engine DAEWOO NUBIRA 2004 Service Repair Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: NUBIRA, Model: DAEWOO NUBIRA 2004Pages: 2643, PDF Size: 80.54 MB

Page 1839 of 2643

FIVE–SPEED MANUAL TRANSAXLE 5B – 15

DAEWOO V–121 BL4

MAINTENANCE AND REPAIR

ON–VEHICLE SERVICE

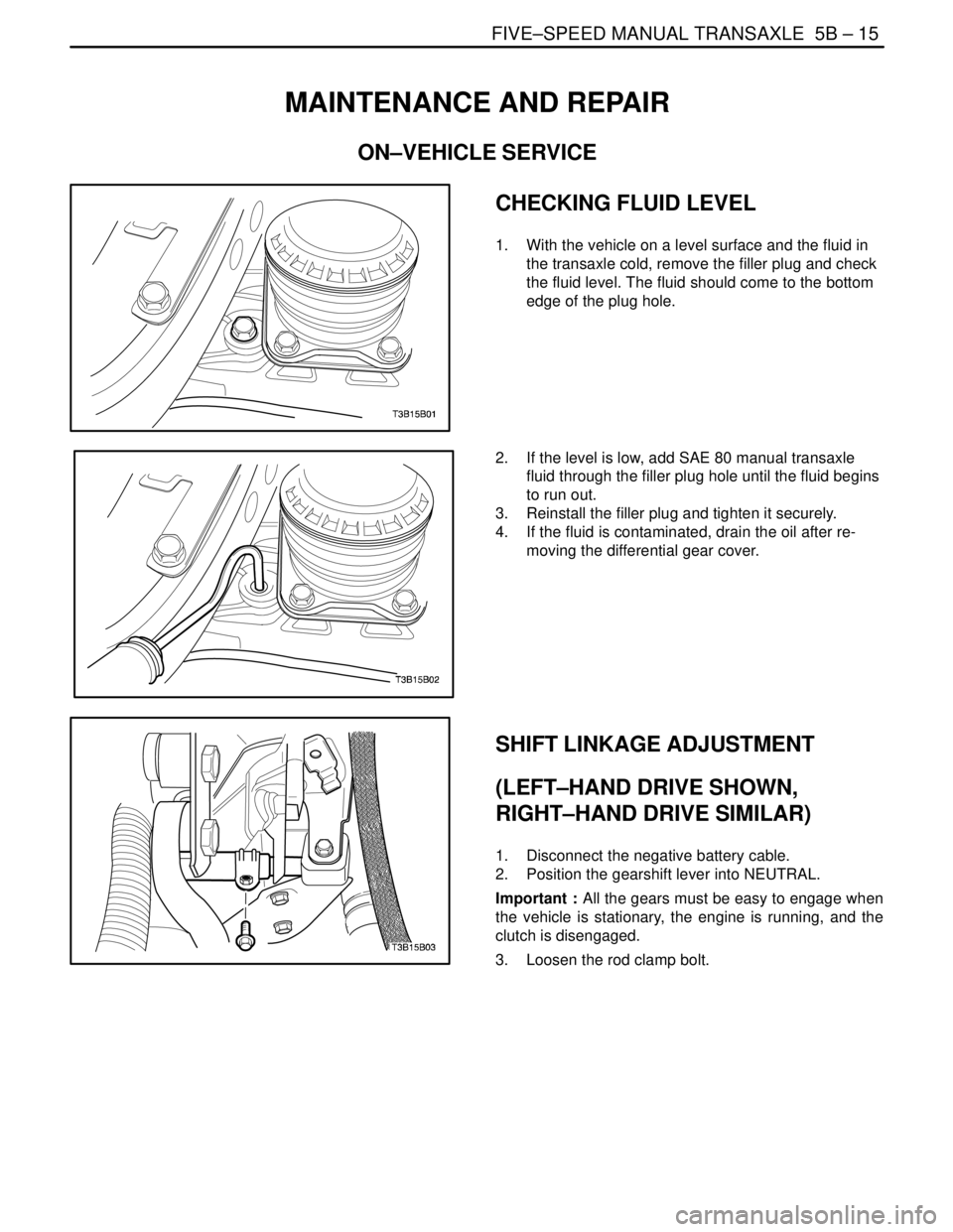

CHECKING FLUID LEVEL

1. With the vehicle on a level surface and the fluid in

the transaxle cold, remove the filler plug and check

the fluid level. The fluid should come to the bottom

edge of the plug hole.

2. If the level is low, add SAE 80 manual transaxle

fluid through the filler plug hole until the fluid begins

to run out.

3. Reinstall the filler plug and tighten it securely.

4. If the fluid is contaminated, drain the oil after re-

moving the differential gear cover.

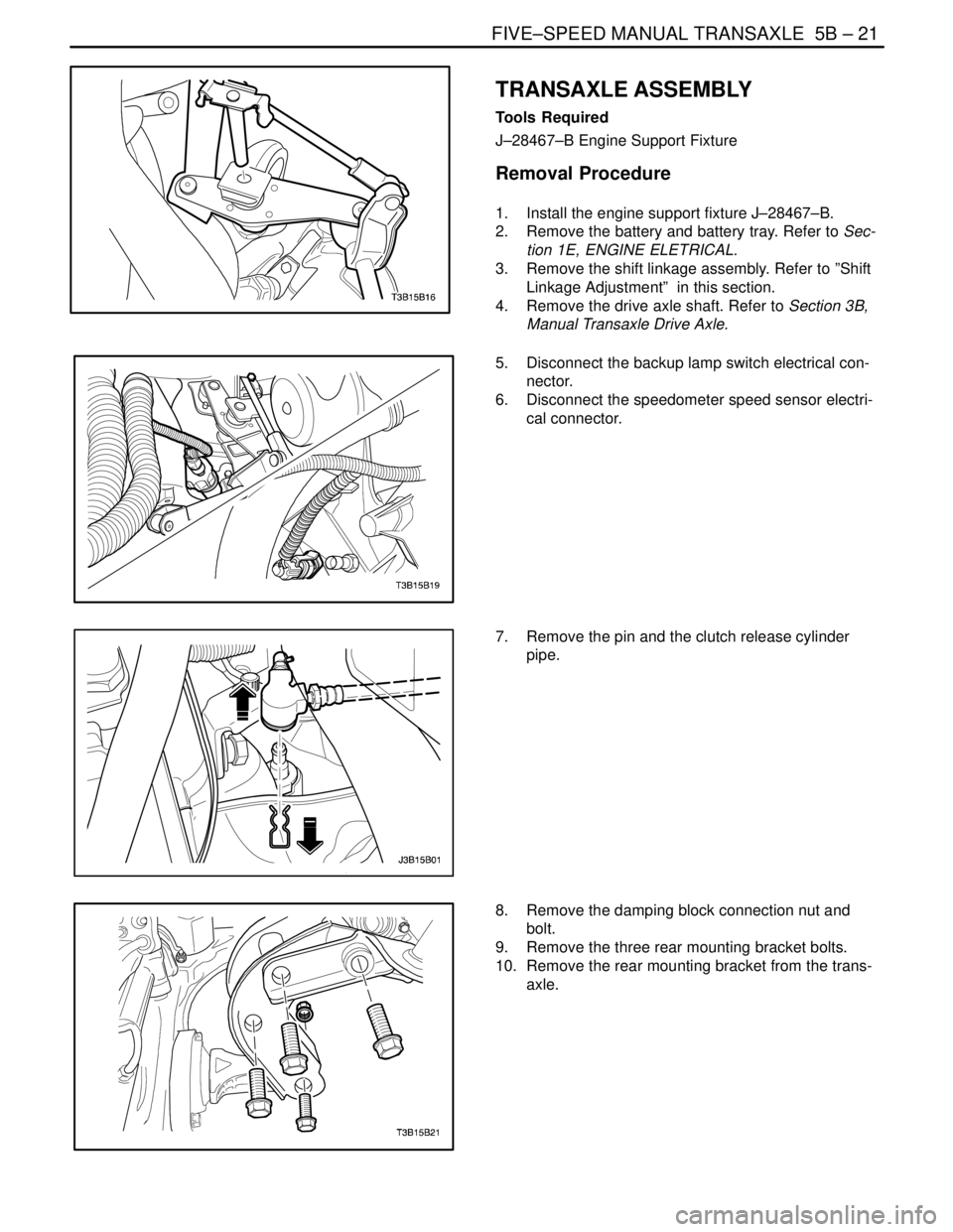

SHIFT LINKAGE ADJUSTMENT

(LEFT–HAND DRIVE SHOWN,

RIGHT–HAND DRIVE SIMILAR)

1. Disconnect the negative battery cable.

2. Position the gearshift lever into NEUTRAL.

Important : All the gears must be easy to engage when

the vehicle is stationary, the engine is running, and the

clutch is disengaged.

3. Loosen the rod clamp bolt.

Page 1845 of 2643

FIVE–SPEED MANUAL TRANSAXLE 5B – 21

DAEWOO V–121 BL4

TRANSAXLE ASSEMBLY

Tools Required

J–28467–B Engine Support Fixture

Removal Procedure

1. Install the engine support fixture J–28467–B.

2. Remove the battery and battery tray. Refer to Sec-

tion 1E, ENGINE ELETRICAL.

3. Remove the shift linkage assembly. Refer to ”Shift

Linkage Adjustment” in this section.

4. Remove the drive axle shaft. Refer to Section 3B,

Manual Transaxle Drive Axle.

5. Disconnect the backup lamp switch electrical con-

nector.

6. Disconnect the speedometer speed sensor electri-

cal connector.

7. Remove the pin and the clutch release cylinder

pipe.

8. Remove the damping block connection nut and

bolt.

9. Remove the three rear mounting bracket bolts.

10. Remove the rear mounting bracket from the trans-

axle.

Page 1847 of 2643

FIVE–SPEED MANUAL TRANSAXLE 5B – 23

DAEWOO V–121 BL4

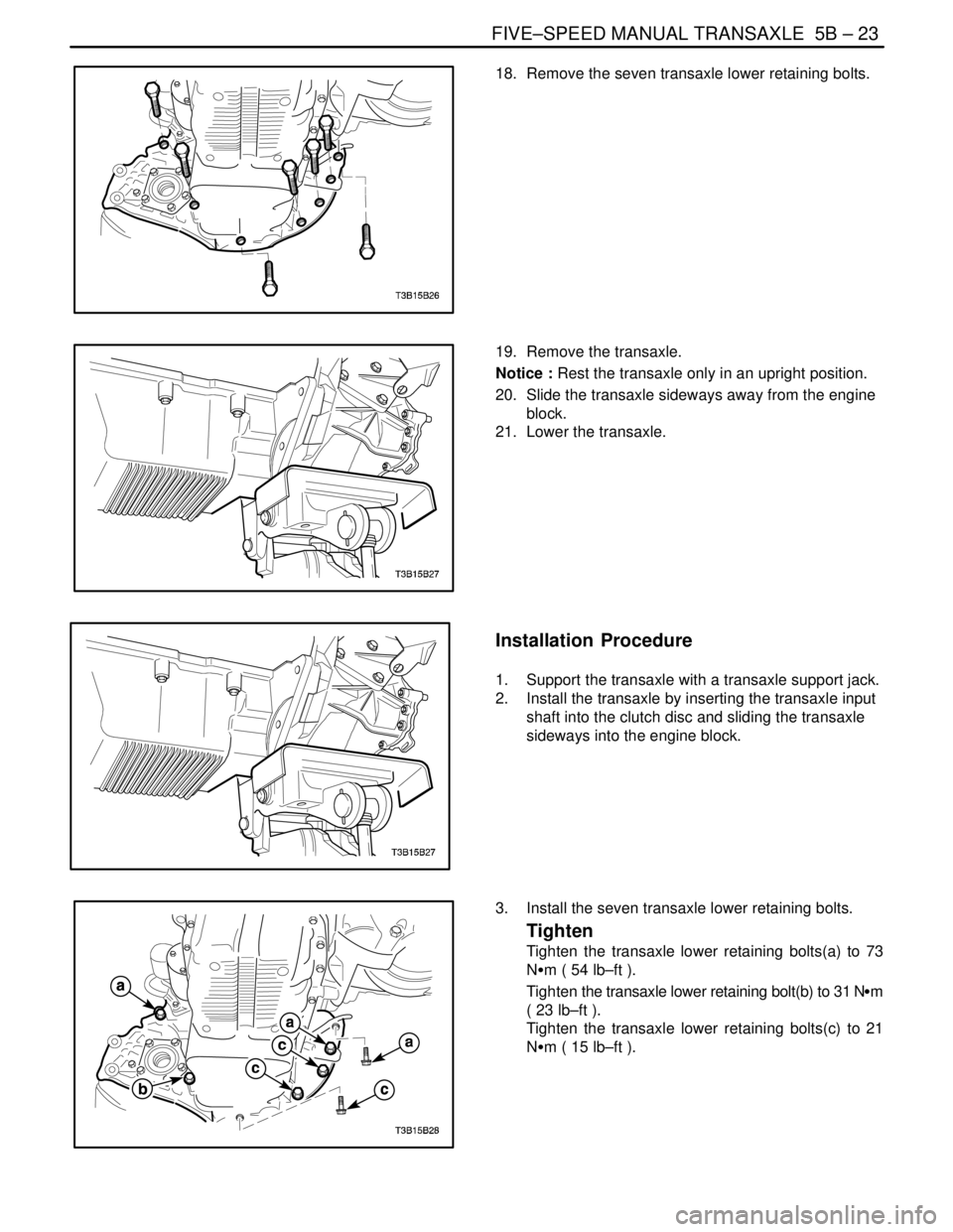

18. Remove the seven transaxle lower retaining bolts.

19. Remove the transaxle.

Notice : Rest the transaxle only in an upright position.

20. Slide the transaxle sideways away from the engine

block.

21. Lower the transaxle.

Installation Procedure

1. Support the transaxle with a transaxle support jack.

2. Install the transaxle by inserting the transaxle input

shaft into the clutch disc and sliding the transaxle

sideways into the engine block.

3. Install the seven transaxle lower retaining bolts.

Tighten

Tighten the transaxle lower retaining bolts(a) to 73

NSm ( 54 lb–ft ).

Tighten the transaxle lower retaining bolt(b) to 31 NSm

( 23 lb–ft ).

Tighten the transaxle lower retaining bolts(c) to 21

NSm ( 15 lb–ft ).

Page 1849 of 2643

FIVE–SPEED MANUAL TRANSAXLE 5B – 25

DAEWOO V–121 BL4

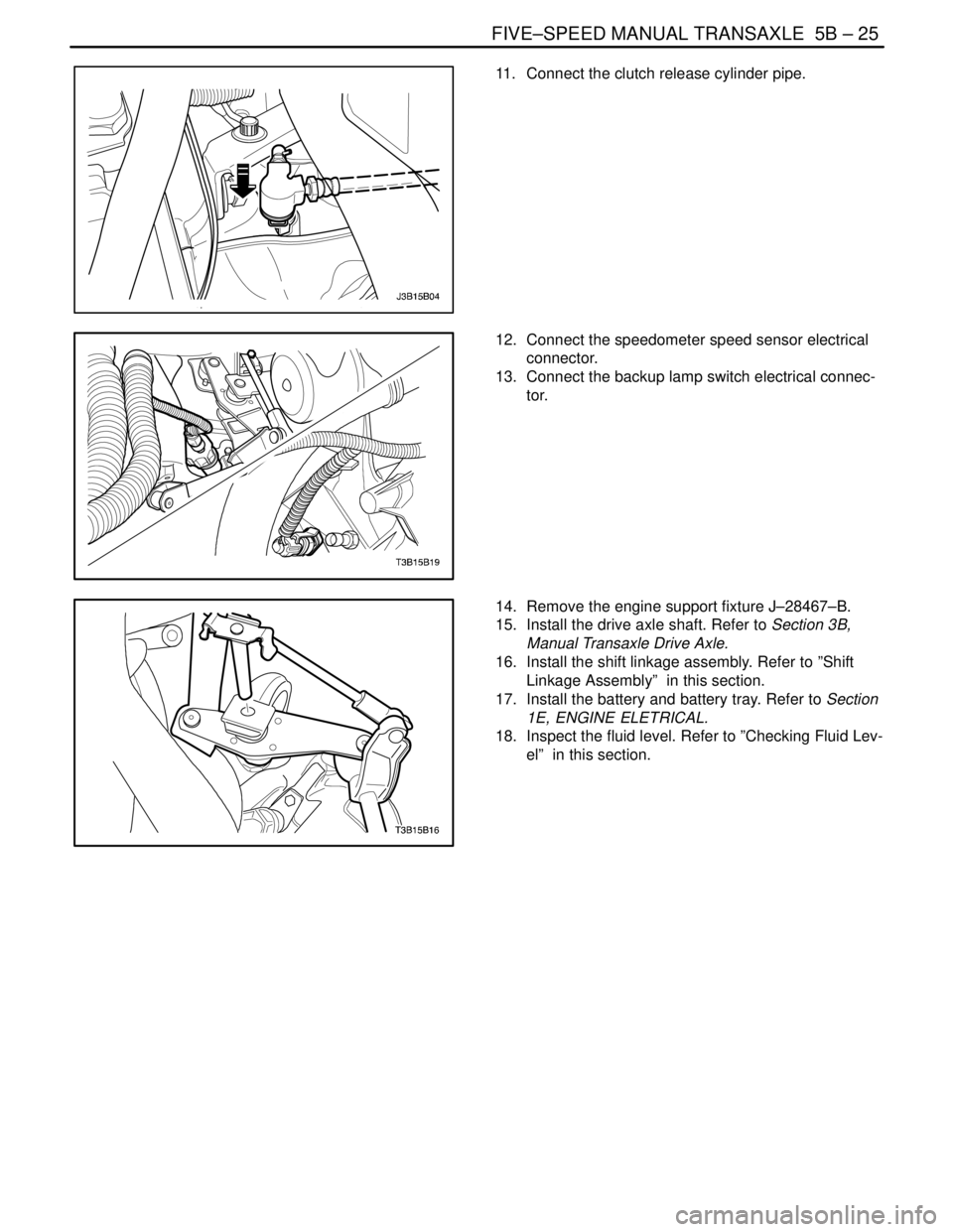

11. Connect the clutch release cylinder pipe.

12. Connect the speedometer speed sensor electrical

connector.

13. Connect the backup lamp switch electrical connec-

tor.

14. Remove the engine support fixture J–28467–B.

15. Install the drive axle shaft. Refer to Section 3B,

Manual Transaxle Drive Axle.

16. Install the shift linkage assembly. Refer to ”Shift

Linkage Assembly” in this section.

17. Install the battery and battery tray. Refer to Section

1E, ENGINE ELETRICAL.

18. Inspect the fluid level. Refer to ”Checking Fluid Lev-

el” in this section.

Page 1895 of 2643

5C – 8ICLUTCH

DAEWOO V–121 BL4

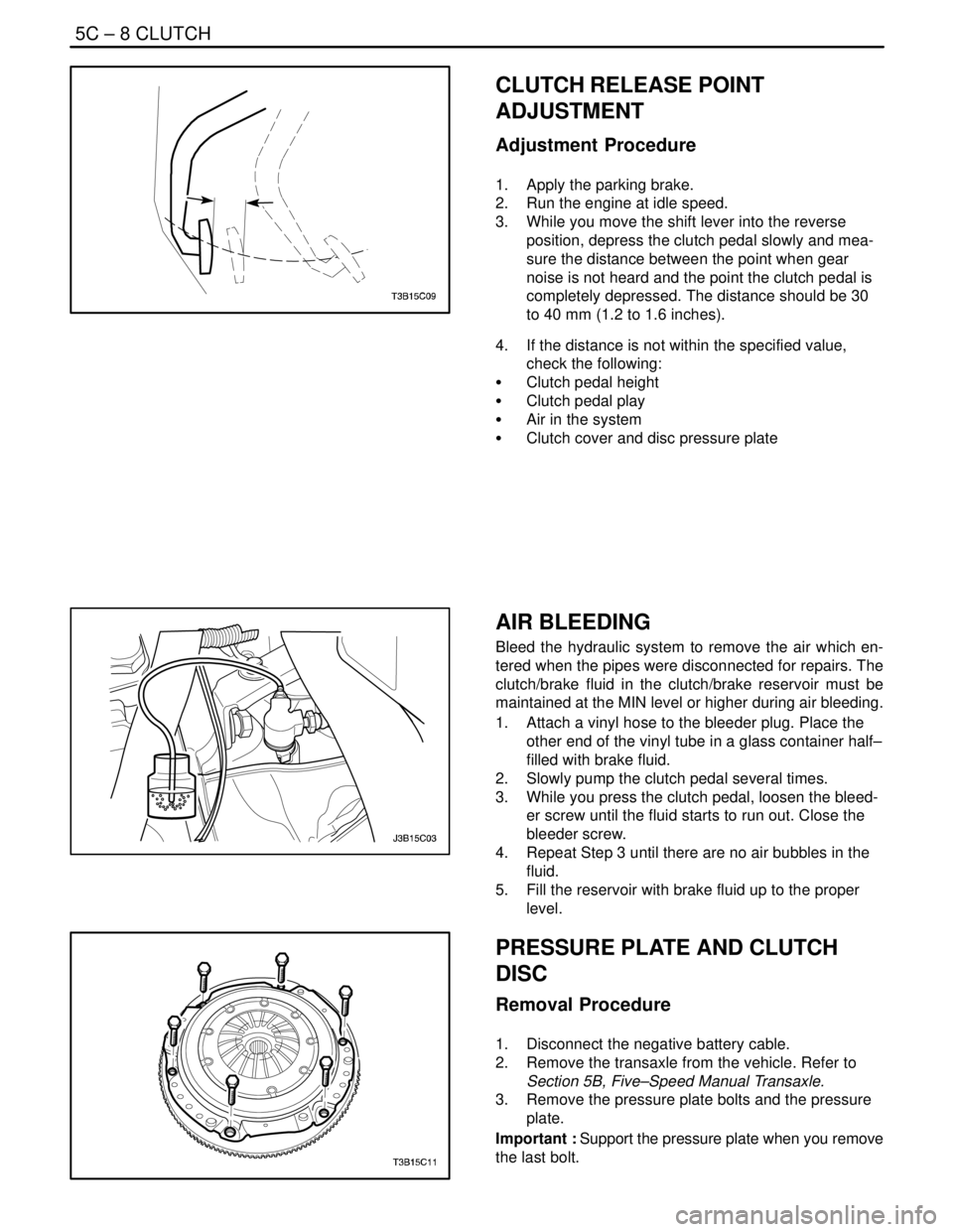

CLUTCH RELEASE POINT

ADJUSTMENT

Adjustment Procedure

1. Apply the parking brake.

2. Run the engine at idle speed.

3. While you move the shift lever into the reverse

position, depress the clutch pedal slowly and mea-

sure the distance between the point when gear

noise is not heard and the point the clutch pedal is

completely depressed. The distance should be 30

to 40 mm (1.2 to 1.6 inches).

4. If the distance is not within the specified value,

check the following:

S Clutch pedal height

S Clutch pedal play

S Air in the system

S Clutch cover and disc pressure plate

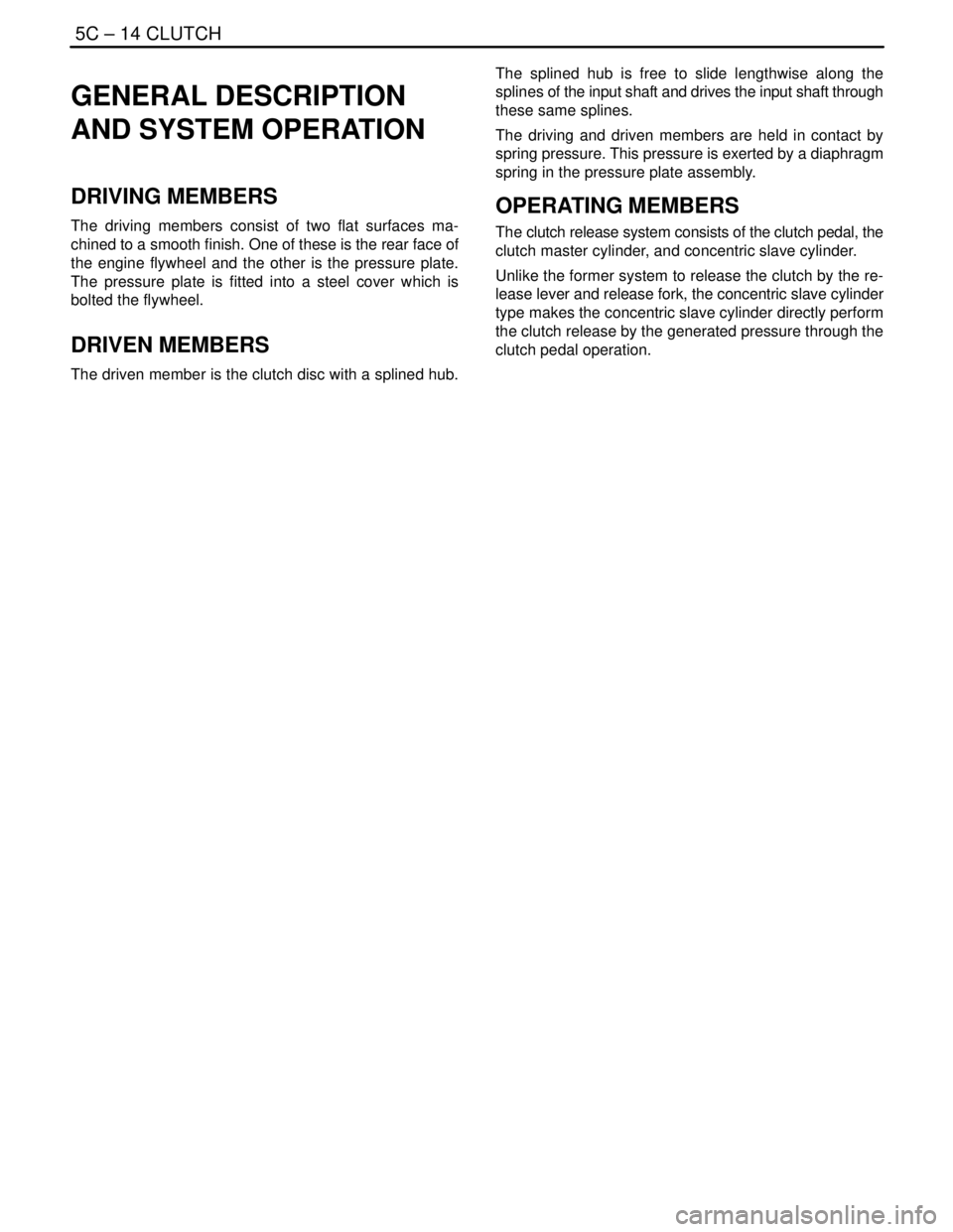

AIR BLEEDING

Bleed the hydraulic system to remove the air which en-

tered when the pipes were disconnected for repairs. The

clutch/brake fluid in the clutch/brake reservoir must be

maintained at the MIN level or higher during air bleeding.

1. Attach a vinyl hose to the bleeder plug. Place the

other end of the vinyl tube in a glass container half–

filled with brake fluid.

2. Slowly pump the clutch pedal several times.

3. While you press the clutch pedal, loosen the bleed-

er screw until the fluid starts to run out. Close the

bleeder screw.

4. Repeat Step 3 until there are no air bubbles in the

fluid.

5. Fill the reservoir with brake fluid up to the proper

level.

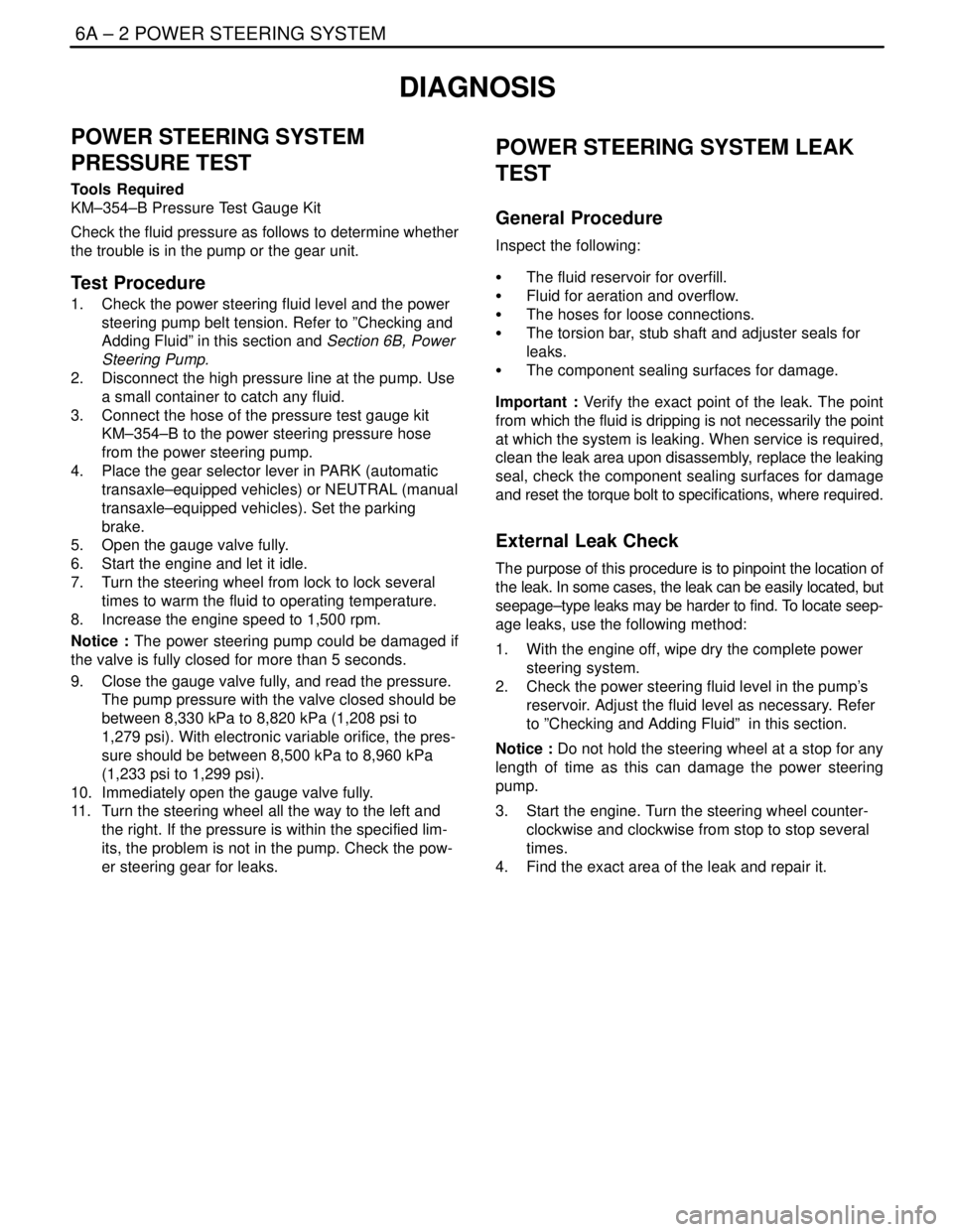

PRESSURE PLATE AND CLUTCH

DISC

Removal Procedure

1. Disconnect the negative battery cable.

2. Remove the transaxle from the vehicle. Refer to

Section 5B, Five–Speed Manual Transaxle.

3. Remove the pressure plate bolts and the pressure

plate.

Important : Support the pressure plate when you remove

the last bolt.

Page 1901 of 2643

5C – 14ICLUTCH

DAEWOO V–121 BL4

GENERAL DESCRIPTION

AND SYSTEM OPERATION

DRIVING MEMBERS

The driving members consist of two flat surfaces ma-

chined to a smooth finish. One of these is the rear face of

the engine flywheel and the other is the pressure plate.

The pressure plate is fitted into a steel cover which is

bolted the flywheel.

DRIVEN MEMBERS

The driven member is the clutch disc with a splined hub.The splined hub is free to slide lengthwise along the

splines of the input shaft and drives the input shaft through

these same splines.

The driving and driven members are held in contact by

spring pressure. This pressure is exerted by a diaphragm

spring in the pressure plate assembly.

OPERATING MEMBERS

The clutch release system consists of the clutch pedal, the

clutch master cylinder, and concentric slave cylinder.

Unlike the former system to release the clutch by the re-

lease lever and release fork, the concentric slave cylinder

type makes the concentric slave cylinder directly perform

the clutch release by the generated pressure through the

clutch pedal operation.

Page 1903 of 2643

6A – 2IPOWER STEERING SYSTEM

DAEWOO V–121 BL4

DIAGNOSIS

POWER STEERING SYSTEM

PRESSURE TEST

Tools Required

KM–354–B Pressure Test Gauge Kit

Check the fluid pressure as follows to determine whether

the trouble is in the pump or the gear unit.

Test Procedure

1. Check the power steering fluid level and the power

steering pump belt tension. Refer to ”Checking and

Adding Fluid” in this section and Section 6B, Power

Steering Pump.

2. Disconnect the high pressure line at the pump. Use

a small container to catch any fluid.

3. Connect the hose of the pressure test gauge kit

KM–354–B to the power steering pressure hose

from the power steering pump.

4. Place the gear selector lever in PARK (automatic

transaxle–equipped vehicles) or NEUTRAL (manual

transaxle–equipped vehicles). Set the parking

brake.

5. Open the gauge valve fully.

6. Start the engine and let it idle.

7. Turn the steering wheel from lock to lock several

times to warm the fluid to operating temperature.

8. Increase the engine speed to 1,500 rpm.

Notice : The power steering pump could be damaged if

the valve is fully closed for more than 5 seconds.

9. Close the gauge valve fully, and read the pressure.

The pump pressure with the valve closed should be

between 8,330 kPa to 8,820 kPa (1,208 psi to

1,279 psi). With electronic variable orifice, the pres-

sure should be between 8,500 kPa to 8,960 kPa

(1,233 psi to 1,299 psi).

10. Immediately open the gauge valve fully.

11. Turn the steering wheel all the way to the left and

the right. If the pressure is within the specified lim-

its, the problem is not in the pump. Check the pow-

er steering gear for leaks.

POWER STEERING SYSTEM LEAK

TEST

General Procedure

Inspect the following:

S The fluid reservoir for overfill.

S Fluid for aeration and overflow.

S The hoses for loose connections.

S The torsion bar, stub shaft and adjuster seals for

leaks.

S The component sealing surfaces for damage.

Important : Verify the exact point of the leak. The point

from which the fluid is dripping is not necessarily the point

at which the system is leaking. When service is required,

clean the leak area upon disassembly, replace the leaking

seal, check the component sealing surfaces for damage

and reset the torque bolt to specifications, where required.

External Leak Check

The purpose of this procedure is to pinpoint the location of

the leak. In some cases, the leak can be easily located, but

seepage–type leaks may be harder to find. To locate seep-

age leaks, use the following method:

1. With the engine off, wipe dry the complete power

steering system.

2. Check the power steering fluid level in the pump’s

reservoir. Adjust the fluid level as necessary. Refer

to ”Checking and Adding Fluid” in this section.

Notice : Do not hold the steering wheel at a stop for any

length of time as this can damage the power steering

pump.

3. Start the engine. Turn the steering wheel counter-

clockwise and clockwise from stop to stop several

times.

4. Find the exact area of the leak and repair it.

Page 1904 of 2643

POWER STEERING SYSTEM 6A – 3

DAEWOO V–121 BL4

MAINTENANCE AND REPAIR

ON–VEHICLE SERVICE

BLEEDING THE POWER STEERING

SYSTEM

If the power steering hydraulic system has been serviced,

an accurate fluid level reading cannot be obtained until the

air is bled from the system. Follow these steps to bleed the

air from the system.

1. Turn the wheels all the way to the left and add the

power steering fluid to the MIN mark on the fluid

level indicator.

Notice : When adding fluid or making a complete fluid

change, always use DEXRON®–II or III power steering

fluid. Failure to use the proper fluid will cause hose and

seal damage and fluid leaks.

2. Start the engine. With the engine running at fast

idle, recheck the fluid level. If necessary, add fluid

to bring the level up to the MIN mark.

3. Bleed the system by turning the wheels from side to

side without reaching the stop at either end. Keep

the fluid level at the MIN mark. The air must be

eliminated from the fluid before normal steering ac-

tion can be obtained.

4. Return the wheels to the center position. Continue

running the engine for 2 to 3 minutes.

5. Road test the car to be sure the steering functions

normally and is free from noise.

6. Recheck the fluid level as described in steps 1 and

2. Make sure the fluid level is at the MAX mark af-

ter the system has stabilized at its normal operating

temperature. Add fluid as needed.

CHECKING AND ADDING FLUID

Notice : When adding fluid or making a complete fluid

change, always use DEXRON®–II or III power steering

fluid. Failure to use the proper fluid will cause hose and

seal damage and fluid leaks.

1. The power steering fluid level is indicated either by

marks on a see–through fluid reservoir or by marks

on a fluid level indicator on the fluid reservoir cap.

2. If the fluid is warmed up to 66°C (150°F), the fluid

level should be between the MAX and MIN marks.

Add fluid as needed.

3. If the fluid is cool, 21°C (70°F), the fluid level

should be at the MIN mark. Add fluid as needed.

Page 1917 of 2643

6B – 8IPOWER STEERING PUMP

DAEWOO V–121 BL4

GENERAL DESCRIPTION

AND SYSTEM OPERATION

POWER STEERING PUMP

The power steering pump is a multivaned hydraulic pump.

The serpentine accessory drive belt on the engine drives

the power steering pump.The power steering pump provides the hydraulic pressure

to the power steering gear.

The power steering gear uses the hydraulic pressure to

assist in steering the vehicle.

The power steering system uses a remote reservoir in or-

der to make available more space in the engine compart-

ment.

Page 1919 of 2643

6C – 2IPOWER STEERING GEAR

DAEWOO V–121 BL4

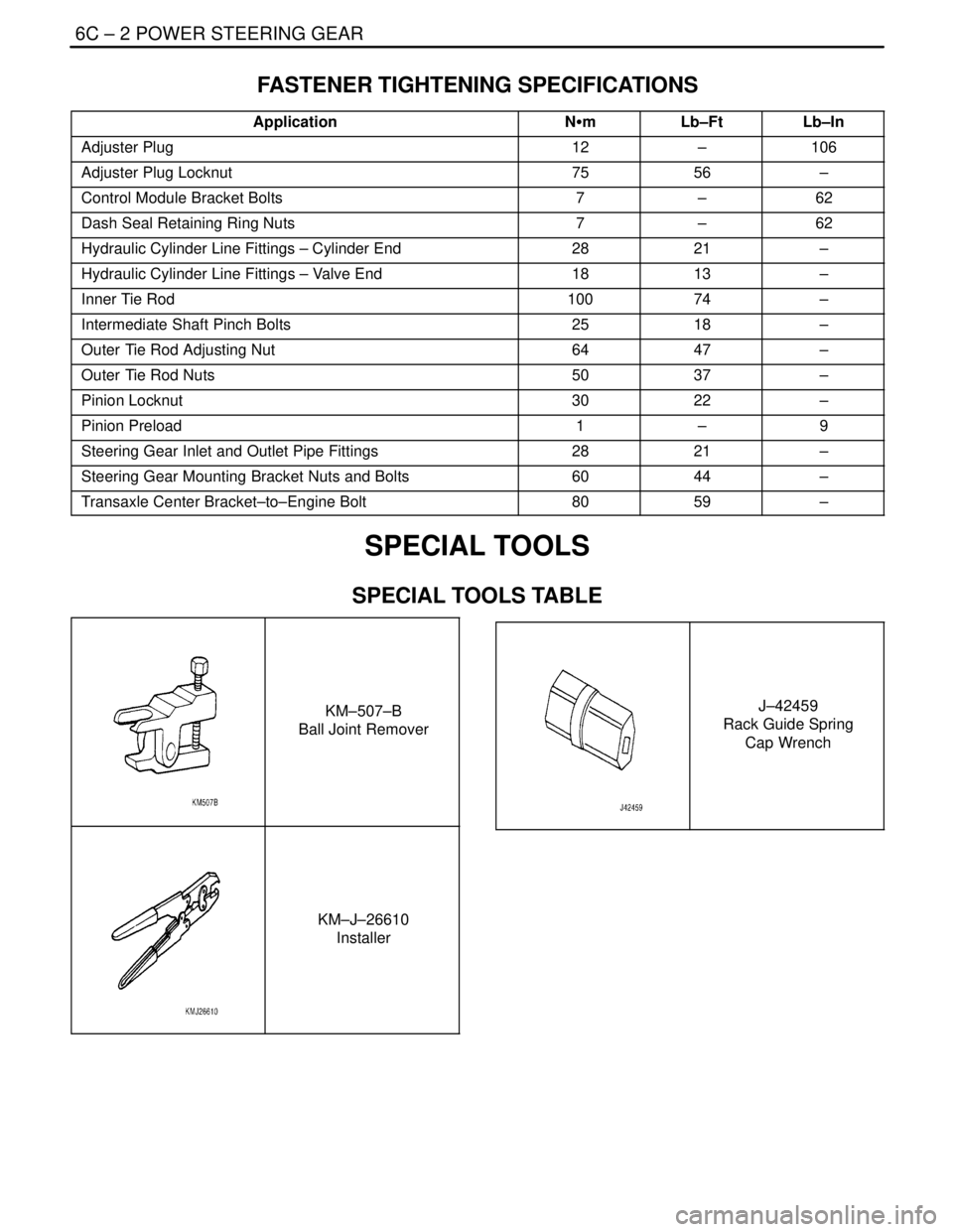

FASTENER TIGHTENING SPECIFICATIONS

ApplicationNSmLb–FtLb–In

Adjuster Plug12–106

Adjuster Plug Locknut7556–

Control Module Bracket Bolts7–62

Dash Seal Retaining Ring Nuts7–62

Hydraulic Cylinder Line Fittings – Cylinder End2821–

Hydraulic Cylinder Line Fittings – Valve End1813–

Inner Tie Rod10074–

Intermediate Shaft Pinch Bolts2518–

Outer Tie Rod Adjusting Nut6447–

Outer Tie Rod Nuts5037–

Pinion Locknut3022–

Pinion Preload1–9

Steering Gear Inlet and Outlet Pipe Fittings2821–

Steering Gear Mounting Bracket Nuts and Bolts6044–

Transaxle Center Bracket–to–Engine Bolt8059–

SPECIAL TOOLS

SPECIAL TOOLS TABLE

KM–507–B

Ball Joint Remover

KM–J–26610

Installer

J–42459

Rack Guide Spring

Cap Wrench