lock DAEWOO LACETTI 2004 Service Repair Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 1956 of 2643

6E – 2ISTEERING WHEEL AND COLUMN

DAEWOO V–121 BL4

SPECIAL TOOLS

SPECIAL TOOLS TABLE

KM–210–A

Steering Wheel Puller

DIAGNOSIS

STEERING COLUMN DIAGNOSIS

Lock System

Lock System Will Not Unlock

ChecksAction

Check the lock cylinder for damage.Replace the lock cylinder.

Check the ignition switch for lack of free movement.Lubricate the ignition switch.

Check the steering column housing for binding or damage.Remove the steering shaft and clear the steering column

housing. Replace the steering column housing as needed.

Lock System Will Not Lock

ChecksAction

Check the lock cylinder for damage.Replace the lock cylinder.

Check the ignition switch for a lack of free movement.Lubricate the ignition switch.

Check the steering column housing for binding or damage.Remove the steering shaft and clear the steering column

housing. Replace the steering column housing as needed.

Page 1957 of 2643

STEERING WHEEL AND COLUMN 6E – 3

DAEWOO V–121 BL4

High Lock Effort

ChecksAction

Check the lock cylinder for damage.Replace the lock cylinder.

Check the ignition switch for lack of free movement.Lubricate the ignition switch.

Check for extreme misalignment of the housing to the cov-

er.Realign the cover on the housing. Replace the cover as

needed.

Check for a bent ignition switch mounting bracket.Replace the ignition switch mounting bracket.

Key Cannot Be Removed in the LOCK Position

ChecksAction

Check to see that the ignition switch is set correctly.Reset the ignition switch.

Check the lock cylinder for damage.Replace the lock cylinder.

Check the fuse F17 from the I/P fuse block.Replace the fuse F17

Check for an open or short in the circuit between terminal

2 of key interlock solenoid and the I/P fuse block.Replace the fuse F17

Select the gear shift lever to ”P” position.

Check the resistance between the terminal 2 and 1 of the

”P” position switch.Replace the ”P” position switch.

Check for an open or short in the circuit between the

ground G202 and terminal 1 of the key interlock unit.Replace the open or short from the circuit.

Turn the ignition ON.

Select the gear shift lever to ”P” position.

Check the resistance between the terminal 1 and 2 of the

key interlock solenoid.Replace the key interlock solenoid.

Page 1959 of 2643

STEERING WHEEL AND COLUMN 6E – 5

DAEWOO V–121 BL4

Column

Noise in the Column

ChecksAction

Check the steering gear–to–column joints for improper

installation.Tighten the steering shaft universal joint pinch bolts.

Replace the steering shaft joints as needed.

Check the steering shaft bearing for wear or damage.Replace the steering shaft bearing.

Check the spherical joint for lack of lubrication.Lubricate the spherical joint.

Check the steering shaft for lack of lubrication.Lubricate the steering shaft bearing.

Check the shaft lock snap ring for improper seating.Adjust the shaft lock snap ring. Replace the shaft lock snap

ring as needed.

High Steering Shaft Effort

ChecksAction

Check the steering shaft bearing for wear or damage.Replace the steering shaft bearing.

Check for an improperly installed or deformed dust seal.Replace the dust seal.

Check for a damaged upper or lower bearing.Replace the upper or the lower bearing.

Check the steering shaft universal joints for a lack of free

movement.Lubricate the steering shaft universal joints. Replace the

steering shaft universal joints as needed.

Lash in the Steering Column

ChecksAction

Check the steering column bracket mounting bolts for im-

proper installation.Tighten the steering column bracket mounting bolts.

Check for broken weld nuts on the steering column jacket.Replace the steering column jacket.

Check for loose steering column housing–to–steering col-

umn jacket support screws.Tighten the support screws.

Loose Steering Wheel

ChecksAction

Check for excessive clearance between the holes in the

steering wheel support or the housing and the pivot–pin di-

ameters.Replace the pivot pins with pivot pins of the correct size.

Check to see if the upper bearing is seated correctly in the

housing.Correctly seat the upper bearing. Replace the upper bear-

ing as needed.

Check for loose steering column housing support screws.Tighten the steering column housing support screws.

Noise When Tilting the Column

ChecksAction

Check for worn upper tilt bumpers.Replace the upper tilt bumpers.

Check for tilt spring binding.Adjust the tilt spring. Replace the tilt spring as needed.

Page 1967 of 2643

STEERING WHEEL AND COLUMN 6E – 13

DAEWOO V–121 BL4

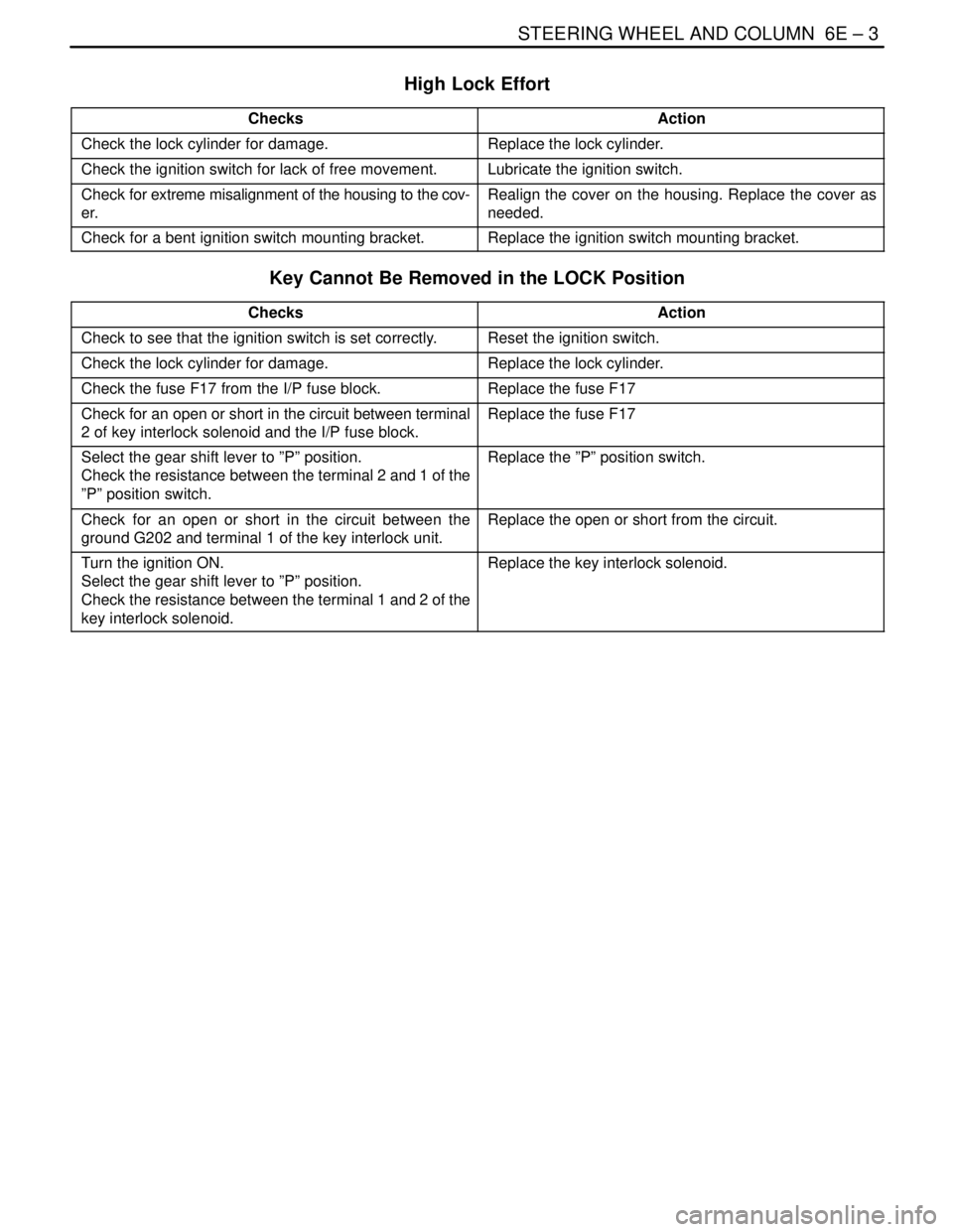

STEERING WHEEL WITH SIR

Tools Required

KM–210–A Steering Wheel Puller

Removal Procedure

1. Disconnect the negative battery cable.

2. Remove the SIR module. Refer to Section 8B, Sup-

plemental Inflatable Restraints.

3. Remove the steering wheel nut and the retaining

clip.

Important : In order to install the steering wheel correctly,

match–mark the steering column shaft to the steering

wheel.

4. Remove the steering wheel using the steering

wheel puller KM–210–A.

5. Unclip the contact ring from the steering wheel, if

necessary.

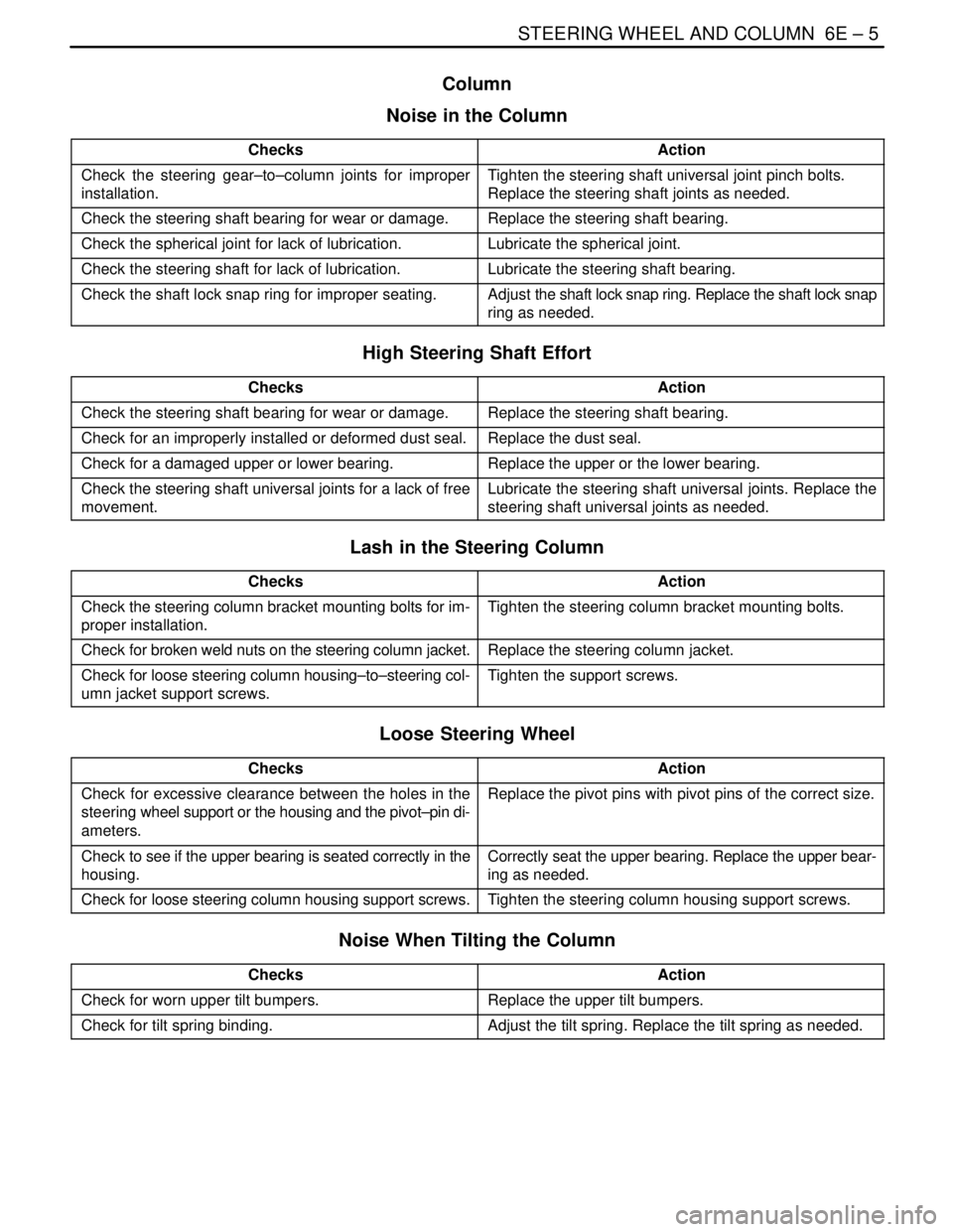

Installation Procedure

1. Clip the contact ring on the steering wheel, if nec-

essary.

Important : In order to correctly install the steering wheel,

match–mark the steering column shaft to the steering

wheel.

2. Align the match marks on the steering wheel and

the steering column shaft. Turn the signal canceling

cam on the wheel to the left.

3. Install the retaining clip and the steering wheel nut.

Tighten

Tighten the steering wheel nut to 38 NSm (28 lb–ft).

4. Bend the tabs to secure the retaining clip.

5. Install the SIR Module. Refer to Section 8B, Sup-

plemental Inflatable Restraints.

6. Connect the negative battery cable.

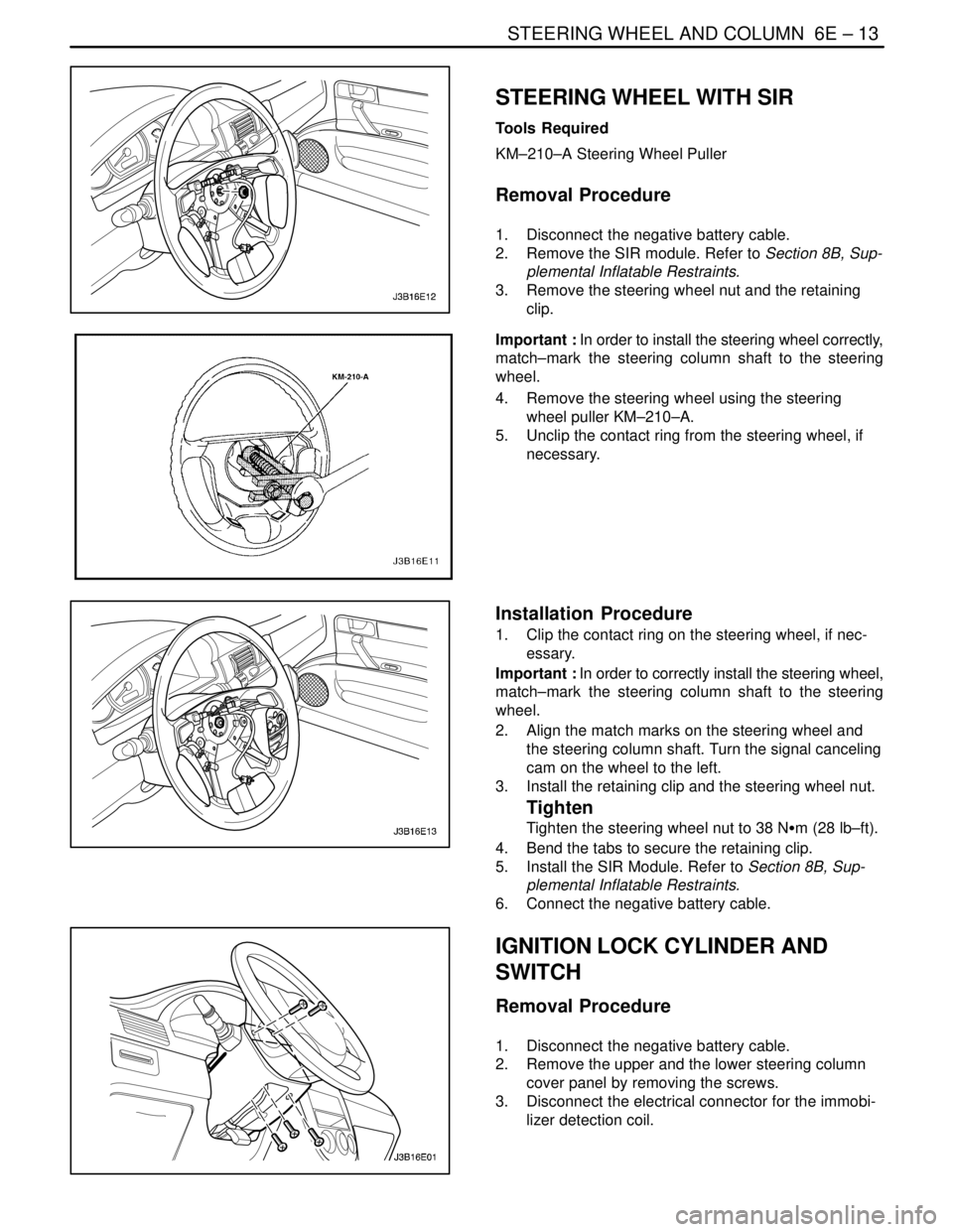

IGNITION LOCK CYLINDER AND

SWITCH

Removal Procedure

1. Disconnect the negative battery cable.

2. Remove the upper and the lower steering column

cover panel by removing the screws.

3. Disconnect the electrical connector for the immobi-

lizer detection coil.

Page 1968 of 2643

6E – 14ISTEERING WHEEL AND COLUMN

DAEWOO V–121 BL4

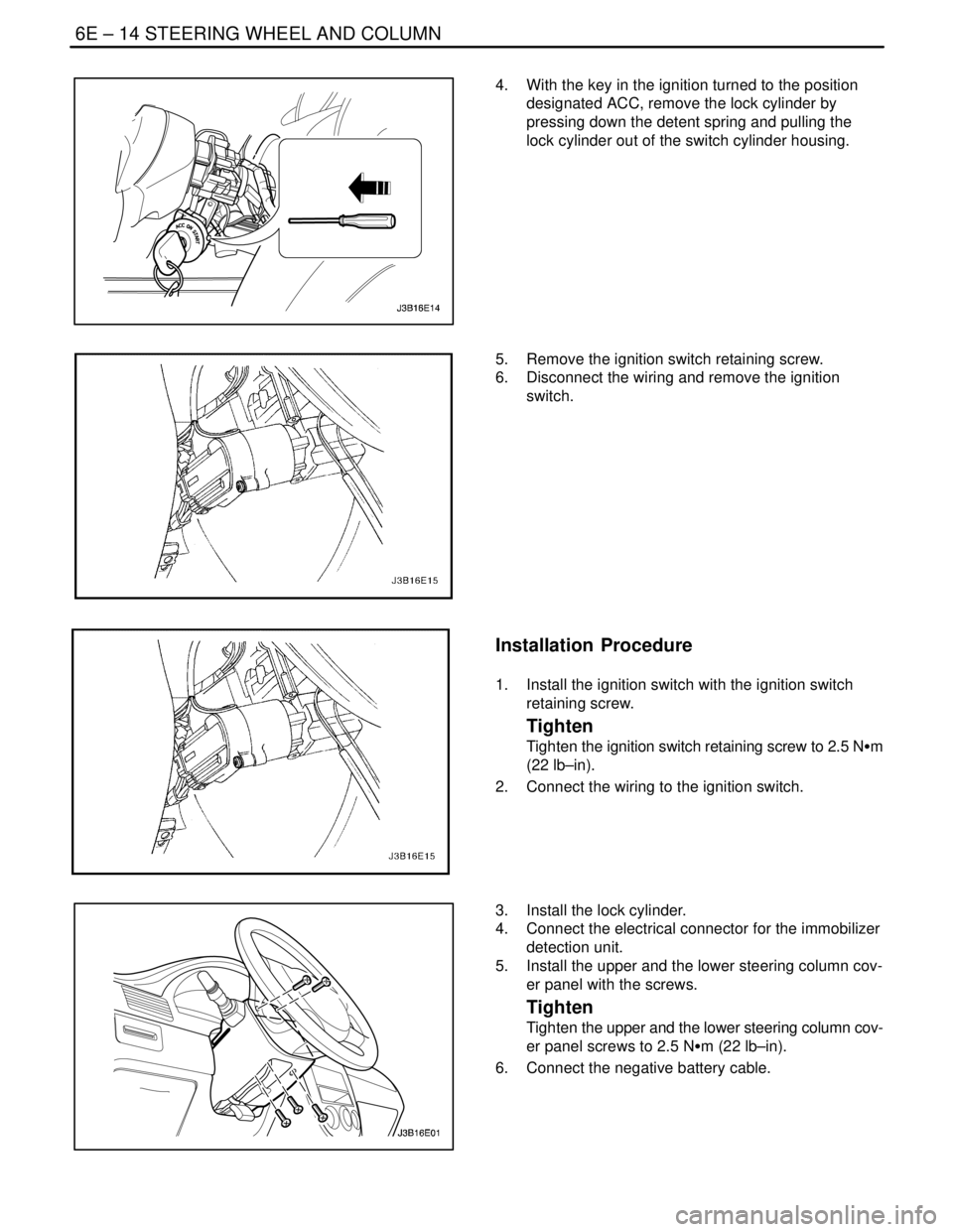

4. With the key in the ignition turned to the position

designated ACC, remove the lock cylinder by

pressing down the detent spring and pulling the

lock cylinder out of the switch cylinder housing.

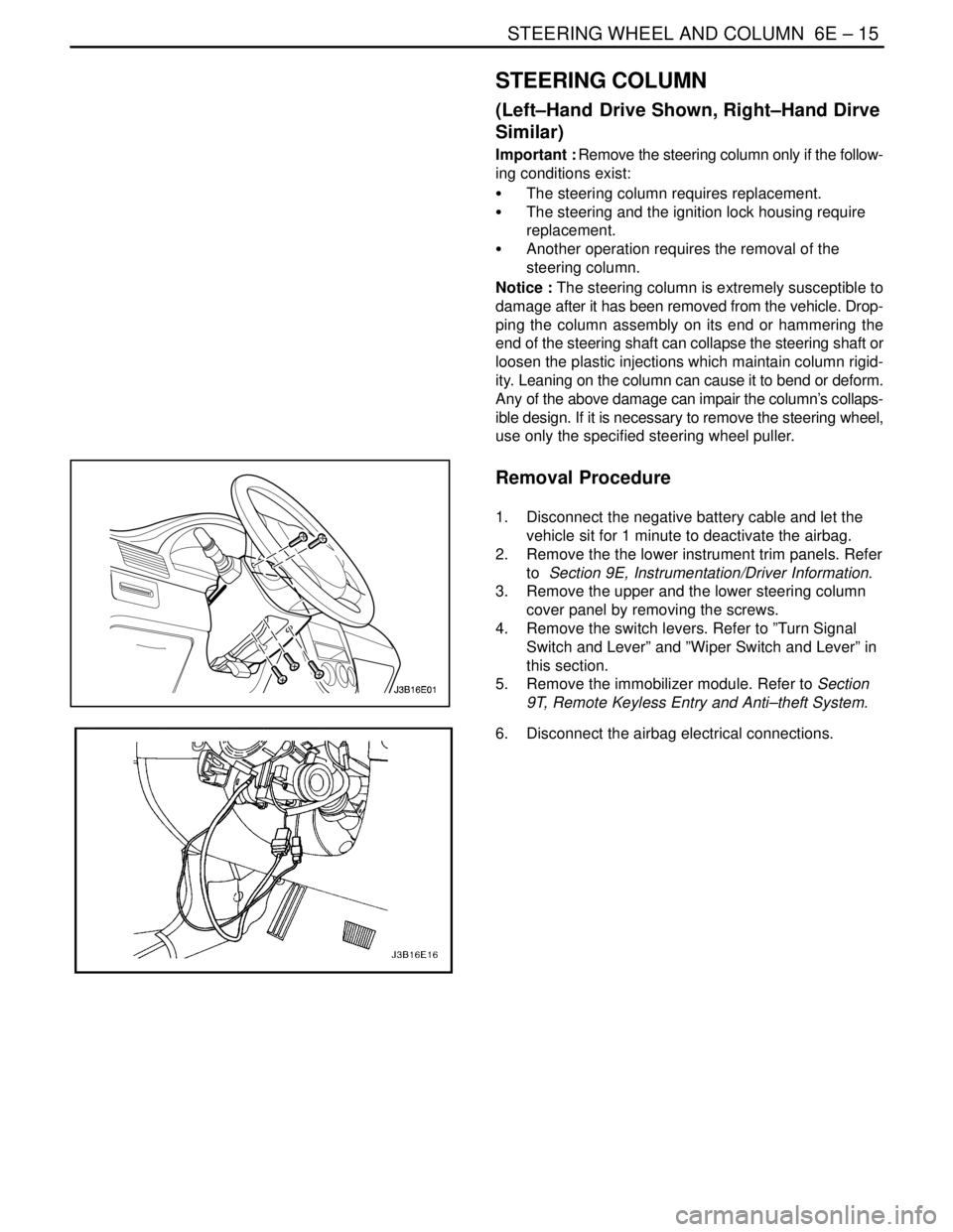

5. Remove the ignition switch retaining screw.

6. Disconnect the wiring and remove the ignition

switch.

Installation Procedure

1. Install the ignition switch with the ignition switch

retaining screw.

Tighten

Tighten the ignition switch retaining screw to 2.5 NSm

(22 lb–in).

2. Connect the wiring to the ignition switch.

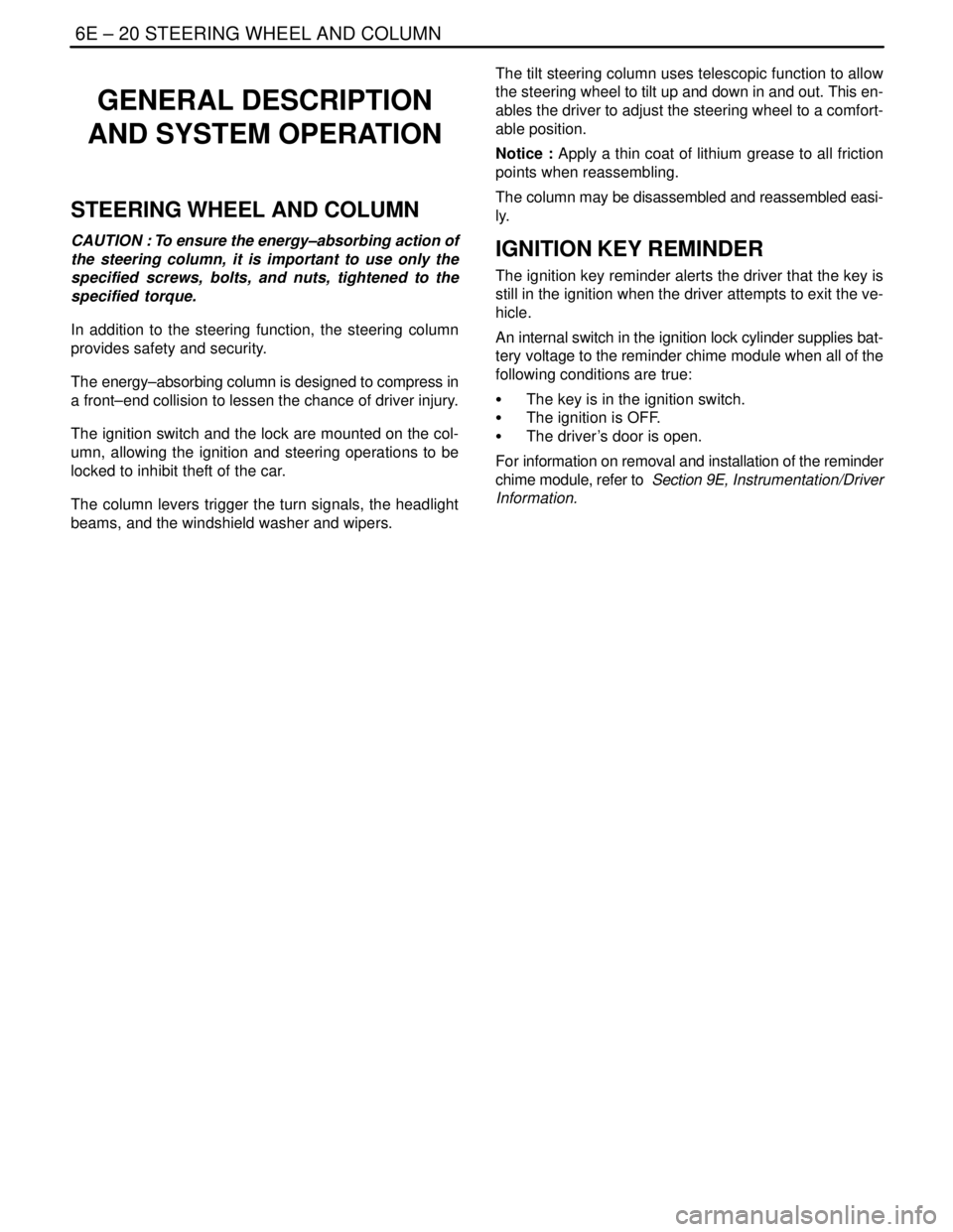

3. Install the lock cylinder.

4. Connect the electrical connector for the immobilizer

detection unit.

5. Install the upper and the lower steering column cov-

er panel with the screws.

Tighten

Tighten the upper and the lower steering column cov-

er panel screws to 2.5 NSm (22 lb–in).

6. Connect the negative battery cable.

Page 1969 of 2643

STEERING WHEEL AND COLUMN 6E – 15

DAEWOO V–121 BL4

STEERING COLUMN

(Left–Hand Drive Shown, Right–Hand Dirve

Similar)

Important : Remove the steering column only if the follow-

ing conditions exist:

S The steering column requires replacement.

S The steering and the ignition lock housing require

replacement.

S Another operation requires the removal of the

steering column.

Notice : The steering column is extremely susceptible to

damage after it has been removed from the vehicle. Drop-

ping the column assembly on its end or hammering the

end of the steering shaft can collapse the steering shaft or

loosen the plastic injections which maintain column rigid-

ity. Leaning on the column can cause it to bend or deform.

Any of the above damage can impair the column’s collaps-

ible design. If it is necessary to remove the steering wheel,

use only the specified steering wheel puller.

Removal Procedure

1. Disconnect the negative battery cable and let the

vehicle sit for 1 minute to deactivate the airbag.

2. Remove the the lower instrument trim panels. Refer

to Section 9E, Instrumentation/Driver Information.

3. Remove the upper and the lower steering column

cover panel by removing the screws.

4. Remove the switch levers. Refer to ”Turn Signal

Switch and Lever” and ”Wiper Switch and Lever” in

this section.

5. Remove the immobilizer module. Refer to Section

9T, Remote Keyless Entry and Anti–theft System.

6. Disconnect the airbag electrical connections.

Page 1974 of 2643

6E – 20ISTEERING WHEEL AND COLUMN

DAEWOO V–121 BL4

GENERAL DESCRIPTION

AND SYSTEM OPERATION

STEERING WHEEL AND COLUMN

CAUTION : To ensure the energy–absorbing action of

the steering column, it is important to use only the

specified screws, bolts, and nuts, tightened to the

specified torque.

In addition to the steering function, the steering column

provides safety and security.

The energy–absorbing column is designed to compress in

a front–end collision to lessen the chance of driver injury.

The ignition switch and the lock are mounted on the col-

umn, allowing the ignition and steering operations to be

locked to inhibit theft of the car.

The column levers trigger the turn signals, the headlight

beams, and the windshield washer and wipers.The tilt steering column uses telescopic function to allow

the steering wheel to tilt up and down in and out. This en-

ables the driver to adjust the steering wheel to a comfort-

able position.

Notice : Apply a thin coat of lithium grease to all friction

points when reassembling.

The column may be disassembled and reassembled easi-

ly.IGNITION KEY REMINDER

The ignition key reminder alerts the driver that the key is

still in the ignition when the driver attempts to exit the ve-

hicle.

An internal switch in the ignition lock cylinder supplies bat-

tery voltage to the reminder chime module when all of the

following conditions are true:

S The key is in the ignition switch.

S The ignition is OFF.

S The driver’s door is open.

For information on removal and installation of the reminder

chime module, refer to Section 9E, Instrumentation/Driver

Information.

Page 1975 of 2643

SECTION : 7A

HEATING AND VENTILATION SYSTEM

CAUTION : Disconnect the negative battery cable before removing or installing any electrical unit or when a tool

or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help

prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise noted.

TABLE OF CONTENTS

SPECIFICATIONS7A–1 . . . . . . . . . . . . . . . . . . . . . . . . . .

Heater Temperature Specifications 7A–1. . . . . . . . . . .

Fastener Tightening Specifications 7A–1. . . . . . . . . . .

SCHEMATIC AND ROUTING DIAGRAMS7A–3 . . . . .

Non–A/C Diagrams 7A–3. . . . . . . . . . . . . . . . . . . . . . . .

Airflow – Typical 7A–4. . . . . . . . . . . . . . . . . . . . . . . . . . .

Airflow with Rear Heating Duct 7A–5. . . . . . . . . . . . . .

DIAGNOSIS7A–6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HEATER SYSTEM 7A–6. . . . . . . . . . . . . . . . . . . . . . . . . .

Insufficient Heating or Defrosting 7A–6. . . . . . . . . . . . .

Blower Electrical 7A–9. . . . . . . . . . . . . . . . . . . . . . . . . . .

Improper Air delivery or No Mode Shift 7A–11. . . . . .

Too Much Heat 7A–13. . . . . . . . . . . . . . . . . . . . . . . . . . .

Controls 7A–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Blower Noise 7A–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . MAINTENANCE AND REPAIR7A–18 . . . . . . . . . . . . . .

ON–VEHICLE SERVICE 7A–18. . . . . . . . . . . . . . . . . . . .

Temperature Cable Adjustment 7A–18. . . . . . . . . . . . .

Temperature Control Cable 7A–18. . . . . . . . . . . . . . . . .

Control Assembly 7A–20. . . . . . . . . . . . . . . . . . . . . . . . .

Control Assembly Knob Lighting 7A–21. . . . . . . . . . . .

Heater/Air Distributor Case Assembly 7A–21. . . . . . .

Blower Motor 7A–23. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

High–Blower Relay 7A–24. . . . . . . . . . . . . . . . . . . . . . . .

Blower Resistor 7A–25. . . . . . . . . . . . . . . . . . . . . . . . . .

Heater Hoses 7A–25. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Heater Core 7A–26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GENERAL DESCRIPTION AND SYSTEM

OPERATION7A–28 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Heating and Ventilation Systems 7A–28. . . . . . . . . . . .

SPECIFICATIONS

HEATER TEMPERATURE SPECIFICATIONS

Ambient Air TemperatureHeater Outlet Air Temperature

–18°C (0°F)54°C (129°F)

– 4°C (25°F)59°C (138°F)

10°C (50°F)64°C (147°F)

24°C (75°F)68°C (154°F)

FASTENER TIGHTENING SPECIFICATIONS

ApplicationNSmLb–FtLb–In

Blower Motor–to–A/C Assembly Screws1.2–11

Blower Motor Resistor Screws1.2–11

Blower Motor Retaining Screws1.2–11

Controller Retaining Screws2–18

Heater/Air Distributor Case Assembly Screw4–35

Page 1983 of 2643

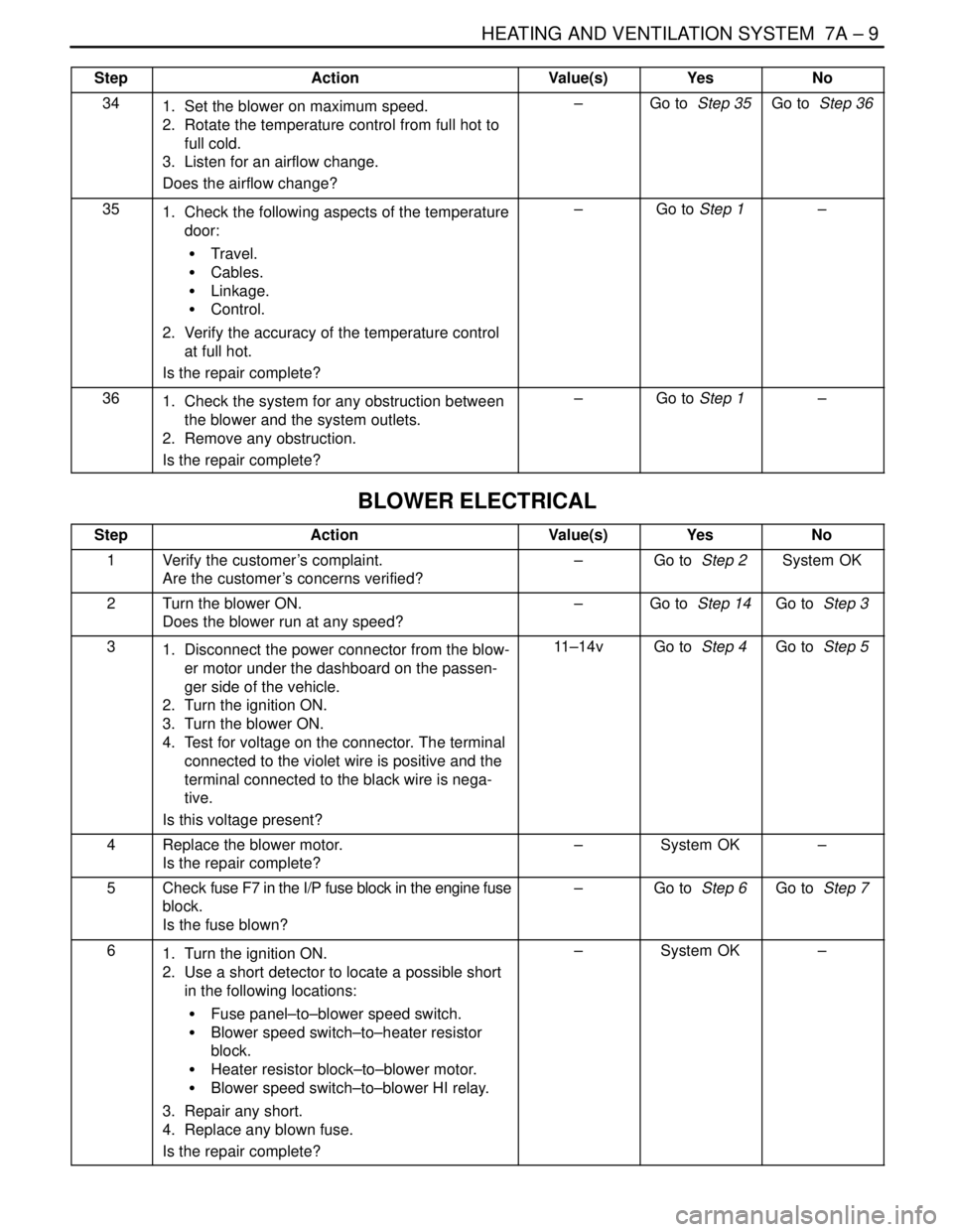

HEATING AND VENTILATION SYSTEM 7A – 9

DAEWOO V–121 BL4

StepNo Yes Value(s) Action

341. Set the blower on maximum speed.

2. Rotate the temperature control from full hot to

full cold.

3. Listen for an airflow change.

Does the airflow change?–Go to Step 35Go to Step 36

351. Check the following aspects of the temperature

door:

S Travel.

S Cables.

S Linkage.

S Control.

2. Verify the accuracy of the temperature control

at full hot.

Is the repair complete?–Go to Step 1–

361. Check the system for any obstruction between

the blower and the system outlets.

2. Remove any obstruction.

Is the repair complete?–Go to Step 1–

BLOWER ELECTRICAL

StepActionValue(s)YesNo

1Verify the customer’s complaint.

Are the customer’s concerns verified?–Go to Step 2System OK

2Turn the blower ON.

Does the blower run at any speed?–Go to Step 14Go to Step 3

31. Disconnect the power connector from the blow-

er motor under the dashboard on the passen-

ger side of the vehicle.

2. Turn the ignition ON.

3. Turn the blower ON.

4. Test for voltage on the connector. The terminal

connected to the violet wire is positive and the

terminal connected to the black wire is nega-

tive.

Is this voltage present?11–14vGo to Step 4Go to Step 5

4Replace the blower motor.

Is the repair complete?–System OK–

5Check fuse F7 in the I/P fuse block in the engine fuse

block.

Is the fuse blown?–Go to Step 6Go to Step 7

61. Turn the ignition ON.

2. Use a short detector to locate a possible short

in the following locations:

S Fuse panel–to–blower speed switch.

S Blower speed switch–to–heater resistor

block.

S Heater resistor block–to–blower motor.

S Blower speed switch–to–blower HI relay.

3. Repair any short.

4. Replace any blown fuse.

Is the repair complete?–System OK–

Page 1984 of 2643

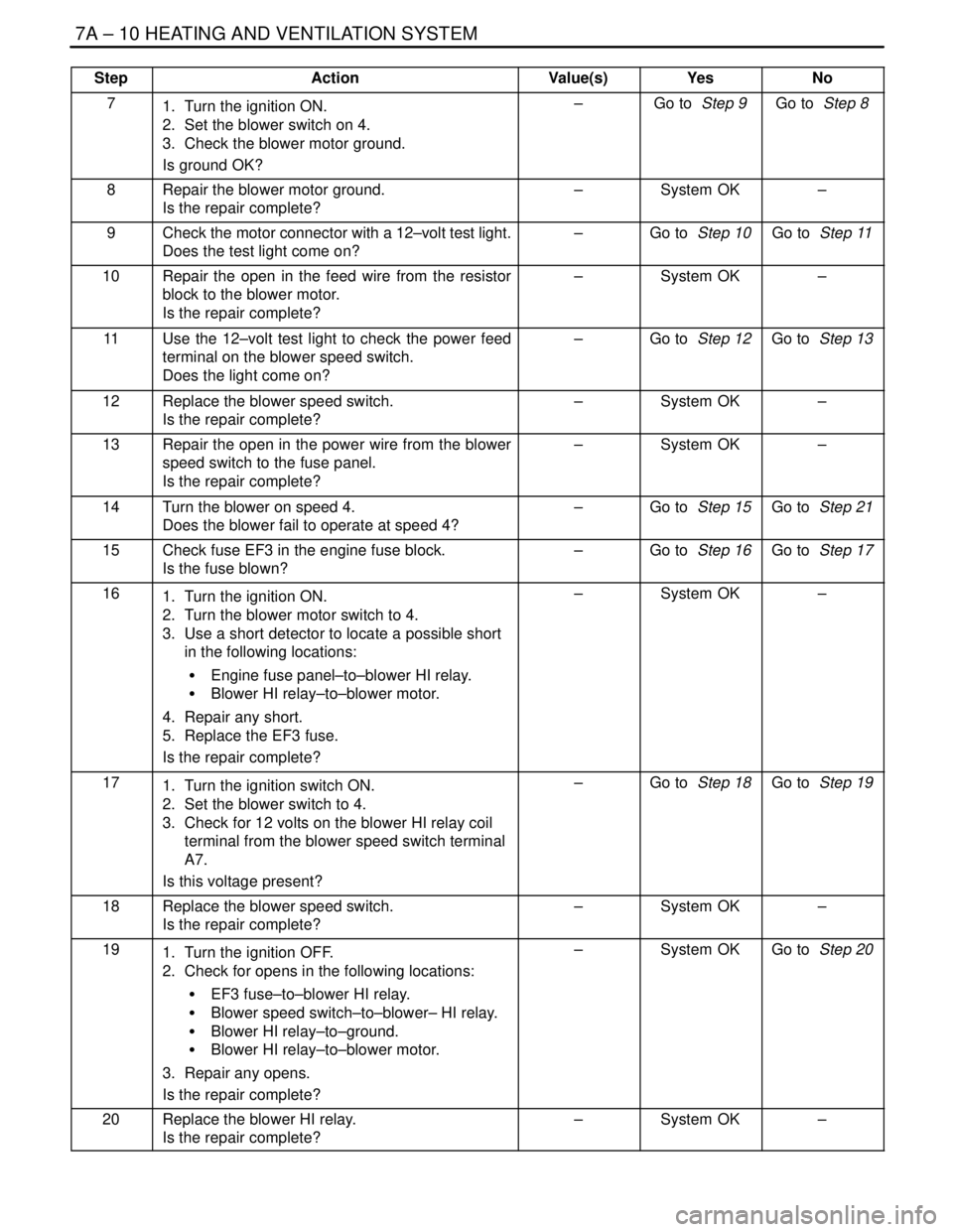

7A – 10IHEATING AND VENTILATION SYSTEM

DAEWOO V–121 BL4

StepNo Yes Value(s) Action

71. Turn the ignition ON.

2. Set the blower switch on 4.

3. Check the blower motor ground.

Is ground OK?–Go to Step 9Go to Step 8

8Repair the blower motor ground.

Is the repair complete?–System OK–

9Check the motor connector with a 12–volt test light.

Does the test light come on?–Go to Step 10Go to Step 11

10Repair the open in the feed wire from the resistor

block to the blower motor.

Is the repair complete?–System OK–

11Use the 12–volt test light to check the power feed

terminal on the blower speed switch.

Does the light come on?–Go to Step 12Go to Step 13

12Replace the blower speed switch.

Is the repair complete?–System OK–

13Repair the open in the power wire from the blower

speed switch to the fuse panel.

Is the repair complete?–System OK–

14Turn the blower on speed 4.

Does the blower fail to operate at speed 4?–Go to Step 15Go to Step 21

15Check fuse EF3 in the engine fuse block.

Is the fuse blown?–Go to Step 16Go to Step 17

161. Turn the ignition ON.

2. Turn the blower motor switch to 4.

3. Use a short detector to locate a possible short

in the following locations:

S Engine fuse panel–to–blower HI relay.

S Blower HI relay–to–blower motor.

4. Repair any short.

5. Replace the EF3 fuse.

Is the repair complete?–System OK–

171. Turn the ignition switch ON.

2. Set the blower switch to 4.

3. Check for 12 volts on the blower HI relay coil

terminal from the blower speed switch terminal

A7.

Is this voltage present?–Go to Step 18Go to Step 19

18Replace the blower speed switch.

Is the repair complete?–System OK–

191. Turn the ignition OFF.

2. Check for opens in the following locations:

S EF3 fuse–to–blower HI relay.

S Blower speed switch–to–blower– HI relay.

S Blower HI relay–to–ground.

S Blower HI relay–to–blower motor.

3. Repair any opens.

Is the repair complete?–System OKGo to Step 20

20Replace the blower HI relay.

Is the repair complete?–System OK–