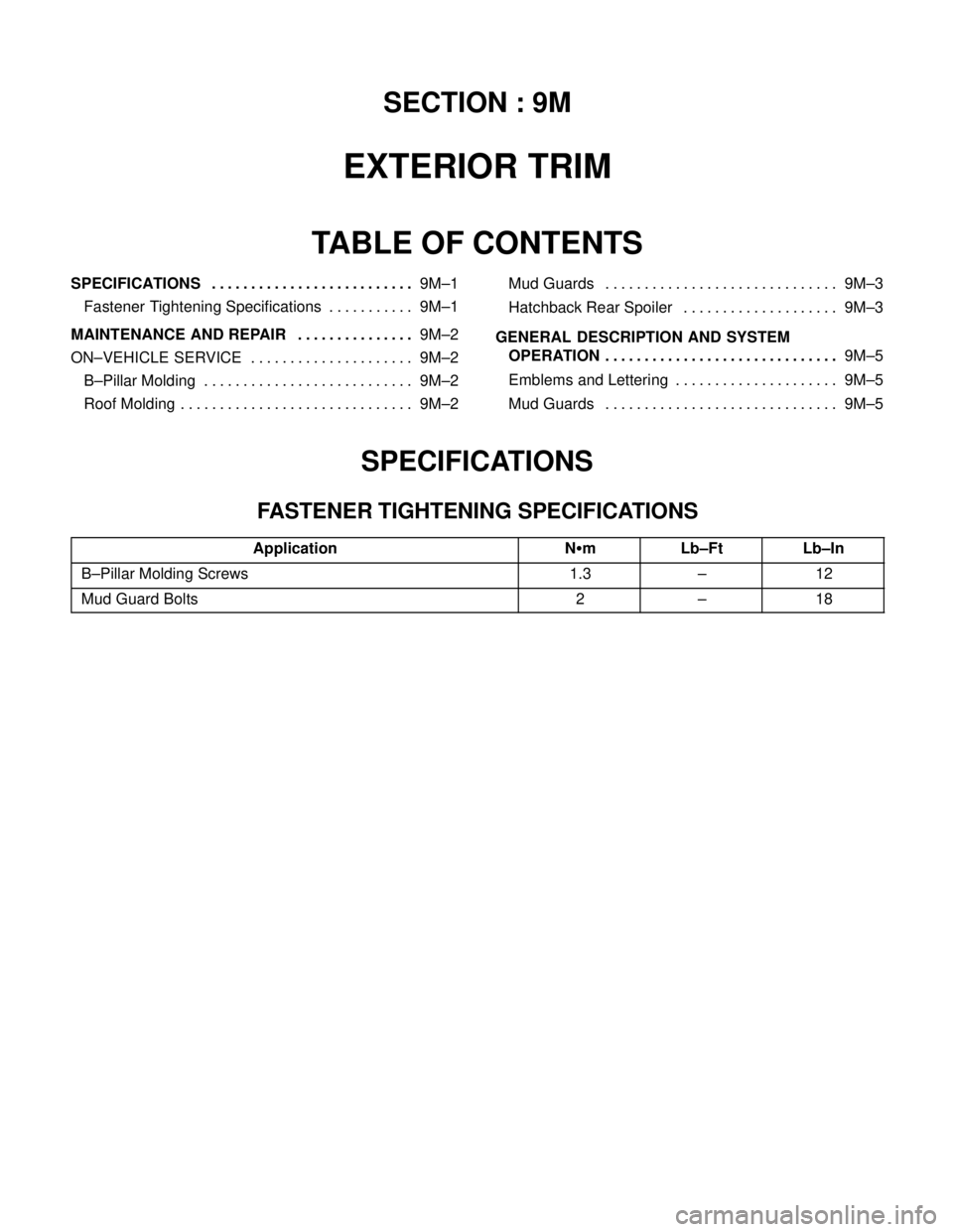

OUTSIDE REARVIEW MIRRORS

Removal Procedure

1. Remove the front door escutcheon.

2. Disconnect the mirror electrical connector if the mir-

ror is electronically controlled.

3. Remove the bolts and the outside rearview mirror

assembly from the door.

Installation Procedure

Notice : Dissimilar metals in direct contact with each other

may corrode rapidly. Make sure to use the correct fasten-

ers to prevent premature corrosion.

1. Install the outside rearview mirror assembly to the

door with the screws.

Tighten

Tighten the outside rearview mirror assembly screws

to 4.5 NSm (40 lb–in).

2. Connect the mirror electrical connector if the mirror

is electronically controlled.

3. Install the front door escutcheon.

FOLDING MIRRORS UNIT

Removal Procedure

1. Disconnect the negative battery cable.

2. Remove the grove box. Refer to Section 9E, Grove

Box.

3. Remove the bolt.

4. Remove the folding mirror unit

Installation Procedure

1. Install the folding mirror unit with the bolt.

Tighten

Tighten the folding mirror unit bolt to 10 NSm (89 lb–

in).

2. Connect the folding mirror unit electrical connector.

3. Connect the negative cable.

Page 2399 of 2643

SECTION : 9M

EXTERIOR TRIM

TABLE OF CONTENTS

SPECIFICATIONS9M–1 . . . . . . . . . . . . . . . . . . . . . . . . . .

Fastener Tightening Specifications 9M–1. . . . . . . . . . .

MAINTENANCE AND REPAIR9M–2 . . . . . . . . . . . . . . .

ON–VEHICLE SERVICE 9M–2. . . . . . . . . . . . . . . . . . . . .

B–Pillar Molding 9M–2. . . . . . . . . . . . . . . . . . . . . . . . . . .

Roof Molding 9M–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Mud Guards 9M–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hatchback Rear Spoiler 9M–3. . . . . . . . . . . . . . . . . . . .

GENERAL DESCRIPTION AND SYSTEM

OPERATION9M–5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Emblems and Lettering 9M–5. . . . . . . . . . . . . . . . . . . . .

Mud Guards 9M–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

ApplicationNSmLb–FtLb–In

B–Pillar Molding Screws1.3–12

Mud Guard Bolts2–18

Page 2404 of 2643

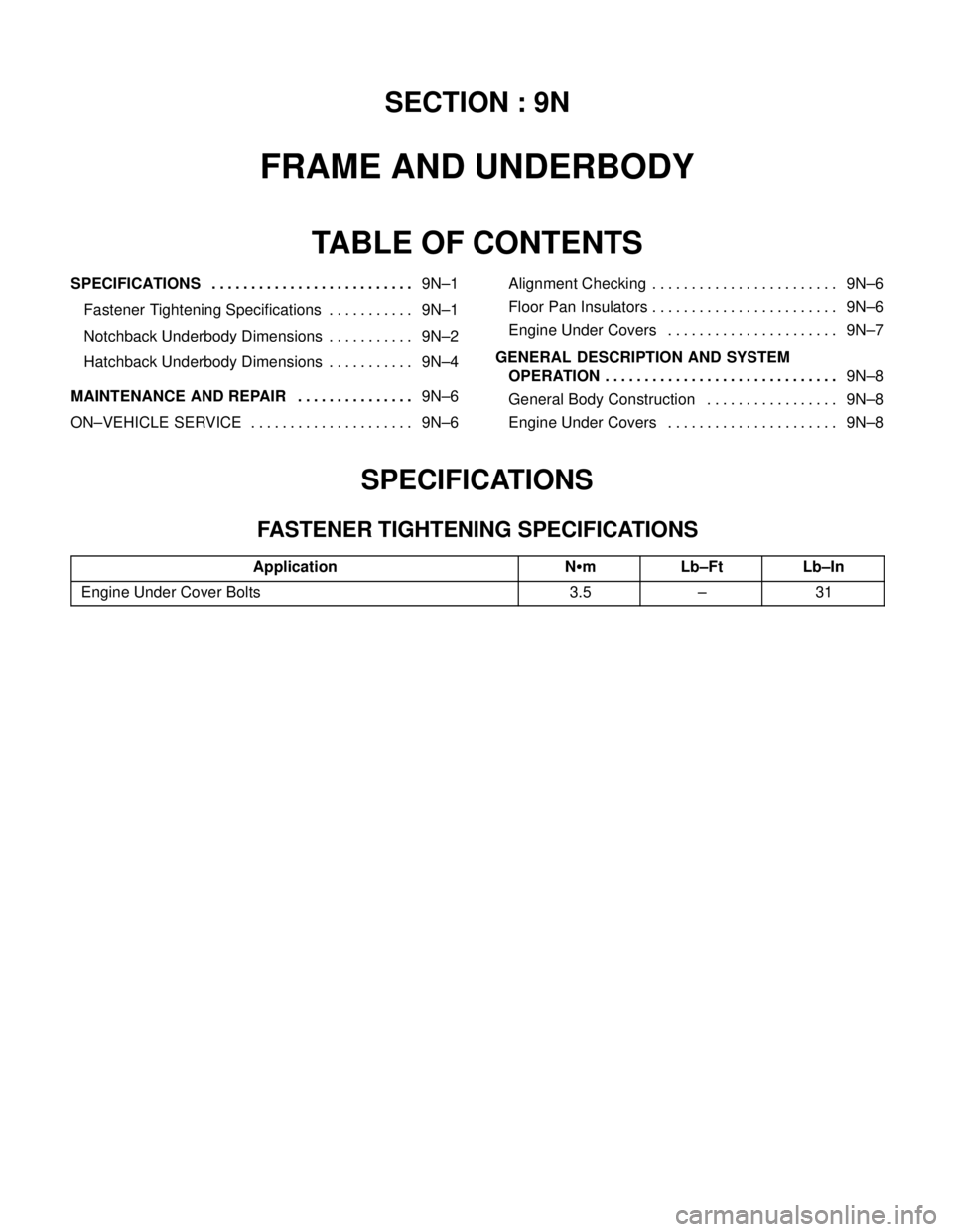

SECTION : 9N

FRAME AND UNDERBODY

TABLE OF CONTENTS

SPECIFICATIONS9N–1 . . . . . . . . . . . . . . . . . . . . . . . . . .

Fastener Tightening Specifications 9N–1. . . . . . . . . . .

Notchback Underbody Dimensions 9N–2. . . . . . . . . . .

Hatchback Underbody Dimensions 9N–4. . . . . . . . . . .

MAINTENANCE AND REPAIR9N–6 . . . . . . . . . . . . . . .

ON–VEHICLE SERVICE 9N–6. . . . . . . . . . . . . . . . . . . . . Alignment Checking 9N–6. . . . . . . . . . . . . . . . . . . . . . . .

Floor Pan Insulators 9N–6. . . . . . . . . . . . . . . . . . . . . . . .

Engine Under Covers 9N–7. . . . . . . . . . . . . . . . . . . . . .

GENERAL DESCRIPTION AND SYSTEM

OPERATION9N–8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Body Construction 9N–8. . . . . . . . . . . . . . . . .

Engine Under Covers 9N–8. . . . . . . . . . . . . . . . . . . . . .

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

ApplicationNSmLb–FtLb–In

Engine Under Cover Bolts3.5–31

Page 2412 of 2643

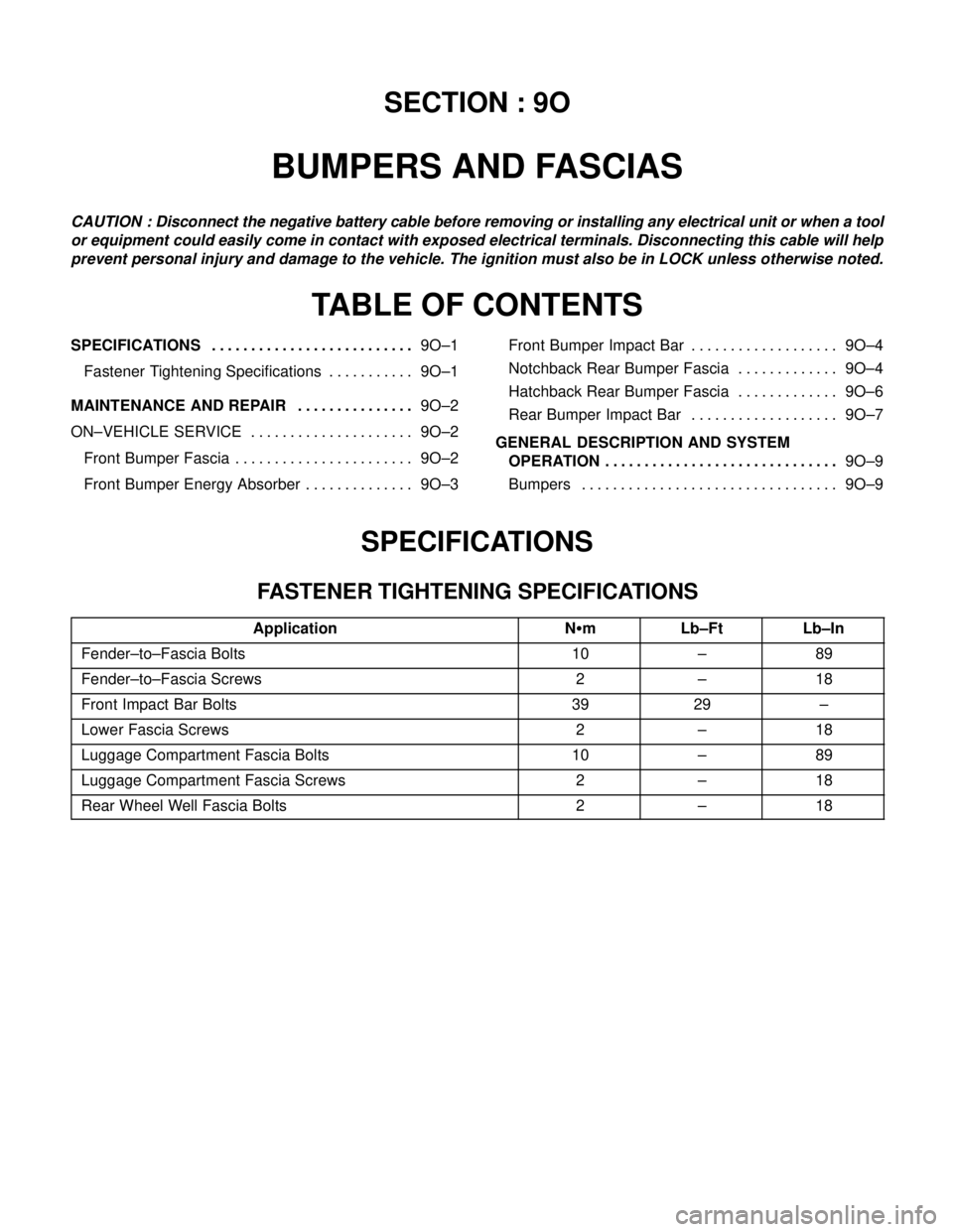

SECTION : 9O

BUMPERS AND FASCIAS

CAUTION : Disconnect the negative battery cable before removing or installing any electrical unit or when a tool

or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help

prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise noted.

TABLE OF CONTENTS

SPECIFICATIONS9O–1 . . . . . . . . . . . . . . . . . . . . . . . . . .

Fastener Tightening Specifications 9O–1. . . . . . . . . . .

MAINTENANCE AND REPAIR9O–2 . . . . . . . . . . . . . . .

ON–VEHICLE SERVICE 9O–2. . . . . . . . . . . . . . . . . . . . .

Front Bumper Fascia 9O–2. . . . . . . . . . . . . . . . . . . . . . .

Front Bumper Energy Absorber 9O–3. . . . . . . . . . . . . . Front Bumper Impact Bar 9O–4. . . . . . . . . . . . . . . . . . .

Notchback Rear Bumper Fascia 9O–4. . . . . . . . . . . . .

Hatchback Rear Bumper Fascia 9O–6. . . . . . . . . . . . .

Rear Bumper Impact Bar 9O–7. . . . . . . . . . . . . . . . . . .

GENERAL DESCRIPTION AND SYSTEM

OPERATION9O–9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bumpers 9O–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

ApplicationNSmLb–FtLb–In

Fender–to–Fascia Bolts10–89

Fender–to–Fascia Screws2–18

Front Impact Bar Bolts3929–

Lower Fascia Screws2–18

Luggage Compartment Fascia Bolts10–89

Luggage Compartment Fascia Screws2–18

Rear Wheel Well Fascia Bolts2–18