ECU DAEWOO NUBIRA 2004 Service Repair Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: NUBIRA, Model: DAEWOO NUBIRA 2004Pages: 2643, PDF Size: 80.54 MB

Page 1704 of 2643

5A2 – 114IAISIN AUTOMATIC TRANSAXLE

DAEWOO V–121 BL4

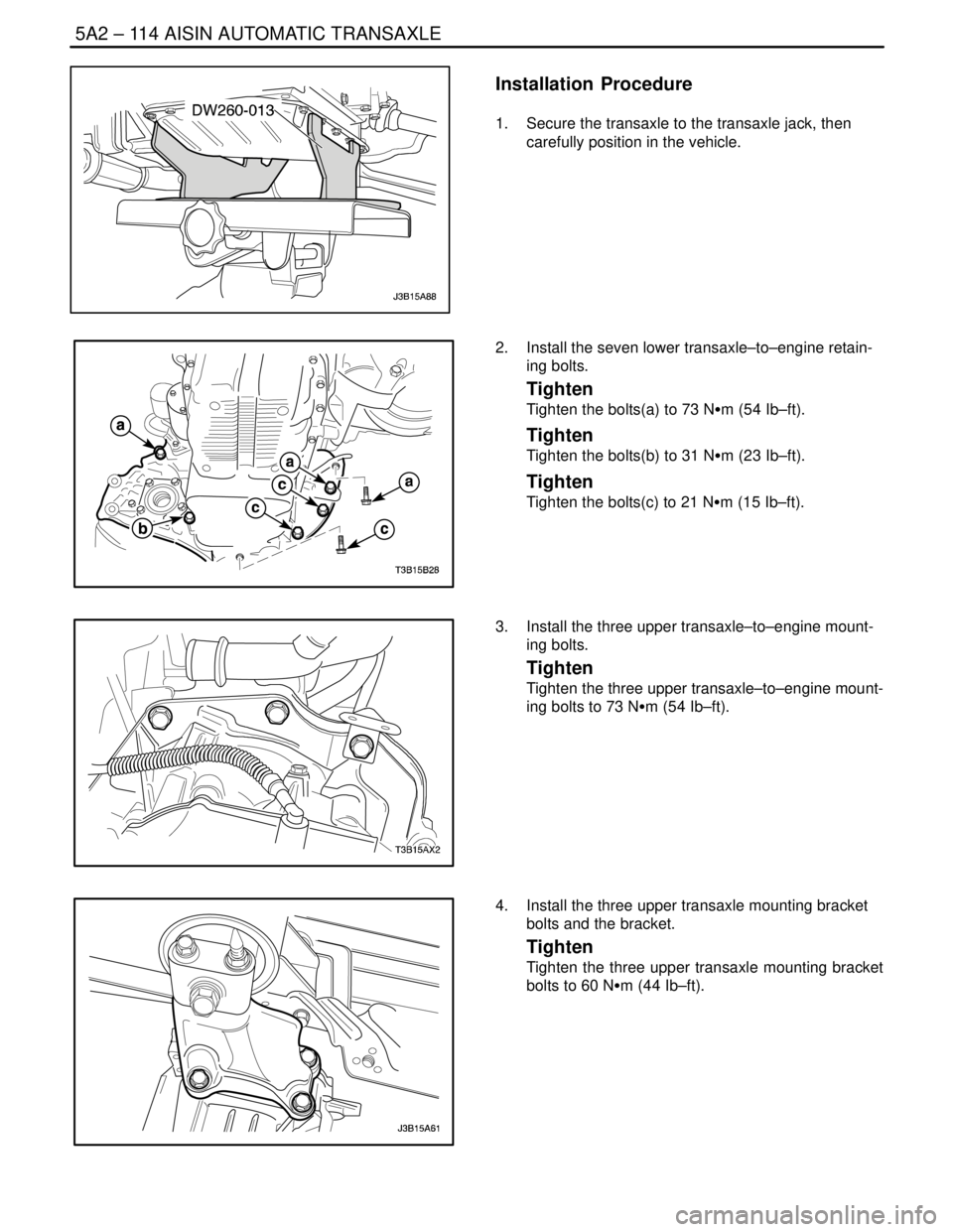

Installation Procedure

1. Secure the transaxle to the transaxle jack, then

carefully position in the vehicle.

2. Install the seven lower transaxle–to–engine retain-

ing bolts.

Tighten

Tighten the bolts(a) to 73 NSm (54 Ib–ft).

Tighten

Tighten the bolts(b) to 31 NSm (23 Ib–ft).

Tighten

Tighten the bolts(c) to 21 NSm (15 Ib–ft).

3. Install the three upper transaxle–to–engine mount-

ing bolts.

Tighten

Tighten the three upper transaxle–to–engine mount-

ing bolts to 73 NSm (54 Ib–ft).

4. Install the three upper transaxle mounting bracket

bolts and the bracket.

Tighten

Tighten the three upper transaxle mounting bracket

bolts to 60 NSm (44 Ib–ft).

Page 1737 of 2643

AISIN AUTOMATIC TRANSAXLE 5A2 – 147

DAEWOO V–121 BL4

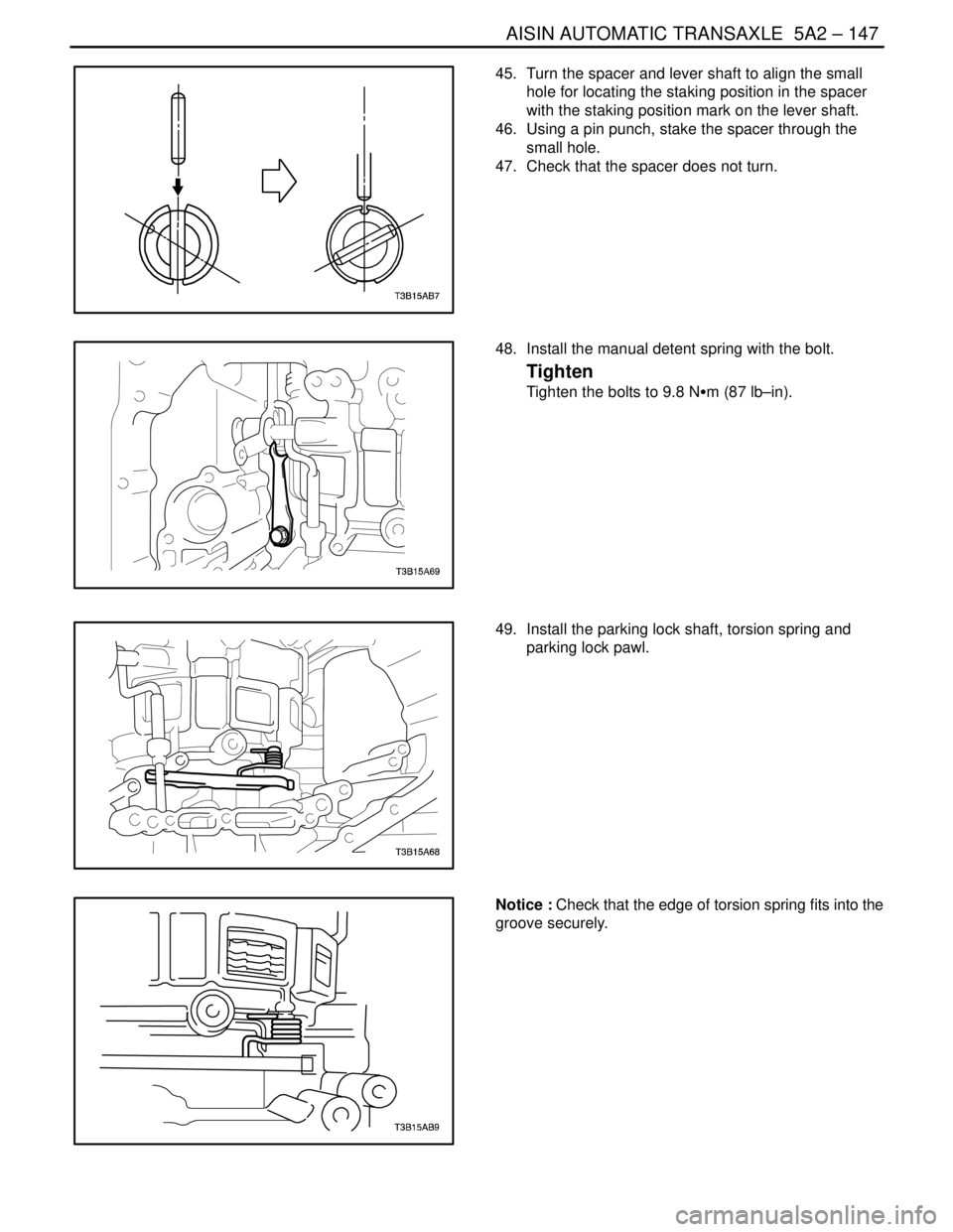

45. Turn the spacer and lever shaft to align the small

hole for locating the staking position in the spacer

with the staking position mark on the lever shaft.

46. Using a pin punch, stake the spacer through the

small hole.

47. Check that the spacer does not turn.

48. Install the manual detent spring with the bolt.

Tighten

Tighten the bolts to 9.8 NSm (87 lb–in).

49. Install the parking lock shaft, torsion spring and

parking lock pawl.

Notice : Check that the edge of torsion spring fits into the

groove securely.

Page 1839 of 2643

FIVE–SPEED MANUAL TRANSAXLE 5B – 15

DAEWOO V–121 BL4

MAINTENANCE AND REPAIR

ON–VEHICLE SERVICE

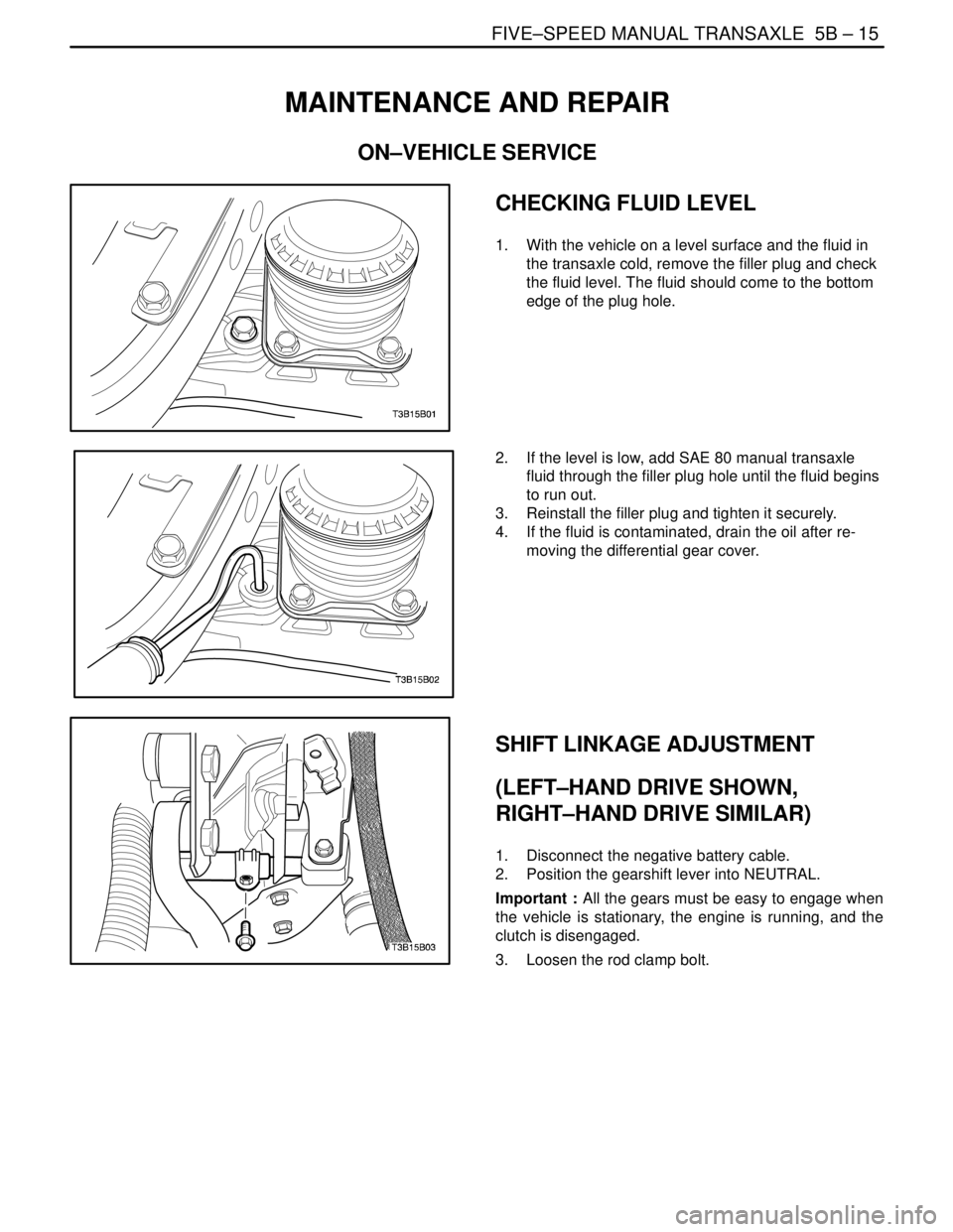

CHECKING FLUID LEVEL

1. With the vehicle on a level surface and the fluid in

the transaxle cold, remove the filler plug and check

the fluid level. The fluid should come to the bottom

edge of the plug hole.

2. If the level is low, add SAE 80 manual transaxle

fluid through the filler plug hole until the fluid begins

to run out.

3. Reinstall the filler plug and tighten it securely.

4. If the fluid is contaminated, drain the oil after re-

moving the differential gear cover.

SHIFT LINKAGE ADJUSTMENT

(LEFT–HAND DRIVE SHOWN,

RIGHT–HAND DRIVE SIMILAR)

1. Disconnect the negative battery cable.

2. Position the gearshift lever into NEUTRAL.

Important : All the gears must be easy to engage when

the vehicle is stationary, the engine is running, and the

clutch is disengaged.

3. Loosen the rod clamp bolt.

Page 1841 of 2643

FIVE–SPEED MANUAL TRANSAXLE 5B – 17

DAEWOO V–121 BL4

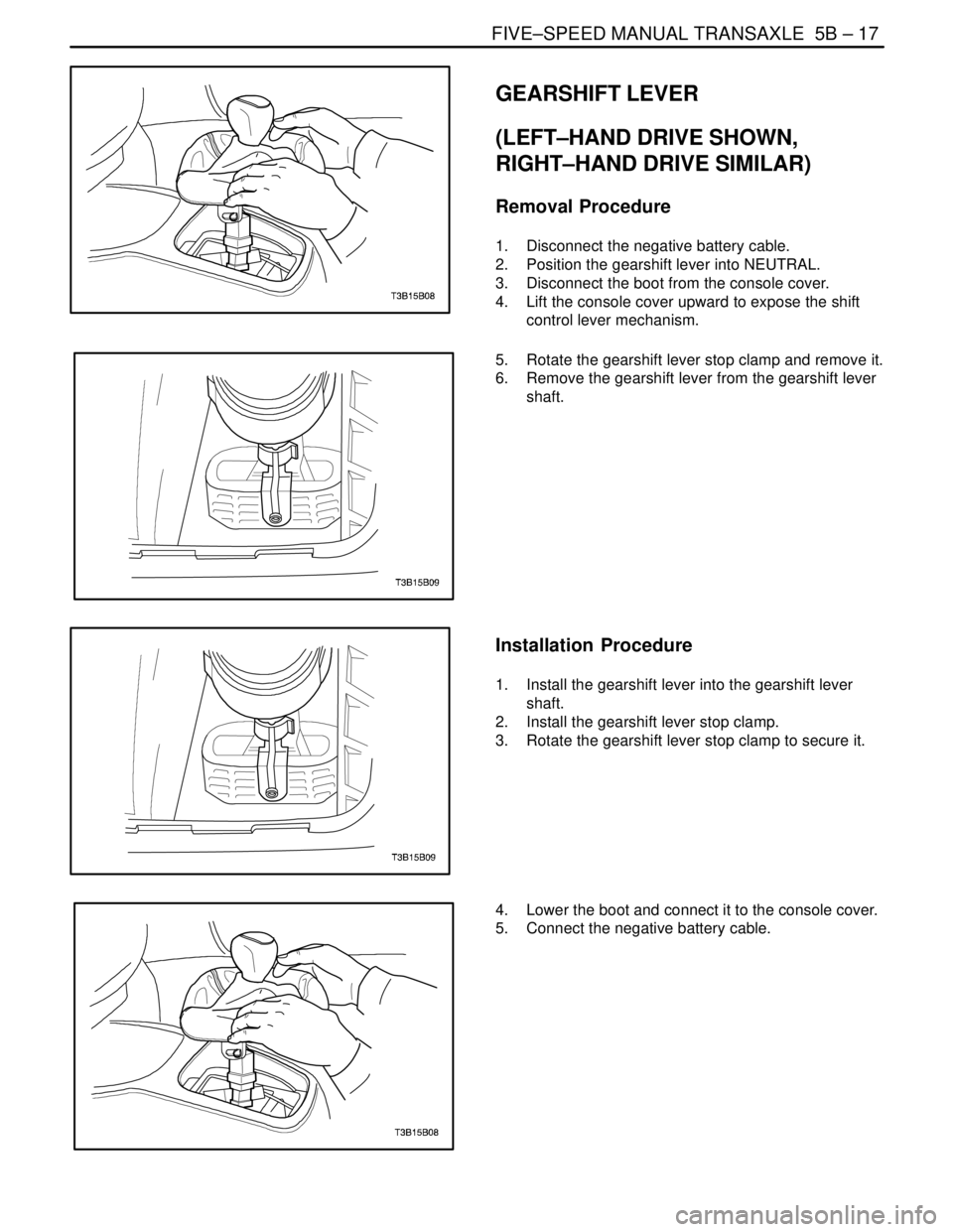

GEARSHIFT LEVER

(LEFT–HAND DRIVE SHOWN,

RIGHT–HAND DRIVE SIMILAR)

Removal Procedure

1. Disconnect the negative battery cable.

2. Position the gearshift lever into NEUTRAL.

3. Disconnect the boot from the console cover.

4. Lift the console cover upward to expose the shift

control lever mechanism.

5. Rotate the gearshift lever stop clamp and remove it.

6. Remove the gearshift lever from the gearshift lever

shaft.

Installation Procedure

1. Install the gearshift lever into the gearshift lever

shaft.

2. Install the gearshift lever stop clamp.

3. Rotate the gearshift lever stop clamp to secure it.

4. Lower the boot and connect it to the console cover.

5. Connect the negative battery cable.

Page 1858 of 2643

5B – 34IFIVE–SPEED MANUAL TRANSAXLE

DAEWOO V–121 BL4

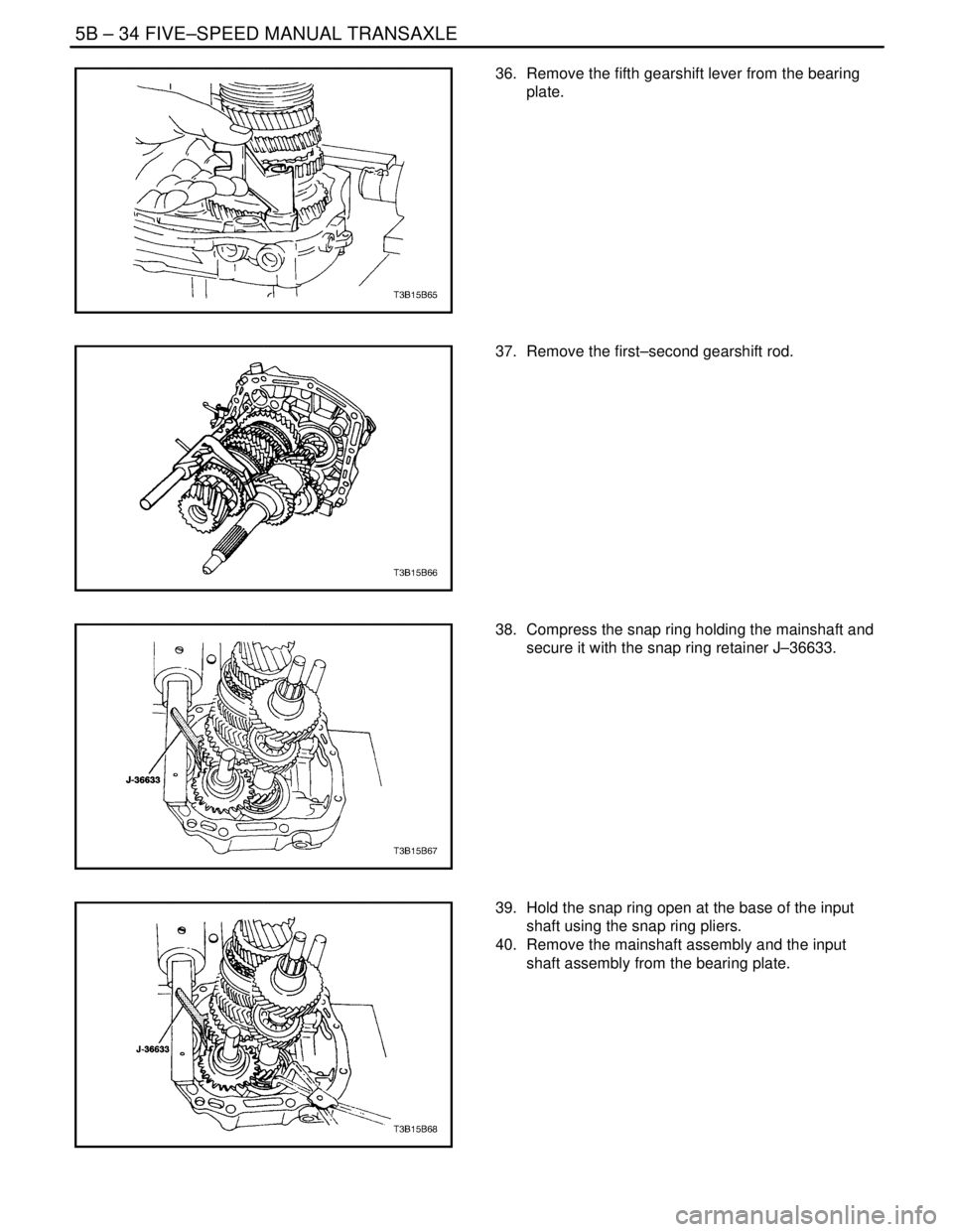

36. Remove the fifth gearshift lever from the bearing

plate.

37. Remove the first–second gearshift rod.

38. Compress the snap ring holding the mainshaft and

secure it with the snap ring retainer J–36633.

39. Hold the snap ring open at the base of the input

shaft using the snap ring pliers.

40. Remove the mainshaft assembly and the input

shaft assembly from the bearing plate.

Page 1883 of 2643

FIVE–SPEED MANUAL TRANSAXLE 5B – 59

DAEWOO V–121 BL4

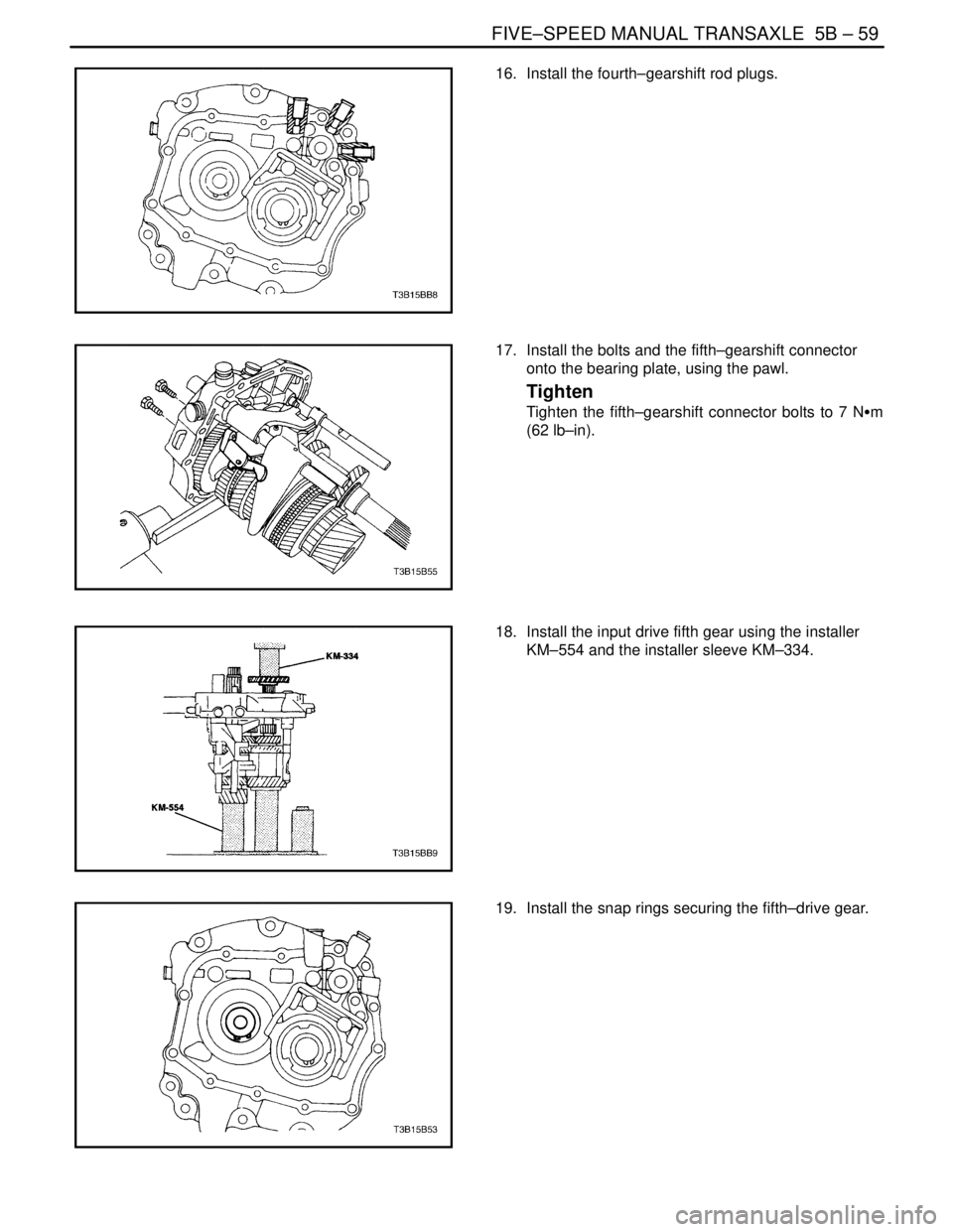

16. Install the fourth–gearshift rod plugs.

17. Install the bolts and the fifth–gearshift connector

onto the bearing plate, using the pawl.

Tighten

Tighten the fifth–gearshift connector bolts to 7 NSm

(62 lb–in).

18. Install the input drive fifth gear using the installer

KM–554 and the installer sleeve KM–334.

19. Install the snap rings securing the fifth–drive gear.

Page 1908 of 2643

POWER STEERING SYSTEM 6A – 7

DAEWOO V–121 BL4

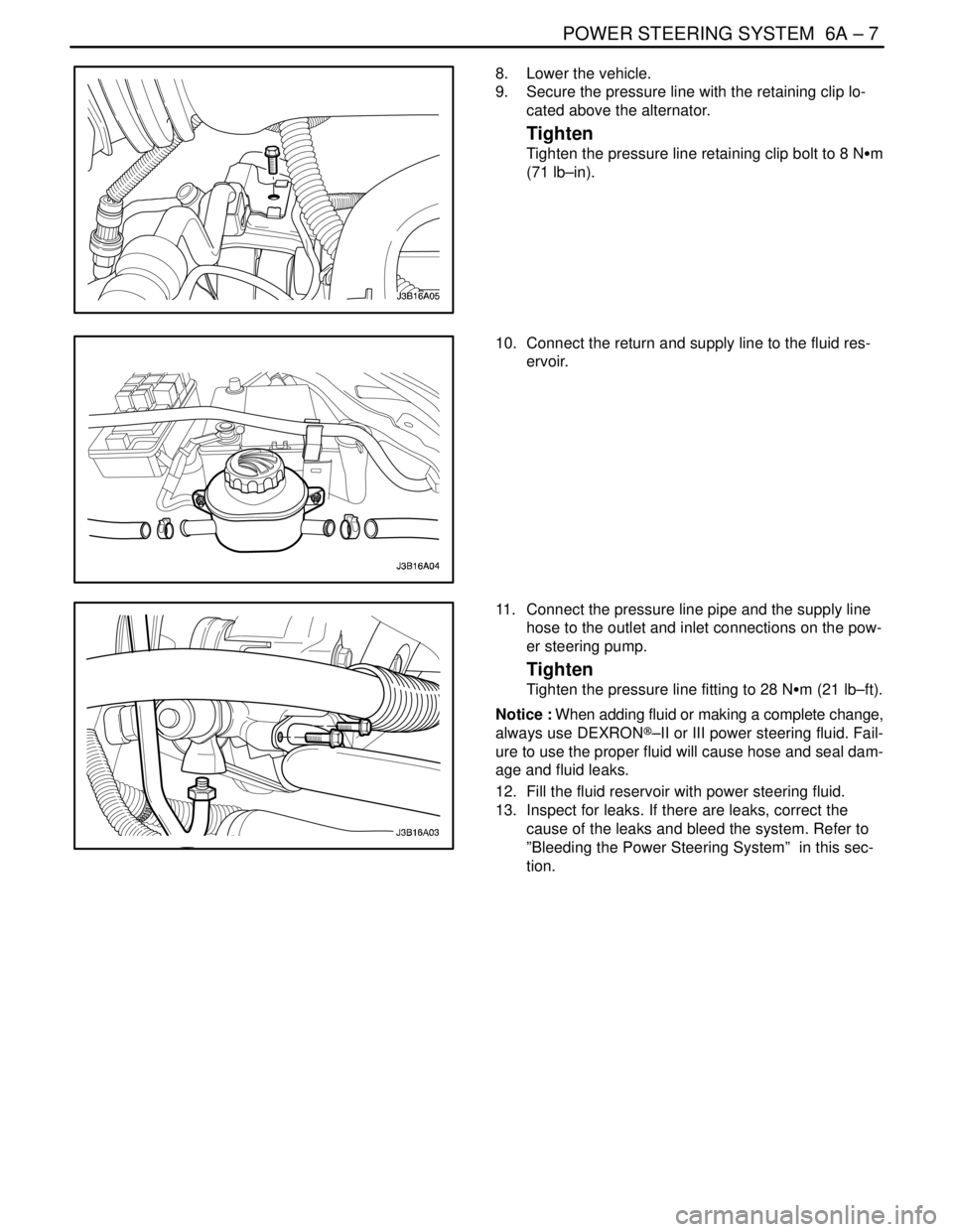

8. Lower the vehicle.

9. Secure the pressure line with the retaining clip lo-

cated above the alternator.

Tighten

Tighten the pressure line retaining clip bolt to 8 NSm

(71 lb–in).

10. Connect the return and supply line to the fluid res-

ervoir.

11. Connect the pressure line pipe and the supply line

hose to the outlet and inlet connections on the pow-

er steering pump.

Tighten

Tighten the pressure line fitting to 28 NSm (21 lb–ft).

Notice : When adding fluid or making a complete change,

always use DEXRON®–II or III power steering fluid. Fail-

ure to use the proper fluid will cause hose and seal dam-

age and fluid leaks.

12. Fill the fluid reservoir with power steering fluid.

13. Inspect for leaks. If there are leaks, correct the

cause of the leaks and bleed the system. Refer to

”Bleeding the Power Steering System” in this sec-

tion.

Page 1929 of 2643

6C – 12IPOWER STEERING GEAR

DAEWOO V–121 BL4

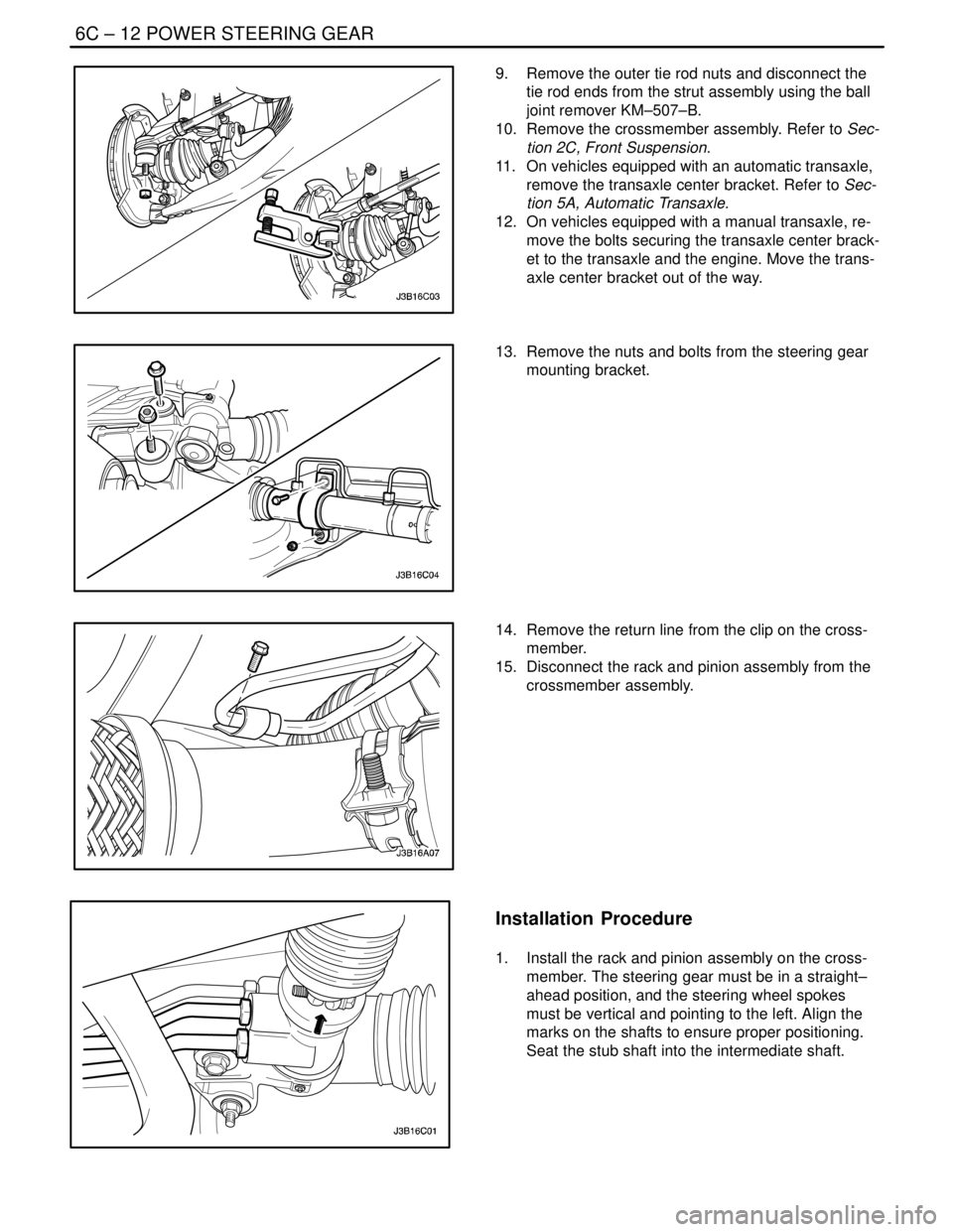

9. Remove the outer tie rod nuts and disconnect the

tie rod ends from the strut assembly using the ball

joint remover KM–507–B.

10. Remove the crossmember assembly. Refer to Sec-

tion 2C, Front Suspension.

11. On vehicles equipped with an automatic transaxle,

remove the transaxle center bracket. Refer to Sec-

tion 5A, Automatic Transaxle.

12. On vehicles equipped with a manual transaxle, re-

move the bolts securing the transaxle center brack-

et to the transaxle and the engine. Move the trans-

axle center bracket out of the way.

13. Remove the nuts and bolts from the steering gear

mounting bracket.

14. Remove the return line from the clip on the cross-

member.

15. Disconnect the rack and pinion assembly from the

crossmember assembly.

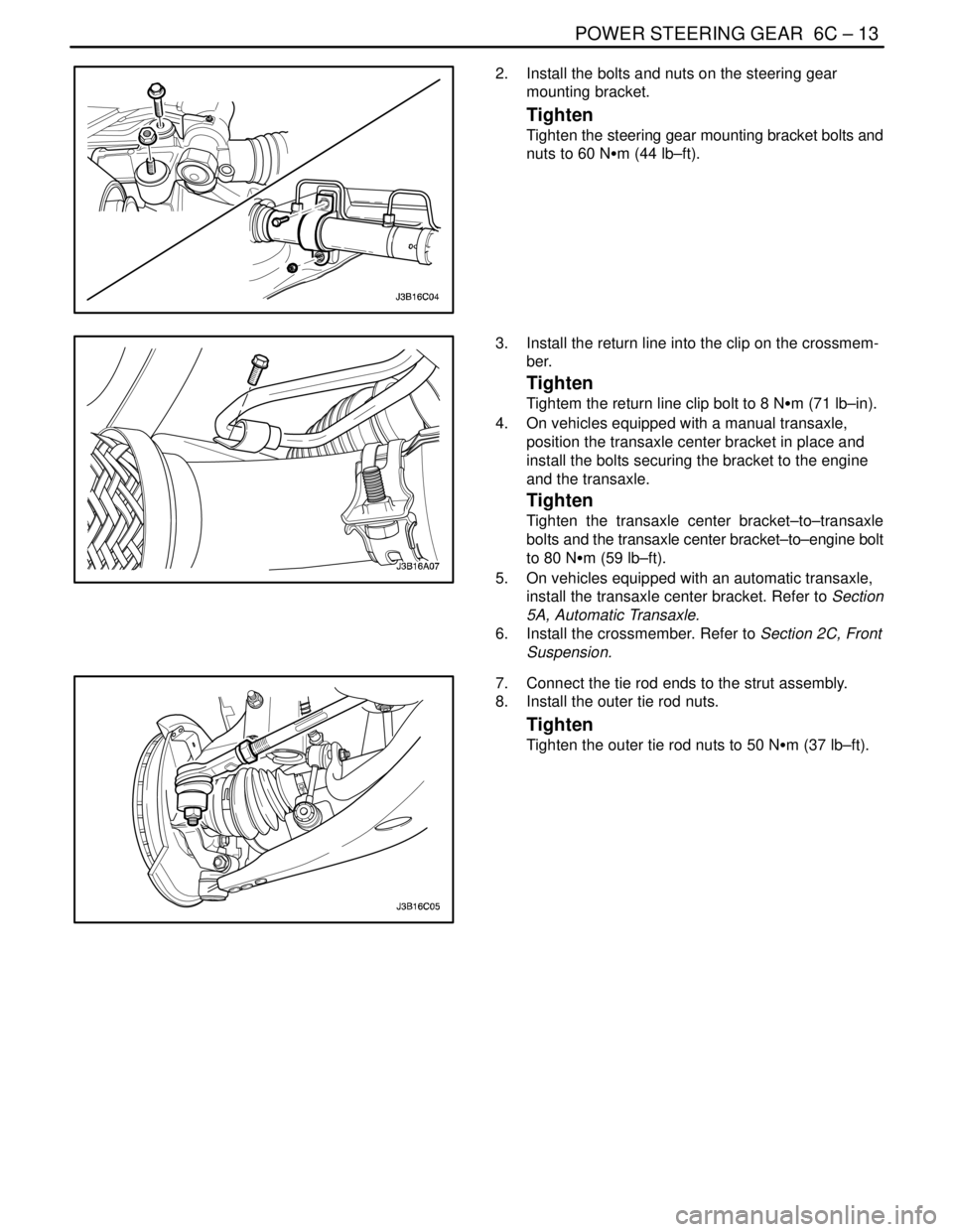

Installation Procedure

1. Install the rack and pinion assembly on the cross-

member. The steering gear must be in a straight–

ahead position, and the steering wheel spokes

must be vertical and pointing to the left. Align the

marks on the shafts to ensure proper positioning.

Seat the stub shaft into the intermediate shaft.

Page 1930 of 2643

POWER STEERING GEAR 6C – 13

DAEWOO V–121 BL4

2. Install the bolts and nuts on the steering gear

mounting bracket.

Tighten

Tighten the steering gear mounting bracket bolts and

nuts to 60 NSm (44 lb–ft).

3. Install the return line into the clip on the crossmem-

ber.

Tighten

Tightem the return line clip bolt to 8 NSm (71 lb–in).

4. On vehicles equipped with a manual transaxle,

position the transaxle center bracket in place and

install the bolts securing the bracket to the engine

and the transaxle.

Tighten

Tighten the transaxle center bracket–to–transaxle

bolts and the transaxle center bracket–to–engine bolt

to 80 NSm (59 lb–ft).

5. On vehicles equipped with an automatic transaxle,

install the transaxle center bracket. Refer to Section

5A, Automatic Transaxle.

6. Install the crossmember. Refer to Section 2C, Front

Suspension.

7. Connect the tie rod ends to the strut assembly.

8. Install the outer tie rod nuts.

Tighten

Tighten the outer tie rod nuts to 50 NSm (37 lb–ft).

Page 1941 of 2643

6C – 24IPOWER STEERING GEAR

DAEWOO V–121 BL4

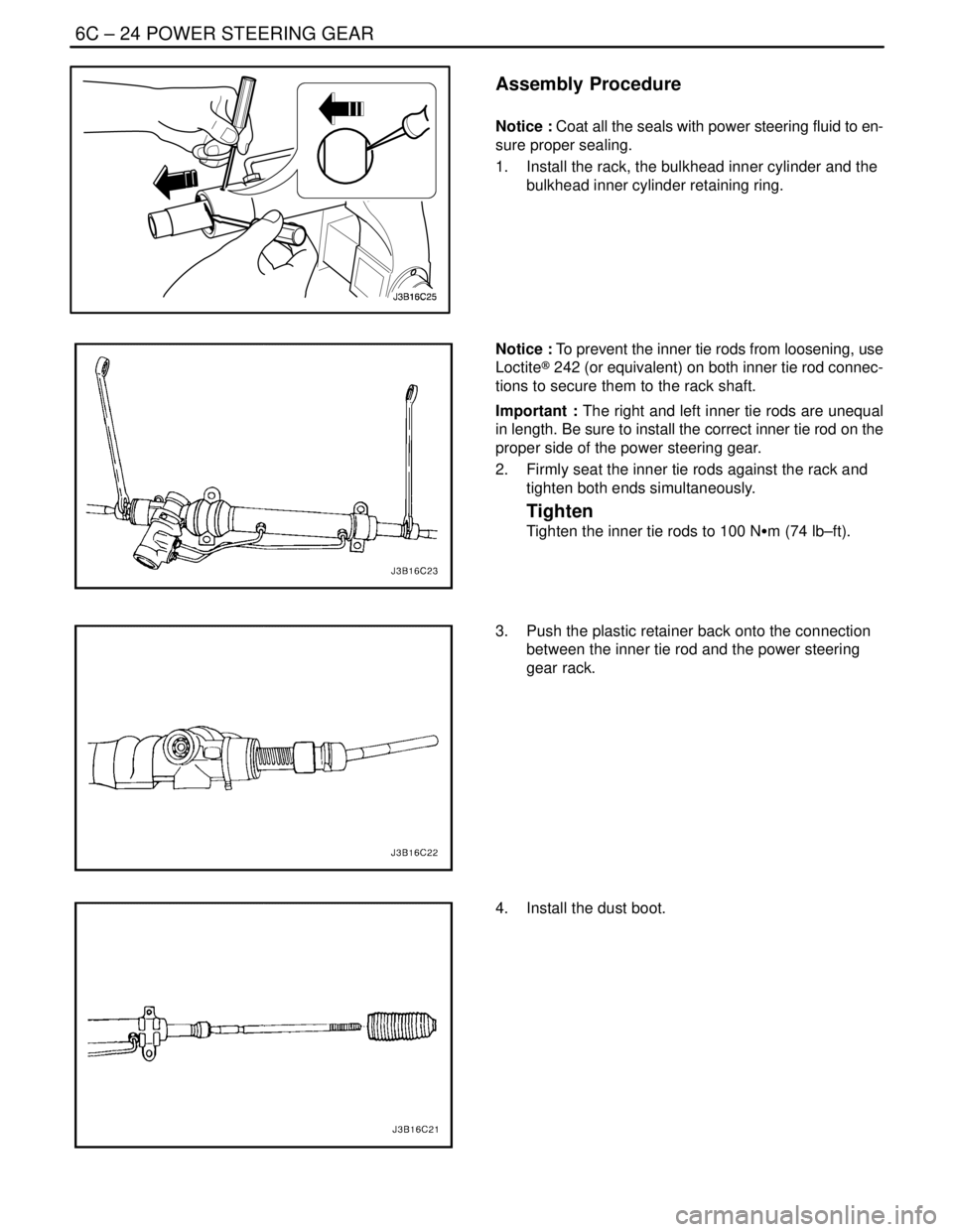

Assembly Procedure

Notice : Coat all the seals with power steering fluid to en-

sure proper sealing.

1. Install the rack, the bulkhead inner cylinder and the

bulkhead inner cylinder retaining ring.

Notice : To prevent the inner tie rods from loosening, use

Loctite® 242 (or equivalent) on both inner tie rod connec-

tions to secure them to the rack shaft.

Important : The right and left inner tie rods are unequal

in length. Be sure to install the correct inner tie rod on the

proper side of the power steering gear.

2. Firmly seat the inner tie rods against the rack and

tighten both ends simultaneously.

Tighten

Tighten the inner tie rods to 100 NSm (74 lb–ft).

3. Push the plastic retainer back onto the connection

between the inner tie rod and the power steering

gear rack.

4. Install the dust boot.