ECU DAEWOO NUBIRA 2004 Service Repair Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: NUBIRA, Model: DAEWOO NUBIRA 2004Pages: 2643, PDF Size: 80.54 MB

Page 2092 of 2643

IAUTOMATIC TEMPERATURE CONTROL HEATING, VENTILATION, AND AIR CONDITIONING SYSTEM 7D – 37

DAEWOO V–121 BL4

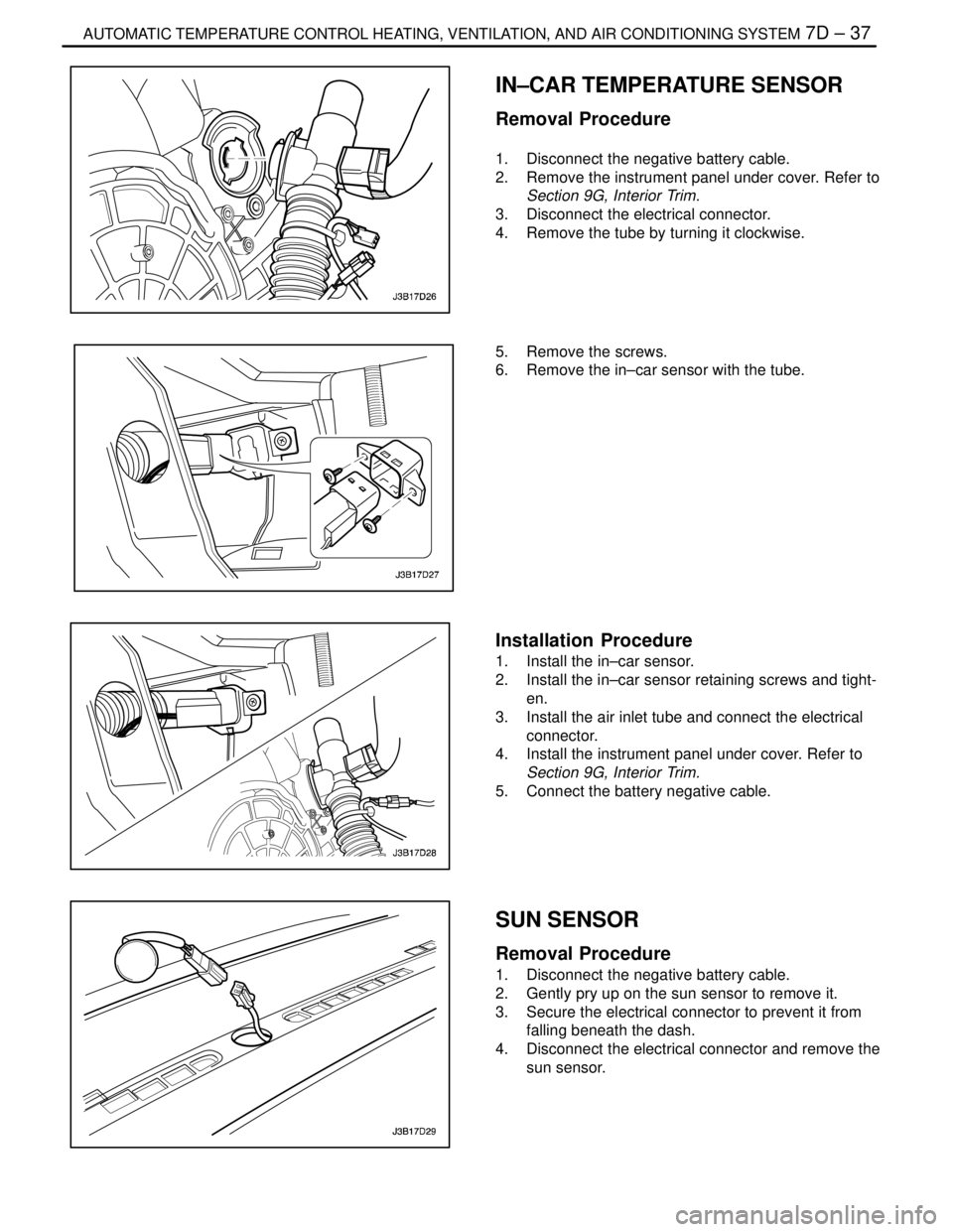

IN–CAR TEMPERATURE SENSOR

Removal Procedure

1. Disconnect the negative battery cable.

2. Remove the instrument panel under cover. Refer to

Section 9G, Interior Trim.

3. Disconnect the electrical connector.

4. Remove the tube by turning it clockwise.

5. Remove the screws.

6. Remove the in–car sensor with the tube.

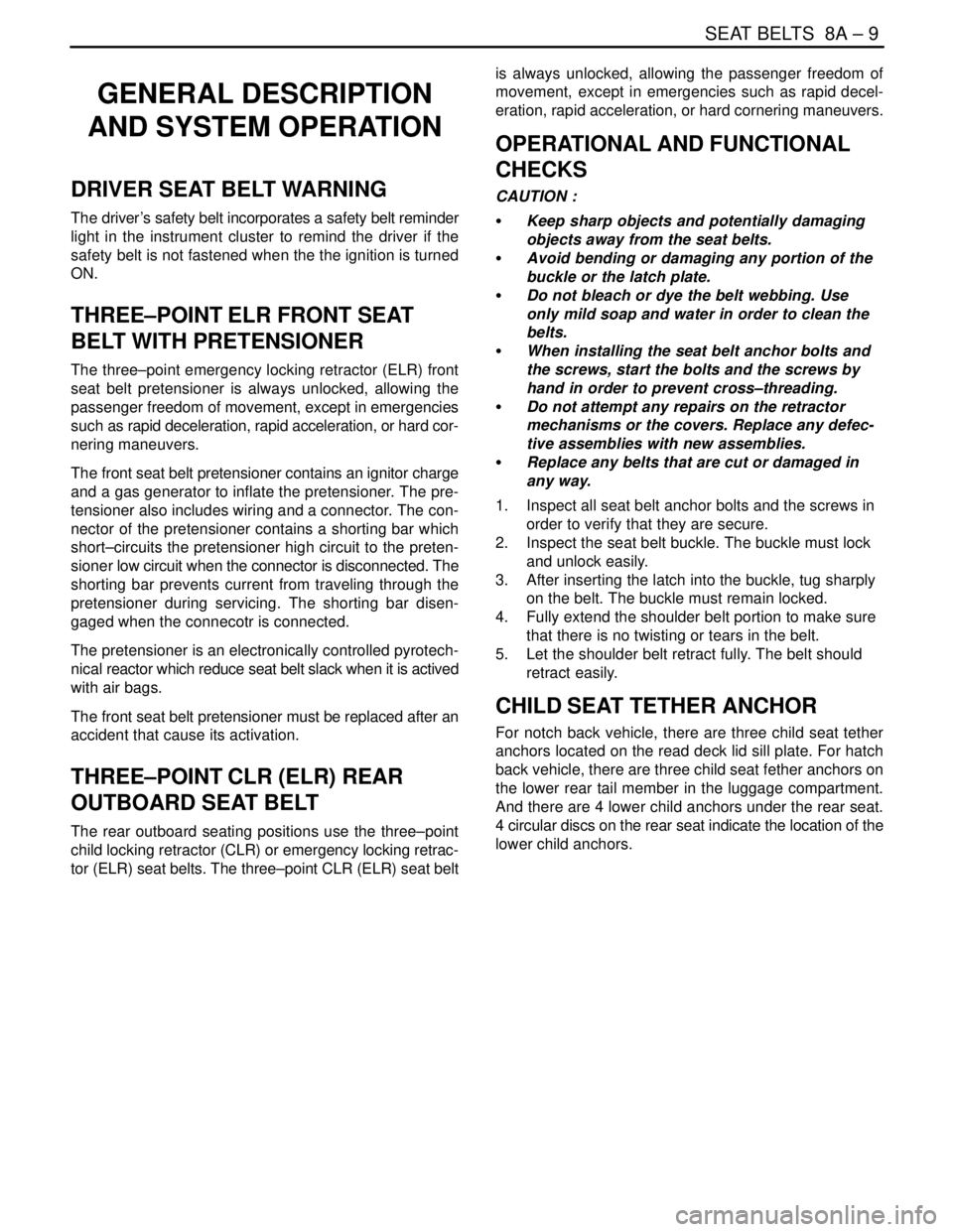

Installation Procedure

1. Install the in–car sensor.

2. Install the in–car sensor retaining screws and tight-

en.

3. Install the air inlet tube and connect the electrical

connector.

4. Install the instrument panel under cover. Refer to

Section 9G, Interior Trim.

5. Connect the battery negative cable.

SUN SENSOR

Removal Procedure

1. Disconnect the negative battery cable.

2. Gently pry up on the sun sensor to remove it.

3. Secure the electrical connector to prevent it from

falling beneath the dash.

4. Disconnect the electrical connector and remove the

sun sensor.

Page 2101 of 2643

8A – 6ISEAT BELTS

DAEWOO V–121 BL4

Installation Procedure

Notice : Dissimilar metals in direct contact with each other

may corrode rapidly. Make sure to use the correct fasten-

ers to prevent premature corrosion.

1. Install the seat belt height adjuster with the bolts.

Tighten

Tighten the front seat belt height adjuster bolts to 23

NSm (17 lb–ft).

2. Install the upper B–pillar trim panel. Refer to Sec-

tion 9G, Interior Trim.

THREE–POINT REAR SEAT BELT

(LH,CENTER, RH)

Removal Procedure

1. Remove the back shelf panel. Refer to Section 9G,

Interior Trim.

2. Remove the rear seat belt retractor securing bolts

(LH, CENTER, RH) from the back panel.

3. Remove the rear seat cushion. Refer to Section 9H,

SEATS.

4. Remove the floor seat belt anchor bolts.

5. Remove the seat belt.

Page 2104 of 2643

SEAT BELTS 8A – 9

DAEWOO V–121 BL4

GENERAL DESCRIPTION

AND SYSTEM OPERATION

DRIVER SEAT BELT WARNING

The driver’s safety belt incorporates a safety belt reminder

light in the instrument cluster to remind the driver if the

safety belt is not fastened when the the ignition is turned

ON.

THREE–POINT ELR FRONT SEAT

BELT WITH PRETENSIONER

The three–point emergency locking retractor (ELR) front

seat belt pretensioner is always unlocked, allowing the

passenger freedom of movement, except in emergencies

such as rapid deceleration, rapid acceleration, or hard cor-

nering maneuvers.

The front seat belt pretensioner contains an ignitor charge

and a gas generator to inflate the pretensioner. The pre-

tensioner also includes wiring and a connector. The con-

nector of the pretensioner contains a shorting bar which

short–circuits the pretensioner high circuit to the preten-

sioner low circuit when the connector is disconnected. The

shorting bar prevents current from traveling through the

pretensioner during servicing. The shorting bar disen-

gaged when the connecotr is connected.

The pretensioner is an electronically controlled pyrotech-

nical reactor which reduce seat belt slack when it is actived

with air bags.

The front seat belt pretensioner must be replaced after an

accident that cause its activation.

THREE–POINT CLR (ELR) REAR

OUTBOARD SEAT BELT

The rear outboard seating positions use the three–point

child locking retractor (CLR) or emergency locking retrac-

tor (ELR) seat belts. The three–point CLR (ELR) seat beltis always unlocked, allowing the passenger freedom of

movement, except in emergencies such as rapid decel-

eration, rapid acceleration, or hard cornering maneuvers.

OPERATIONAL AND FUNCTIONAL

CHECKS

CAUTION :

S Keep sharp objects and potentially damaging

objects away from the seat belts.

S Avoid bending or damaging any portion of the

buckle or the latch plate.

S Do not bleach or dye the belt webbing. Use

only mild soap and water in order to clean the

belts.

S When installing the seat belt anchor bolts and

the screws, start the bolts and the screws by

hand in order to prevent cross–threading.

S Do not attempt any repairs on the retractor

mechanisms or the covers. Replace any defec-

tive assemblies with new assemblies.

S Replace any belts that are cut or damaged in

any way.

1. Inspect all seat belt anchor bolts and the screws in

order to verify that they are secure.

2. Inspect the seat belt buckle. The buckle must lock

and unlock easily.

3. After inserting the latch into the buckle, tug sharply

on the belt. The buckle must remain locked.

4. Fully extend the shoulder belt portion to make sure

that there is no twisting or tears in the belt.

5. Let the shoulder belt retract fully. The belt should

retract easily.

CHILD SEAT TETHER ANCHOR

For notch back vehicle, there are three child seat tether

anchors located on the read deck lid sill plate. For hatch

back vehicle, there are three child seat fether anchors on

the lower rear tail member in the luggage compartment.

And there are 4 lower child anchors under the rear seat.

4 circular discs on the rear seat indicate the location of the

lower child anchors.

Page 2199 of 2643

SUPPLEMENTAL INFLATABLE RESTRAINTS (SIR) 8B – 95

DAEWOO V–121 BL4

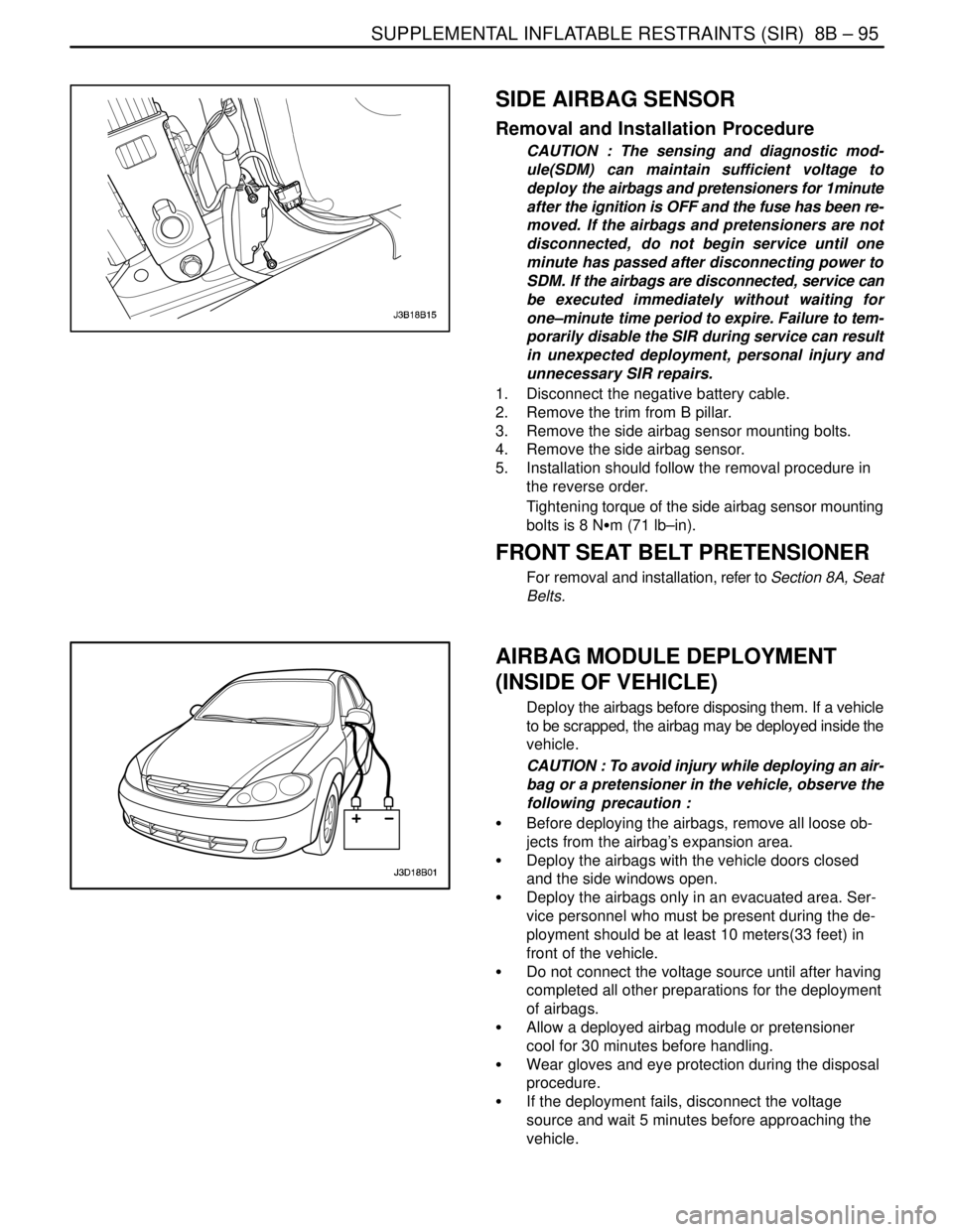

SIDE AIRBAG SENSOR

Removal and Installation Procedure

CAUTION : The sensing and diagnostic mod-

ule(SDM) can maintain sufficient voltage to

deploy the airbags and pretensioners for 1minute

after the ignition is OFF and the fuse has been re-

moved. If the airbags and pretensioners are not

disconnected, do not begin service until one

minute has passed after disconnecting power to

SDM. If the airbags are disconnected, service can

be executed immediately without waiting for

one–minute time period to expire. Failure to tem-

porarily disable the SIR during service can result

in unexpected deployment, personal injury and

unnecessary SIR repairs.

1. Disconnect the negative battery cable.

2. Remove the trim from B pillar.

3. Remove the side airbag sensor mounting bolts.

4. Remove the side airbag sensor.

5. Installation should follow the removal procedure in

the reverse order.

Tightening torque of the side airbag sensor mounting

bolts is 8 NSm (71 lb–in).

FRONT SEAT BELT PRETENSIONER

For removal and installation, refer to Section 8A, Seat

Belts.

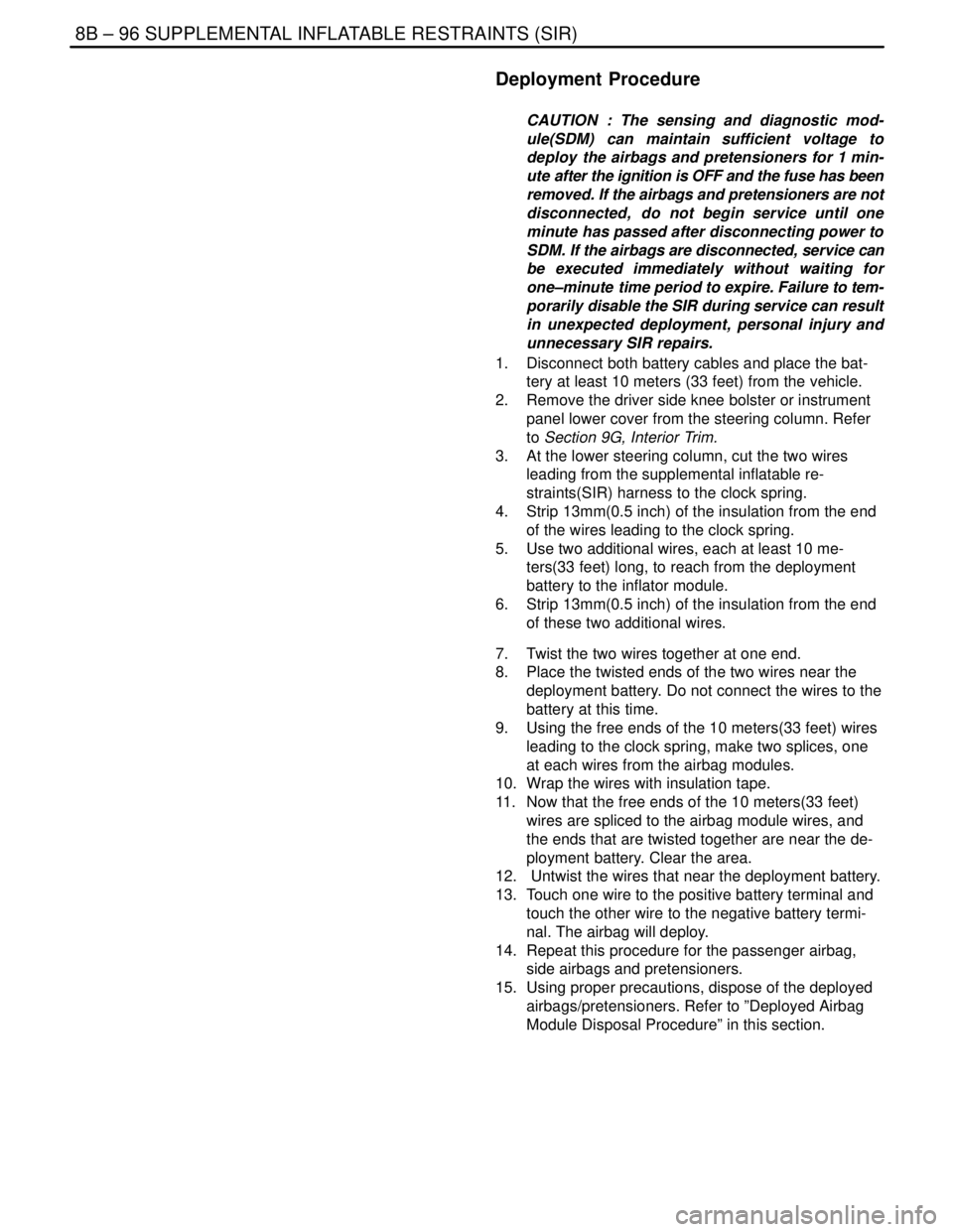

AIRBAG MODULE DEPLOYMENT

(INSIDE OF VEHICLE)

Deploy the airbags before disposing them. If a vehicle

to be scrapped, the airbag may be deployed inside the

vehicle.

CAUTION : To avoid injury while deploying an air-

bag or a pretensioner in the vehicle, observe the

following precaution :

S Before deploying the airbags, remove all loose ob-

jects from the airbag’s expansion area.

S Deploy the airbags with the vehicle doors closed

and the side windows open.

S Deploy the airbags only in an evacuated area. Ser-

vice personnel who must be present during the de-

ployment should be at least 10 meters(33 feet) in

front of the vehicle.

S Do not connect the voltage source until after having

completed all other preparations for the deployment

of airbags.

S Allow a deployed airbag module or pretensioner

cool for 30 minutes before handling.

S Wear gloves and eye protection during the disposal

procedure.

S If the deployment fails, disconnect the voltage

source and wait 5 minutes before approaching the

vehicle.

Page 2200 of 2643

8B – 96ISUPPLEMENTAL INFLATABLE RESTRAINTS (SIR)

DAEWOO V–121 BL4

Deployment Procedure

CAUTION : The sensing and diagnostic mod-

ule(SDM) can maintain sufficient voltage to

deploy the airbags and pretensioners for 1 min-

ute after the ignition is OFF and the fuse has been

removed. If the airbags and pretensioners are not

disconnected, do not begin service until one

minute has passed after disconnecting power to

SDM. If the airbags are disconnected, service can

be executed immediately without waiting for

one–minute time period to expire. Failure to tem-

porarily disable the SIR during service can result

in unexpected deployment, personal injury and

unnecessary SIR repairs.

1. Disconnect both battery cables and place the bat-

tery at least 10 meters (33 feet) from the vehicle.

2. Remove the driver side knee bolster or instrument

panel lower cover from the steering column. Refer

to Section 9G, Interior Trim.

3. At the lower steering column, cut the two wires

leading from the supplemental inflatable re-

straints(SIR) harness to the clock spring.

4. Strip 13mm(0.5 inch) of the insulation from the end

of the wires leading to the clock spring.

5. Use two additional wires, each at least 10 me-

ters(33 feet) long, to reach from the deployment

battery to the inflator module.

6. Strip 13mm(0.5 inch) of the insulation from the end

of these two additional wires.

7. Twist the two wires together at one end.

8. Place the twisted ends of the two wires near the

deployment battery. Do not connect the wires to the

battery at this time.

9. Using the free ends of the 10 meters(33 feet) wires

leading to the clock spring, make two splices, one

at each wires from the airbag modules.

10. Wrap the wires with insulation tape.

11. Now that the free ends of the 10 meters(33 feet)

wires are spliced to the airbag module wires, and

the ends that are twisted together are near the de-

ployment battery. Clear the area.

12. Untwist the wires that near the deployment battery.

13. Touch one wire to the positive battery terminal and

touch the other wire to the negative battery termi-

nal. The airbag will deploy.

14. Repeat this procedure for the passenger airbag,

side airbags and pretensioners.

15. Using proper precautions, dispose of the deployed

airbags/pretensioners. Refer to ”Deployed Airbag

Module Disposal Procedure” in this section.

Page 2202 of 2643

8B – 98ISUPPLEMENTAL INFLATABLE RESTRAINTS (SIR)

DAEWOO V–121 BL4

11. Using the free ends of the 10 meters(33 feet) wires

leading to the airbag module/pretensioner, make

two splices, one at each wires from the airbag mod-

ule/pretensioner.

12. Wrap the splices with insulating tape.

13. Now that the free ends of the 10 meters(33 feet)

wires are spliced to the airbag module/pretensioner

wires, and the ends that are twisted together are

near the deployment battery, clear the area.

14. Untwist the wires that near the deployment battery.

15. Touch one wire to the positive battery terminal and

touch the other wire to the negative battery termi-

nal. The airbag will deploy.

16. Using proper precautions, dispose of the deployed

airbags/pretensioners. Refer to ”Deployed Airbag

Module Disposal Procedure” in this section.

DEPLOYED AIRBAG MODULE

DISPOSAL PROCEDURE

CAUTION : After deployment, a powdery residue

may be on the surface of the airbag. The powder

primarily consists of cornstarch(used to lubri-

cate the bag as it inflates) and by–products of the

chemical reaction. The sodium hydroxide then

quickly reacts with atmospheric moisture and is

converted to sodium carbonate and sodium bi-

carbonate(also known as baking soda). There-

fore, it is unlikely that sodium hydroxide will be

presents after deployment.

CAUTION : Be sure to wear gloves and eye

protection during the disposal procedure.

CAUTION : After deployment, the metal surfaces

of the airbag module will be hot. In order to avoid

the risk of an injury or a fire do not place the

deployed airbag module near any flammable ob-

jects, and allow the airbag module to cool 30 min-

utes before handling.

Deploy an airbag or pretensioner before disposing of

it.

This includes those in a whole vehicle being

scrapped. If the vehicle is still within the warranty peri-

od contact the Daewoo regional service manager for

approval or special instructions before deploying an

airbag module or a pretensioner. Deployed airbag

module or pretensioner should be disposed of in the

same manner as other scrap parts, with the addition

of the following steps :

1. Place the deployed airbag or pretensioner in a

sturdy plastic bag.

2. Seal the plastic bag securely.

3. Wash your hands and rinse them with water after

handling a deployed airbag.

Page 2291 of 2643

9D – 14IWIPERS/WASHER SYSTEMS

DAEWOO V–121 BL4

MAINTENANCE AND REPAIR

ON–VEHICLE SERVICE

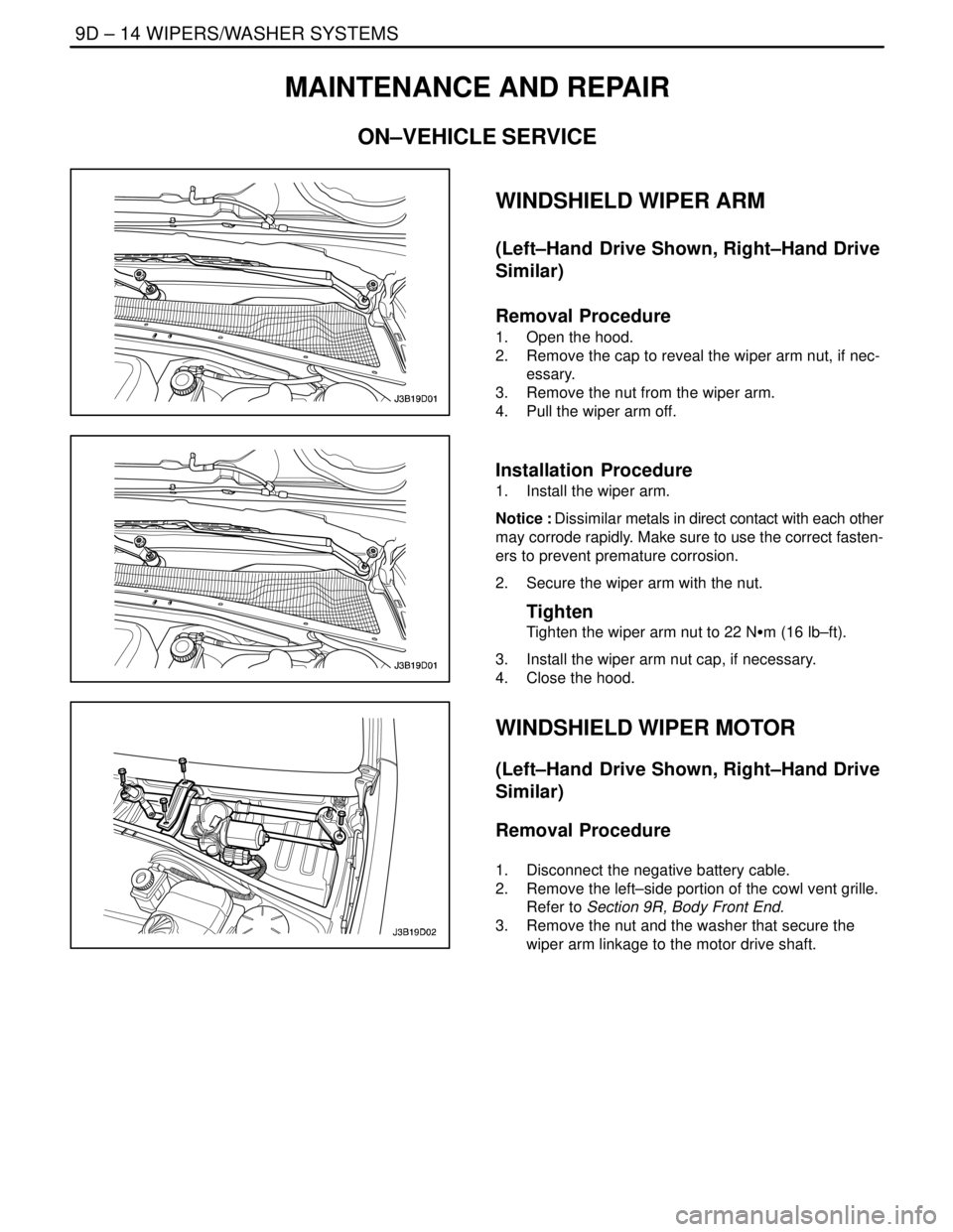

WINDSHIELD WIPER ARM

(Left–Hand Drive Shown, Right–Hand Drive

Similar)

Removal Procedure

1. Open the hood.

2. Remove the cap to reveal the wiper arm nut, if nec-

essary.

3. Remove the nut from the wiper arm.

4. Pull the wiper arm off.

Installation Procedure

1. Install the wiper arm.

Notice : Dissimilar metals in direct contact with each other

may corrode rapidly. Make sure to use the correct fasten-

ers to prevent premature corrosion.

2. Secure the wiper arm with the nut.

Tighten

Tighten the wiper arm nut to 22 NSm (16 lb–ft).

3. Install the wiper arm nut cap, if necessary.

4. Close the hood.

WINDSHIELD WIPER MOTOR

(Left–Hand Drive Shown, Right–Hand Drive

Similar)

Removal Procedure

1. Disconnect the negative battery cable.

2. Remove the left–side portion of the cowl vent grille.

Refer to Section 9R, Body Front End.

3. Remove the nut and the washer that secure the

wiper arm linkage to the motor drive shaft.

Page 2324 of 2643

INSTRUMENTATION/DRIVER INFORMATION 9E – 25

DAEWOO V–121 BL4

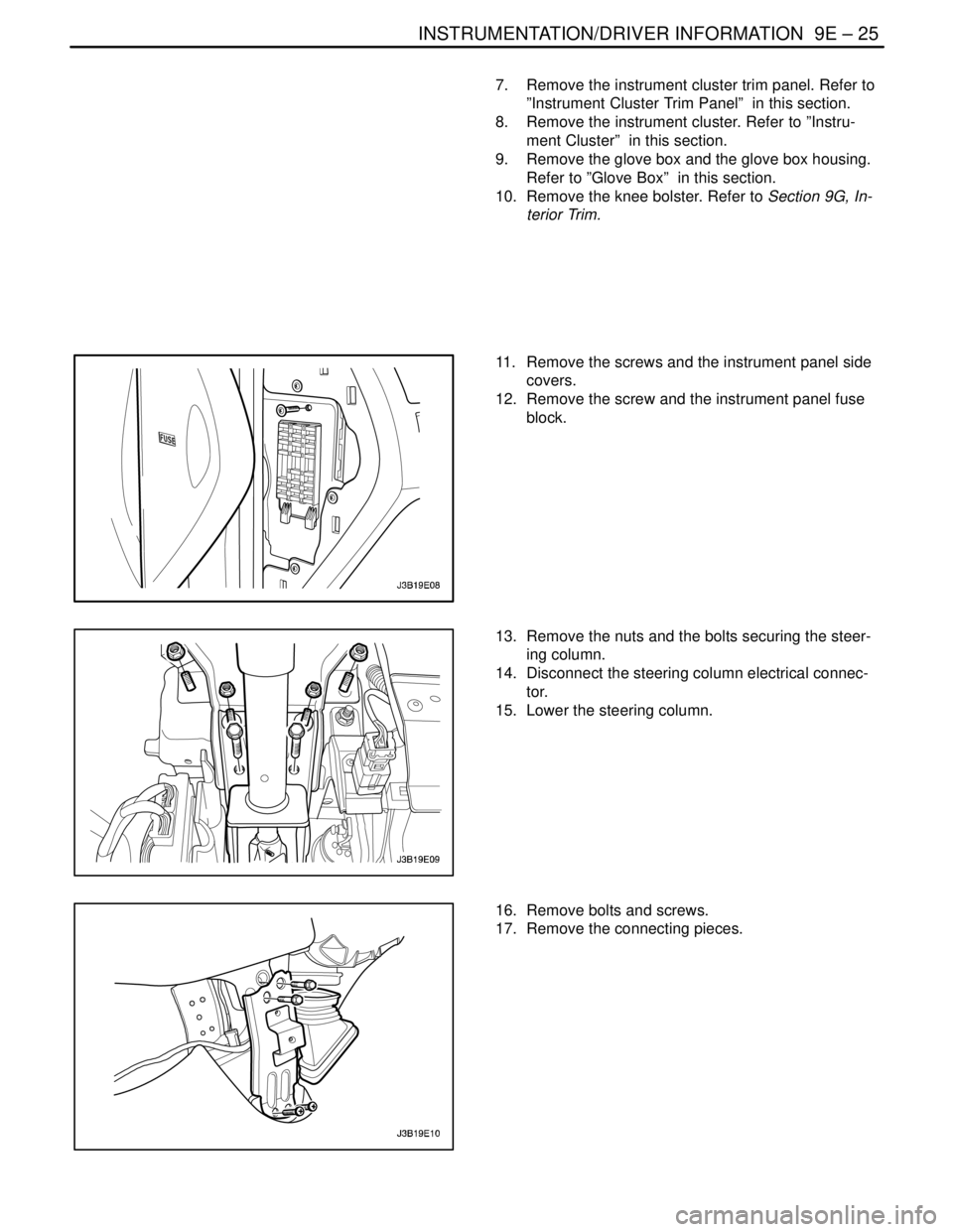

7. Remove the instrument cluster trim panel. Refer to

”Instrument Cluster Trim Panel” in this section.

8. Remove the instrument cluster. Refer to ”Instru-

ment Cluster” in this section.

9. Remove the glove box and the glove box housing.

Refer to ”Glove Box” in this section.

10. Remove the knee bolster. Refer to Section 9G, In-

terior Trim.

11. Remove the screws and the instrument panel side

covers.

12. Remove the screw and the instrument panel fuse

block.

13. Remove the nuts and the bolts securing the steer-

ing column.

14. Disconnect the steering column electrical connec-

tor.

15. Lower the steering column.

16. Remove bolts and screws.

17. Remove the connecting pieces.

Page 2325 of 2643

9E – 26IINSTRUMENTATION/DRIVER INFORMATION

DAEWOO V–121 BL4

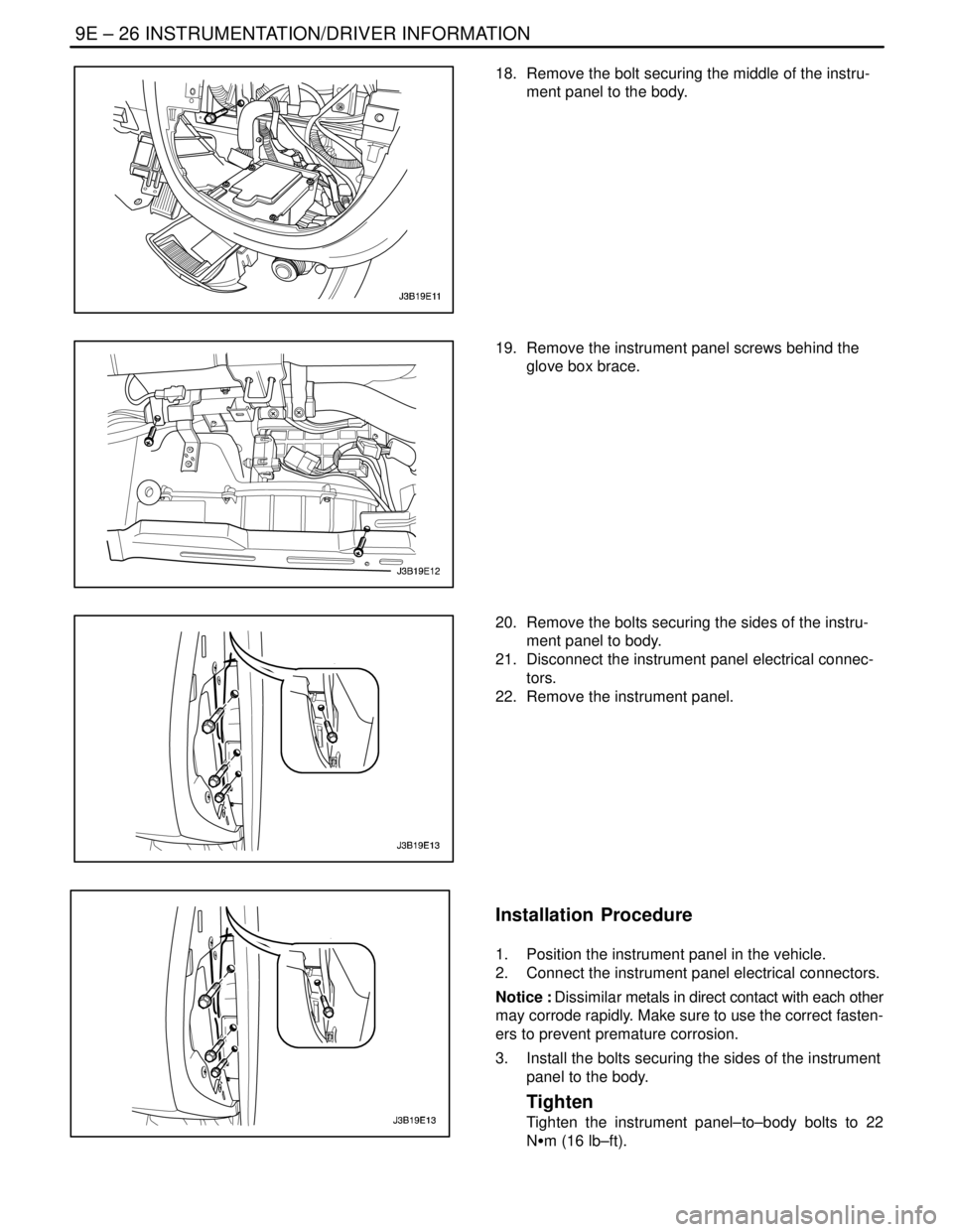

18. Remove the bolt securing the middle of the instru-

ment panel to the body.

19. Remove the instrument panel screws behind the

glove box brace.

20. Remove the bolts securing the sides of the instru-

ment panel to body.

21. Disconnect the instrument panel electrical connec-

tors.

22. Remove the instrument panel.

Installation Procedure

1. Position the instrument panel in the vehicle.

2. Connect the instrument panel electrical connectors.

Notice : Dissimilar metals in direct contact with each other

may corrode rapidly. Make sure to use the correct fasten-

ers to prevent premature corrosion.

3. Install the bolts securing the sides of the instrument

panel to the body.

Tighten

Tighten the instrument panel–to–body bolts to 22

NSm (16 lb–ft).

Page 2326 of 2643

INSTRUMENTATION/DRIVER INFORMATION 9E – 27

DAEWOO V–121 BL4

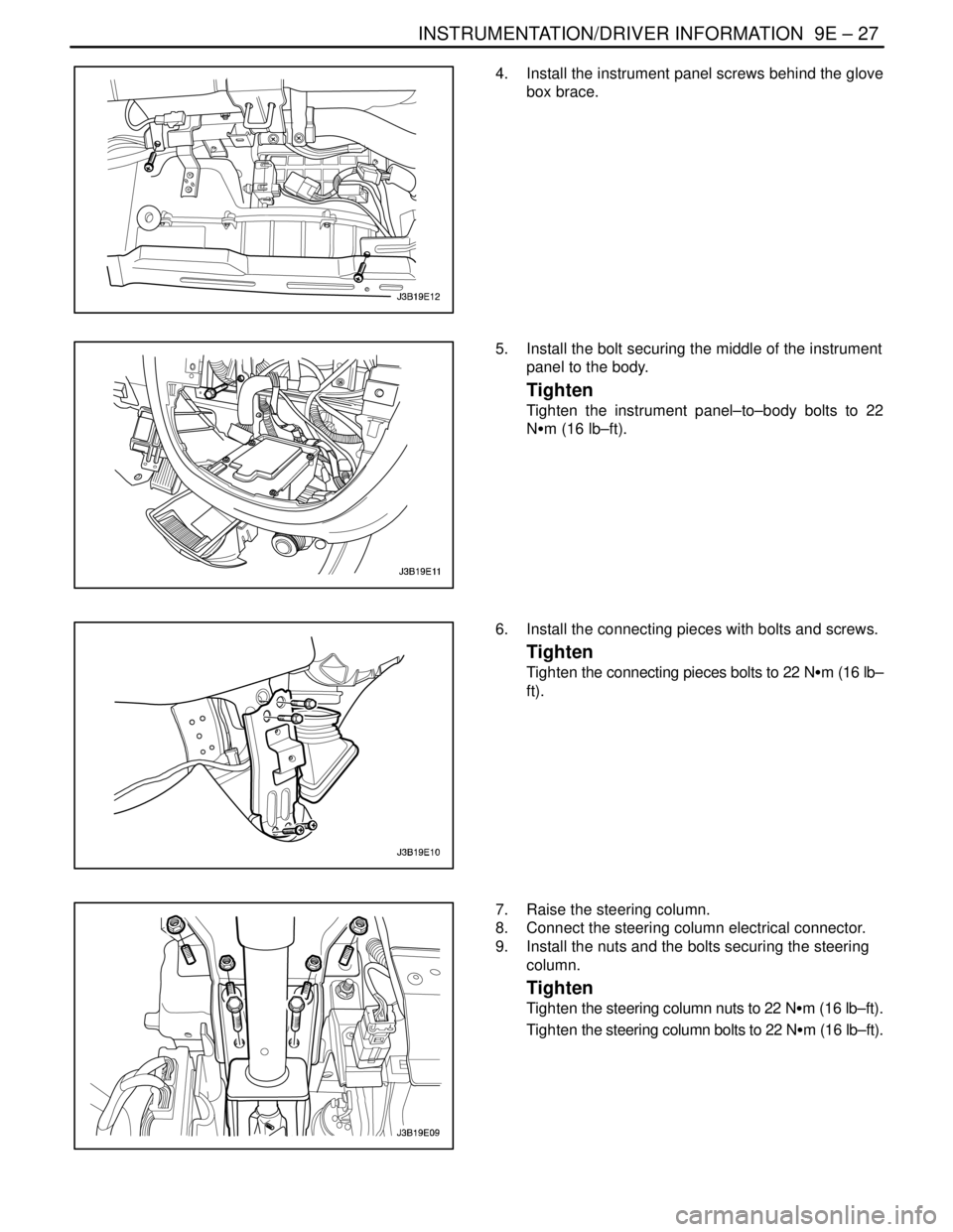

4. Install the instrument panel screws behind the glove

box brace.

5. Install the bolt securing the middle of the instrument

panel to the body.

Tighten

Tighten the instrument panel–to–body bolts to 22

NSm (16 lb–ft).

6. Install the connecting pieces with bolts and screws.

Tighten

Tighten the connecting pieces bolts to 22 NSm (16 lb–

ft).

7. Raise the steering column.

8. Connect the steering column electrical connector.

9. Install the nuts and the bolts securing the steering

column.

Tighten

Tighten the steering column nuts to 22 NSm (16 lb–ft).

Tighten the steering column bolts to 22 NSm (16 lb–ft).