Transaxle DAEWOO LACETTI 2004 Service Owner's Guide

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 245 of 2643

ENGINE ELECTRICAL 1E – 31

DAEWOO V–121 BL4

trolyte and the plates are at room temperature. A

battery that is extremely cold may not accept cur-

rent for several hours after starting the charger.

3. Charge the battery until the green dot appears. The

battery should be checked every half–hour while

charging. Tipping or shaking the battery may be

necessary to make the green dot appear.

4. After charging, the battery should be load tested.

Refer to ”Starter Motor” in this section.

CHARGING TIME REQUIRED

The time required to charge a battery will vary depending

upon the following factors:

S Size of Battery – A completely discharged large

heavy–duty battery requires more than twice the re-

charging time as a completely discharged small pas-

senger car battery.

S Temperature – A longer time will be needed to

charge any battery at –18°C (0°F) than at 27°C

(80°F). When a fast charger is connected to a cold

battery, the current accepted by the battery will be

very low at first. The battery will accept a higher cur-

rent rate as the battery warms.

S Charger Capacity – A charger which can supply only

5 amperes will require a much longer charging period

than a charger that can supply 30 amperes or more.

S State–of–Charge – A completely discharged battery

requires more than twice as much charge as a one–

half charged battery. Because the electrolyte is nearly

pure water and a poor conductor in a completely dis-

charged battery, the current accepted by the battery

is very low at first. Later, as the charging current

causes the electrolyte acid content to increase, the

charging current will likewise increase.

CHARGING A COMPLETELY

DISCHARGED BATTERY (OFF THE

VEHICLE)

Unless this procedure is properly followed, a perfectly

good battery may need to be replaced.

The following procedure should be used to recharge a

completely discharged battery:

1. Measure the voltage at the battery terminals with

an accurate voltmeter. If the reading is below 10

volts, the charge current will be very low, and it

could take some time before the battery accepts

the current in excess of a few milliamperes. Refer

to ””Charging Time Required” in this section, which

focuses on the factors affecting both the charging

time required and the rough estimates in the table

below. Such low current may not be detectable on

ammeters available in the field.

2. Set the battery charger on the high setting.Important : Some chargers feature polarity protection cir-

cuitry, which prevents charging unless the charger leads

are correctly connected to the battery terminals. A com-

pletely discharged battery may not have enough voltage

to activate this circuitry, even though the leads are con-

nected properly, making it appear that the battery will not

accept charging current. Therefore, follow the specific

charger manufacturer’s instruction for bypassing or over-

riding the circuitry so that the charger will turn on and

charge a low–voltage battery.

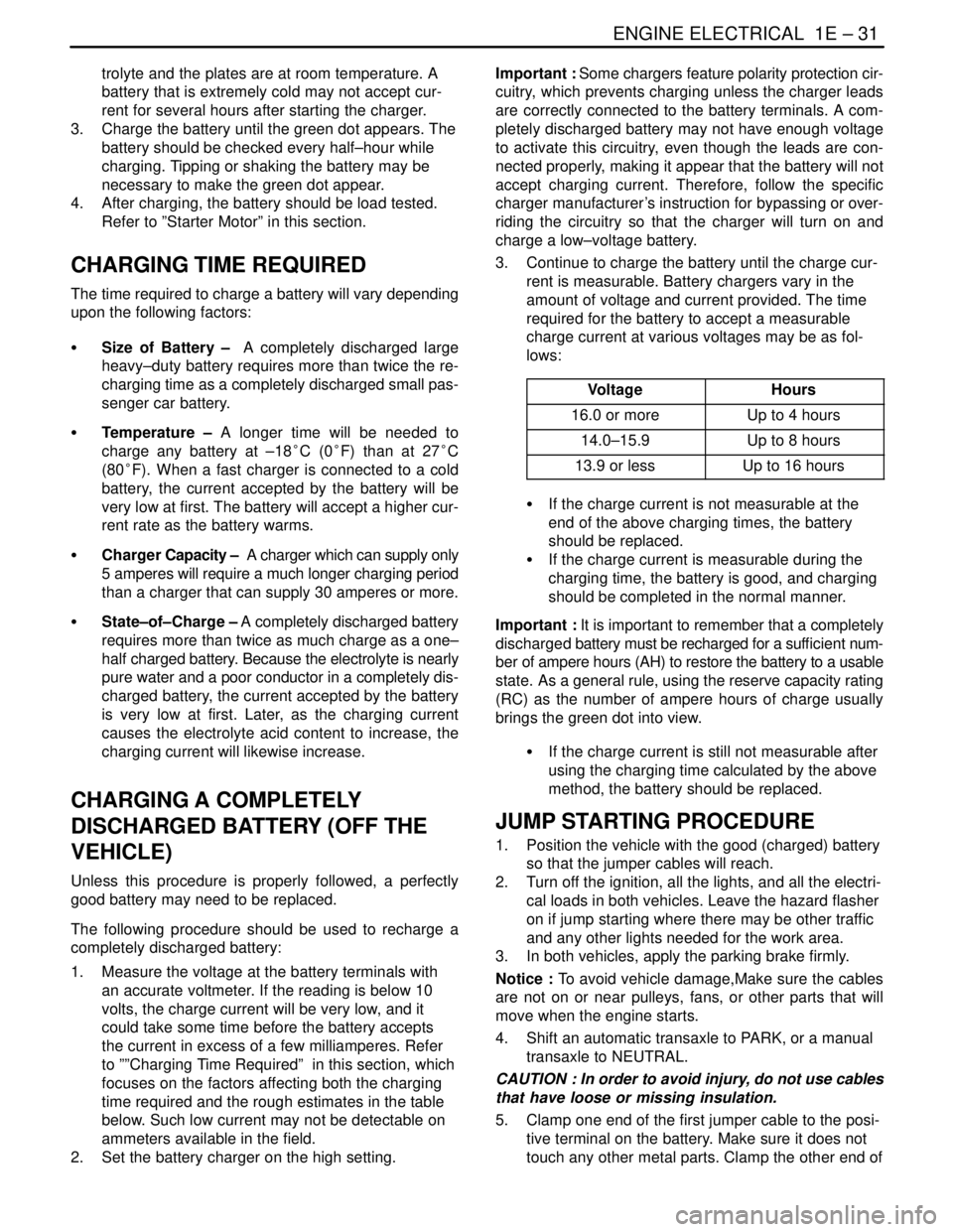

3. Continue to charge the battery until the charge cur-

rent is measurable. Battery chargers vary in the

amount of voltage and current provided. The time

required for the battery to accept a measurable

charge current at various voltages may be as fol-

lows:

Voltage

Hours

16.0 or moreUp to 4 hours

14.0–15.9Up to 8 hours

13.9 or lessUp to 16 hours

S If the charge current is not measurable at the

end of the above charging times, the battery

should be replaced.

S If the charge current is measurable during the

charging time, the battery is good, and charging

should be completed in the normal manner.

Important : It is important to remember that a completely

discharged battery must be recharged for a sufficient num-

ber of ampere hours (AH) to restore the battery to a usable

state. As a general rule, using the reserve capacity rating

(RC) as the number of ampere hours of charge usually

brings the green dot into view.

S If the charge current is still not measurable after

using the charging time calculated by the above

method, the battery should be replaced.

JUMP STARTING PROCEDURE

1. Position the vehicle with the good (charged) battery

so that the jumper cables will reach.

2. Turn off the ignition, all the lights, and all the electri-

cal loads in both vehicles. Leave the hazard flasher

on if jump starting where there may be other traffic

and any other lights needed for the work area.

3. In both vehicles, apply the parking brake firmly.

Notice : To avoid vehicle damage,Make sure the cables

are not on or near pulleys, fans, or other parts that will

move when the engine starts.

4. Shift an automatic transaxle to PARK, or a manual

transaxle to NEUTRAL.

CAUTION : In order to avoid injury, do not use cables

that have loose or missing insulation.

5. Clamp one end of the first jumper cable to the posi-

tive terminal on the battery. Make sure it does not

touch any other metal parts. Clamp the other end of

Page 250 of 2643

1F – 4IENGINE CONTROLS

DAEWOO V–121 BL4

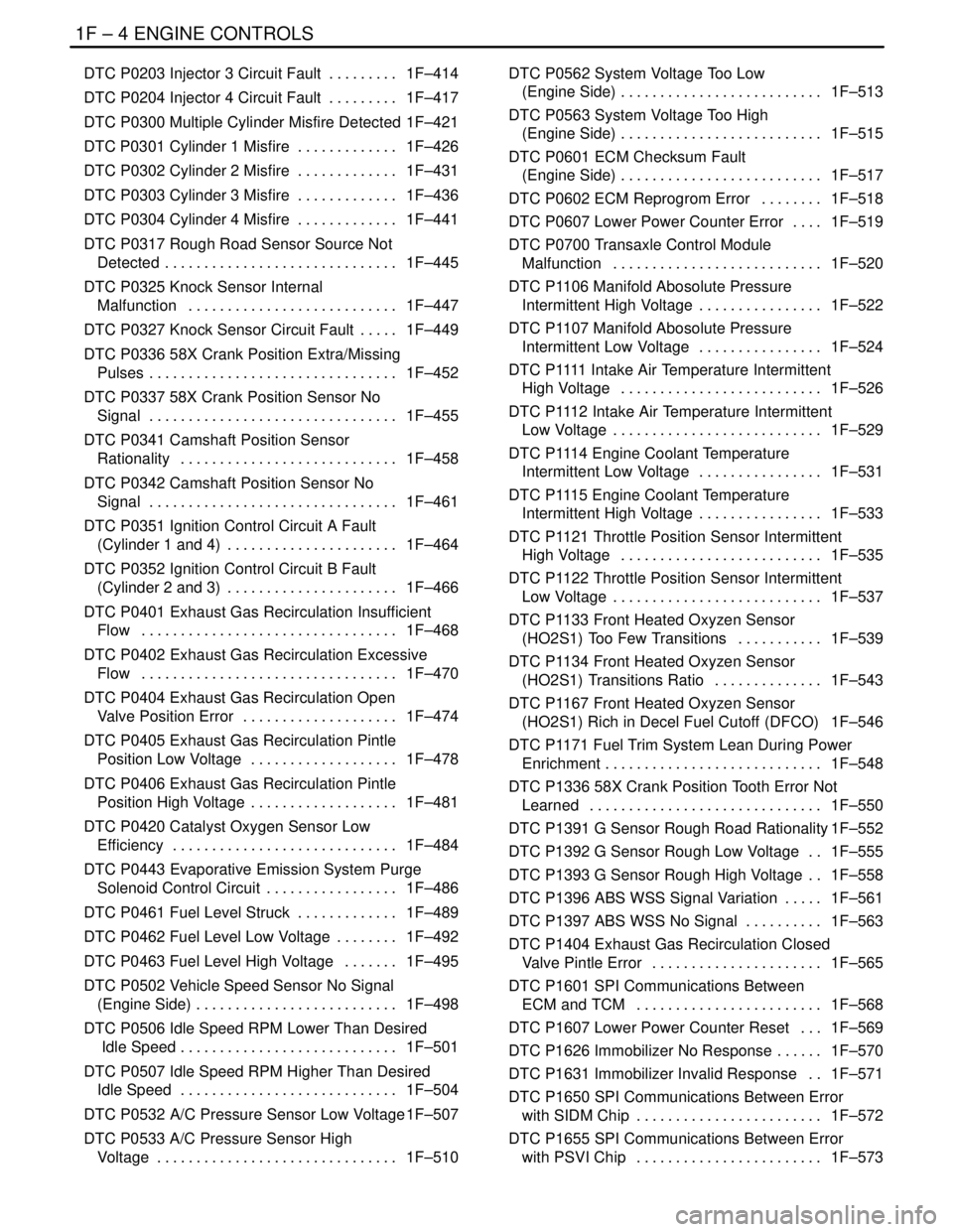

DTC P0203 Injector 3 Circuit Fault 1F–414. . . . . . . . .

DTC P0204 Injector 4 Circuit Fault 1F–417. . . . . . . . .

DTC P0300 Multiple Cylinder Misfire Detected 1F–421

DTC P0301 Cylinder 1 Misfire 1F–426. . . . . . . . . . . . .

DTC P0302 Cylinder 2 Misfire 1F–431. . . . . . . . . . . . .

DTC P0303 Cylinder 3 Misfire 1F–436. . . . . . . . . . . . .

DTC P0304 Cylinder 4 Misfire 1F–441. . . . . . . . . . . . .

DTC P0317 Rough Road Sensor Source Not

Detected 1F–445. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0325 Knock Sensor Internal

Malfunction 1F–447. . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0327 Knock Sensor Circuit Fault 1F–449. . . . .

DTC P0336 58X Crank Position Extra/Missing

Pulses 1F–452. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0337 58X Crank Position Sensor No

Signal 1F–455. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0341 Camshaft Position Sensor

Rationality 1F–458. . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0342 Camshaft Position Sensor No

Signal 1F–461. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0351 Ignition Control Circuit A Fault

(Cylinder 1 and 4) 1F–464. . . . . . . . . . . . . . . . . . . . . .

DTC P0352 Ignition Control Circuit B Fault

(Cylinder 2 and 3) 1F–466. . . . . . . . . . . . . . . . . . . . . .

DTC P0401 Exhaust Gas Recirculation Insufficient

Flow 1F–468. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0402 Exhaust Gas Recirculation Excessive

Flow 1F–470. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0404 Exhaust Gas Recirculation Open

Valve Position Error 1F–474. . . . . . . . . . . . . . . . . . . .

DTC P0405 Exhaust Gas Recirculation Pintle

Position Low Voltage 1F–478. . . . . . . . . . . . . . . . . . .

DTC P0406 Exhaust Gas Recirculation Pintle

Position High Voltage 1F–481. . . . . . . . . . . . . . . . . . .

DTC P0420 Catalyst Oxygen Sensor Low

Efficiency 1F–484. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0443 Evaporative Emission System Purge

Solenoid Control Circuit 1F–486. . . . . . . . . . . . . . . . .

DTC P0461 Fuel Level Struck 1F–489. . . . . . . . . . . . .

DTC P0462 Fuel Level Low Voltage 1F–492. . . . . . . .

DTC P0463 Fuel Level High Voltage 1F–495. . . . . . .

DTC P0502 Vehicle Speed Sensor No Signal

(Engine Side) 1F–498. . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0506 Idle Speed RPM Lower Than Desired

Idle Speed 1F–501. . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0507 Idle Speed RPM Higher Than Desired

Idle Speed 1F–504. . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0532 A/C Pressure Sensor Low Voltage 1F–507

DTC P0533 A/C Pressure Sensor High

Voltage 1F–510. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . DTC P0562 System Voltage Too Low

(Engine Side) 1F–513. . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0563 System Voltage Too High

(Engine Side) 1F–515. . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0601 ECM Checksum Fault

(Engine Side) 1F–517. . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0602 ECM Reprogrom Error 1F–518. . . . . . . .

DTC P0607 Lower Power Counter Error 1F–519. . . .

DTC P0700 Transaxle Control Module

Malfunction 1F–520. . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P1106 Manifold Abosolute Pressure

Intermittent High Voltage 1F–522. . . . . . . . . . . . . . . .

DTC P1107 Manifold Abosolute Pressure

Intermittent Low Voltage 1F–524. . . . . . . . . . . . . . . .

DTC P1111 Intake Air Temperature Intermittent

High Voltage 1F–526. . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P1112 Intake Air Temperature Intermittent

Low Voltage 1F–529. . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P1114 Engine Coolant Temperature

Intermittent Low Voltage 1F–531. . . . . . . . . . . . . . . .

DTC P1115 Engine Coolant Temperature

Intermittent High Voltage 1F–533. . . . . . . . . . . . . . . .

DTC P1121 Throttle Position Sensor Intermittent

High Voltage 1F–535. . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P1122 Throttle Position Sensor Intermittent

Low Voltage 1F–537. . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P1133 Front Heated Oxyzen Sensor

(HO2S1) Too Few Transitions 1F–539. . . . . . . . . . .

DTC P1134 Front Heated Oxyzen Sensor

(HO2S1) Transitions Ratio 1F–543. . . . . . . . . . . . . .

DTC P1167 Front Heated Oxyzen Sensor

(HO2S1) Rich in Decel Fuel Cutoff (DFCO) 1F–546

DTC P1171 Fuel Trim System Lean During Power

Enrichment 1F–548. . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P1336 58X Crank Position Tooth Error Not

Learned 1F–550. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P1391 G Sensor Rough Road Rationality 1F–552

DTC P1392 G Sensor Rough Low Voltage 1F–555. .

DTC P1393 G Sensor Rough High Voltage 1F–558. .

DTC P1396 ABS WSS Signal Variation 1F–561. . . . .

DTC P1397 ABS WSS No Signal 1F–563. . . . . . . . . .

DTC P1404 Exhaust Gas Recirculation Closed

Valve Pintle Error 1F–565. . . . . . . . . . . . . . . . . . . . . .

DTC P1601 SPI Communications Between

ECM and TCM 1F–568. . . . . . . . . . . . . . . . . . . . . . . .

DTC P1607 Lower Power Counter Reset 1F–569. . .

DTC P1626 Immobilizer No Response 1F–570. . . . . .

DTC P1631 Immobilizer Invalid Response 1F–571. .

DTC P1650 SPI Communications Between Error

with SIDM Chip 1F–572. . . . . . . . . . . . . . . . . . . . . . . .

DTC P1655 SPI Communications Between Error

with PSVI Chip 1F–573. . . . . . . . . . . . . . . . . . . . . . . .

Page 276 of 2643

1F – 30IENGINE CONTROLS

DAEWOO V–121 BL4

DIAGNOSIS

SYSTEM DIAGNOSIS

DIAGNOSTIC AIDS

If an intermittent problem is evident, follow the guidelines

below.

Preliminary Checks

Before using this section you should have already per-

formed the ”On–Board Diagnostic System Check.”

Perform a thorough visual inspection. This inspection can

often lead to correcting a problem without further checks

and can save valuable time. Inspect for the following con-

ditions:

S Engine control module (ECM) grounds for being

clean, tight, and in their proper location.

S Vacuum hoses for splits, kinks, collapsing and prop-

er connections as shown on the Vehicle Emission

Control Information label. Inspect thoroughly for

any type of leak or restriction.

S Air leaks at the throttle body mounting area and the

intake manifold sealing surfaces.

S Ignition wires for cracks, hardness, proper routing,

and carbon tracking.

S Wiring for proper connections.

S Wiring for pinches or cuts.

Diagnostic Trouble Code Tables

Do not use the Diagnostic Trouble Code (DTC) tables to

try to correct an intermittent fault. The fault must be pres-

ent to locate the problem.

Incorrect use of the DTC tables may result in the unneces-

sary replacement of parts.

Faulty Electrical Connections or Wiring

Most intermittent problems are caused by faulty electrical

connections or wiring. Perform a careful inspection of sus-

pect circuits for the following:

S Poor mating of the connector halves.

S Terminals not fully seated in the connector body.

S Improperly formed or damaged terminals. All con-

nector terminals in a problem circuit should be care-

fully inspected, reformed, or replaced to insure con-

tact tension.S Poor terminal–to–wire connection. This requires

removing the terminal from the connector body.

Road Test

If a visual inspection does not find the cause of the prob-

lem, the vehicle can be driven with a voltmeter or a scan

tool connected to a suspected circuit. An abnormal voltage

or scan tool reading will indicate that the problem is in that

circuit.

If there are no wiring or connector problems found and a

DTC was stored for a circuit having a sensor, except for

DTC P0171 and DTC P0172, replace the sensor.

Fuel System

Some intermittent driveability problems can be attributed

to poor fuel quality. If a vehicle is occasionally running

rough, stalling, or otherwise performing badly, ask the cus-

tomer about the following fuel buying habits:

S Do they always buy from the same source? If so,

fuel quality problems can usually be discounted.

S Do they buy their fuel from whichever fuel station

that is advertising the lowest price? If so, check the

fuel tank for signs of debris, water, or other contam-

ination.

IDLE LEARN PROCEDURE

Whenever the battery cables, the engine control module

(ECM), or the ECM fuse is disconnected or replaced, the

following idle learn procedure must be performed:

1. Turn the ignition ON for 5 seconds.

2. Turn the ignition OFF for 5 seconds.

3. Turn the ignition ON for 5 seconds.

4. Start the engine in park/neutral.

5. Allow the engine to run until the engine coolant is

above 185° F (85°C ).

6. Turn the A/C ON for 10 seconds, if equipped.

7. Turn the A/C OFF for 10 seconds, if equipped.

8. If the vehicle is equipped with an automatic trans-

axle, apply the parking brake. While pressing the

brake pedal, place the transaxle in D (drive).

9. Turn the A/C ON for 10 seconds, if equipped.

10. Turn the A/C OFF for 10 seconds, if equipped.

11. Turn the ignition OFF. The idle learn procedure is

complete.

Page 282 of 2643

1F – 36IENGINE CONTROLS

DAEWOO V–121 BL4

MULTIPLE ECM INFORMATION SENSOR DTCS SET

Circuit Description

The Engine Control Module (ECM) monitors various sen-

sors to determine engine operating conditions. The ECM

controls fuel delivery, spark advance, transaxle operation,

and emission control device operation based on the sen-

sor inputs.

The ECM provides a sensor ground to all of the sensors.

The ECM applies 5 volts through a pull–up resistor and

monitors the voltage present between the sensor and the

resistor to determine the status of the Engine Coolant

Temperature (ECT) sensor, the Intake Air Temperature

(IAT) sensor. The ECM provides the Exhaust Gas Recir-

culation (EGR) Pintle Position Sensor, the Throttle Posi-

tion (TP) sensor, the Manifold Absolute Pressure (MAP)

sensor, and the Fuel Tank Pressure Sensor with a 5 volt

reference and a sensor ground signal. The ECM monitors

the separate feedback signals from these sensors to de-

termine their operating status.

Diagnostic Aids

Be sure to inspect the ECM and the engine grounds for be-

ing secure and clean.

A short to voltage in one of the sensor circuits can cause

one or more of the following DTCs to be set: P0108,

P0113, P0118, P0123, P1106, P1111, P1115, P1121,

P0463, P0533.

If a sensor input circuit has been shorted to voltage, en-

sure that the sensor is not damaged. A damaged sensor

will continue to indicate a high or low voltage after the af-

fected circuit has been repaired. If the sensor has been

damaged, replace it.

An open in the sensor ground circuit between the ECM and

the splice will cause one or more of the following DTCs to

be set: P0107, P0108, P0113, P0118, P0122, P0123,

P1106, P1111, P1115, P1121, P0462, P0532.

A short to ground in the 5 volt reference circuit or an open

in the 5 volt reference circuit between the ECM and the

splice will cause one or more of the following DTCs to be

set: P0107, P0112, P0117, P0122, P1107, P1112, P1114,

P1122, P0462, P0532.Check for the following conditions:

S Inspect for a poor connection at the ECM. Inspect

harness connectors for backed–out terminals, im-

proper mating, broken locks, improperly formed or

damaged terminals, and poor terminal–to–wire con-

nection.

S Inspect the wiring harness for damage. If the har-

ness appears to be OK, observe an affected sen-

sor ’s displayed value on the scan tool with the igni-

tion ON and the engine OFF while moving

connectors and wiring harnesses related to the af-

fected sensors. A change in the affected sensor’s

displayed value will indicate the location of the fault.

Test Description

Number(s) below refer to the step number(s) on the Diag-

nostic Table.

1. The Powertrain On–Board Diagnostic (EOBD) Sys-

tem Check prompts the technician to complete

some basic checks and store the freeze frame and

failure records data on the scan tool if applicable.

This creates an electronic copy of the data taken

when the malfunction occurred. The information is

then stored on the scan tool for later reference.

9. A faulty EGR valve can leak a small amount of cur-

rent from the ignition feed circuit to the 5 volt refer-

ence circuit. If the problem does not exist with the

EGR valve disconnected, replace the EGR valve.

0. If a sensor input circuit has been shorted to voltage,

ensure that the sensor has not been damaged. A

damaged IAT or ECT sensor will continue to indi-

cate a high voltage or low temperature after the

affected circuit has been repaired. A damaged ACT,

TP, MAP, Fuel Tank Pressure, or EGR Pintle Posi-

tion sensor will indicate a high or low voltage or

may be stuck at a fixed value after the affected cir-

cuit has been repaired. If the sensor has been dam-

aged, replace it.

21. The replacement ECM must be reprogrammed.

Refer to the latest Techline procedure for ECM re-

programming.

Page 328 of 2643

1F – 82IENGINE CONTROLS

DAEWOO V–121 BL4

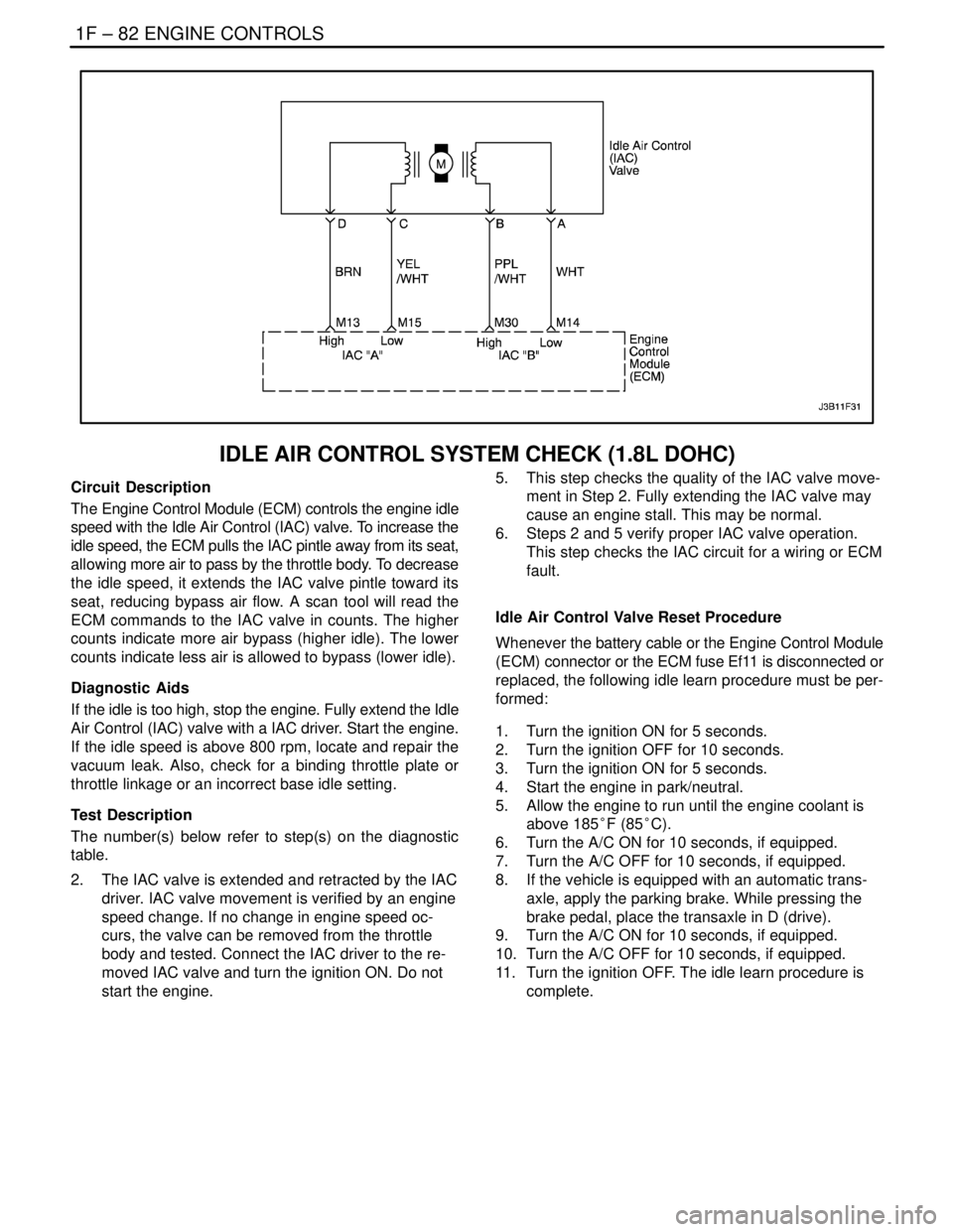

IDLE AIR CONTROL SYSTEM CHECK (1.8L DOHC)

Circuit Description

The Engine Control Module (ECM) controls the engine idle

speed with the Idle Air Control (IAC) valve. To increase the

idle speed, the ECM pulls the IAC pintle away from its seat,

allowing more air to pass by the throttle body. To decrease

the idle speed, it extends the IAC valve pintle toward its

seat, reducing bypass air flow. A scan tool will read the

ECM commands to the IAC valve in counts. The higher

counts indicate more air bypass (higher idle). The lower

counts indicate less air is allowed to bypass (lower idle).

Diagnostic Aids

If the idle is too high, stop the engine. Fully extend the Idle

Air Control (IAC) valve with a IAC driver. Start the engine.

If the idle speed is above 800 rpm, locate and repair the

vacuum leak. Also, check for a binding throttle plate or

throttle linkage or an incorrect base idle setting.

Test Description

The number(s) below refer to step(s) on the diagnostic

table.

2. The IAC valve is extended and retracted by the IAC

driver. IAC valve movement is verified by an engine

speed change. If no change in engine speed oc-

curs, the valve can be removed from the throttle

body and tested. Connect the IAC driver to the re-

moved IAC valve and turn the ignition ON. Do not

start the engine.5. This step checks the quality of the IAC valve move-

ment in Step 2. Fully extending the IAC valve may

cause an engine stall. This may be normal.

6. Steps 2 and 5 verify proper IAC valve operation.

This step checks the IAC circuit for a wiring or ECM

fault.

Idle Air Control Valve Reset Procedure

Whenever the battery cable or the Engine Control Module

(ECM) connector or the ECM fuse Ef11 is disconnected or

replaced, the following idle learn procedure must be per-

formed:

1. Turn the ignition ON for 5 seconds.

2. Turn the ignition OFF for 10 seconds.

3. Turn the ignition ON for 5 seconds.

4. Start the engine in park/neutral.

5. Allow the engine to run until the engine coolant is

above 185°F (85°C).

6. Turn the A/C ON for 10 seconds, if equipped.

7. Turn the A/C OFF for 10 seconds, if equipped.

8. If the vehicle is equipped with an automatic trans-

axle, apply the parking brake. While pressing the

brake pedal, place the transaxle in D (drive).

9. Turn the A/C ON for 10 seconds, if equipped.

10. Turn the A/C OFF for 10 seconds, if equipped.

11. Turn the ignition OFF. The idle learn procedure is

complete.

Page 417 of 2643

ENGINE CONTROLS 1F – 171

DAEWOO V–121 BL4

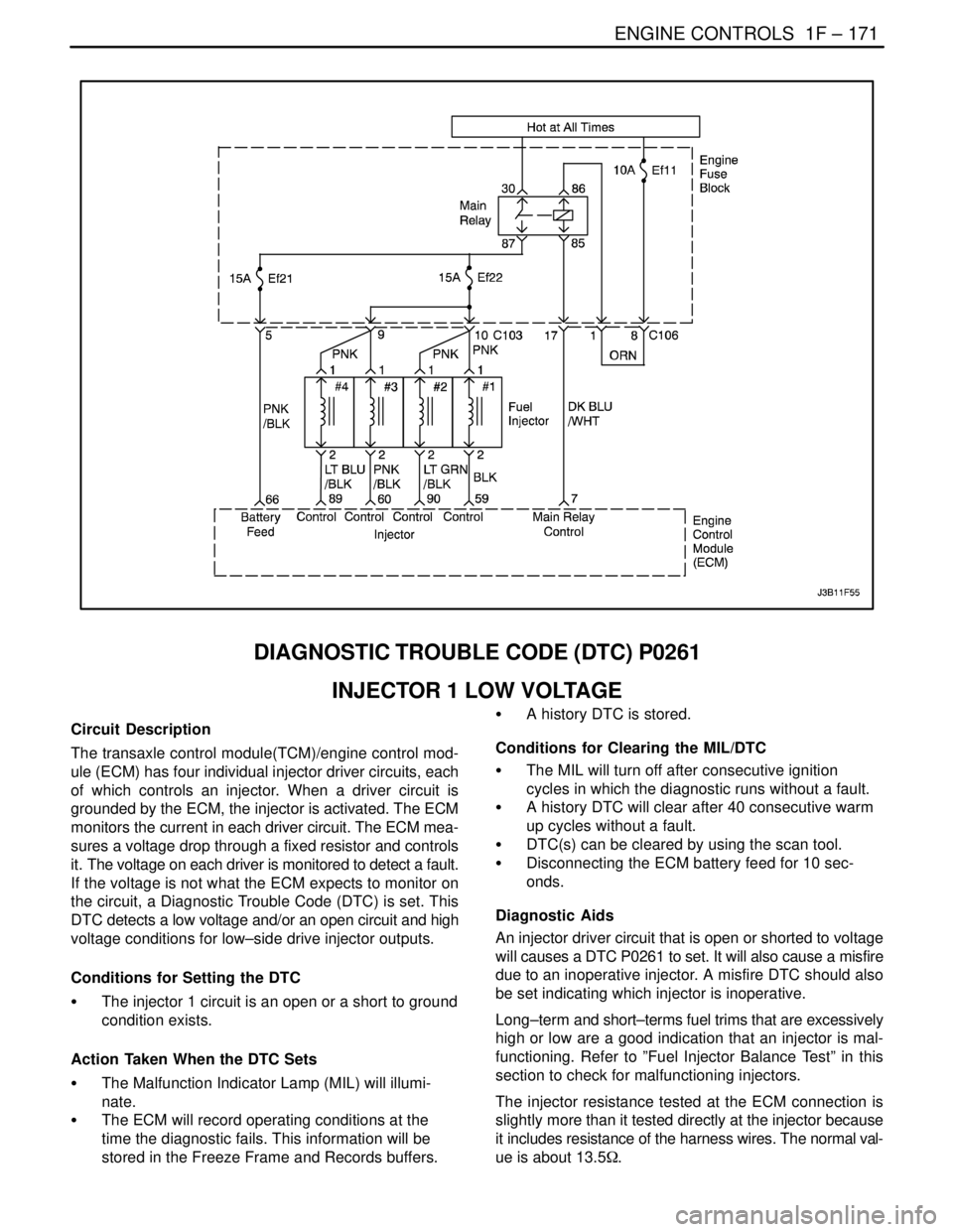

DIAGNOSTIC TROUBLE CODE (DTC) P0261

INJECTOR 1 LOW VOLTAGE

Circuit Description

The transaxle control module(TCM)/engine control mod-

ule (ECM) has four individual injector driver circuits, each

of which controls an injector. When a driver circuit is

grounded by the ECM, the injector is activated. The ECM

monitors the current in each driver circuit. The ECM mea-

sures a voltage drop through a fixed resistor and controls

it. The voltage on each driver is monitored to detect a fault.

If the voltage is not what the ECM expects to monitor on

the circuit, a Diagnostic Trouble Code (DTC) is set. This

DTC detects a low voltage and/or an open circuit and high

voltage conditions for low–side drive injector outputs.

Conditions for Setting the DTC

S The injector 1 circuit is an open or a short to ground

condition exists.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will illumi-

nate.

S The ECM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Freeze Frame and Records buffers.S A history DTC is stored.

Conditions for Clearing the MIL/DTC

S The MIL will turn off after consecutive ignition

cycles in which the diagnostic runs without a fault.

S A history DTC will clear after 40 consecutive warm

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for 10 sec-

onds.

Diagnostic Aids

An injector driver circuit that is open or shorted to voltage

will causes a DTC P0261 to set. It will also cause a misfire

due to an inoperative injector. A misfire DTC should also

be set indicating which injector is inoperative.

Long–term and short–terms fuel trims that are excessively

high or low are a good indication that an injector is mal-

functioning. Refer to ”Fuel Injector Balance Test” in this

section to check for malfunctioning injectors.

The injector resistance tested at the ECM connection is

slightly more than it tested directly at the injector because

it includes resistance of the harness wires. The normal val-

ue is about 13.5W.

Page 419 of 2643

ENGINE CONTROLS 1F – 173

DAEWOO V–121 BL4

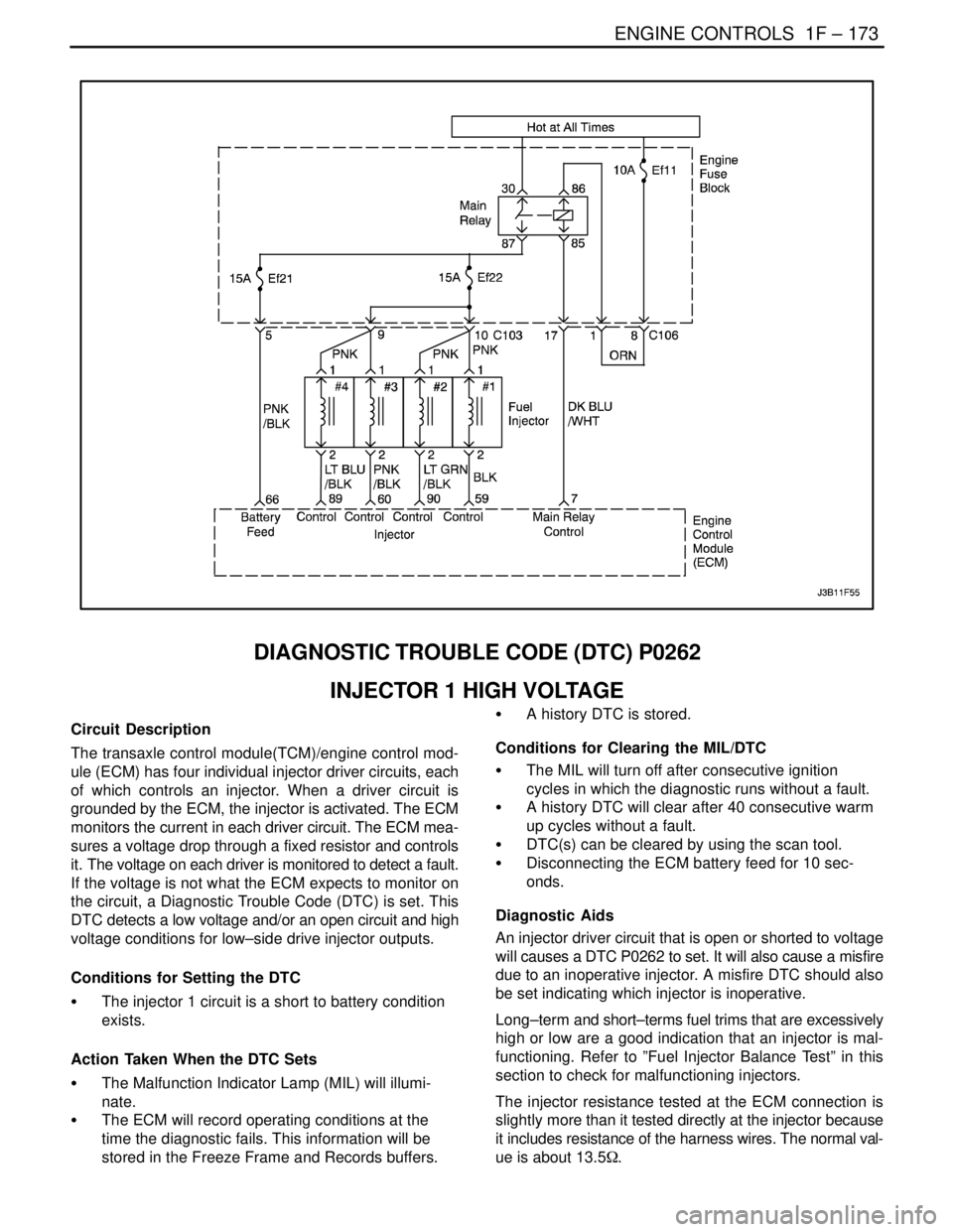

DIAGNOSTIC TROUBLE CODE (DTC) P0262

INJECTOR 1 HIGH VOLTAGE

Circuit Description

The transaxle control module(TCM)/engine control mod-

ule (ECM) has four individual injector driver circuits, each

of which controls an injector. When a driver circuit is

grounded by the ECM, the injector is activated. The ECM

monitors the current in each driver circuit. The ECM mea-

sures a voltage drop through a fixed resistor and controls

it. The voltage on each driver is monitored to detect a fault.

If the voltage is not what the ECM expects to monitor on

the circuit, a Diagnostic Trouble Code (DTC) is set. This

DTC detects a low voltage and/or an open circuit and high

voltage conditions for low–side drive injector outputs.

Conditions for Setting the DTC

S The injector 1 circuit is a short to battery condition

exists.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will illumi-

nate.

S The ECM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Freeze Frame and Records buffers.S A history DTC is stored.

Conditions for Clearing the MIL/DTC

S The MIL will turn off after consecutive ignition

cycles in which the diagnostic runs without a fault.

S A history DTC will clear after 40 consecutive warm

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for 10 sec-

onds.

Diagnostic Aids

An injector driver circuit that is open or shorted to voltage

will causes a DTC P0262 to set. It will also cause a misfire

due to an inoperative injector. A misfire DTC should also

be set indicating which injector is inoperative.

Long–term and short–terms fuel trims that are excessively

high or low are a good indication that an injector is mal-

functioning. Refer to ”Fuel Injector Balance Test” in this

section to check for malfunctioning injectors.

The injector resistance tested at the ECM connection is

slightly more than it tested directly at the injector because

it includes resistance of the harness wires. The normal val-

ue is about 13.5W.

Page 421 of 2643

ENGINE CONTROLS 1F – 175

DAEWOO V–121 BL4

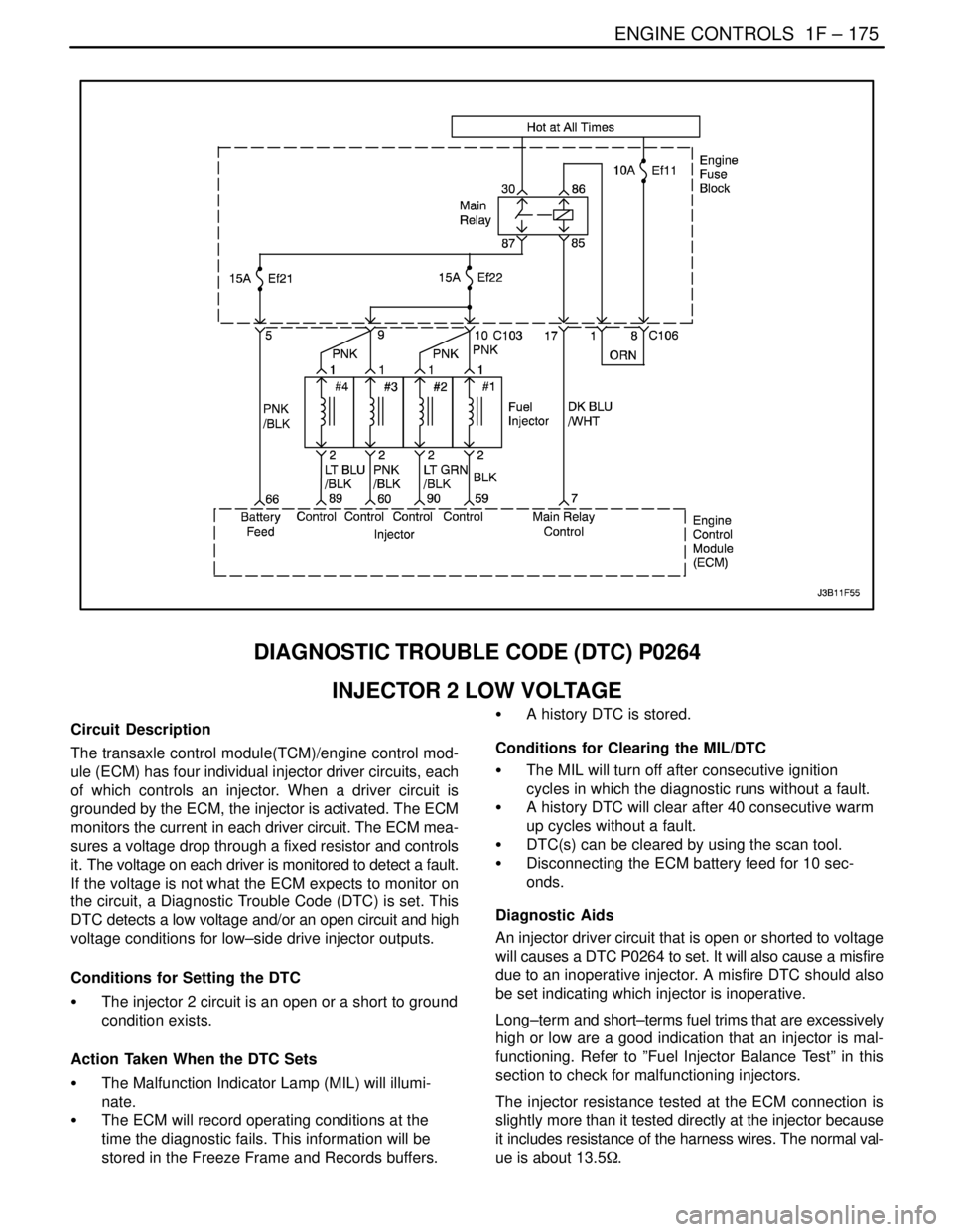

DIAGNOSTIC TROUBLE CODE (DTC) P0264

INJECTOR 2 LOW VOLTAGE

Circuit Description

The transaxle control module(TCM)/engine control mod-

ule (ECM) has four individual injector driver circuits, each

of which controls an injector. When a driver circuit is

grounded by the ECM, the injector is activated. The ECM

monitors the current in each driver circuit. The ECM mea-

sures a voltage drop through a fixed resistor and controls

it. The voltage on each driver is monitored to detect a fault.

If the voltage is not what the ECM expects to monitor on

the circuit, a Diagnostic Trouble Code (DTC) is set. This

DTC detects a low voltage and/or an open circuit and high

voltage conditions for low–side drive injector outputs.

Conditions for Setting the DTC

S The injector 2 circuit is an open or a short to ground

condition exists.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will illumi-

nate.

S The ECM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Freeze Frame and Records buffers.S A history DTC is stored.

Conditions for Clearing the MIL/DTC

S The MIL will turn off after consecutive ignition

cycles in which the diagnostic runs without a fault.

S A history DTC will clear after 40 consecutive warm

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for 10 sec-

onds.

Diagnostic Aids

An injector driver circuit that is open or shorted to voltage

will causes a DTC P0264 to set. It will also cause a misfire

due to an inoperative injector. A misfire DTC should also

be set indicating which injector is inoperative.

Long–term and short–terms fuel trims that are excessively

high or low are a good indication that an injector is mal-

functioning. Refer to ”Fuel Injector Balance Test” in this

section to check for malfunctioning injectors.

The injector resistance tested at the ECM connection is

slightly more than it tested directly at the injector because

it includes resistance of the harness wires. The normal val-

ue is about 13.5W.

Page 423 of 2643

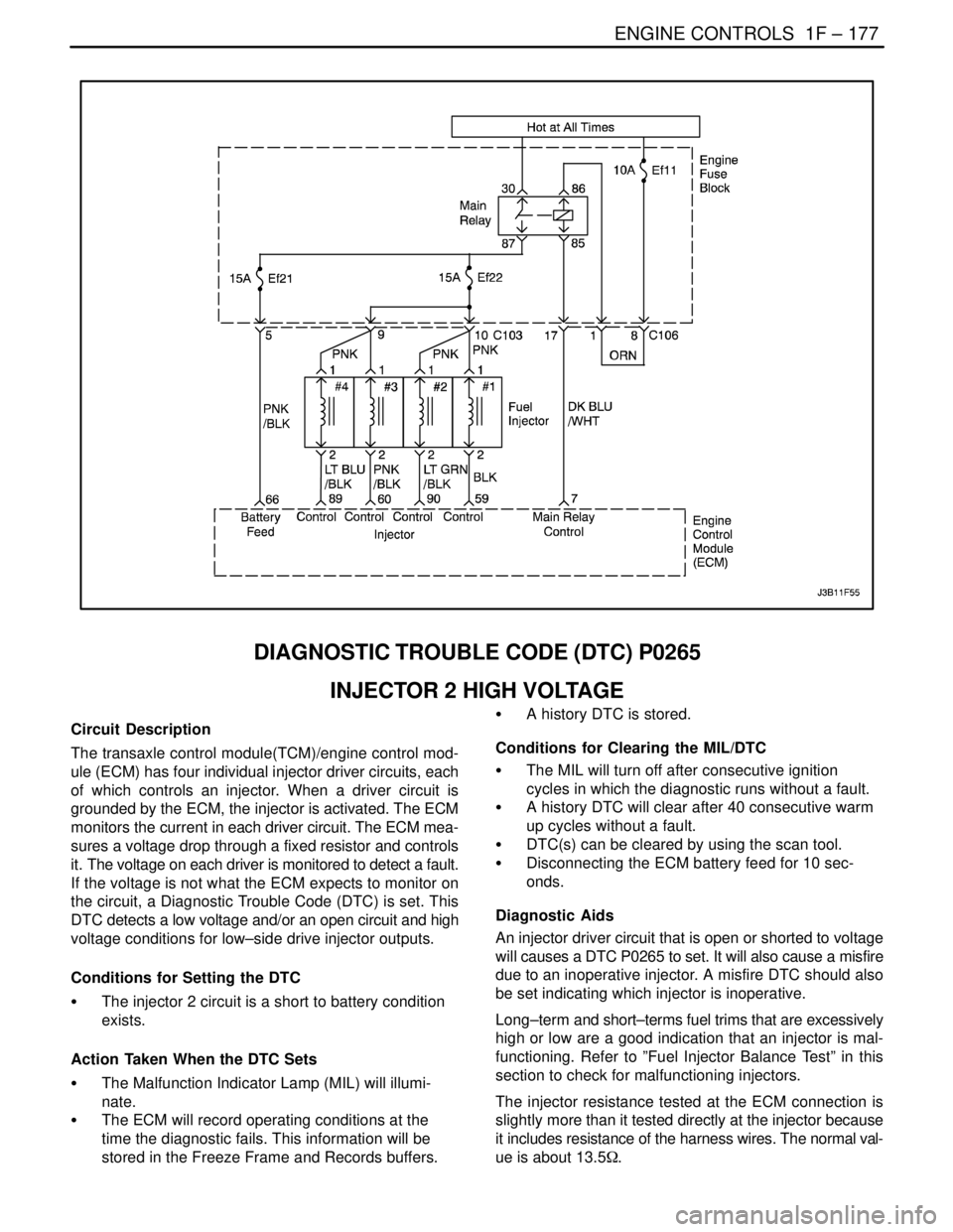

ENGINE CONTROLS 1F – 177

DAEWOO V–121 BL4

DIAGNOSTIC TROUBLE CODE (DTC) P0265

INJECTOR 2 HIGH VOLTAGE

Circuit Description

The transaxle control module(TCM)/engine control mod-

ule (ECM) has four individual injector driver circuits, each

of which controls an injector. When a driver circuit is

grounded by the ECM, the injector is activated. The ECM

monitors the current in each driver circuit. The ECM mea-

sures a voltage drop through a fixed resistor and controls

it. The voltage on each driver is monitored to detect a fault.

If the voltage is not what the ECM expects to monitor on

the circuit, a Diagnostic Trouble Code (DTC) is set. This

DTC detects a low voltage and/or an open circuit and high

voltage conditions for low–side drive injector outputs.

Conditions for Setting the DTC

S The injector 2 circuit is a short to battery condition

exists.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will illumi-

nate.

S The ECM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Freeze Frame and Records buffers.S A history DTC is stored.

Conditions for Clearing the MIL/DTC

S The MIL will turn off after consecutive ignition

cycles in which the diagnostic runs without a fault.

S A history DTC will clear after 40 consecutive warm

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for 10 sec-

onds.

Diagnostic Aids

An injector driver circuit that is open or shorted to voltage

will causes a DTC P0265 to set. It will also cause a misfire

due to an inoperative injector. A misfire DTC should also

be set indicating which injector is inoperative.

Long–term and short–terms fuel trims that are excessively

high or low are a good indication that an injector is mal-

functioning. Refer to ”Fuel Injector Balance Test” in this

section to check for malfunctioning injectors.

The injector resistance tested at the ECM connection is

slightly more than it tested directly at the injector because

it includes resistance of the harness wires. The normal val-

ue is about 13.5W.

Page 425 of 2643

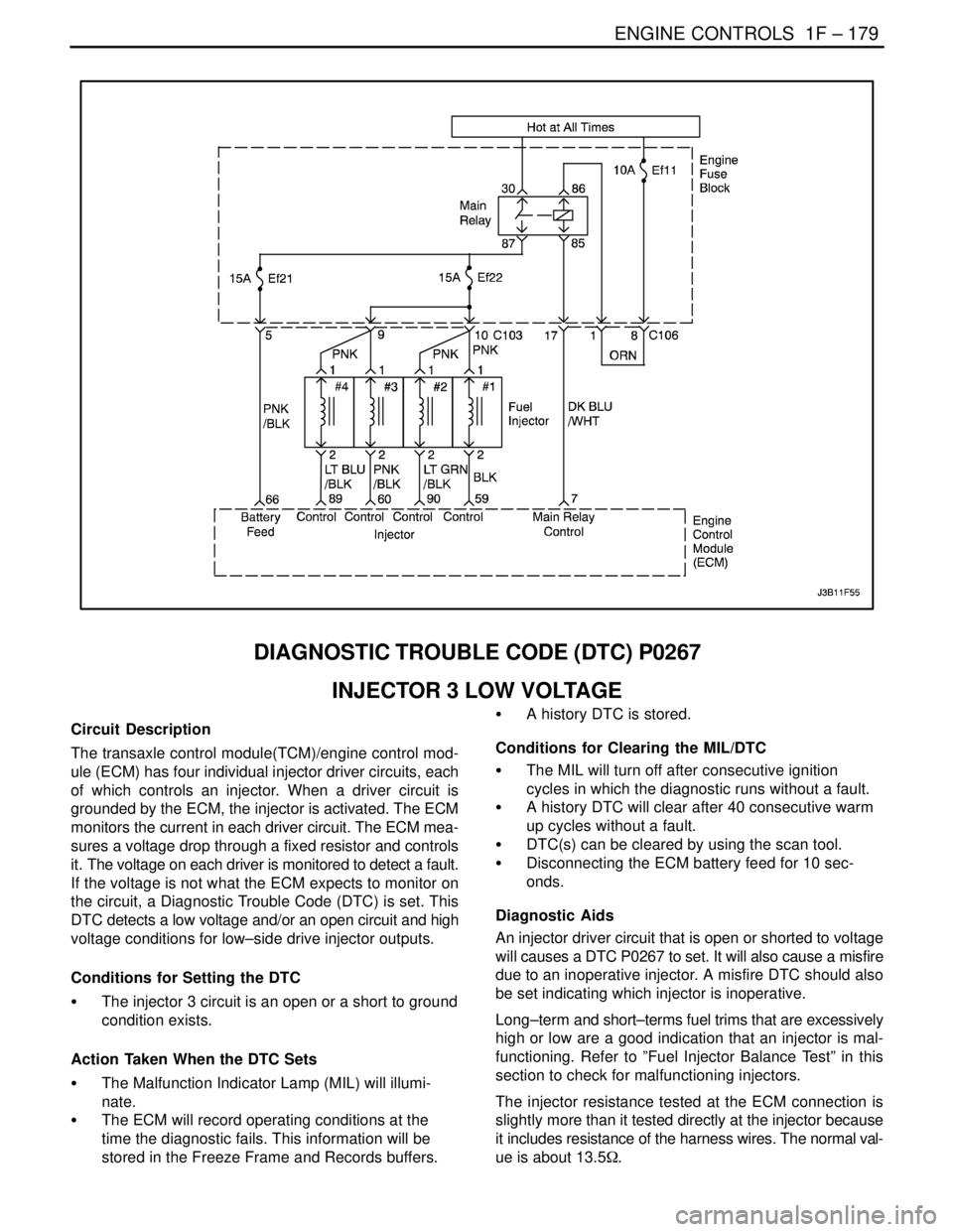

ENGINE CONTROLS 1F – 179

DAEWOO V–121 BL4

DIAGNOSTIC TROUBLE CODE (DTC) P0267

INJECTOR 3 LOW VOLTAGE

Circuit Description

The transaxle control module(TCM)/engine control mod-

ule (ECM) has four individual injector driver circuits, each

of which controls an injector. When a driver circuit is

grounded by the ECM, the injector is activated. The ECM

monitors the current in each driver circuit. The ECM mea-

sures a voltage drop through a fixed resistor and controls

it. The voltage on each driver is monitored to detect a fault.

If the voltage is not what the ECM expects to monitor on

the circuit, a Diagnostic Trouble Code (DTC) is set. This

DTC detects a low voltage and/or an open circuit and high

voltage conditions for low–side drive injector outputs.

Conditions for Setting the DTC

S The injector 3 circuit is an open or a short to ground

condition exists.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will illumi-

nate.

S The ECM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Freeze Frame and Records buffers.S A history DTC is stored.

Conditions for Clearing the MIL/DTC

S The MIL will turn off after consecutive ignition

cycles in which the diagnostic runs without a fault.

S A history DTC will clear after 40 consecutive warm

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for 10 sec-

onds.

Diagnostic Aids

An injector driver circuit that is open or shorted to voltage

will causes a DTC P0267 to set. It will also cause a misfire

due to an inoperative injector. A misfire DTC should also

be set indicating which injector is inoperative.

Long–term and short–terms fuel trims that are excessively

high or low are a good indication that an injector is mal-

functioning. Refer to ”Fuel Injector Balance Test” in this

section to check for malfunctioning injectors.

The injector resistance tested at the ECM connection is

slightly more than it tested directly at the injector because

it includes resistance of the harness wires. The normal val-

ue is about 13.5W.