clock DAEWOO NUBIRA 2004 Service Workshop Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: NUBIRA, Model: DAEWOO NUBIRA 2004Pages: 2643, PDF Size: 80.54 MB

Page 1913 of 2643

6B – 4IPOWER STEERING PUMP

DAEWOO V–121 BL4

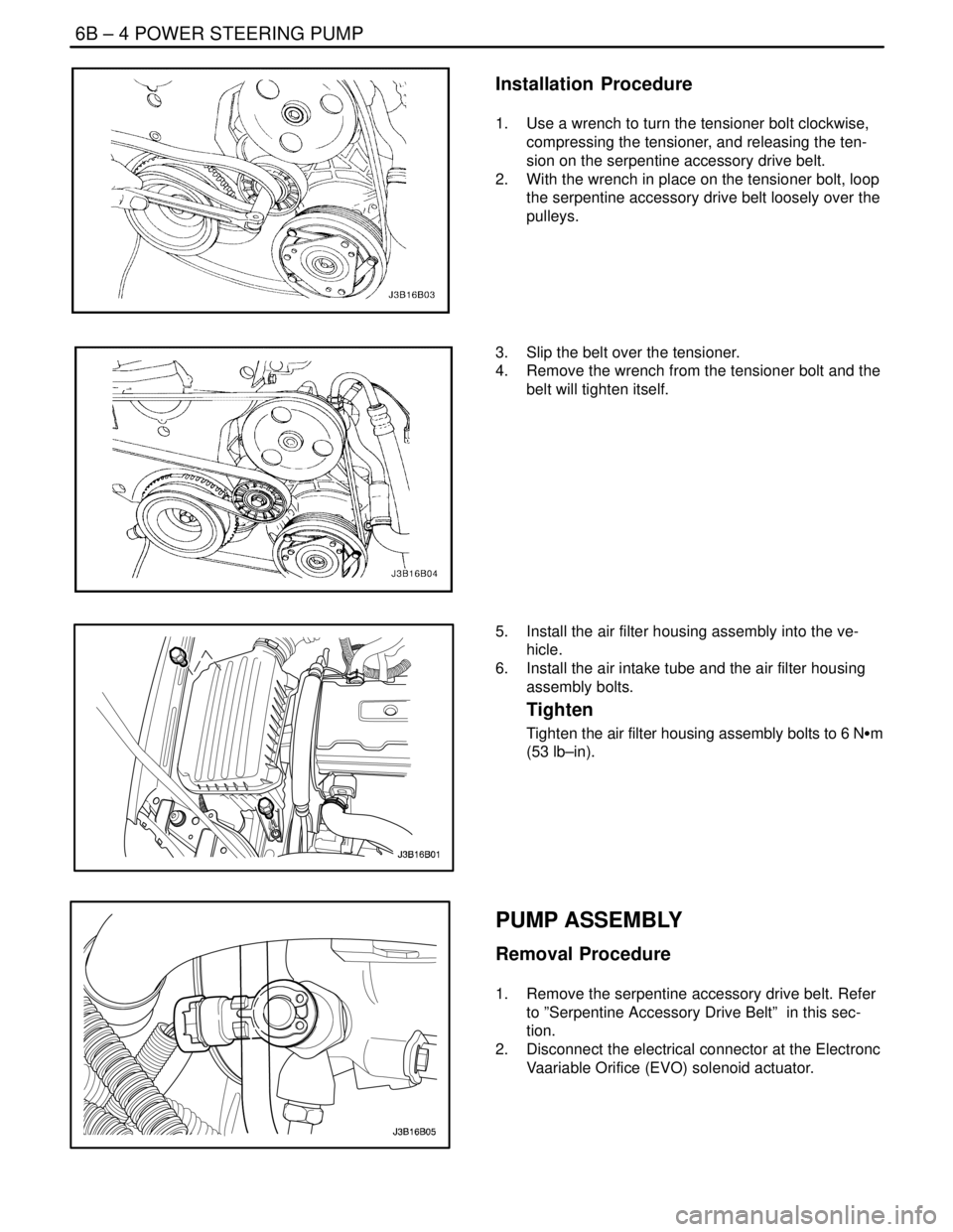

Installation Procedure

1. Use a wrench to turn the tensioner bolt clockwise,

compressing the tensioner, and releasing the ten-

sion on the serpentine accessory drive belt.

2. With the wrench in place on the tensioner bolt, loop

the serpentine accessory drive belt loosely over the

pulleys.

3. Slip the belt over the tensioner.

4. Remove the wrench from the tensioner bolt and the

belt will tighten itself.

5. Install the air filter housing assembly into the ve-

hicle.

6. Install the air intake tube and the air filter housing

assembly bolts.

Tighten

Tighten the air filter housing assembly bolts to 6 NSm

(53 lb–in).

PUMP ASSEMBLY

Removal Procedure

1. Remove the serpentine accessory drive belt. Refer

to ”Serpentine Accessory Drive Belt” in this sec-

tion.

2. Disconnect the electrical connector at the Electronc

Vaariable Orifice (EVO) solenoid actuator.

Page 1946 of 2643

POWER STEERING GEAR 6C – 29

DAEWOO V–121 BL4

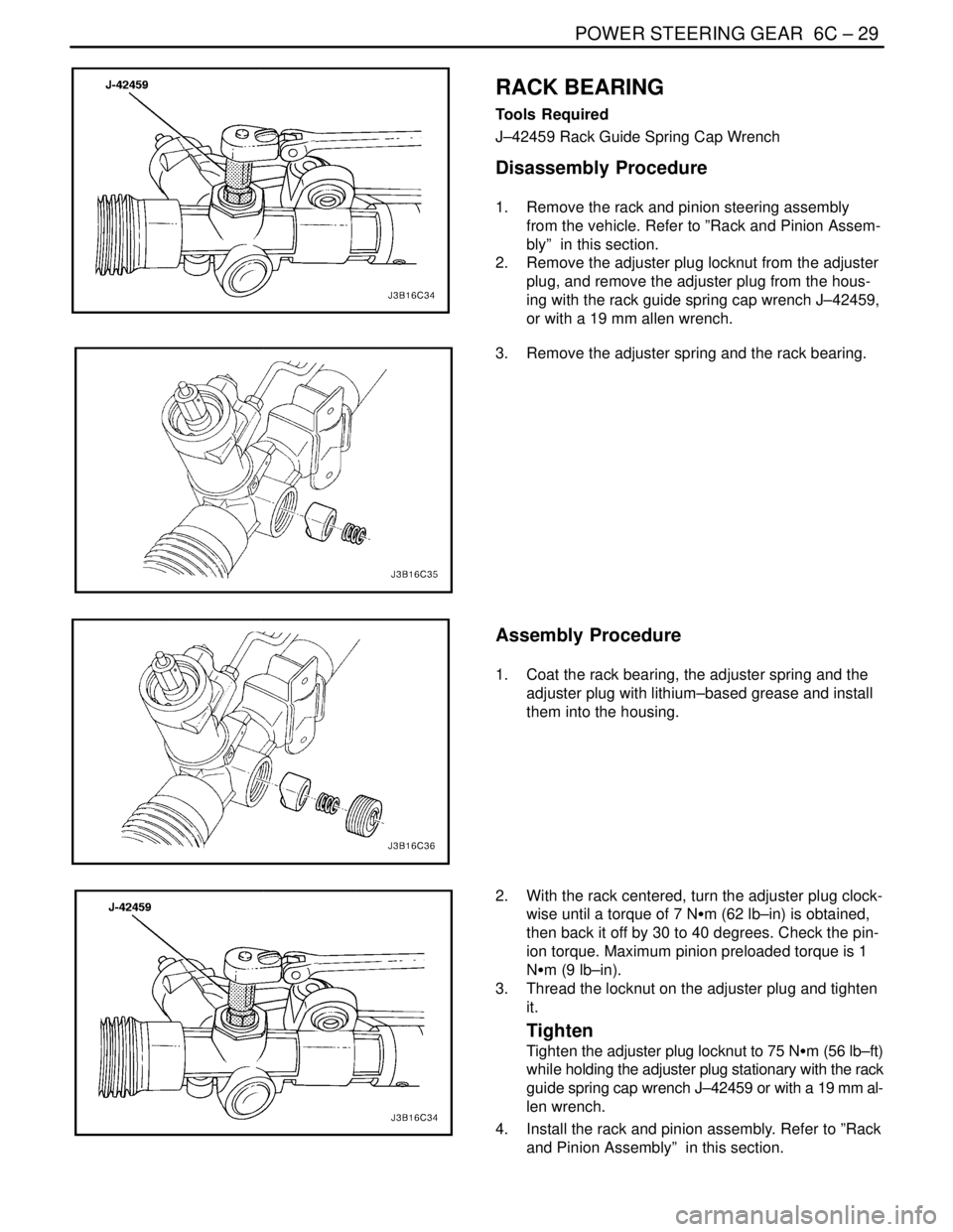

RACK BEARING

Tools Required

J–42459 Rack Guide Spring Cap Wrench

Disassembly Procedure

1. Remove the rack and pinion steering assembly

from the vehicle. Refer to ”Rack and Pinion Assem-

bly” in this section.

2. Remove the adjuster plug locknut from the adjuster

plug, and remove the adjuster plug from the hous-

ing with the rack guide spring cap wrench J–42459,

or with a 19 mm allen wrench.

3. Remove the adjuster spring and the rack bearing.

Assembly Procedure

1. Coat the rack bearing, the adjuster spring and the

adjuster plug with lithium–based grease and install

them into the housing.

2. With the rack centered, turn the adjuster plug clock-

wise until a torque of 7 NSm (62 lb–in) is obtained,

then back it off by 30 to 40 degrees. Check the pin-

ion torque. Maximum pinion preloaded torque is 1

NSm (9 lb–in).

3. Thread the locknut on the adjuster plug and tighten

it.

Tighten

Tighten the adjuster plug locknut to 75 NSm (56 lb–ft)

while holding the adjuster plug stationary with the rack

guide spring cap wrench J–42459 or with a 19 mm al-

len wrench.

4. Install the rack and pinion assembly. Refer to ”Rack

and Pinion Assembly” in this section.

Page 1947 of 2643

6C – 30IPOWER STEERING GEAR

DAEWOO V–121 BL4

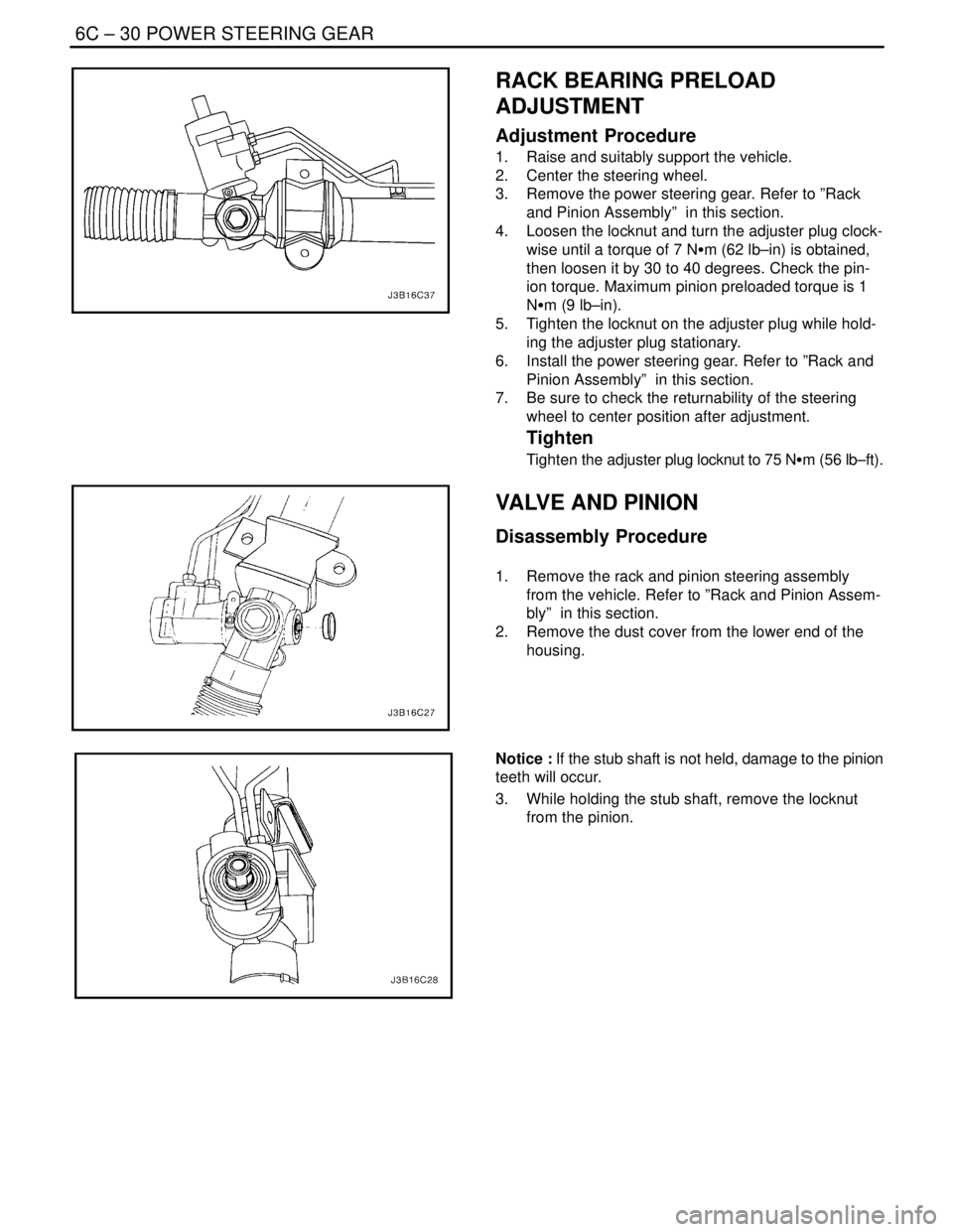

RACK BEARING PRELOAD

ADJUSTMENT

Adjustment Procedure

1. Raise and suitably support the vehicle.

2. Center the steering wheel.

3. Remove the power steering gear. Refer to ”Rack

and Pinion Assembly” in this section.

4. Loosen the locknut and turn the adjuster plug clock-

wise until a torque of 7 NSm (62 lb–in) is obtained,

then loosen it by 30 to 40 degrees. Check the pin-

ion torque. Maximum pinion preloaded torque is 1

NSm (9 lb–in).

5. Tighten the locknut on the adjuster plug while hold-

ing the adjuster plug stationary.

6. Install the power steering gear. Refer to ”Rack and

Pinion Assembly” in this section.

7. Be sure to check the returnability of the steering

wheel to center position after adjustment.

Tighten

Tighten the adjuster plug locknut to 75 NSm (56 lb–ft).

VALVE AND PINION

Disassembly Procedure

1. Remove the rack and pinion steering assembly

from the vehicle. Refer to ”Rack and Pinion Assem-

bly” in this section.

2. Remove the dust cover from the lower end of the

housing.

Notice : If the stub shaft is not held, damage to the pinion

teeth will occur.

3. While holding the stub shaft, remove the locknut

from the pinion.

Page 2042 of 2643

7B – 40IMANUAL CONTROL HEATING, VENTILATION AND AIR CONDITIONING SYSTEM

DAEWOO V–121 BL4

11. Remove the compressor from the bench vise and

remove the J–34992 compressor holding fixture

from the compressor.

12. Install the compressor. Refer to ”Compressor” in

this section.

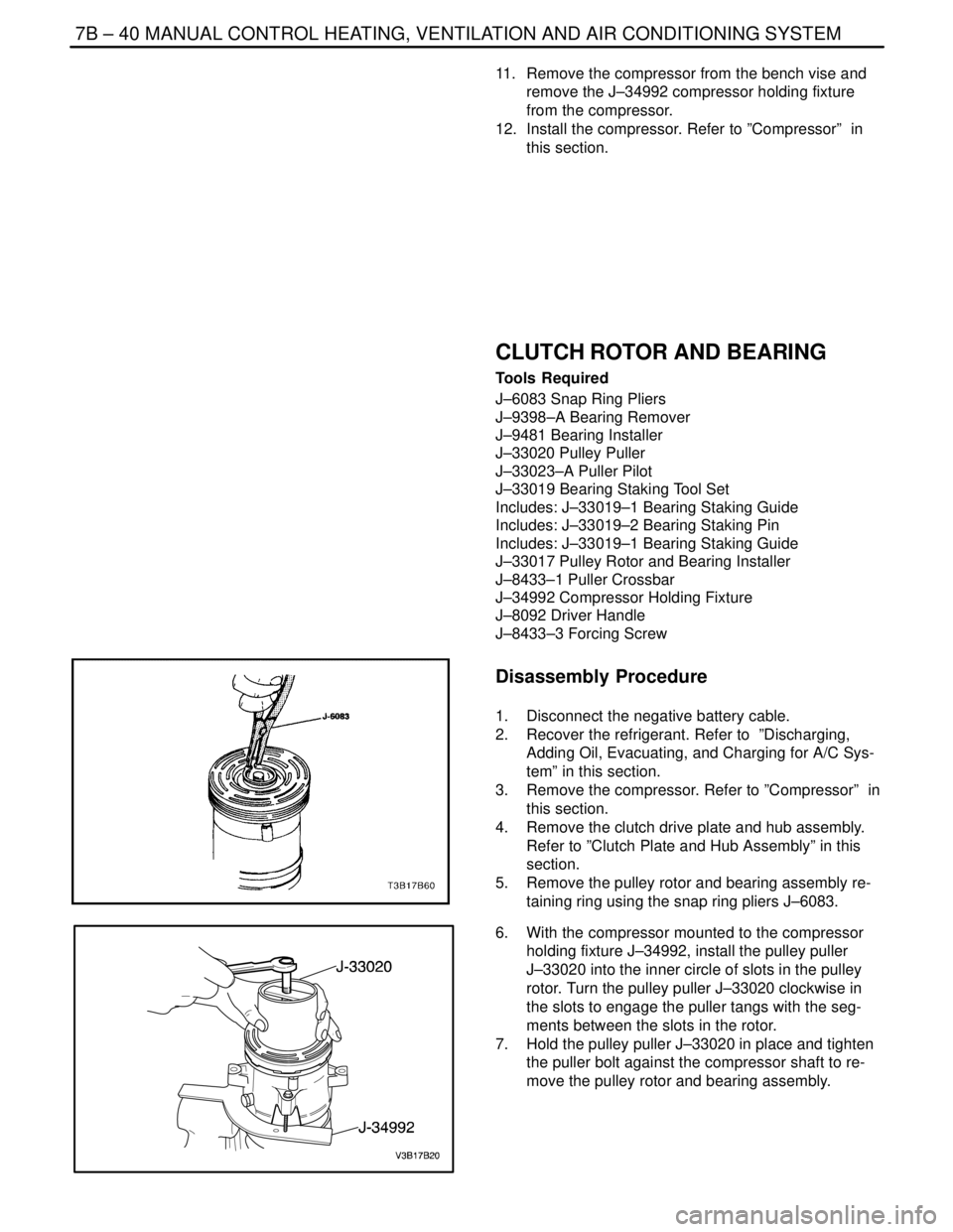

CLUTCH ROTOR AND BEARING

Tools Required

J–6083 Snap Ring Pliers

J–9398–A Bearing Remover

J–9481 Bearing Installer

J–33020 Pulley Puller

J–33023–A Puller Pilot

J–33019 Bearing Staking Tool Set

Includes: J–33019–1 Bearing Staking Guide

Includes: J–33019–2 Bearing Staking Pin

Includes: J–33019–1 Bearing Staking Guide

J–33017 Pulley Rotor and Bearing Installer

J–8433–1 Puller Crossbar

J–34992 Compressor Holding Fixture

J–8092 Driver Handle

J–8433–3 Forcing Screw

Disassembly Procedure

1. Disconnect the negative battery cable.

2. Recover the refrigerant. Refer to ”Discharging,

Adding Oil, Evacuating, and Charging for A/C Sys-

tem” in this section.

3. Remove the compressor. Refer to ”Compressor” in

this section.

4. Remove the clutch drive plate and hub assembly.

Refer to ”Clutch Plate and Hub Assembly” in this

section.

5. Remove the pulley rotor and bearing assembly re-

taining ring using the snap ring pliers J–6083.

6. With the compressor mounted to the compressor

holding fixture J–34992, install the pulley puller

J–33020 into the inner circle of slots in the pulley

rotor. Turn the pulley puller J–33020 clockwise in

the slots to engage the puller tangs with the seg-

ments between the slots in the rotor.

7. Hold the pulley puller J–33020 in place and tighten

the puller bolt against the compressor shaft to re-

move the pulley rotor and bearing assembly.

Page 2046 of 2643

7B – 44IMANUAL CONTROL HEATING, VENTILATION AND AIR CONDITIONING SYSTEM

DAEWOO V–121 BL4

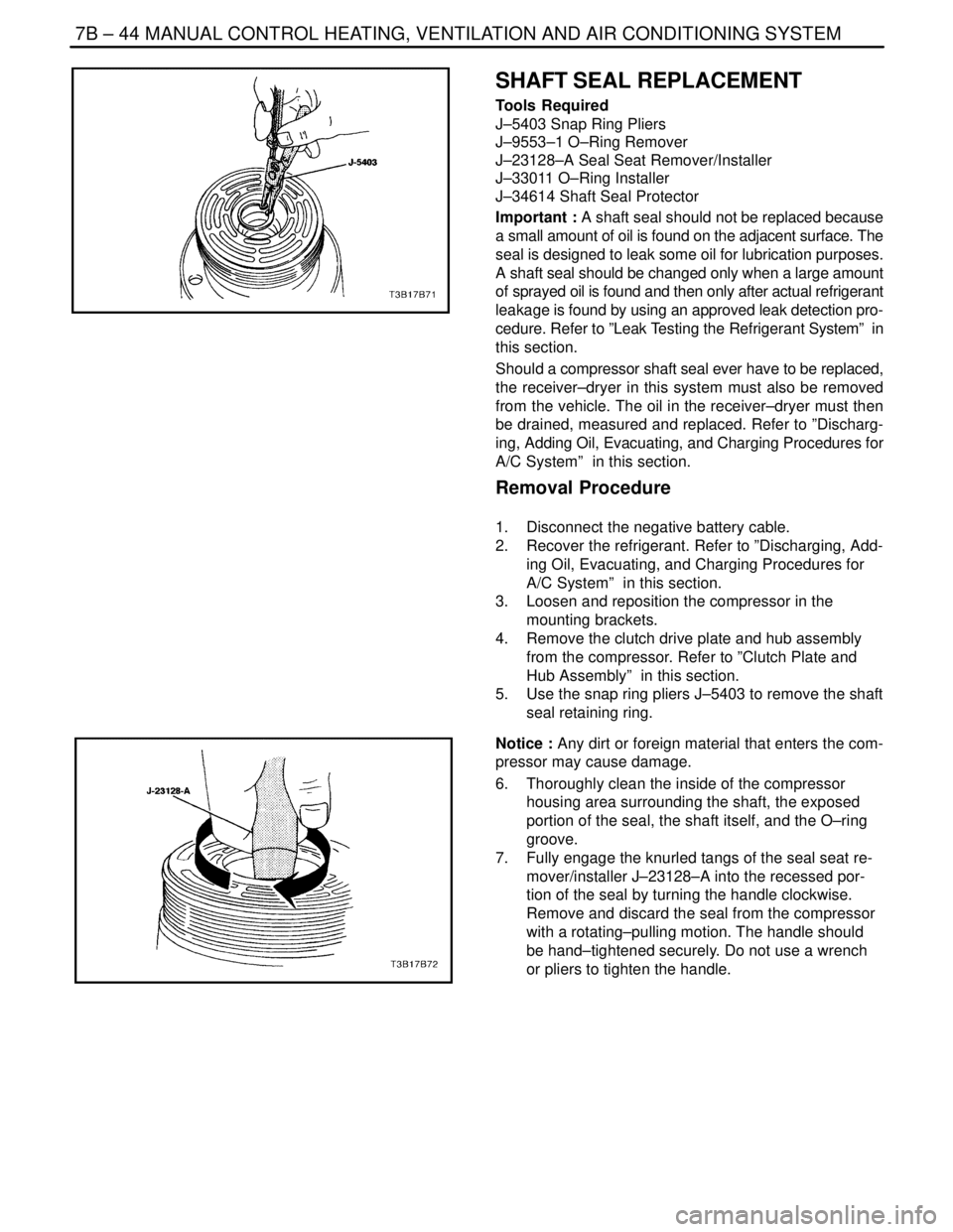

SHAFT SEAL REPLACEMENT

Tools Required

J–5403 Snap Ring Pliers

J–9553–1 O–Ring Remover

J–23128–A Seal Seat Remover/Installer

J–33011 O–Ring Installer

J–34614 Shaft Seal Protector

Important : A shaft seal should not be replaced because

a small amount of oil is found on the adjacent surface. The

seal is designed to leak some oil for lubrication purposes.

A shaft seal should be changed only when a large amount

of sprayed oil is found and then only after actual refrigerant

leakage is found by using an approved leak detection pro-

cedure. Refer to ”Leak Testing the Refrigerant System” in

this section.

Should a compressor shaft seal ever have to be replaced,

the receiver–dryer in this system must also be removed

from the vehicle. The oil in the receiver–dryer must then

be drained, measured and replaced. Refer to ”Discharg-

ing, Adding Oil, Evacuating, and Charging Procedures for

A/C System” in this section.

Removal Procedure

1. Disconnect the negative battery cable.

2. Recover the refrigerant. Refer to ”Discharging, Add-

ing Oil, Evacuating, and Charging Procedures for

A/C System” in this section.

3. Loosen and reposition the compressor in the

mounting brackets.

4. Remove the clutch drive plate and hub assembly

from the compressor. Refer to ”Clutch Plate and

Hub Assembly” in this section.

5. Use the snap ring pliers J–5403 to remove the shaft

seal retaining ring.

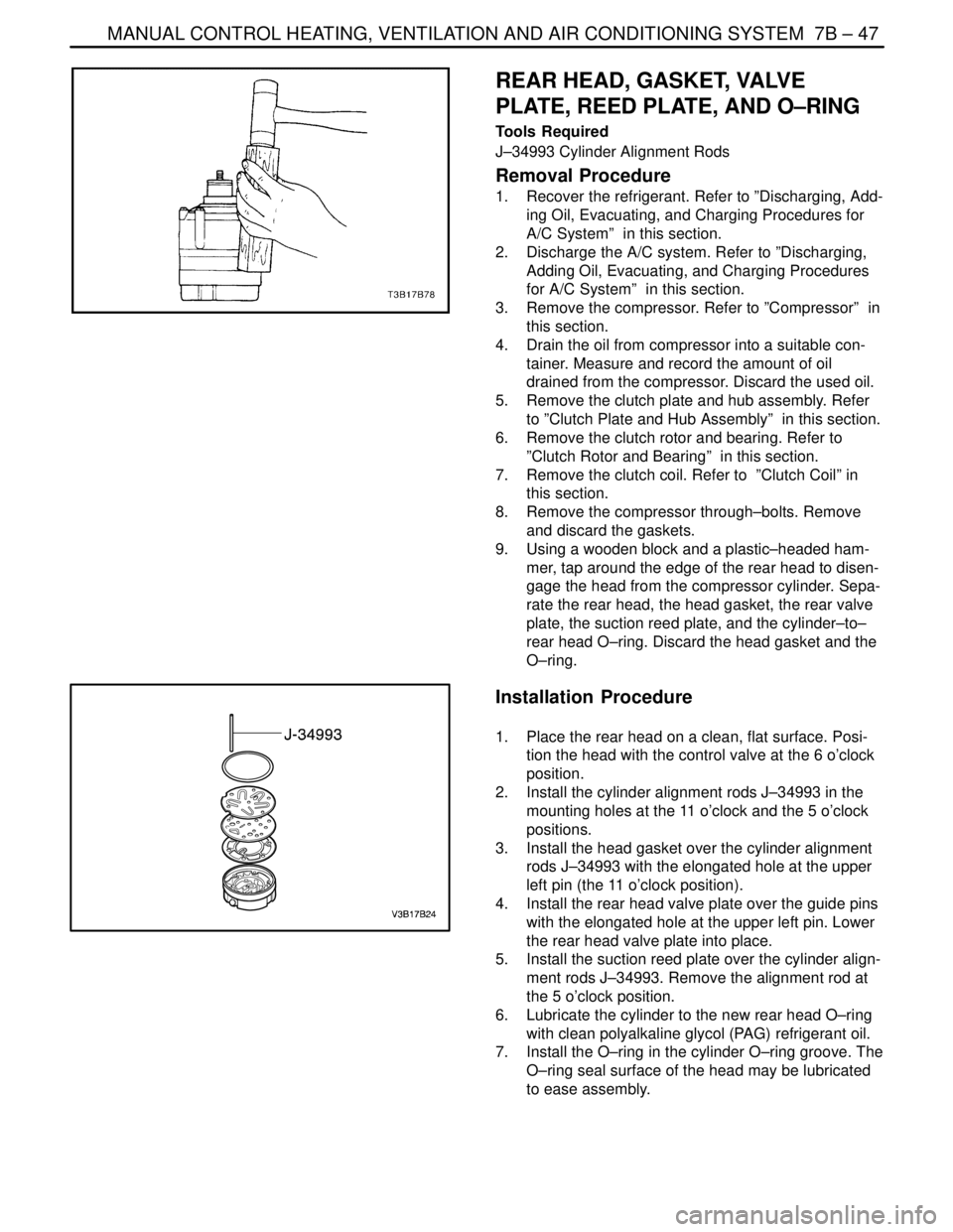

Notice : Any dirt or foreign material that enters the com-

pressor may cause damage.

6. Thoroughly clean the inside of the compressor

housing area surrounding the shaft, the exposed

portion of the seal, the shaft itself, and the O–ring

groove.

7. Fully engage the knurled tangs of the seal seat re-

mover/installer J–23128–A into the recessed por-

tion of the seal by turning the handle clockwise.

Remove and discard the seal from the compressor

with a rotating–pulling motion. The handle should

be hand–tightened securely. Do not use a wrench

or pliers to tighten the handle.

Page 2049 of 2643

MANUAL CONTROL HEATING, VENTILATION AND AIR CONDITIONING SYSTEM 7B – 47

DAEWOO V–121 BL4

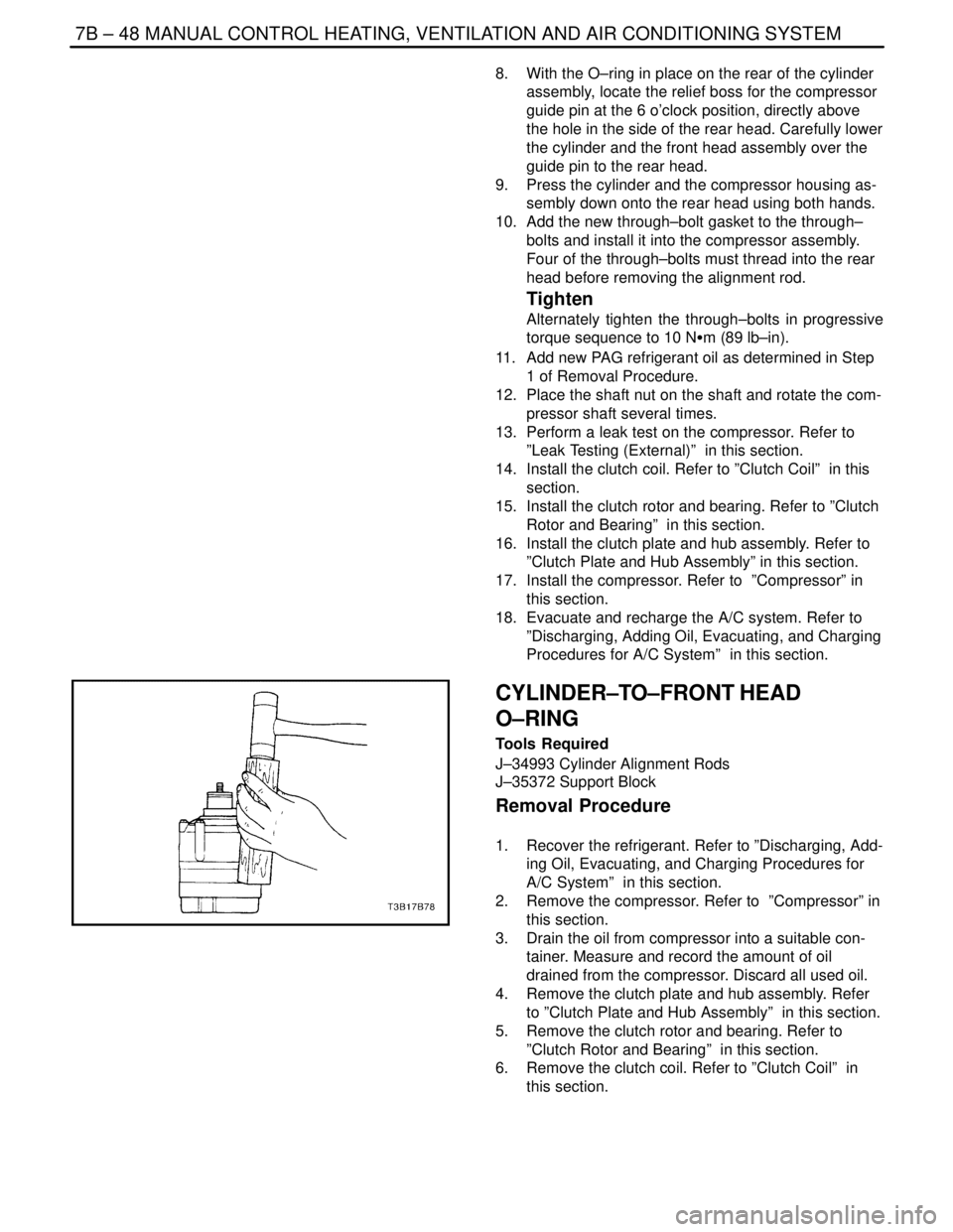

REAR HEAD, GASKET, VALVE

PLATE, REED PLATE, AND O–RING

Tools Required

J–34993 Cylinder Alignment Rods

Removal Procedure

1. Recover the refrigerant. Refer to ”Discharging, Add-

ing Oil, Evacuating, and Charging Procedures for

A/C System” in this section.

2. Discharge the A/C system. Refer to ”Discharging,

Adding Oil, Evacuating, and Charging Procedures

for A/C System” in this section.

3. Remove the compressor. Refer to ”Compressor” in

this section.

4. Drain the oil from compressor into a suitable con-

tainer. Measure and record the amount of oil

drained from the compressor. Discard the used oil.

5. Remove the clutch plate and hub assembly. Refer

to ”Clutch Plate and Hub Assembly” in this section.

6. Remove the clutch rotor and bearing. Refer to

”Clutch Rotor and Bearing” in this section.

7. Remove the clutch coil. Refer to ”Clutch Coil” in

this section.

8. Remove the compressor through–bolts. Remove

and discard the gaskets.

9. Using a wooden block and a plastic–headed ham-

mer, tap around the edge of the rear head to disen-

gage the head from the compressor cylinder. Sepa-

rate the rear head, the head gasket, the rear valve

plate, the suction reed plate, and the cylinder–to–

rear head O–ring. Discard the head gasket and the

O–ring.

Installation Procedure

1. Place the rear head on a clean, flat surface. Posi-

tion the head with the control valve at the 6 o’clock

position.

2. Install the cylinder alignment rods J–34993 in the

mounting holes at the 11 o’clock and the 5 o’clock

positions.

3. Install the head gasket over the cylinder alignment

rods J–34993 with the elongated hole at the upper

left pin (the 11 o’clock position).

4. Install the rear head valve plate over the guide pins

with the elongated hole at the upper left pin. Lower

the rear head valve plate into place.

5. Install the suction reed plate over the cylinder align-

ment rods J–34993. Remove the alignment rod at

the 5 o’clock position.

6. Lubricate the cylinder to the new rear head O–ring

with clean polyalkaline glycol (PAG) refrigerant oil.

7. Install the O–ring in the cylinder O–ring groove. The

O–ring seal surface of the head may be lubricated

to ease assembly.

Page 2050 of 2643

7B – 48IMANUAL CONTROL HEATING, VENTILATION AND AIR CONDITIONING SYSTEM

DAEWOO V–121 BL4

8. With the O–ring in place on the rear of the cylinder

assembly, locate the relief boss for the compressor

guide pin at the 6 o’clock position, directly above

the hole in the side of the rear head. Carefully lower

the cylinder and the front head assembly over the

guide pin to the rear head.

9. Press the cylinder and the compressor housing as-

sembly down onto the rear head using both hands.

10. Add the new through–bolt gasket to the through–

bolts and install it into the compressor assembly.

Four of the through–bolts must thread into the rear

head before removing the alignment rod.

Tighten

Alternately tighten the through–bolts in progressive

torque sequence to 10 NSm (89 lb–in).

11. Add new PAG refrigerant oil as determined in Step

1 of Removal Procedure.

12. Place the shaft nut on the shaft and rotate the com-

pressor shaft several times.

13. Perform a leak test on the compressor. Refer to

”Leak Testing (External)” in this section.

14. Install the clutch coil. Refer to ”Clutch Coil” in this

section.

15. Install the clutch rotor and bearing. Refer to ”Clutch

Rotor and Bearing” in this section.

16. Install the clutch plate and hub assembly. Refer to

”Clutch Plate and Hub Assembly” in this section.

17. Install the compressor. Refer to ”Compressor” in

this section.

18. Evacuate and recharge the A/C system. Refer to

”Discharging, Adding Oil, Evacuating, and Charging

Procedures for A/C System” in this section.

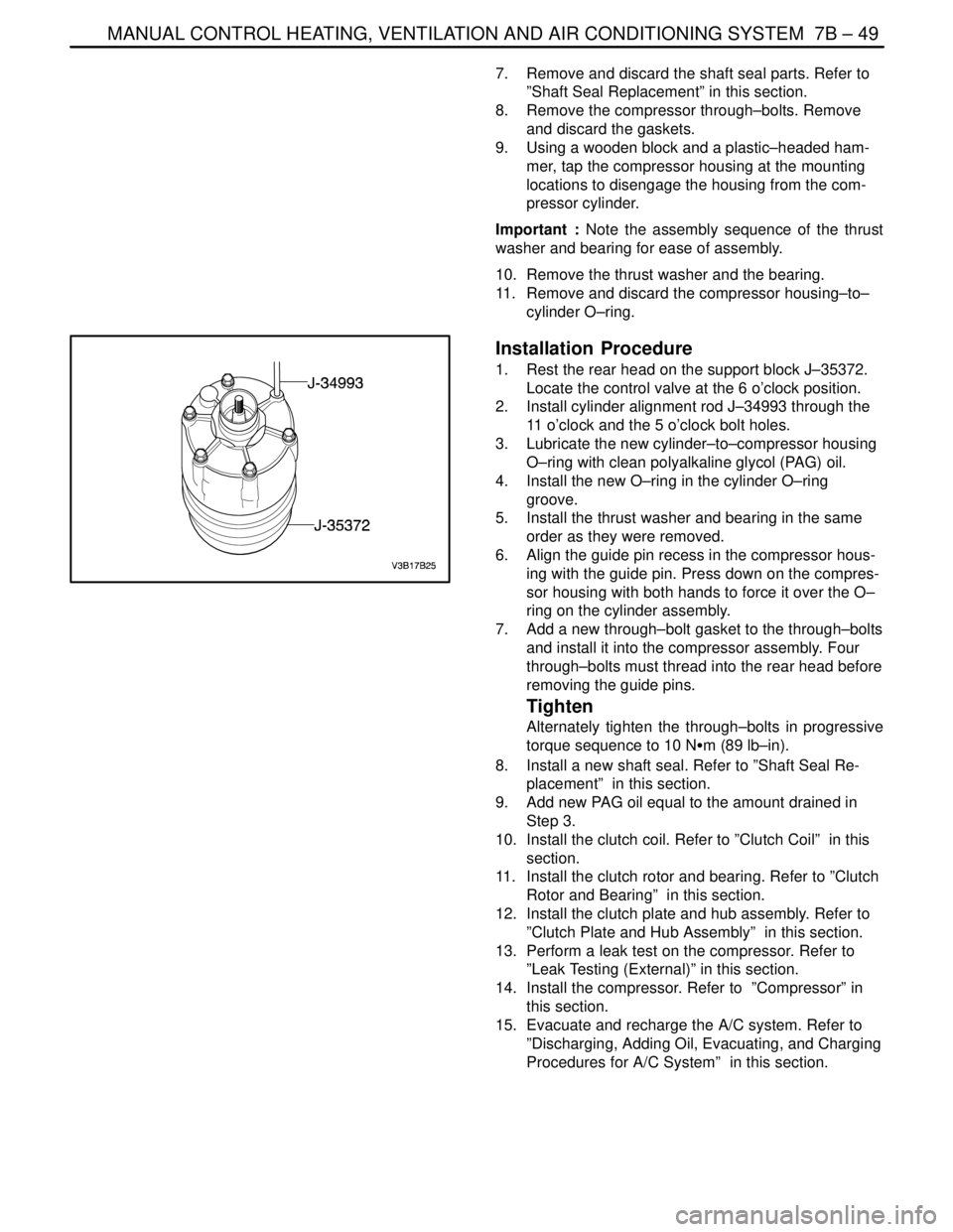

CYLINDER–TO–FRONT HEAD

O–RING

Tools Required

J–34993 Cylinder Alignment Rods

J–35372 Support Block

Removal Procedure

1. Recover the refrigerant. Refer to ”Discharging, Add-

ing Oil, Evacuating, and Charging Procedures for

A/C System” in this section.

2. Remove the compressor. Refer to ”Compressor” in

this section.

3. Drain the oil from compressor into a suitable con-

tainer. Measure and record the amount of oil

drained from the compressor. Discard all used oil.

4. Remove the clutch plate and hub assembly. Refer

to ”Clutch Plate and Hub Assembly” in this section.

5. Remove the clutch rotor and bearing. Refer to

”Clutch Rotor and Bearing” in this section.

6. Remove the clutch coil. Refer to ”Clutch Coil” in

this section.

Page 2051 of 2643

MANUAL CONTROL HEATING, VENTILATION AND AIR CONDITIONING SYSTEM 7B – 49

DAEWOO V–121 BL4

7. Remove and discard the shaft seal parts. Refer to

”Shaft Seal Replacement” in this section.

8. Remove the compressor through–bolts. Remove

and discard the gaskets.

9. Using a wooden block and a plastic–headed ham-

mer, tap the compressor housing at the mounting

locations to disengage the housing from the com-

pressor cylinder.

Important : Note the assembly sequence of the thrust

washer and bearing for ease of assembly.

10. Remove the thrust washer and the bearing.

11. Remove and discard the compressor housing–to–

cylinder O–ring.

Installation Procedure

1. Rest the rear head on the support block J–35372.

Locate the control valve at the 6 o’clock position.

2. Install cylinder alignment rod J–34993 through the

11 o’clock and the 5 o’clock bolt holes.

3. Lubricate the new cylinder–to–compressor housing

O–ring with clean polyalkaline glycol (PAG) oil.

4. Install the new O–ring in the cylinder O–ring

groove.

5. Install the thrust washer and bearing in the same

order as they were removed.

6. Align the guide pin recess in the compressor hous-

ing with the guide pin. Press down on the compres-

sor housing with both hands to force it over the O–

ring on the cylinder assembly.

7. Add a new through–bolt gasket to the through–bolts

and install it into the compressor assembly. Four

through–bolts must thread into the rear head before

removing the guide pins.

Tighten

Alternately tighten the through–bolts in progressive

torque sequence to 10 NSm (89 lb–in).

8. Install a new shaft seal. Refer to ”Shaft Seal Re-

placement” in this section.

9. Add new PAG oil equal to the amount drained in

Step 3.

10. Install the clutch coil. Refer to ”Clutch Coil” in this

section.

11. Install the clutch rotor and bearing. Refer to ”Clutch

Rotor and Bearing” in this section.

12. Install the clutch plate and hub assembly. Refer to

”Clutch Plate and Hub Assembly” in this section.

13. Perform a leak test on the compressor. Refer to

”Leak Testing (External)” in this section.

14. Install the compressor. Refer to ”Compressor” in

this section.

15. Evacuate and recharge the A/C system. Refer to

”Discharging, Adding Oil, Evacuating, and Charging

Procedures for A/C System” in this section.

Page 2092 of 2643

IAUTOMATIC TEMPERATURE CONTROL HEATING, VENTILATION, AND AIR CONDITIONING SYSTEM 7D – 37

DAEWOO V–121 BL4

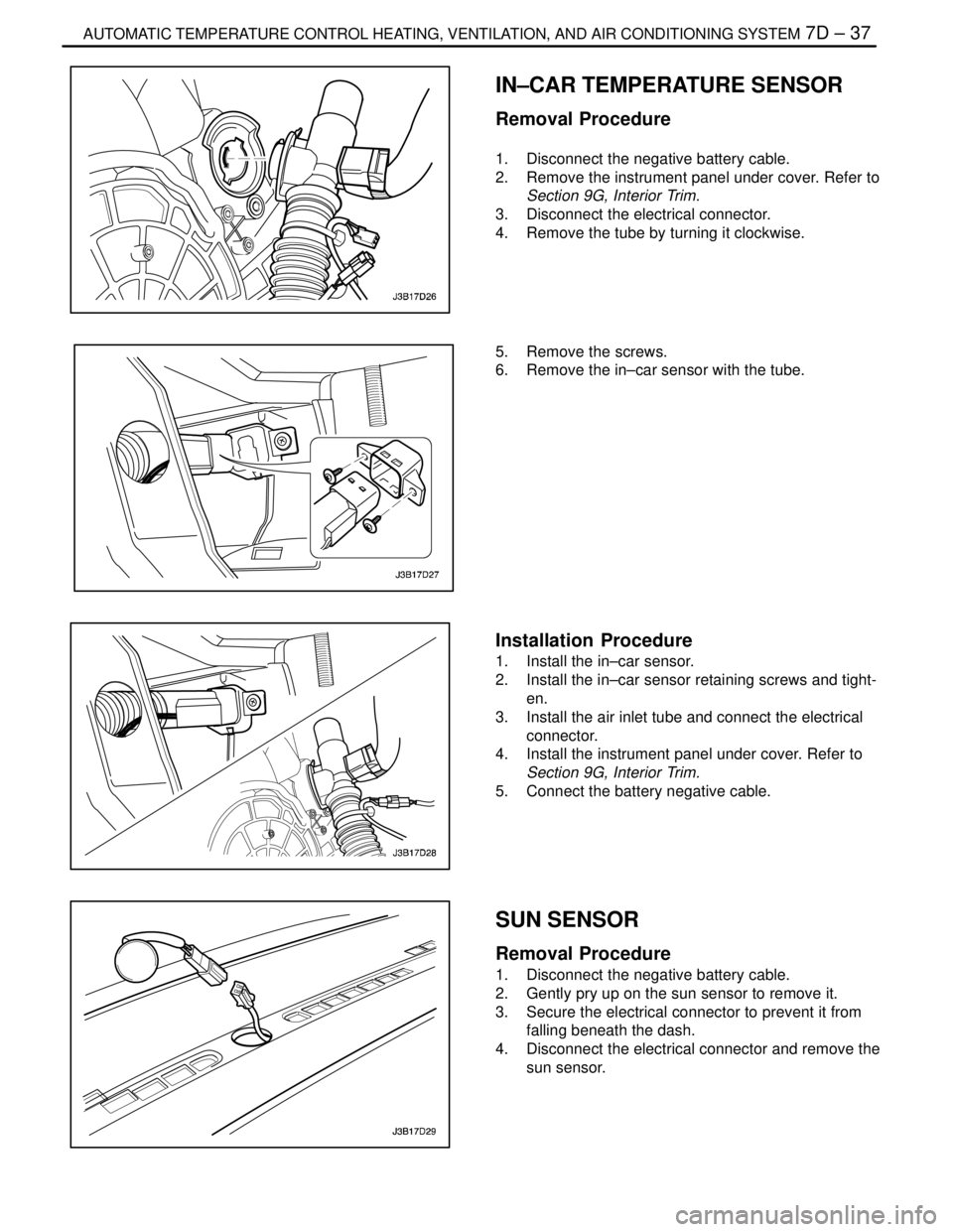

IN–CAR TEMPERATURE SENSOR

Removal Procedure

1. Disconnect the negative battery cable.

2. Remove the instrument panel under cover. Refer to

Section 9G, Interior Trim.

3. Disconnect the electrical connector.

4. Remove the tube by turning it clockwise.

5. Remove the screws.

6. Remove the in–car sensor with the tube.

Installation Procedure

1. Install the in–car sensor.

2. Install the in–car sensor retaining screws and tight-

en.

3. Install the air inlet tube and connect the electrical

connector.

4. Install the instrument panel under cover. Refer to

Section 9G, Interior Trim.

5. Connect the battery negative cable.

SUN SENSOR

Removal Procedure

1. Disconnect the negative battery cable.

2. Gently pry up on the sun sensor to remove it.

3. Secure the electrical connector to prevent it from

falling beneath the dash.

4. Disconnect the electrical connector and remove the

sun sensor.

Page 2106 of 2643

8B – 2ISUPPLEMENTAL INFLATABLE RESTRAINTS (SIR)

DAEWOO V–121 BL4

DTC 80 Driver Side Airbag Sensor Loop Is

Shorted To Power 8B–72. . . . . . . . . . . . . . . . . . . . . . .

DTC 81 Driver Side Airbag Sensor Loop Is

Shorted To Ground 8B–74. . . . . . . . . . . . . . . . . . . . . .

DTC 82 Driver Side Airbag Sensor Communication

Error 8B–76. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC 83 Driver Side Airbag Sensor Failure 8B–78. . .

DTC 84 Passenger Side Airbag Sensor Loop Is

Shorted To Power 8B–80. . . . . . . . . . . . . . . . . . . . . . .

DTC 85 Passenger Side Airbag Sensor Loop Is

Shorted To Ground 8B–82. . . . . . . . . . . . . . . . . . . . . .

DTC 86 Passenger Side Airbag Sensor

Communication Error 8B–84. . . . . . . . . . . . . . . . . . . .

DTC 87 Passenger Side Airbag Sensor Failure 8B–86

MAINTENANCE AND REPAIR8B–88 . . . . . . . . . . . . . .

ON–VEHICLE SERVICE 8B–88. . . . . . . . . . . . . . . . . . . .

Disabling the Supplemental Inflatable

Restraints(SIR) 8B–88. . . . . . . . . . . . . . . . . . . . . . . . .

Enabling the Supplemental Inflatable

Restraints(SIR) 8B–88. . . . . . . . . . . . . . . . . . . . . . . . .

Handling, Installation and Diagnosis 8B–89. . . . . . . . .

Repairs and Inspections Required After an

Accident 8B–89. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accident With Deployment Components

Replacements 8B–90. . . . . . . . . . . . . . . . . . . . . . . . . . Accident Without Deployment Component

Inspection 8B–90. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sensing and Diagnostic Module (SDM) 8B–90. . . . . .

Driver Airbag Module 8B–91. . . . . . . . . . . . . . . . . . . . . .

Clock Spring 8B–92. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Clock Spring Alignment 8B–93. . . . . . . . . . . . . . . . . . . .

Passenger Airbag Module 8B–94. . . . . . . . . . . . . . . . . .

Side Airbag Sensor 8B–95. . . . . . . . . . . . . . . . . . . . . . .

Front Seat Belt Pretensioner 8B–95. . . . . . . . . . . . . . .

Airbag Module Deployment (Inside of Vehicle) 8B–95

Airbag Module Deployment (Outside of Vehicle) 8B–97

Deployed Airbag Module Disposal Procedure 8B–98.

SIR Wiring Repair 8B–99. . . . . . . . . . . . . . . . . . . . . . . .

GENERAL DESCRIPTION AND SYSTEM

OPERATION8B–100 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Supplemental Inflatable Restraints(SIR) 8B–100. . . .

Airbag Modules 8B–100. . . . . . . . . . . . . . . . . . . . . . . . . .

Front Seat Belt Pretensioners 8B–101. . . . . . . . . . . . .

Sensing and Diagnostic Module (SDM) 8B–101. . . . .

Airbag Warning Lamp 8B–101. . . . . . . . . . . . . . . . . . . .

Clock Spring 8B–101. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wiring Harness Connectors 8B–102. . . . . . . . . . . . . . .