Transaxle DAEWOO LACETTI 2004 Service Workshop Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 522 of 2643

1F – 276IENGINE CONTROLS

DAEWOO V–121 BL4

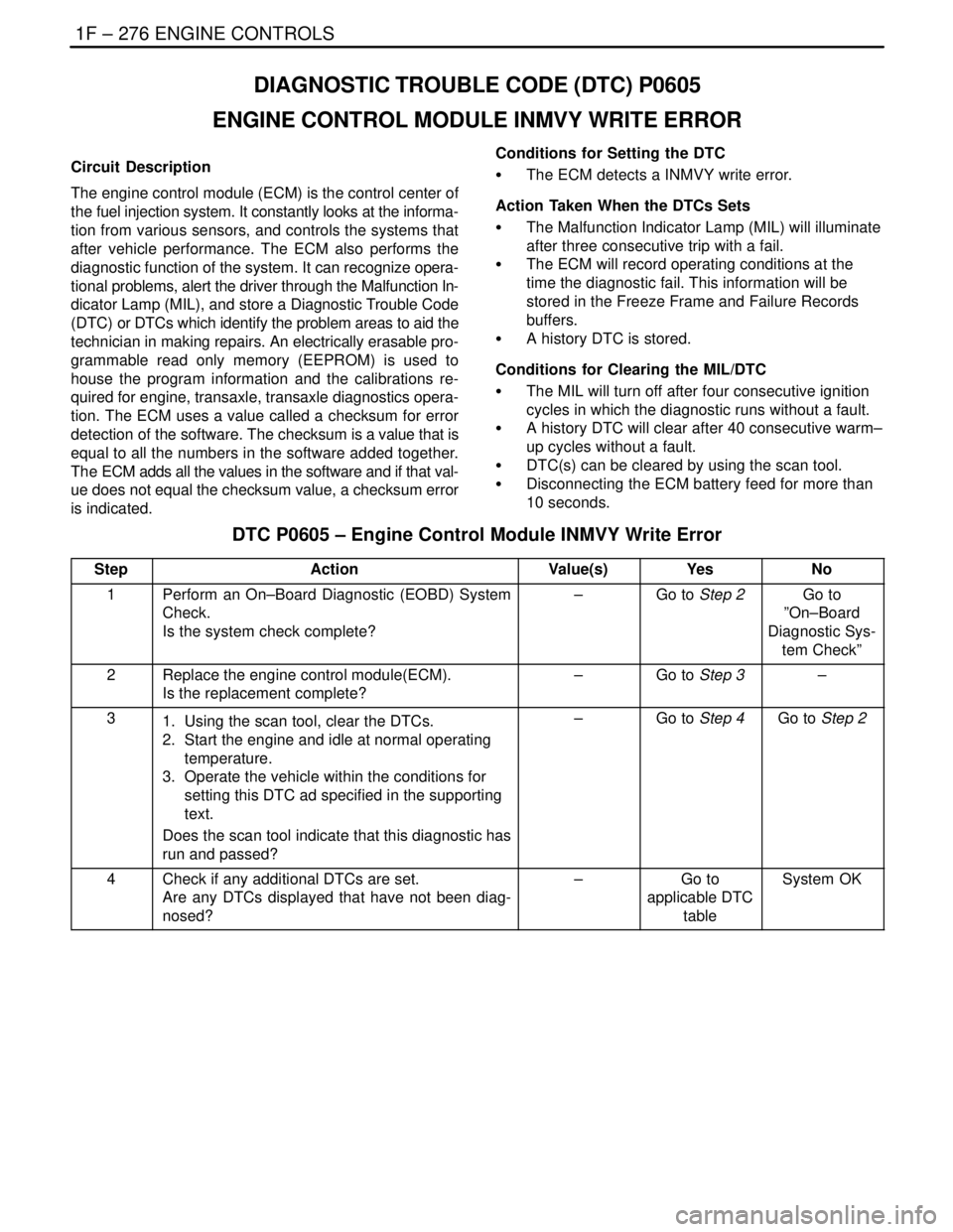

DIAGNOSTIC TROUBLE CODE (DTC) P0605

ENGINE CONTROL MODULE INMVY WRITE ERROR

Circuit Description

The engine control module (ECM) is the control center of

the fuel injection system. It constantly looks at the informa-

tion from various sensors, and controls the systems that

after vehicle performance. The ECM also performs the

diagnostic function of the system. It can recognize opera-

tional problems, alert the driver through the Malfunction In-

dicator Lamp (MIL), and store a Diagnostic Trouble Code

(DTC) or DTCs which identify the problem areas to aid the

technician in making repairs. An electrically erasable pro-

grammable read only memory (EEPROM) is used to

house the program information and the calibrations re-

quired for engine, transaxle, transaxle diagnostics opera-

tion. The ECM uses a value called a checksum for error

detection of the software. The checksum is a value that is

equal to all the numbers in the software added together.

The ECM adds all the values in the software and if that val-

ue does not equal the checksum value, a checksum error

is indicated.Conditions for Setting the DTC

S The ECM detects a INMVY write error.

Action Taken When the DTCs Sets

S The Malfunction Indicator Lamp (MIL) will illuminate

after three consecutive trip with a fail.

S The ECM will record operating conditions at the

time the diagnostic fail. This information will be

stored in the Freeze Frame and Failure Records

buffers.

S A history DTC is stored.

Conditions for Clearing the MIL/DTC

S The MIL will turn off after four consecutive ignition

cycles in which the diagnostic runs without a fault.

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

DTC P0605 – Engine Control Module INMVY Write Error

StepActionValue(s)YesNo

1Perform an On–Board Diagnostic (EOBD) System

Check.

Is the system check complete?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

2Replace the engine control module(ECM).

Is the replacement complete?–Go to Step 3–

31. Using the scan tool, clear the DTCs.

2. Start the engine and idle at normal operating

temperature.

3. Operate the vehicle within the conditions for

setting this DTC ad specified in the supporting

text.

Does the scan tool indicate that this diagnostic has

run and passed?–Go to Step 4Go to Step 2

4Check if any additional DTCs are set.

Are any DTCs displayed that have not been diag-

nosed?–Go to

applicable DTC

tableSystem OK

Page 591 of 2643

ENGINE CONTROLS 1F – 345

DAEWOO V–121 BL4

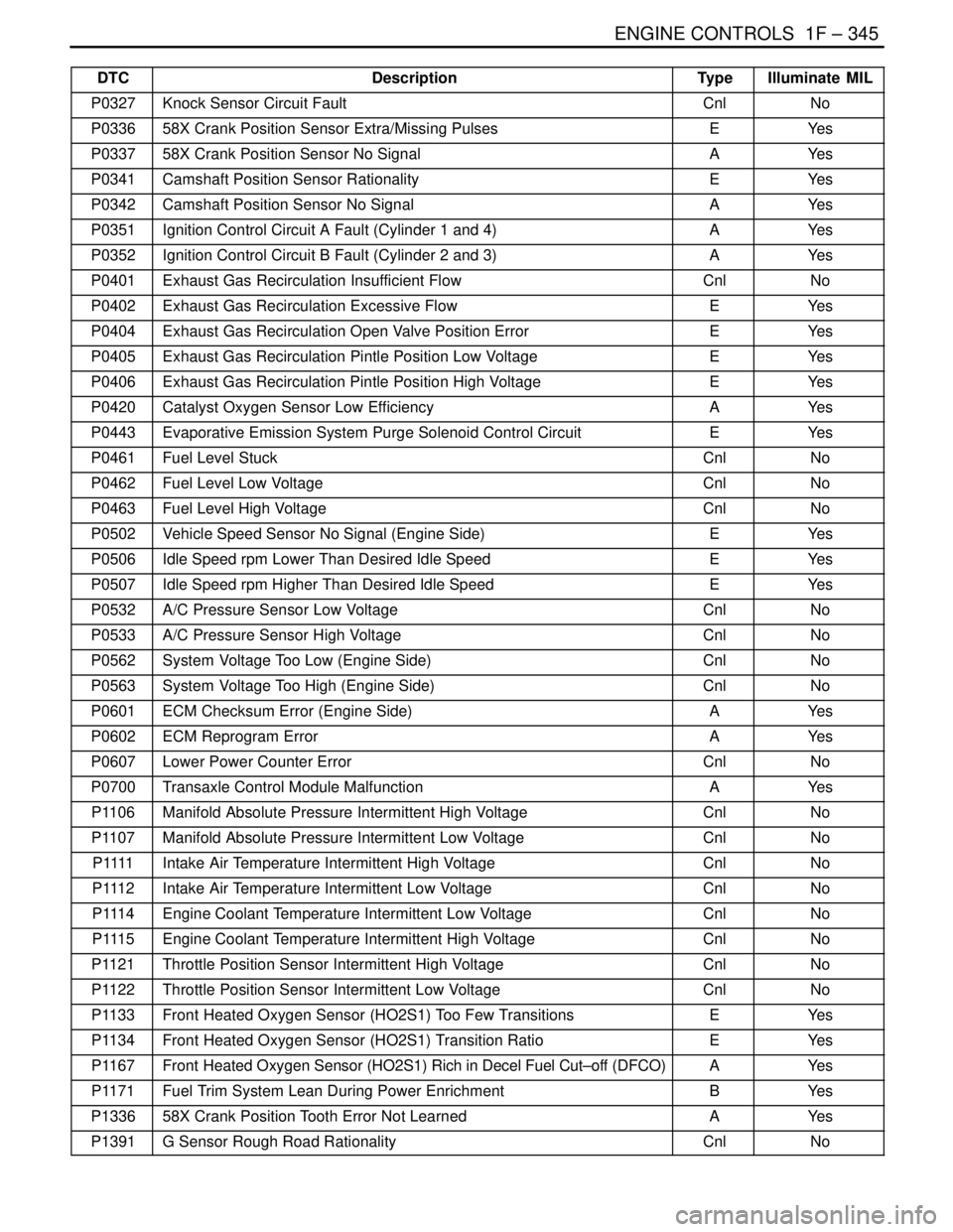

DTCIlluminate MIL Type Description

P0327Knock Sensor Circuit FaultCnlNo

P033658X Crank Position Sensor Extra/Missing PulsesEYe s

P033758X Crank Position Sensor No SignalAYe s

P0341Camshaft Position Sensor RationalityEYe s

P0342Camshaft Position Sensor No SignalAYe s

P0351Ignition Control Circuit A Fault (Cylinder 1 and 4)AYe s

P0352Ignition Control Circuit B Fault (Cylinder 2 and 3)AYe s

P0401Exhaust Gas Recirculation Insufficient FlowCnlNo

P0402Exhaust Gas Recirculation Excessive FlowEYe s

P0404Exhaust Gas Recirculation Open Valve Position ErrorEYe s

P0405Exhaust Gas Recirculation Pintle Position Low VoltageEYe s

P0406Exhaust Gas Recirculation Pintle Position High VoltageEYe s

P0420Catalyst Oxygen Sensor Low EfficiencyAYe s

P0443Evaporative Emission System Purge Solenoid Control CircuitEYe s

P0461Fuel Level StuckCnlNo

P0462Fuel Level Low VoltageCnlNo

P0463Fuel Level High VoltageCnlNo

P0502Vehicle Speed Sensor No Signal (Engine Side)EYe s

P0506Idle Speed rpm Lower Than Desired Idle SpeedEYe s

P0507Idle Speed rpm Higher Than Desired Idle SpeedEYe s

P0532A/C Pressure Sensor Low VoltageCnlNo

P0533A/C Pressure Sensor High VoltageCnlNo

P0562System Voltage Too Low (Engine Side)CnlNo

P0563System Voltage Too High (Engine Side)CnlNo

P0601ECM Checksum Error (Engine Side)AYe s

P0602ECM Reprogram ErrorAYe s

P0607Lower Power Counter ErrorCnlNo

P0700Transaxle Control Module MalfunctionAYe s

P1106Manifold Absolute Pressure Intermittent High VoltageCnlNo

P1107Manifold Absolute Pressure Intermittent Low VoltageCnlNo

P 1111Intake Air Temperature Intermittent High VoltageCnlNo

P1112Intake Air Temperature Intermittent Low VoltageCnlNo

P1114Engine Coolant Temperature Intermittent Low VoltageCnlNo

P1115Engine Coolant Temperature Intermittent High VoltageCnlNo

P1121Throttle Position Sensor Intermittent High VoltageCnlNo

P1122Throttle Position Sensor Intermittent Low VoltageCnlNo

P1133Front Heated Oxygen Sensor (HO2S1) Too Few TransitionsEYe s

P1134Front Heated Oxygen Sensor (HO2S1) Transition RatioEYe s

P1167Front Heated Oxygen Sensor (HO2S1) Rich in Decel Fuel Cut–off (DFCO)AYe s

P1171Fuel Trim System Lean During Power EnrichmentBYe s

P133658X Crank Position Tooth Error Not LearnedAYe s

P1391G Sensor Rough Road RationalityCnlNo

Page 714 of 2643

1F – 468IENGINE CONTROLS

DAEWOO V–121 BL4

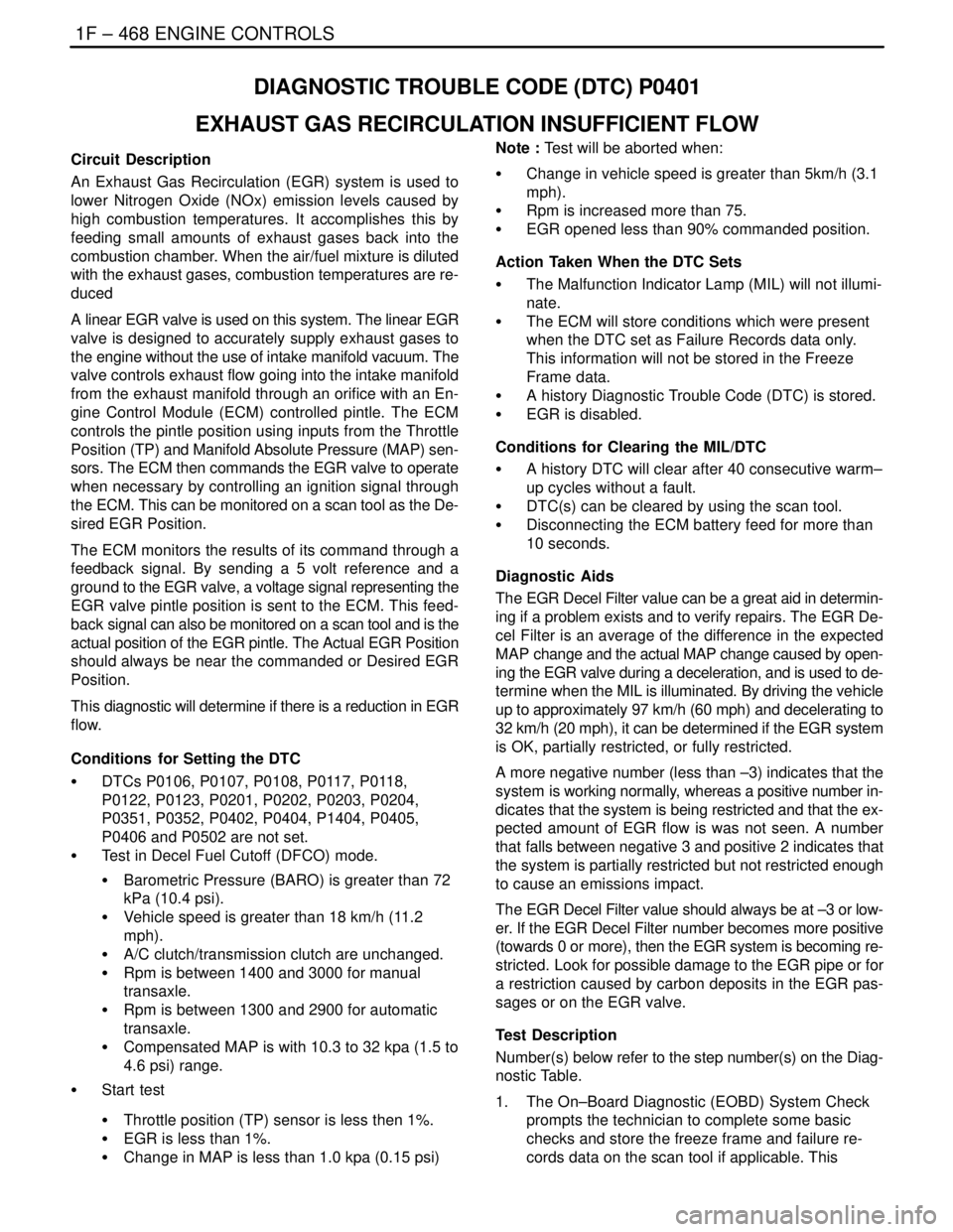

DIAGNOSTIC TROUBLE CODE (DTC) P0401

EXHAUST GAS RECIRCULATION INSUFFICIENT FLOW

Circuit Description

An Exhaust Gas Recirculation (EGR) system is used to

lower Nitrogen Oxide (NOx) emission levels caused by

high combustion temperatures. It accomplishes this by

feeding small amounts of exhaust gases back into the

combustion chamber. When the air/fuel mixture is diluted

with the exhaust gases, combustion temperatures are re-

duced

A linear EGR valve is used on this system. The linear EGR

valve is designed to accurately supply exhaust gases to

the engine without the use of intake manifold vacuum. The

valve controls exhaust flow going into the intake manifold

from the exhaust manifold through an orifice with an En-

gine Control Module (ECM) controlled pintle. The ECM

controls the pintle position using inputs from the Throttle

Position (TP) and Manifold Absolute Pressure (MAP) sen-

sors. The ECM then commands the EGR valve to operate

when necessary by controlling an ignition signal through

the ECM. This can be monitored on a scan tool as the De-

sired EGR Position.

The ECM monitors the results of its command through a

feedback signal. By sending a 5 volt reference and a

ground to the EGR valve, a voltage signal representing the

EGR valve pintle position is sent to the ECM. This feed-

back signal can also be monitored on a scan tool and is the

actual position of the EGR pintle. The Actual EGR Position

should always be near the commanded or Desired EGR

Position.

This diagnostic will determine if there is a reduction in EGR

flow.

Conditions for Setting the DTC

S DTCs P0106, P0107, P0108, P0117, P0118,

P0122, P0123, P0201, P0202, P0203, P0204,

P0351, P0352, P0402, P0404, P1404, P0405,

P0406 and P0502 are not set.

S Test in Decel Fuel Cutoff (DFCO) mode.

S Barometric Pressure (BARO) is greater than 72

kPa (10.4 psi).

S Vehicle speed is greater than 18 km/h (11.2

mph).

S A/C clutch/transmission clutch are unchanged.

S Rpm is between 1400 and 3000 for manual

transaxle.

S Rpm is between 1300 and 2900 for automatic

transaxle.

S Compensated MAP is with 10.3 to 32 kpa (1.5 to

4.6 psi) range.

S Start test

S Throttle position (TP) sensor is less then 1%.

S EGR is less than 1%.

S Change in MAP is less than 1.0 kpa (0.15 psi)Note : Test will be aborted when:

S Change in vehicle speed is greater than 5km/h (3.1

mph).

S Rpm is increased more than 75.

S EGR opened less than 90% commanded position.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will not illumi-

nate.

S The ECM will store conditions which were present

when the DTC set as Failure Records data only.

This information will not be stored in the Freeze

Frame data.

S A history Diagnostic Trouble Code (DTC) is stored.

S EGR is disabled.

Conditions for Clearing the MIL/DTC

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

The EGR Decel Filter value can be a great aid in determin-

ing if a problem exists and to verify repairs. The EGR De-

cel Filter is an average of the difference in the expected

MAP change and the actual MAP change caused by open-

ing the EGR valve during a deceleration, and is used to de-

termine when the MIL is illuminated. By driving the vehicle

up to approximately 97 km/h (60 mph) and decelerating to

32 km/h (20 mph), it can be determined if the EGR system

is OK, partially restricted, or fully restricted.

A more negative number (less than –3) indicates that the

system is working normally, whereas a positive number in-

dicates that the system is being restricted and that the ex-

pected amount of EGR flow is was not seen. A number

that falls between negative 3 and positive 2 indicates that

the system is partially restricted but not restricted enough

to cause an emissions impact.

The EGR Decel Filter value should always be at –3 or low-

er. If the EGR Decel Filter number becomes more positive

(towards 0 or more), then the EGR system is becoming re-

stricted. Look for possible damage to the EGR pipe or for

a restriction caused by carbon deposits in the EGR pas-

sages or on the EGR valve.

Test Description

Number(s) below refer to the step number(s) on the Diag-

nostic Table.

1. The On–Board Diagnostic (EOBD) System Check

prompts the technician to complete some basic

checks and store the freeze frame and failure re-

cords data on the scan tool if applicable. This

Page 730 of 2643

1F – 484IENGINE CONTROLS

DAEWOO V–121 BL4

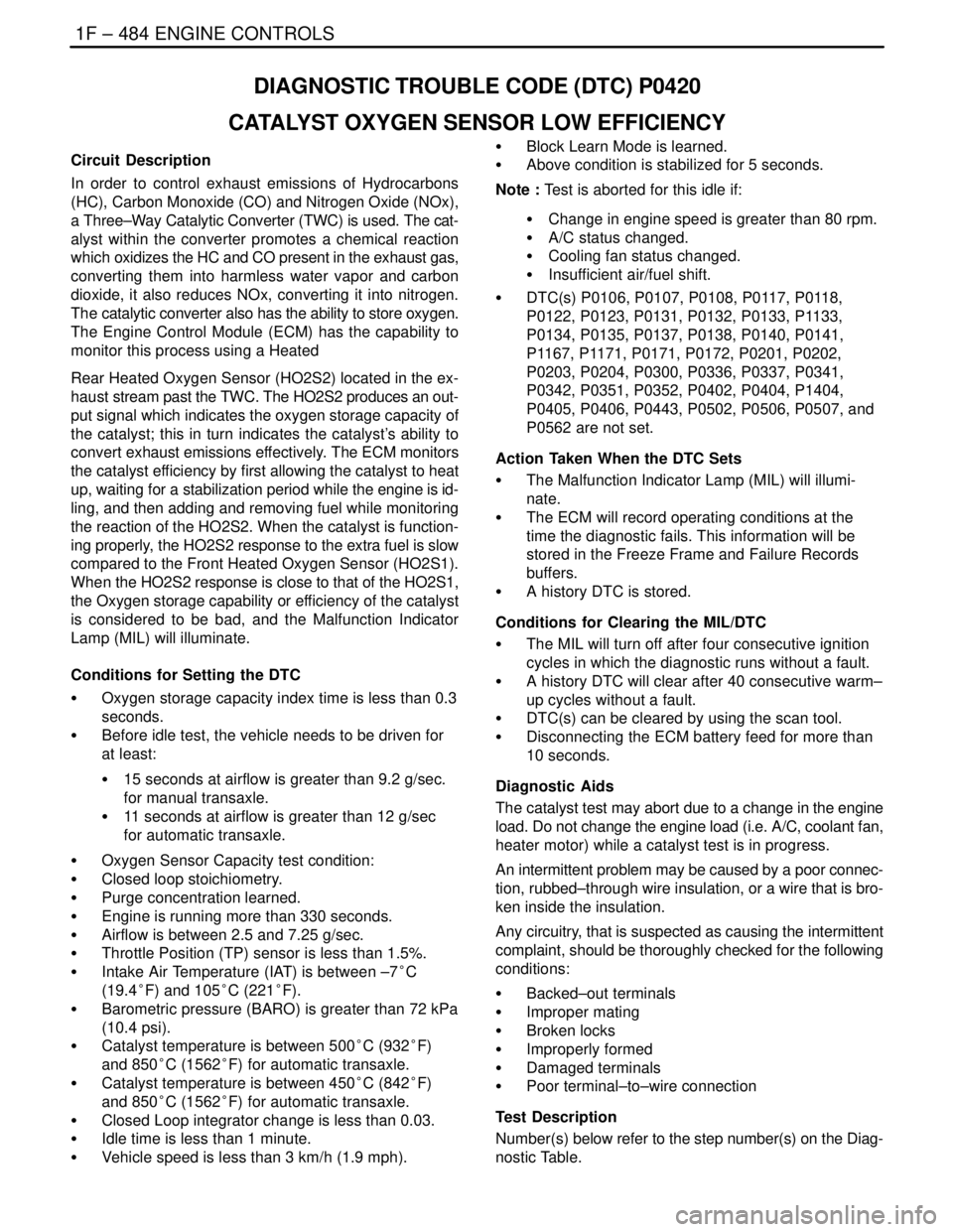

DIAGNOSTIC TROUBLE CODE (DTC) P0420

CATALYST OXYGEN SENSOR LOW EFFICIENCY

Circuit Description

In order to control exhaust emissions of Hydrocarbons

(HC), Carbon Monoxide (CO) and Nitrogen Oxide (NOx),

a Three–Way Catalytic Converter (TWC) is used. The cat-

alyst within the converter promotes a chemical reaction

which oxidizes the HC and CO present in the exhaust gas,

converting them into harmless water vapor and carbon

dioxide, it also reduces NOx, converting it into nitrogen.

The catalytic converter also has the ability to store oxygen.

The Engine Control Module (ECM) has the capability to

monitor this process using a Heated

Rear Heated Oxygen Sensor (HO2S2) located in the ex-

haust stream past the TWC. The HO2S2 produces an out-

put signal which indicates the oxygen storage capacity of

the catalyst; this in turn indicates the catalyst’s ability to

convert exhaust emissions effectively. The ECM monitors

the catalyst efficiency by first allowing the catalyst to heat

up, waiting for a stabilization period while the engine is id-

ling, and then adding and removing fuel while monitoring

the reaction of the HO2S2. When the catalyst is function-

ing properly, the HO2S2 response to the extra fuel is slow

compared to the Front Heated Oxygen Sensor (HO2S1).

When the HO2S2 response is close to that of the HO2S1,

the Oxygen storage capability or efficiency of the catalyst

is considered to be bad, and the Malfunction Indicator

Lamp (MIL) will illuminate.

Conditions for Setting the DTC

S Oxygen storage capacity index time is less than 0.3

seconds.

S Before idle test, the vehicle needs to be driven for

at least:

S 15 seconds at airflow is greater than 9.2 g/sec.

for manual transaxle.

S 11 seconds at airflow is greater than 12 g/sec

for automatic transaxle.

S Oxygen Sensor Capacity test condition:

S Closed loop stoichiometry.

S Purge concentration learned.

S Engine is running more than 330 seconds.

S Airflow is between 2.5 and 7.25 g/sec.

S Throttle Position (TP) sensor is less than 1.5%.

S Intake Air Temperature (IAT) is between –7°C

(19.4°F) and 105°C (221°F).

S Barometric pressure (BARO) is greater than 72 kPa

(10.4 psi).

S Catalyst temperature is between 500°C (932°F)

and 850°C (1562°F) for automatic transaxle.

S Catalyst temperature is between 450°C (842°F)

and 850°C (1562°F) for automatic transaxle.

S Closed Loop integrator change is less than 0.03.

S Idle time is less than 1 minute.

S Vehicle speed is less than 3 km/h (1.9 mph).S Block Learn Mode is learned.

S Above condition is stabilized for 5 seconds.

Note : Test is aborted for this idle if:

S Change in engine speed is greater than 80 rpm.

S A/C status changed.

S Cooling fan status changed.

S Insufficient air/fuel shift.

S DTC(s) P0106, P0107, P0108, P0117, P0118,

P0122, P0123, P0131, P0132, P0133, P1133,

P0134, P0135, P0137, P0138, P0140, P0141,

P1167, P1171, P0171, P0172, P0201, P0202,

P0203, P0204, P0300, P0336, P0337, P0341,

P0342, P0351, P0352, P0402, P0404, P1404,

P0405, P0406, P0443, P0502, P0506, P0507, and

P0562 are not set.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will illumi-

nate.

S The ECM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Freeze Frame and Failure Records

buffers.

S A history DTC is stored.

Conditions for Clearing the MIL/DTC

S The MIL will turn off after four consecutive ignition

cycles in which the diagnostic runs without a fault.

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

The catalyst test may abort due to a change in the engine

load. Do not change the engine load (i.e. A/C, coolant fan,

heater motor) while a catalyst test is in progress.

An intermittent problem may be caused by a poor connec-

tion, rubbed–through wire insulation, or a wire that is bro-

ken inside the insulation.

Any circuitry, that is suspected as causing the intermittent

complaint, should be thoroughly checked for the following

conditions:

S Backed–out terminals

S Improper mating

S Broken locks

S Improperly formed

S Damaged terminals

S Poor terminal–to–wire connection

Test Description

Number(s) below refer to the step number(s) on the Diag-

nostic Table.

Page 744 of 2643

1F – 498IENGINE CONTROLS

DAEWOO V–121 BL4

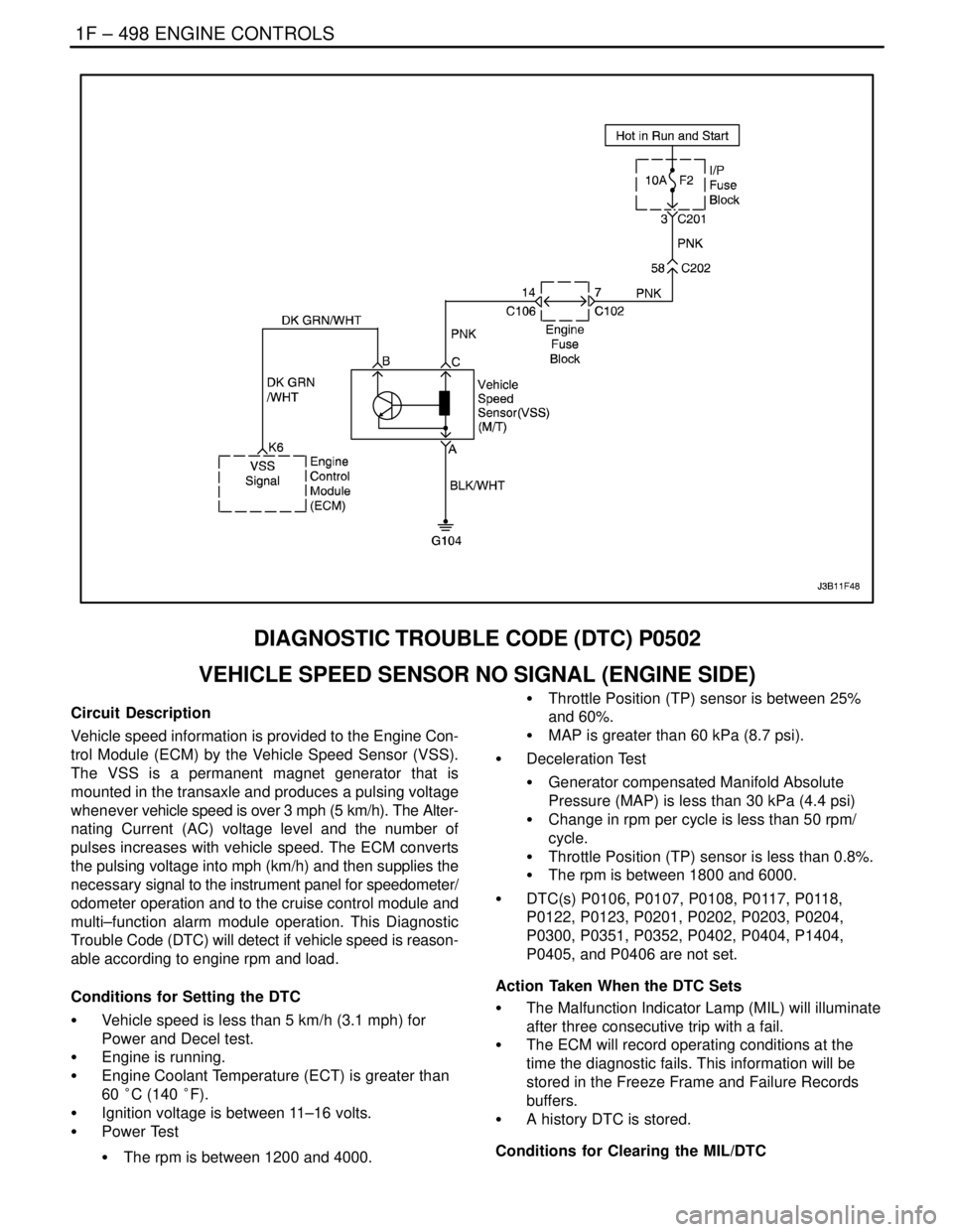

DIAGNOSTIC TROUBLE CODE (DTC) P0502

VEHICLE SPEED SENSOR NO SIGNAL (ENGINE SIDE)

Circuit Description

Vehicle speed information is provided to the Engine Con-

trol Module (ECM) by the Vehicle Speed Sensor (VSS).

The VSS is a permanent magnet generator that is

mounted in the transaxle and produces a pulsing voltage

whenever vehicle speed is over 3 mph (5 km/h). The Alter-

nating Current (AC) voltage level and the number of

pulses increases with vehicle speed. The ECM converts

the pulsing voltage into mph (km/h) and then supplies the

necessary signal to the instrument panel for speedometer/

odometer operation and to the cruise control module and

multi–function alarm module operation. This Diagnostic

Trouble Code (DTC) will detect if vehicle speed is reason-

able according to engine rpm and load.

Conditions for Setting the DTC

S Vehicle speed is less than 5 km/h (3.1 mph) for

Power and Decel test.

S Engine is running.

S Engine Coolant Temperature (ECT) is greater than

60 °C (140 °F).

S Ignition voltage is between 11–16 volts.

S Power Test

S The rpm is between 1200 and 4000.S Throttle Position (TP) sensor is between 25%

and 60%.

S MAP is greater than 60 kPa (8.7 psi).

S Deceleration Test

S Generator compensated Manifold Absolute

Pressure (MAP) is less than 30 kPa (4.4 psi)

S Change in rpm per cycle is less than 50 rpm/

cycle.

S Throttle Position (TP) sensor is less than 0.8%.

S The rpm is between 1800 and 6000.

S DTC(s) P0106, P0107, P0108, P0117, P0118,

P0122, P0123, P0201, P0202, P0203, P0204,

P0300, P0351, P0352, P0402, P0404, P1404,

P0405, and P0406 are not set.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will illuminate

after three consecutive trip with a fail.

S The ECM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Freeze Frame and Failure Records

buffers.

S A history DTC is stored.

Conditions for Clearing the MIL/DTC

Page 766 of 2643

1F – 520IENGINE CONTROLS

DAEWOO V–121 BL4

DIAGNOSTIC TROUBLE CODE (DTC) P0700

TRANSAXLE CONTROL MODULE MALFUNCTION

Circuit Description

The Transmission Control Module (TCM) and the Engine

Control Module (ECM) are connected through the serial

data link circuit. The TCM sends a Class–II P–code status

message to the ECM every 100 milliseconds to confirm

the transmission is functioning correctly.

If the TCM detects either an A– or B–type malfunction

within the transmission, the TCM will send to the ECM a

P–code status message to turn the Malfunction Indicator

Lamp (MIL) ON and set DTC P0700.

Conditions for Setting the DTC

S Received message from the TCM indicating mal-

function is detected in TCM.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will illumi-

nate.

S The ECM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Freeze Frame and/or Failure Records

buffers.S A history DTC is stored.

Conditions for Clearing the MIL/DTC

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

An intermittent may be caused by a poor connection,

rubbed–through wire insulation or a wire broken inside the

insulation.

Check for a poor connection or damaged ECM/TCM har-

ness. Inspect the serial data link circuit for the following

conditions:

S Improper mating

S Broken locks

S Improperly formed

S Damaged terminals

S Poor terminal–to–wiring connections

S Damaged harness

DTC P0700 – Transaxle Control Module Malfunction

StepActionValue(s)YesNo

1Perform an On–Board Diagnostic (EOBD) System

Check.

Was the check performed?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Install a scan tool to the Data Link Connector

(DLC).

2. Turn the ignition ON.

3. Select Transmission Control Module (TCM)

Diagnostic Trouble Code (DTC) with scan tool.

Is a transmission DTC displayed?–Go to Step 3Go to Step 4

31. Repair transmission malfunction. Refer to the

applicable DTC table in the transmission repair

section.

2. Using a scan tool, clear the TCM DTC.

Is the repair complete?–Go to Step 4–

Page 814 of 2643

1F – 568IENGINE CONTROLS

DAEWOO V–121 BL4

DIAGNOSTIC TROUBLE CODE (DTC) P1601

SPI COMMUNICATIONS BETWEEN ECM AND TCM

Circuit Description

The Serial Peripheral Interface (SPI) communication is

used internally by the Engine Control Module (ECM) to

send message between the engine processor and the au-

tomatic transaxle processor. Included in each message

sent between the two processor is a checksum of the mes-

sage. Both the engine processor automatic transaxle

processor will compare this checksum value with calcu-

lated checksum. If the checksum do not match, the proc-

essor will review the new data as being corrupted and ig-

nore the value. The processor then use the previous

message. The receiving processor will then send a mes-

sage to the sending processor informing it that its last mes-

sage was corrupted.

The ECM monitor periodic TCM status message and if

message is not received fail counter incremented and

Diagnostic trouble Code (DTC) will stored.

Conditions for Setting the DTC

S Ignition switch is turned to ON.S Ignition voltage is greater than 11 volts.

S Engine is running more than 2 seconds.

S Device Control not active.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will illumi-

nate.

S The ECM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Freeze Frame and Failure Records

buffers.

S A history DTC is stored.

Conditions for Clearing the MIL/DTC

S The MIL turn off after four consecutive ignition

cycles in which the diagnostic runs without a fault.

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

DTC P1601 SPI Communications Between ECM and TCM

StepActionValue(s)YesNo

1Perform an On–Board Diagnostic (EOBD) System

Check.

Was the check performed?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Turn the ignition OFF.

2. Replace the Engine Control Module (ECM).

Is the repair complete?–Go to Step 3–

31. Using the scan tool, clear the Diagnostic

Trouble Codes (DTCs).

2. Start the engine and idle at normal operating

temperature.

3. Operate the vehicle within the Conditions for

setting this DTC as specified in the supporting

text.

Does the scan tool indicate that this diagnostic has

run and passed?–Go to Step 4Go to Step 2

4Check if any additional DTCs are set.

Are any DTCs displayed that have not been diag-

nosed?–Go to

Applicable DTC

tableSystem OK

Page 827 of 2643

ENGINE CONTROLS 1F – 581

DAEWOO V–121 BL4

LACK OF POWER, SLUGGISHNESS, OR SPONGINESS

Definition : The engine delivers less than expected power. There is little or no increase in speed when the accelerator pedal

is partially applied.

Step

ActionValue(s)YesNo

1Were the Important Preliminary Checks performed?–Go toStep 2Go to

”Important Pre-

liminary

Checks”

21. Verify the customer’s complaint.

2. Compare the performance of the customer’s

vehicle with a similar unit.

Does the problem exist?–Go toStep 3System OK

31. Inspect the air filter for excessive contamina-

tion.

2. Replace the air filter as needed.

3. Check the transaxle shift pattern and downshift

operation.

Does the transaxle operate properly?–Go toStep 4Go toStep 5

4Check the fuel system pressure.

Is the fuel system pressure within specifications?41–47 psi

(284–325 kPa)Go toStep 7Go toStep 6

5Repair the transaxle as needed.

Is the repair complete?–System OK–

6Repair the fuel system as needed.

Is the repair complete?–System OK–

7Check for a restricted fuel filter or contaminated fuel.

Is the problem found?–Go toStep 8Go toStep 9

8Repair or replace any components as needed.

Is the repair complete?–System OK–

91. Check the ignition system output for all of the

cylinders using a spark tester.

2. Check for proper ignition control operation.

Is the ignition system operating properly?–Go toStep 10Go toStep 11

101. With the engine at normal operating tempera-

ture, connect a vacuum gauge to a vacuum

port on the intake manifold.

2. Operate the engine at 1,000 rpm.

3. Record the vacuum reading.

4. Increase the engine speed to 2,500 rpm.

5. Note the vacuum reading at a steady 2,500

rpm.

Does the vacuum decrease more than the value

specified?10 kPa

(3 in. Hg)Go toStep 12Go toStep 15

11Repair or replace any ignition system components

as needed.

Is the repair complete?–System OK–

12Inspect the exhaust system for restrictions and dam-

aged or collapsed pipes.

Is the problem found?–Go toStep 13Go toStep 15

13Repair or replace any components as needed.

Is the repair complete?–System OK–

Page 833 of 2643

ENGINE CONTROLS 1F – 587

DAEWOO V–121 BL4

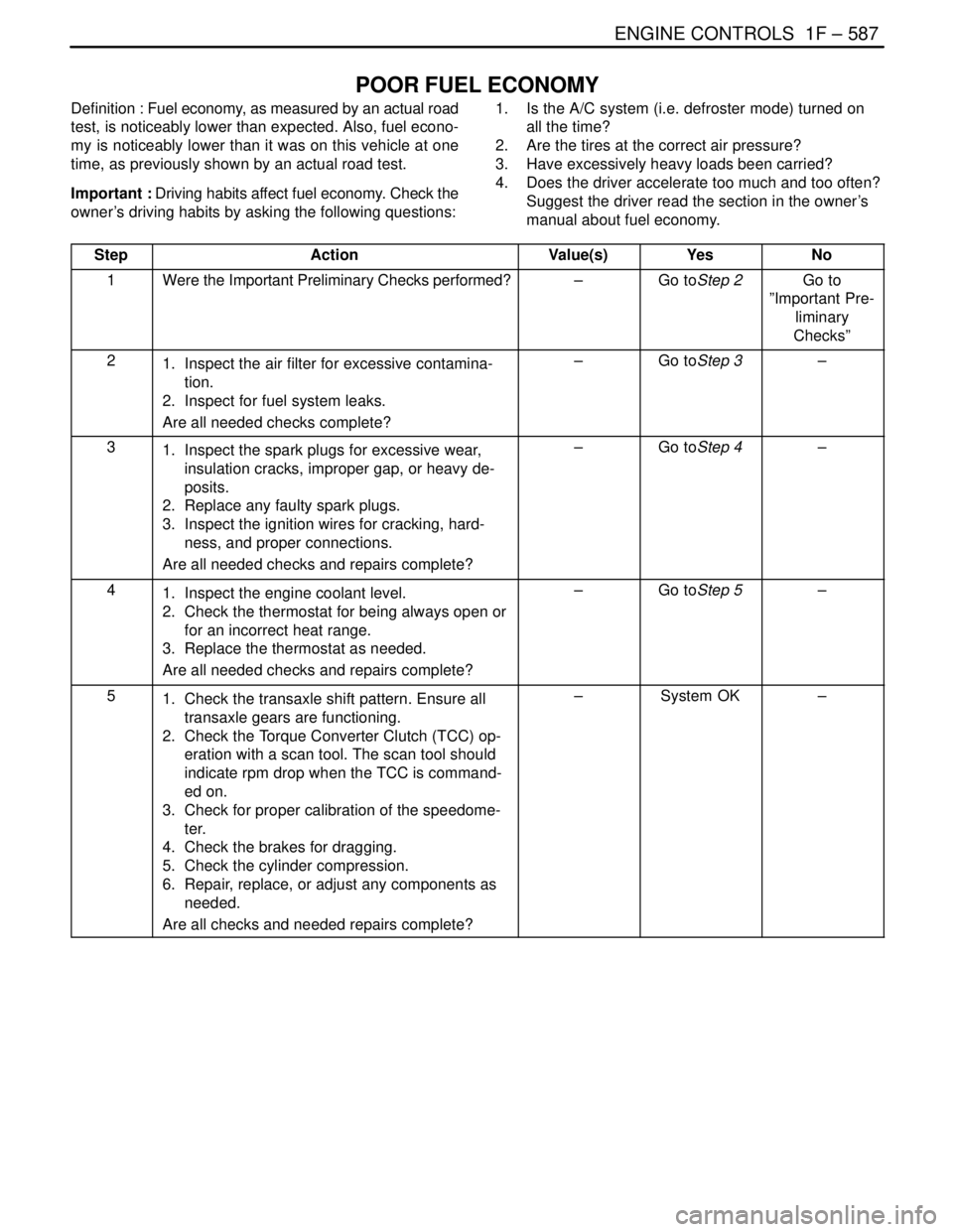

POOR FUEL ECONOMY

Definition : Fuel economy, as measured by an actual road

test, is noticeably lower than expected. Also, fuel econo-

my is noticeably lower than it was on this vehicle at one

time, as previously shown by an actual road test.

Important : Driving habits affect fuel economy. Check the

owner’s driving habits by asking the following questions:1. Is the A/C system (i.e. defroster mode) turned on

all the time?

2. Are the tires at the correct air pressure?

3. Have excessively heavy loads been carried?

4. Does the driver accelerate too much and too often?

Suggest the driver read the section in the owner’s

manual about fuel economy.

Step

ActionValue(s)YesNo

1Were the Important Preliminary Checks performed?–Go toStep 2Go to

”Important Pre-

liminary

Checks”

21. Inspect the air filter for excessive contamina-

tion.

2. Inspect for fuel system leaks.

Are all needed checks complete?–Go toStep 3–

31. Inspect the spark plugs for excessive wear,

insulation cracks, improper gap, or heavy de-

posits.

2. Replace any faulty spark plugs.

3. Inspect the ignition wires for cracking, hard-

ness, and proper connections.

Are all needed checks and repairs complete?–Go toStep 4–

41. Inspect the engine coolant level.

2. Check the thermostat for being always open or

for an incorrect heat range.

3. Replace the thermostat as needed.

Are all needed checks and repairs complete?–Go toStep 5–

51. Check the transaxle shift pattern. Ensure all

transaxle gears are functioning.

2. Check the Torque Converter Clutch (TCC) op-

eration with a scan tool. The scan tool should

indicate rpm drop when the TCC is command-

ed on.

3. Check for proper calibration of the speedome-

ter.

4. Check the brakes for dragging.

5. Check the cylinder compression.

6. Repair, replace, or adjust any components as

needed.

Are all checks and needed repairs complete?–System OK–

Page 872 of 2643

1F – 626IENGINE CONTROLS

DAEWOO V–121 BL4

EXHAUST GAS RECIRCULATION

VA LV E

The Exhaust Gas Recirculation (EGR) system is used on

engines equipped with an automatic transaxle to lower

NOx (oxides of nitrogen) emission levels caused by high

combustion temperature. The EGR valve is controlled by

the engine control module (ECM). The EGR valve feeds

small amounts of exhaust gas into the intake manifold to

decrease combustion temperature. The amount of ex-

haust gas recirculated is controlled by variations in vacu-

um and exhaust back pressure. If too much exhaust gas

enters, combustion will not take place. For this reason,

very little exhaust gas is allowed to pass through the valve,

especially at idle.

The EGR valve is usually open under the following condi-

tions:

S Warm engine operation.

S Above idle speed.

Results of Incorrect Operation

Too much EGR flow tends to weaken combustion, causing

the engine to run roughly or to stop. With too much EGR

flow at idle, cruise, or cold operation, any of the following

conditions may occur:

S The engine stops after a cold start.

S The engine stops at idle after deceleration.

S The vehicle surges during cruise.

S Rough idle.

If the EGR valve stays open all the time, the engine may

not idle. Too little or no EGR flow allows combustion tem-

peratures to get too high during acceleration and load con-

ditions. This could cause the following conditions:

S Spark knock (detonation)

S Engine overheating

S Emission test failure

INTAKE AIR TEMPERATURE

SENSOR

The Intake Air Temperature (IAT) sensor is a thermistor,

a resistor which changes value based on the temperature

of the air entering the engine. Low temperature produces

a high resistance (4,500 ohms at –40°F [–40°C]), while

high temperature causes a low resistance (70 ohms at

266°F [130°C]).

The engine control module (ECM) provides 5 volts to the

IAT sensor through a resistor in the ECM and measures

the change in voltage to determine the IAT. The voltage will

be high when the manifold air is cold and low when the air

is hot. The ECM knows the intake IAT by measuring the

voltage.

The IAT sensor is also used to control spark timing when

the manifold air is cold.

A failure in the IAT sensor circuit sets a diagnostic trouble

code P0112 or P0113.

IDLE AIR CONTROL VALVE

Notice : Do not attempt to remove the protective cap to

readjust the stop screw. Misadjustment may result in dam-

age to the Idle Air Control (IAC) valve or to the throttle

body.

The IAC valve is mounted on the throttle body where it

controls the engine idle speed under the command of the

engine control module (ECM). The ECM sends voltage

pulses to the IAC valve motor windings, causing the IAC

valve pintle to move in or out a given distance (a step or

count) for each pulse. The pintle movement controls the

airflow around the throttle valves which, in turn, control the

engine idle speed.

The desired idle speeds for all engine operating conditions

are programmed into the calibration of the ECM. These

programmed engine speeds are based on the coolant

temperature, the park/neutral position switch status, the

vehicle speed, the battery voltage, and the A/C system

pressure (if equipped).

The ECM ”learns” the proper IAC valve positions to

achieve warm, stabilized idle speeds (rpm) desired for the

various conditions (park/neutral or drive, A/C on or off, if

equipped). This information is stored in ECM ”keep alive”

memories. Information is retained after the ignition is

turned OFF. All other IAC valve positioning is calculated

based on these memory values. As a result, engine varia-

tions due to wear and variations in the minimum throttle

valve position (within limits) do not affect engine idle

speeds. This system provides correct idle control under all

conditions. This also means that disconnecting power to

the ECM can result in incorrect idle control or the necessity

to partially press the accelerator when starting until the

ECM relearns idle control.

Engine idle speed is a function of total airflow into the en-

gine based on the IAC valve pintle position, the throttle

valve opening, and the calibrated vacuum loss through ac-

cessories. The minimum throttle valve position is set at the

factory with a stop screw. This setting allows enough air-

flow by the throttle valve to cause the IAC valve pintle to

be positioned a calibrated number of steps (counts) from

the seat during ”controlled” idle operation. The minimum

throttle valve position setting on this engine should not be

considered the ”minimum idle speed,” as on other fuel in-

jected engines. The throttle stop screw is covered with a

plug at the factory following adjustment.

If the IAC valve is suspected as the cause of improper idle

speed, refer to ”Idle Air Control System Check” in this sec-

tion.

MANIFOLD ABSOLUTE PRESSURE

SENSOR

The Manifold Absolute Pressure (MAP) sensor measures

the changes in the intake manifold pressure which result

from engine load and speed changes. It converts these to

a voltage output.