run flat DAEWOO NUBIRA 2004 Service User Guide

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: NUBIRA, Model: DAEWOO NUBIRA 2004Pages: 2643, PDF Size: 80.54 MB

Page 964 of 2643

2E – 2ITIRES AND WHEELS

DAEWOO V–121 BL4

INFLATION PRESSURE CONVERSION SPECIFICATIONS

kPaPsikPaPsikPaPsi

140201852723534

145211902824035

155222002925036

160232053027540

165242153131045

170252203234550

FASTENER TIGHTENING SPECIFICATIONS

ApplicationNSmLb–FtLb–In

Wheel Bolt (Alloy Wheel)10074–

Wheel Bolt (Steel Wheel)10074–

DIAGNOSIS

WHEEL RUNOUT

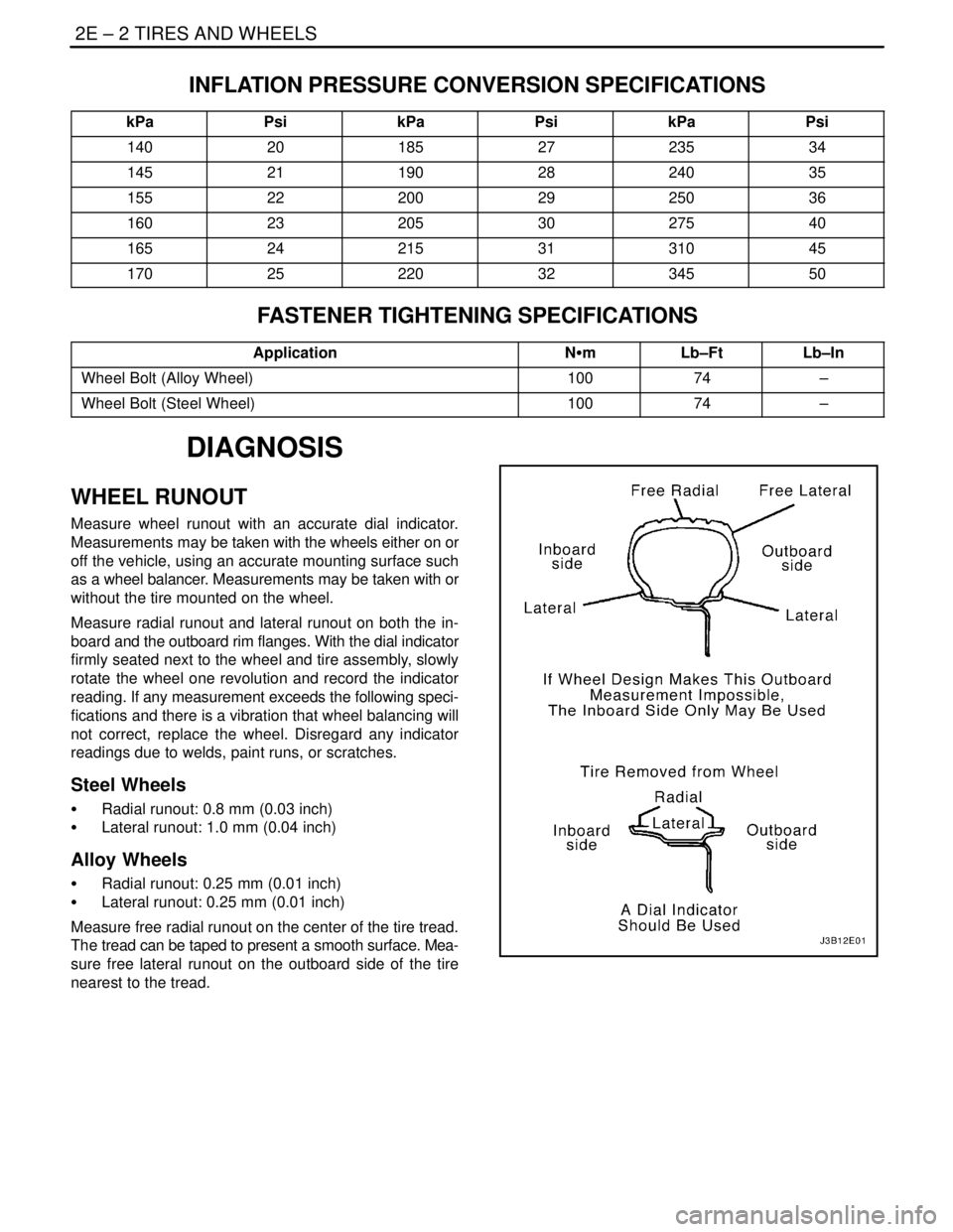

Measure wheel runout with an accurate dial indicator.

Measurements may be taken with the wheels either on or

off the vehicle, using an accurate mounting surface such

as a wheel balancer. Measurements may be taken with or

without the tire mounted on the wheel.

Measure radial runout and lateral runout on both the in-

board and the outboard rim flanges. With the dial indicator

firmly seated next to the wheel and tire assembly, slowly

rotate the wheel one revolution and record the indicator

reading. If any measurement exceeds the following speci-

fications and there is a vibration that wheel balancing will

not correct, replace the wheel. Disregard any indicator

readings due to welds, paint runs, or scratches.

Steel Wheels

S Radial runout: 0.8 mm (0.03 inch)

S Lateral runout: 1.0 mm (0.04 inch)

Alloy Wheels

S Radial runout: 0.25 mm (0.01 inch)

S Lateral runout: 0.25 mm (0.01 inch)

Measure free radial runout on the center of the tire tread.

The tread can be taped to present a smooth surface. Mea-

sure free lateral runout on the outboard side of the tire

nearest to the tread.

Page 972 of 2643

2E – 10ITIRES AND WHEELS

DAEWOO V–121 BL4

turers of tire chains have a specific chain size for each tire

size to ensure a proper fit when the chain is installed. Be

sure to purchase the correct chains for the tires on which

they are to be used. Use rubber adjusters to take up any

slack or clearance in loose chains.

Use of chains may adversely affect vehicle handling.

When tire chains are installed, follow these precautions:

S Adjust speed to road conditions.

S Avoid sharp turns.

S Avoid locked–wheel braking.

To prevent chain damage to the vehicle, install the chains

on the front tires as tightly as possible. Tighten them again

after driving 0.4 to 0.8 kilometer (0.3 to 0.5 mile). The use

of chains on the rear tires is not recommended because

they may contact the vehicle and possibly damage it. If

chains must be used on the rear tires, be sure there is suffi-

cient clearance between the chains and the body. Do not

exceed 70 km/h (45 mph) or the chain manufacturer’s

speed limit, if lower. Avoid large bumps, potholes, severe

turns and any other maneuvers which could cause the

tires to bounce. Follow any other instructions of the chain

manufacturer which do not disagree with the above in-

structions.

REPLACEMENT TIRES

A tire performance criteria (TPC) specification number is

molded in the sidewall near the tire size of all original

equipment tires. This specification number assures that

the tire meets performance standards for traction, endur-

ance, dimensions, noise, handling and rolling resis–tance.

Usually a specific TPC number is assigned to each tire

size.

CAUTION : Do not mix different types of tires on the

same vehicle such as radial, bias and bias–belted

tires except in emergencies, because vehicle han-

dling may be seriously affected and may result in loss

of control.

Use only replacement tires with the same size, load range,

and construction as the original. The use of any other tire

size or construction type may seriously affect ride, han-

dling, speedometer/odometer calibration, vehicle ground

clearance, and tire clearance to the body and the chassis.

This does not apply to the spare tire furnished with the ve-

hicle.

It is recommended that new tires be installed in pairs on

the same axle.

If it is necessary to replace only one tire, pair it with the tire

having the most tread to equalize the braking action.

Although they may appear different in tread design, tires

built by different manufacturers with identical TPC specifi-

cations may be used on the same vehicle.

ALL SEASON TIRES

Most vehicles are now equipped with steel–belted all sea-

son radial tires as standard equipment. These tires qualify

as snow tires, with a 37 percent higher average rating for

snow traction than the non–all season radial tires pre-

viously used. Other performance areas, such as wet trac-

tion, rolling resistance, tread life, and air retention, have

also been improved. This was done by improvements in

both tread design and tread compounds. These tires are

identified by an ”M + S” molded in the tire sidewall following

the size number. The suffix ”MS” is also molded in the side-

wall after the TPC specification number.

The optional handling tires used on some vehicles are not

all season tires. These will not have the ”MS” marking after

the tire size or the TPC specification number.

PASSENGER METRIC SIZED TIRES

All Daewoo vehicles now use Passenger (P) metric sized

tires. P–metric tires are available in two load ranges: stan-

dard load (35 psi maximum) and extra load (41 psi maxi-

mum). Most passenger vehicle tires are standard load.

Most P–metric tire sizes do not have exact corresponding

alphanumeric tire sizes. For example, a P175/70R13 is

not exactly equal in size and load–carrying capacity to an

FR70–13. For this reason, replacement tires should be of

the same TPC specification number as the originals. If P–

metric tires must be replaced with other sizes, consult a

tire dealer. Tire companies can best recommend the clos-

est match of alphanumeric to P–metric sizes within their

own tire lines.

The metric term for measuring tire inflation pressure is the

kilopascal (kPa). Tire pressure may be printed in both kPa

and psi. One psi equals 6.895 kPa.

See the tire label or refer to ”Tire Size and Pressure Speci-

fications” in this section for tire inflation pressures.

TIRE LABEL

The tire label is permanently located on the rear face of the

driver’s door and should be referred to for tire information.

It lists the maximum vehicle load, the tire size (including

the spare tire), and the cold inflation pressure (including

the spare tire).

SPARE TIRE

The notchback and the wagon come equipped with a full–

sized tire on a steel wheel. The hatchback comes

equipped with a reduced–sized temporary tire on a steel

wheel.

WHEELS

Wheels must be replaced if they are bent, dented, have

excessive lateral or radial runout, leak air through welds,

have elongated bolt holes, or if the wheel bolts won’t stay

tight or are heavily rusted. Wheels with excessive runout

may cause vehicle vibration. Replacement wheels must

be equivalent to the original equipment wheels in load ca-

Page 1021 of 2643

HYDRAULIC BRAKES 4A – 5

DAEWOO V–121 BL4

DIAGNOSIS

BRAKE SYSTEM TESTING

Brakes should be tested on a dry, clean, reasonably

smooth and level roadway. A true test of brake perfor-

mance cannot be made if the roadway is wet, greasy, or

covered with loose dirt whereby all tires do not grip the

road equally. Testing will also be adversely affected if the

roadway is crowned so as to throw the weight so roughly

that the wheels tend to bounce.

Test the brakes at different vehicle speeds with both light

and heavy pedal pressure; however, avoid locking the

brakes and sliding the tires. Locked brakes and sliding

tires do not indicate brake efficiency since heavily braked,

but turning, wheels will stop the vehicle in less distance

than locked brakes. More tire–to–road friction is present

with a heavily–braked, turning tire than with a sliding tire.

Because of the high deceleration capability, a firmer pedal

may be felt at higher deceleration levels.

There are three major external conditions that affect brake

performance:

S Tires having unequal contact and grip of the road

will cause unequal braking. Tires must be equally

inflated, and the tread pattern of the right and the

left tires must be approximately equal.

S Unequal loading of the vehicle can affect the brake

performance since the most heavily loaded wheels

require more braking power, and thus more braking

effort, than the others.

S Misalignment of the wheels, particularly conditions

of excessive camber and caster, will cause the

brakes to pull to one side.

To check for brake fluid leaks, hold constant foot pressure

on the pedal with the engine running at idle and the shift

lever in NEUTRAL. If the pedal gradually falls away with

the constant pressure, the hydraulic system may be leak-

ing. Perform a visual check to confirm any suspected

leaks.

Check the master cylinder fluid level. While a slight drop

in the reservoir level results from normal lining wear, an ab-

normally low level indicates a leak in the system. The hy-

draulic system may be leaking either internally or external-

ly. Refer to the procedure below to check the master

cylinder. Also, the system may appear to pass this test

while still having a slight leak. If the fluid level is normal,

check the vacuum booster pushrod length. If an incorrect

pushrod length is found, adjust or replace the rod.

Check the master cylinder using the following procedure:

S Check for a cracked master cylinder casting or

brake fluid leaking around the master cylinder.

Leaks are indicated only if there is at least one drop

of fluid. A damp condition is not abnormal.S Check for a binding pedal linkage and for an incor-

rect pushrod length. If both of these parts are in

satisfactory condition, disassemble the master cyl-

inder and check for an elongated or swollen primary

cylinder or piston seals. If swollen seals are found,

substandard or contaminated brake fluid should be

suspected. If contaminated brake fluid is found, all

the components should be disassembled and

cleaned, and all the rubber components should be

replaced. All of the pipes must also be flushed.

Improper brake fluid, or mineral oil or water in the fluid,

may cause the brake fluid to boil or cause deterioration of

the rubber components. If the primary piston cups in the

master cylinder are swollen, then the rubber parts have

deteriorated. This deterioration may also be evidenced by

swollen wheel cylinder piston seals on the drum brake

wheels.

If deterioration of rubber is evident, disassemble all the hy-

draulic parts and wash the parts with alcohol. Dry these

parts with compressed air before reassembly to keep alco-

hol out of the system. Replace all the rubber parts in the

system, including the hoses. Also, when working on the

brake mechanisms, check for fluid on the linings. If exces-

sive fluid is found, replace the linings.

If the master cylinder piston seals are in satisfactory condi-

tion, check for leaks or excessive heat conditions. If these

conditions are not found, drain the fluid, flush the master

cylinder with brake fluid, refill the master cylinder, and

bleed the system. Refer to ”Manual Bleeding the Brakes”

or”Pressure Bleeding the Brakes” in this section.

BRAKE HOSE INSPECTION

The hydraulic brake hoses should be inspected at least

twice a year. The brake hose assembly should be checked

for road hazard damage, cracks, chafing of the outer cov-

er, and for leaks or blisters. Inspect the hoses for proper

routing and mounting. A brake hose that rubs on a suspen-

sion component will wear and eventually fail. A light and

a mirror may be needed for an adequate inspection. If any

of the above conditions are observed on the brake hose,

adjust or replace the hose as necessary.

WARNING LAMP OPERATION

This brake system uses a BRAKE warning lamp located

in the instrument panel cluster. When the ignition switch

is in the START position, the BRAKE warning lamp should

glow and go OFF when the ignition switch returns to the

RUN position.

The following conditions will activate the BRAKE lamp:

S Parking brake applied. The light should be ON

whenever the parking brake is applied and the igni-

tion switch is ON.

S Low fluid level. A low fluid level in the master cylin-

der will turn the BRAKE lamp ON.

S EBD system is disabled. The light should be ON

when the EBD system is malfunctioning.

Page 1050 of 2643

4D – 2IFRONT DISC BRAKES

DAEWOO V–121 BL4

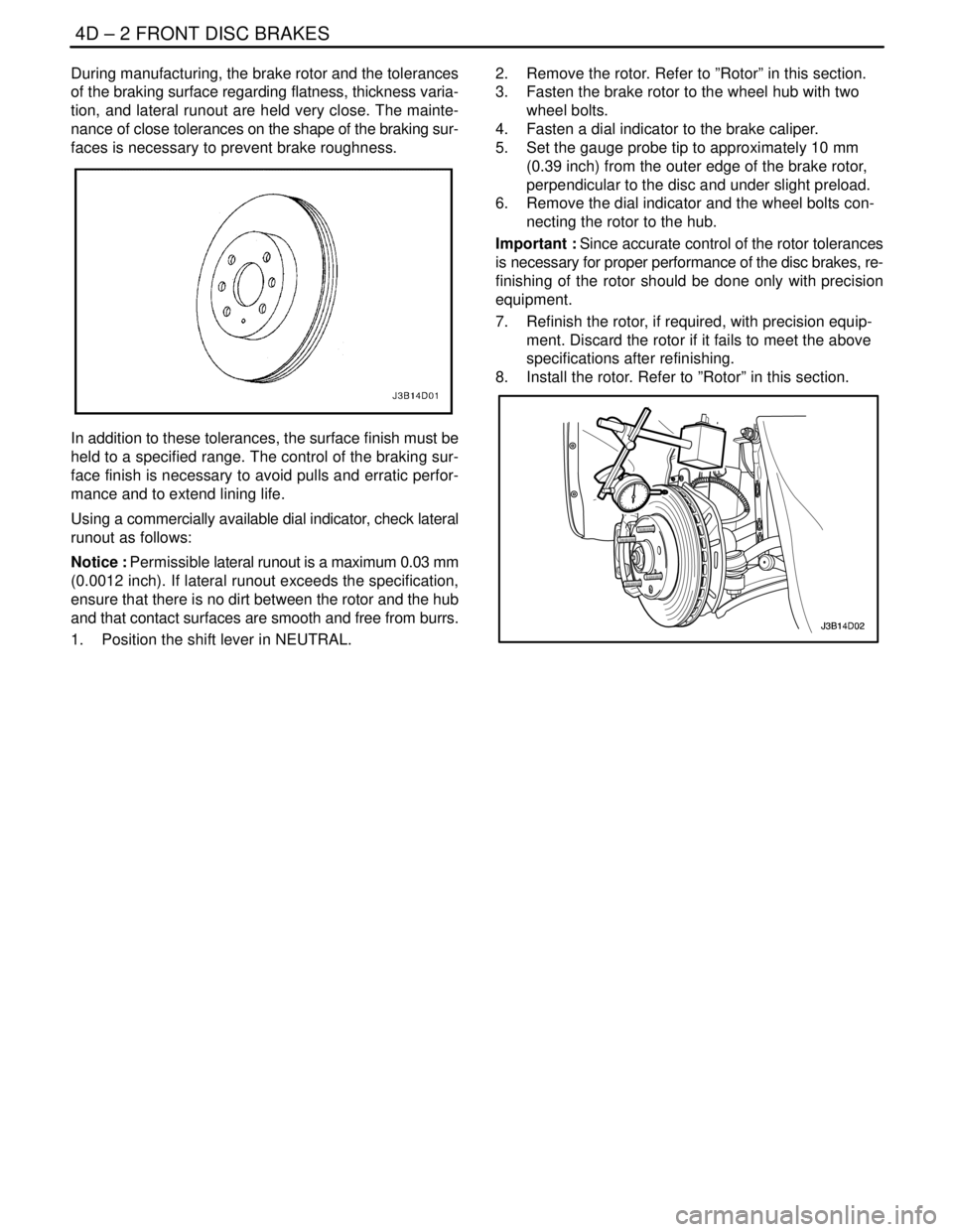

During manufacturing, the brake rotor and the tolerances

of the braking surface regarding flatness, thickness varia-

tion, and lateral runout are held very close. The mainte-

nance of close tolerances on the shape of the braking sur-

faces is necessary to prevent brake roughness.

In addition to these tolerances, the surface finish must be

held to a specified range. The control of the braking sur-

face finish is necessary to avoid pulls and erratic perfor-

mance and to extend lining life.

Using a commercially available dial indicator, check lateral

runout as follows:

Notice : Permissible lateral runout is a maximum 0.03 mm

(0.0012 inch). If lateral runout exceeds the specification,

ensure that there is no dirt between the rotor and the hub

and that contact surfaces are smooth and free from burrs.

1. Position the shift lever in NEUTRAL.2. Remove the rotor. Refer to ”Rotor” in this section.

3. Fasten the brake rotor to the wheel hub with two

wheel bolts.

4. Fasten a dial indicator to the brake caliper.

5. Set the gauge probe tip to approximately 10 mm

(0.39 inch) from the outer edge of the brake rotor,

perpendicular to the disc and under slight preload.

6. Remove the dial indicator and the wheel bolts con-

necting the rotor to the hub.

Important : Since accurate control of the rotor tolerances

is necessary for proper performance of the disc brakes, re-

finishing of the rotor should be done only with precision

equipment.

7. Refinish the rotor, if required, with precision equip-

ment. Discard the rotor if it fails to meet the above

specifications after refinishing.

8. Install the rotor. Refer to ”Rotor” in this section.

Page 1058 of 2643

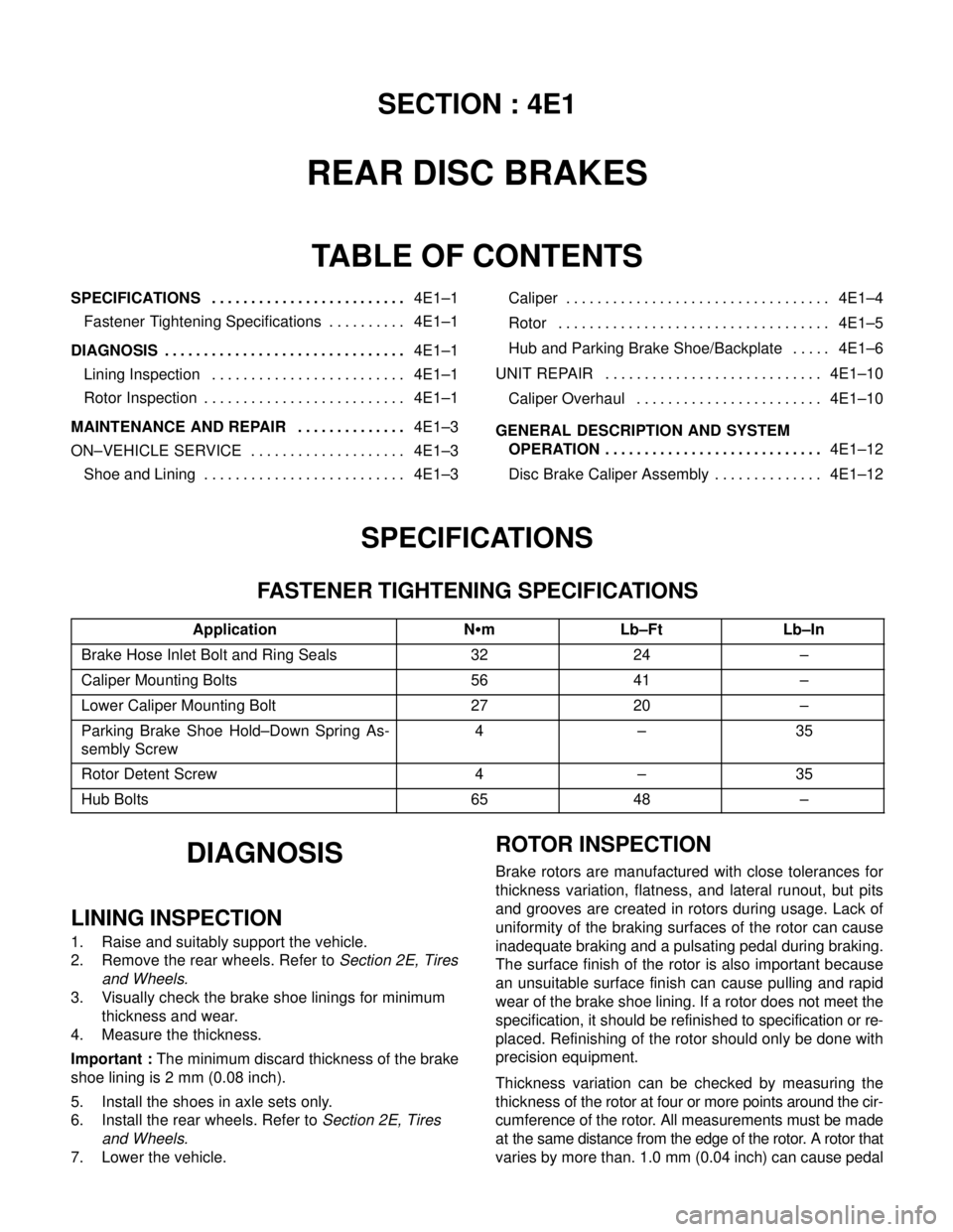

SECTION : 4E1

REAR DISC BRAKES

TABLE OF CONTENTS

SPECIFICATIONS4E1–1 . . . . . . . . . . . . . . . . . . . . . . . . .

Fastener Tightening Specifications 4E1–1. . . . . . . . . .

DIAGNOSIS4E1–1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lining Inspection 4E1–1. . . . . . . . . . . . . . . . . . . . . . . . .

Rotor Inspection 4E1–1. . . . . . . . . . . . . . . . . . . . . . . . . .

MAINTENANCE AND REPAIR4E1–3 . . . . . . . . . . . . . .

ON–VEHICLE SERVICE 4E1–3. . . . . . . . . . . . . . . . . . . .

Shoe and Lining 4E1–3. . . . . . . . . . . . . . . . . . . . . . . . . . Caliper 4E1–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rotor 4E1–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hub and Parking Brake Shoe/Backplate 4E1–6. . . . .

UNIT REPAIR 4E1–10. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Caliper Overhaul 4E1–10. . . . . . . . . . . . . . . . . . . . . . . .

GENERAL DESCRIPTION AND SYSTEM

OPERATION4E1–12 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disc Brake Caliper Assembly 4E1–12. . . . . . . . . . . . . .

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

ApplicationNSmLb–FtLb–In

Brake Hose Inlet Bolt and Ring Seals3224–

Caliper Mounting Bolts5641–

Lower Caliper Mounting Bolt2720–

Parking Brake Shoe Hold–Down Spring As-

sembly Screw4–35

Rotor Detent Screw4–35

Hub Bolts6548–

DIAGNOSIS

LINING INSPECTION

1. Raise and suitably support the vehicle.

2. Remove the rear wheels. Refer to Section 2E, Tires

and Wheels.

3. Visually check the brake shoe linings for minimum

thickness and wear.

4. Measure the thickness.

Important : The minimum discard thickness of the brake

shoe lining is 2 mm (0.08 inch).

5. Install the shoes in axle sets only.

6. Install the rear wheels. Refer to Section 2E, Tires

and Wheels.

7. Lower the vehicle.

ROTOR INSPECTION

Brake rotors are manufactured with close tolerances for

thickness variation, flatness, and lateral runout, but pits

and grooves are created in rotors during usage. Lack of

uniformity of the braking surfaces of the rotor can cause

inadequate braking and a pulsating pedal during braking.

The surface finish of the rotor is also important because

an unsuitable surface finish can cause pulling and rapid

wear of the brake shoe lining. If a rotor does not meet the

specification, it should be refinished to specification or re-

placed. Refinishing of the rotor should only be done with

precision equipment.

Thickness variation can be checked by measuring the

thickness of the rotor at four or more points around the cir-

cumference of the rotor. All measurements must be made

at the same distance from the edge of the rotor. A rotor that

varies by more than. 1.0 mm (0.04 inch) can cause pedal

Page 1394 of 2643

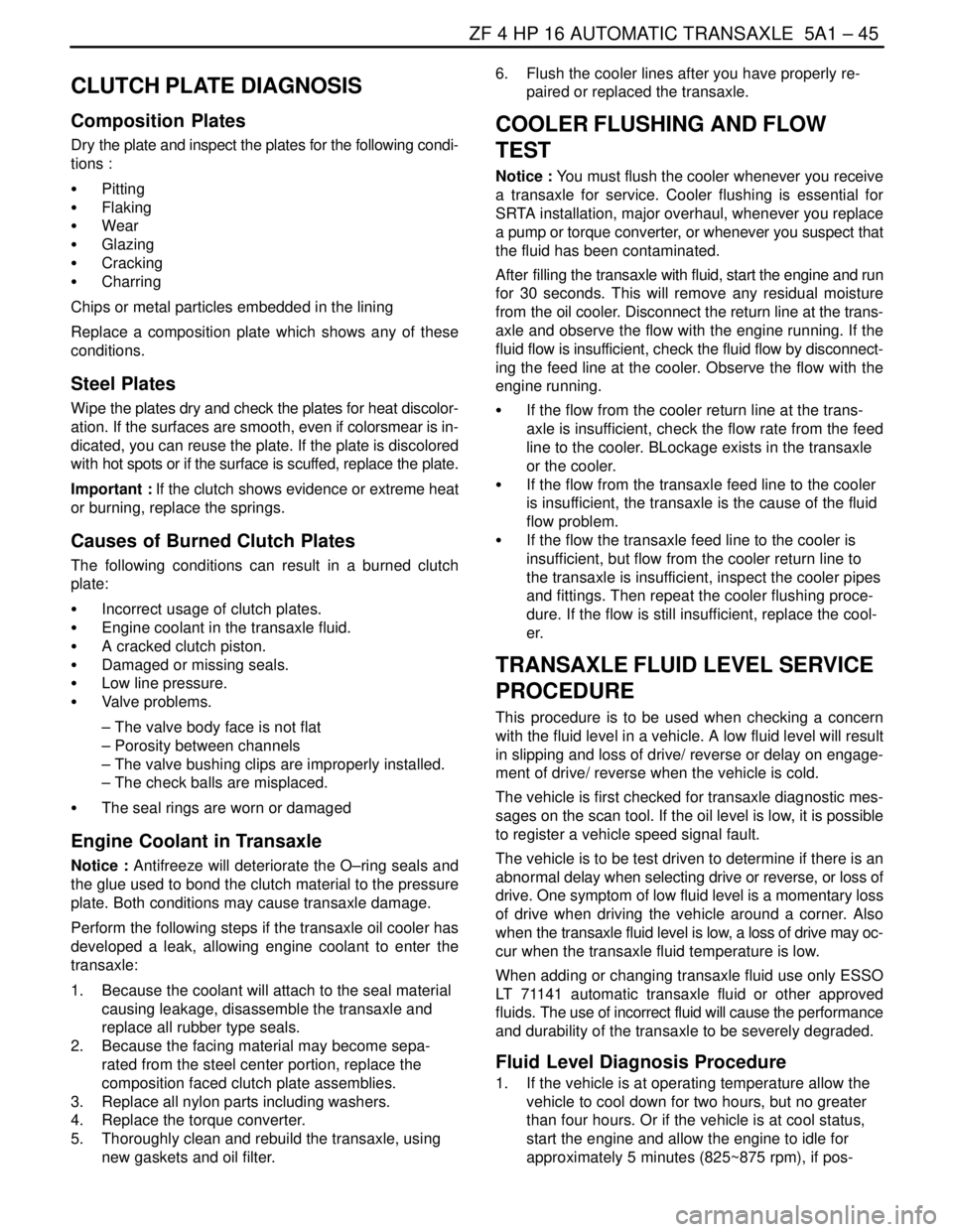

ZF 4 HP 16 AUTOMATIC TRANSAXLE 5A1 – 45

DAEWOO V–121 BL4

CLUTCH PLATE DIAGNOSIS

Composition Plates

Dry the plate and inspect the plates for the following condi-

tions :

S Pitting

S Flaking

S Wear

S Glazing

S Cracking

S Charring

Chips or metal particles embedded in the lining

Replace a composition plate which shows any of these

conditions.

Steel Plates

Wipe the plates dry and check the plates for heat discolor-

ation. If the surfaces are smooth, even if colorsmear is in-

dicated, you can reuse the plate. If the plate is discolored

with hot spots or if the surface is scuffed, replace the plate.

Important : If the clutch shows evidence or extreme heat

or burning, replace the springs.

Causes of Burned Clutch Plates

The following conditions can result in a burned clutch

plate:

S Incorrect usage of clutch plates.

S Engine coolant in the transaxle fluid.

S A cracked clutch piston.

S Damaged or missing seals.

S Low line pressure.

S Valve problems.

– The valve body face is not flat

– Porosity between channels

– The valve bushing clips are improperly installed.

– The check balls are misplaced.

S The seal rings are worn or damaged

Engine Coolant in Transaxle

Notice : Antifreeze will deteriorate the O–ring seals and

the glue used to bond the clutch material to the pressure

plate. Both conditions may cause transaxle damage.

Perform the following steps if the transaxle oil cooler has

developed a leak, allowing engine coolant to enter the

transaxle:

1. Because the coolant will attach to the seal material

causing leakage, disassemble the transaxle and

replace all rubber type seals.

2. Because the facing material may become sepa-

rated from the steel center portion, replace the

composition faced clutch plate assemblies.

3. Replace all nylon parts including washers.

4. Replace the torque converter.

5. Thoroughly clean and rebuild the transaxle, using

new gaskets and oil filter.6. Flush the cooler lines after you have properly re-

paired or replaced the transaxle.

COOLER FLUSHING AND FLOW

TEST

Notice : You must flush the cooler whenever you receive

a transaxle for service. Cooler flushing is essential for

SRTA installation, major overhaul, whenever you replace

a pump or torque converter, or whenever you suspect that

the fluid has been contaminated.

After filling the transaxle with fluid, start the engine and run

for 30 seconds. This will remove any residual moisture

from the oil cooler. Disconnect the return line at the trans-

axle and observe the flow with the engine running. If the

fluid flow is insufficient, check the fluid flow by disconnect-

ing the feed line at the cooler. Observe the flow with the

engine running.

S If the flow from the cooler return line at the trans-

axle is insufficient, check the flow rate from the feed

line to the cooler. BLockage exists in the transaxle

or the cooler.

S If the flow from the transaxle feed line to the cooler

is insufficient, the transaxle is the cause of the fluid

flow problem.

S If the flow the transaxle feed line to the cooler is

insufficient, but flow from the cooler return line to

the transaxle is insufficient, inspect the cooler pipes

and fittings. Then repeat the cooler flushing proce-

dure. If the flow is still insufficient, replace the cool-

er.

TRANSAXLE FLUID LEVEL SERVICE

PROCEDURE

This procedure is to be used when checking a concern

with the fluid level in a vehicle. A low fluid level will result

in slipping and loss of drive/ reverse or delay on engage-

ment of drive/ reverse when the vehicle is cold.

The vehicle is first checked for transaxle diagnostic mes-

sages on the scan tool. If the oil level is low, it is possible

to register a vehicle speed signal fault.

The vehicle is to be test driven to determine if there is an

abnormal delay when selecting drive or reverse, or loss of

drive. One symptom of low fluid level is a momentary loss

of drive when driving the vehicle around a corner. Also

when the transaxle fluid level is low, a loss of drive may oc-

cur when the transaxle fluid temperature is low.

When adding or changing transaxle fluid use only ESSO

LT 71141 automatic transaxle fluid or other approved

fluids. The use of incorrect fluid will cause the performance

and durability of the transaxle to be severely degraded.

Fluid Level Diagnosis Procedure

1. If the vehicle is at operating temperature allow the

vehicle to cool down for two hours, but no greater

than four hours. Or if the vehicle is at cool status,

start the engine and allow the engine to idle for

approximately 5 minutes (825~875 rpm), if pos-

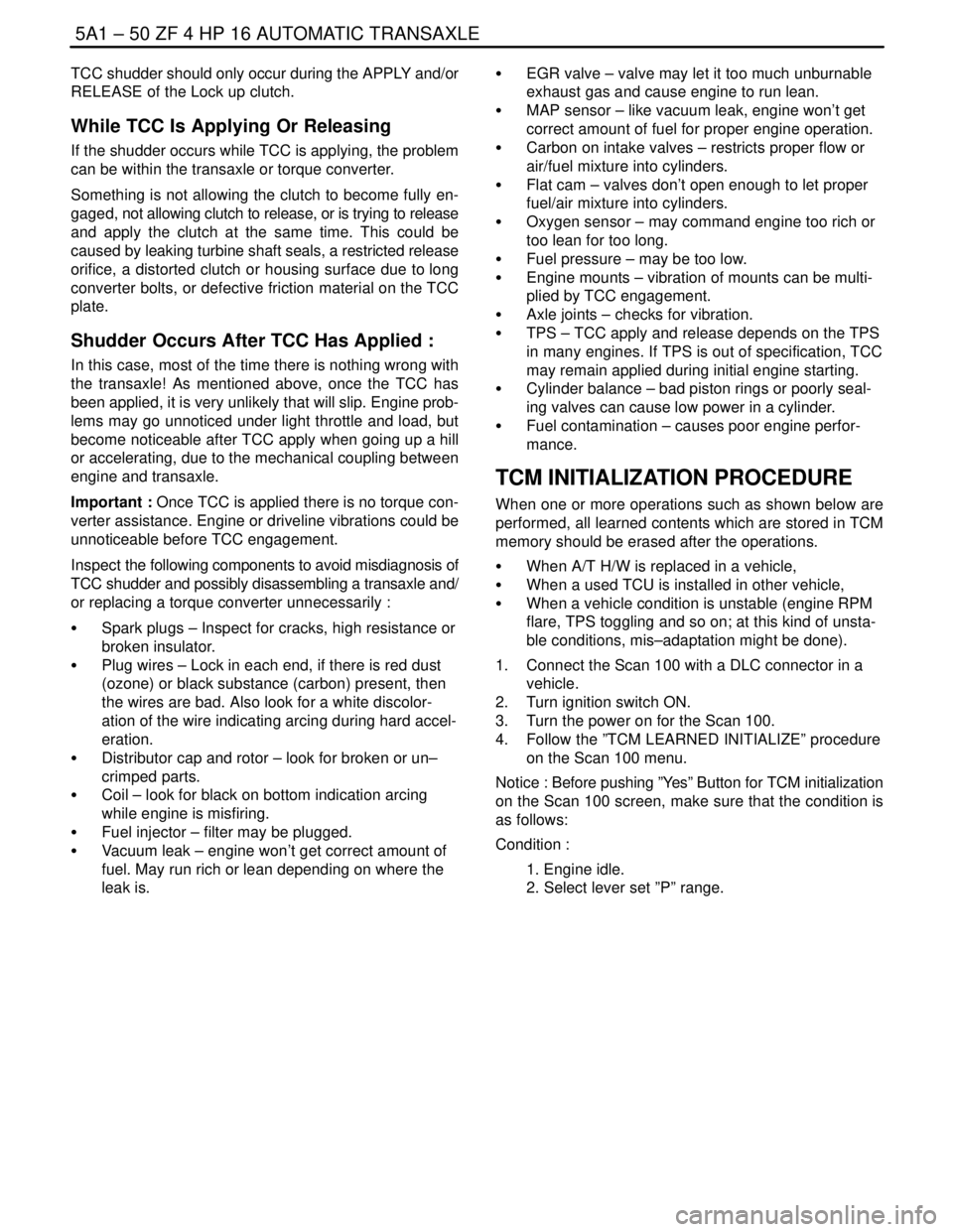

Page 1399 of 2643

5A1 – 50IZF 4 HP 16 AUTOMATIC TRANSAXLE

DAEWOO V–121 BL4

TCC shudder should only occur during the APPLY and/or

RELEASE of the Lock up clutch.

While TCC Is Applying Or Releasing

If the shudder occurs while TCC is applying, the problem

can be within the transaxle or torque converter.

Something is not allowing the clutch to become fully en-

gaged, not allowing clutch to release, or is trying to release

and apply the clutch at the same time. This could be

caused by leaking turbine shaft seals, a restricted release

orifice, a distorted clutch or housing surface due to long

converter bolts, or defective friction material on the TCC

plate.

Shudder Occurs After TCC Has Applied :

In this case, most of the time there is nothing wrong with

the transaxle! As mentioned above, once the TCC has

been applied, it is very unlikely that will slip. Engine prob-

lems may go unnoticed under light throttle and load, but

become noticeable after TCC apply when going up a hill

or accelerating, due to the mechanical coupling between

engine and transaxle.

Important : Once TCC is applied there is no torque con-

verter assistance. Engine or driveline vibrations could be

unnoticeable before TCC engagement.

Inspect the following components to avoid misdiagnosis of

TCC shudder and possibly disassembling a transaxle and/

or replacing a torque converter unnecessarily :

S Spark plugs – Inspect for cracks, high resistance or

broken insulator.

S Plug wires – Lock in each end, if there is red dust

(ozone) or black substance (carbon) present, then

the wires are bad. Also look for a white discolor-

ation of the wire indicating arcing during hard accel-

eration.

S Distributor cap and rotor – look for broken or un–

crimped parts.

S Coil – look for black on bottom indication arcing

while engine is misfiring.

S Fuel injector – filter may be plugged.

S Vacuum leak – engine won’t get correct amount of

fuel. May run rich or lean depending on where the

leak is.S EGR valve – valve may let it too much unburnable

exhaust gas and cause engine to run lean.

S MAP sensor – like vacuum leak, engine won’t get

correct amount of fuel for proper engine operation.

S Carbon on intake valves – restricts proper flow or

air/fuel mixture into cylinders.

S Flat cam – valves don’t open enough to let proper

fuel/air mixture into cylinders.

S Oxygen sensor – may command engine too rich or

too lean for too long.

S Fuel pressure – may be too low.

S Engine mounts – vibration of mounts can be multi-

plied by TCC engagement.

S Axle joints – checks for vibration.

S TPS – TCC apply and release depends on the TPS

in many engines. If TPS is out of specification, TCC

may remain applied during initial engine starting.

S Cylinder balance – bad piston rings or poorly seal-

ing valves can cause low power in a cylinder.

S Fuel contamination – causes poor engine perfor-

mance.

TCM INITIALIZATION PROCEDURE

When one or more operations such as shown below are

performed, all learned contents which are stored in TCM

memory should be erased after the operations.

S When A/T H/W is replaced in a vehicle,

S When a used TCU is installed in other vehicle,

S When a vehicle condition is unstable (engine RPM

flare, TPS toggling and so on; at this kind of unsta-

ble conditions, mis–adaptation might be done).

1. Connect the Scan 100 with a DLC connector in a

vehicle.

2. Turn ignition switch ON.

3. Turn the power on for the Scan 100.

4. Follow the ”TCM LEARNED INITIALIZE” procedure

on the Scan 100 menu.

Notice : Before pushing ”Yes” Button for TCM initialization

on the Scan 100 screen, make sure that the condition is

as follows:

Condition :

1. Engine idle.

2. Select lever set ”P” range.

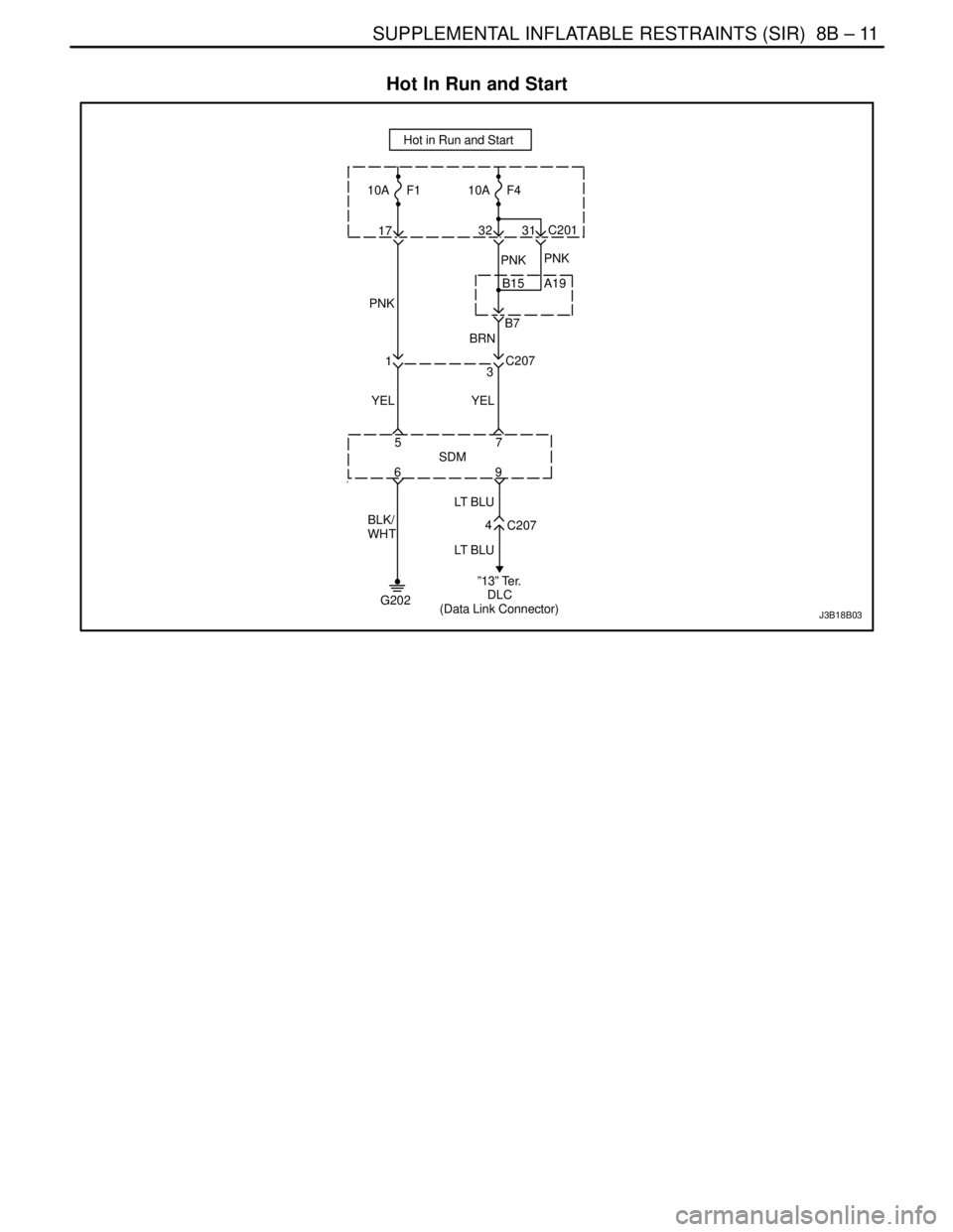

Page 2115 of 2643

SUPPLEMENTAL INFLATABLE RESTRAINTS (SIR) 8B – 11

DAEWOO V–121 BL4

Hot In Run and Start

J3B18B03

LT BLU

LT BLU

”13” Ter.

DLC

(Data Link Connector) YEL YEL

10A

1C207 PNKPNKPNK

BLK/

WHTBRN

SDM F1

Hot in Run and Start

3

65

97 17

10A F4

32

B15

B7A19 31C201

G202

C207 4

Page 2148 of 2643

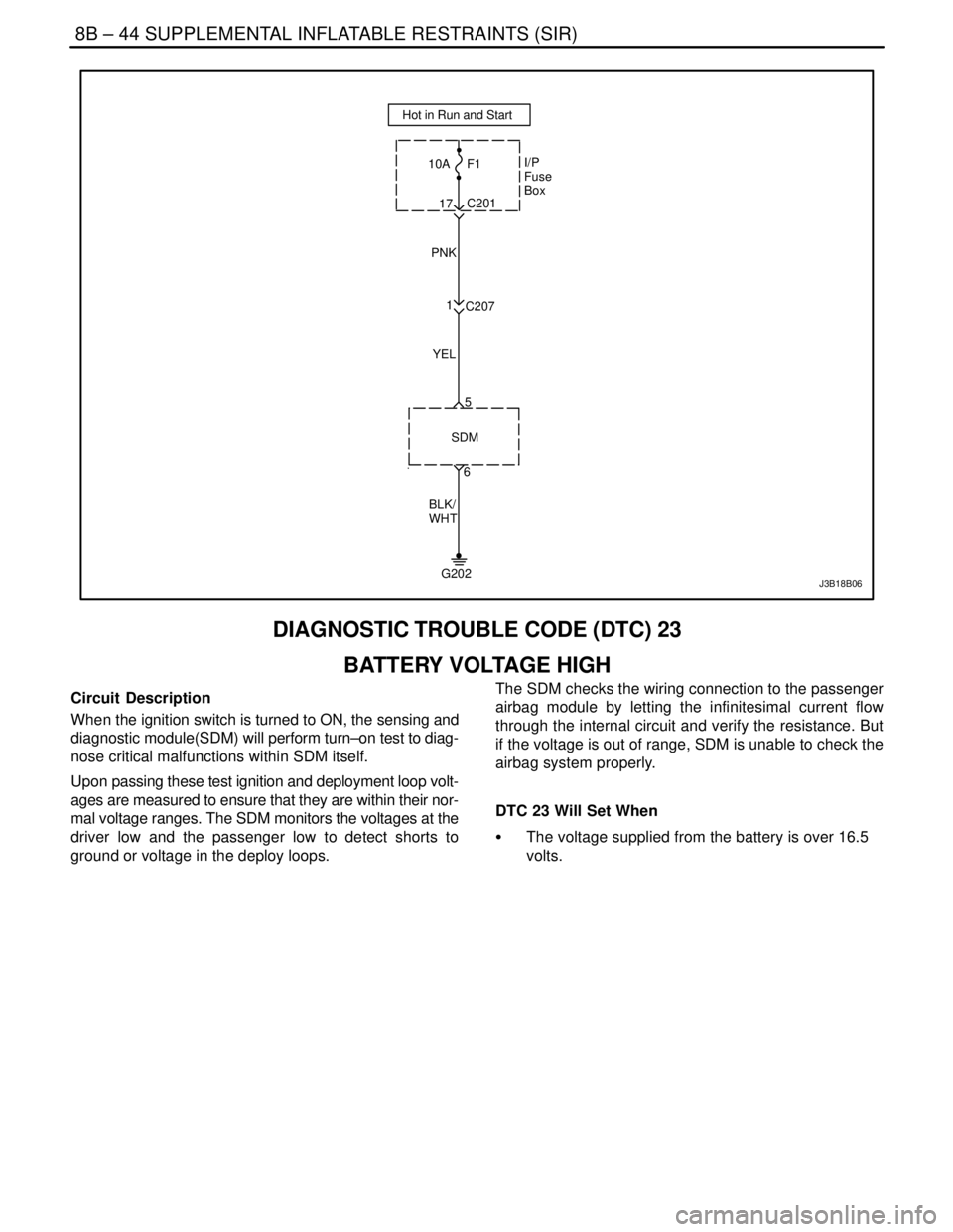

8B – 44ISUPPLEMENTAL INFLATABLE RESTRAINTS (SIR)

DAEWOO V–121 BL4

J3B18B06

YEL

10AI/P

Fuse

Box

1 PNKC201

C207

SDM

BLK/

WHTF1

Hot in Run and Start

65 17

G202

DIAGNOSTIC TROUBLE CODE (DTC) 23

BATTERY VOLTAGE HIGH

Circuit Description

When the ignition switch is turned to ON, the sensing and

diagnostic module(SDM) will perform turn–on test to diag-

nose critical malfunctions within SDM itself.

Upon passing these test ignition and deployment loop volt-

ages are measured to ensure that they are within their nor-

mal voltage ranges. The SDM monitors the voltages at the

driver low and the passenger low to detect shorts to

ground or voltage in the deploy loops.The SDM checks the wiring connection to the passenger

airbag module by letting the infinitesimal current flow

through the internal circuit and verify the resistance. But

if the voltage is out of range, SDM is unable to check the

airbag system properly.

DTC 23 Will Set When

S The voltage supplied from the battery is over 16.5

volts.

Page 2150 of 2643

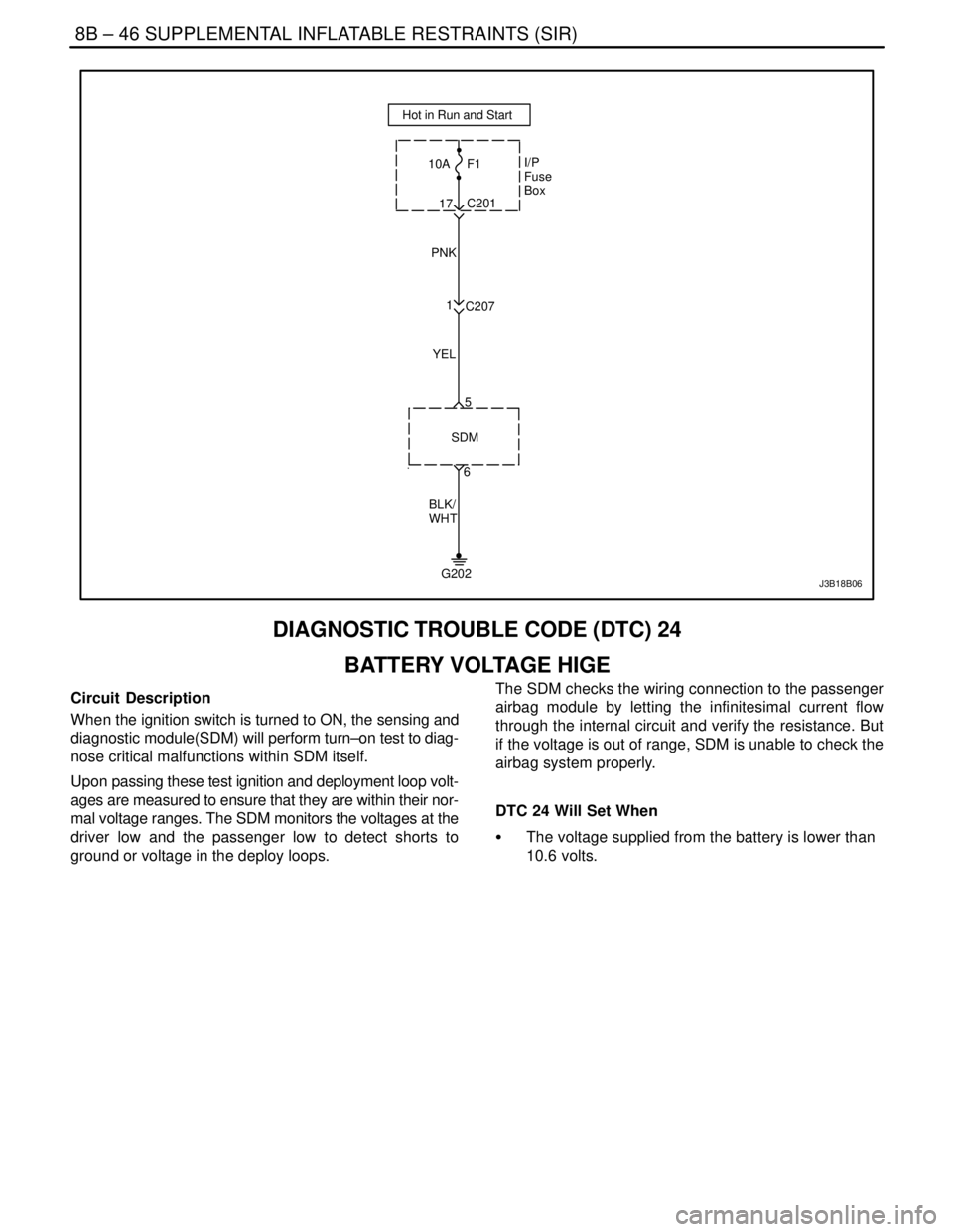

8B – 46ISUPPLEMENTAL INFLATABLE RESTRAINTS (SIR)

DAEWOO V–121 BL4

J3B18B06

YEL

10AI/P

Fuse

Box

1 PNKC201

C207

SDM

BLK/

WHTF1

Hot in Run and Start

65 17

G202

DIAGNOSTIC TROUBLE CODE (DTC) 24

BATTERY VOLTAGE HIGE

Circuit Description

When the ignition switch is turned to ON, the sensing and

diagnostic module(SDM) will perform turn–on test to diag-

nose critical malfunctions within SDM itself.

Upon passing these test ignition and deployment loop volt-

ages are measured to ensure that they are within their nor-

mal voltage ranges. The SDM monitors the voltages at the

driver low and the passenger low to detect shorts to

ground or voltage in the deploy loops.The SDM checks the wiring connection to the passenger

airbag module by letting the infinitesimal current flow

through the internal circuit and verify the resistance. But

if the voltage is out of range, SDM is unable to check the

airbag system properly.

DTC 24 Will Set When

S The voltage supplied from the battery is lower than

10.6 volts.