Transaxle DAEWOO LACETTI 2004 Service Manual PDF

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 919 of 2643

2C – 2IFRONT SUSPENSION

DAEWOO V–121 BL4

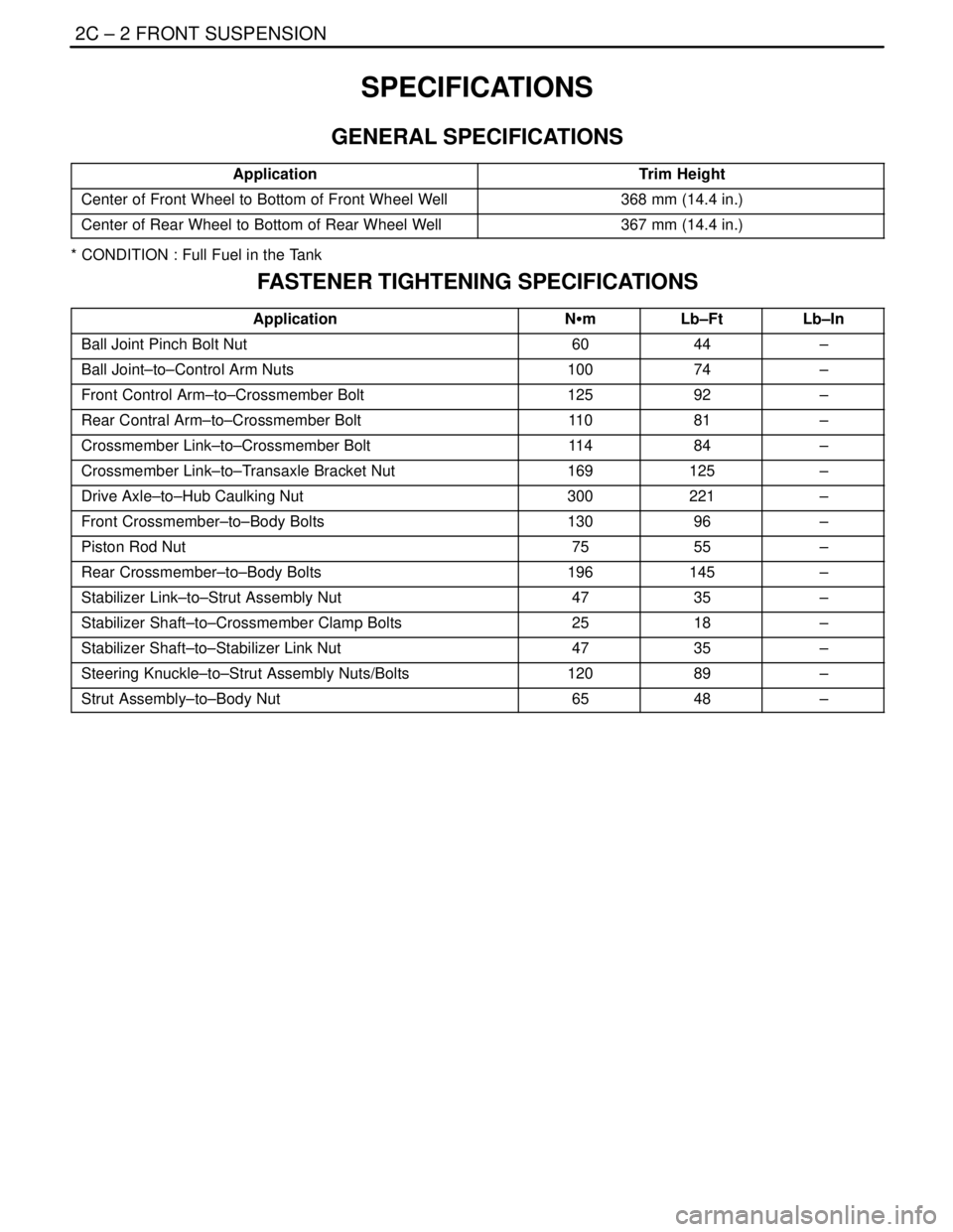

SPECIFICATIONS

GENERAL SPECIFICATIONS

ApplicationTrim Height

Center of Front Wheel to Bottom of Front Wheel Well368 mm (14.4 in.)

Center of Rear Wheel to Bottom of Rear Wheel Well367 mm (14.4 in.)

* CONDITION : Full Fuel in the Tank

FASTENER TIGHTENING SPECIFICATIONS

ApplicationNSmLb–FtLb–In

Ball Joint Pinch Bolt Nut6044–

Ball Joint–to–Control Arm Nuts10074–

Front Control Arm–to–Crossmember Bolt12592–

Rear Contral Arm–to–Crossmember Bolt11 081–

Crossmember Link–to–Crossmember Bolt11 484–

Crossmember Link–to–Transaxle Bracket Nut169125–

Drive Axle–to–Hub Caulking Nut300221–

Front Crossmember–to–Body Bolts13096–

Piston Rod Nut7555–

Rear Crossmember–to–Body Bolts196145–

Stabilizer Link–to–Strut Assembly Nut4735–

Stabilizer Shaft–to–Crossmember Clamp Bolts2518–

Stabilizer Shaft–to–Stabilizer Link Nut4735–

Steering Knuckle–to–Strut Assembly Nuts/Bolts12089–

Strut Assembly–to–Body Nut6548–

Page 935 of 2643

2C – 18IFRONT SUSPENSION

DAEWOO V–121 BL4

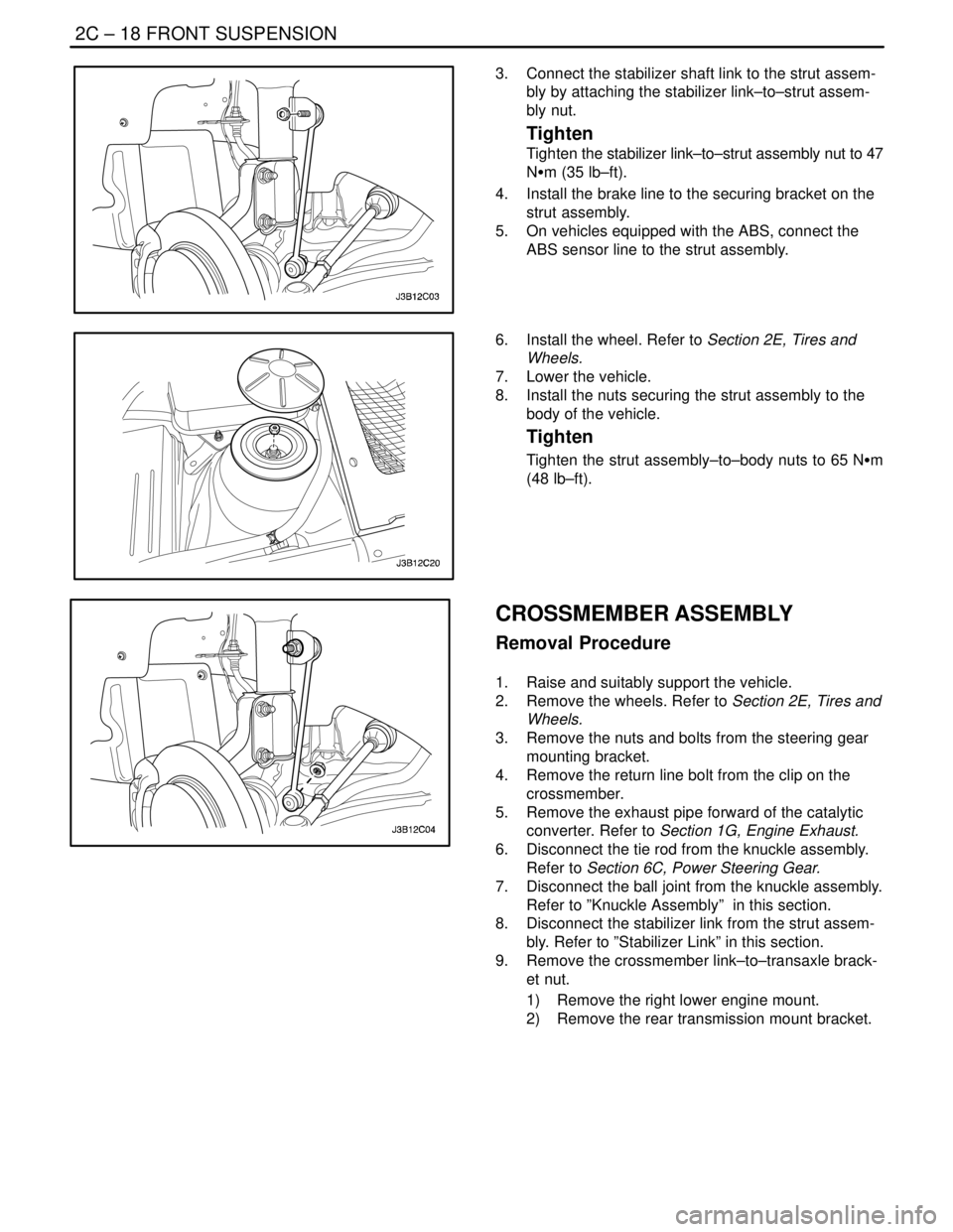

3. Connect the stabilizer shaft link to the strut assem-

bly by attaching the stabilizer link–to–strut assem-

bly nut.

Tighten

Tighten the stabilizer link–to–strut assembly nut to 47

NSm (35 lb–ft).

4. Install the brake line to the securing bracket on the

strut assembly.

5. On vehicles equipped with the ABS, connect the

ABS sensor line to the strut assembly.

6. Install the wheel. Refer to Section 2E, Tires and

Wheels.

7. Lower the vehicle.

8. Install the nuts securing the strut assembly to the

body of the vehicle.

Tighten

Tighten the strut assembly–to–body nuts to 65 NSm

(48 lb–ft).

CROSSMEMBER ASSEMBLY

Removal Procedure

1. Raise and suitably support the vehicle.

2. Remove the wheels. Refer to Section 2E, Tires and

Wheels.

3. Remove the nuts and bolts from the steering gear

mounting bracket.

4. Remove the return line bolt from the clip on the

crossmember.

5. Remove the exhaust pipe forward of the catalytic

converter. Refer to Section 1G, Engine Exhaust.

6. Disconnect the tie rod from the knuckle assembly.

Refer to Section 6C, Power Steering Gear.

7. Disconnect the ball joint from the knuckle assembly.

Refer to ”Knuckle Assembly” in this section.

8. Disconnect the stabilizer link from the strut assem-

bly. Refer to ”Stabilizer Link” in this section.

9. Remove the crossmember link–to–transaxle brack-

et nut.

1) Remove the right lower engine mount.

2) Remove the rear transmission mount bracket.

Page 937 of 2643

2C – 20IFRONT SUSPENSION

DAEWOO V–121 BL4

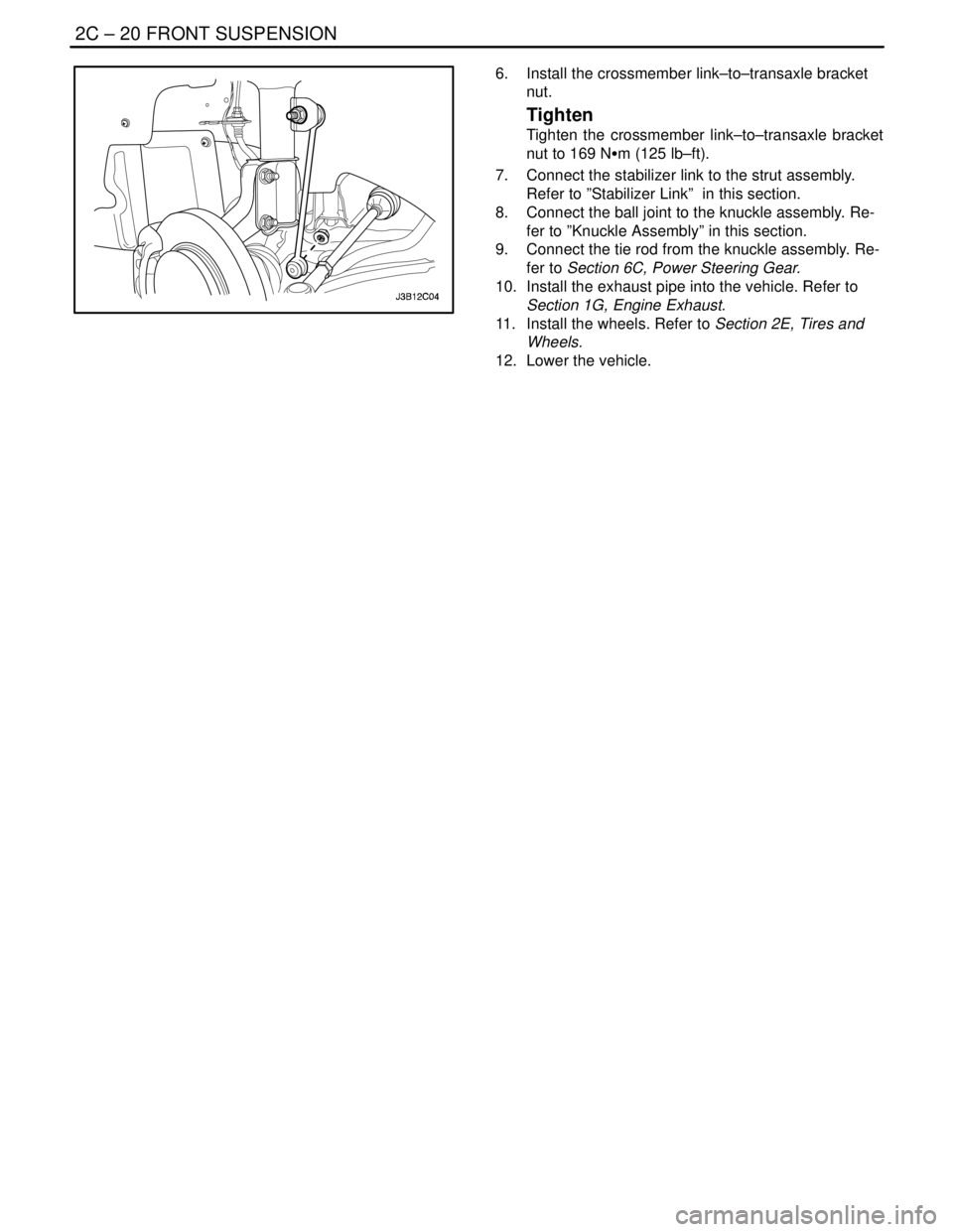

6. Install the crossmember link–to–transaxle bracket

nut.

Tighten

Tighten the crossmember link–to–transaxle bracket

nut to 169 NSm (125 lb–ft).

7. Connect the stabilizer link to the strut assembly.

Refer to ”Stabilizer Link” in this section.

8. Connect the ball joint to the knuckle assembly. Re-

fer to ”Knuckle Assembly” in this section.

9. Connect the tie rod from the knuckle assembly. Re-

fer to Section 6C, Power Steering Gear.

10. Install the exhaust pipe into the vehicle. Refer to

Section 1G, Engine Exhaust.

11. Install the wheels. Refer to Section 2E, Tires and

Wheels.

12. Lower the vehicle.

Page 990 of 2643

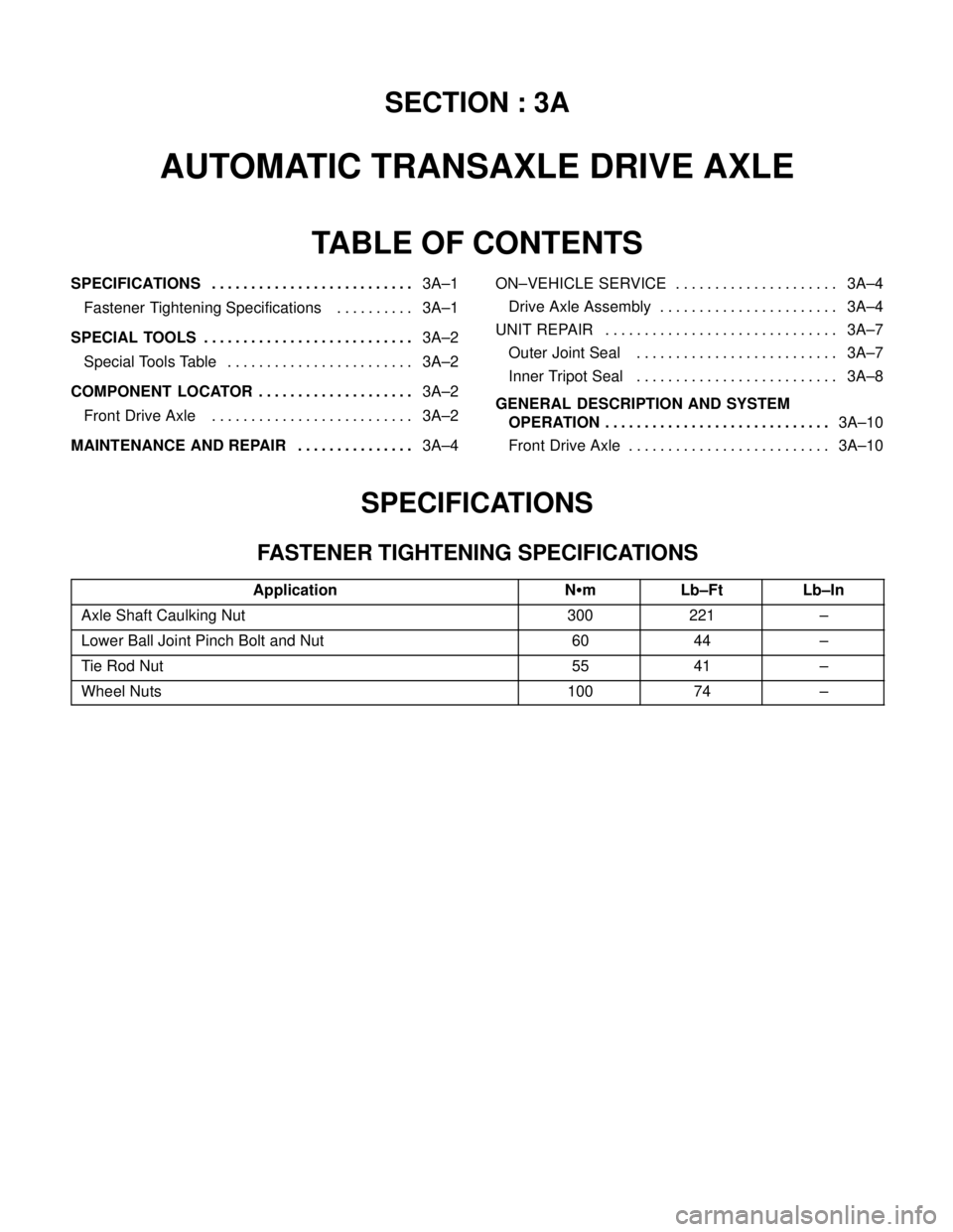

SECTION : 3A

AUTOMATIC TRANSAXLE DRIVE AXLE

TABLE OF CONTENTS

SPECIFICATIONS3A–1 . . . . . . . . . . . . . . . . . . . . . . . . . .

Fastener Tightening Specifications 3A–1. . . . . . . . . .

SPECIAL TOOLS3A–2 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Special Tools Table 3A–2. . . . . . . . . . . . . . . . . . . . . . . .

COMPONENT LOCATOR3A–2 . . . . . . . . . . . . . . . . . . . .

Front Drive Axle 3A–2. . . . . . . . . . . . . . . . . . . . . . . . . .

MAINTENANCE AND REPAIR3A–4 . . . . . . . . . . . . . . . ON–VEHICLE SERVICE 3A–4. . . . . . . . . . . . . . . . . . . . .

Drive Axle Assembly 3A–4. . . . . . . . . . . . . . . . . . . . . . .

UNIT REPAIR 3A–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Outer Joint Seal 3A–7. . . . . . . . . . . . . . . . . . . . . . . . . .

Inner Tripot Seal 3A–8. . . . . . . . . . . . . . . . . . . . . . . . . .

GENERAL DESCRIPTION AND SYSTEM

OPERATION3A–10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Drive Axle 3A–10. . . . . . . . . . . . . . . . . . . . . . . . . .

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

ApplicationNSmLb–FtLb–In

Axle Shaft Caulking Nut300221–

Lower Ball Joint Pinch Bolt and Nut6044–

Tie Rod Nut5541–

Wheel Nuts10074–

Page 991 of 2643

3A – 2IAUTOMATIC TRANSAXLE DRIVE AXLE

DAEWOO V–121 BL4

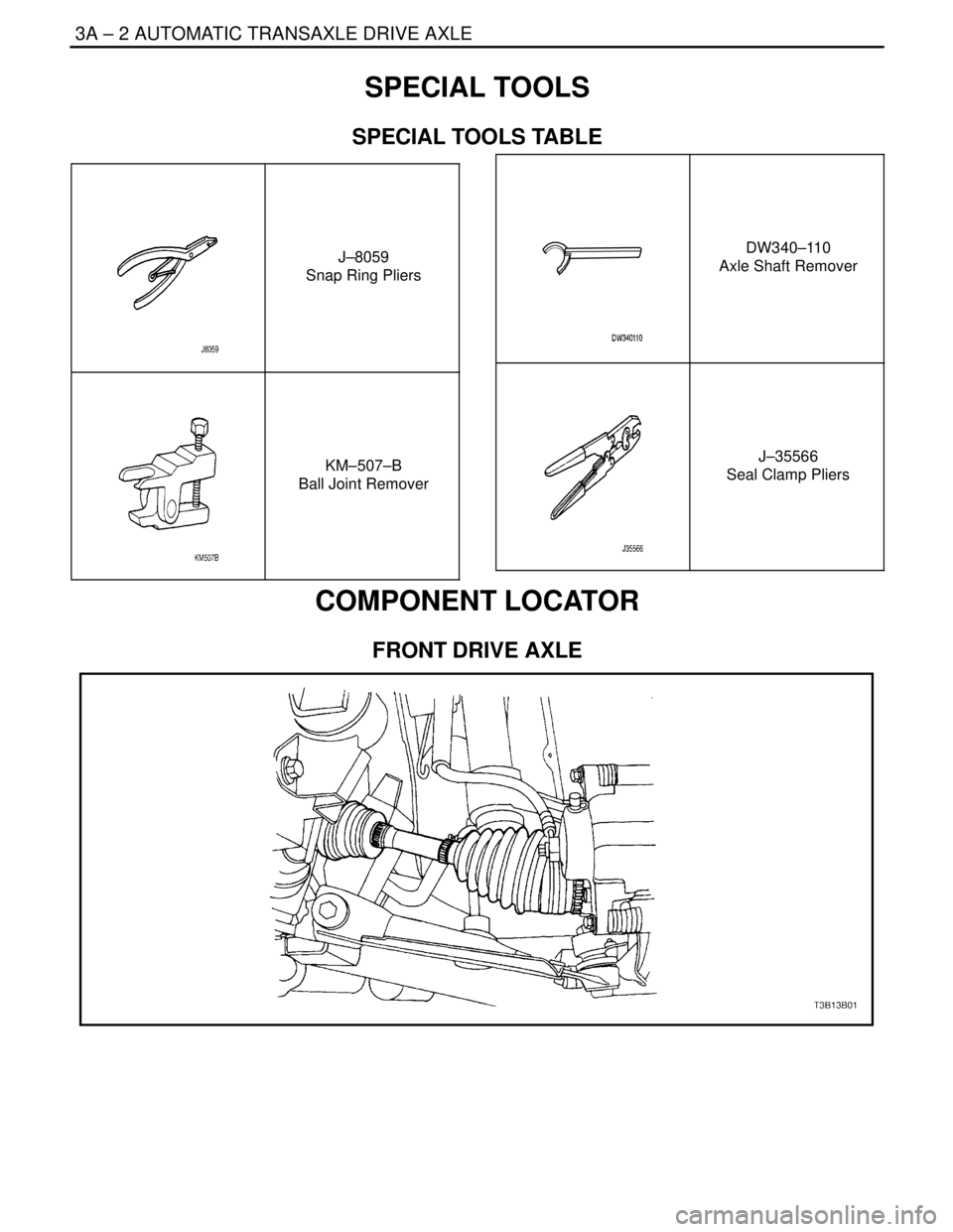

SPECIAL TOOLS

SPECIAL TOOLS TABLE

J–8059

Snap Ring Pliers

KM–507–B

Ball Joint Remover

DW340–110

Axle Shaft Remover

J–35566

Seal Clamp Pliers

COMPONENT LOCATOR

FRONT DRIVE AXLE

Page 992 of 2643

AUTOMATIC TRANSAXLE DRIVE AXLE 3A – 3

DAEWOO V–121 BL4

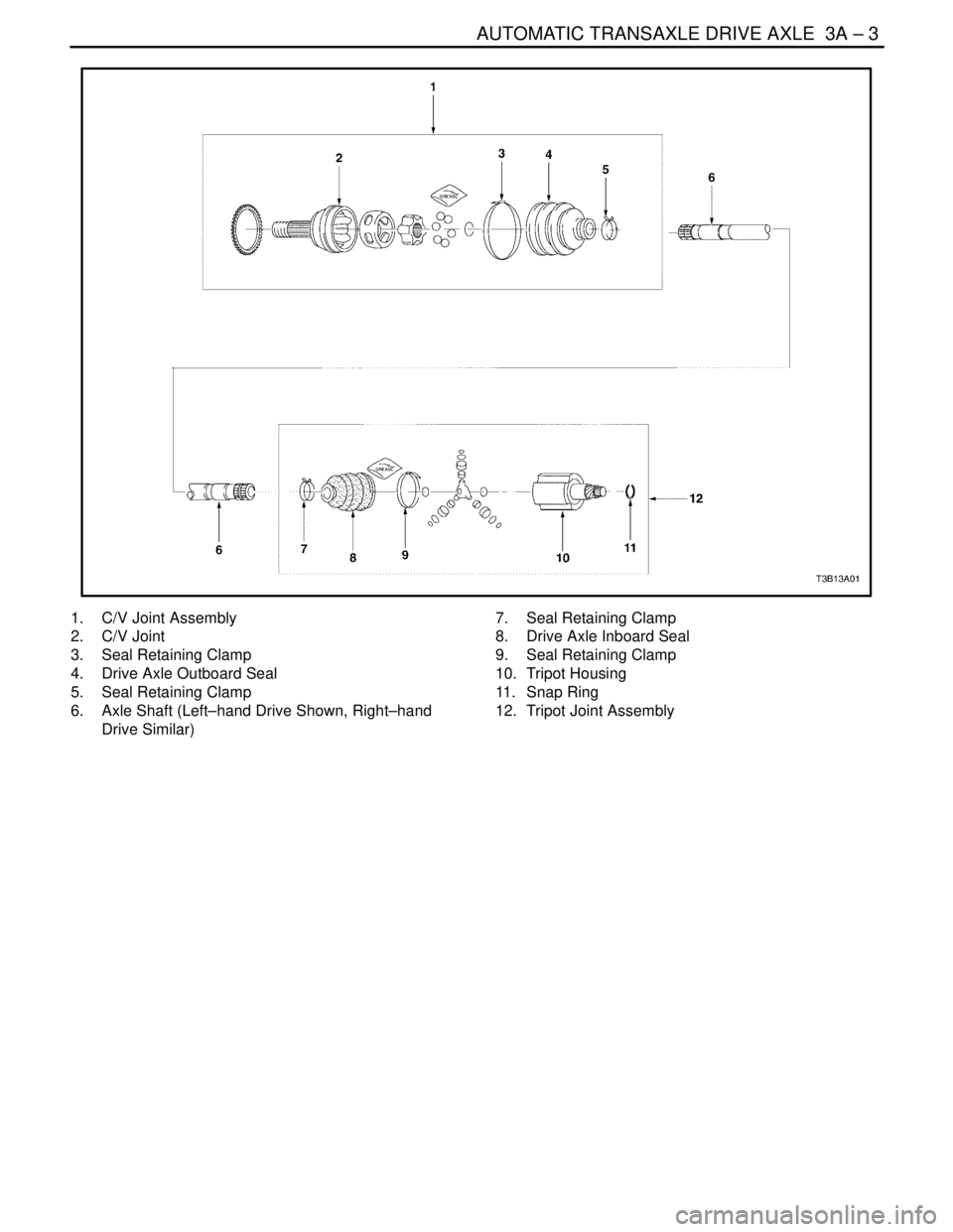

1. C/V Joint Assembly

2. C/V Joint

3. Seal Retaining Clamp

4. Drive Axle Outboard Seal

5. Seal Retaining Clamp

6. Axle Shaft (Left–hand Drive Shown, Right–hand

Drive Similar)7. Seal Retaining Clamp

8. Drive Axle Inboard Seal

9. Seal Retaining Clamp

10. Tripot Housing

11. Snap Ring

12. Tripot Joint Assembly

Page 993 of 2643

3A – 4IAUTOMATIC TRANSAXLE DRIVE AXLE

DAEWOO V–121 BL4

MAINTENANCE AND REPAIR

ON–VEHICLE SERVICE

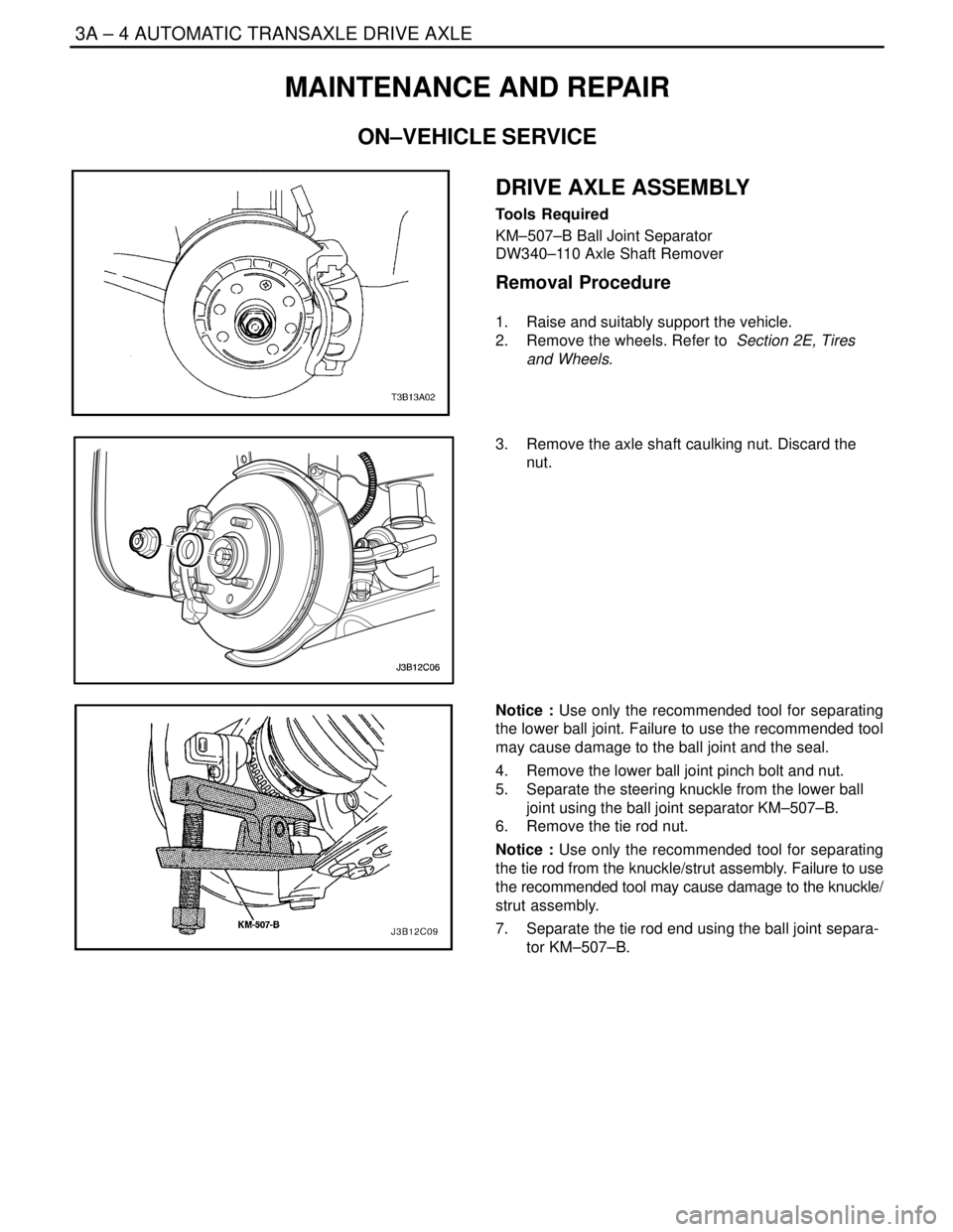

DRIVE AXLE ASSEMBLY

Tools Required

KM–507–B Ball Joint Separator

DW340–110 Axle Shaft Remover

Removal Procedure

1. Raise and suitably support the vehicle.

2. Remove the wheels. Refer to Section 2E, Tires

and Wheels.

3. Remove the axle shaft caulking nut. Discard the

nut.

Notice : Use only the recommended tool for separating

the lower ball joint. Failure to use the recommended tool

may cause damage to the ball joint and the seal.

4. Remove the lower ball joint pinch bolt and nut.

5. Separate the steering knuckle from the lower ball

joint using the ball joint separator KM–507–B.

6. Remove the tie rod nut.

Notice : Use only the recommended tool for separating

the tie rod from the knuckle/strut assembly. Failure to use

the recommended tool may cause damage to the knuckle/

strut assembly.

7. Separate the tie rod end using the ball joint separa-

tor KM–507–B.

Page 994 of 2643

AUTOMATIC TRANSAXLE DRIVE AXLE 3A – 5

DAEWOO V–121 BL4

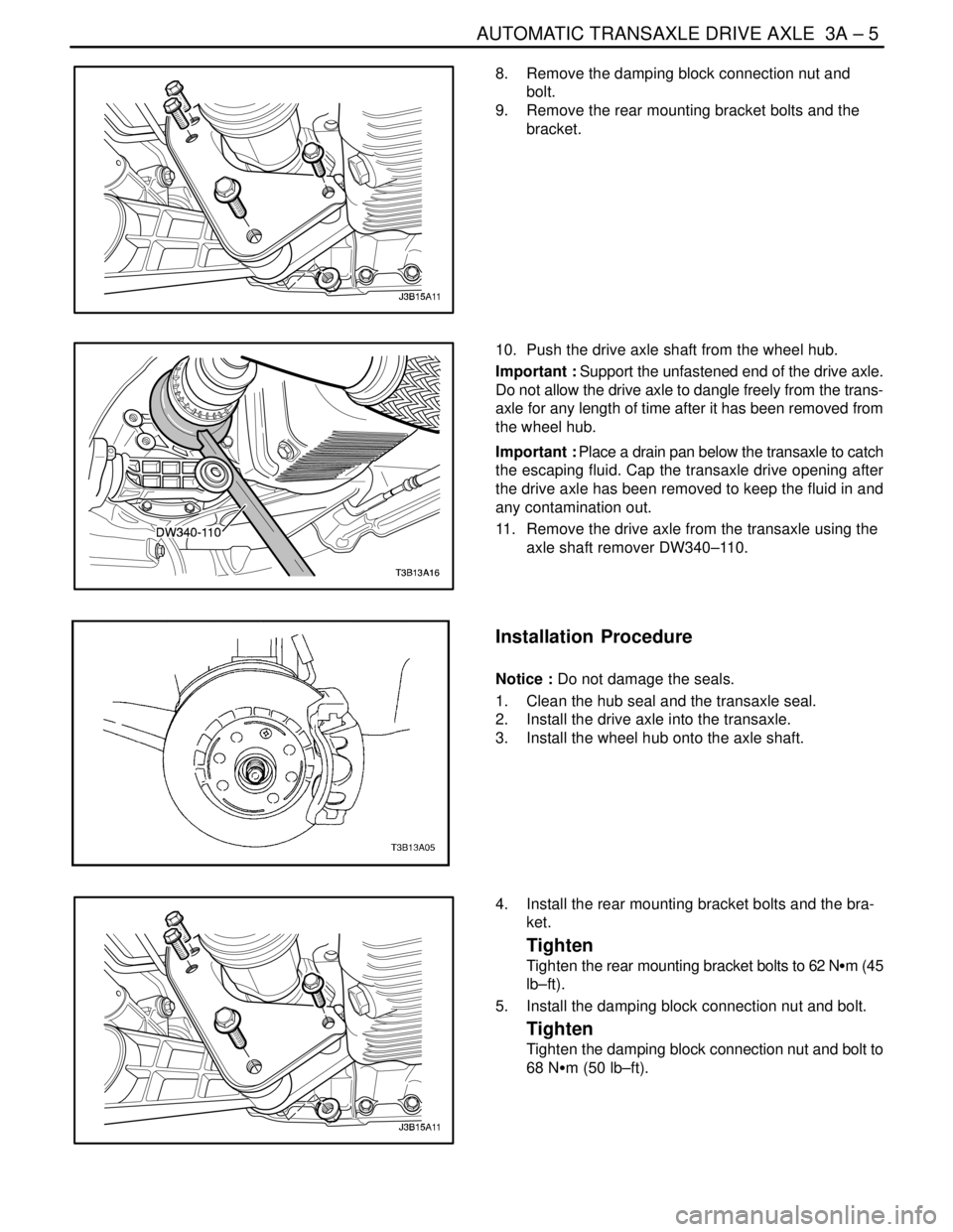

8. Remove the damping block connection nut and

bolt.

9. Remove the rear mounting bracket bolts and the

bracket.

10. Push the drive axle shaft from the wheel hub.

Important : Support the unfastened end of the drive axle.

Do not allow the drive axle to dangle freely from the trans-

axle for any length of time after it has been removed from

the wheel hub.

Important : Place a drain pan below the transaxle to catch

the escaping fluid. Cap the transaxle drive opening after

the drive axle has been removed to keep the fluid in and

any contamination out.

11. Remove the drive axle from the transaxle using the

axle shaft remover DW340–110.

Installation Procedure

Notice : Do not damage the seals.

1. Clean the hub seal and the transaxle seal.

2. Install the drive axle into the transaxle.

3. Install the wheel hub onto the axle shaft.

4. Install the rear mounting bracket bolts and the bra-

ket.

Tighten

Tighten the rear mounting bracket bolts to 62 NSm (45

lb–ft).

5. Install the damping block connection nut and bolt.

Tighten

Tighten the damping block connection nut and bolt to

68 NSm (50 lb–ft).

Page 995 of 2643

3A – 6IAUTOMATIC TRANSAXLE DRIVE AXLE

DAEWOO V–121 BL4

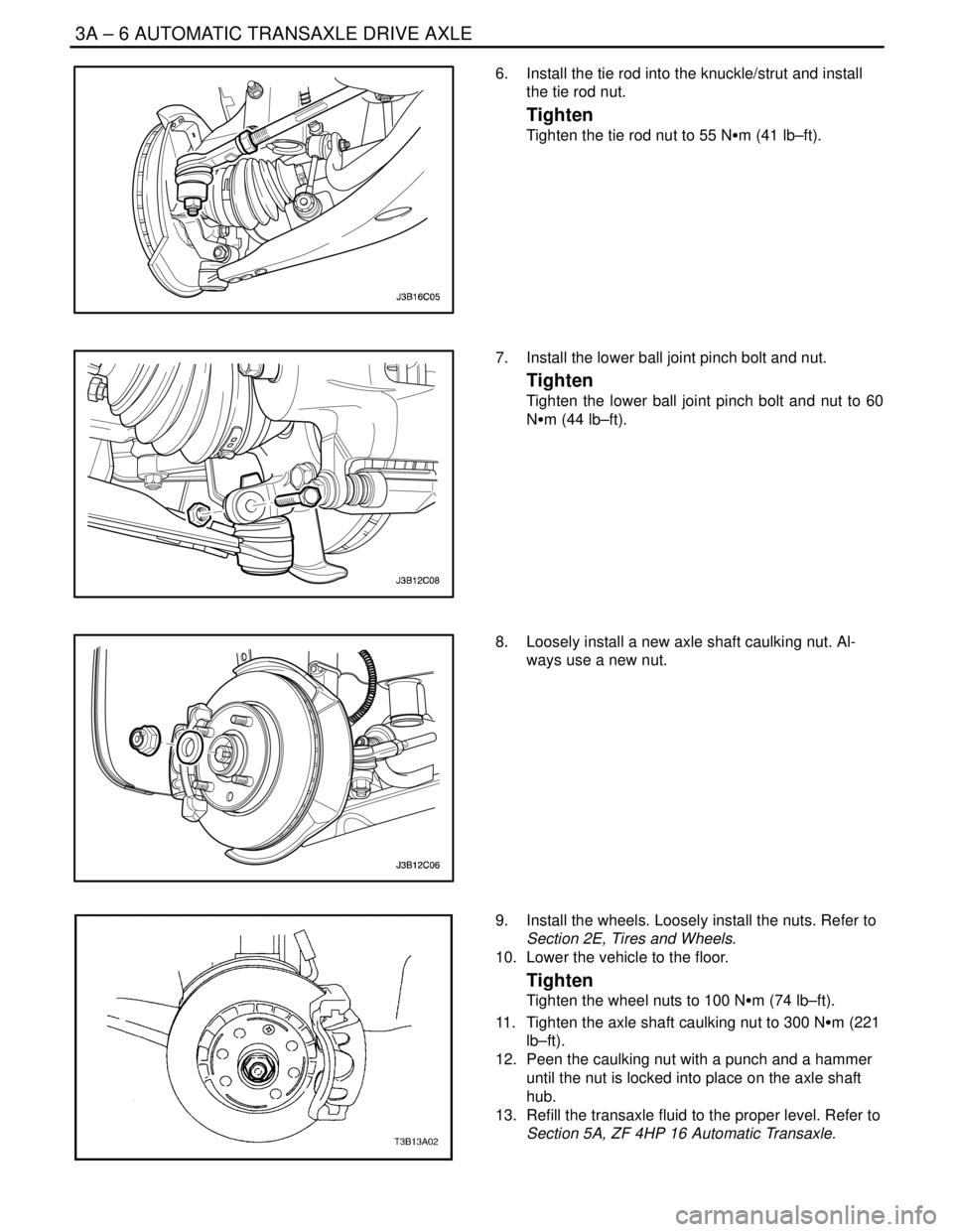

6. Install the tie rod into the knuckle/strut and install

the tie rod nut.

Tighten

Tighten the tie rod nut to 55 NSm (41 lb–ft).

7. Install the lower ball joint pinch bolt and nut.

Tighten

Tighten the lower ball joint pinch bolt and nut to 60

NSm (44 lb–ft).

8. Loosely install a new axle shaft caulking nut. Al-

ways use a new nut.

9. Install the wheels. Loosely install the nuts. Refer to

Section 2E, Tires and Wheels.

10. Lower the vehicle to the floor.

Tighten

Tighten the wheel nuts to 100 NSm (74 lb–ft).

11. Tighten the axle shaft caulking nut to 300 NSm (221

lb–ft).

12. Peen the caulking nut with a punch and a hammer

until the nut is locked into place on the axle shaft

hub.

13. Refill the transaxle fluid to the proper level. Refer to

Section 5A, ZF 4HP 16 Automatic Transaxle.

Page 996 of 2643

AUTOMATIC TRANSAXLE DRIVE AXLE 3A – 7

DAEWOO V–121 BL4

UNIT REPAIR

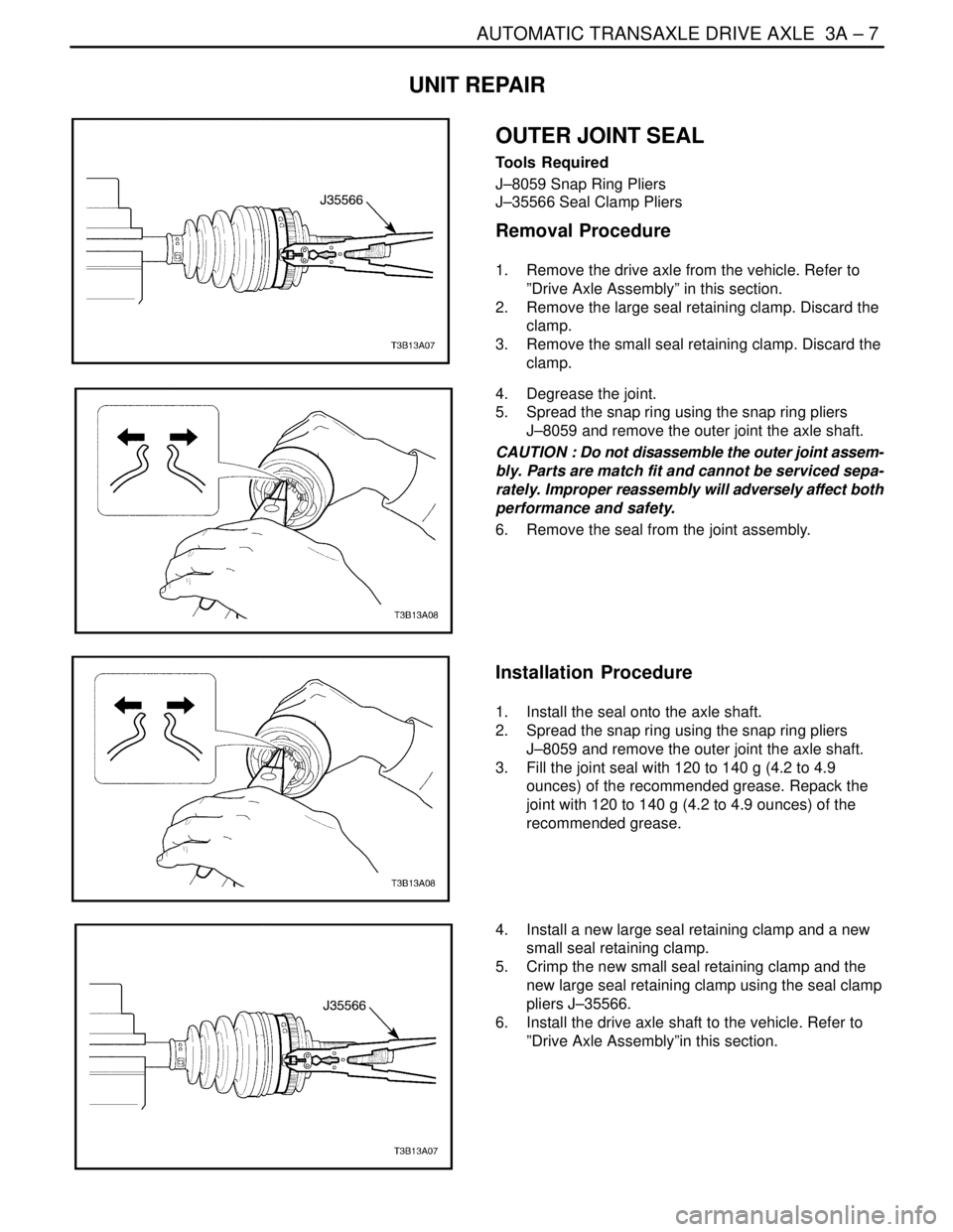

OUTER JOINT SEAL

Tools Required

J–8059 Snap Ring Pliers

J–35566 Seal Clamp Pliers

Removal Procedure

1. Remove the drive axle from the vehicle. Refer to

”Drive Axle Assembly” in this section.

2. Remove the large seal retaining clamp. Discard the

clamp.

3. Remove the small seal retaining clamp. Discard the

clamp.

4. Degrease the joint.

5. Spread the snap ring using the snap ring pliers

J–8059 and remove the outer joint the axle shaft.

CAUTION : Do not disassemble the outer joint assem-

bly. Parts are match fit and cannot be serviced sepa-

rately. Improper reassembly will adversely affect both

performance and safety.

6. Remove the seal from the joint assembly.

Installation Procedure

1. Install the seal onto the axle shaft.

2. Spread the snap ring using the snap ring pliers

J–8059 and remove the outer joint the axle shaft.

3. Fill the joint seal with 120 to 140 g (4.2 to 4.9

ounces) of the recommended grease. Repack the

joint with 120 to 140 g (4.2 to 4.9 ounces) of the

recommended grease.

4. Install a new large seal retaining clamp and a new

small seal retaining clamp.

5. Crimp the new small seal retaining clamp and the

new large seal retaining clamp using the seal clamp

pliers J–35566.

6. Install the drive axle shaft to the vehicle. Refer to

”Drive Axle Assembly”in this section.