Reverse DAEWOO LACETTI 2004 Service Manual PDF

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 1982 of 2643

7A – 8IHEATING AND VENTILATION SYSTEM

DAEWOO V–121 BL4

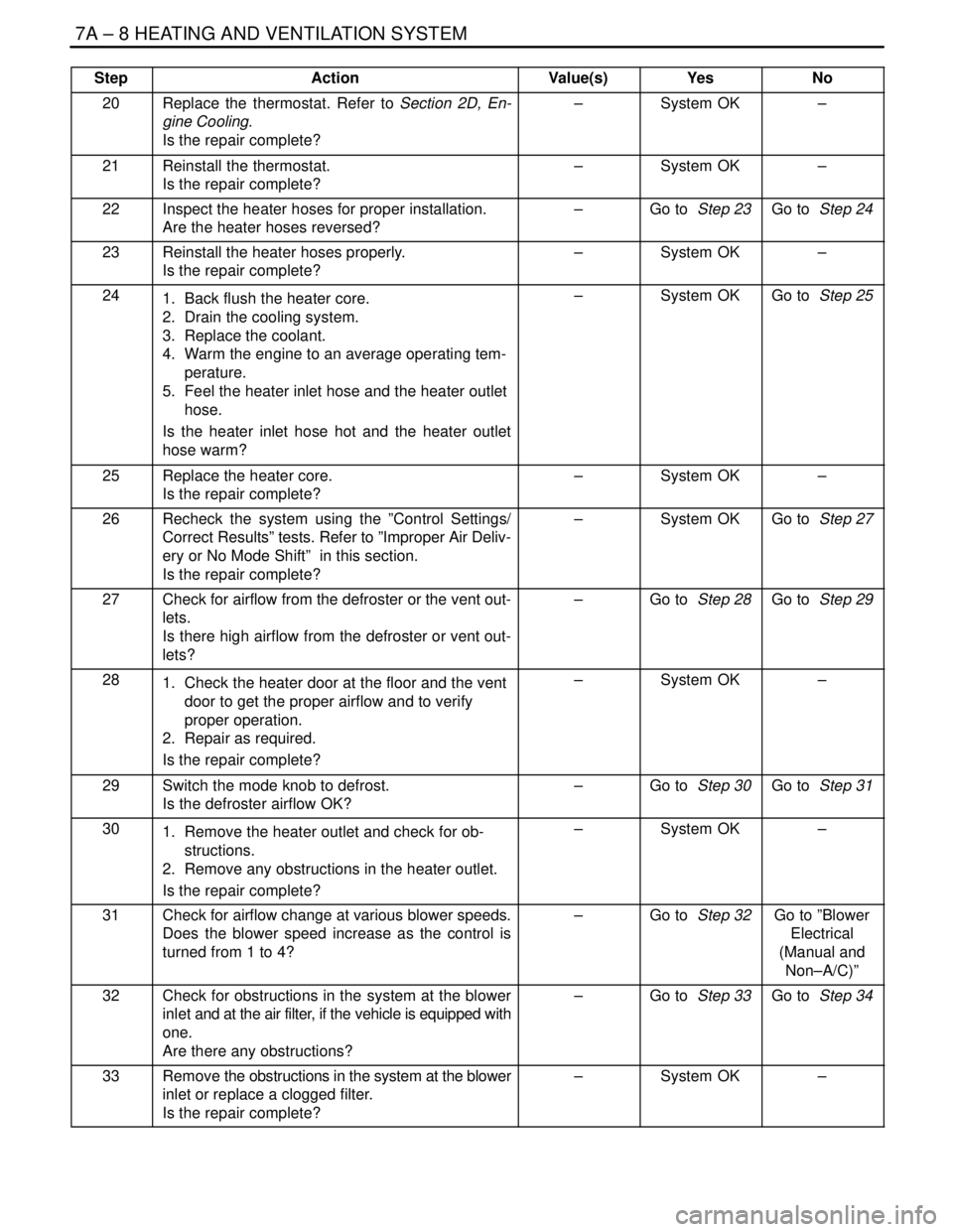

StepNo Yes Value(s) Action

20Replace the thermostat. Refer to Section 2D, En-

gine Cooling.

Is the repair complete?–System OK–

21Reinstall the thermostat.

Is the repair complete?–System OK–

22Inspect the heater hoses for proper installation.

Are the heater hoses reversed?–Go to Step 23Go to Step 24

23Reinstall the heater hoses properly.

Is the repair complete?–System OK–

241. Back flush the heater core.

2. Drain the cooling system.

3. Replace the coolant.

4. Warm the engine to an average operating tem-

perature.

5. Feel the heater inlet hose and the heater outlet

hose.

Is the heater inlet hose hot and the heater outlet

hose warm?–System OKGo to Step 25

25Replace the heater core.

Is the repair complete?–System OK–

26Recheck the system using the ”Control Settings/

Correct Results” tests. Refer to ”Improper Air Deliv-

ery or No Mode Shift” in this section.

Is the repair complete?–System OKGo to Step 27

27Check for airflow from the defroster or the vent out-

lets.

Is there high airflow from the defroster or vent out-

lets?–Go to Step 28Go to Step 29

281. Check the heater door at the floor and the vent

door to get the proper airflow and to verify

proper operation.

2. Repair as required.

Is the repair complete?–System OK–

29Switch the mode knob to defrost.

Is the defroster airflow OK?–Go to Step 30Go to Step 31

301. Remove the heater outlet and check for ob-

structions.

2. Remove any obstructions in the heater outlet.

Is the repair complete?–System OK–

31Check for airflow change at various blower speeds.

Does the blower speed increase as the control is

turned from 1 to 4?–Go to Step 32Go to ”Blower

Electrical

(Manual and

Non–A/C)”

32Check for obstructions in the system at the blower

inlet and at the air filter, if the vehicle is equipped with

one.

Are there any obstructions?–Go to Step 33Go to Step 34

33Remove the obstructions in the system at the blower

inlet or replace a clogged filter.

Is the repair complete?–System OK–

Page 2041 of 2643

MANUAL CONTROL HEATING, VENTILATION AND AIR CONDITIONING SYSTEM 7B – 39

DAEWOO V–121 BL4

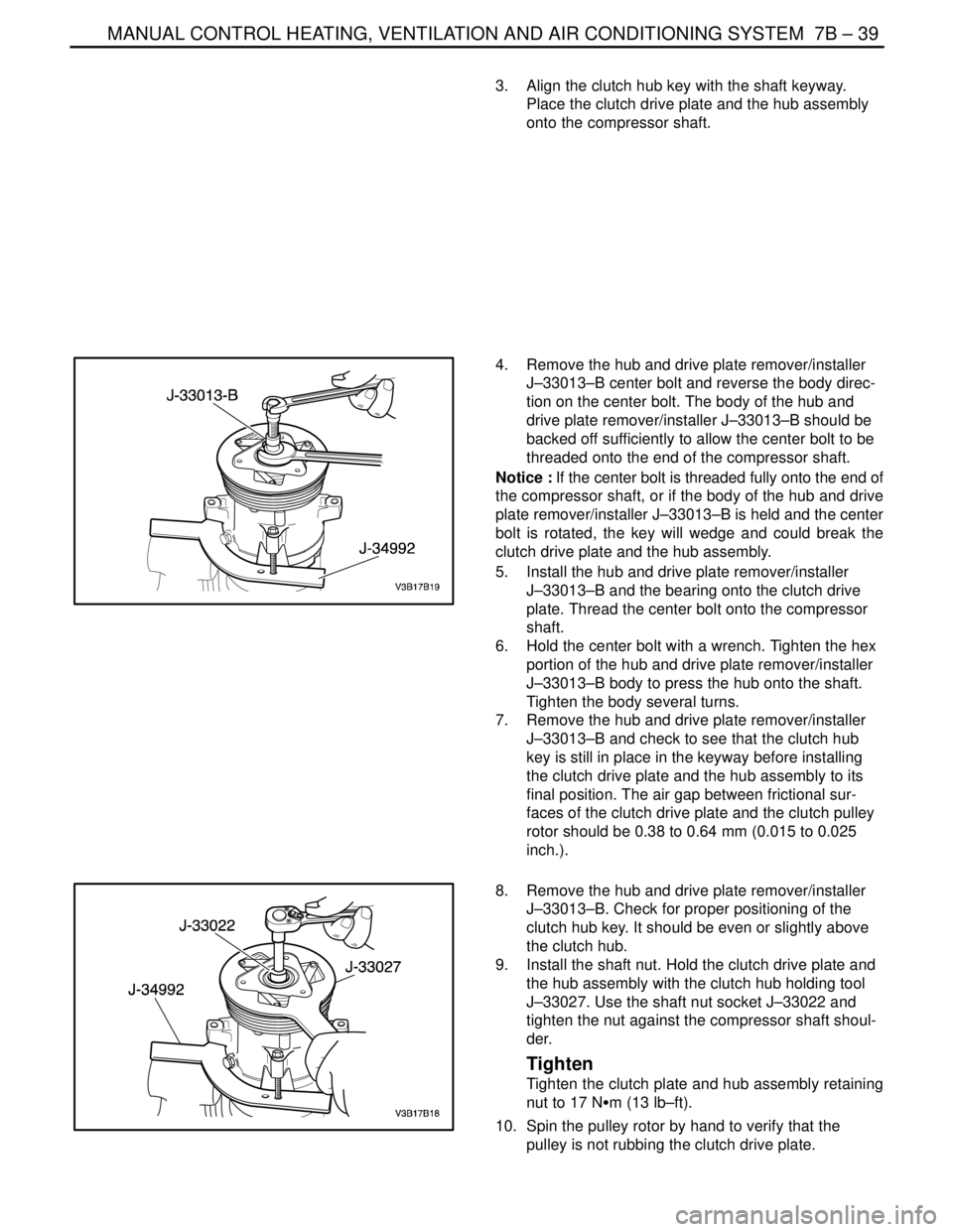

3. Align the clutch hub key with the shaft keyway.

Place the clutch drive plate and the hub assembly

onto the compressor shaft.

4. Remove the hub and drive plate remover/installer

J–33013–B center bolt and reverse the body direc-

tion on the center bolt. The body of the hub and

drive plate remover/installer J–33013–B should be

backed off sufficiently to allow the center bolt to be

threaded onto the end of the compressor shaft.

Notice : If the center bolt is threaded fully onto the end of

the compressor shaft, or if the body of the hub and drive

plate remover/installer J–33013–B is held and the center

bolt is rotated, the key will wedge and could break the

clutch drive plate and the hub assembly.

5. Install the hub and drive plate remover/installer

J–33013–B and the bearing onto the clutch drive

plate. Thread the center bolt onto the compressor

shaft.

6. Hold the center bolt with a wrench. Tighten the hex

portion of the hub and drive plate remover/installer

J–33013–B body to press the hub onto the shaft.

Tighten the body several turns.

7. Remove the hub and drive plate remover/installer

J–33013–B and check to see that the clutch hub

key is still in place in the keyway before installing

the clutch drive plate and the hub assembly to its

final position. The air gap between frictional sur-

faces of the clutch drive plate and the clutch pulley

rotor should be 0.38 to 0.64 mm (0.015 to 0.025

inch.).

8. Remove the hub and drive plate remover/installer

J–33013–B. Check for proper positioning of the

clutch hub key. It should be even or slightly above

the clutch hub.

9. Install the shaft nut. Hold the clutch drive plate and

the hub assembly with the clutch hub holding tool

J–33027. Use the shaft nut socket J–33022 and

tighten the nut against the compressor shaft shoul-

der.

Tighten

Tighten the clutch plate and hub assembly retaining

nut to 17 NSm (13 lb–ft).

10. Spin the pulley rotor by hand to verify that the

pulley is not rubbing the clutch drive plate.

Page 2195 of 2643

SUPPLEMENTAL INFLATABLE RESTRAINTS (SIR) 8B – 91

DAEWOO V–121 BL4

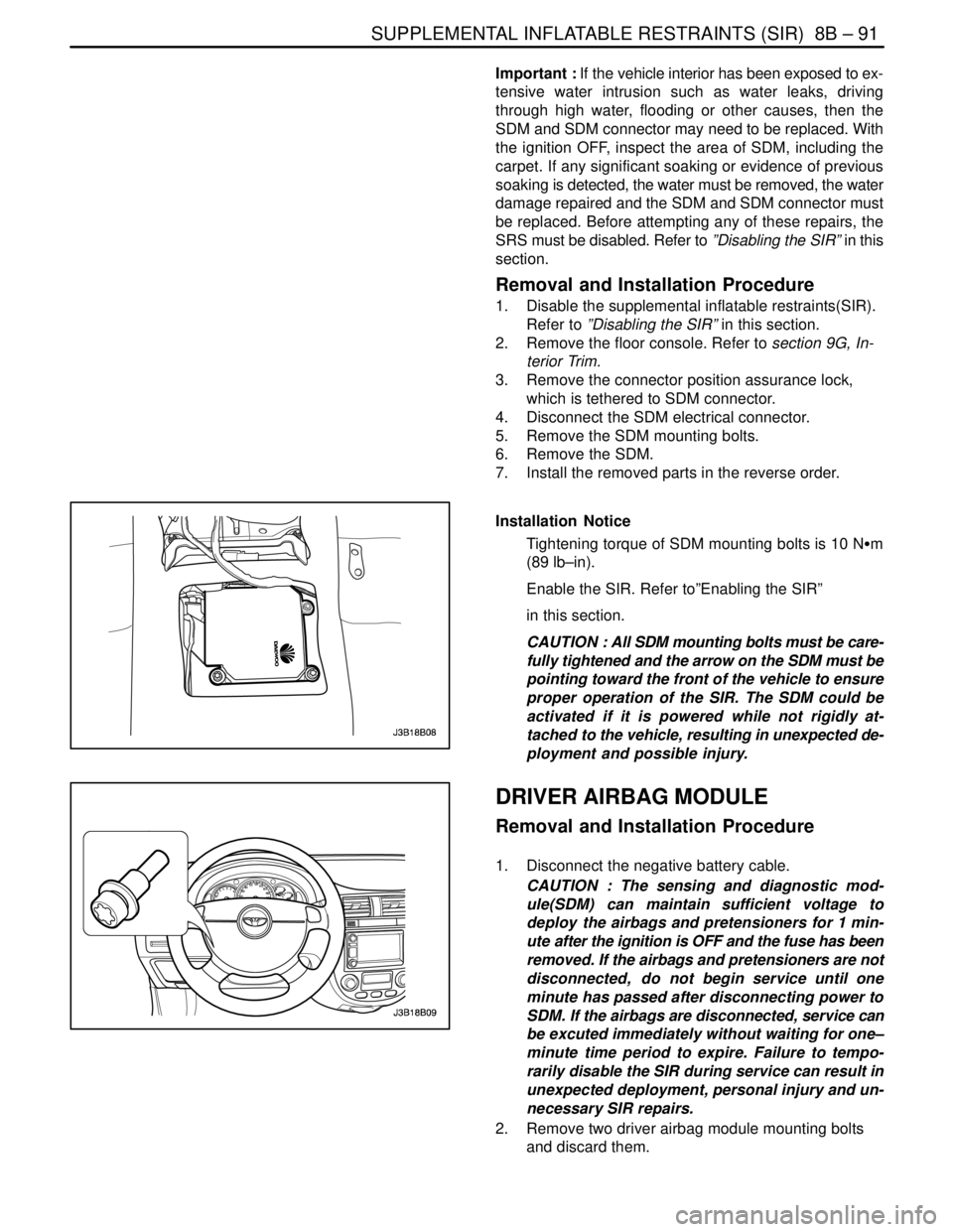

Important : If the vehicle interior has been exposed to ex-

tensive water intrusion such as water leaks, driving

through high water, flooding or other causes, then the

SDM and SDM connector may need to be replaced. With

the ignition OFF, inspect the area of SDM, including the

carpet. If any significant soaking or evidence of previous

soaking is detected, the water must be removed, the water

damage repaired and the SDM and SDM connector must

be replaced. Before attempting any of these repairs, the

SRS must be disabled. Refer to ”Disabling the SIR” in this

section.

Removal and Installation Procedure

1. Disable the supplemental inflatable restraints(SIR).

Refer to ”Disabling the SIR” in this section.

2. Remove the floor console. Refer to section 9G, In-

terior Trim.

3. Remove the connector position assurance lock,

which is tethered to SDM connector.

4. Disconnect the SDM electrical connector.

5. Remove the SDM mounting bolts.

6. Remove the SDM.

7. Install the removed parts in the reverse order.

Installation Notice

Tightening torque of SDM mounting bolts is 10 NSm

(89 lb–in).

Enable the SIR. Refer to”Enabling the SIR”

in this section.

CAUTION : All SDM mounting bolts must be care-

fully tightened and the arrow on the SDM must be

pointing toward the front of the vehicle to ensure

proper operation of the SIR. The SDM could be

activated if it is powered while not rigidly at-

tached to the vehicle, resulting in unexpected de-

ployment and possible injury.

0

DRIVER AIRBAG MODULE

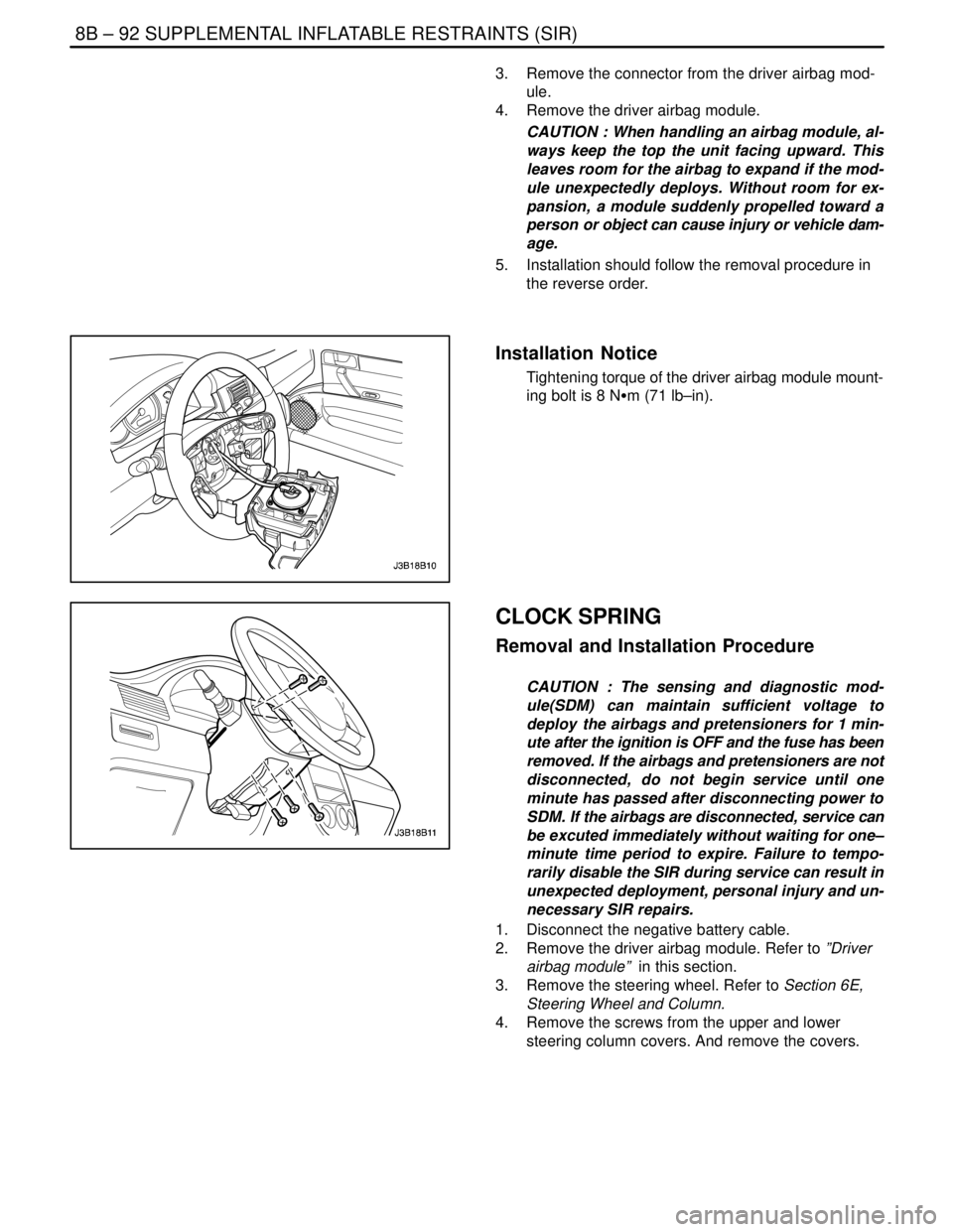

Removal and Installation Procedure

1. Disconnect the negative battery cable.

CAUTION : The sensing and diagnostic mod-

ule(SDM) can maintain sufficient voltage to

deploy the airbags and pretensioners for 1 min-

ute after the ignition is OFF and the fuse has been

removed. If the airbags and pretensioners are not

disconnected, do not begin service until one

minute has passed after disconnecting power to

SDM. If the airbags are disconnected, service can

be excuted immediately without waiting for one–

minute time period to expire. Failure to tempo-

rarily disable the SIR during service can result in

unexpected deployment, personal injury and un-

necessary SIR repairs.

2. Remove two driver airbag module mounting bolts

and discard them.

Page 2196 of 2643

8B – 92ISUPPLEMENTAL INFLATABLE RESTRAINTS (SIR)

DAEWOO V–121 BL4

3. Remove the connector from the driver airbag mod-

ule.

4. Remove the driver airbag module.

CAUTION : When handling an airbag module, al-

ways keep the top the unit facing upward. This

leaves room for the airbag to expand if the mod-

ule unexpectedly deploys. Without room for ex-

pansion, a module suddenly propelled toward a

person or object can cause injury or vehicle dam-

age.

5. Installation should follow the removal procedure in

the reverse order.

Installation Notice

Tightening torque of the driver airbag module mount-

ing bolt is 8 NSm (71 lb–in).

CLOCK SPRING

Removal and Installation Procedure

CAUTION : The sensing and diagnostic mod-

ule(SDM) can maintain sufficient voltage to

deploy the airbags and pretensioners for 1 min-

ute after the ignition is OFF and the fuse has been

removed. If the airbags and pretensioners are not

disconnected, do not begin service until one

minute has passed after disconnecting power to

SDM. If the airbags are disconnected, service can

be excuted immediately without waiting for one–

minute time period to expire. Failure to tempo-

rarily disable the SIR during service can result in

unexpected deployment, personal injury and un-

necessary SIR repairs.

1. Disconnect the negative battery cable.

2. Remove the driver airbag module. Refer to ”Driver

airbag module” in this section.

3. Remove the steering wheel. Refer to Section 6E,

Steering Wheel and Column.

4. Remove the screws from the upper and lower

steering column covers. And remove the covers.

Page 2197 of 2643

SUPPLEMENTAL INFLATABLE RESTRAINTS (SIR) 8B – 93

DAEWOO V–121 BL4

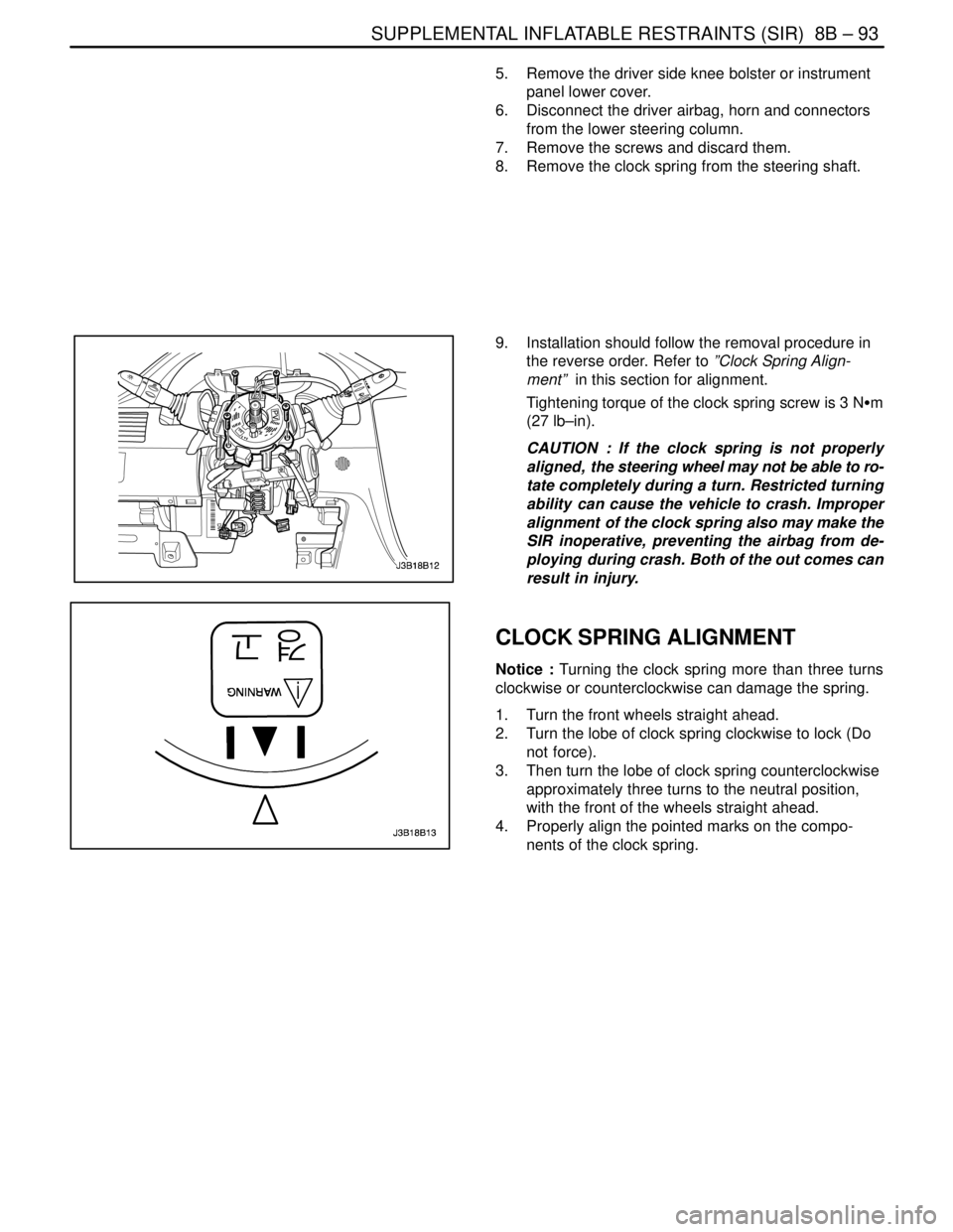

5. Remove the driver side knee bolster or instrument

panel lower cover.

6. Disconnect the driver airbag, horn and connectors

from the lower steering column.

7. Remove the screws and discard them.

8. Remove the clock spring from the steering shaft.

9. Installation should follow the removal procedure in

the reverse order. Refer to ”Clock Spring Align-

ment” in this section for alignment.

Tightening torque of the clock spring screw is 3 NSm

(27 lb–in).

CAUTION : If the clock spring is not properly

aligned, the steering wheel may not be able to ro-

tate completely during a turn. Restricted turning

ability can cause the vehicle to crash. Improper

alignment of the clock spring also may make the

SIR inoperative, preventing the airbag from de-

ploying during crash. Both of the out comes can

result in injury.

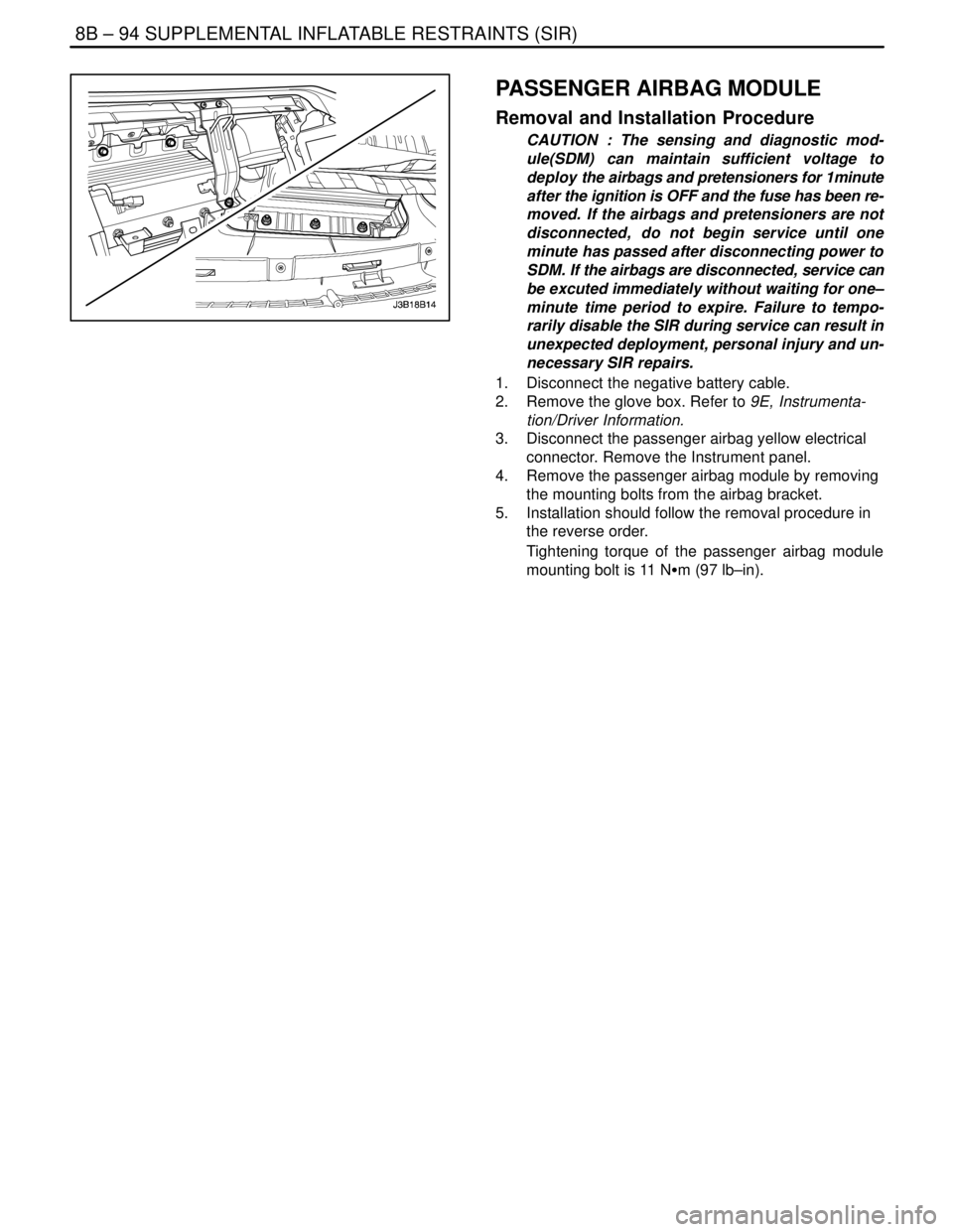

CLOCK SPRING ALIGNMENT

Notice : Turning the clock spring more than three turns

clockwise or counterclockwise can damage the spring.

1. Turn the front wheels straight ahead.

2. Turn the lobe of clock spring clockwise to lock (Do

not force).

3. Then turn the lobe of clock spring counterclockwise

approximately three turns to the neutral position,

with the front of the wheels straight ahead.

4. Properly align the pointed marks on the compo-

nents of the clock spring.

Page 2198 of 2643

8B – 94ISUPPLEMENTAL INFLATABLE RESTRAINTS (SIR)

DAEWOO V–121 BL4

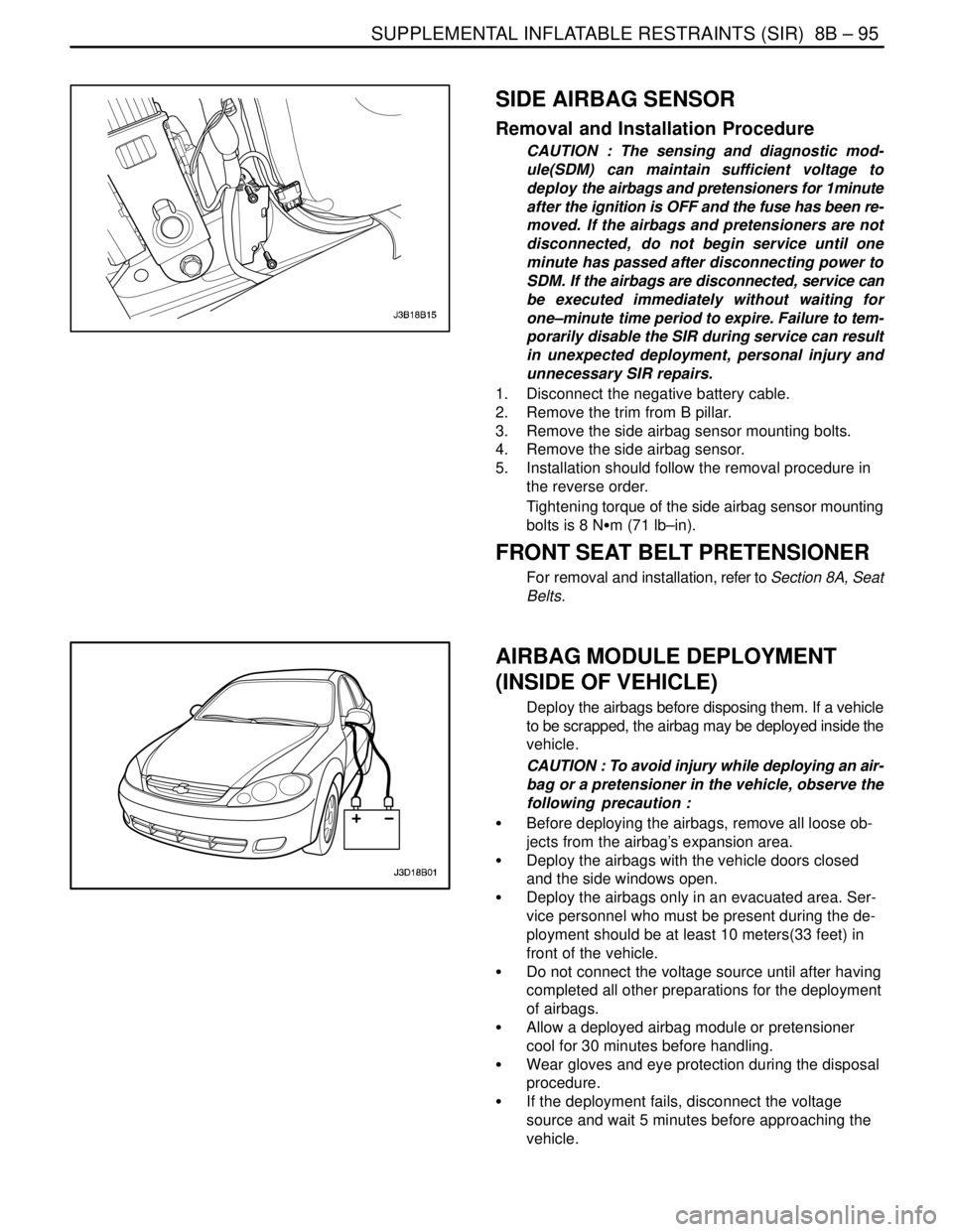

PASSENGER AIRBAG MODULE

Removal and Installation Procedure

CAUTION : The sensing and diagnostic mod-

ule(SDM) can maintain sufficient voltage to

deploy the airbags and pretensioners for 1minute

after the ignition is OFF and the fuse has been re-

moved. If the airbags and pretensioners are not

disconnected, do not begin service until one

minute has passed after disconnecting power to

SDM. If the airbags are disconnected, service can

be excuted immediately without waiting for one–

minute time period to expire. Failure to tempo-

rarily disable the SIR during service can result in

unexpected deployment, personal injury and un-

necessary SIR repairs.

1. Disconnect the negative battery cable.

2. Remove the glove box. Refer to 9E, Instrumenta-

tion/Driver Information.

3. Disconnect the passenger airbag yellow electrical

connector. Remove the Instrument panel.

4. Remove the passenger airbag module by removing

the mounting bolts from the airbag bracket.

5. Installation should follow the removal procedure in

the reverse order.

Tightening torque of the passenger airbag module

mounting bolt is 11 NSm (97 lb–in).

Page 2199 of 2643

SUPPLEMENTAL INFLATABLE RESTRAINTS (SIR) 8B – 95

DAEWOO V–121 BL4

SIDE AIRBAG SENSOR

Removal and Installation Procedure

CAUTION : The sensing and diagnostic mod-

ule(SDM) can maintain sufficient voltage to

deploy the airbags and pretensioners for 1minute

after the ignition is OFF and the fuse has been re-

moved. If the airbags and pretensioners are not

disconnected, do not begin service until one

minute has passed after disconnecting power to

SDM. If the airbags are disconnected, service can

be executed immediately without waiting for

one–minute time period to expire. Failure to tem-

porarily disable the SIR during service can result

in unexpected deployment, personal injury and

unnecessary SIR repairs.

1. Disconnect the negative battery cable.

2. Remove the trim from B pillar.

3. Remove the side airbag sensor mounting bolts.

4. Remove the side airbag sensor.

5. Installation should follow the removal procedure in

the reverse order.

Tightening torque of the side airbag sensor mounting

bolts is 8 NSm (71 lb–in).

FRONT SEAT BELT PRETENSIONER

For removal and installation, refer to Section 8A, Seat

Belts.

AIRBAG MODULE DEPLOYMENT

(INSIDE OF VEHICLE)

Deploy the airbags before disposing them. If a vehicle

to be scrapped, the airbag may be deployed inside the

vehicle.

CAUTION : To avoid injury while deploying an air-

bag or a pretensioner in the vehicle, observe the

following precaution :

S Before deploying the airbags, remove all loose ob-

jects from the airbag’s expansion area.

S Deploy the airbags with the vehicle doors closed

and the side windows open.

S Deploy the airbags only in an evacuated area. Ser-

vice personnel who must be present during the de-

ployment should be at least 10 meters(33 feet) in

front of the vehicle.

S Do not connect the voltage source until after having

completed all other preparations for the deployment

of airbags.

S Allow a deployed airbag module or pretensioner

cool for 30 minutes before handling.

S Wear gloves and eye protection during the disposal

procedure.

S If the deployment fails, disconnect the voltage

source and wait 5 minutes before approaching the

vehicle.

Page 2220 of 2643

9A – 14IBODY WIRING SYSTEM

DAEWOO V–121 BL4

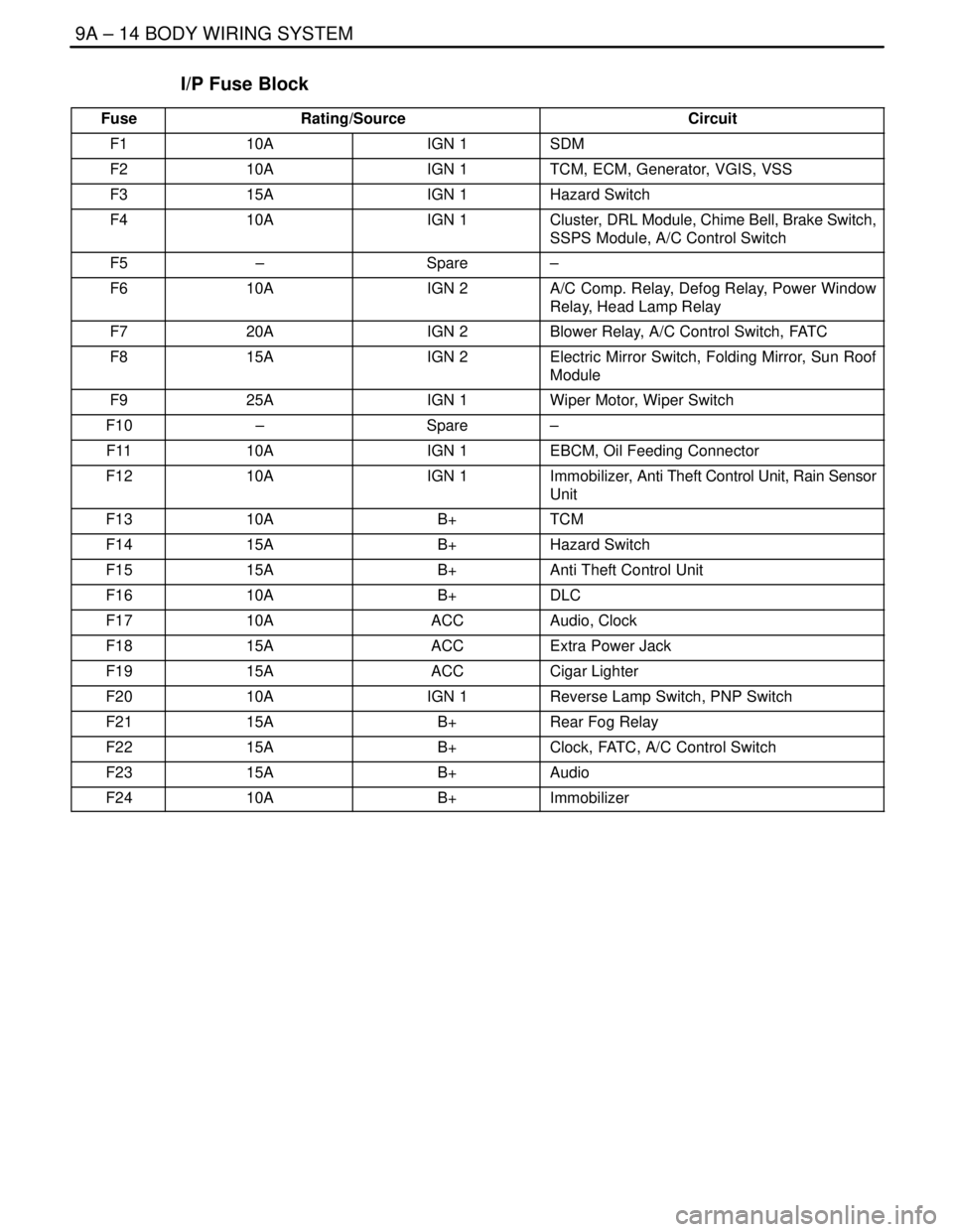

I/P Fuse Block

FuseRating/SourceCircuit

F110AIGN 1SDM

F210AIGN 1TCM, ECM, Generator, VGIS, VSS

F315AIGN 1Hazard Switch

F410AIGN 1Cluster, DRL Module, Chime Bell, Brake Switch,

SSPS Module, A/C Control Switch

F5–Spare–

F610AIGN 2A/C Comp. Relay, Defog Relay, Power Window

Relay, Head Lamp Relay

F720AIGN 2Blower Relay, A/C Control Switch, FATC

F815AIGN 2Electric Mirror Switch, Folding Mirror, Sun Roof

Module

F925AIGN 1Wiper Motor, Wiper Switch

F10–Spare–

F1110AIGN 1EBCM, Oil Feeding Connector

F1210AIGN 1Immobilizer, Anti Theft Control Unit, Rain Sensor

Unit

F1310AB+TCM

F1415AB+Hazard Switch

F1515AB+Anti Theft Control Unit

F1610AB+DLC

F1710AACCAudio, Clock

F1815AACCExtra Power Jack

F1915AACCCigar Lighter

F2010AIGN 1Reverse Lamp Switch, PNP Switch

F2115AB+Rear Fog Relay

F2215AB+Clock, FATC, A/C Control Switch

F2315AB+Audio

F2410AB+Immobilizer

Page 2252 of 2643

9B – 26ILIGHTING SYSTEMS

DAEWOO V–121 BL4

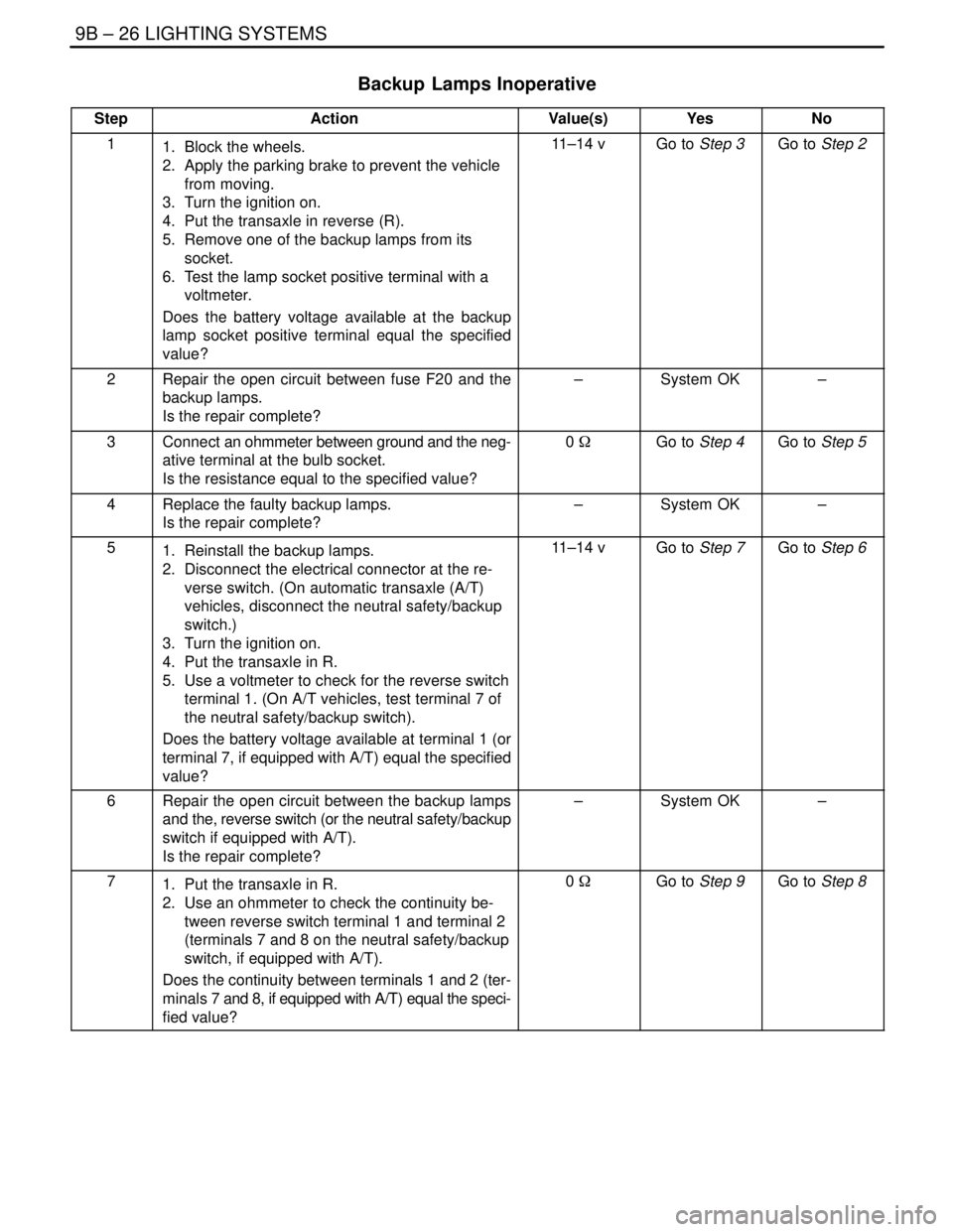

Backup Lamps Inoperative

StepActionValue(s)YesNo

11. Block the wheels.

2. Apply the parking brake to prevent the vehicle

from moving.

3. Turn the ignition on.

4. Put the transaxle in reverse (R).

5. Remove one of the backup lamps from its

socket.

6. Test the lamp socket positive terminal with a

voltmeter.

Does the battery voltage available at the backup

lamp socket positive terminal equal the specified

value?11–14 vGo to Step 3Go to Step 2

2Repair the open circuit between fuse F20 and the

backup lamps.

Is the repair complete?–System OK–

3Connect an ohmmeter between ground and the neg-

ative terminal at the bulb socket.

Is the resistance equal to the specified value?0 WGo to Step 4Go to Step 5

4Replace the faulty backup lamps.

Is the repair complete?–System OK–

51. Reinstall the backup lamps.

2. Disconnect the electrical connector at the re-

verse switch. (On automatic transaxle (A/T)

vehicles, disconnect the neutral safety/backup

switch.)

3. Turn the ignition on.

4. Put the transaxle in R.

5. Use a voltmeter to check for the reverse switch

terminal 1. (On A/T vehicles, test terminal 7 of

the neutral safety/backup switch).

Does the battery voltage available at terminal 1 (or

terminal 7, if equipped with A/T) equal the specified

value?11–14 vGo to Step 7Go to Step 6

6Repair the open circuit between the backup lamps

and the, reverse switch (or the neutral safety/backup

switch if equipped with A/T).

Is the repair complete?–System OK–

71. Put the transaxle in R.

2. Use an ohmmeter to check the continuity be-

tween reverse switch terminal 1 and terminal 2

(terminals 7 and 8 on the neutral safety/backup

switch, if equipped with A/T).

Does the continuity between terminals 1 and 2 (ter-

minals 7 and 8, if equipped with A/T) equal the speci-

fied value?0 WGo to Step 9Go to Step 8

Page 2253 of 2643

LIGHTING SYSTEMS 9B – 27

DAEWOO V–121 BL4

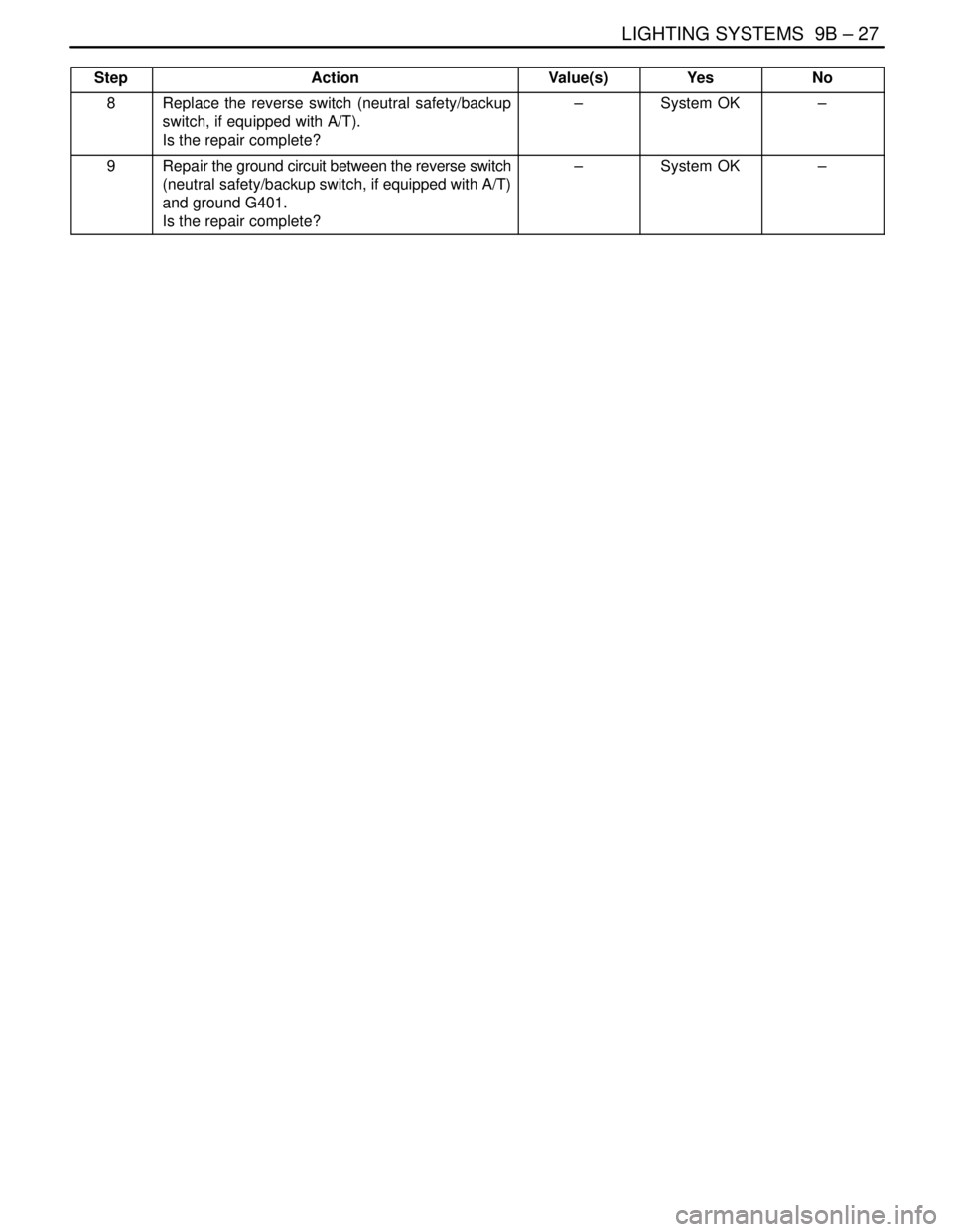

StepNo Yes Value(s) Action

8Replace the reverse switch (neutral safety/backup

switch, if equipped with A/T).

Is the repair complete?–System OK–

9Repair the ground circuit between the reverse switch

(neutral safety/backup switch, if equipped with A/T)

and ground G401.

Is the repair complete?–System OK–