oxygen sensor DAEWOO LACETTI 2004 Service Manual Online

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: LACETTI, Model: DAEWOO LACETTI 2004Pages: 2643, PDF Size: 80.54 MB

Page 821 of 2643

ENGINE CONTROLS 1F – 575

DAEWOO V–121 BL4

StepNo Yes Value(s) Action

5Replace the sensor in the affected circuit, if a Diag-

nostic Trouble Code (DTC) was stored for this circuit

(except for the DTCs P0171 and P0172.

Is the repair complete?–System OK–

6Does an intermittent Malfunction Indicator Lamp

(MIL) or DTC occur?–Go toStep 7Go toStep 8

71. Check for a faulty relay, electronic control mod-

ule (ECM) driven solenoid, or switch.

2. Check for improper installation of electrical de-

vices, such as lights, two–way radios, electric

motors, etc.

3. Inspect the ignition control wires for proper

routing (away from ignition wires, ignition sys-

tem components, and the generator).

4. Check for a short–to–ground in the MIL circuit

or the DLC ”test” terminal.

5. Inspect the ECM ground connections.

6. Correct or repair the affected circuits as need-

ed.

Is the repair complete?–System OK–

81. Check for a loss of DTC memory.

2. 2. Disconnect the Throttle Position Sensor.

3. Run the engine at idle until the MIL comes on.

4. Turn the ignition OFF.

Is DTC P0122 stored in memory?–Go toStep 10Go toStep 9

9Replace the ECM.

Is the repair complete?–System OK–

10Does the vehicle stall while driving?–Go toStep 11Go toStep 12

11Monitor the Front Heated Oxygen Sensor (HO2S1)

and the injector base pulse width with the scan tool.

Does the scan tool display a steady low voltage

(about 0 mv) for the HO2S1 sensor with the control

module commanding an injector base pulse width of

the value specified?8 msGo toStep 9Go toStep 12

121. Check for an open diode across the A/C clutch

and for other open diodes.

2. Repair or replace any components as needed.

Is the repair complete?–System OK–

Page 825 of 2643

ENGINE CONTROLS 1F – 579

DAEWOO V–121 BL4

SURGES OR CHUGGLES

Definition : Engine power varies under steady throttle or

cruise, making it feel as if the vehicle speeds up and slows

down with no change in the accelerator pedal position.

Important : Make sure the driver understands Torque

Converter Clutch (TCC) and A/C compressor operation as

described in the owner’s manualThe speedometer reading and the speed reading on the

scan tool should be equal.

Before diagnosing the symptom, check service bulletins

for updates.

Step

ActionValue(s)YesNo

1Were the Important Preliminary Checks performed?–Go toStep 2Go to

”Important Pre-

liminary

Checks”

2Connect the scan tool to the Data Link Connector

(DLC).

Does the Front Heated Oxygen Sensor (HO2S1) re-

spond quickly to different throttle positions?–Go toStep 4Go toStep 3

31. Check the HO2S1 sensor for silicone or other

contaminants from fuel or use of improper

Room Temperature Vulcanizing (RTV) sealant.

2. Replace the contaminated HO2S1 sensor.

Is the repair complete?–System OK–

41. Drive the vehicle at the speed of the complaint.

2. Monitor the long term fuel trim reading using

the scan tool.

Is the long term fuel trim reading within the value

specified?–20–25%Go toStep 7Go toStep 5

5Is the long term fuel trim reading below the value

specified?–20%Go to

”Diagnostic

Aids for DTC

P0172”Go toStep 6

6Is the long term fuel trim reading above the value

specified?25%Go to

”Diagnostic

Aids for DTC

P0171”–

7Check the fuel system pressure while the condition

exists.

Is the fuel system pressure within specifications?41–47 psi

(284–325 kPa)Go toStep 8Go toStep 17

8Check the in–line fuel filter.

Is the filter dirty or plugged?–Go toStep 18Go toStep 9

9Perform an injector diagnosis.

Does the injector balance test pinpoint the problem?–Go toStep 19Go toStep 10

101. Check for proper ignition voltage output using a

spark tester.

2. Inspect the spark plugs for cracks, wear, im-

proper gap, burned electrodes, or heavy de-

posits.

Is the problem found?–Go toStep 11Go toStep 12

11Repair or replace any ignition system components

as needed.

Is the repair complete?–System OK–

Page 834 of 2643

1F – 588IENGINE CONTROLS

DAEWOO V–121 BL4

ROUGH, UNSTABLE, OR INCORRECT LDLE, STALLING

Definition : The engine runs unevenly at idle. If the condi-

tion is bad enough, the vehicle may shake. Also, the idle

varies in rpm (called ”hunting”). Either condition may be

severe enough to cause stalling. The engine idles at incor-

rect idle speed.Important : Before diagnosing the symptom, check ser-

vice bulletins for updates.

Step

ActionValue(s)YesNo

1Were the Important Preliminary Checks performed?–Go toStep 2Go to

”Important Pre-

liminary

Checks”

21. Connect the scan tool to the Data Link Con-

nector (DLC).

2. Monitor the Front Heated Oxygen Sensor

(HO2S1) reading at different throttle positions.

Does the HO2S sensor change quickly from rich to

lean at the different throttle positions?–Go toStep 5Go toStep 3

3Check the HO2S1 sensor for contamination from

fuel or improper use of Room Temperature Vulcaniz-

ing (RTV) sealant.

Is the HO2S1 sensor contaminated?–Go toStep 4Go toStep 5

4Replace the contaminated HO2S sensor as needed.

Is the repair complete?–System OK–

51. Check for a sticking throttle shaft or binding

throttle linkage that may cause incorrect

Throttle Position (TP) sensor voltage.

2. Check the TP sensor voltage reading with the

throttle closed.

Is the TP sensor voltage within the value specified?0.4–0.8 vGo toStep 6Go to

”Diagnostic

Aids for DTC

P0123”

61. Check the Engine Coolant Temperature (ECT)

sensor voltage reading using the scan tool.

2. Compare the ECT reading with the ambient

temperature when the engine is cold.

Does the ECT temperature reading differ from the

ambient temperature by more than the value speci-

fied?5°F (3°C)Go toStep 7Go toStep 9

7Check for high resistance in the ECT sensor circuit

or the sensor itself.

Is the problem found?–Go toStep 8Go toStep 9

8Replace the ECT sensor or repair the circuit as

needed.

Is the repair complete?–System OK–

9Check the Manifold Absolute Pressure (MAP) sen-

sor for response and accuracy.

Is the problem found?–Go toStep 10Go toStep 11

10Replace the MAP sensor or repair the MAP sensor

circuit as needed.

Is the repair complete?–System OK–

Page 852 of 2643

1F – 606IENGINE CONTROLS

DAEWOO V–121 BL4

7. Connect the TP sensor connector and the IAC

valve connector.

8. Connect the coolant hoses to the throttle body.

9. Connect the vacuum hoses to the throttle body.

Important : Make sure the throttle/cruise control cables

do not hold the throttle open. With the engine off, check to

see that the accelerator pedal is free.

10. Connect the throttle cable.

11. Install the air intake tube.

12. Connect the breather hose to the valve cover.

13. Connect the IAT sensor connector.

14. Connect the negative battery cable.

15. Fill the cooling system.

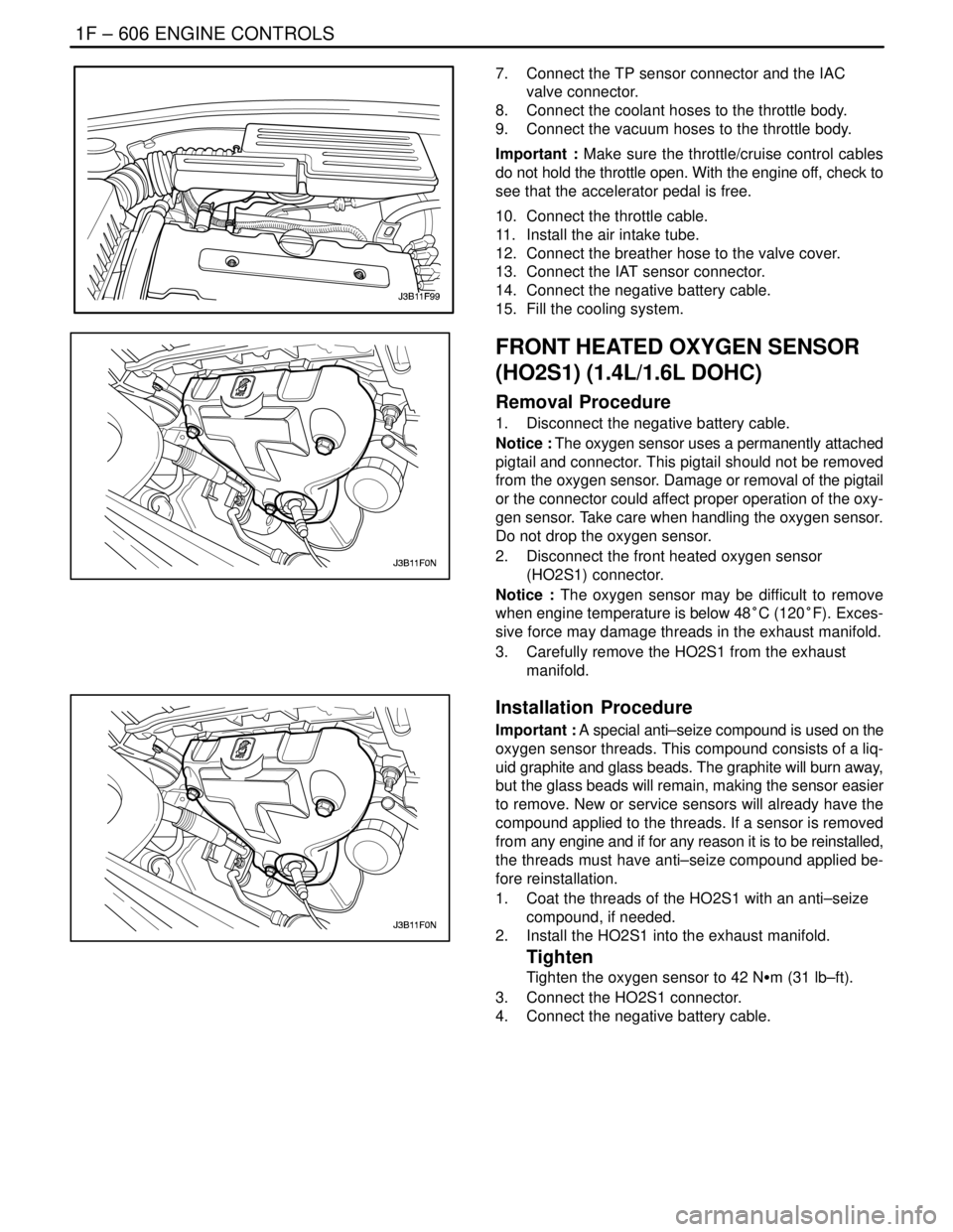

FRONT HEATED OXYGEN SENSOR

(HO2S1) (1.4L/1.6L DOHC)

Removal Procedure

1. Disconnect the negative battery cable.

Notice : The oxygen sensor uses a permanently attached

pigtail and connector. This pigtail should not be removed

from the oxygen sensor. Damage or removal of the pigtail

or the connector could affect proper operation of the oxy-

gen sensor. Take care when handling the oxygen sensor.

Do not drop the oxygen sensor.

2. Disconnect the front heated oxygen sensor

(HO2S1) connector.

Notice : The oxygen sensor may be difficult to remove

when engine temperature is below 48°C (120°F). Exces-

sive force may damage threads in the exhaust manifold.

3. Carefully remove the HO2S1 from the exhaust

manifold.

Installation Procedure

Important : A special anti–seize compound is used on the

oxygen sensor threads. This compound consists of a liq-

uid graphite and glass beads. The graphite will burn away,

but the glass beads will remain, making the sensor easier

to remove. New or service sensors will already have the

compound applied to the threads. If a sensor is removed

from any engine and if for any reason it is to be reinstalled,

the threads must have anti–seize compound applied be-

fore reinstallation.

1. Coat the threads of the HO2S1 with an anti–seize

compound, if needed.

2. Install the HO2S1 into the exhaust manifold.

Tighten

Tighten the oxygen sensor to 42 NSm (31 lb–ft).

3. Connect the HO2S1 connector.

4. Connect the negative battery cable.

Page 853 of 2643

ENGINE CONTROLS 1F – 607

DAEWOO V–121 BL4

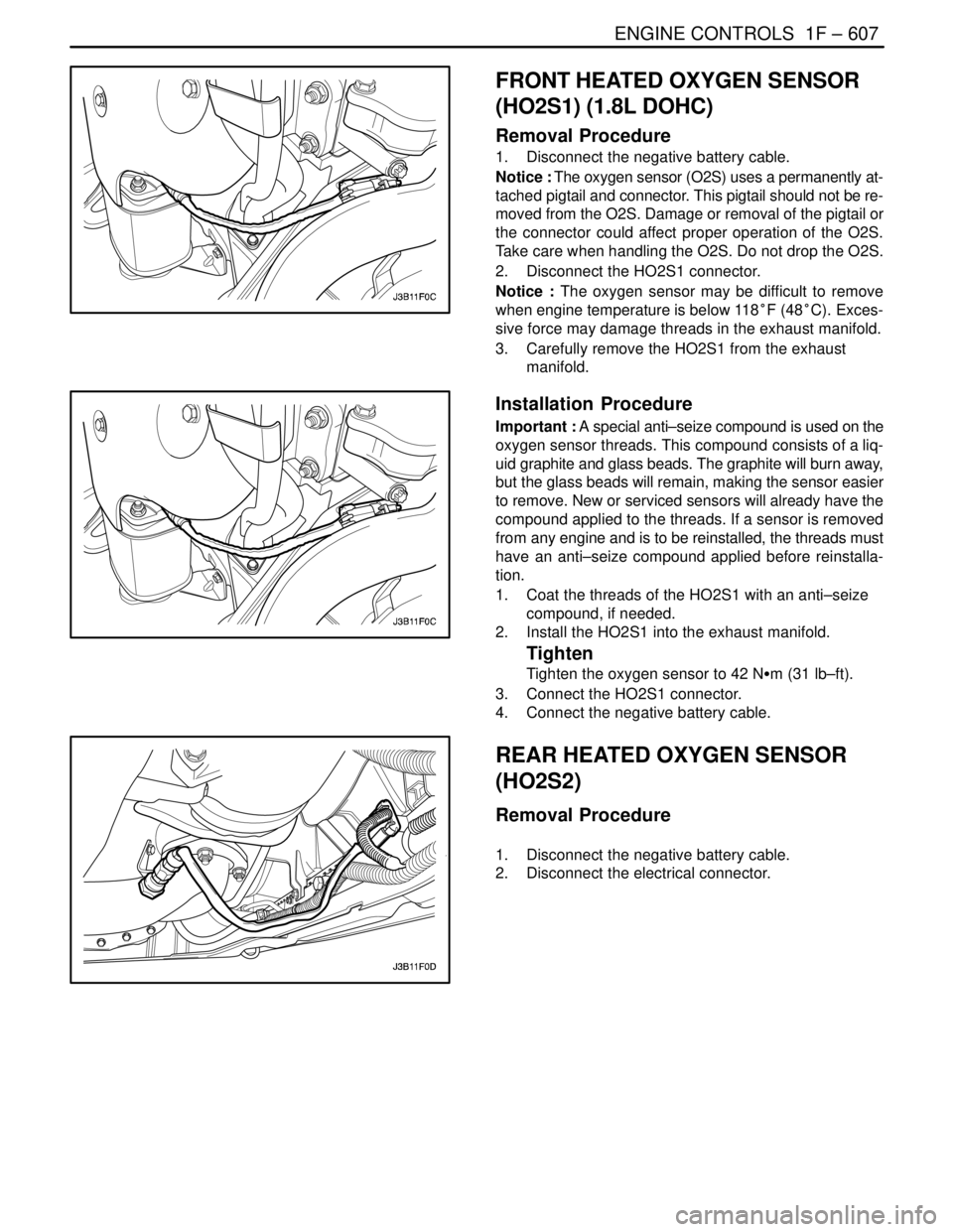

FRONT HEATED OXYGEN SENSOR

(HO2S1) (1.8L DOHC)

Removal Procedure

1. Disconnect the negative battery cable.

Notice : The oxygen sensor (O2S) uses a permanently at-

tached pigtail and connector. This pigtail should not be re-

moved from the O2S. Damage or removal of the pigtail or

the connector could affect proper operation of the O2S.

Take care when handling the O2S. Do not drop the O2S.

2. Disconnect the HO2S1 connector.

Notice : The oxygen sensor may be difficult to remove

when engine temperature is below 118°F (48°C). Exces-

sive force may damage threads in the exhaust manifold.

3. Carefully remove the HO2S1 from the exhaust

manifold.

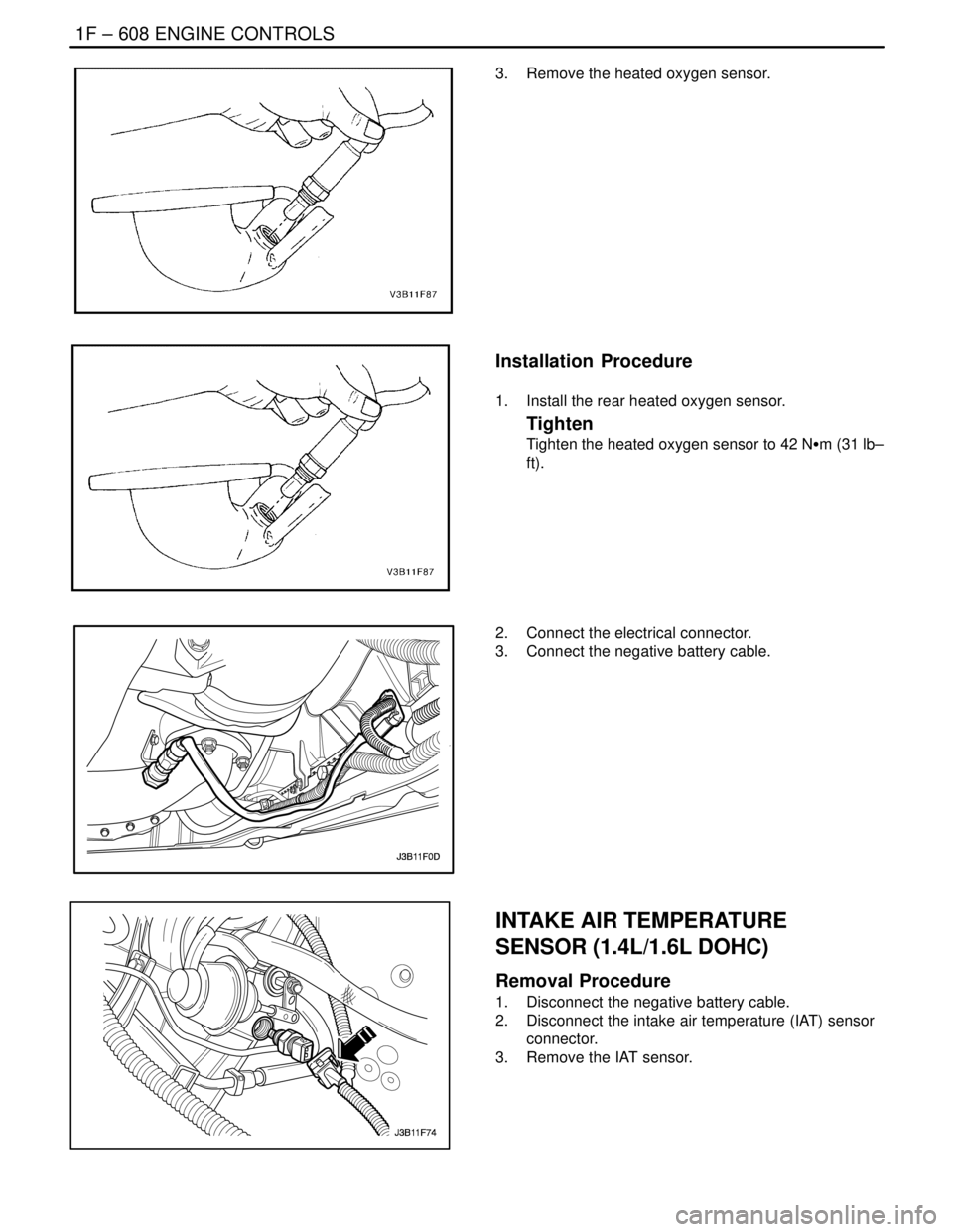

Installation Procedure

Important : A special anti–seize compound is used on the

oxygen sensor threads. This compound consists of a liq-

uid graphite and glass beads. The graphite will burn away,

but the glass beads will remain, making the sensor easier

to remove. New or serviced sensors will already have the

compound applied to the threads. If a sensor is removed

from any engine and is to be reinstalled, the threads must

have an anti–seize compound applied before reinstalla-

tion.

1. Coat the threads of the HO2S1 with an anti–seize

compound, if needed.

2. Install the HO2S1 into the exhaust manifold.

Tighten

Tighten the oxygen sensor to 42 NSm (31 lb–ft).

3. Connect the HO2S1 connector.

4. Connect the negative battery cable.

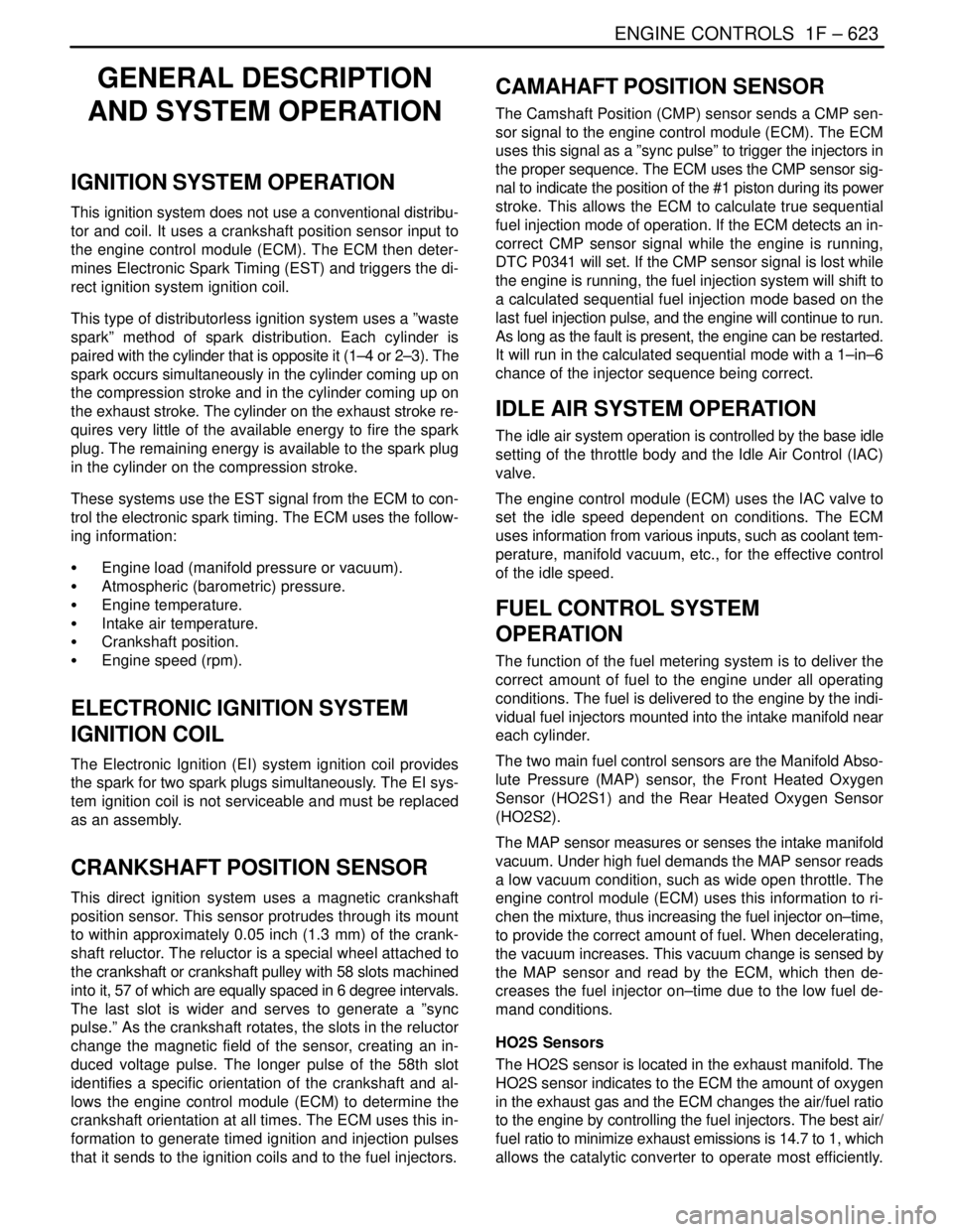

REAR HEATED OXYGEN SENSOR

(HO2S2)

Removal Procedure

1. Disconnect the negative battery cable.

2. Disconnect the electrical connector.

Page 854 of 2643

1F – 608IENGINE CONTROLS

DAEWOO V–121 BL4

3. Remove the heated oxygen sensor.

Installation Procedure

1. Install the rear heated oxygen sensor.

Tighten

Tighten the heated oxygen sensor to 42 NSm (31 lb–

ft).

2. Connect the electrical connector.

3. Connect the negative battery cable.

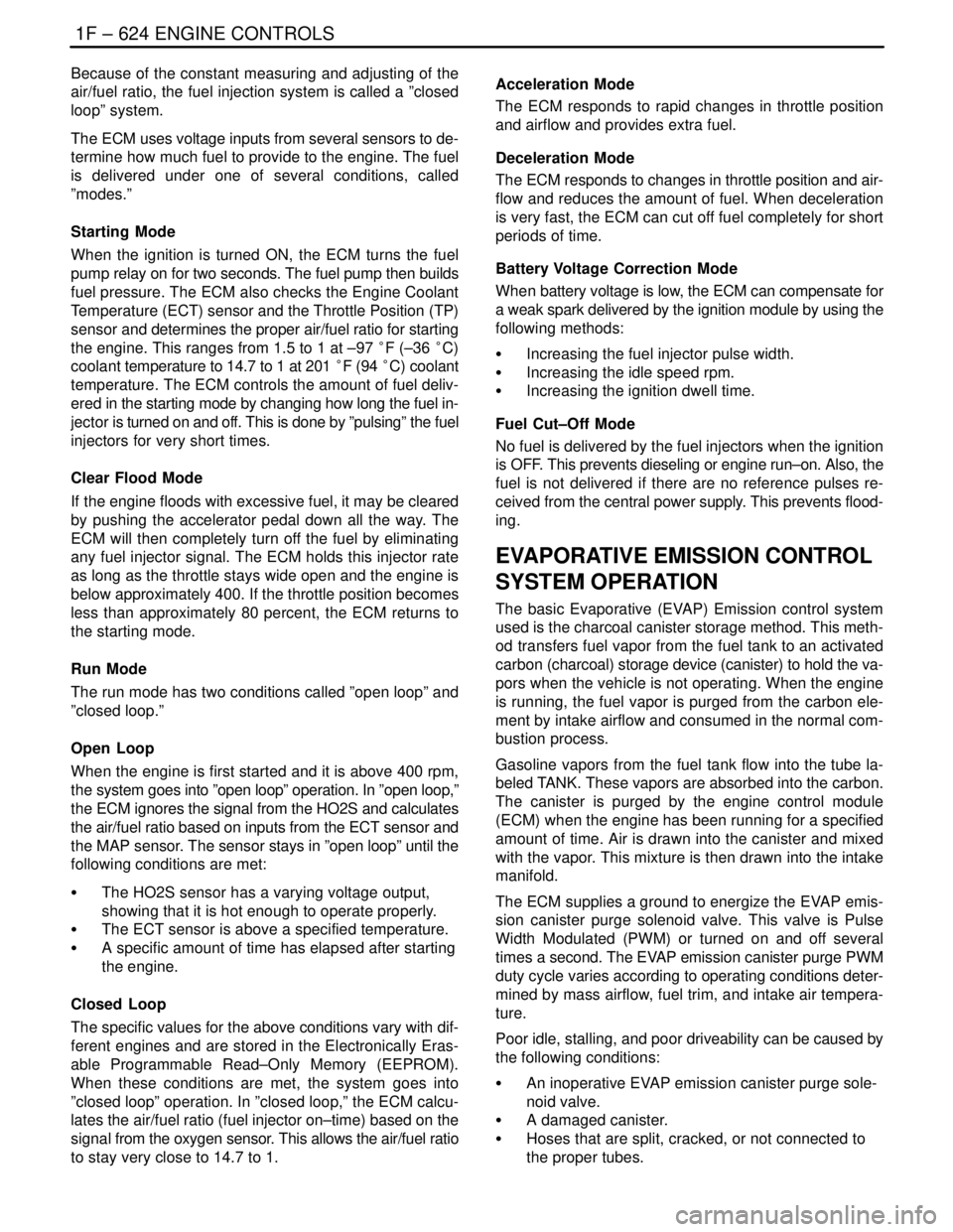

INTAKE AIR TEMPERATURE

SENSOR (1.4L/1.6L DOHC)

Removal Procedure

1. Disconnect the negative battery cable.

2. Disconnect the intake air temperature (IAT) sensor

connector.

3. Remove the IAT sensor.

Page 869 of 2643

ENGINE CONTROLS 1F – 623

DAEWOO V–121 BL4

GENERAL DESCRIPTION

AND SYSTEM OPERATION

IGNITION SYSTEM OPERATION

This ignition system does not use a conventional distribu-

tor and coil. It uses a crankshaft position sensor input to

the engine control module (ECM). The ECM then deter-

mines Electronic Spark Timing (EST) and triggers the di-

rect ignition system ignition coil.

This type of distributorless ignition system uses a ”waste

spark” method of spark distribution. Each cylinder is

paired with the cylinder that is opposite it (1–4 or 2–3). The

spark occurs simultaneously in the cylinder coming up on

the compression stroke and in the cylinder coming up on

the exhaust stroke. The cylinder on the exhaust stroke re-

quires very little of the available energy to fire the spark

plug. The remaining energy is available to the spark plug

in the cylinder on the compression stroke.

These systems use the EST signal from the ECM to con-

trol the electronic spark timing. The ECM uses the follow-

ing information:

S Engine load (manifold pressure or vacuum).

S Atmospheric (barometric) pressure.

S Engine temperature.

S Intake air temperature.

S Crankshaft position.

S Engine speed (rpm).

ELECTRONIC IGNITION SYSTEM

IGNITION COIL

The Electronic Ignition (EI) system ignition coil provides

the spark for two spark plugs simultaneously. The EI sys-

tem ignition coil is not serviceable and must be replaced

as an assembly.

CRANKSHAFT POSITION SENSOR

This direct ignition system uses a magnetic crankshaft

position sensor. This sensor protrudes through its mount

to within approximately 0.05 inch (1.3 mm) of the crank-

shaft reluctor. The reluctor is a special wheel attached to

the crankshaft or crankshaft pulley with 58 slots machined

into it, 57 of which are equally spaced in 6 degree intervals.

The last slot is wider and serves to generate a ”sync

pulse.” As the crankshaft rotates, the slots in the reluctor

change the magnetic field of the sensor, creating an in-

duced voltage pulse. The longer pulse of the 58th slot

identifies a specific orientation of the crankshaft and al-

lows the engine control module (ECM) to determine the

crankshaft orientation at all times. The ECM uses this in-

formation to generate timed ignition and injection pulses

that it sends to the ignition coils and to the fuel injectors.

CAMAHAFT POSITION SENSOR

The Camshaft Position (CMP) sensor sends a CMP sen-

sor signal to the engine control module (ECM). The ECM

uses this signal as a ”sync pulse” to trigger the injectors in

the proper sequence. The ECM uses the CMP sensor sig-

nal to indicate the position of the #1 piston during its power

stroke. This allows the ECM to calculate true sequential

fuel injection mode of operation. If the ECM detects an in-

correct CMP sensor signal while the engine is running,

DTC P0341 will set. If the CMP sensor signal is lost while

the engine is running, the fuel injection system will shift to

a calculated sequential fuel injection mode based on the

last fuel injection pulse, and the engine will continue to run.

As long as the fault is present, the engine can be restarted.

It will run in the calculated sequential mode with a 1–in–6

chance of the injector sequence being correct.

IDLE AIR SYSTEM OPERATION

The idle air system operation is controlled by the base idle

setting of the throttle body and the Idle Air Control (IAC)

valve.

The engine control module (ECM) uses the IAC valve to

set the idle speed dependent on conditions. The ECM

uses information from various inputs, such as coolant tem-

perature, manifold vacuum, etc., for the effective control

of the idle speed.

FUEL CONTROL SYSTEM

OPERATION

The function of the fuel metering system is to deliver the

correct amount of fuel to the engine under all operating

conditions. The fuel is delivered to the engine by the indi-

vidual fuel injectors mounted into the intake manifold near

each cylinder.

The two main fuel control sensors are the Manifold Abso-

lute Pressure (MAP) sensor, the Front Heated Oxygen

Sensor (HO2S1) and the Rear Heated Oxygen Sensor

(HO2S2).

The MAP sensor measures or senses the intake manifold

vacuum. Under high fuel demands the MAP sensor reads

a low vacuum condition, such as wide open throttle. The

engine control module (ECM) uses this information to ri-

chen the mixture, thus increasing the fuel injector on–time,

to provide the correct amount of fuel. When decelerating,

the vacuum increases. This vacuum change is sensed by

the MAP sensor and read by the ECM, which then de-

creases the fuel injector on–time due to the low fuel de-

mand conditions.

HO2S Sensors

The HO2S sensor is located in the exhaust manifold. The

HO2S sensor indicates to the ECM the amount of oxygen

in the exhaust gas and the ECM changes the air/fuel ratio

to the engine by controlling the fuel injectors. The best air/

fuel ratio to minimize exhaust emissions is 14.7 to 1, which

allows the catalytic converter to operate most efficiently.

Page 870 of 2643

1F – 624IENGINE CONTROLS

DAEWOO V–121 BL4

Because of the constant measuring and adjusting of the

air/fuel ratio, the fuel injection system is called a ”closed

loop” system.

The ECM uses voltage inputs from several sensors to de-

termine how much fuel to provide to the engine. The fuel

is delivered under one of several conditions, called

”modes.”

Starting Mode

When the ignition is turned ON, the ECM turns the fuel

pump relay on for two seconds. The fuel pump then builds

fuel pressure. The ECM also checks the Engine Coolant

Temperature (ECT) sensor and the Throttle Position (TP)

sensor and determines the proper air/fuel ratio for starting

the engine. This ranges from 1.5 to 1 at –97 °F (–36 °C)

coolant temperature to 14.7 to 1 at 201 °F (94 °C) coolant

temperature. The ECM controls the amount of fuel deliv-

ered in the starting mode by changing how long the fuel in-

jector is turned on and off. This is done by ”pulsing” the fuel

injectors for very short times.

Clear Flood Mode

If the engine floods with excessive fuel, it may be cleared

by pushing the accelerator pedal down all the way. The

ECM will then completely turn off the fuel by eliminating

any fuel injector signal. The ECM holds this injector rate

as long as the throttle stays wide open and the engine is

below approximately 400. If the throttle position becomes

less than approximately 80 percent, the ECM returns to

the starting mode.

Run Mode

The run mode has two conditions called ”open loop” and

”closed loop.”

Open Loop

When the engine is first started and it is above 400 rpm,

the system goes into ”open loop” operation. In ”open loop,”

the ECM ignores the signal from the HO2S and calculates

the air/fuel ratio based on inputs from the ECT sensor and

the MAP sensor. The sensor stays in ”open loop” until the

following conditions are met:

S The HO2S sensor has a varying voltage output,

showing that it is hot enough to operate properly.

S The ECT sensor is above a specified temperature.

S A specific amount of time has elapsed after starting

the engine.

Closed Loop

The specific values for the above conditions vary with dif-

ferent engines and are stored in the Electronically Eras-

able Programmable Read–Only Memory (EEPROM).

When these conditions are met, the system goes into

”closed loop” operation. In ”closed loop,” the ECM calcu-

lates the air/fuel ratio (fuel injector on–time) based on the

signal from the oxygen sensor. This allows the air/fuel ratio

to stay very close to 14.7 to 1.Acceleration Mode

The ECM responds to rapid changes in throttle position

and airflow and provides extra fuel.

Deceleration Mode

The ECM responds to changes in throttle position and air-

flow and reduces the amount of fuel. When deceleration

is very fast, the ECM can cut off fuel completely for short

periods of time.

Battery Voltage Correction Mode

When battery voltage is low, the ECM can compensate for

a weak spark delivered by the ignition module by using the

following methods:

S Increasing the fuel injector pulse width.

S Increasing the idle speed rpm.

S Increasing the ignition dwell time.

Fuel Cut–Off Mode

No fuel is delivered by the fuel injectors when the ignition

is OFF. This prevents dieseling or engine run–on. Also, the

fuel is not delivered if there are no reference pulses re-

ceived from the central power supply. This prevents flood-

ing.

EVAPORATIVE EMISSION CONTROL

SYSTEM OPERATION

The basic Evaporative (EVAP) Emission control system

used is the charcoal canister storage method. This meth-

od transfers fuel vapor from the fuel tank to an activated

carbon (charcoal) storage device (canister) to hold the va-

pors when the vehicle is not operating. When the engine

is running, the fuel vapor is purged from the carbon ele-

ment by intake airflow and consumed in the normal com-

bustion process.

Gasoline vapors from the fuel tank flow into the tube la-

beled TANK. These vapors are absorbed into the carbon.

The canister is purged by the engine control module

(ECM) when the engine has been running for a specified

amount of time. Air is drawn into the canister and mixed

with the vapor. This mixture is then drawn into the intake

manifold.

The ECM supplies a ground to energize the EVAP emis-

sion canister purge solenoid valve. This valve is Pulse

Width Modulated (PWM) or turned on and off several

times a second. The EVAP emission canister purge PWM

duty cycle varies according to operating conditions deter-

mined by mass airflow, fuel trim, and intake air tempera-

ture.

Poor idle, stalling, and poor driveability can be caused by

the following conditions:

S An inoperative EVAP emission canister purge sole-

noid valve.

S A damaged canister.

S Hoses that are split, cracked, or not connected to

the proper tubes.

Page 871 of 2643

ENGINE CONTROLS 1F – 625

DAEWOO V–121 BL4

EVAPORATIVE EMISSION CANISTER

The Evaporative (EVAP) Emission canister is an emission

control device containing activated charcoal granules.

The EVAP emission canister is used to store fuel vapors

from the fuel tank. Once certain conditions are met, the en-

gine control module (ECM) activates the EVAP canister

purge solenoid, allowing the fuel vapors to be drawn into

the engine cylinders and burned.

POSITIVE CRANKCASE

VENTILATION SYSTEM OPERATION

A Positive Crankcase Ventilation (PCV) system is used to

provide complete use of the crankcase vapors. Fresh air

from the air cleaner is supplied to the crankcase. The fresh

air is mixed with blowby gases which are then passed

through a vacuum hose into the intake manifold.

Periodically inspect the hoses and the clamps. Replace

any crankcase ventilation components as required.

A restricted or plugged PCV hose may cause the following

conditions:

S Rough idle

S Stalling or low idle speed

S Oil leaks

S Oil in the air cleaner

S Sludge in the engine

A leaking PCV hose may cause the following conditions:

S Rough idle

S Stalling

S High idle speed

ENGINE COOLANT TEMPERATURE

SENSOR

The Engine Coolant Temperature (ECT) sensor is a

thermistor (a resistor which changes value based on tem-

perature) mounted in the engine coolant stream. Low cool-

ant temperature produces a high resistance (100,000

ohms at –40 °F [–40 °C]) while high temperature causes

low resistance (70 ohms at 266 °F [130 °C]).

The engine control module (ECM) supplies 5 volts to the

ECT sensor through a resistor in the ECM and measures

the change in voltage. The voltage will be high when the

engine is cold, and low when the engine is hot. By measur-

ing the change in voltage, the ECM can determine the

coolant temperature. The engine coolant temperature af-

fects most of the systems that the ECM controls. A failure

in the ECT sensor circuit should set a diagnostic trouble

code P0117 or P0118. Remember, these diagnostic

trouble codes indicate a failure in the ECT sensor circuit,

so proper use of the chart will lead either to repairing a wir-

ing problem or to replacing the sensor to repair a problem

properly.

THROTTLE POSITION SENSOR

The Throttle Position (TP) sensor is a potentiometer con-

nected to the throttle shaft of the throttle body. The TP sen-

sor electrical circuit consists of a 5 volt supply line and a

ground line, both provided by the engine control module

(ECM). The ECM calculates the throttle position by moni-

toring the voltage on this signal line. The TP sensor output

changes as the accelerator pedal is moved, changing the

throttle valve angle. At a closed throttle position, the output

of the TP sensor is low, about 0.5 volt. As the throttle valve

opens, the output increases so that, at Wide Open Throttle

(WOT), the output voltage will be about 5 volts.

The ECM can determine fuel delivery based on throttle

valve angle (driver demand). A broken or loose TP sensor

can cause intermittent bursts of fuel from the injector and

an unstable idle, because the ECM thinks the throttle is

moving. A problem in any of the TP sensor circuits should

set a diagnostic trouble code (DTC) P0121 or P0122.

Once the DTC is set, the ECM will substitute a default val-

ue for the TP sensor and some vehicle performance will

return. A DTC P0121 will cause a high idle speed.

CATALYST MONITOR OXYGEN

SENSORS

Three–way catalytic converters are used to control emis-

sions of hydrocarbons (HC), carbon monoxide (CO), and

oxides of nitrogen (NOx). The catalyst within the convert-

ers promotes a chemical reaction. This reaction oxidizes

the HC and CO present in the exhaust gas and converts

them into harmless water vapor and carbon dioxide. The

catalyst also reduces NOx by converting it to nitrogen. The

engine control module (ECM) can monitor this process us-

ing the HO2S1 and HO2S2 sensor. These sensors pro-

duce an output signal which indicates the amount of oxy-

gen present in the exhaust gas entering and leaving the

three–way converter. This indicates the catalyst’s ability to

efficiently convert exhaust gasses. If the catalyst is operat-

ing efficiently, the HO2S1 sensor signals will be more ac-

tive than the signals produced by the HO2S2 sensor. The

catalyst monitor sensors operate the same way as the fuel

control sensors. The sensor’s main function is catalyst

monitoring, but they also have a limited role in fuel control.

If a sensor output indicates a voltage either above or below

the 450 mv bias voltage for an extended period of time, the

ECM will make a slight adjustment to fuel trim to ensure

that fuel delivery is correct for catalyst monitoring.

A problem with the HO2S1 sensor circuit will set DTC

P0131, P0132, P0133 or P0134 depending, on the special

condition. A problem with the HO2S2 sensor signal will set

DTC P0137, P0138, P0140 or P0141, depending on the

special condition.

A fault in the Rear Heated Oxygen Sensor (HO2S2) heat-

er element or its ignition feed or ground will result in lower

oxygen sensor response. This may cause incorrect cata-

lyst monitor diagnostic results.

Page 875 of 2643

ENGINE CONTROLS 1F – 629

DAEWOO V–121 BL4

tentially interfere with the operation of the Exhaust Gas

Recirculation (EGR) valve and thereby turn on the MIL.

Small leaks in the exhaust system near the post catalyst

oxygen sensor can also cause the MIL to turn on.

Aftermarket electronics, such as cellular phones, stereos,

and anti–theft devices, may radiate electromagnetic inter-

ference (EMI) into the control system if they are improperly

installed. This may cause a false sensor reading and turn

on the MIL.

Environment

Temporary environmental conditions, such as localized

flooding, will have an effect on the vehicle ignition system.

If the ignition system is rain–soaked, it can temporarily

cause engine misfire and turn on the MIL.

Refueling

A new EOBD diagnostic checks the integrity of the entire

Evaporative (EVAP) Emission system. If the vehicle is re-

started after refueling and the fuel cap is not secured cor-

rectly, the on–board diagnostic system will sense this as

a system fault, turn on the MIL, and set DTC P0440.

Vehicle Marshaling

The transportation of new vehicles from the assembly

plant to the dealership can involve as many as 60 key

cycles within 2 to 3 miles of driving. This type of operation

contributes to the fuel fouling of the spark plugs and will

turn on the MIL with a set DTC P0300.

Poor Vehicle Maintenance

The sensitivity of EOBD diagnostics will cause the MIL to

turn on if the vehicle is not maintained properly. Restricted

air filters, fuel filters, and crankcase deposits due to lack

of oil changes or improper oil viscosity can trigger actual

vehicle faults that were not previously monitored prior to

EOBD. Poor vehicle maintenance can not be classified as

a ”non–vehicle fault,” but with the sensitivity of EOBD

diagnostics, vehicle maintenance schedules must be

more closely followed.

Severe Vibration

The Misfire diagnostic measures small changes in the

rotational speed of the crankshaft. Severe driveline vibra-

tions in the vehicle, such as caused by an excessive

amount of mud on the wheels, can have the same effect

on crankshaft speed as misfire and, therefore, may set

DTC P0300.

Related System Faults

Many of the EOBD system diagnostics will not run if the

engine controlmodule (ECM) detects a fault on a related

system or component. One example would be that if the

ECM detected a Misfire fault, the diagnostics on the cata-

lytic converter would be suspended until the Misfire fault

was repaired. If the Misfire fault is severe enough, the cat-

alytic converter can be damaged due to overheating andwill never set a Catalyst DTC until the Misfire fault is re-

paired and the Catalyst diagnostic is allowed to run to

completion. If this happens, the customer may have to

make two trips to the dealership in order to repair the ve-

hicle.

SERIAL DATA COMMUNICATIONS

Class II Serial Data Communications

Government regulations require that all vehicle manufac-

turers establish a common communication system. This

vehicle utilizes the ”Class II” communication system. Each

bit of information can have one of two lengths: long or

short. This allows vehicle wiring to be reduced by transmit-

ting and receiving multiple signals over a single wire. The

messages carried on Class II data streams are also priori-

tized. If two messages attempt to establish communica-

tions on the data line at the same time, only the message

with higher priority will continue. The device with the lower

priority message must wait. Themost significant result of

this regulation is that it provides scan tool manufacturers

with the capability to access data from any make or model

vehicle that is sold.

The data displayed on the other scan tool will appear the

same, with some exceptions. Some scan tools will only be

able to display certain vehicle parameters as values that

are a coded representation of the true or actual value. On

this vehicle the scan tool displays the actual values for ve-

hicle parameters. It will not be necessary to perform any

conversions from coded values to actual values.

ON–BOARD DIAGNOSTIC (EOBD)

On–Board Diagnostic Tests

A diagnostic test is a series of steps, the result of which is

a pass or fail reported to the diagnostic executive. When

a diagnostic test reports a pass result, the diagnostic

executive records the following data:

S The diagnostic test has been completed since the

last ignition cycle.

S The diagnostic test has passed during the current

ignition cycle.

S The fault identified by the diagnostic test is not cur-

rently active.

When a diagnostic test reports a fail result, the diagnostic

executive records the following data:

S The diagnostic test has been completed since the

last ignition cycle.

S The fault identified by the diagnostic test is current-

ly active.

S The fault has been active during this ignition cycle.

S The operating conditions at the time of the failure.

Remember, a fuel trim Diagnostic Trouble Code (DTC)

may be triggered by a list of vehicle faults. Make use of all

information available (other DTCs stored, rich or lean con-

dition, etc.) when diagnosing a fuel trim fault.