clock DAEWOO NUBIRA 2004 Service User Guide

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: NUBIRA, Model: DAEWOO NUBIRA 2004Pages: 2643, PDF Size: 80.54 MB

Page 158 of 2643

1C2 – 38I1.8L DOHC ENGINE MECHANICAL

DAEWOO V–121 BL4

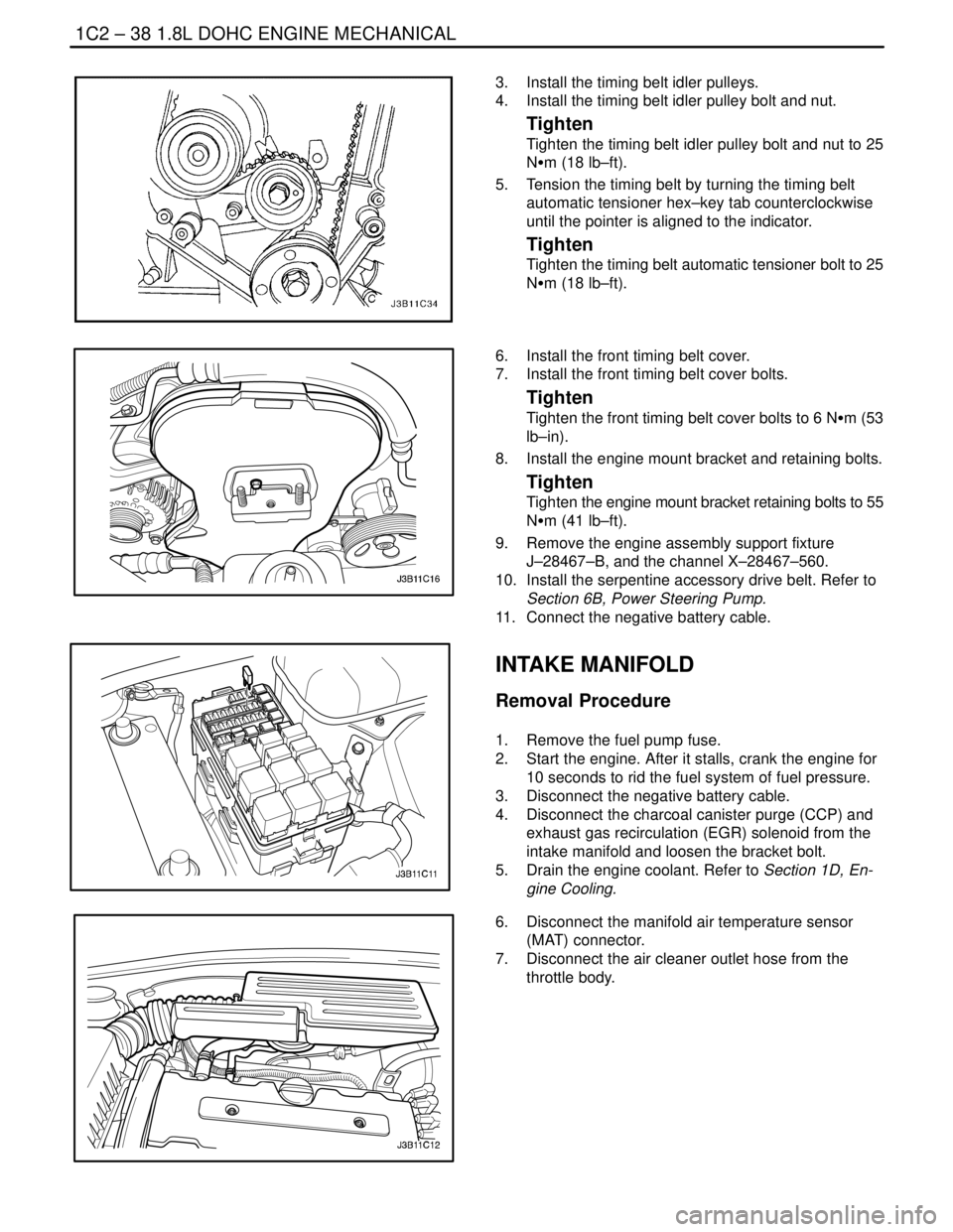

3. Install the timing belt idler pulleys.

4. Install the timing belt idler pulley bolt and nut.

Tighten

Tighten the timing belt idler pulley bolt and nut to 25

NSm (18 lb–ft).

5. Tension the timing belt by turning the timing belt

automatic tensioner hex–key tab counterclockwise

until the pointer is aligned to the indicator.

Tighten

Tighten the timing belt automatic tensioner bolt to 25

NSm (18 lb–ft).

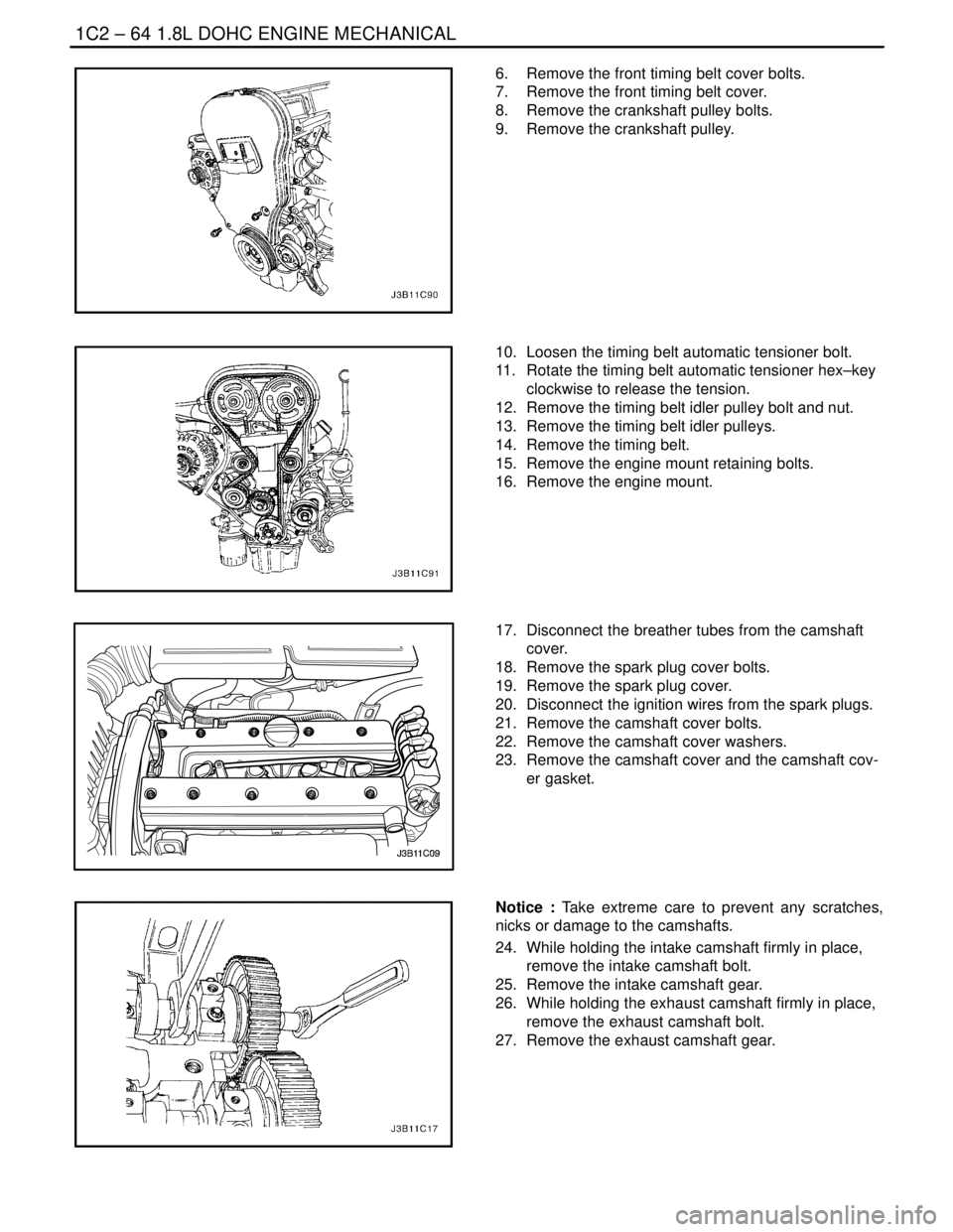

6. Install the front timing belt cover.

7. Install the front timing belt cover bolts.

Tighten

Tighten the front timing belt cover bolts to 6 NSm (53

lb–in).

8. Install the engine mount bracket and retaining bolts.

Tighten

Tighten the engine mount bracket retaining bolts to 55

NSm (41 lb–ft).

9. Remove the engine assembly support fixture

J–28467–B, and the channel X–28467–560.

10. Install the serpentine accessory drive belt. Refer to

Section 6B, Power Steering Pump.

11. Connect the negative battery cable.

INTAKE MANIFOLD

Removal Procedure

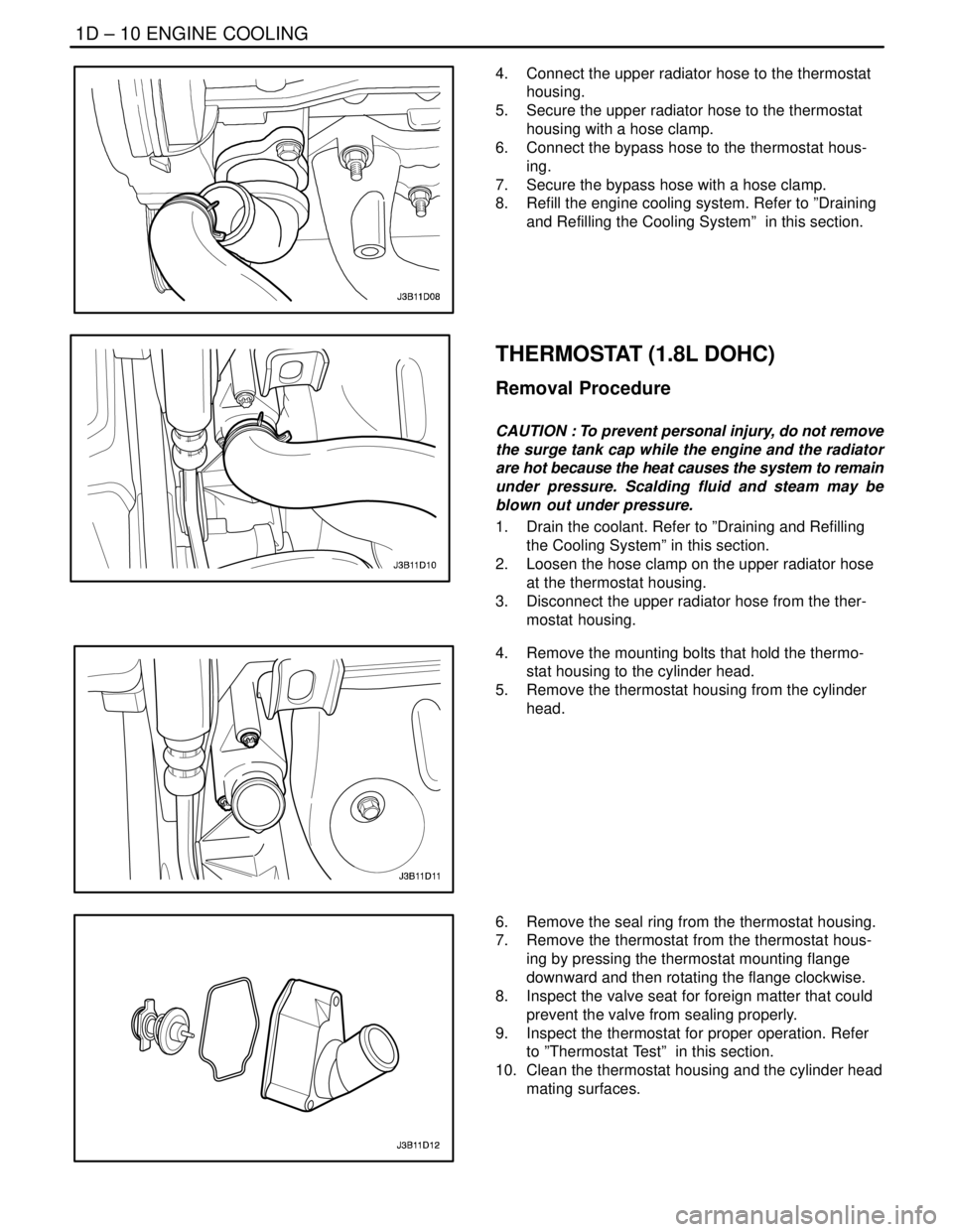

1. Remove the fuel pump fuse.

2. Start the engine. After it stalls, crank the engine for

10 seconds to rid the fuel system of fuel pressure.

3. Disconnect the negative battery cable.

4. Disconnect the charcoal canister purge (CCP) and

exhaust gas recirculation (EGR) solenoid from the

intake manifold and loosen the bracket bolt.

5. Drain the engine coolant. Refer to Section 1D, En-

gine Cooling.

6. Disconnect the manifold air temperature sensor

(MAT) connector.

7. Disconnect the air cleaner outlet hose from the

throttle body.

Page 184 of 2643

1C2 – 64I1.8L DOHC ENGINE MECHANICAL

DAEWOO V–121 BL4

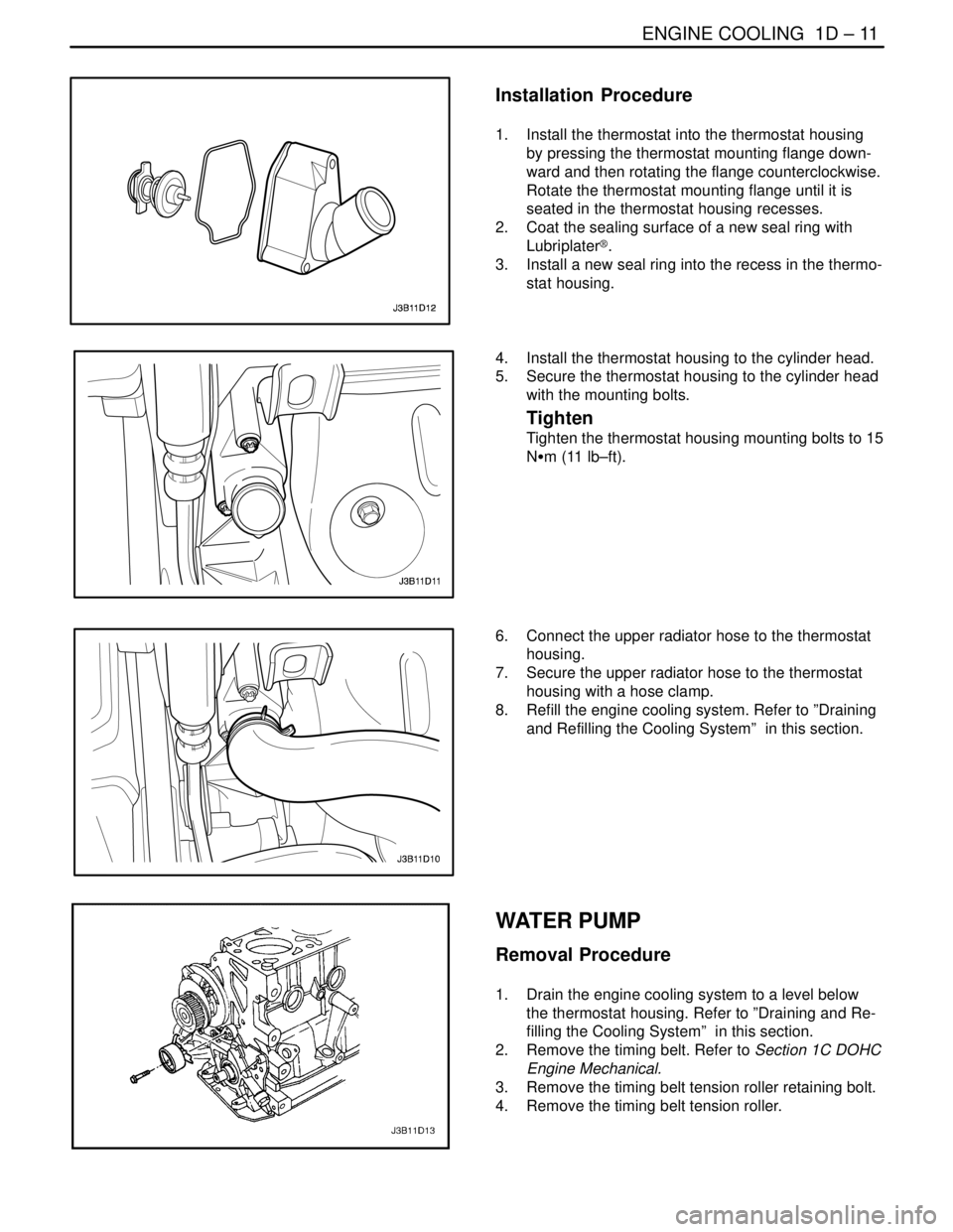

6. Remove the front timing belt cover bolts.

7. Remove the front timing belt cover.

8. Remove the crankshaft pulley bolts.

9. Remove the crankshaft pulley.

10. Loosen the timing belt automatic tensioner bolt.

11. Rotate the timing belt automatic tensioner hex–key

clockwise to release the tension.

12. Remove the timing belt idler pulley bolt and nut.

13. Remove the timing belt idler pulleys.

14. Remove the timing belt.

15. Remove the engine mount retaining bolts.

16. Remove the engine mount.

17. Disconnect the breather tubes from the camshaft

cover.

18. Remove the spark plug cover bolts.

19. Remove the spark plug cover.

20. Disconnect the ignition wires from the spark plugs.

21. Remove the camshaft cover bolts.

22. Remove the camshaft cover washers.

23. Remove the camshaft cover and the camshaft cov-

er gasket.

Notice : Take extreme care to prevent any scratches,

nicks or damage to the camshafts.

24. While holding the intake camshaft firmly in place,

remove the intake camshaft bolt.

25. Remove the intake camshaft gear.

26. While holding the exhaust camshaft firmly in place,

remove the exhaust camshaft bolt.

27. Remove the exhaust camshaft gear.

Page 205 of 2643

1D – 10IENGINE COOLING

DAEWOO V–121 BL4

4. Connect the upper radiator hose to the thermostat

housing.

5. Secure the upper radiator hose to the thermostat

housing with a hose clamp.

6. Connect the bypass hose to the thermostat hous-

ing.

7. Secure the bypass hose with a hose clamp.

8. Refill the engine cooling system. Refer to ”Draining

and Refilling the Cooling System” in this section.

THERMOSTAT (1.8L DOHC)

Removal Procedure

CAUTION : To prevent personal injury, do not remove

the surge tank cap while the engine and the radiator

are hot because the heat causes the system to remain

under pressure. Scalding fluid and steam may be

blown out under pressure.

1. Drain the coolant. Refer to ”Draining and Refilling

the Cooling System” in this section.

2. Loosen the hose clamp on the upper radiator hose

at the thermostat housing.

3. Disconnect the upper radiator hose from the ther-

mostat housing.

4. Remove the mounting bolts that hold the thermo-

stat housing to the cylinder head.

5. Remove the thermostat housing from the cylinder

head.

6. Remove the seal ring from the thermostat housing.

7. Remove the thermostat from the thermostat hous-

ing by pressing the thermostat mounting flange

downward and then rotating the flange clockwise.

8. Inspect the valve seat for foreign matter that could

prevent the valve from sealing properly.

9. Inspect the thermostat for proper operation. Refer

to ”Thermostat Test” in this section.

10. Clean the thermostat housing and the cylinder head

mating surfaces.

Page 206 of 2643

ENGINE COOLING 1D – 11

DAEWOO V–121 BL4

Installation Procedure

1. Install the thermostat into the thermostat housing

by pressing the thermostat mounting flange down-

ward and then rotating the flange counterclockwise.

Rotate the thermostat mounting flange until it is

seated in the thermostat housing recesses.

2. Coat the sealing surface of a new seal ring with

Lubriplater®.

3. Install a new seal ring into the recess in the thermo-

stat housing.

4. Install the thermostat housing to the cylinder head.

5. Secure the thermostat housing to the cylinder head

with the mounting bolts.

Tighten

Tighten the thermostat housing mounting bolts to 15

NSm (11 lb–ft).

6. Connect the upper radiator hose to the thermostat

housing.

7. Secure the upper radiator hose to the thermostat

housing with a hose clamp.

8. Refill the engine cooling system. Refer to ”Draining

and Refilling the Cooling System” in this section.

WATER PUMP

Removal Procedure

1. Drain the engine cooling system to a level below

the thermostat housing. Refer to ”Draining and Re-

filling the Cooling System” in this section.

2. Remove the timing belt. Refer to Section 1C DOHC

Engine Mechanical.

3. Remove the timing belt tension roller retaining bolt.

4. Remove the timing belt tension roller.

Page 225 of 2643

ENGINE ELECTRICAL 1E – 11

DAEWOO V–121 BL4

MAINTENANCE AND REPAIR

ON–VEHICLE SERVICE

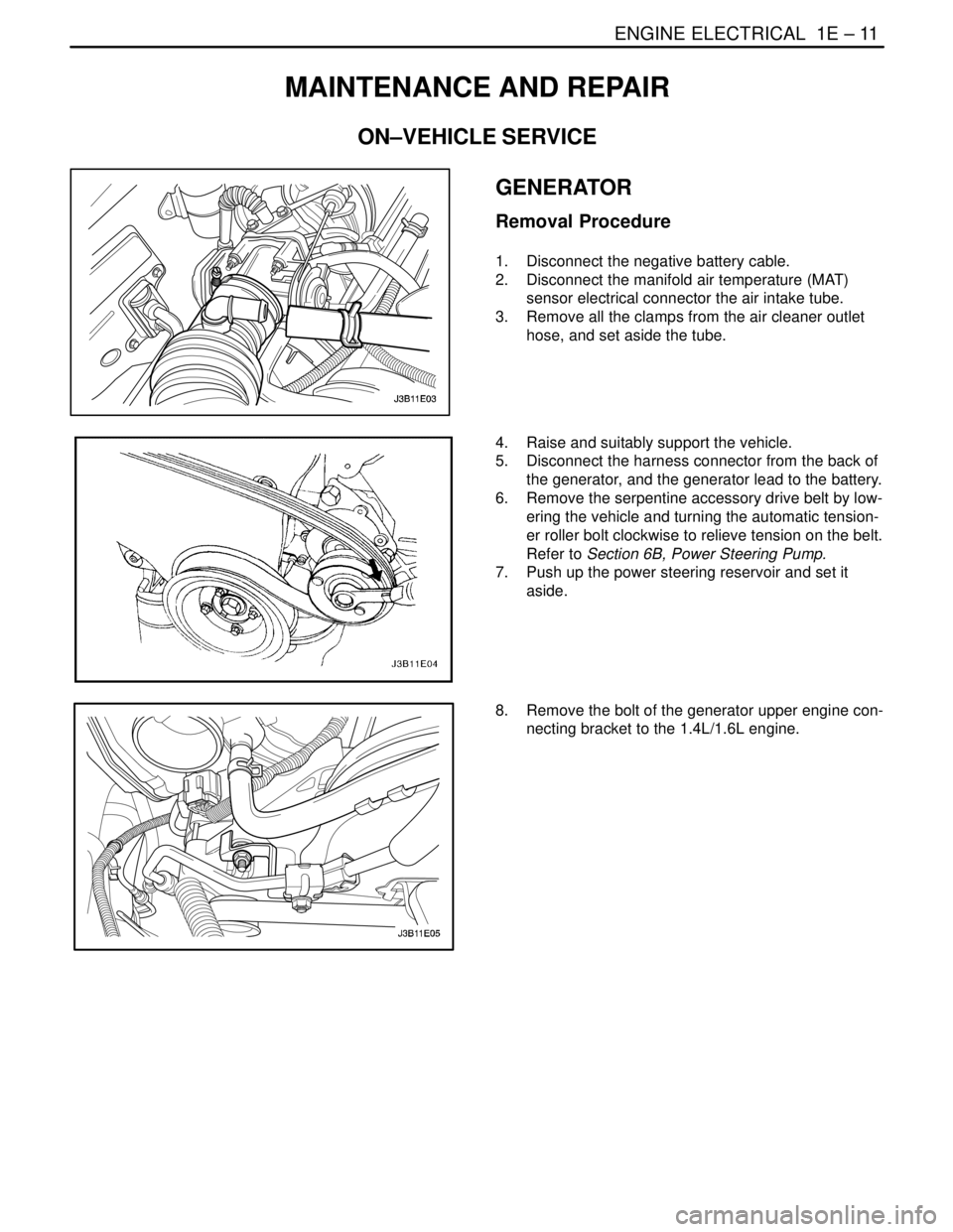

GENERATOR

Removal Procedure

1. Disconnect the negative battery cable.

2. Disconnect the manifold air temperature (MAT)

sensor electrical connector the air intake tube.

3. Remove all the clamps from the air cleaner outlet

hose, and set aside the tube.

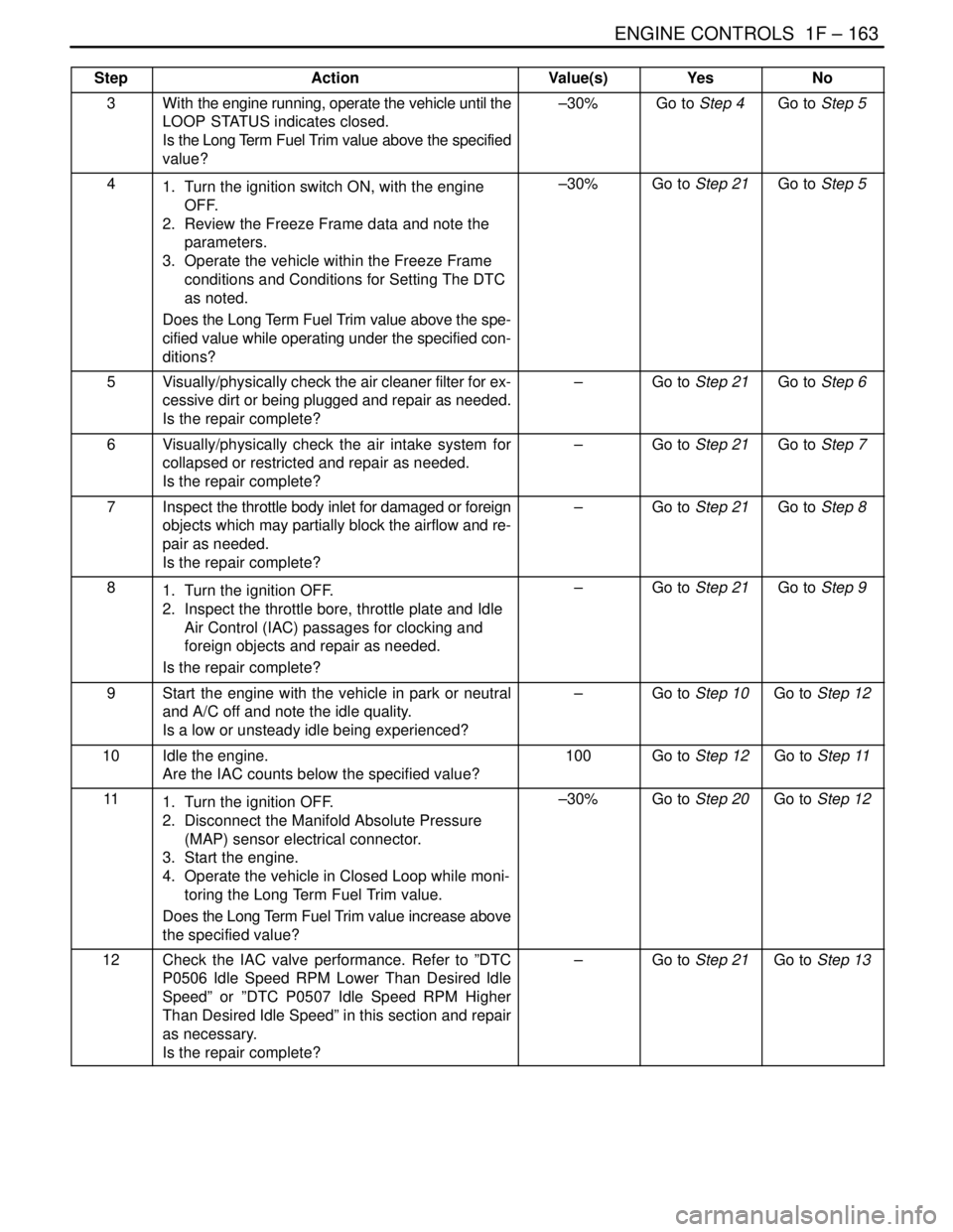

4. Raise and suitably support the vehicle.

5. Disconnect the harness connector from the back of

the generator, and the generator lead to the battery.

6. Remove the serpentine accessory drive belt by low-

ering the vehicle and turning the automatic tension-

er roller bolt clockwise to relieve tension on the belt.

Refer to Section 6B, Power Steering Pump.

7. Push up the power steering reservoir and set it

aside.

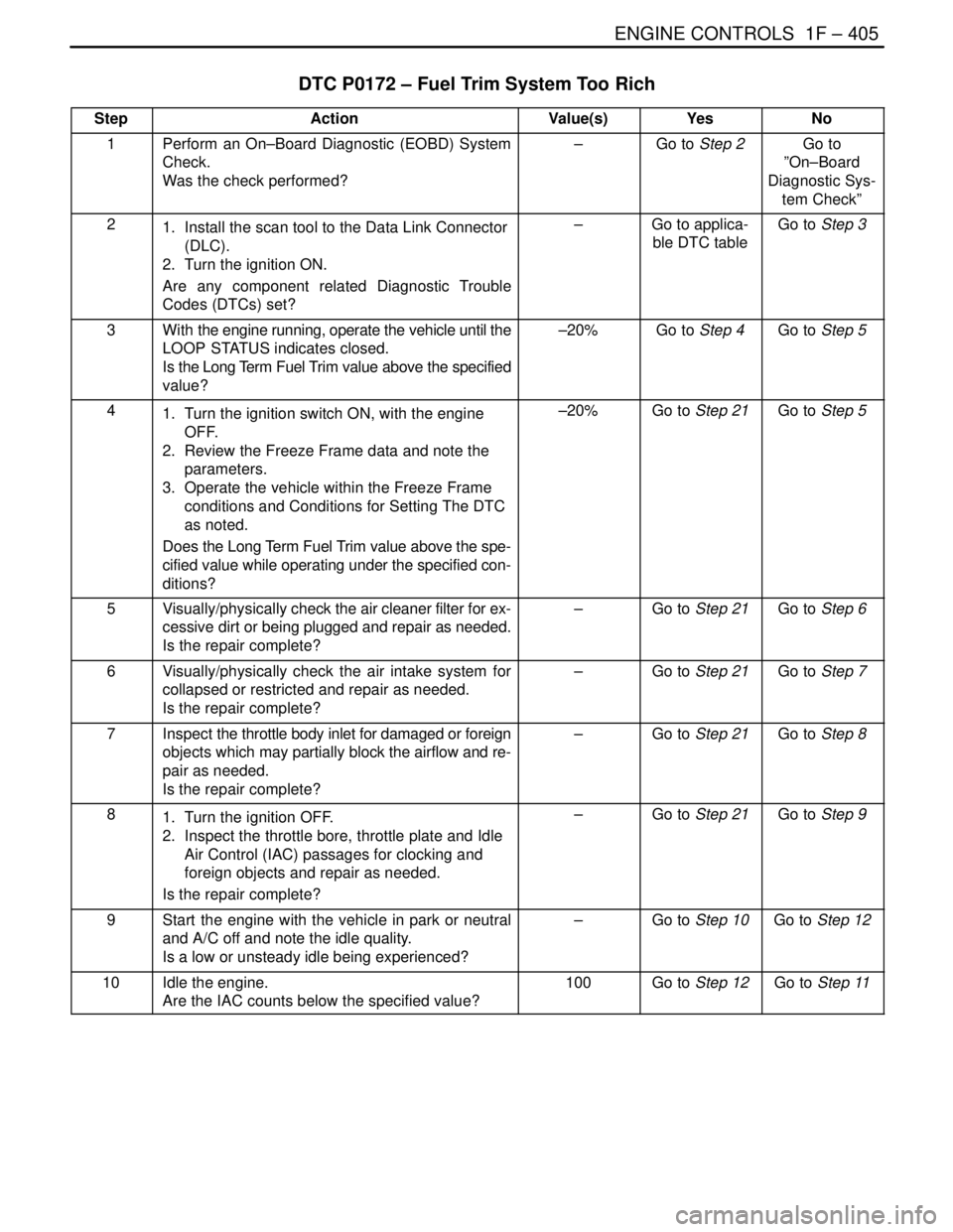

8. Remove the bolt of the generator upper engine con-

necting bracket to the 1.4L/1.6L engine.

Page 409 of 2643

ENGINE CONTROLS 1F – 163

DAEWOO V–121 BL4

StepNo Yes Value(s) Action

3With the engine running, operate the vehicle until the

LOOP STATUS indicates closed.

Is the Long Term Fuel Trim value above the specified

value?–30%Go to Step 4Go to Step 5

41. Turn the ignition switch ON, with the engine

OFF.

2. Review the Freeze Frame data and note the

parameters.

3. Operate the vehicle within the Freeze Frame

conditions and Conditions for Setting The DTC

as noted.

Does the Long Term Fuel Trim value above the spe-

cified value while operating under the specified con-

ditions?–30%Go to Step 21Go to Step 5

5Visually/physically check the air cleaner filter for ex-

cessive dirt or being plugged and repair as needed.

Is the repair complete?–Go to Step 21Go to Step 6

6Visually/physically check the air intake system for

collapsed or restricted and repair as needed.

Is the repair complete?–Go to Step 21Go to Step 7

7Inspect the throttle body inlet for damaged or foreign

objects which may partially block the airflow and re-

pair as needed.

Is the repair complete?–Go to Step 21Go to Step 8

81. Turn the ignition OFF.

2. Inspect the throttle bore, throttle plate and Idle

Air Control (IAC) passages for clocking and

foreign objects and repair as needed.

Is the repair complete?–Go to Step 21Go to Step 9

9Start the engine with the vehicle in park or neutral

and A/C off and note the idle quality.

Is a low or unsteady idle being experienced?–Go to Step 10Go to Step 12

10Idle the engine.

Are the IAC counts below the specified value?100Go to Step 12Go to Step 11

111. Turn the ignition OFF.

2. Disconnect the Manifold Absolute Pressure

(MAP) sensor electrical connector.

3. Start the engine.

4. Operate the vehicle in Closed Loop while moni-

toring the Long Term Fuel Trim value.

Does the Long Term Fuel Trim value increase above

the specified value?–30%Go to Step 20Go to Step 12

12Check the IAC valve performance. Refer to ”DTC

P0506 Idle Speed RPM Lower Than Desired Idle

Speed” or ”DTC P0507 Idle Speed RPM Higher

Than Desired Idle Speed” in this section and repair

as necessary.

Is the repair complete?–Go to Step 21Go to Step 13

Page 651 of 2643

ENGINE CONTROLS 1F – 405

DAEWOO V–121 BL4

DTC P0172 – Fuel Trim System Too Rich

StepActionValue(s)YesNo

1Perform an On–Board Diagnostic (EOBD) System

Check.

Was the check performed?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Install the scan tool to the Data Link Connector

(DLC).

2. Turn the ignition ON.

Are any component related Diagnostic Trouble

Codes (DTCs) set?–Go to applica-

ble DTC tableGo to Step 3

3With the engine running, operate the vehicle until the

LOOP STATUS indicates closed.

Is the Long Term Fuel Trim value above the specified

value?–20%Go to Step 4Go to Step 5

41. Turn the ignition switch ON, with the engine

OFF.

2. Review the Freeze Frame data and note the

parameters.

3. Operate the vehicle within the Freeze Frame

conditions and Conditions for Setting The DTC

as noted.

Does the Long Term Fuel Trim value above the spe-

cified value while operating under the specified con-

ditions?–20%Go to Step 21Go to Step 5

5Visually/physically check the air cleaner filter for ex-

cessive dirt or being plugged and repair as needed.

Is the repair complete?–Go to Step 21Go to Step 6

6Visually/physically check the air intake system for

collapsed or restricted and repair as needed.

Is the repair complete?–Go to Step 21Go to Step 7

7Inspect the throttle body inlet for damaged or foreign

objects which may partially block the airflow and re-

pair as needed.

Is the repair complete?–Go to Step 21Go to Step 8

81. Turn the ignition OFF.

2. Inspect the throttle bore, throttle plate and Idle

Air Control (IAC) passages for clocking and

foreign objects and repair as needed.

Is the repair complete?–Go to Step 21Go to Step 9

9Start the engine with the vehicle in park or neutral

and A/C off and note the idle quality.

Is a low or unsteady idle being experienced?–Go to Step 10Go to Step 12

10Idle the engine.

Are the IAC counts below the specified value?100Go to Step 12Go to Step 11

Page 843 of 2643

ENGINE CONTROLS 1F – 597

DAEWOO V–121 BL4

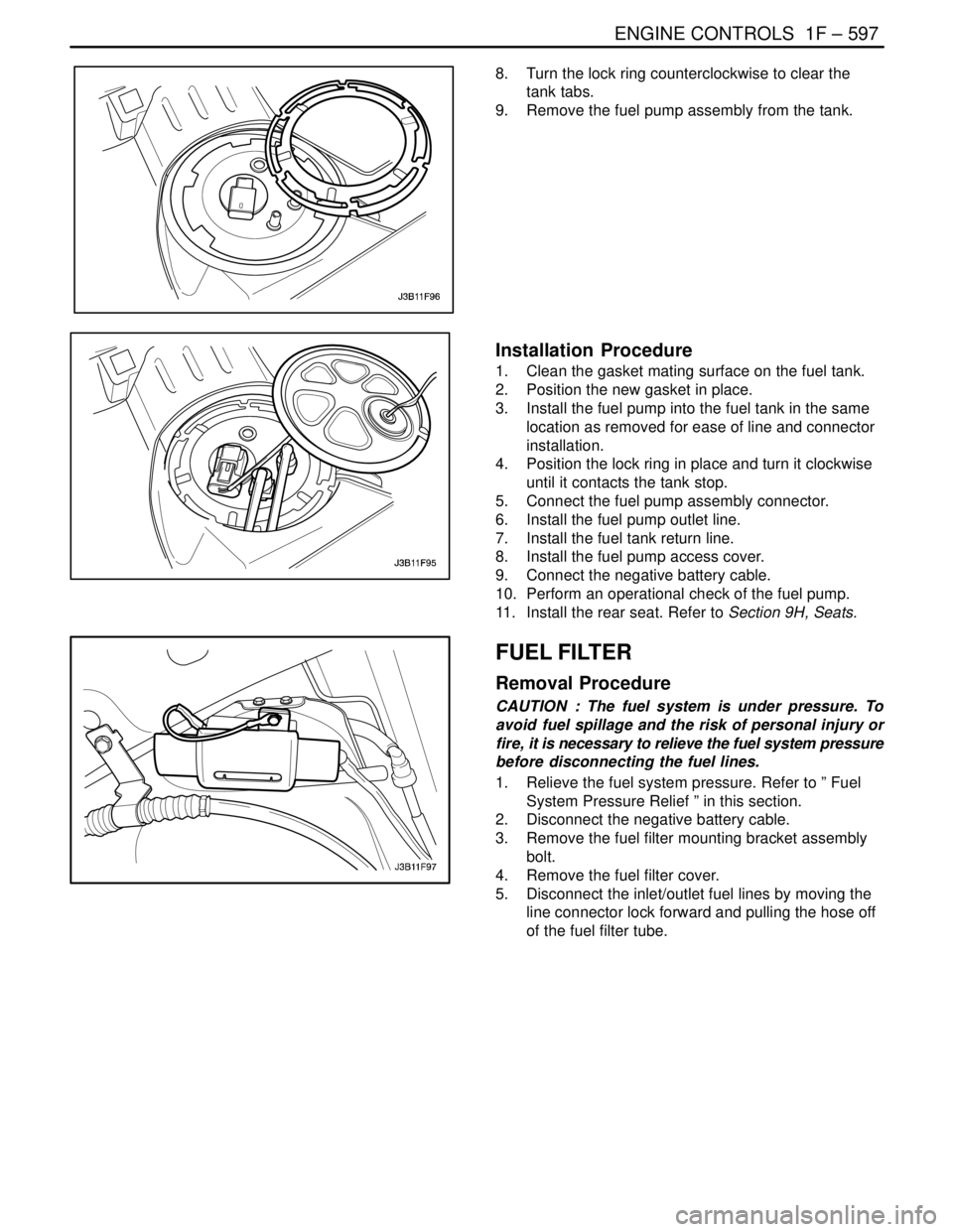

8. Turn the lock ring counterclockwise to clear the

tank tabs.

9. Remove the fuel pump assembly from the tank.

Installation Procedure

1. Clean the gasket mating surface on the fuel tank.

2. Position the new gasket in place.

3. Install the fuel pump into the fuel tank in the same

location as removed for ease of line and connector

installation.

4. Position the lock ring in place and turn it clockwise

until it contacts the tank stop.

5. Connect the fuel pump assembly connector.

6. Install the fuel pump outlet line.

7. Install the fuel tank return line.

8. Install the fuel pump access cover.

9. Connect the negative battery cable.

10. Perform an operational check of the fuel pump.

11. Install the rear seat. Refer to Section 9H, Seats.

FUEL FILTER

Removal Procedure

CAUTION : The fuel system is under pressure. To

avoid fuel spillage and the risk of personal injury or

fire, it is necessary to relieve the fuel system pressure

before disconnecting the fuel lines.

1. Relieve the fuel system pressure. Refer to ” Fuel

System Pressure Relief ” in this section.

2. Disconnect the negative battery cable.

3. Remove the fuel filter mounting bracket assembly

bolt.

4. Remove the fuel filter cover.

5. Disconnect the inlet/outlet fuel lines by moving the

line connector lock forward and pulling the hose off

of the fuel filter tube.

Page 1015 of 2643

USAGE AND CAPACITY OF FUSES IN FUSE BLOCKW4–3

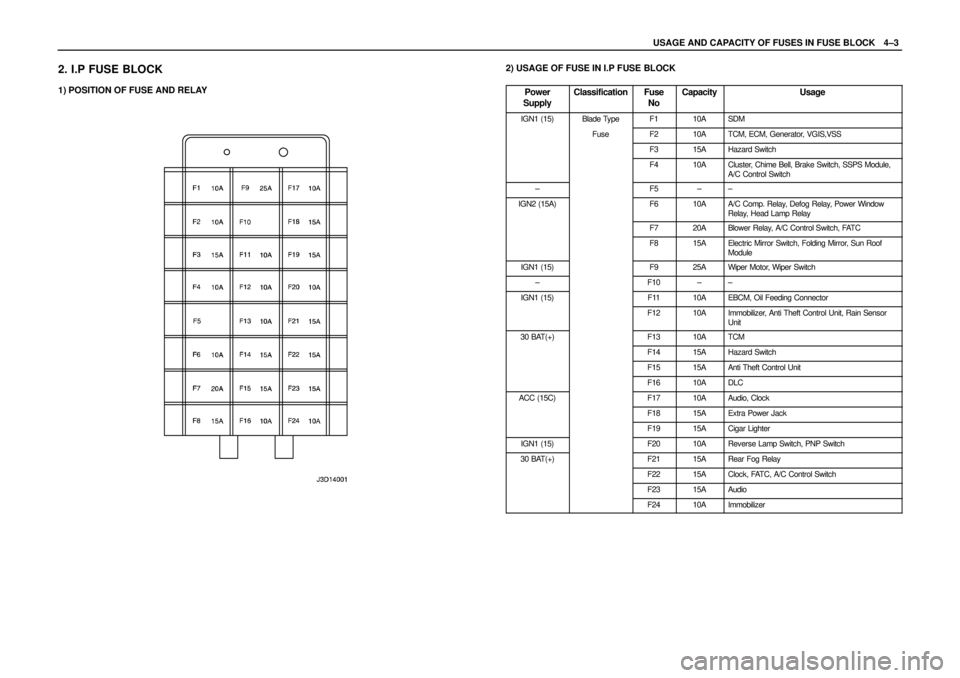

2. I.P FUSE BLOCK

1) POSITION OF FUSE AND RELAY

2) USAGE OF FUSE IN I.P FUSE BLOCK

Power

Supply

ClassificationFuse

NoCapacityUsage

IGN1 (15)Blade TypeF110ASDM

FuseF210ATCM, ECM, Generator, VGIS,VSS

F315AHazard Switch

F410ACluster, Chime Bell, Brake Switch, SSPS Module,

A/C Control Switch

–F5––

IGN2 (15A)F610AA/C Comp. Relay, Defog Relay, Power Window

Relay, Head Lamp Relay

F720ABlower Relay, A/C Control Switch, FATC

F815AElectric Mirror Switch, Folding Mirror, Sun Roof

Module

IGN1 (15)F925AWiper Motor, Wiper Switch

–F10––

IGN1 (15)F1110AEBCM, Oil Feeding Connector

F1210AImmobilizer, Anti Theft Control Unit, Rain Sensor

Unit

30 BAT(+)F1310ATCM

F1415AHazard Switch

F1515AAnti Theft Control Unit

F1610ADLC

ACC (15C)F1710AAudio, Clock

F1815AExtra Power Jack

F1915ACigar Lighter

IGN1 (15)F2010AReverse Lamp Switch, PNP Switch

30 BAT(+)F2115ARear Fog Relay

F2215AClock, FATC, A/C Control Switch

F2315AAudio

F2410AImmobilizer

Page 1155 of 2643

PARKING BRAKE 4G – 3

DAEWOO V–121 BL4

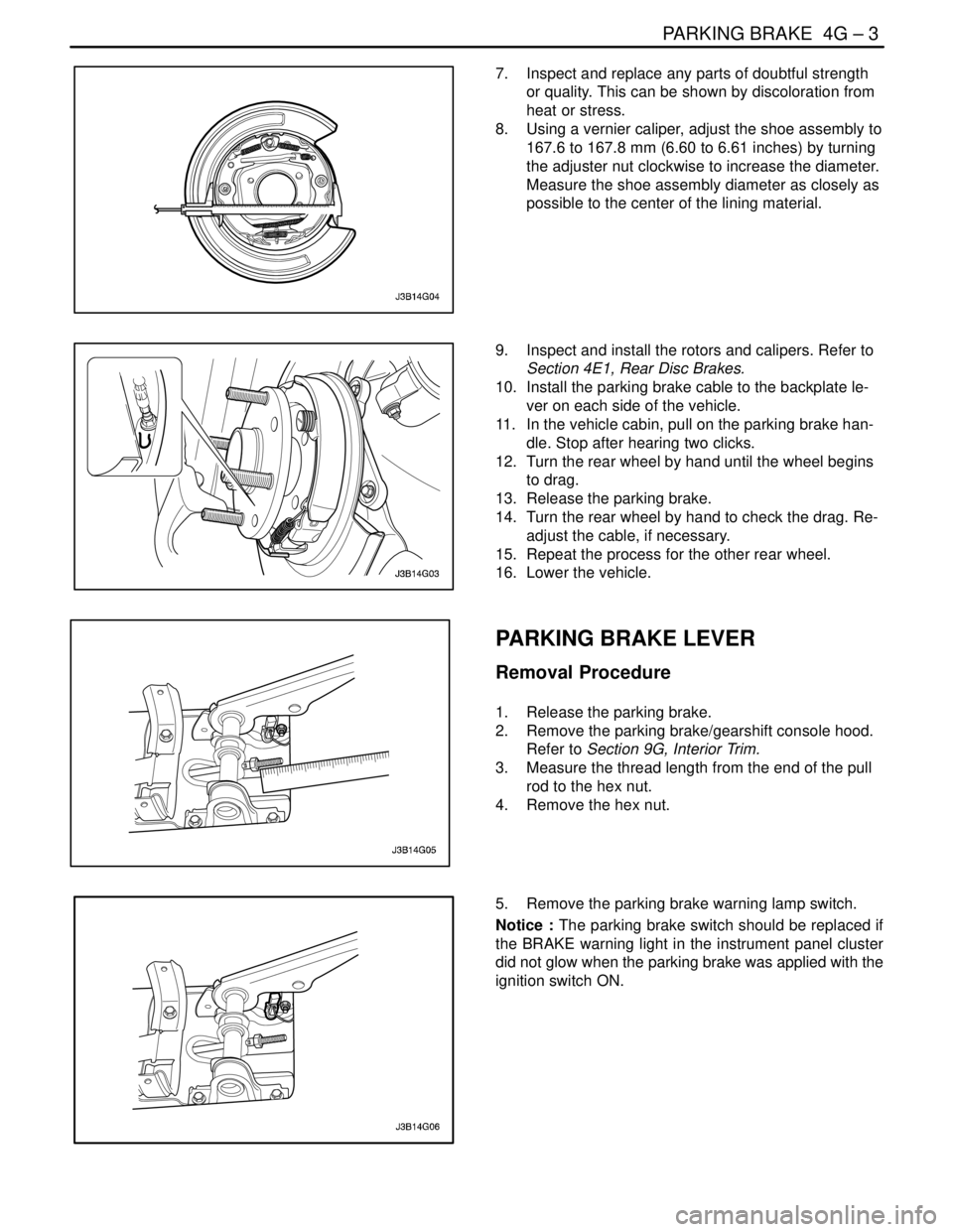

7. Inspect and replace any parts of doubtful strength

or quality. This can be shown by discoloration from

heat or stress.

8. Using a vernier caliper, adjust the shoe assembly to

167.6 to 167.8 mm (6.60 to 6.61 inches) by turning

the adjuster nut clockwise to increase the diameter.

Measure the shoe assembly diameter as closely as

possible to the center of the lining material.

9. Inspect and install the rotors and calipers. Refer to

Section 4E1, Rear Disc Brakes.

10. Install the parking brake cable to the backplate le-

ver on each side of the vehicle.

11. In the vehicle cabin, pull on the parking brake han-

dle. Stop after hearing two clicks.

12. Turn the rear wheel by hand until the wheel begins

to drag.

13. Release the parking brake.

14. Turn the rear wheel by hand to check the drag. Re-

adjust the cable, if necessary.

15. Repeat the process for the other rear wheel.

16. Lower the vehicle.

PARKING BRAKE LEVER

Removal Procedure

1. Release the parking brake.

2. Remove the parking brake/gearshift console hood.

Refer to Section 9G, Interior Trim.

3. Measure the thread length from the end of the pull

rod to the hex nut.

4. Remove the hex nut.

5. Remove the parking brake warning lamp switch.

Notice : The parking brake switch should be replaced if

the BRAKE warning light in the instrument panel cluster

did not glow when the parking brake was applied with the

ignition switch ON.