acc DAEWOO LACETTI 2004 Service Workshop Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 412 of 2643

1F – 166IENGINE CONTROLS

DAEWOO V–121 BL4

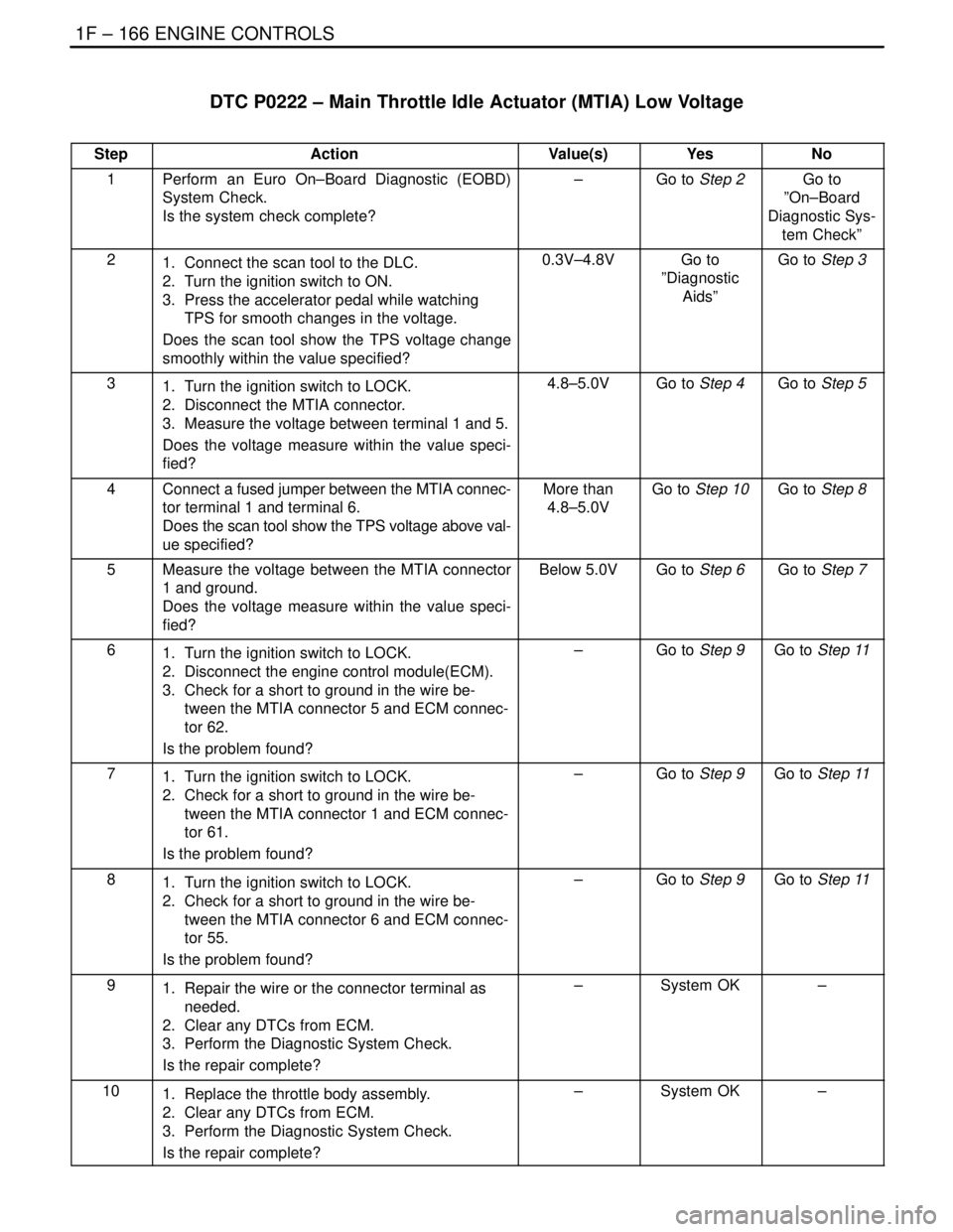

DTC P0222 – Main Throttle Idle Actuator (MTIA) Low Voltage

StepActionValue(s)YesNo

1Perform an Euro On–Board Diagnostic (EOBD)

System Check.

Is the system check complete?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Connect the scan tool to the DLC.

2. Turn the ignition switch to ON.

3. Press the accelerator pedal while watching

TPS for smooth changes in the voltage.

Does the scan tool show the TPS voltage change

smoothly within the value specified?0.3V–4.8VGo to

”Diagnostic

Aids”Go to Step 3

31. Turn the ignition switch to LOCK.

2. Disconnect the MTIA connector.

3. Measure the voltage between terminal 1 and 5.

Does the voltage measure within the value speci-

fied?4.8–5.0VGo to Step 4Go to Step 5

4Connect a fused jumper between the MTIA connec-

tor terminal 1 and terminal 6.

Does the scan tool show the TPS voltage above val-

ue specified?More than

4.8–5.0VGo to Step 10Go to Step 8

5Measure the voltage between the MTIA connector

1 and ground.

Does the voltage measure within the value speci-

fied?Below 5.0VGo to Step 6Go to Step 7

61. Turn the ignition switch to LOCK.

2. Disconnect the engine control module(ECM).

3. Check for a short to ground in the wire be-

tween the MTIA connector 5 and ECM connec-

tor 62.

Is the problem found?–Go to Step 9Go to Step 11

71. Turn the ignition switch to LOCK.

2. Check for a short to ground in the wire be-

tween the MTIA connector 1 and ECM connec-

tor 61.

Is the problem found?–Go to Step 9Go to Step 11

81. Turn the ignition switch to LOCK.

2. Check for a short to ground in the wire be-

tween the MTIA connector 6 and ECM connec-

tor 55.

Is the problem found?–Go to Step 9Go to Step 11

91. Repair the wire or the connector terminal as

needed.

2. Clear any DTCs from ECM.

3. Perform the Diagnostic System Check.

Is the repair complete?–System OK–

101. Replace the throttle body assembly.

2. Clear any DTCs from ECM.

3. Perform the Diagnostic System Check.

Is the repair complete?–System OK–

Page 414 of 2643

1F – 168IENGINE CONTROLS

DAEWOO V–121 BL4

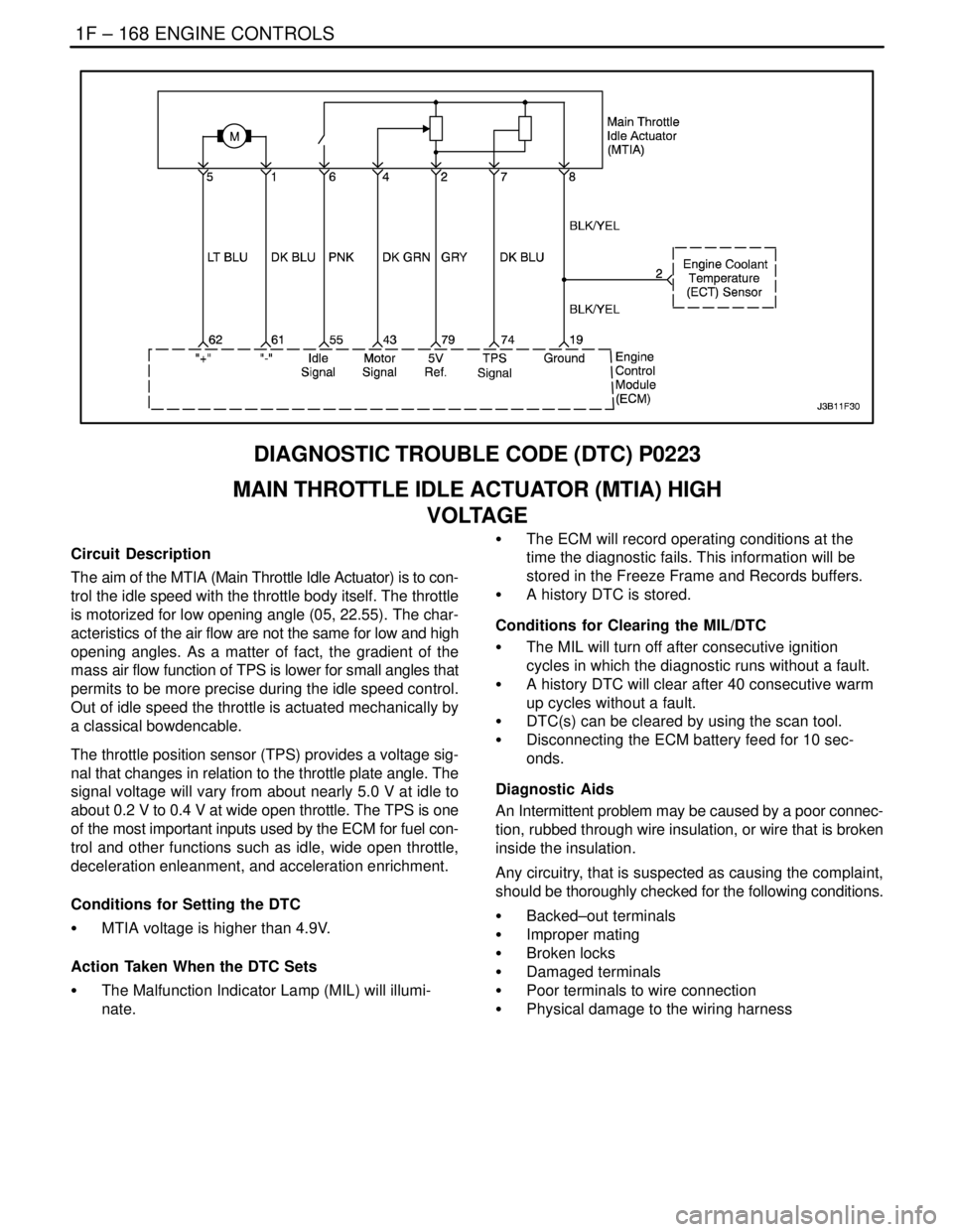

DIAGNOSTIC TROUBLE CODE (DTC) P0223

MAIN THROTTLE IDLE ACTUATOR (MTIA) HIGH

VOLTAGE

Circuit Description

The aim of the MTIA (Main Throttle Idle Actuator) is to con-

trol the idle speed with the throttle body itself. The throttle

is motorized for low opening angle (05, 22.55). The char-

acteristics of the air flow are not the same for low and high

opening angles. As a matter of fact, the gradient of the

mass air flow function of TPS is lower for small angles that

permits to be more precise during the idle speed control.

Out of idle speed the throttle is actuated mechanically by

a classical bowdencable.

The throttle position sensor (TPS) provides a voltage sig-

nal that changes in relation to the throttle plate angle. The

signal voltage will vary from about nearly 5.0 V at idle to

about 0.2 V to 0.4 V at wide open throttle. The TPS is one

of the most important inputs used by the ECM for fuel con-

trol and other functions such as idle, wide open throttle,

deceleration enleanment, and acceleration enrichment.

Conditions for Setting the DTC

S MTIA voltage is higher than 4.9V.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will illumi-

nate.S The ECM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Freeze Frame and Records buffers.

S A history DTC is stored.

Conditions for Clearing the MIL/DTC

S The MIL will turn off after consecutive ignition

cycles in which the diagnostic runs without a fault.

S A history DTC will clear after 40 consecutive warm

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for 10 sec-

onds.

Diagnostic Aids

An Intermittent problem may be caused by a poor connec-

tion, rubbed through wire insulation, or wire that is broken

inside the insulation.

Any circuitry, that is suspected as causing the complaint,

should be thoroughly checked for the following conditions.

S Backed–out terminals

S Improper mating

S Broken locks

S Damaged terminals

S Poor terminals to wire connection

S Physical damage to the wiring harness

Page 415 of 2643

ENGINE CONTROLS 1F – 169

DAEWOO V–121 BL4

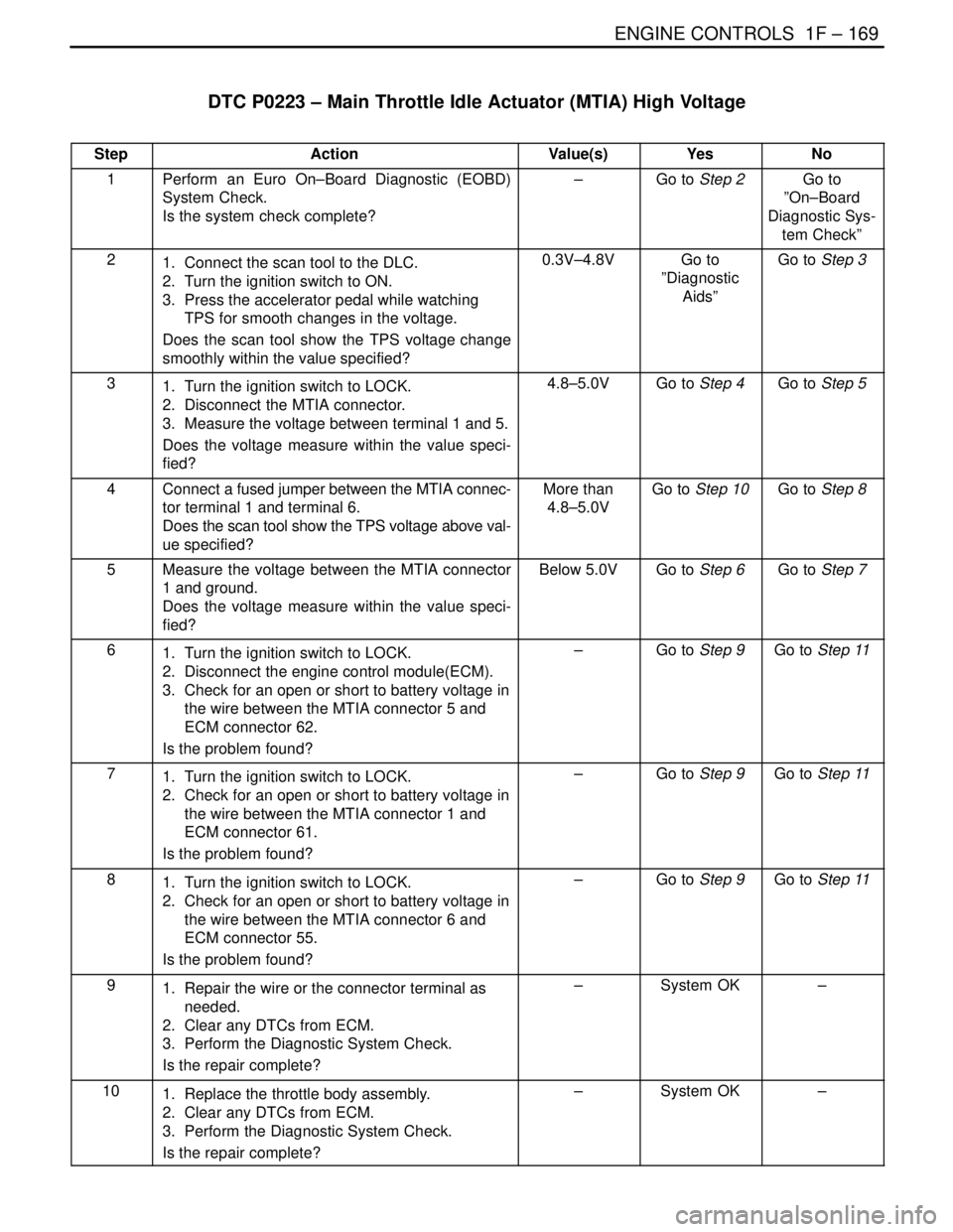

DTC P0223 – Main Throttle Idle Actuator (MTIA) High Voltage

StepActionValue(s)YesNo

1Perform an Euro On–Board Diagnostic (EOBD)

System Check.

Is the system check complete?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Connect the scan tool to the DLC.

2. Turn the ignition switch to ON.

3. Press the accelerator pedal while watching

TPS for smooth changes in the voltage.

Does the scan tool show the TPS voltage change

smoothly within the value specified?0.3V–4.8VGo to

”Diagnostic

Aids”Go to Step 3

31. Turn the ignition switch to LOCK.

2. Disconnect the MTIA connector.

3. Measure the voltage between terminal 1 and 5.

Does the voltage measure within the value speci-

fied?4.8–5.0VGo to Step 4Go to Step 5

4Connect a fused jumper between the MTIA connec-

tor terminal 1 and terminal 6.

Does the scan tool show the TPS voltage above val-

ue specified?More than

4.8–5.0VGo to Step 10Go to Step 8

5Measure the voltage between the MTIA connector

1 and ground.

Does the voltage measure within the value speci-

fied?Below 5.0VGo to Step 6Go to Step 7

61. Turn the ignition switch to LOCK.

2. Disconnect the engine control module(ECM).

3. Check for an open or short to battery voltage in

the wire between the MTIA connector 5 and

ECM connector 62.

Is the problem found?–Go to Step 9Go to Step 11

71. Turn the ignition switch to LOCK.

2. Check for an open or short to battery voltage in

the wire between the MTIA connector 1 and

ECM connector 61.

Is the problem found?–Go to Step 9Go to Step 11

81. Turn the ignition switch to LOCK.

2. Check for an open or short to battery voltage in

the wire between the MTIA connector 6 and

ECM connector 55.

Is the problem found?–Go to Step 9Go to Step 11

91. Repair the wire or the connector terminal as

needed.

2. Clear any DTCs from ECM.

3. Perform the Diagnostic System Check.

Is the repair complete?–System OK–

101. Replace the throttle body assembly.

2. Clear any DTCs from ECM.

3. Perform the Diagnostic System Check.

Is the repair complete?–System OK–

Page 464 of 2643

1F – 218IENGINE CONTROLS

DAEWOO V–121 BL4

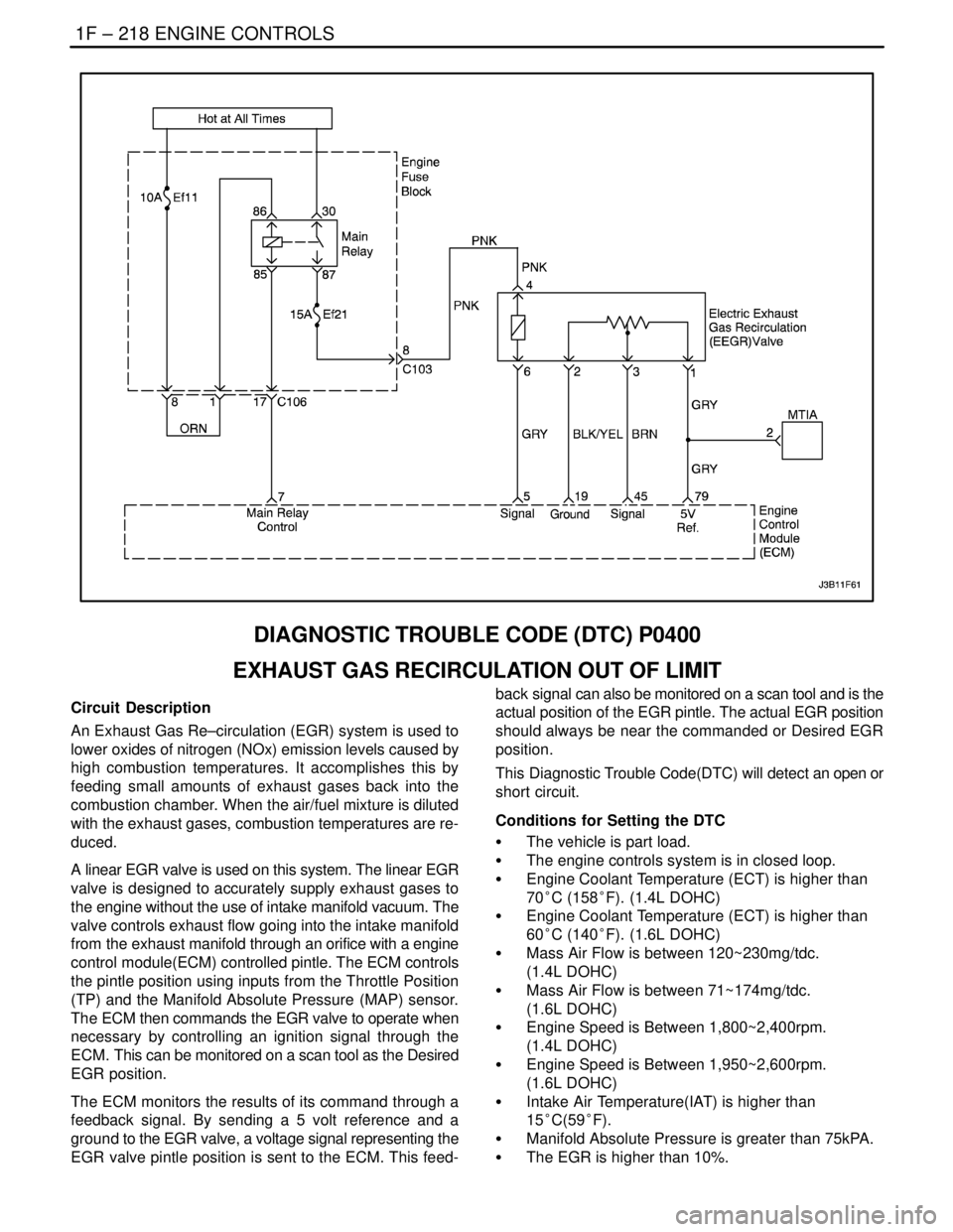

DIAGNOSTIC TROUBLE CODE (DTC) P0400

EXHAUST GAS RECIRCULATION OUT OF LIMIT

Circuit Description

An Exhaust Gas Re–circulation (EGR) system is used to

lower oxides of nitrogen (NOx) emission levels caused by

high combustion temperatures. It accomplishes this by

feeding small amounts of exhaust gases back into the

combustion chamber. When the air/fuel mixture is diluted

with the exhaust gases, combustion temperatures are re-

duced.

A linear EGR valve is used on this system. The linear EGR

valve is designed to accurately supply exhaust gases to

the engine without the use of intake manifold vacuum. The

valve controls exhaust flow going into the intake manifold

from the exhaust manifold through an orifice with a engine

control module(ECM) controlled pintle. The ECM controls

the pintle position using inputs from the Throttle Position

(TP) and the Manifold Absolute Pressure (MAP) sensor.

The ECM then commands the EGR valve to operate when

necessary by controlling an ignition signal through the

ECM. This can be monitored on a scan tool as the Desired

EGR position.

The ECM monitors the results of its command through a

feedback signal. By sending a 5 volt reference and a

ground to the EGR valve, a voltage signal representing the

EGR valve pintle position is sent to the ECM. This feed-back signal can also be monitored on a scan tool and is the

actual position of the EGR pintle. The actual EGR position

should always be near the commanded or Desired EGR

position.

This Diagnostic Trouble Code(DTC) will detect an open or

short circuit.

Conditions for Setting the DTC

S The vehicle is part load.

S The engine controls system is in closed loop.

S Engine Coolant Temperature (ECT) is higher than

70°C (158°F). (1.4L DOHC)

S Engine Coolant Temperature (ECT) is higher than

60°C (140°F). (1.6L DOHC)

S Mass Air Flow is between 120~230mg/tdc.

(1.4L DOHC)

S Mass Air Flow is between 71~174mg/tdc.

(1.6L DOHC)

S Engine Speed is Between 1,800~2,400rpm.

(1.4L DOHC)

S Engine Speed is Between 1,950~2,600rpm.

(1.6L DOHC)

S Intake Air Temperature(IAT) is higher than

15°C(59°F).

S Manifold Absolute Pressure is greater than 75kPA.

S The EGR is higher than 10%.

Page 467 of 2643

ENGINE CONTROLS 1F – 221

DAEWOO V–121 BL4

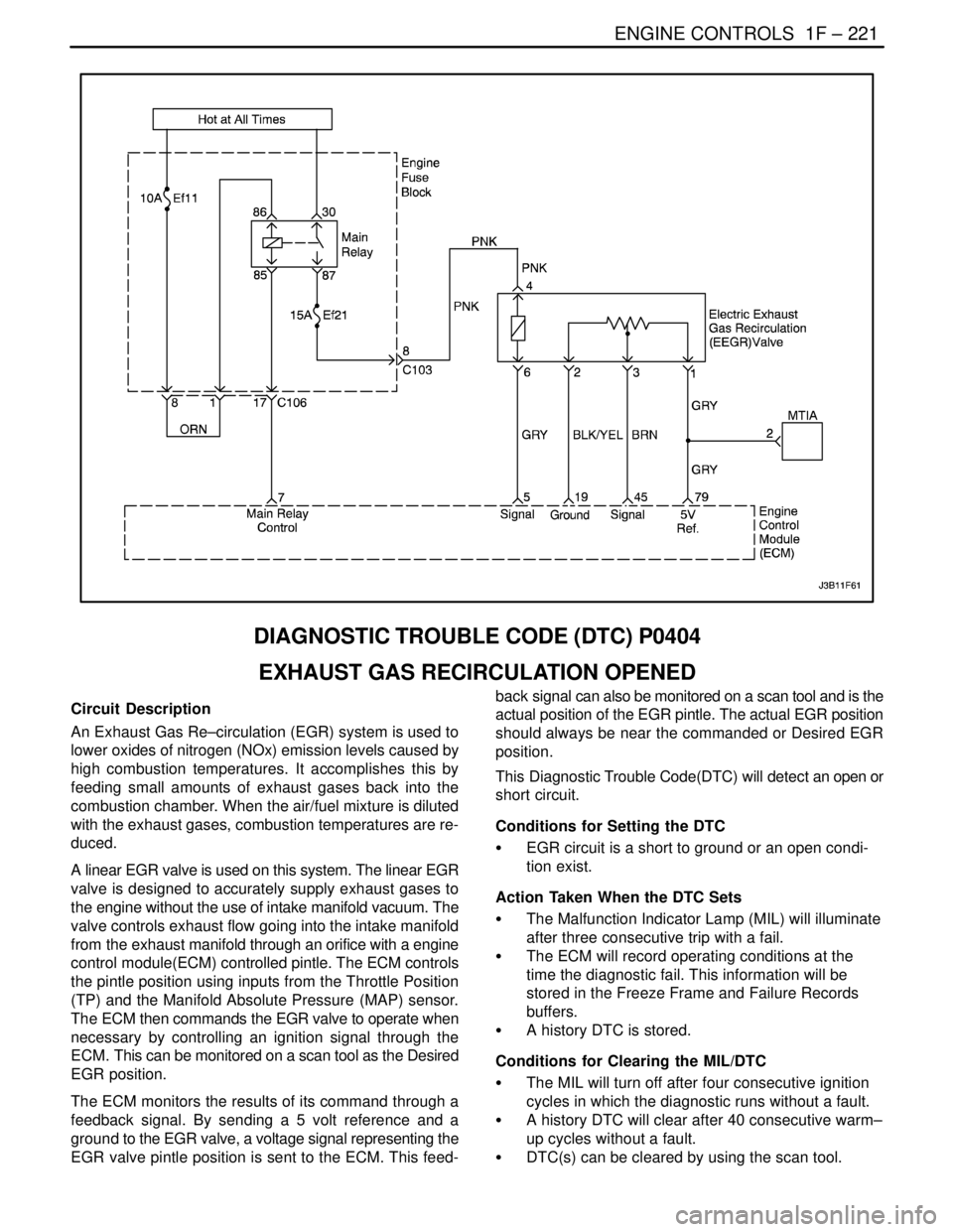

DIAGNOSTIC TROUBLE CODE (DTC) P0404

EXHAUST GAS RECIRCULATION OPENED

Circuit Description

An Exhaust Gas Re–circulation (EGR) system is used to

lower oxides of nitrogen (NOx) emission levels caused by

high combustion temperatures. It accomplishes this by

feeding small amounts of exhaust gases back into the

combustion chamber. When the air/fuel mixture is diluted

with the exhaust gases, combustion temperatures are re-

duced.

A linear EGR valve is used on this system. The linear EGR

valve is designed to accurately supply exhaust gases to

the engine without the use of intake manifold vacuum. The

valve controls exhaust flow going into the intake manifold

from the exhaust manifold through an orifice with a engine

control module(ECM) controlled pintle. The ECM controls

the pintle position using inputs from the Throttle Position

(TP) and the Manifold Absolute Pressure (MAP) sensor.

The ECM then commands the EGR valve to operate when

necessary by controlling an ignition signal through the

ECM. This can be monitored on a scan tool as the Desired

EGR position.

The ECM monitors the results of its command through a

feedback signal. By sending a 5 volt reference and a

ground to the EGR valve, a voltage signal representing the

EGR valve pintle position is sent to the ECM. This feed-back signal can also be monitored on a scan tool and is the

actual position of the EGR pintle. The actual EGR position

should always be near the commanded or Desired EGR

position.

This Diagnostic Trouble Code(DTC) will detect an open or

short circuit.

Conditions for Setting the DTC

S EGR circuit is a short to ground or an open condi-

tion exist.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will illuminate

after three consecutive trip with a fail.

S The ECM will record operating conditions at the

time the diagnostic fail. This information will be

stored in the Freeze Frame and Failure Records

buffers.

S A history DTC is stored.

Conditions for Clearing the MIL/DTC

S The MIL will turn off after four consecutive ignition

cycles in which the diagnostic runs without a fault.

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

Page 470 of 2643

1F – 224IENGINE CONTROLS

DAEWOO V–121 BL4

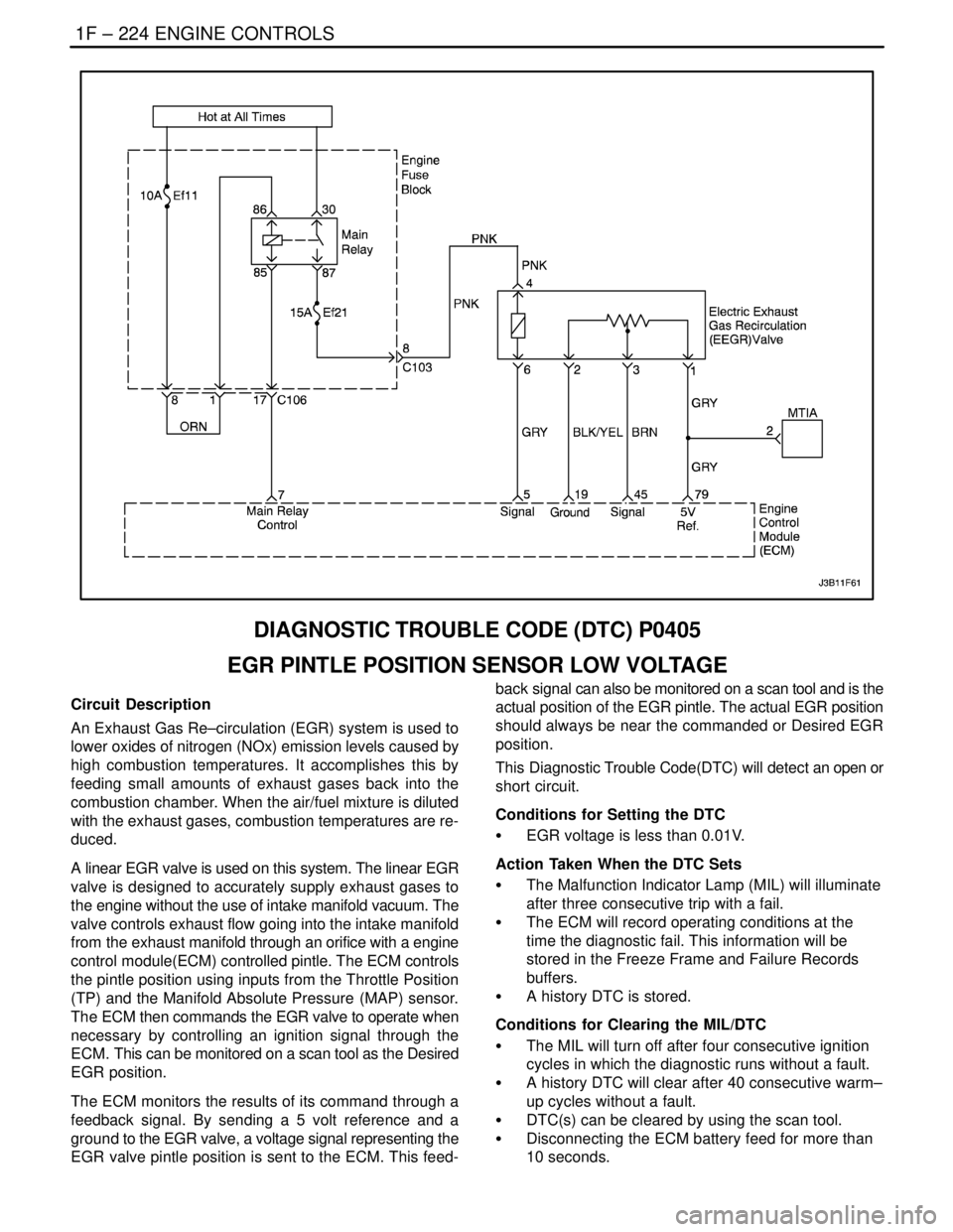

DIAGNOSTIC TROUBLE CODE (DTC) P0405

EGR PINTLE POSITION SENSOR LOW VOLTAGE

Circuit Description

An Exhaust Gas Re–circulation (EGR) system is used to

lower oxides of nitrogen (NOx) emission levels caused by

high combustion temperatures. It accomplishes this by

feeding small amounts of exhaust gases back into the

combustion chamber. When the air/fuel mixture is diluted

with the exhaust gases, combustion temperatures are re-

duced.

A linear EGR valve is used on this system. The linear EGR

valve is designed to accurately supply exhaust gases to

the engine without the use of intake manifold vacuum. The

valve controls exhaust flow going into the intake manifold

from the exhaust manifold through an orifice with a engine

control module(ECM) controlled pintle. The ECM controls

the pintle position using inputs from the Throttle Position

(TP) and the Manifold Absolute Pressure (MAP) sensor.

The ECM then commands the EGR valve to operate when

necessary by controlling an ignition signal through the

ECM. This can be monitored on a scan tool as the Desired

EGR position.

The ECM monitors the results of its command through a

feedback signal. By sending a 5 volt reference and a

ground to the EGR valve, a voltage signal representing the

EGR valve pintle position is sent to the ECM. This feed-back signal can also be monitored on a scan tool and is the

actual position of the EGR pintle. The actual EGR position

should always be near the commanded or Desired EGR

position.

This Diagnostic Trouble Code(DTC) will detect an open or

short circuit.

Conditions for Setting the DTC

S EGR voltage is less than 0.01V.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will illuminate

after three consecutive trip with a fail.

S The ECM will record operating conditions at the

time the diagnostic fail. This information will be

stored in the Freeze Frame and Failure Records

buffers.

S A history DTC is stored.

Conditions for Clearing the MIL/DTC

S The MIL will turn off after four consecutive ignition

cycles in which the diagnostic runs without a fault.

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Page 473 of 2643

ENGINE CONTROLS 1F – 227

DAEWOO V–121 BL4

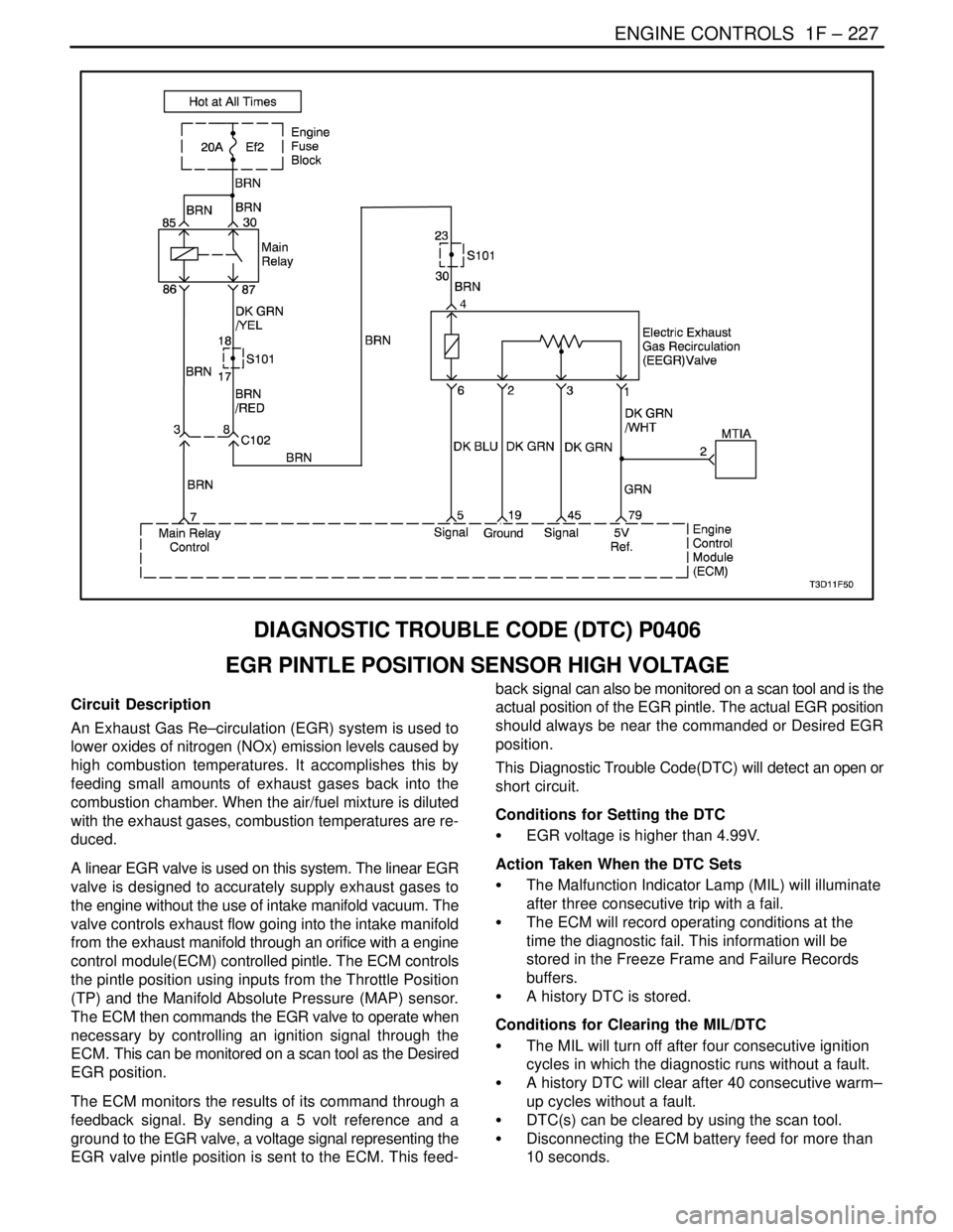

DIAGNOSTIC TROUBLE CODE (DTC) P0406

EGR PINTLE POSITION SENSOR HIGH VOLTAGE

Circuit Description

An Exhaust Gas Re–circulation (EGR) system is used to

lower oxides of nitrogen (NOx) emission levels caused by

high combustion temperatures. It accomplishes this by

feeding small amounts of exhaust gases back into the

combustion chamber. When the air/fuel mixture is diluted

with the exhaust gases, combustion temperatures are re-

duced.

A linear EGR valve is used on this system. The linear EGR

valve is designed to accurately supply exhaust gases to

the engine without the use of intake manifold vacuum. The

valve controls exhaust flow going into the intake manifold

from the exhaust manifold through an orifice with a engine

control module(ECM) controlled pintle. The ECM controls

the pintle position using inputs from the Throttle Position

(TP) and the Manifold Absolute Pressure (MAP) sensor.

The ECM then commands the EGR valve to operate when

necessary by controlling an ignition signal through the

ECM. This can be monitored on a scan tool as the Desired

EGR position.

The ECM monitors the results of its command through a

feedback signal. By sending a 5 volt reference and a

ground to the EGR valve, a voltage signal representing the

EGR valve pintle position is sent to the ECM. This feed-back signal can also be monitored on a scan tool and is the

actual position of the EGR pintle. The actual EGR position

should always be near the commanded or Desired EGR

position.

This Diagnostic Trouble Code(DTC) will detect an open or

short circuit.

Conditions for Setting the DTC

S EGR voltage is higher than 4.99V.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will illuminate

after three consecutive trip with a fail.

S The ECM will record operating conditions at the

time the diagnostic fail. This information will be

stored in the Freeze Frame and Failure Records

buffers.

S A history DTC is stored.

Conditions for Clearing the MIL/DTC

S The MIL will turn off after four consecutive ignition

cycles in which the diagnostic runs without a fault.

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Page 484 of 2643

1F – 238IENGINE CONTROLS

DAEWOO V–121 BL4

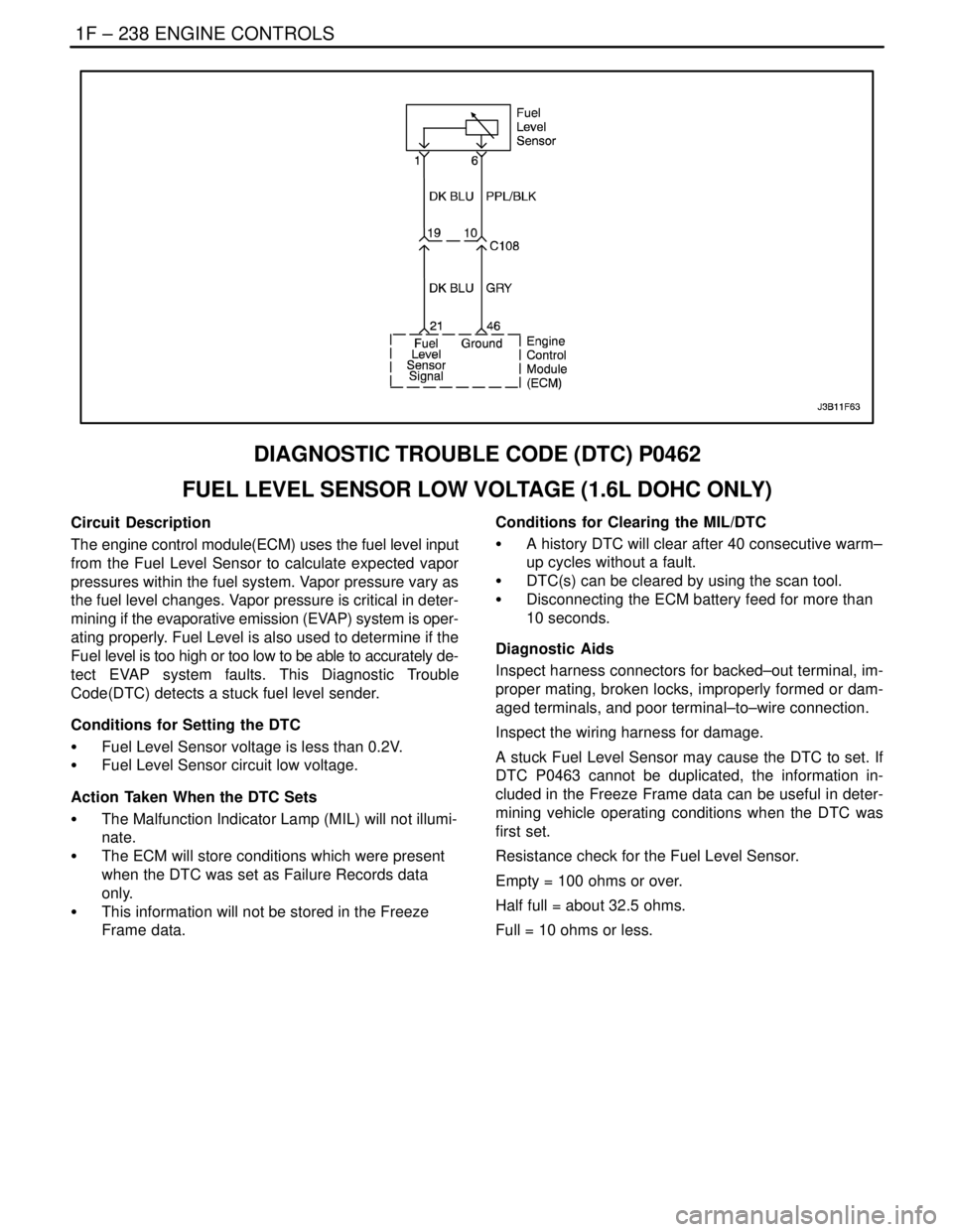

DIAGNOSTIC TROUBLE CODE (DTC) P0462

FUEL LEVEL SENSOR LOW VOLTAGE (1.6L DOHC ONLY)

Circuit Description

The engine control module(ECM) uses the fuel level input

from the Fuel Level Sensor to calculate expected vapor

pressures within the fuel system. Vapor pressure vary as

the fuel level changes. Vapor pressure is critical in deter-

mining if the evaporative emission (EVAP) system is oper-

ating properly. Fuel Level is also used to determine if the

Fuel level is too high or too low to be able to accurately de-

tect EVAP system faults. This Diagnostic Trouble

Code(DTC) detects a stuck fuel level sender.

Conditions for Setting the DTC

S Fuel Level Sensor voltage is less than 0.2V.

S Fuel Level Sensor circuit low voltage.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will not illumi-

nate.

S The ECM will store conditions which were present

when the DTC was set as Failure Records data

only.

S This information will not be stored in the Freeze

Frame data.Conditions for Clearing the MIL/DTC

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

Inspect harness connectors for backed–out terminal, im-

proper mating, broken locks, improperly formed or dam-

aged terminals, and poor terminal–to–wire connection.

Inspect the wiring harness for damage.

A stuck Fuel Level Sensor may cause the DTC to set. If

DTC P0463 cannot be duplicated, the information in-

cluded in the Freeze Frame data can be useful in deter-

mining vehicle operating conditions when the DTC was

first set.

Resistance check for the Fuel Level Sensor.

Empty = 100 ohms or over.

Half full = about 32.5 ohms.

Full = 10 ohms or less.

Page 487 of 2643

ENGINE CONTROLS 1F – 241

DAEWOO V–121 BL4

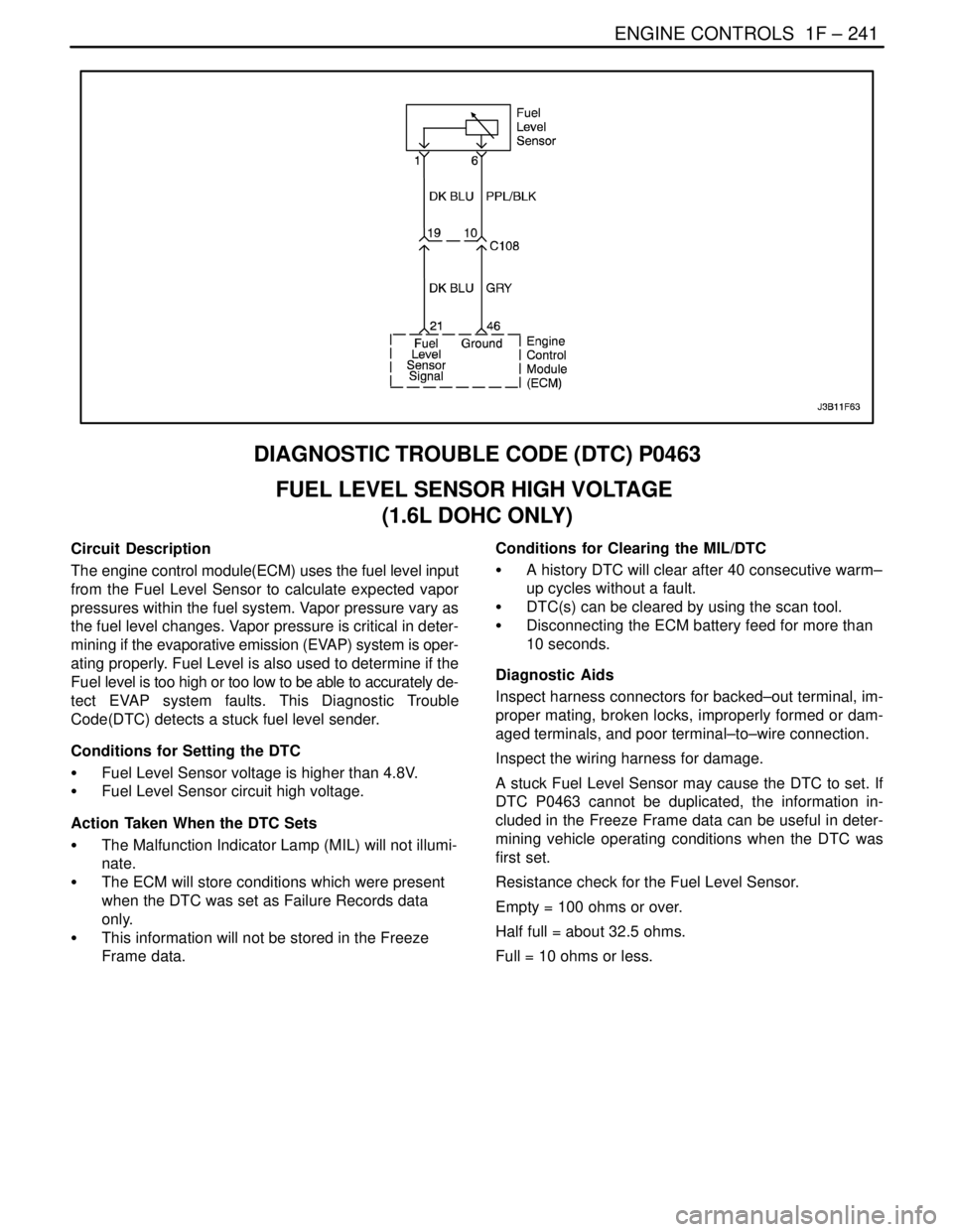

DIAGNOSTIC TROUBLE CODE (DTC) P0463

FUEL LEVEL SENSOR HIGH VOLTAGE

(1.6L DOHC ONLY)

Circuit Description

The engine control module(ECM) uses the fuel level input

from the Fuel Level Sensor to calculate expected vapor

pressures within the fuel system. Vapor pressure vary as

the fuel level changes. Vapor pressure is critical in deter-

mining if the evaporative emission (EVAP) system is oper-

ating properly. Fuel Level is also used to determine if the

Fuel level is too high or too low to be able to accurately de-

tect EVAP system faults. This Diagnostic Trouble

Code(DTC) detects a stuck fuel level sender.

Conditions for Setting the DTC

S Fuel Level Sensor voltage is higher than 4.8V.

S Fuel Level Sensor circuit high voltage.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will not illumi-

nate.

S The ECM will store conditions which were present

when the DTC was set as Failure Records data

only.

S This information will not be stored in the Freeze

Frame data.Conditions for Clearing the MIL/DTC

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

S Disconnecting the ECM battery feed for more than

10 seconds.

Diagnostic Aids

Inspect harness connectors for backed–out terminal, im-

proper mating, broken locks, improperly formed or dam-

aged terminals, and poor terminal–to–wire connection.

Inspect the wiring harness for damage.

A stuck Fuel Level Sensor may cause the DTC to set. If

DTC P0463 cannot be duplicated, the information in-

cluded in the Freeze Frame data can be useful in deter-

mining vehicle operating conditions when the DTC was

first set.

Resistance check for the Fuel Level Sensor.

Empty = 100 ohms or over.

Half full = about 32.5 ohms.

Full = 10 ohms or less.

Page 503 of 2643

ENGINE CONTROLS 1F – 257

DAEWOO V–121 BL4

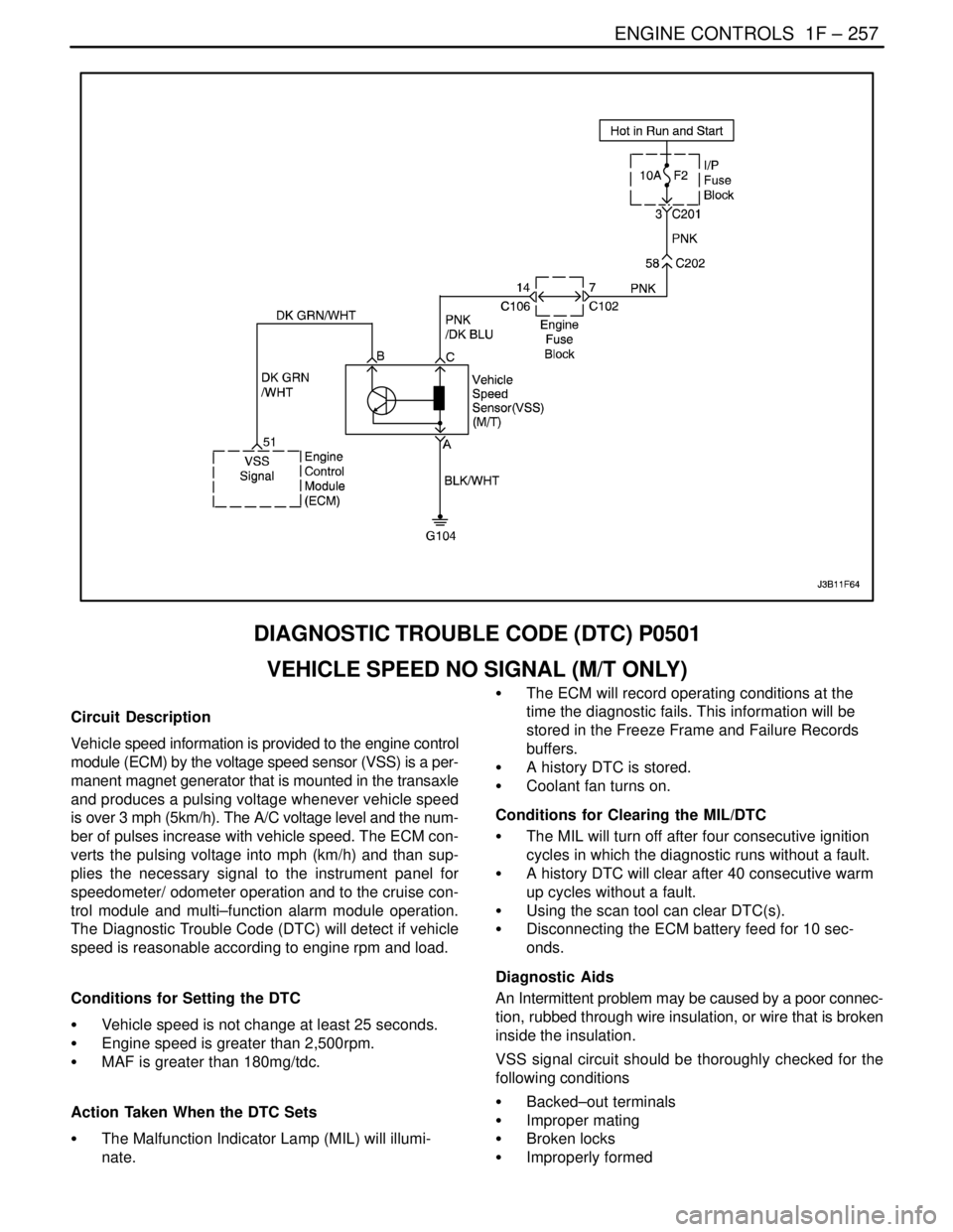

DIAGNOSTIC TROUBLE CODE (DTC) P0501

VEHICLE SPEED NO SIGNAL (M/T ONLY)

Circuit Description

Vehicle speed information is provided to the engine control

module (ECM) by the voltage speed sensor (VSS) is a per-

manent magnet generator that is mounted in the transaxle

and produces a pulsing voltage whenever vehicle speed

is over 3 mph (5km/h). The A/C voltage level and the num-

ber of pulses increase with vehicle speed. The ECM con-

verts the pulsing voltage into mph (km/h) and than sup-

plies the necessary signal to the instrument panel for

speedometer/ odometer operation and to the cruise con-

trol module and multi–function alarm module operation.

The Diagnostic Trouble Code (DTC) will detect if vehicle

speed is reasonable according to engine rpm and load.

Conditions for Setting the DTC

S Vehicle speed is not change at least 25 seconds.

S Engine speed is greater than 2,500rpm.

S MAF is greater than 180mg/tdc.

Action Taken When the DTC Sets

S The Malfunction Indicator Lamp (MIL) will illumi-

nate.S The ECM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Freeze Frame and Failure Records

buffers.

S A history DTC is stored.

S Coolant fan turns on.

Conditions for Clearing the MIL/DTC

S The MIL will turn off after four consecutive ignition

cycles in which the diagnostic runs without a fault.

S A history DTC will clear after 40 consecutive warm

up cycles without a fault.

S Using the scan tool can clear DTC(s).

S Disconnecting the ECM battery feed for 10 sec-

onds.

Diagnostic Aids

An Intermittent problem may be caused by a poor connec-

tion, rubbed through wire insulation, or wire that is broken

inside the insulation.

VSS signal circuit should be thoroughly checked for the

following conditions

S Backed–out terminals

S Improper mating

S Broken locks

S Improperly formed