lock DAEWOO LACETTI 2004 Service Repair Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 1919 of 2643

6C – 2IPOWER STEERING GEAR

DAEWOO V–121 BL4

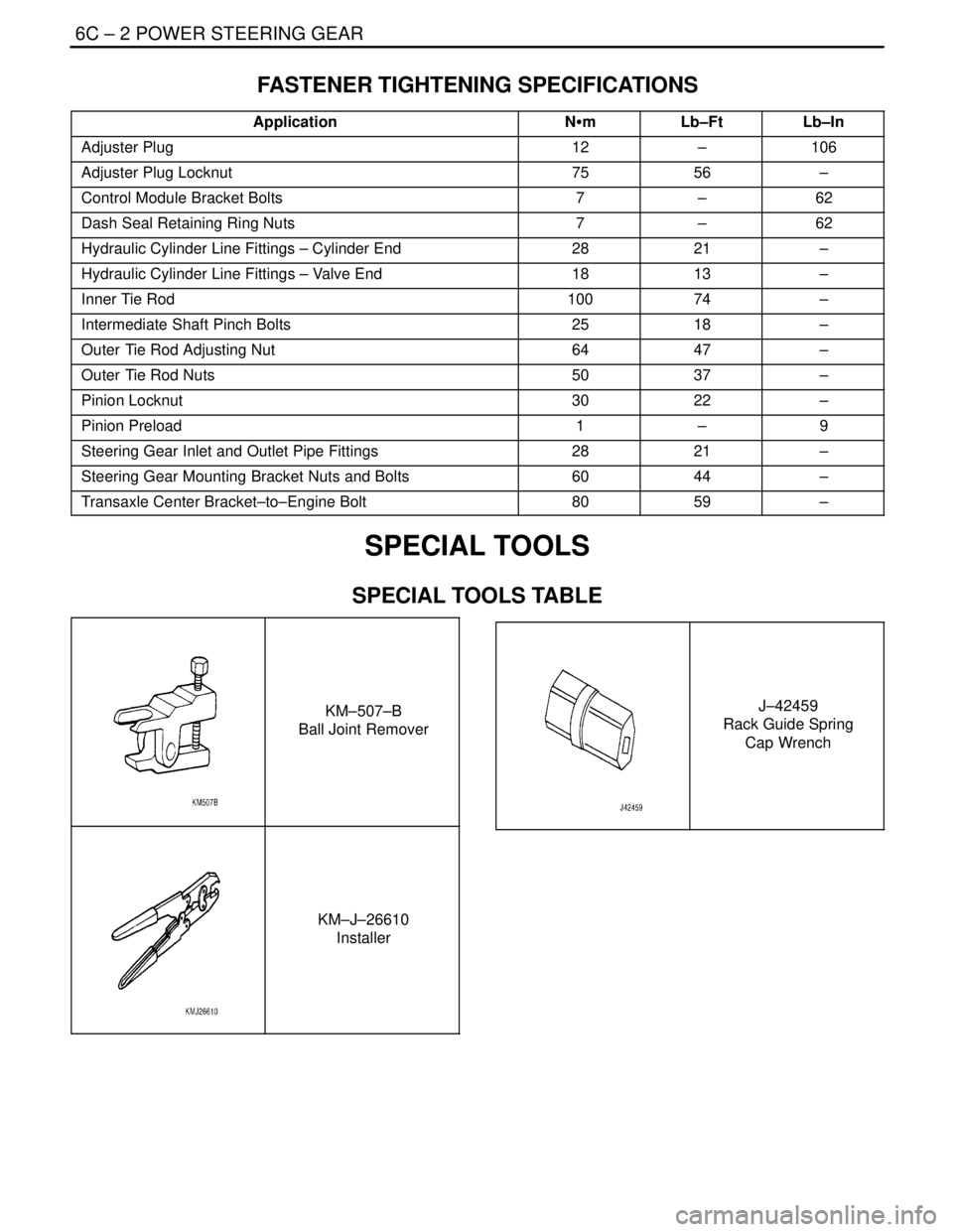

FASTENER TIGHTENING SPECIFICATIONS

ApplicationNSmLb–FtLb–In

Adjuster Plug12–106

Adjuster Plug Locknut7556–

Control Module Bracket Bolts7–62

Dash Seal Retaining Ring Nuts7–62

Hydraulic Cylinder Line Fittings – Cylinder End2821–

Hydraulic Cylinder Line Fittings – Valve End1813–

Inner Tie Rod10074–

Intermediate Shaft Pinch Bolts2518–

Outer Tie Rod Adjusting Nut6447–

Outer Tie Rod Nuts5037–

Pinion Locknut3022–

Pinion Preload1–9

Steering Gear Inlet and Outlet Pipe Fittings2821–

Steering Gear Mounting Bracket Nuts and Bolts6044–

Transaxle Center Bracket–to–Engine Bolt8059–

SPECIAL TOOLS

SPECIAL TOOLS TABLE

KM–507–B

Ball Joint Remover

KM–J–26610

Installer

J–42459

Rack Guide Spring

Cap Wrench

Page 1924 of 2643

POWER STEERING GEAR 6C – 7

DAEWOO V–121 BL4

SPEED SENSITIVE POWER STEERING SYSTEM

OPERATING WITH FULL ASSIST AT ALL TIMES

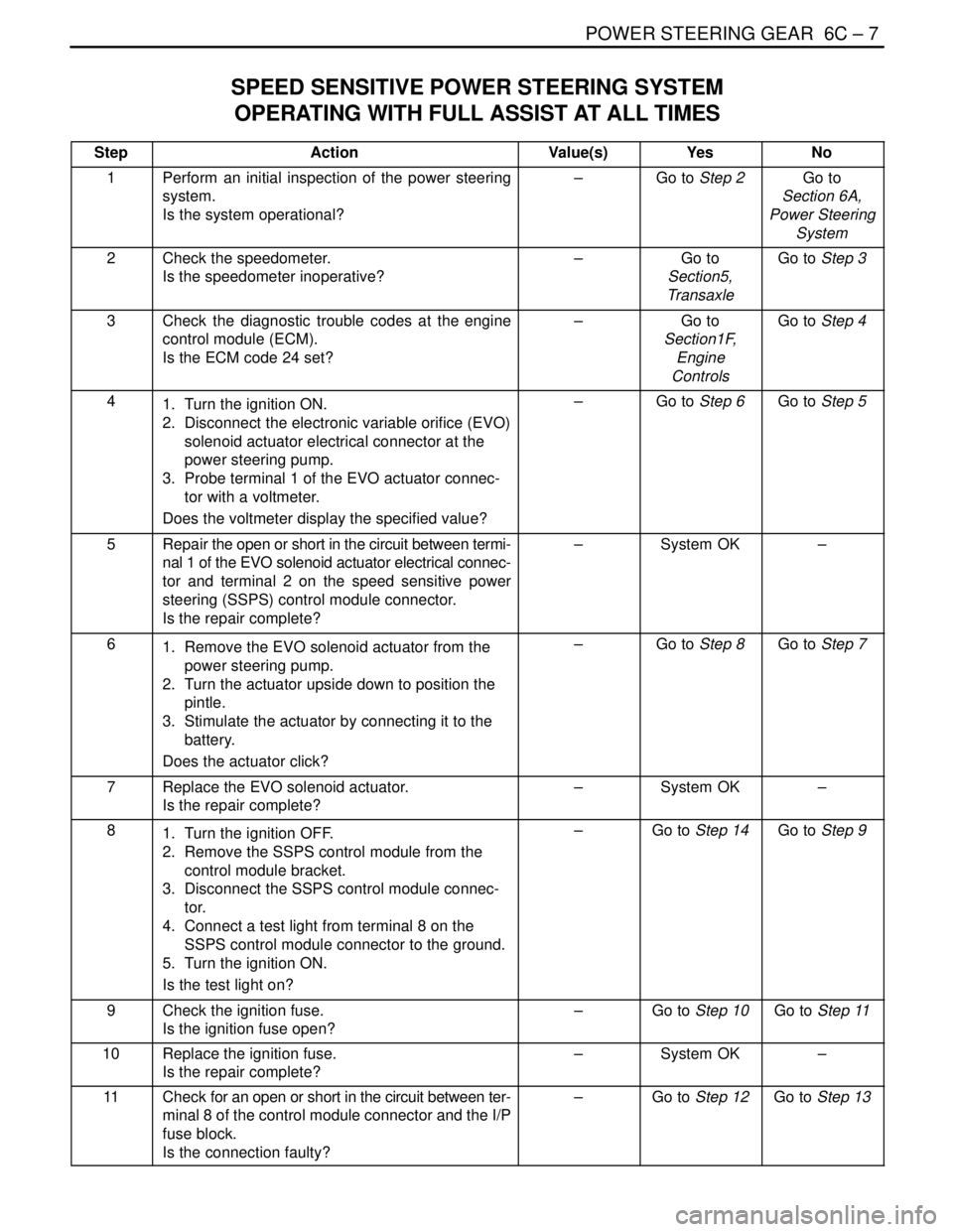

StepActionValue(s)YesNo

1Perform an initial inspection of the power steering

system.

Is the system operational?–Go to Step 2Go to

Section 6A,

Power Steering

System

2Check the speedometer.

Is the speedometer inoperative?–Go to

Section5,

TransaxleGo to Step 3

3Check the diagnostic trouble codes at the engine

control module (ECM).

Is the ECM code 24 set?–Go to

Section1F,

Engine

ControlsGo to Step 4

41. Turn the ignition ON.

2. Disconnect the electronic variable orifice (EVO)

solenoid actuator electrical connector at the

power steering pump.

3. Probe terminal 1 of the EVO actuator connec-

tor with a voltmeter.

Does the voltmeter display the specified value?–Go to Step 6Go to Step 5

5Repair the open or short in the circuit between termi-

nal 1 of the EVO solenoid actuator electrical connec-

tor and terminal 2 on the speed sensitive power

steering (SSPS) control module connector.

Is the repair complete?–System OK–

61. Remove the EVO solenoid actuator from the

power steering pump.

2. Turn the actuator upside down to position the

pintle.

3. Stimulate the actuator by connecting it to the

battery.

Does the actuator click?–Go to Step 8Go to Step 7

7Replace the EVO solenoid actuator.

Is the repair complete?–System OK–

81. Turn the ignition OFF.

2. Remove the SSPS control module from the

control module bracket.

3. Disconnect the SSPS control module connec-

tor.

4. Connect a test light from terminal 8 on the

SSPS control module connector to the ground.

5. Turn the ignition ON.

Is the test light on?–Go to Step 14Go to Step 9

9Check the ignition fuse.

Is the ignition fuse open?–Go to Step 10Go to Step 11

10Replace the ignition fuse.

Is the repair complete?–System OK–

11Check for an open or short in the circuit between ter-

minal 8 of the control module connector and the I/P

fuse block.

Is the connection faulty?–Go to Step 12Go to Step 13

Page 1925 of 2643

6C – 8IPOWER STEERING GEAR

DAEWOO V–121 BL4

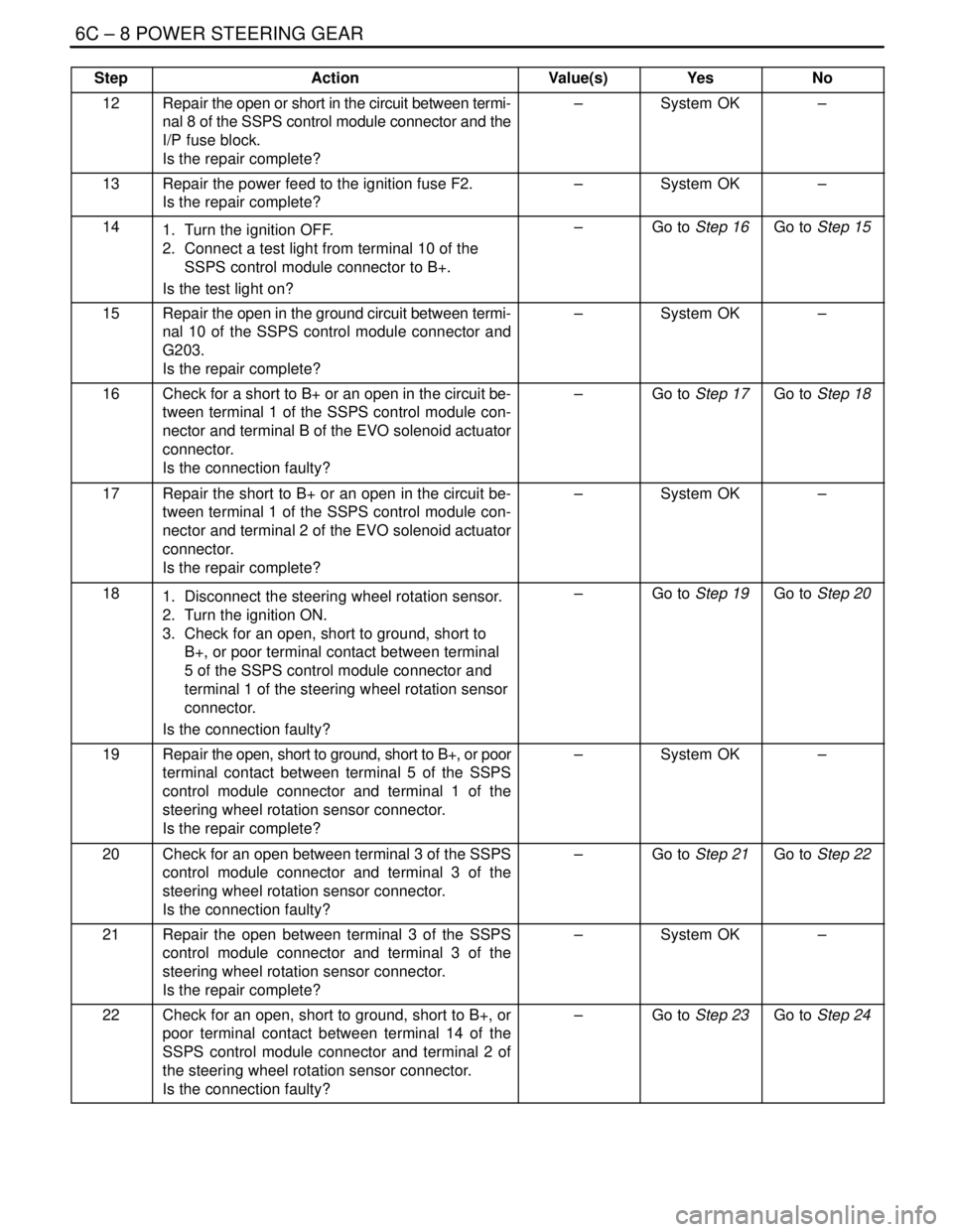

StepNo Yes Value(s) Action

12Repair the open or short in the circuit between termi-

nal 8 of the SSPS control module connector and the

I/P fuse block.

Is the repair complete?–System OK–

13Repair the power feed to the ignition fuse F2.

Is the repair complete?–System OK–

141. Turn the ignition OFF.

2. Connect a test light from terminal 10 of the

SSPS control module connector to B+.

Is the test light on?–Go to Step 16Go to Step 15

15Repair the open in the ground circuit between termi-

nal 10 of the SSPS control module connector and

G203.

Is the repair complete?–System OK–

16Check for a short to B+ or an open in the circuit be-

tween terminal 1 of the SSPS control module con-

nector and terminal B of the EVO solenoid actuator

connector.

Is the connection faulty?–Go to Step 17Go to Step 18

17Repair the short to B+ or an open in the circuit be-

tween terminal 1 of the SSPS control module con-

nector and terminal 2 of the EVO solenoid actuator

connector.

Is the repair complete?–System OK–

181. Disconnect the steering wheel rotation sensor.

2. Turn the ignition ON.

3. Check for an open, short to ground, short to

B+, or poor terminal contact between terminal

5 of the SSPS control module connector and

terminal 1 of the steering wheel rotation sensor

connector.

Is the connection faulty?–Go to Step 19Go to Step 20

19Repair the open, short to ground, short to B+, or poor

terminal contact between terminal 5 of the SSPS

control module connector and terminal 1 of the

steering wheel rotation sensor connector.

Is the repair complete?–System OK–

20Check for an open between terminal 3 of the SSPS

control module connector and terminal 3 of the

steering wheel rotation sensor connector.

Is the connection faulty?–Go to Step 21Go to Step 22

21Repair the open between terminal 3 of the SSPS

control module connector and terminal 3 of the

steering wheel rotation sensor connector.

Is the repair complete?–System OK–

22Check for an open, short to ground, short to B+, or

poor terminal contact between terminal 14 of the

SSPS control module connector and terminal 2 of

the steering wheel rotation sensor connector.

Is the connection faulty?–Go to Step 23Go to Step 24

Page 1943 of 2643

6C – 26IPOWER STEERING GEAR

DAEWOO V–121 BL4

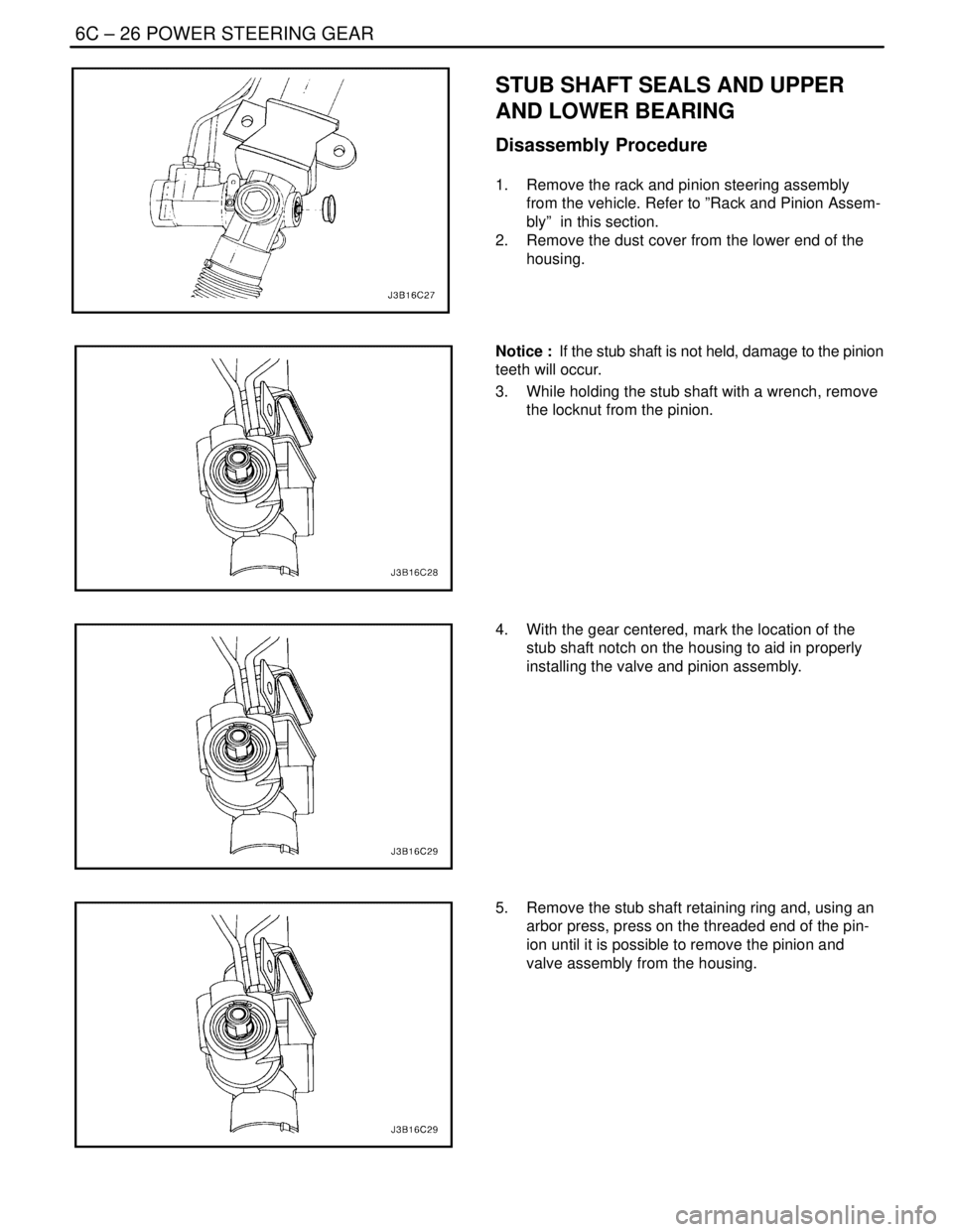

STUB SHAFT SEALS AND UPPER

AND LOWER BEARING

Disassembly Procedure

1. Remove the rack and pinion steering assembly

from the vehicle. Refer to ”Rack and Pinion Assem-

bly” in this section.

2. Remove the dust cover from the lower end of the

housing.

Notice : If the stub shaft is not held, damage to the pinion

teeth will occur.

3. While holding the stub shaft with a wrench, remove

the locknut from the pinion.

4. With the gear centered, mark the location of the

stub shaft notch on the housing to aid in properly

installing the valve and pinion assembly.

5. Remove the stub shaft retaining ring and, using an

arbor press, press on the threaded end of the pin-

ion until it is possible to remove the pinion and

valve assembly from the housing.

Page 1945 of 2643

6C – 28IPOWER STEERING GEAR

DAEWOO V–121 BL4

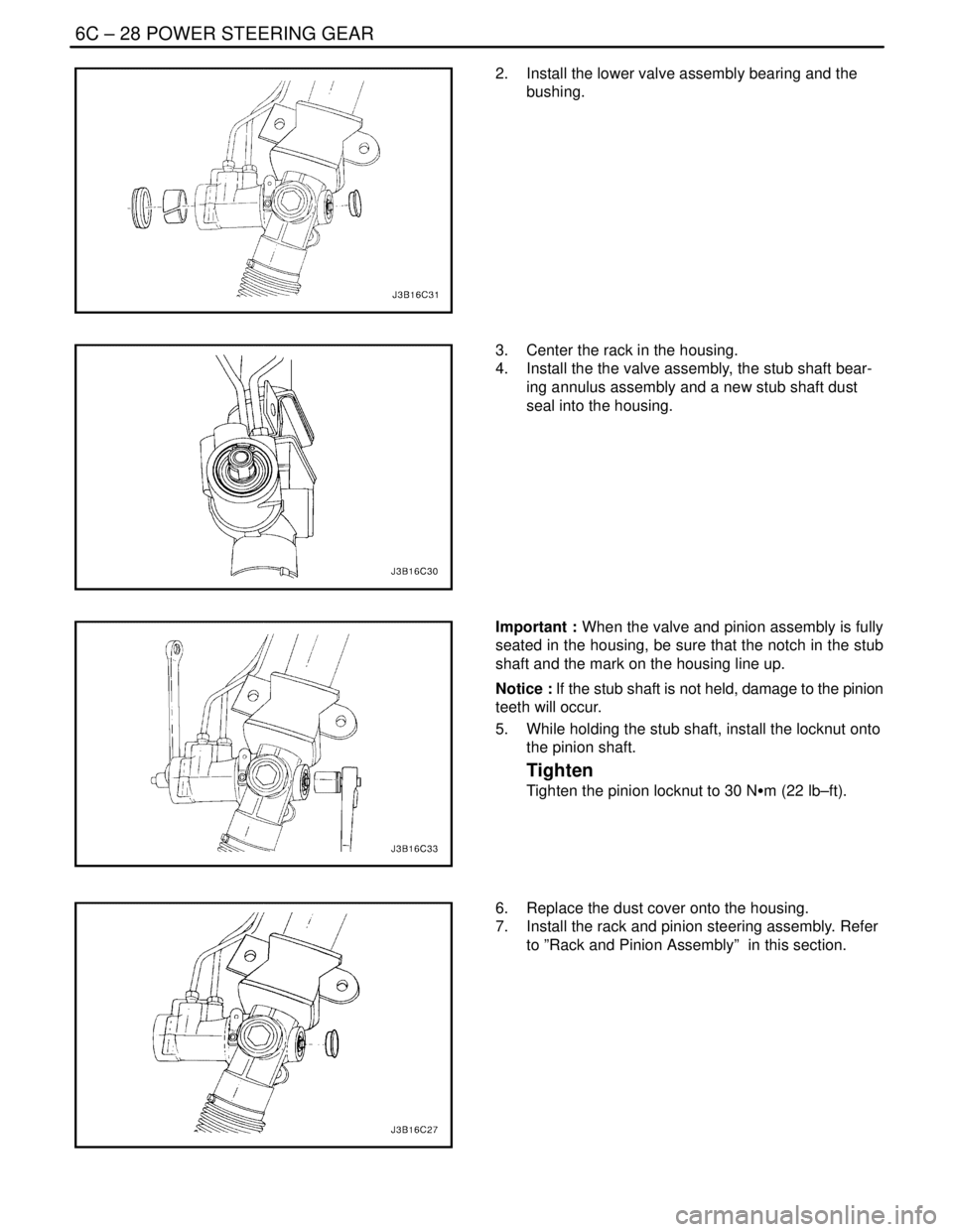

2. Install the lower valve assembly bearing and the

bushing.

3. Center the rack in the housing.

4. Install the the valve assembly, the stub shaft bear-

ing annulus assembly and a new stub shaft dust

seal into the housing.

Important : When the valve and pinion assembly is fully

seated in the housing, be sure that the notch in the stub

shaft and the mark on the housing line up.

Notice : If the stub shaft is not held, damage to the pinion

teeth will occur.

5. While holding the stub shaft, install the locknut onto

the pinion shaft.

Tighten

Tighten the pinion locknut to 30 NSm (22 lb–ft).

6. Replace the dust cover onto the housing.

7. Install the rack and pinion steering assembly. Refer

to ”Rack and Pinion Assembly” in this section.

Page 1946 of 2643

POWER STEERING GEAR 6C – 29

DAEWOO V–121 BL4

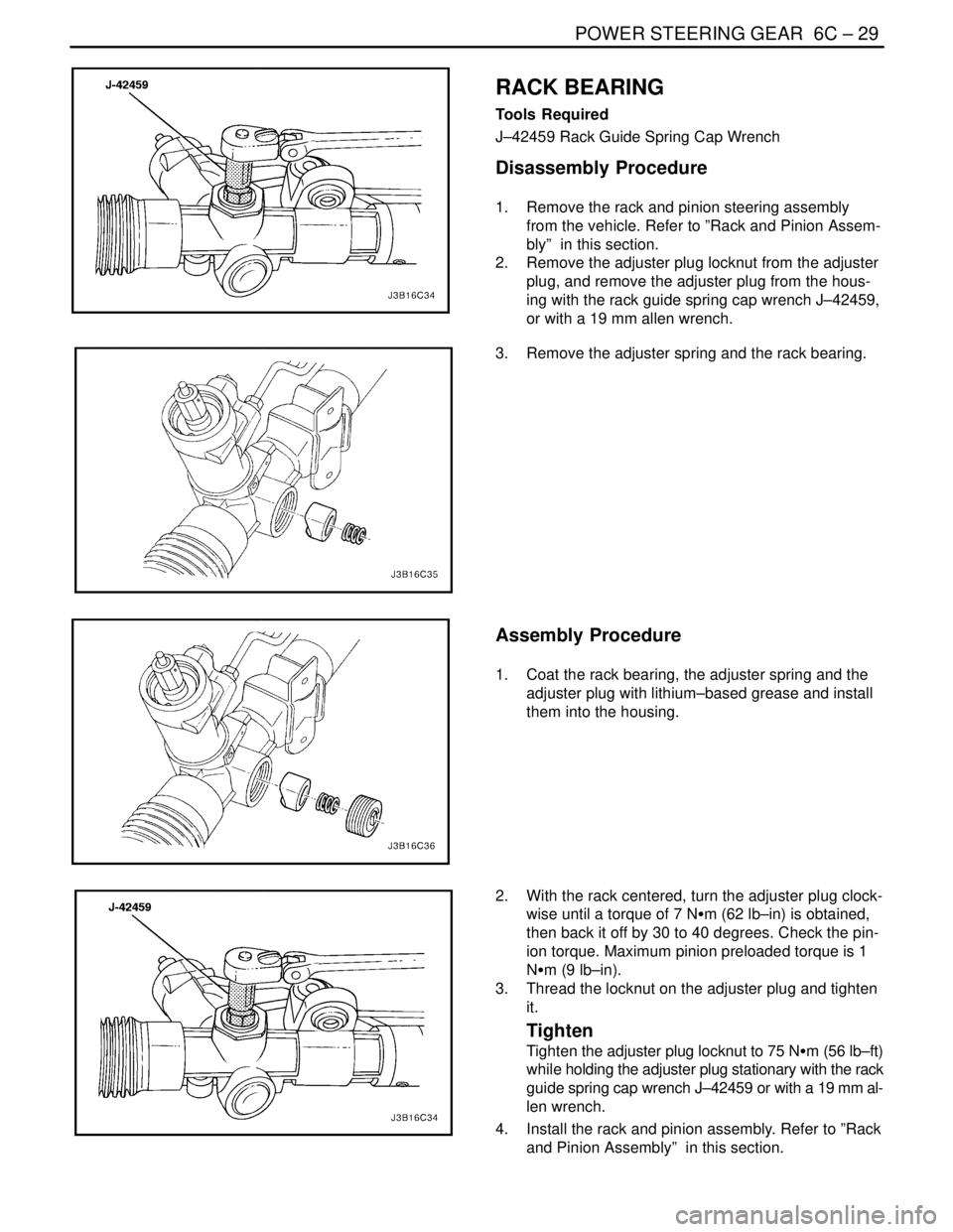

RACK BEARING

Tools Required

J–42459 Rack Guide Spring Cap Wrench

Disassembly Procedure

1. Remove the rack and pinion steering assembly

from the vehicle. Refer to ”Rack and Pinion Assem-

bly” in this section.

2. Remove the adjuster plug locknut from the adjuster

plug, and remove the adjuster plug from the hous-

ing with the rack guide spring cap wrench J–42459,

or with a 19 mm allen wrench.

3. Remove the adjuster spring and the rack bearing.

Assembly Procedure

1. Coat the rack bearing, the adjuster spring and the

adjuster plug with lithium–based grease and install

them into the housing.

2. With the rack centered, turn the adjuster plug clock-

wise until a torque of 7 NSm (62 lb–in) is obtained,

then back it off by 30 to 40 degrees. Check the pin-

ion torque. Maximum pinion preloaded torque is 1

NSm (9 lb–in).

3. Thread the locknut on the adjuster plug and tighten

it.

Tighten

Tighten the adjuster plug locknut to 75 NSm (56 lb–ft)

while holding the adjuster plug stationary with the rack

guide spring cap wrench J–42459 or with a 19 mm al-

len wrench.

4. Install the rack and pinion assembly. Refer to ”Rack

and Pinion Assembly” in this section.

Page 1947 of 2643

6C – 30IPOWER STEERING GEAR

DAEWOO V–121 BL4

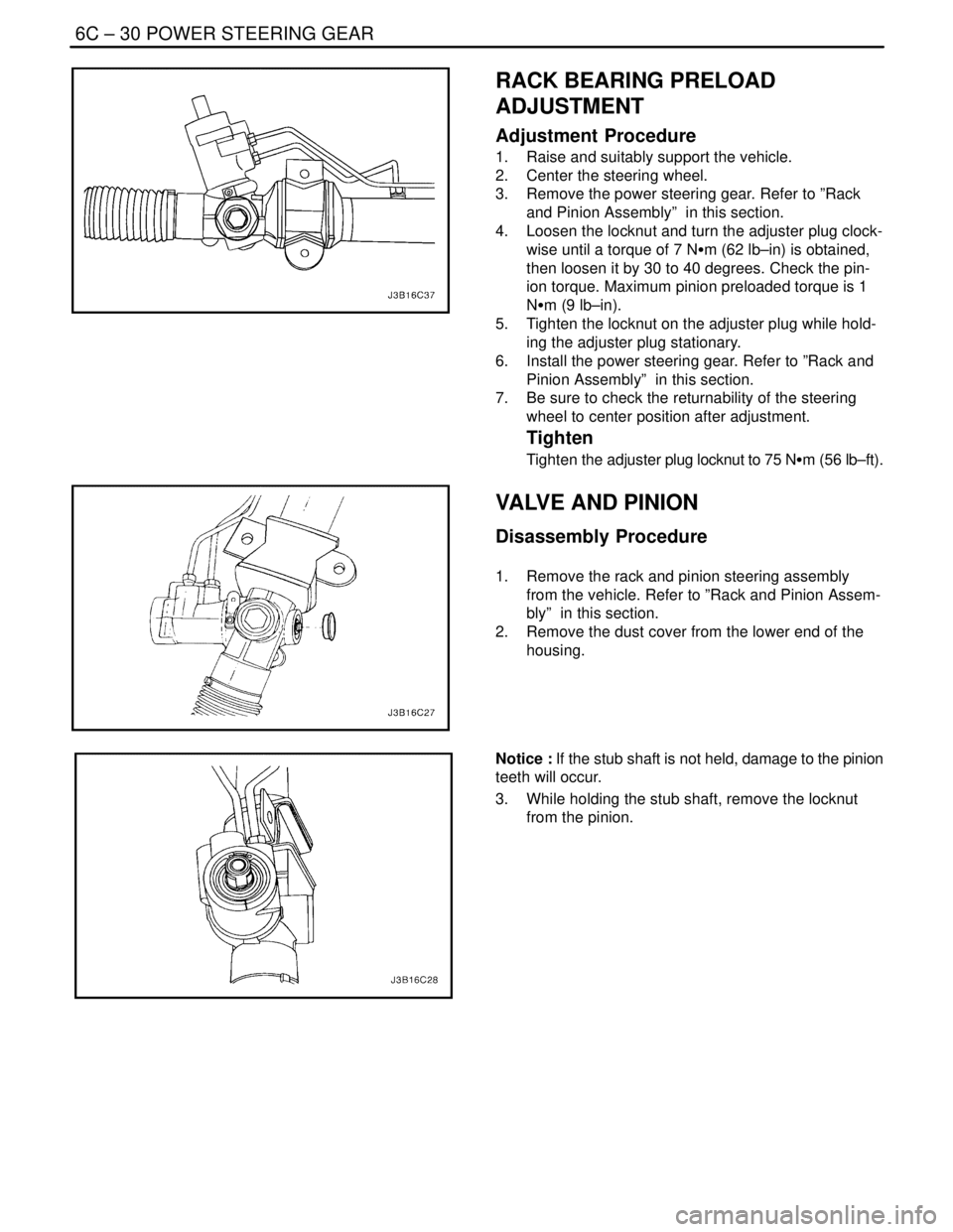

RACK BEARING PRELOAD

ADJUSTMENT

Adjustment Procedure

1. Raise and suitably support the vehicle.

2. Center the steering wheel.

3. Remove the power steering gear. Refer to ”Rack

and Pinion Assembly” in this section.

4. Loosen the locknut and turn the adjuster plug clock-

wise until a torque of 7 NSm (62 lb–in) is obtained,

then loosen it by 30 to 40 degrees. Check the pin-

ion torque. Maximum pinion preloaded torque is 1

NSm (9 lb–in).

5. Tighten the locknut on the adjuster plug while hold-

ing the adjuster plug stationary.

6. Install the power steering gear. Refer to ”Rack and

Pinion Assembly” in this section.

7. Be sure to check the returnability of the steering

wheel to center position after adjustment.

Tighten

Tighten the adjuster plug locknut to 75 NSm (56 lb–ft).

VALVE AND PINION

Disassembly Procedure

1. Remove the rack and pinion steering assembly

from the vehicle. Refer to ”Rack and Pinion Assem-

bly” in this section.

2. Remove the dust cover from the lower end of the

housing.

Notice : If the stub shaft is not held, damage to the pinion

teeth will occur.

3. While holding the stub shaft, remove the locknut

from the pinion.

Page 1949 of 2643

6C – 32IPOWER STEERING GEAR

DAEWOO V–121 BL4

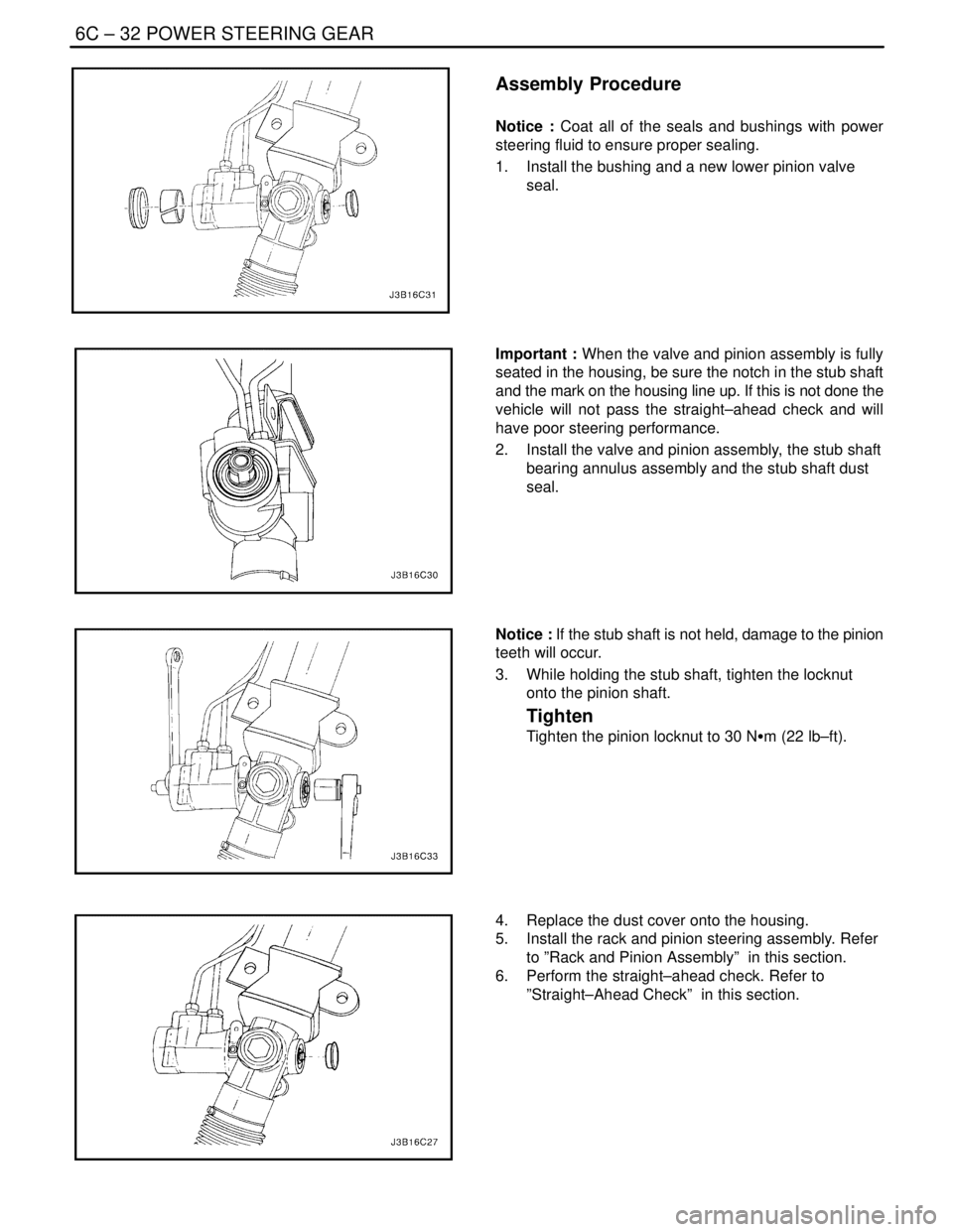

Assembly Procedure

Notice : Coat all of the seals and bushings with power

steering fluid to ensure proper sealing.

1. Install the bushing and a new lower pinion valve

seal.

Important : When the valve and pinion assembly is fully

seated in the housing, be sure the notch in the stub shaft

and the mark on the housing line up. If this is not done the

vehicle will not pass the straight–ahead check and will

have poor steering performance.

2. Install the valve and pinion assembly, the stub shaft

bearing annulus assembly and the stub shaft dust

seal.

Notice : If the stub shaft is not held, damage to the pinion

teeth will occur.

3. While holding the stub shaft, tighten the locknut

onto the pinion shaft.

Tighten

Tighten the pinion locknut to 30 NSm (22 lb–ft).

4. Replace the dust cover onto the housing.

5. Install the rack and pinion steering assembly. Refer

to ”Rack and Pinion Assembly” in this section.

6. Perform the straight–ahead check. Refer to

”Straight–Ahead Check” in this section.

Page 1950 of 2643

POWER STEERING GEAR 6C – 33

DAEWOO V–121 BL4

GENERAL DESCRIPTION

AND SYSTEM OPERATION

POWER RACK AND PINION

The power rack and pinion steering system has a rotary

control valve that directs hydraulic fluid coming from the

hydraulic pump to one side or the other side of the rack pis-

ton. The integral rack piston is attached to the rack. The

rack piston converts hydraulic pressure to a linear force

that moves the rack left or right. That force is then trans-

mitted through the tie rods to the steering knuckles, which

turn the wheels.

If power rack and pinion steering is not available, manual

rack and pinion control is used; however, with this system,

more steering effort is required. The movement of the

steering wheel is transferred to the pinion. The rotary

movement of the pinion is then transferred through the pin-

ion threads, which mesh with teeth on the rack, thereby

causing the rack to move in a linear direction.

A vane–type of hydraulic pump provides hydraulic pres-

sure for both steering systems.

SPEED SENSITIVE POWER

STEERING SYSTEM

The speed sensitive power steering (SSPS) system varies

the driver effort required to steer as the vehicle speed

changes. At low speeds, the system provides maximum

power assist for easy turning and parking maneuvers. At

higher speeds, the steering power is reduced to provide

the driver with firmer steering and directional stability. The

SSPS system accomplishes this by reducing the amount

of power steering fluid flow from the power steering pump

to the power steering gear as the vehicle speed increases.

When the vehicle is stationary, the SSPS system provides

maximum fluid flow to the steering gear. As the vehicle

speed increases, the fluid flow to the steering gear is de-

creased.

Control Module

The SSPS control module processes the vehicle speed in-

formation from the engine control module (ECM) and uses

the steering wheel rotation sensor to provide a control sig-

nal to the electronic variable orifice (EVO) actuator located

on the power steering pump.

Electronic Variable Orifice (EVO) Actuator

The electronic variable orifice (EVO) actuator is located on

the power steering pump and contains a solenoid– oper-

ated pintle valve. Fluid leaving the pump passes through

an orifice in the actuator tip. When the EVO actuator is

powered by the SSPS control module, the pintle moves

into the orifice and reduces the power steering fluid flow.As the vehicle speed increases, current from the SSPS

control module increases, and the pintle blocks more and

more of the orifice.

Steering Wheel Rotation Sensor

The steering wheel rotation sensor is located at the end of

the steering column housing and is used to send a signal

to the controller when abrupt or evasive steering maneu-

vers are needed.

Power Steering Pressure Hose

SSPS vehicles have a specific pressure hose assembly

which includes an in–line check valve in the rack and pin-

ion assembly. This reduces the amount of steering wheel

”kick” when driving over irregular road surfaces while oper-

ating at speeds with reduced flow rate and pressure.

Power Rack and Pinion

Except for differences in valve machining, the design of

the SSPS power rack and pinion assembly is the same as

for the a non–SSPS system. The steering wheel move-

ment is transferred to the pinion via the intermediate shaft.

The pinion moves the rack left or right through meshing the

pinion and the rack teeth. The force is then transmitted

through the tie rods and steering knuckle to steer the

wheels.

The power rack and pinion steering system has a rotary

control valve which directs the hydraulic fluid from the

power steering pump to one side or the other side of the

rack piston. The piston is attached to the rack and uses hy-

draulic pressure to move the rack left or right. The rotary

control valve regulates the degree of assist by responding

to the driver’s torque input.

If hydraulic assist is not available, manual control is main-

tained. However, under this condition, more steering effort

is required.

Power Steering Pump

The standard vane–type pump, which provides hydraulic

pressure for the system, incorporates a special discharge

fitting to hold the EVO actuator.

System Operation

System operation originates with input from the vehicle

speed sensor via the engine control module to the SSPS

control module. The SSPS control module sends a signal

to the SSPS actuator to vary the rate of fluid flow output

by the power steering pump.

Circuit Operation

The SSPS system uses inputs from the speed sensor and

steering wheel rotation sensor to the SSPS controller to

determine the desired amount of power steering assist.

The SSPS control module constantly compares the

amount of current flowing through the EVO actuator to the

desired current it has calculated. The EVO actuator has a

pintle that moves in and out of an orifice, regulating power

Page 1955 of 2643

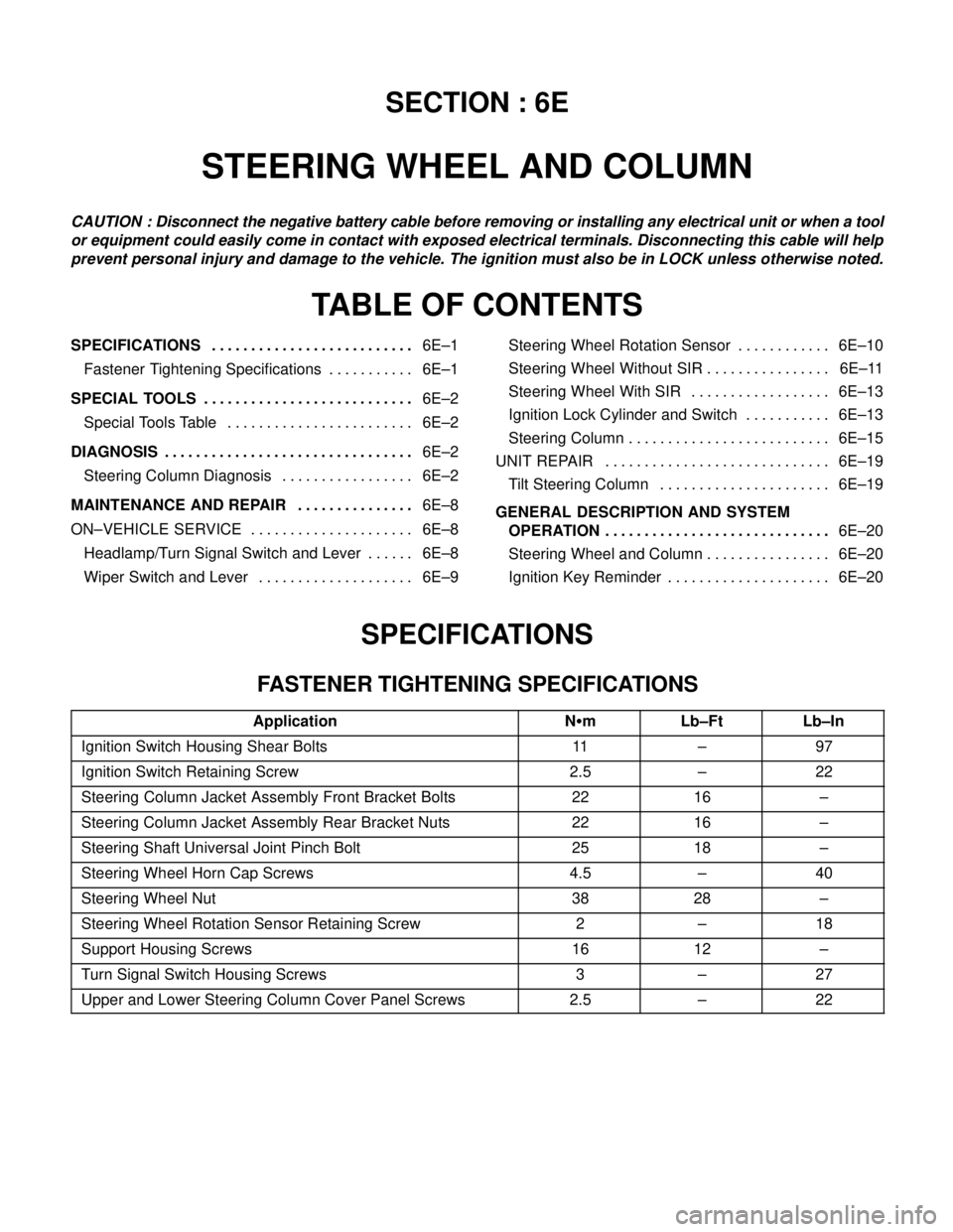

SECTION : 6E

STEERING WHEEL AND COLUMN

CAUTION : Disconnect the negative battery cable before removing or installing any electrical unit or when a tool

or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help

prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise noted.

TABLE OF CONTENTS

SPECIFICATIONS6E–1 . . . . . . . . . . . . . . . . . . . . . . . . . .

Fastener Tightening Specifications 6E–1. . . . . . . . . . .

SPECIAL TOOLS6E–2 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Special Tools Table 6E–2. . . . . . . . . . . . . . . . . . . . . . . .

DIAGNOSIS6E–2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Steering Column Diagnosis 6E–2. . . . . . . . . . . . . . . . .

MAINTENANCE AND REPAIR6E–8 . . . . . . . . . . . . . . .

ON–VEHICLE SERVICE 6E–8. . . . . . . . . . . . . . . . . . . . .

Headlamp/Turn Signal Switch and Lever 6E–8. . . . . .

Wiper Switch and Lever 6E–9. . . . . . . . . . . . . . . . . . . . Steering Wheel Rotation Sensor 6E–10. . . . . . . . . . . .

Steering Wheel Without SIR 6E–11. . . . . . . . . . . . . . . .

Steering Wheel With SIR 6E–13. . . . . . . . . . . . . . . . . .

Ignition Lock Cylinder and Switch 6E–13. . . . . . . . . . .

Steering Column 6E–15. . . . . . . . . . . . . . . . . . . . . . . . . .

UNIT REPAIR 6E–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tilt Steering Column 6E–19. . . . . . . . . . . . . . . . . . . . . .

GENERAL DESCRIPTION AND SYSTEM

OPERATION6E–20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Steering Wheel and Column 6E–20. . . . . . . . . . . . . . . .

Ignition Key Reminder 6E–20. . . . . . . . . . . . . . . . . . . . .

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

ApplicationNSmLb–FtLb–In

Ignition Switch Housing Shear Bolts11–97

Ignition Switch Retaining Screw2.5–22

Steering Column Jacket Assembly Front Bracket Bolts2216–

Steering Column Jacket Assembly Rear Bracket Nuts2216–

Steering Shaft Universal Joint Pinch Bolt2518–

Steering Wheel Horn Cap Screws4.5–40

Steering Wheel Nut3828–

Steering Wheel Rotation Sensor Retaining Screw2–18

Support Housing Screws1612–

Turn Signal Switch Housing Screws3–27

Upper and Lower Steering Column Cover Panel Screws2.5–22