pillar DAEWOO LACETTI 2004 Service Manual PDF

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 2439 of 2643

DOORS 9P – 19

DAEWOO V–121 BL4

Installation Procedure

1. Install the front door secondary weatherstrip.

2. Install the outside rearview mirror. Refer to Section

9L, Glass and Mirrors.

REAR DOOR SECONDARY

WEATHERSTRIP

Removal Procedure

1. Remove the interior garnish molding.

2. Remove the screws and the exterior garnish mold-

ing.

3. Remove the rear door secondary weatherstrip.

Installation Procedure

1. Install the rear door secondary weatherstrip.

Notice : Dissimilar metals in direct contact with each other

may corrode rapidly. Make sure to use the correct fasten-

ers to prevent premature corrosion.

2. Install the exterior garnish molding with the screws.

3. Install the interior garnish molding.

FRONT DOOR OPENING

WEATHERSTRIP

Removal Procedure

1. Remove the kick panel, the front rocker panel, and

the lower B–pillar trim panel. Refer to Section 9G,

Interior Trim.

2. Remove the front door opening weatherstrip.

Page 2440 of 2643

9P – 20IDOORS

DAEWOO V–121 BL4

Installation Procedure

1. Install the front door opening weatherstrip.

2. Install the kick panel, the front rocker panel, and the

lower B–pillar trim panel. Refer to Section 9G, Inte-

rior Trim.

REAR DOOR OPENING

WEATHERSTRIP

Removal Procedure

1. Remove the rear rocker panel and the lower B–pil-

lar trim panel. Refer to Section 9G, Interior Trim.

2. Remove the rear door opening weatherstrip.

Installation Procedure

1. Install the rear door opening weatherstrip.

2. Install the rear rocker panel and the lower B–pillar

trim panel. Refer to Section 9G, Interior Trim.

DOOR SEAL TRIM

(Front Door Shown, Rear Door Similar)

Removal Procedure

1. Remove the door trim panel. Refer to Section 9G,

Interior Trim.

2. Remove the door seal trim.

Page 2442 of 2643

9P – 22IDOORS

DAEWOO V–121 BL4

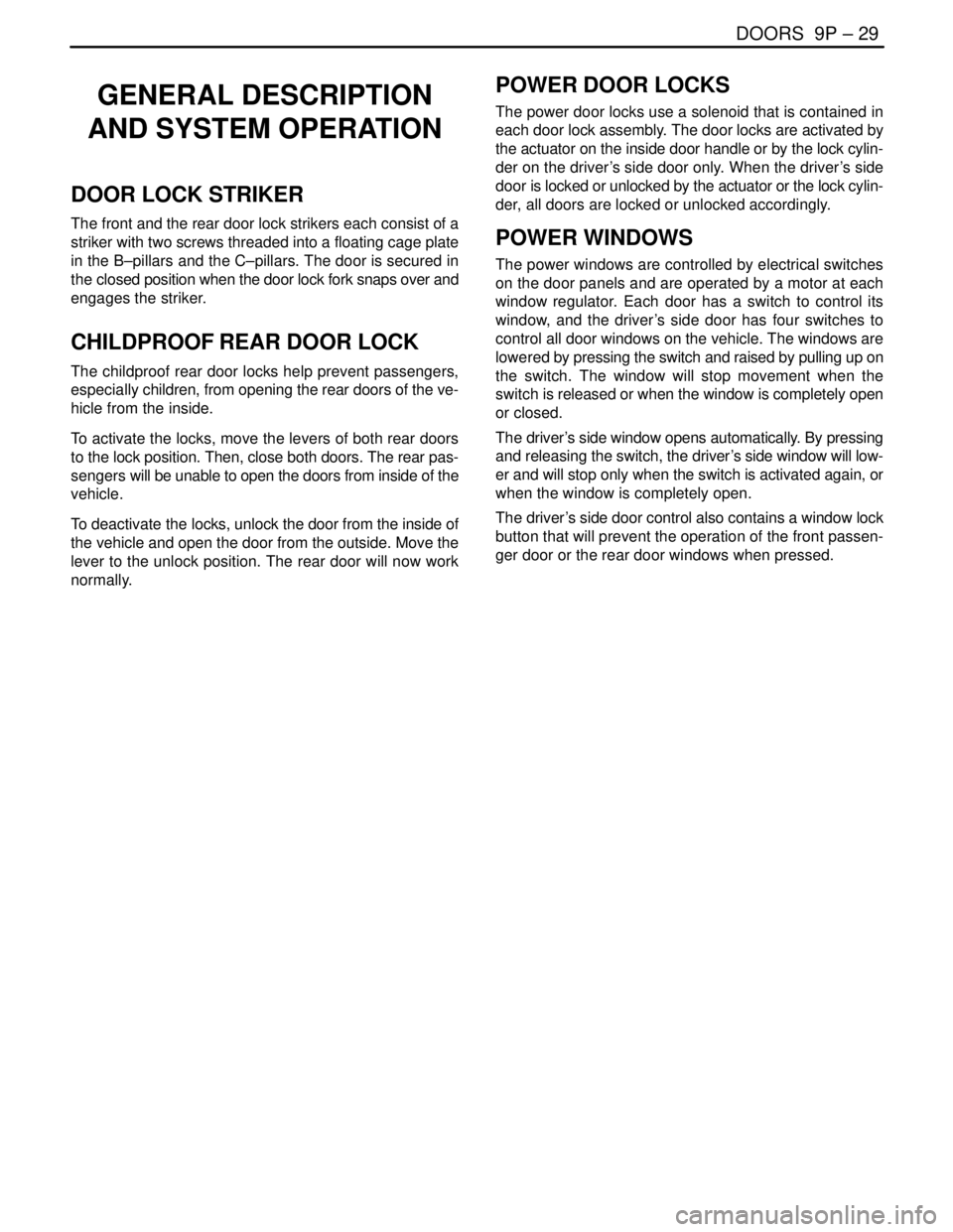

DOOR LOCK STRIKER ADJUSTMENT

(Front Door Shown, Rear Door Similar)

The door lock striker consists of a striker with two screws

that are threaded into a tapped, floating cage plate located

in the appropriate body pillar. This floating cage plate al-

lows the striker to be easily adjusted in and out or up and

down.

The door is secured in the closed position when the door

lock fork snaps over and engages the striker.

Notice : The door lock striker is an important attaching

part that can affect the performance of vital components

and systems. It can cause major repair expenses. If re-

placement becomes necessary, the door lock striker must

be replaced by one with the same part number or with an

equivalent. Do not use a replacement part of lesser quality

or of a substitute design. The specified torque values must

be used during reassembly to ensure the proper retention

of the part.

Up/Down or In/Out Adjustment

An adjustment of the striker in the up and down or in and

out directions may be necessary for a number of reasons:

S Vehicle frame damage as the result of a collision.

S Installation of new door weatherstripping.

S Customer complaints of excessive windnoise.

S Difficulty in opening or closing the door.

To adjust the door striker in an up and down or in and out

direction, perform the following procedure:

1. The door must be properly aligned.

2. Loosen the striker screws.

3. The floating cage plate can be moved slightly using

the ends of the striker screws. Move the floating

cage plate to the desired position.

4. If proper adjustment requires that the floating cage

plate be moved more than is possible, use an elec-

tric hand drill and a 3/8–inch rotary file bit with a flat

head to enlarge the body opening in the direction

required.

Notice : It is important to use a flat–tipped drill bit to pre-

vent damage to the tapped floating cage plate. The striker

screws and the tapped floating cage plate are important

attaching parts that could affect the performance of vital

components and systems.

5. Tighten the door lock striker screws to the correct

position.

Tighten

Tighten the door lock striker screws to 24 NSm (18 lb–

ft).

Page 2449 of 2643

DOORS 9P – 29

DAEWOO V–121 BL4

GENERAL DESCRIPTION

AND SYSTEM OPERATION

DOOR LOCK STRIKER

The front and the rear door lock strikers each consist of a

striker with two screws threaded into a floating cage plate

in the B–pillars and the C–pillars. The door is secured in

the closed position when the door lock fork snaps over and

engages the striker.

CHILDPROOF REAR DOOR LOCK

The childproof rear door locks help prevent passengers,

especially children, from opening the rear doors of the ve-

hicle from the inside.

To activate the locks, move the levers of both rear doors

to the lock position. Then, close both doors. The rear pas-

sengers will be unable to open the doors from inside of the

vehicle.

To deactivate the locks, unlock the door from the inside of

the vehicle and open the door from the outside. Move the

lever to the unlock position. The rear door will now work

normally.

POWER DOOR LOCKS

The power door locks use a solenoid that is contained in

each door lock assembly. The door locks are activated by

the actuator on the inside door handle or by the lock cylin-

der on the driver’s side door only. When the driver’s side

door is locked or unlocked by the actuator or the lock cylin-

der, all doors are locked or unlocked accordingly.

POWER WINDOWS

The power windows are controlled by electrical switches

on the door panels and are operated by a motor at each

window regulator. Each door has a switch to control its

window, and the driver’s side door has four switches to

control all door windows on the vehicle. The windows are

lowered by pressing the switch and raised by pulling up on

the switch. The window will stop movement when the

switch is released or when the window is completely open

or closed.

The driver’s side window opens automatically. By pressing

and releasing the switch, the driver ’s side window will low-

er and will stop only when the switch is activated again, or

when the window is completely open.

The driver’s side door control also contains a window lock

button that will prevent the operation of the front passen-

ger door or the rear door windows when pressed.

Page 2458 of 2643

ROOF 9Q – 9

DAEWOO V–121 BL4

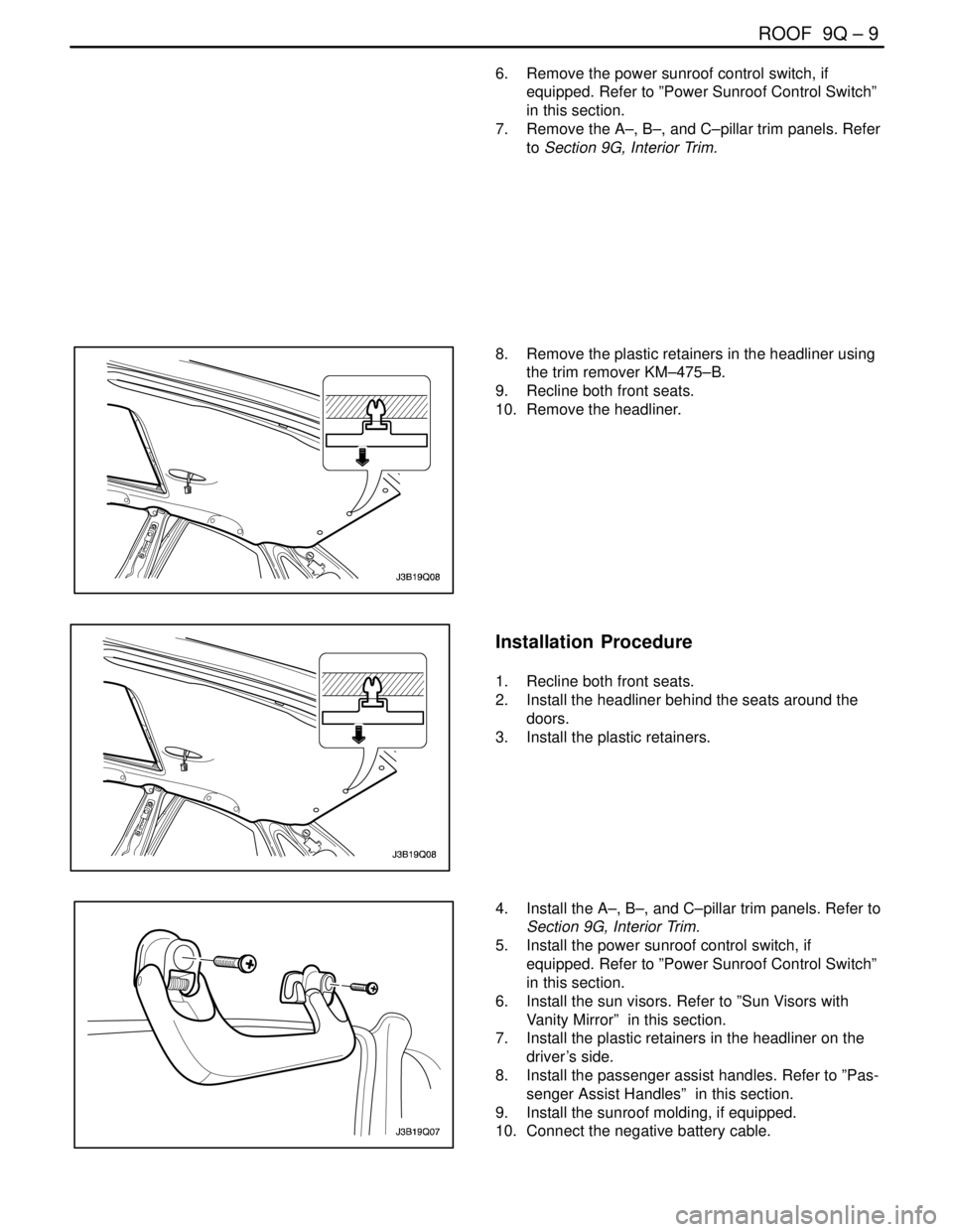

6. Remove the power sunroof control switch, if

equipped. Refer to ”Power Sunroof Control Switch”

in this section.

7. Remove the A–, B–, and C–pillar trim panels. Refer

to Section 9G, Interior Trim.

8. Remove the plastic retainers in the headliner using

the trim remover KM–475–B.

9. Recline both front seats.

10. Remove the headliner.

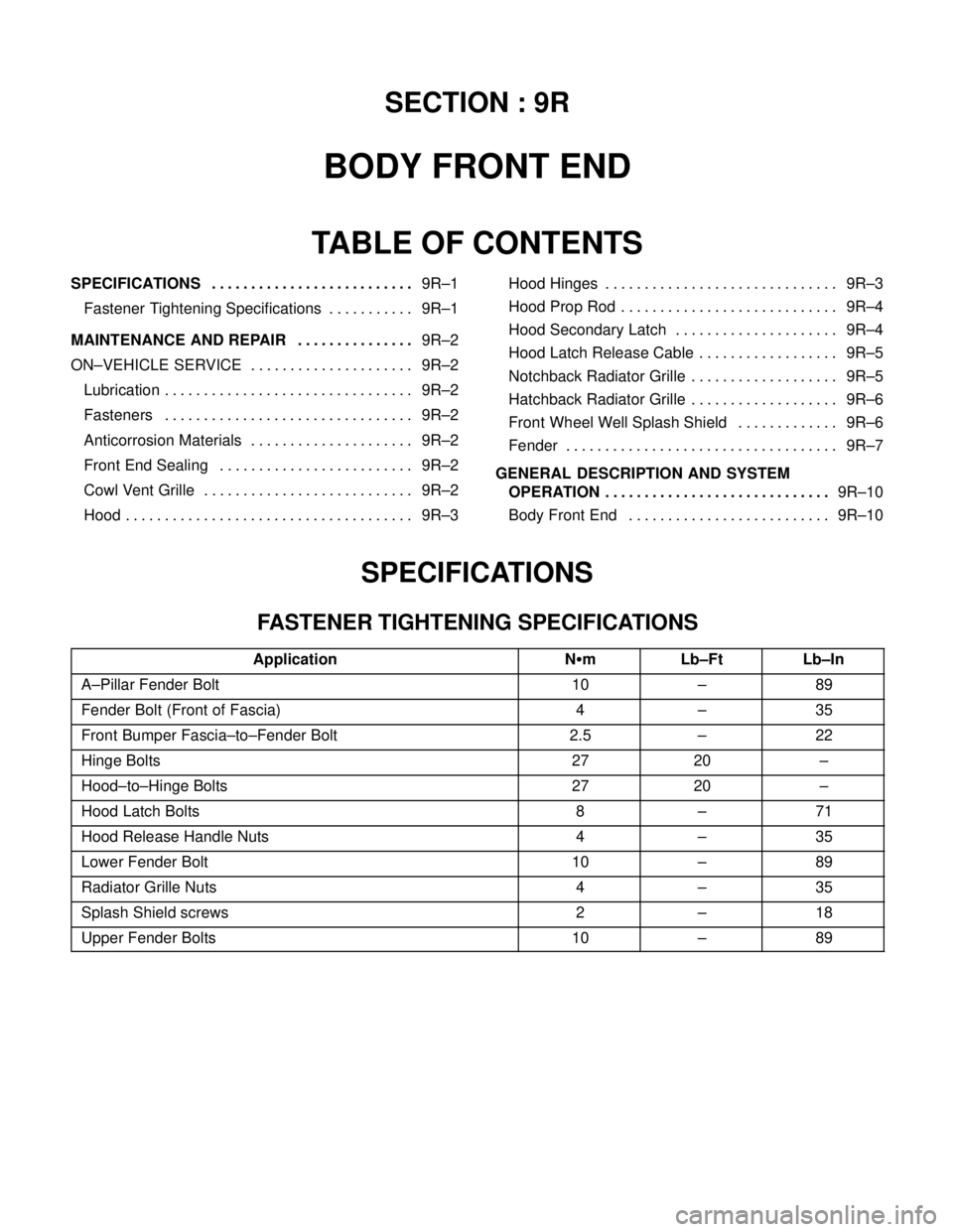

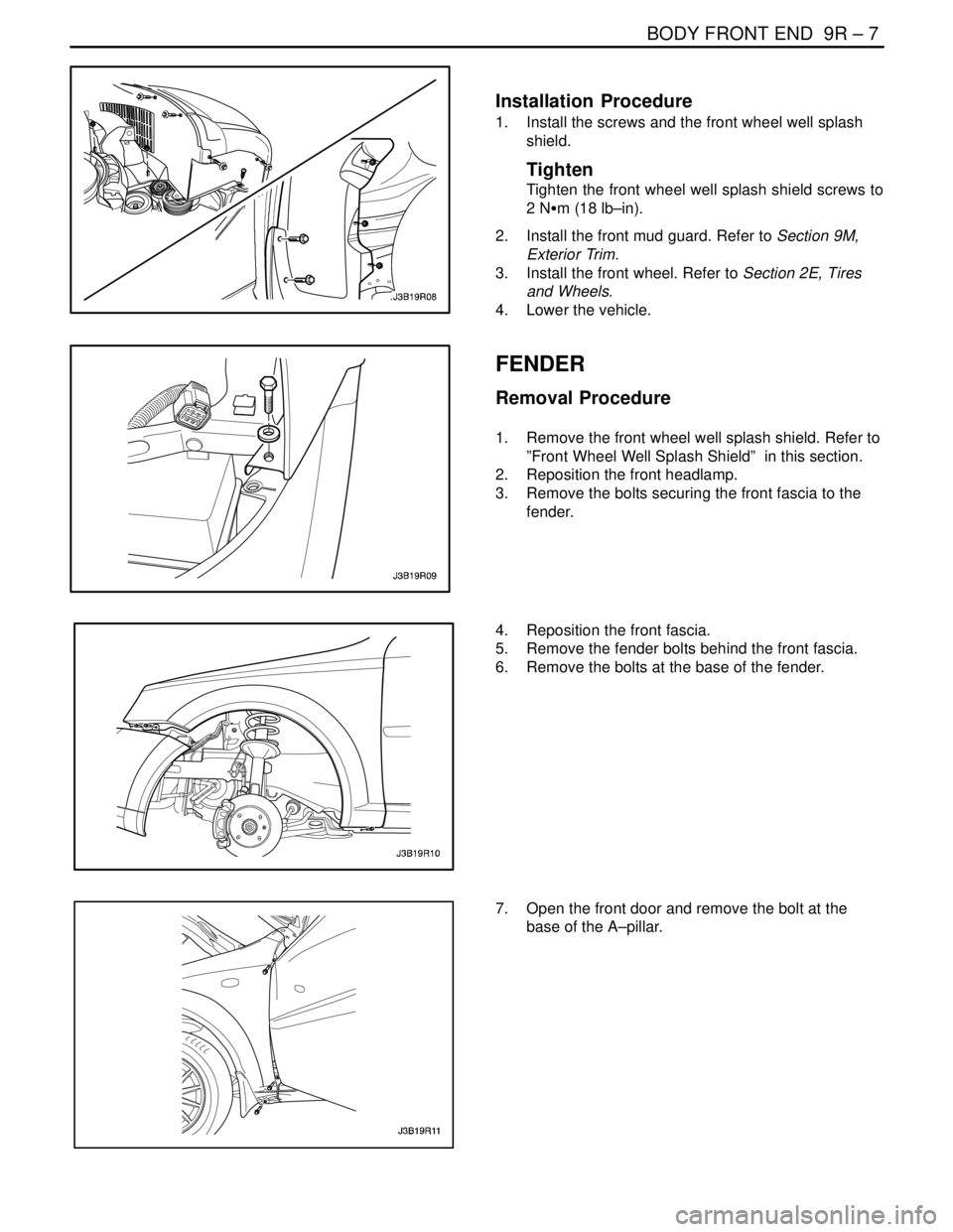

Installation Procedure

1. Recline both front seats.

2. Install the headliner behind the seats around the

doors.

3. Install the plastic retainers.

4. Install the A–, B–, and C–pillar trim panels. Refer to

Section 9G, Interior Trim.

5. Install the power sunroof control switch, if

equipped. Refer to ”Power Sunroof Control Switch”

in this section.

6. Install the sun visors. Refer to ”Sun Visors with

Vanity Mirror” in this section.

7. Install the plastic retainers in the headliner on the

driver’s side.

8. Install the passenger assist handles. Refer to ”Pas-

senger Assist Handles” in this section.

9. Install the sunroof molding, if equipped.

10. Connect the negative battery cable.

Page 2462 of 2643

SECTION : 9R

BODY FRONT END

TABLE OF CONTENTS

SPECIFICATIONS9R–1 . . . . . . . . . . . . . . . . . . . . . . . . . .

Fastener Tightening Specifications 9R–1. . . . . . . . . . .

MAINTENANCE AND REPAIR9R–2 . . . . . . . . . . . . . . .

ON–VEHICLE SERVICE 9R–2. . . . . . . . . . . . . . . . . . . . .

Lubrication 9R–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fasteners 9R–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Anticorrosion Materials 9R–2. . . . . . . . . . . . . . . . . . . . .

Front End Sealing 9R–2. . . . . . . . . . . . . . . . . . . . . . . . .

Cowl Vent Grille 9R–2. . . . . . . . . . . . . . . . . . . . . . . . . . .

Hood 9R–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Hood Hinges 9R–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hood Prop Rod 9R–4. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hood Secondary Latch 9R–4. . . . . . . . . . . . . . . . . . . . .

Hood Latch Release Cable 9R–5. . . . . . . . . . . . . . . . . .

Notchback Radiator Grille 9R–5. . . . . . . . . . . . . . . . . . .

Hatchback Radiator Grille 9R–6. . . . . . . . . . . . . . . . . . .

Front Wheel Well Splash Shield 9R–6. . . . . . . . . . . . .

Fender 9R–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GENERAL DESCRIPTION AND SYSTEM

OPERATION9R–10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Body Front End 9R–10. . . . . . . . . . . . . . . . . . . . . . . . . .

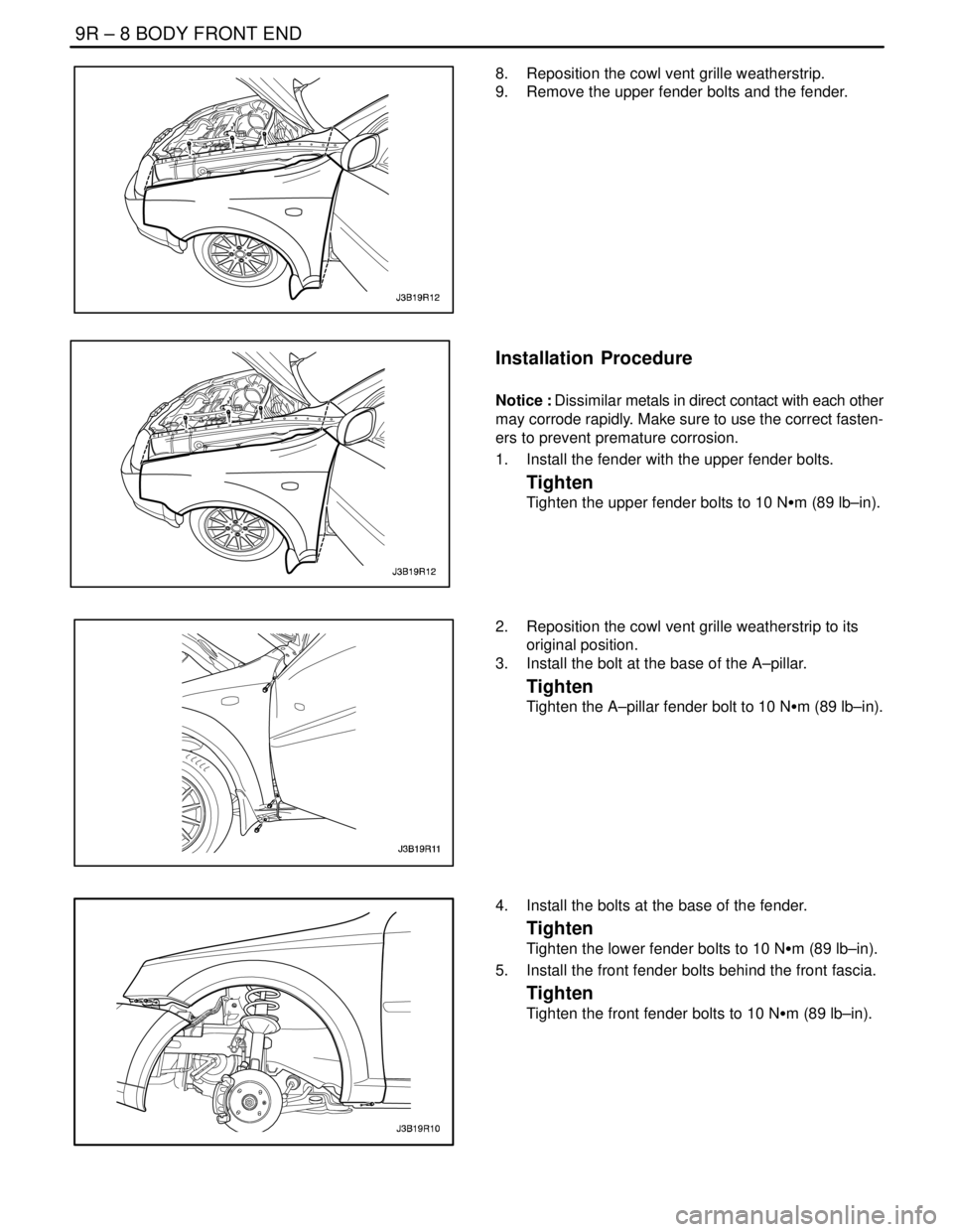

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

ApplicationNSmLb–FtLb–In

A–Pillar Fender Bolt10–89

Fender Bolt (Front of Fascia)4–35

Front Bumper Fascia–to–Fender Bolt2.5–22

Hinge Bolts2720–

Hood–to–Hinge Bolts2720–

Hood Latch Bolts8–71

Hood Release Handle Nuts4–35

Lower Fender Bolt10–89

Radiator Grille Nuts4–35

Splash Shield screws2–18

Upper Fender Bolts10–89

Page 2468 of 2643

BODY FRONT END 9R – 7

DAEWOO V–121 BL4

Installation Procedure

1. Install the screws and the front wheel well splash

shield.

Tighten

Tighten the front wheel well splash shield screws to

2 NSm (18 lb–in).

2. Install the front mud guard. Refer to Section 9M,

Exterior Trim.

3. Install the front wheel. Refer to Section 2E, Tires

and Wheels.

4. Lower the vehicle.

FENDER

Removal Procedure

1. Remove the front wheel well splash shield. Refer to

”Front Wheel Well Splash Shield” in this section.

2. Reposition the front headlamp.

3. Remove the bolts securing the front fascia to the

fender.

4. Reposition the front fascia.

5. Remove the fender bolts behind the front fascia.

6. Remove the bolts at the base of the fender.

7. Open the front door and remove the bolt at the

base of the A–pillar.

Page 2469 of 2643

9R – 8IBODY FRONT END

DAEWOO V–121 BL4

8. Reposition the cowl vent grille weatherstrip.

9. Remove the upper fender bolts and the fender.

Installation Procedure

Notice : Dissimilar metals in direct contact with each other

may corrode rapidly. Make sure to use the correct fasten-

ers to prevent premature corrosion.

1. Install the fender with the upper fender bolts.

Tighten

Tighten the upper fender bolts to 10 NSm (89 lb–in).

2. Reposition the cowl vent grille weatherstrip to its

original position.

3. Install the bolt at the base of the A–pillar.

Tighten

Tighten the A–pillar fender bolt to 10 NSm (89 lb–in).

4. Install the bolts at the base of the fender.

Tighten

Tighten the lower fender bolts to 10 NSm (89 lb–in).

5. Install the front fender bolts behind the front fascia.

Tighten

Tighten the front fender bolts to 10 NSm (89 lb–in).

Page 2472 of 2643

SECTION : 9S

BODY REAR END

CAUTION : Disconnect the negative battery cable before removing or installing any electrical unit or when a tool

or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help

prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise noted.

TABLE OF CONTENTS

SPECIFICATIONS9S–1 . . . . . . . . . . . . . . . . . . . . . . . . . .

Fastener Tightening Specifications 9S–1. . . . . . . . . . .

MAINTENANCE AND REPAIR9S–2 . . . . . . . . . . . . . . .

ON–VEHICLE SERVICE 9S–2. . . . . . . . . . . . . . . . . . . . .

Fuel Filler Door 9S–2. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Filler Door Remote Handle and Cable 9S–2. . . .

Rear Deck Lid 9S–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear Deck Lid Torque Rods 9S–5. . . . . . . . . . . . . . . . .

Luggage Compartment Lock Cylinder 9S–5. . . . . . . .

Luggage Compartment Lock Striker 9S–6. . . . . . . . . .

Luggage Compartment Lock 9S–6. . . . . . . . . . . . . . . . Weatherstrip 9S–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hatchback Weatherstrip 9S–7. . . . . . . . . . . . . . . . . . . .

Hatchback Door 9S–8. . . . . . . . . . . . . . . . . . . . . . . . . . .

Gas Support Assemblies 9S–8. . . . . . . . . . . . . . . . . . .

Hatchback Door Lock Striker 9S–9. . . . . . . . . . . . . . . .

Hatchback Door Lock 9S–9. . . . . . . . . . . . . . . . . . . . . .

GENERAL DESCRIPTION AND SYSTEM

OPERATION9S–10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Filler Door 9S–10. . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear Deck Lid (Notchback) 9S–10. . . . . . . . . . . . . . . .

Hatchback Door 9S–10. . . . . . . . . . . . . . . . . . . . . . . . . .

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

ApplicationNSmLb–FtLb–In

Fuel Filler Door Screws4–35

Fuel Filler Door Remote Cable Handle Cover Screw3–27

Fuel Filler Door Remote Cable Handle Screws10–89

Lower B–Pillar Seat Belt Anchor Bolt3828–

Luggage Compartment Lock Cylinder Nuts8–71

Luggage Compartment Lock Screws6–53

Luggage Compartment Lock Striker Bolts8–71

Rear Deck Lid Bolts10–89

Page 2474 of 2643

BODY REAR END 9S – 3

DAEWOO V–121 BL4

4. Remove the lower B–pillar seat belt bolt and the

anchor.

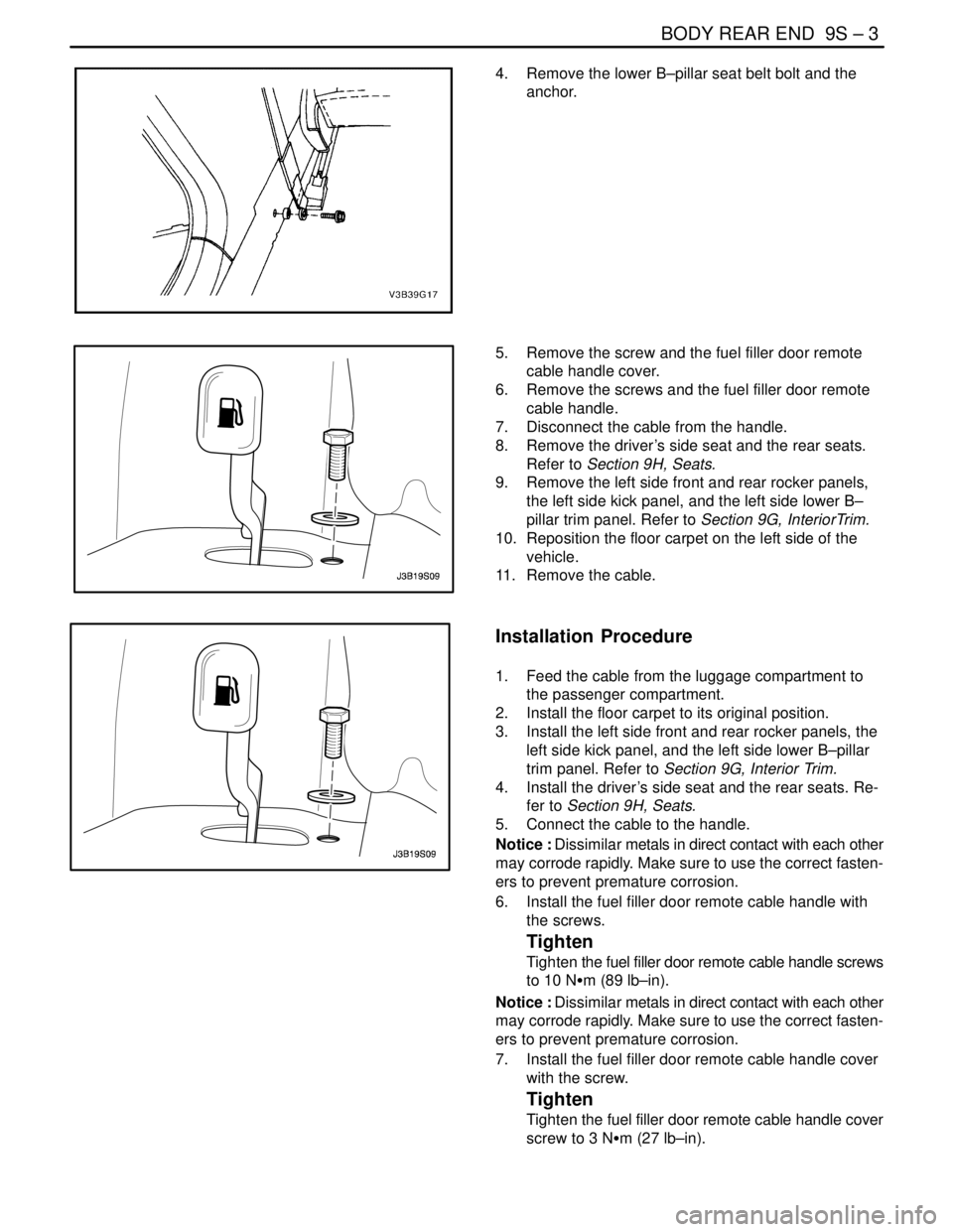

5. Remove the screw and the fuel filler door remote

cable handle cover.

6. Remove the screws and the fuel filler door remote

cable handle.

7. Disconnect the cable from the handle.

8. Remove the driver’s side seat and the rear seats.

Refer to Section 9H, Seats.

9. Remove the left side front and rear rocker panels,

the left side kick panel, and the left side lower B–

pillar trim panel. Refer to Section 9G, InteriorTrim.

10. Reposition the floor carpet on the left side of the

vehicle.

11. Remove the cable.

Installation Procedure

1. Feed the cable from the luggage compartment to

the passenger compartment.

2. Install the floor carpet to its original position.

3. Install the left side front and rear rocker panels, the

left side kick panel, and the left side lower B–pillar

trim panel. Refer to Section 9G, Interior Trim.

4. Install the driver’s side seat and the rear seats. Re-

fer to Section 9H, Seats.

5. Connect the cable to the handle.

Notice : Dissimilar metals in direct contact with each other

may corrode rapidly. Make sure to use the correct fasten-

ers to prevent premature corrosion.

6. Install the fuel filler door remote cable handle with

the screws.

Tighten

Tighten the fuel filler door remote cable handle screws

to 10 NSm (89 lb–in).

Notice : Dissimilar metals in direct contact with each other

may corrode rapidly. Make sure to use the correct fasten-

ers to prevent premature corrosion.

7. Install the fuel filler door remote cable handle cover

with the screw.

Tighten

Tighten the fuel filler door remote cable handle cover

screw to 3 NSm (27 lb–in).