pillar DAEWOO LACETTI 2004 Service Workshop Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 2347 of 2643

INTERIOR TRIM 9G – 7

DAEWOO V–121 BL4

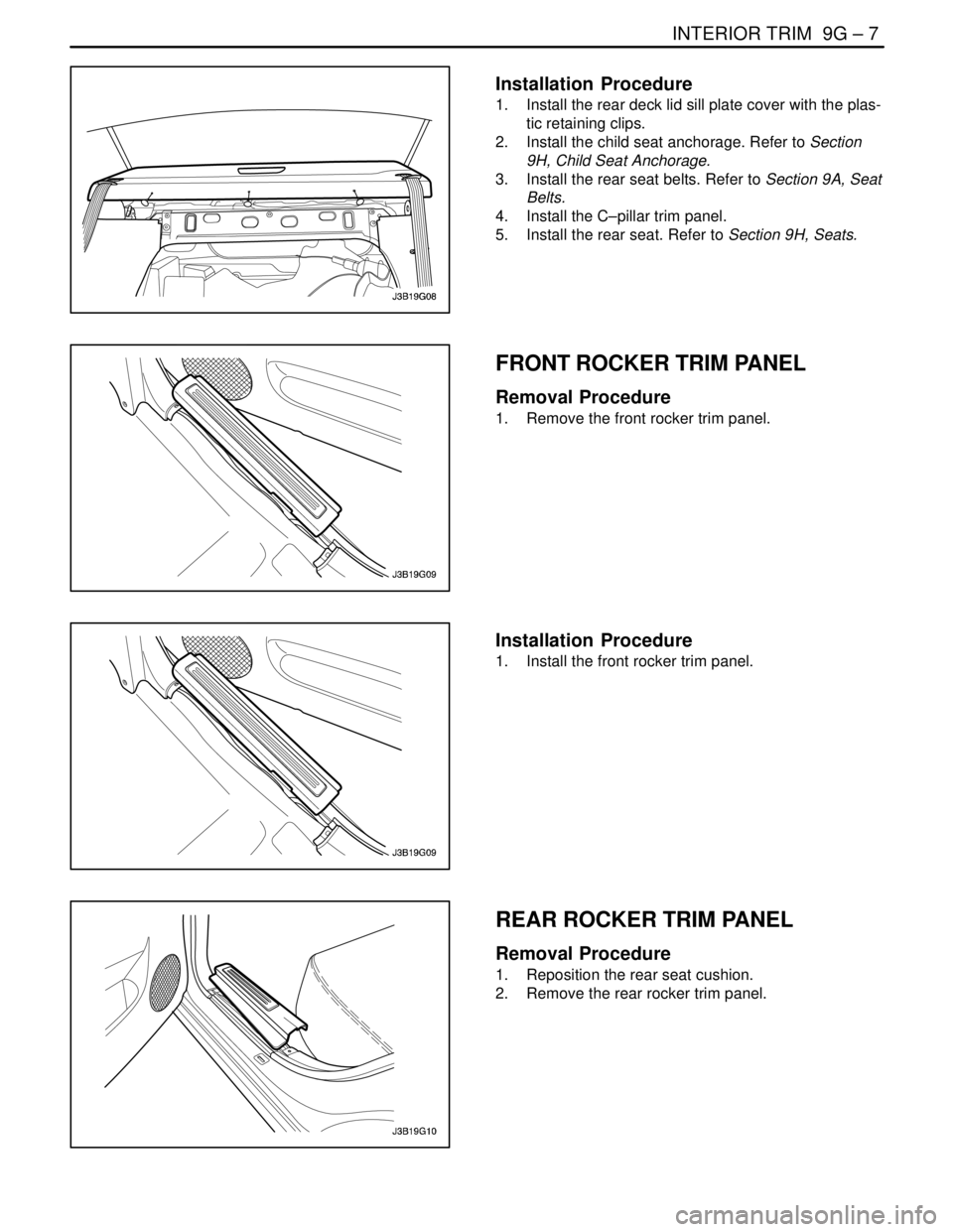

Installation Procedure

1. Install the rear deck lid sill plate cover with the plas-

tic retaining clips.

2. Install the child seat anchorage. Refer to Section

9H, Child Seat Anchorage.

3. Install the rear seat belts. Refer to Section 9A, Seat

Belts.

4. Install the C–pillar trim panel.

5. Install the rear seat. Refer to Section 9H, Seats.

FRONT ROCKER TRIM PANEL

Removal Procedure

1. Remove the front rocker trim panel.

Installation Procedure

1. Install the front rocker trim panel.

REAR ROCKER TRIM PANEL

Removal Procedure

1. Reposition the rear seat cushion.

2. Remove the rear rocker trim panel.

Page 2350 of 2643

9G – 10IINTERIOR TRIM

DAEWOO V–121 BL4

4. Install the screws to the rear portion of the floor

console.

5. Connect the negative battery cable.

6. Install the glove box, instrument panel lower cover,

cigar lighter trim panel and stereo cassette player.

7. Install the console cover.

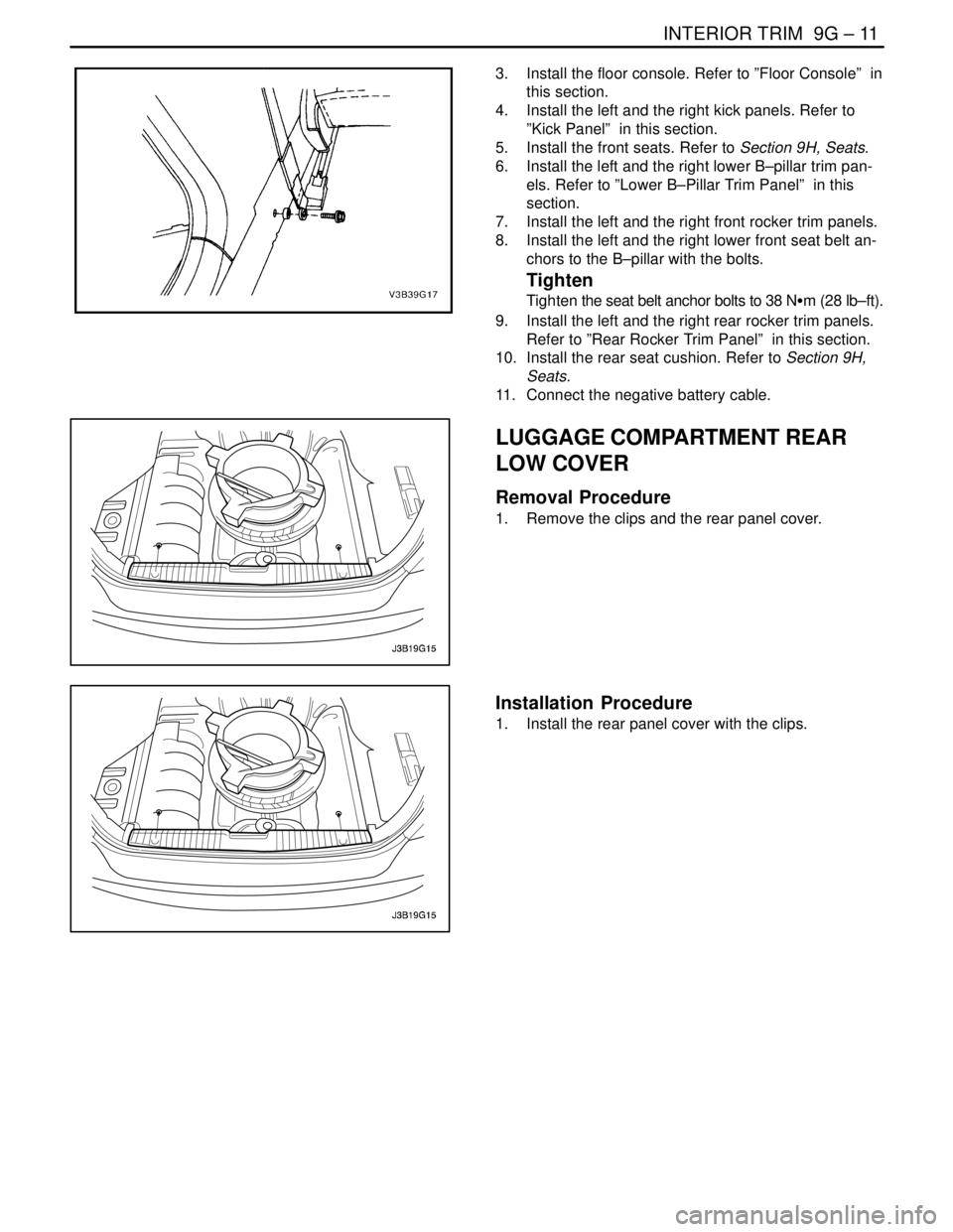

FLOOR CARPET

Removal Procedure

1. Disconnect the negative battery cable.

2. Remove the rear seat cushion. Refer to Section 9H,

Seats.

3. Remove the left and the right rear rocker trim pan-

els. Refer to ”Rear Rocker Trim Panel” in this sec-

tion.

4. Remove the bolts and the left and the right lower

front seat belt anchors from the B–pillar.

5. Remove the left and the right front rocker trim pan-

els.

6. Remove the left and the right lower B–pillar trim

panels. Refer to ”Lower B–Pillar Trim Panel” in this

section.

7. Remove the front seats. Refer to Section 9H,

Seats.

8. Remove the left and the right kick panels. Refer to

”Kick Panel” in this section.

9. Remove the floor console. Refer to ”Floor Console”

in this section.

10. Remove the gearshift housing bolts and nuts and

reposition the gearshift housing.

11. Remove the floor carpet.

Installation Procedure

1. Install the floor carpet.

2. Install the gearshift housing with the bolts.

Tighten

Tighten the gearshift housing bolts and nuts to 8 NSm

(70 lb–in).

Page 2351 of 2643

INTERIOR TRIM 9G – 11

DAEWOO V–121 BL4

3. Install the floor console. Refer to ”Floor Console” in

this section.

4. Install the left and the right kick panels. Refer to

”Kick Panel” in this section.

5. Install the front seats. Refer to Section 9H, Seats.

6. Install the left and the right lower B–pillar trim pan-

els. Refer to ”Lower B–Pillar Trim Panel” in this

section.

7. Install the left and the right front rocker trim panels.

8. Install the left and the right lower front seat belt an-

chors to the B–pillar with the bolts.

Tighten

Tighten the seat belt anchor bolts to 38 NSm (28 lb–ft).

9. Install the left and the right rear rocker trim panels.

Refer to ”Rear Rocker Trim Panel” in this section.

10. Install the rear seat cushion. Refer to Section 9H,

Seats.

11. Connect the negative battery cable.

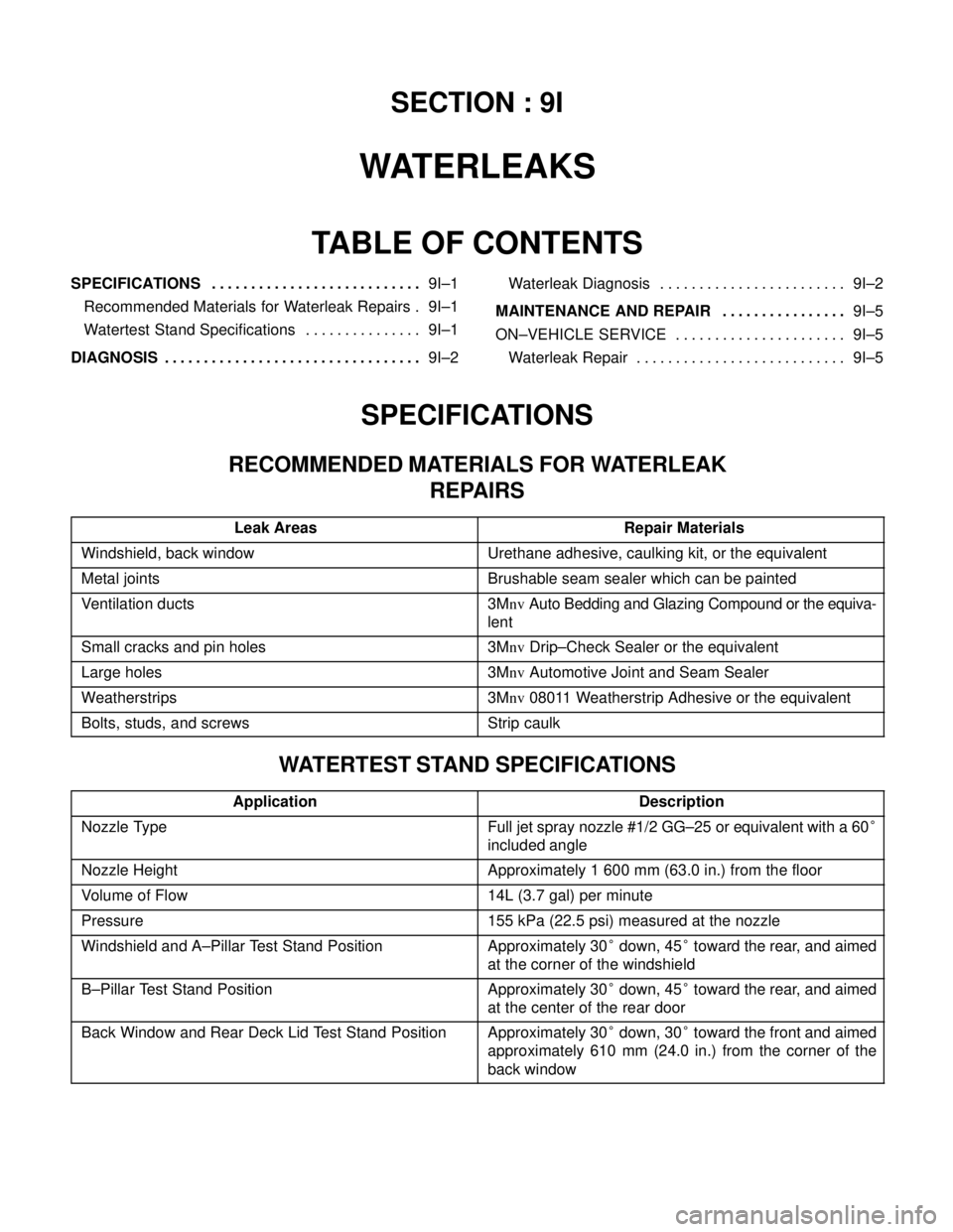

LUGGAGE COMPARTMENT REAR

LOW COVER

Removal Procedure

1. Remove the clips and the rear panel cover.

Installation Procedure

1. Install the rear panel cover with the clips.

Page 2369 of 2643

SECTION : 9I

WATERLEAKS

TABLE OF CONTENTS

SPECIFICATIONS9I–1 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Recommended Materials for Waterleak Repairs 9I–1.

Watertest Stand Specifications 9I–1. . . . . . . . . . . . . . .

DIAGNOSIS9I–2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Waterleak Diagnosis 9I–2. . . . . . . . . . . . . . . . . . . . . . . .

MAINTENANCE AND REPAIR9I–5 . . . . . . . . . . . . . . . .

ON–VEHICLE SERVICE 9I–5. . . . . . . . . . . . . . . . . . . . . .

Waterleak Repair 9I–5. . . . . . . . . . . . . . . . . . . . . . . . . . .

SPECIFICATIONS

RECOMMENDED MATERIALS FOR WATERLEAK

REPAIRS

Leak Areas Repair Materials

Windshield, back windowUrethane adhesive, caulking kit, or the equivalent

Metal jointsBrushable seam sealer which can be painted

Ventilation ducts3Mnv Auto Bedding and Glazing Compound or the equiva-

lent

Small cracks and pin holes3Mnv Drip–Check Sealer or the equivalent

Large holes3Mnv Automotive Joint and Seam Sealer

Weatherstrips3Mnv 08011 Weatherstrip Adhesive or the equivalent

Bolts, studs, and screwsStrip caulk

WATERTEST STAND SPECIFICATIONS

ApplicationDescription

Nozzle TypeFull jet spray nozzle #1/2 GG–25 or equivalent with a 60°

included angle

Nozzle HeightApproximately 1 600 mm (63.0 in.) from the floor

Volume of Flow14L (3.7 gal) per minute

Pressure155 kPa (22.5 psi) measured at the nozzle

Windshield and A–Pillar Test Stand PositionApproximately 30° down, 45° toward the rear, and aimed

at the corner of the windshield

B–Pillar Test Stand PositionApproximately 30° down, 45° toward the rear, and aimed

at the center of the rear door

Back Window and Rear Deck Lid Test Stand PositionApproximately 30° down, 30° toward the front and aimed

approximately 610 mm (24.0 in.) from the corner of the

back window

Page 2375 of 2643

SECTION : 9J

WINDNOISE

TABLE OF CONTENTS

DIAGNOSIS9J–1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Windnoise Diagnosis 9J–1. . . . . . . . . . . . . . . . . . . . . . . .

MAINTENANCE AND REPAIR9J–2 . . . . . . . . . . . . . . . . ON–VEHICLE SERVICE 9J–2. . . . . . . . . . . . . . . . . . . . . .

Windnoise Repair 9J–2. . . . . . . . . . . . . . . . . . . . . . . . . . .

DIAGNOSIS

WINDNOISE DIAGNOSIS

CAUTION : An assistant should drive the vehicle

while the technician checks for the location of the

windnoise, in order to prevent personal injury or ve-

hicle damage.

A test drive in the vehicle is necessary to accurately deter-

mine the location of the windnoise. Often there is a primary

leak and secondary leaks. Failure to repair all leaks will

only reduce the windnoise, not eliminate it.

During the test drive the technician should bring the follow-

ing items to aid in determining the location of the wind-

noise.

S A mechanics stethoscope or vacuum hose

S Masking tape

S Strip caulk

S A china marking pencil

S A screwdriver

Perform the following steps in order to conduct the road

test:

1. Choose a route that includes smooth straight

streets that run in all four directions (north, south,

east, and west).

2. Choose streets with little traffic or noise that would

interfere with the test.

3. Drive the vehicle at the speeds at which the noise

was noticed by the customer or until the noise is

produced. Do not exceed legal speed limits.

4. The windnoise is external if any of the following

conditions occur:

S The windnoise is caused by the wind.S The windnoise can be heard with the door glass

lowered and while the vehicle is being driven.

S The windnoise is eliminated when tape is placed

over various moldings and gaps.

5. Internal windnoise is air leaving the vehicle and

should be repaired in the following manner.

S In order to locate the leak, tape off the body lock

pillar pressure relief valves. This will cause air

pressure to build up inside the vehicle and en-

hance the windnoise.

S Use a stethoscope or a vacuum hose to locate

the leak.

S Temporarily repair the leak with masking tape.

S Continue testing in order to determine if the

noise has been eliminated or if other leaks exist.

S When all leaks have been found, return to the

shop and make permanent repairs with the

proper alignment techniques and sealing materi-

als.

Page 2390 of 2643

GLASS AND MIRRORS 9L – 11

DAEWOO V–121 BL4

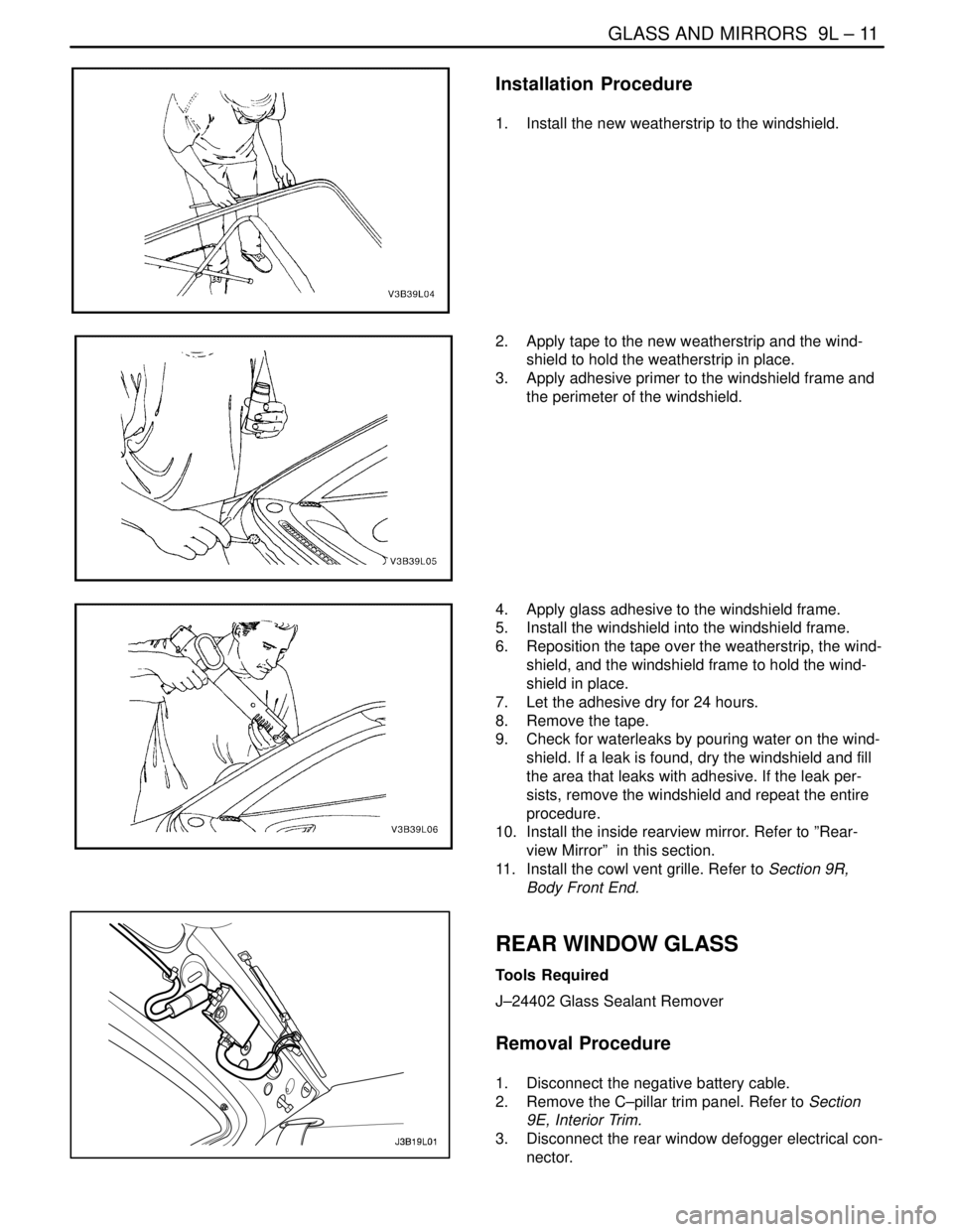

Installation Procedure

1. Install the new weatherstrip to the windshield.

2. Apply tape to the new weatherstrip and the wind-

shield to hold the weatherstrip in place.

3. Apply adhesive primer to the windshield frame and

the perimeter of the windshield.

4. Apply glass adhesive to the windshield frame.

5. Install the windshield into the windshield frame.

6. Reposition the tape over the weatherstrip, the wind-

shield, and the windshield frame to hold the wind-

shield in place.

7. Let the adhesive dry for 24 hours.

8. Remove the tape.

9. Check for waterleaks by pouring water on the wind-

shield. If a leak is found, dry the windshield and fill

the area that leaks with adhesive. If the leak per-

sists, remove the windshield and repeat the entire

procedure.

10. Install the inside rearview mirror. Refer to ”Rear-

view Mirror” in this section.

11. Install the cowl vent grille. Refer to Section 9R,

Body Front End.

REAR WINDOW GLASS

Tools Required

J–24402 Glass Sealant Remover

Removal Procedure

1. Disconnect the negative battery cable.

2. Remove the C–pillar trim panel. Refer to Section

9E, Interior Trim.

3. Disconnect the rear window defogger electrical con-

nector.

Page 2392 of 2643

GLASS AND MIRRORS 9L – 13

DAEWOO V–121 BL4

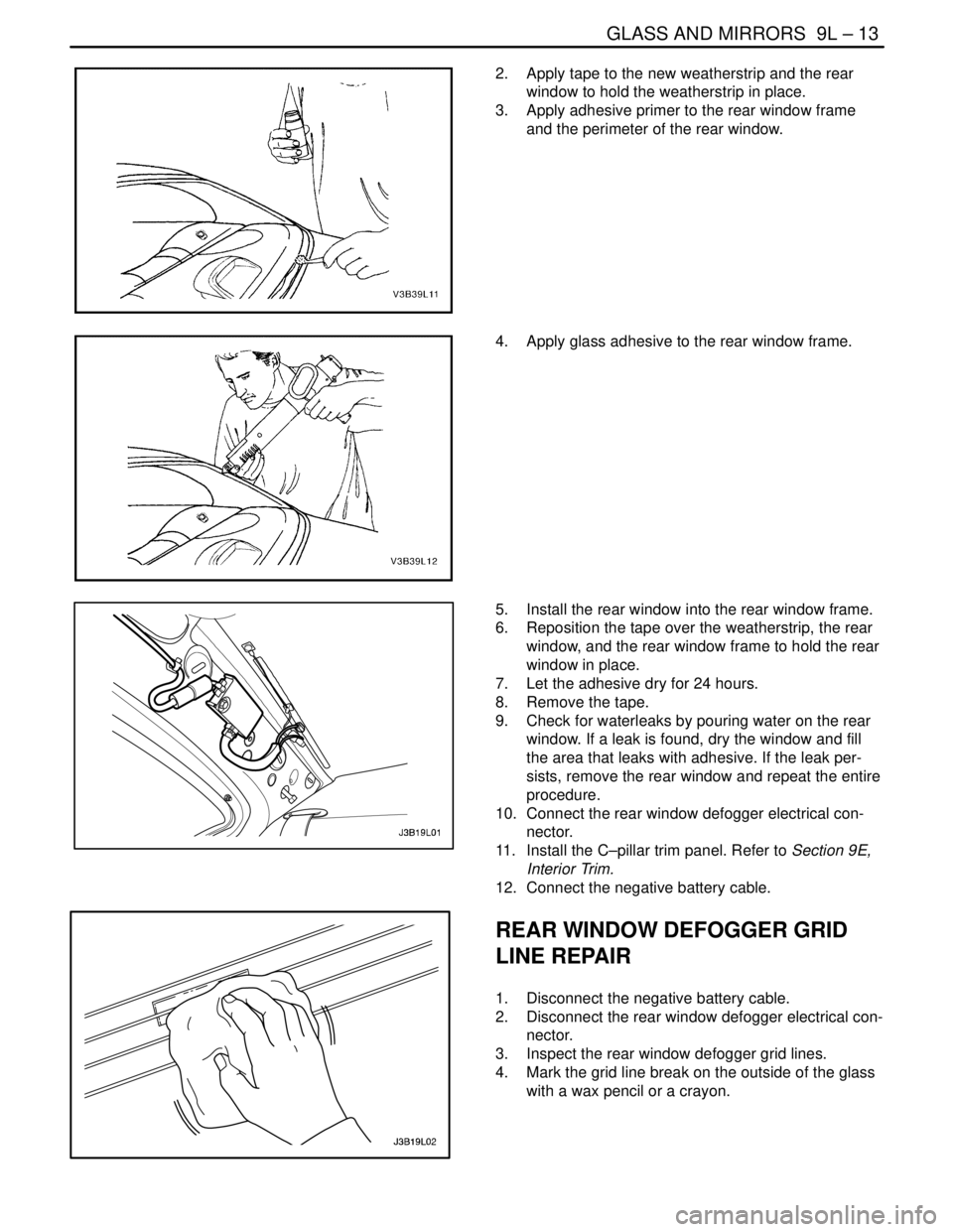

2. Apply tape to the new weatherstrip and the rear

window to hold the weatherstrip in place.

3. Apply adhesive primer to the rear window frame

and the perimeter of the rear window.

4. Apply glass adhesive to the rear window frame.

5. Install the rear window into the rear window frame.

6. Reposition the tape over the weatherstrip, the rear

window, and the rear window frame to hold the rear

window in place.

7. Let the adhesive dry for 24 hours.

8. Remove the tape.

9. Check for waterleaks by pouring water on the rear

window. If a leak is found, dry the window and fill

the area that leaks with adhesive. If the leak per-

sists, remove the rear window and repeat the entire

procedure.

10. Connect the rear window defogger electrical con-

nector.

11. Install the C–pillar trim panel. Refer to Section 9E,

Interior Trim.

12. Connect the negative battery cable.

REAR WINDOW DEFOGGER GRID

LINE REPAIR

1. Disconnect the negative battery cable.

2. Disconnect the rear window defogger electrical con-

nector.

3. Inspect the rear window defogger grid lines.

4. Mark the grid line break on the outside of the glass

with a wax pencil or a crayon.

Page 2395 of 2643

9L – 16IGLASS AND MIRRORS

DAEWOO V–121 BL4

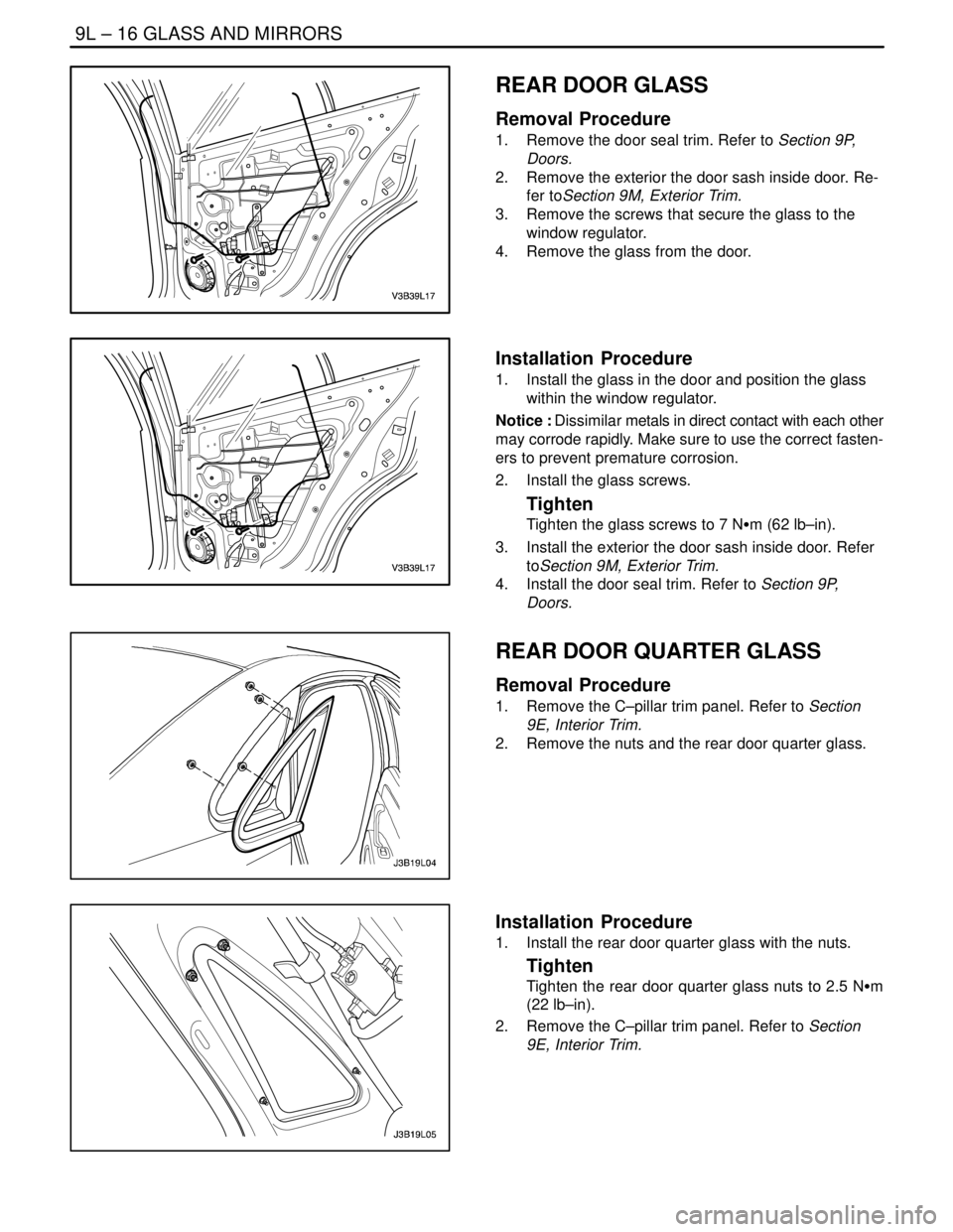

REAR DOOR GLASS

Removal Procedure

1. Remove the door seal trim. Refer to Section 9P,

Doors.

2. Remove the exterior the door sash inside door. Re-

fer toSection 9M, Exterior Trim.

3. Remove the screws that secure the glass to the

window regulator.

4. Remove the glass from the door.

Installation Procedure

1. Install the glass in the door and position the glass

within the window regulator.

Notice : Dissimilar metals in direct contact with each other

may corrode rapidly. Make sure to use the correct fasten-

ers to prevent premature corrosion.

2. Install the glass screws.

Tighten

Tighten the glass screws to 7 NSm (62 lb–in).

3. Install the exterior the door sash inside door. Refer

toSection 9M, Exterior Trim.

4. Install the door seal trim. Refer to Section 9P,

Doors.

REAR DOOR QUARTER GLASS

Removal Procedure

1. Remove the C–pillar trim panel. Refer to Section

9E, Interior Trim.

2. Remove the nuts and the rear door quarter glass.

Installation Procedure

1. Install the rear door quarter glass with the nuts.

Tighten

Tighten the rear door quarter glass nuts to 2.5 NSm

(22 lb–in).

2. Remove the C–pillar trim panel. Refer to Section

9E, Interior Trim.

Page 2399 of 2643

SECTION : 9M

EXTERIOR TRIM

TABLE OF CONTENTS

SPECIFICATIONS9M–1 . . . . . . . . . . . . . . . . . . . . . . . . . .

Fastener Tightening Specifications 9M–1. . . . . . . . . . .

MAINTENANCE AND REPAIR9M–2 . . . . . . . . . . . . . . .

ON–VEHICLE SERVICE 9M–2. . . . . . . . . . . . . . . . . . . . .

B–Pillar Molding 9M–2. . . . . . . . . . . . . . . . . . . . . . . . . . .

Roof Molding 9M–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Mud Guards 9M–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hatchback Rear Spoiler 9M–3. . . . . . . . . . . . . . . . . . . .

GENERAL DESCRIPTION AND SYSTEM

OPERATION9M–5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Emblems and Lettering 9M–5. . . . . . . . . . . . . . . . . . . . .

Mud Guards 9M–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

ApplicationNSmLb–FtLb–In

B–Pillar Molding Screws1.3–12

Mud Guard Bolts2–18

Page 2400 of 2643

9M – 2IEXTERIOR TRIM

DAEWOO V–121 BL4

MAINTENANCE AND REPAIR

ON–VEHICLE SERVICE

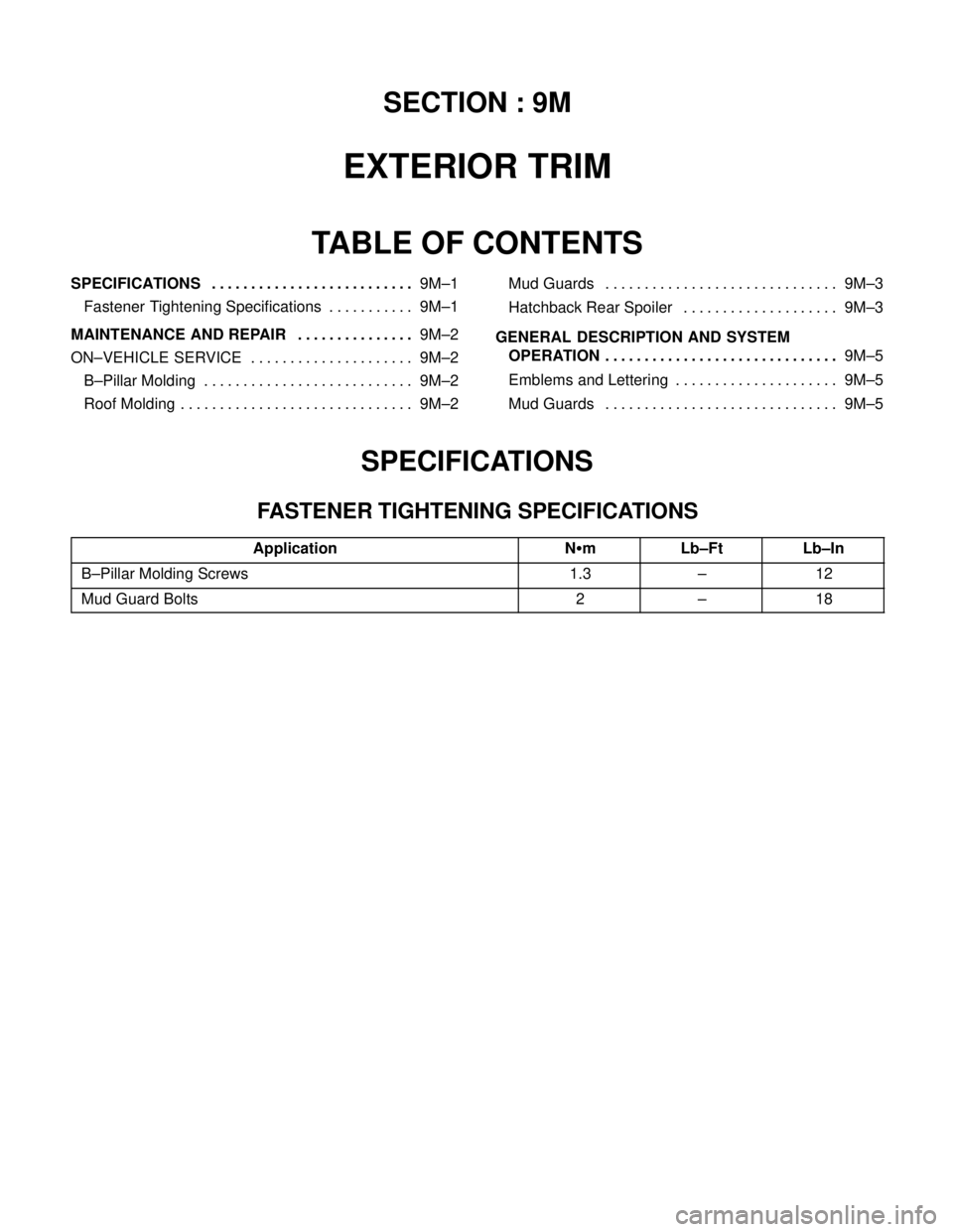

B–PILLAR MOLDING

Removal Procedure

1. Remove the outside channel molding. Refer to Sec-

tion 9P, Doors.

2. Reposition the weatherstrip in order to access the

screws.

3. Remove the screws and the B–pillar molding (front

door B–pillar molding shown, rear door C–pillar

molding similar).

Installation Procedure

Notice : Dissimilar metals in direct contact with each other

may corrode rapidly. Make sure to use the correct fasten-

ers to prevent premature corrosion.

1. Install the screws and the B–pillar molding (front

door B–pillar molding shown, rear door C–pillar

molding similar).

Tighten

Tighten the B–pillar molding screws to 1.3 NSm 12

(lb–in).

2. Install the weatherstrip to its original position.

3. Install the outside channel molding. Refer to Sec-

tion 9P, Doors.

ROOF MOLDING

Removal Procedure

1. Remove the roof molding from the metal clips.