automatic transaxle DAEWOO NUBIRA 2004 Service Owner's Guide

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: NUBIRA, Model: DAEWOO NUBIRA 2004Pages: 2643, PDF Size: 80.54 MB

Page 995 of 2643

3A – 6IAUTOMATIC TRANSAXLE DRIVE AXLE

DAEWOO V–121 BL4

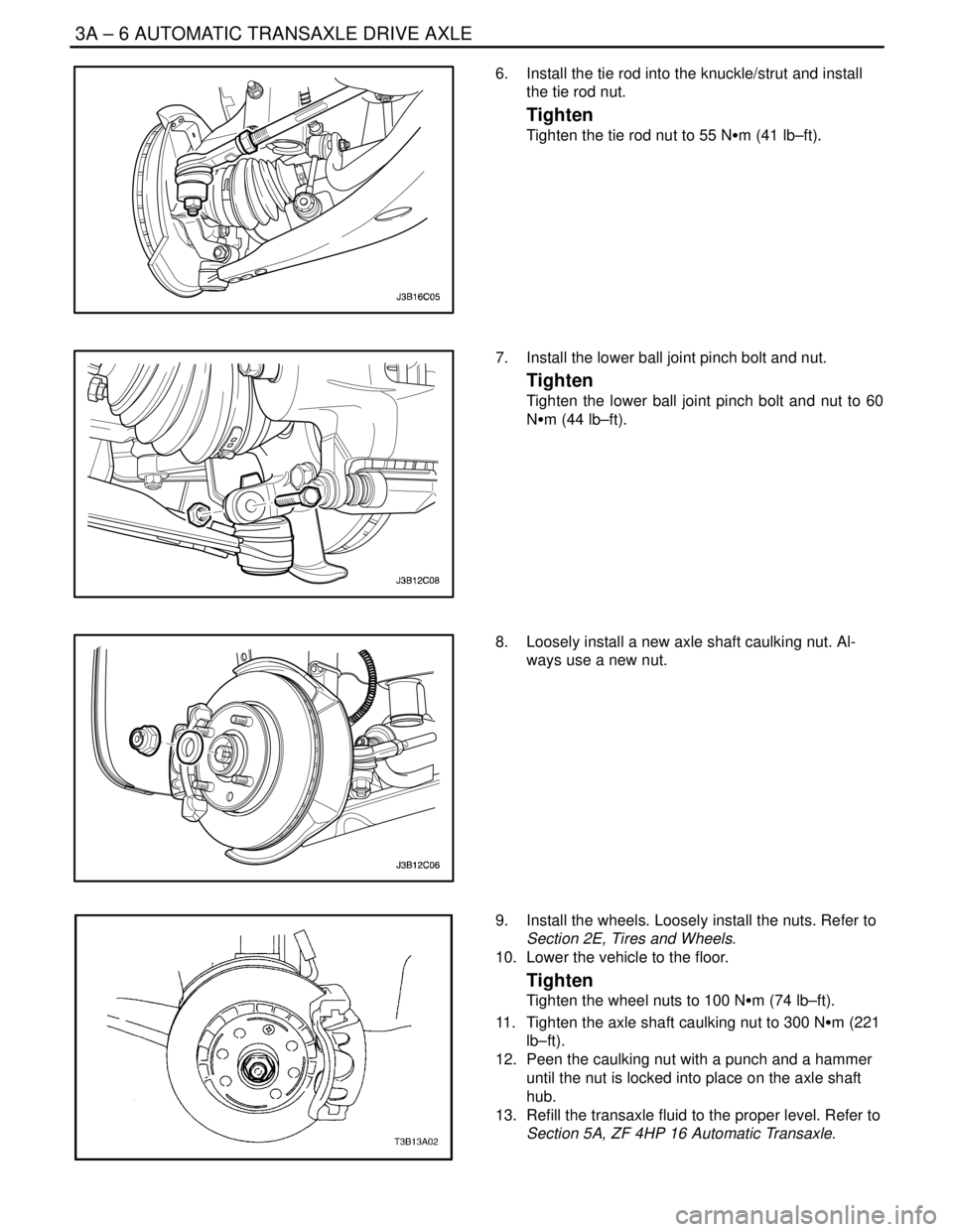

6. Install the tie rod into the knuckle/strut and install

the tie rod nut.

Tighten

Tighten the tie rod nut to 55 NSm (41 lb–ft).

7. Install the lower ball joint pinch bolt and nut.

Tighten

Tighten the lower ball joint pinch bolt and nut to 60

NSm (44 lb–ft).

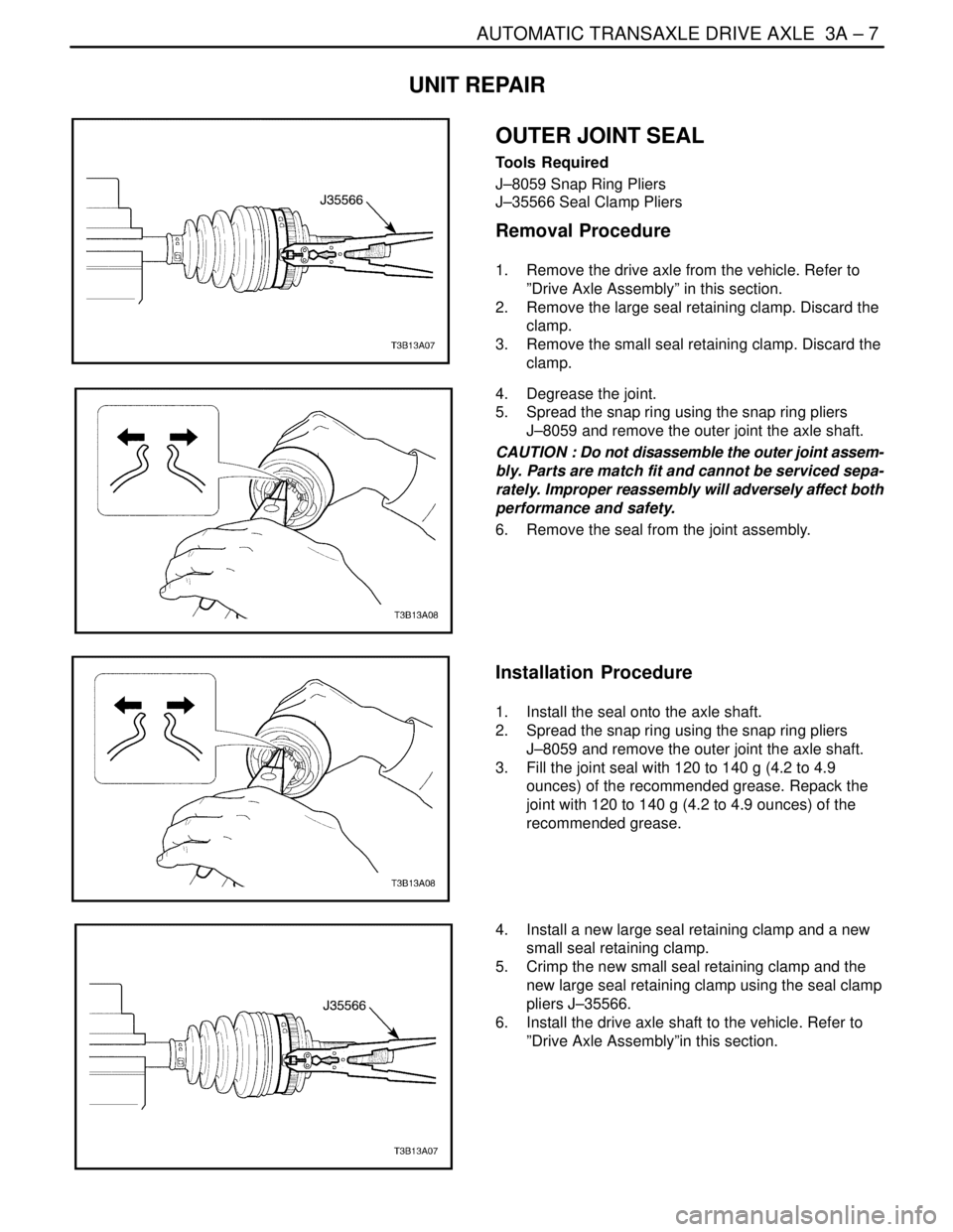

8. Loosely install a new axle shaft caulking nut. Al-

ways use a new nut.

9. Install the wheels. Loosely install the nuts. Refer to

Section 2E, Tires and Wheels.

10. Lower the vehicle to the floor.

Tighten

Tighten the wheel nuts to 100 NSm (74 lb–ft).

11. Tighten the axle shaft caulking nut to 300 NSm (221

lb–ft).

12. Peen the caulking nut with a punch and a hammer

until the nut is locked into place on the axle shaft

hub.

13. Refill the transaxle fluid to the proper level. Refer to

Section 5A, ZF 4HP 16 Automatic Transaxle.

Page 996 of 2643

AUTOMATIC TRANSAXLE DRIVE AXLE 3A – 7

DAEWOO V–121 BL4

UNIT REPAIR

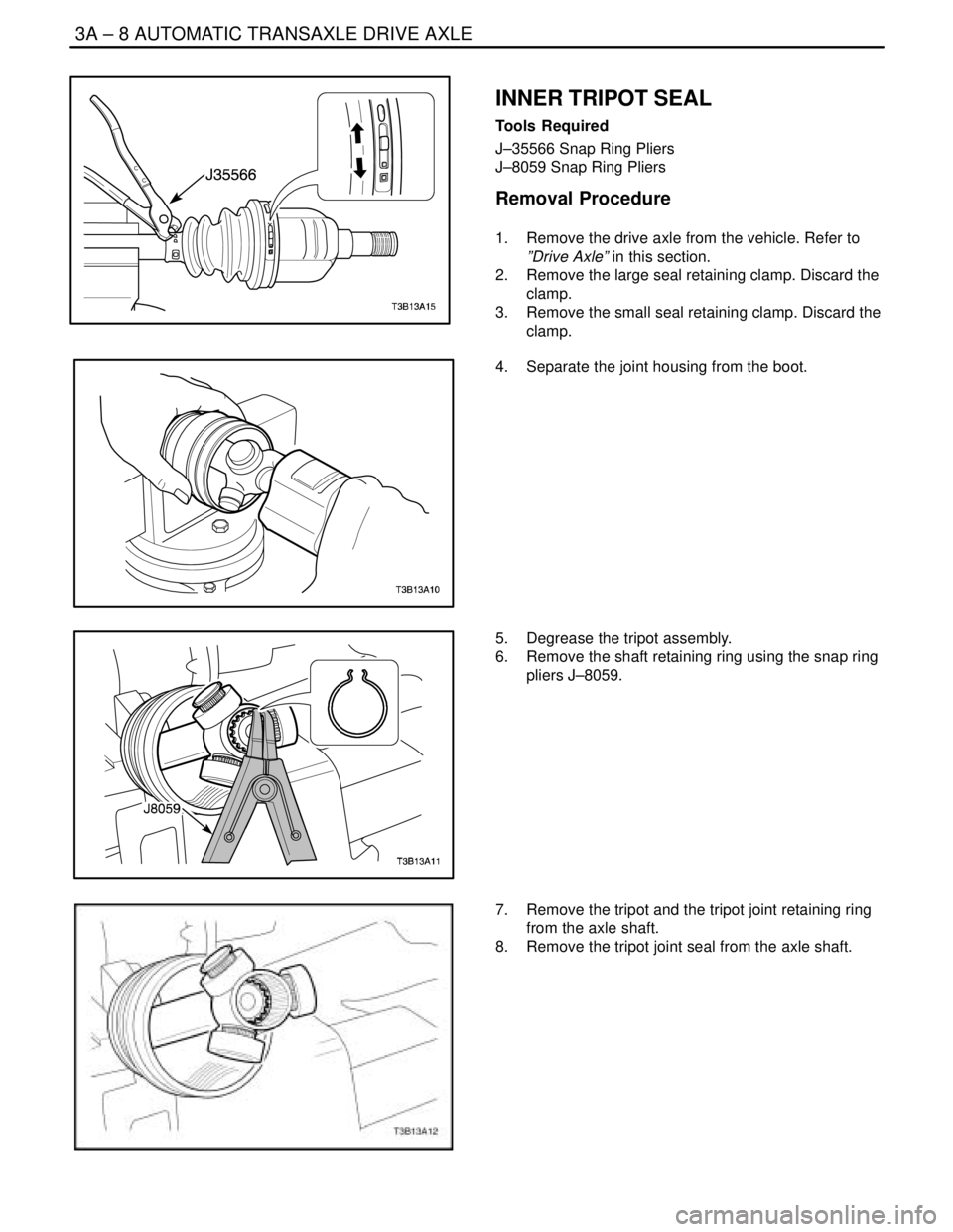

OUTER JOINT SEAL

Tools Required

J–8059 Snap Ring Pliers

J–35566 Seal Clamp Pliers

Removal Procedure

1. Remove the drive axle from the vehicle. Refer to

”Drive Axle Assembly” in this section.

2. Remove the large seal retaining clamp. Discard the

clamp.

3. Remove the small seal retaining clamp. Discard the

clamp.

4. Degrease the joint.

5. Spread the snap ring using the snap ring pliers

J–8059 and remove the outer joint the axle shaft.

CAUTION : Do not disassemble the outer joint assem-

bly. Parts are match fit and cannot be serviced sepa-

rately. Improper reassembly will adversely affect both

performance and safety.

6. Remove the seal from the joint assembly.

Installation Procedure

1. Install the seal onto the axle shaft.

2. Spread the snap ring using the snap ring pliers

J–8059 and remove the outer joint the axle shaft.

3. Fill the joint seal with 120 to 140 g (4.2 to 4.9

ounces) of the recommended grease. Repack the

joint with 120 to 140 g (4.2 to 4.9 ounces) of the

recommended grease.

4. Install a new large seal retaining clamp and a new

small seal retaining clamp.

5. Crimp the new small seal retaining clamp and the

new large seal retaining clamp using the seal clamp

pliers J–35566.

6. Install the drive axle shaft to the vehicle. Refer to

”Drive Axle Assembly”in this section.

Page 997 of 2643

3A – 8IAUTOMATIC TRANSAXLE DRIVE AXLE

DAEWOO V–121 BL4

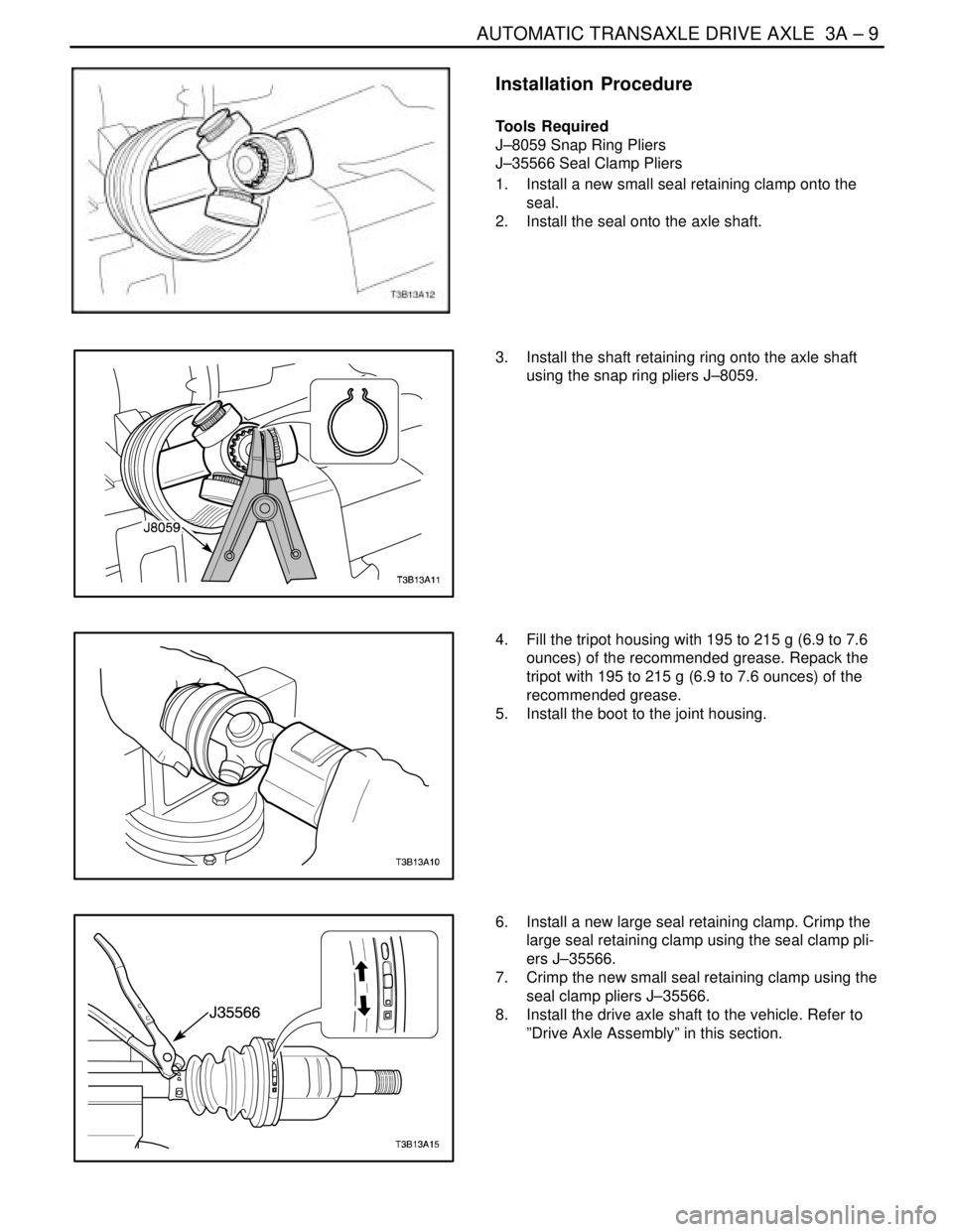

INNER TRIPOT SEAL

Tools Required

J–35566 Snap Ring Pliers

J–8059 Snap Ring Pliers

Removal Procedure

1. Remove the drive axle from the vehicle. Refer to

”Drive Axle” in this section.

2. Remove the large seal retaining clamp. Discard the

clamp.

3. Remove the small seal retaining clamp. Discard the

clamp.

4. Separate the joint housing from the boot.

5. Degrease the tripot assembly.

6. Remove the shaft retaining ring using the snap ring

pliers J–8059.

7. Remove the tripot and the tripot joint retaining ring

from the axle shaft.

8. Remove the tripot joint seal from the axle shaft.

Page 998 of 2643

AUTOMATIC TRANSAXLE DRIVE AXLE 3A – 9

DAEWOO V–121 BL4

Installation Procedure

Tools Required

J–8059 Snap Ring Pliers

J–35566 Seal Clamp Pliers

1. Install a new small seal retaining clamp onto the

seal.

2. Install the seal onto the axle shaft.

3. Install the shaft retaining ring onto the axle shaft

using the snap ring pliers J–8059.

4. Fill the tripot housing with 195 to 215 g (6.9 to 7.6

ounces) of the recommended grease. Repack the

tripot with 195 to 215 g (6.9 to 7.6 ounces) of the

recommended grease.

5. Install the boot to the joint housing.

6. Install a new large seal retaining clamp. Crimp the

large seal retaining clamp using the seal clamp pli-

ers J–35566.

7. Crimp the new small seal retaining clamp using the

seal clamp pliers J–35566.

8. Install the drive axle shaft to the vehicle. Refer to

”Drive Axle Assembly” in this section.

Page 999 of 2643

3A – 10IAUTOMATIC TRANSAXLE DRIVE AXLE

DAEWOO V–121 BL4

GENERAL DESCRIPTION

AND SYSTEM OPERATION

FRONT DRIVE AXLE

General Description

Drive axles are flexible shaft assemblies that transmit

rotational force from the transaxle to the front–wheel as-

semblies. Each axle assembly consists of an inner and anouter constant–velocity joint connected to an axle shaft.

The inner joint is completely flexible and has the ability to

move in and out. The outer joint is also flexible, but it can-

not move in and out.

The drive axles use one type of outboard joint and one type

of inboard joint. The inboard ends of both drive axles incor-

porate a female spline that installs over a stub shaft pro-

truding from the transaxle.

Page 1350 of 2643

SECTION : 5A1

ZF 4 HP 16 AUTOMATIC TRANSAXLE

CAUTION : Disconnect the negative battery cable before removing or installing any electrical unit or when a tool

or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help

prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise noted.

TABLE OF CONTENTS

INTRODUCTION5A1–3 . . . . . . . . . . . . . . . . . . . . . . . . . . .

ZF 4HP 16 Automatic Transaxle 5A1–3. . . . . . . . . . . .

Transaxle Components 5A1–4. . . . . . . . . . . . . . . . . . . .

SPECIFICATIONS5A1–5 . . . . . . . . . . . . . . . . . . . . . . . . .

General Specifications 5A1–5. . . . . . . . . . . . . . . . . . . .

Transaxle Gear Ratio 5A1–5. . . . . . . . . . . . . . . . . . . . . .

Fluid Capacity 5A1–5. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fastener Tightening Specifications 5A1–5. . . . . . . . . .

Shift Speed Chart 5A1–7. . . . . . . . . . . . . . . . . . . . . . . . .

Line Pressure 5A1–8. . . . . . . . . . . . . . . . . . . . . . . . . . . .

SPECIAL TOOLS5A1–9 . . . . . . . . . . . . . . . . . . . . . . . . . .

Special Tools Table 5A1–9. . . . . . . . . . . . . . . . . . . . . . .

SCHEMATIC AND ROUTING DIAGRAMS5A1–11 . . .

Transaxle Control Module (1 of 2) 5A1–11. . . . . . . . . .

Transaxle Control Module (2 of 2) 5A1–12. . . . . . . . . .

Shift Mode Diagram 5A1–13. . . . . . . . . . . . . . . . . . . . . .

Power Flow Diagram 5A1–17. . . . . . . . . . . . . . . . . . . . .

COMPONENT LOCATOR5A1–33 . . . . . . . . . . . . . . . . . .

Transaxle Identification Information 5A1–33. . . . . . . .

Torque Converter 5A1–34. . . . . . . . . . . . . . . . . . . . . . . .

Transaxle Housing 5A1–35. . . . . . . . . . . . . . . . . . . . . . .

Oil Pump 5A1–36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear Cover & Oil Pan Cover 5A1–37. . . . . . . . . . . . . .

Parking Lever 5A1–38. . . . . . . . . . . . . . . . . . . . . . . . . . .

Input Shaft & Shift Gear 5A1–39. . . . . . . . . . . . . . . . . .

Valve Body 5A1–41. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Gear Shift Control 5A1–42. . . . . . . . . . . . . . . . . . . . . . .

DIAGNOSTIC INFORMATION AND PROCEDURES

DIAGNOSIS5A1–43 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Basic Knowledge Required 5A1–43. . . . . . . . . . . . . . . .

Functional Check Procedure 5A1–43. . . . . . . . . . . . . .

Line Pressure Check Procedure 5A1–43. . . . . . . . . . .

Clutch Plate Diagnosis 5A1–45. . . . . . . . . . . . . . . . . . .

Cooler Flushing and Flow Test 5A1–45. . . . . . . . . . . . . Transaxle Fluid Level Service Procedure 5A1–45. . . .

Electrical/Garage Shift Test 5A1–47. . . . . . . . . . . . . . .

Road Test Procedure 5A1–47. . . . . . . . . . . . . . . . . . . . .

Torque Converter Lock–Up Clutch(TCC)

Diagnosis 5A1–48. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TCM Initialization Procedure 5A1–50. . . . . . . . . . . . . .

Shift Speed Chart 5A1–51. . . . . . . . . . . . . . . . . . . . . . . .

Internal Wiring Harness Check 5A1–51. . . . . . . . . . . .

Transaxle Wiring Harness Connector 5A1–54. . . . . . .

Symptom Diagnosis 5A1–56. . . . . . . . . . . . . . . . . . . . . .

DIAGNOSTIC TROUBLE CODE DIAGNOSIS5A1–60

Diagnostic Trouble Code (DTC) Identification 5A1–60

DTC P0562 – System Voltage Low 5A1–68. . . . . . . . .

DTC P0563 – System Voltage High 5A1–71. . . . . . . .

DTC P0601 – Internal Control Module Memory

Checksum Error 5A1–74. . . . . . . . . . . . . . . . . . . . . . .

DTC P0603 – Internal Control Module Keep

Alive Memory(KAM) Error 5A1–76. . . . . . . . . . . . . . .

DTC P0604 – Internal Control Module Random

Access Memory(RAM) Error 5A1–78. . . . . . . . . . . . .

DTC P0606 – Transaxle Control Module

Processor Fault 5A1–80. . . . . . . . . . . . . . . . . . . . . . . .

DTC P0703 – Brake Switch Circuit

Malfunction 5A1–83. . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0705 – Transmission Range Sensor

Circuit Malfunction(PRNDL Input) 5A1–86. . . . . . . .

DTC P0710 – Transmission Fluid Temperature

Sensor Circuit Malfunction 5A1–89. . . . . . . . . . . . . .

DTC P0715 – Input Speed Sensor(ISS) Circuit

Malfunction 5A1–92. . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0716 – Input Speed Sensor(ISS) Circuit

Range/Performance 5A1–95. . . . . . . . . . . . . . . . . . . .

DTC P0717 – Input Speed Sensor(ISS) Circuit

No Signal 5A1–98. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0720 – Output Speed Sensor(OSS)

Circuit Malfunction 5A1–101. . . . . . . . . . . . . . . . . . . .

DTC P0721 – Output Speed Sensor(OSS)

Circuit Range/Performance 5A1–104. . . . . . . . . . . . .

Page 1351 of 2643

5A1 – 2IZF 4 HP 16 AUTOMATIC TRANSAXLE

DAEWOO V–121 BL4

DTC P0722 – Output Speed Sensor(OSS)

Circuit No Signal 5A1–107. . . . . . . . . . . . . . . . . . . . . .

DTC P0725 – Engine Speed Input Circuit

Malfunction 5A1–110. . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0726 – Engine Speed Input Circuit

Range/Performance 5A1–112. . . . . . . . . . . . . . . . . . .

DTC P0727 – Engine Speed Input Circuit No

Signal 5A1–114. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0731 – Gear 1 Incorrect Ratio 5A1–116. . . . . .

DTC P0732 – Gear 2 Incorrect Ratio 5A1–118. . . . . .

DTC P0733 – Gear 3 Incorrect Ratio 5A1–120. . . . . .

DTC P0734 – Gear 4 Incorrect Ratio 5A1–122. . . . . .

DTC P0781 – 1–2 Shift Malfunction 5A1–124. . . . . . .

DTC P0782 – 2–3 Shift Malfunction 5A1–126. . . . . . .

DTC P0783 – 3–4 Shift Malfunction 5A1–128. . . . . . .

DTC P1604 – Data Check of Internal &

Extended Ram Failed 5A1–130. . . . . . . . . . . . . . . . . .

DTC P1606 – Failure Of External Watchdog 5A1–132

DTC P1671 – CAN Transmit Message

Failure 5A1–134. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P1672 – CAN Bus Off Failure 5A1–136. . . . . . . .

DTC P1673 – CAN Receive ECM Message

Failure 5A1–138. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P1839 – EDS 3 Output Shorted To

Ground 5A1–140. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P1840 – EDS 3 Output Shorted To

Power 5A1–142. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P1841 – EDS 3 Output Open 5A1–144. . . . . . . .

DTC P1850 – Solenoid 1 Output Shorted To

Ground 5A1–146. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P1851 – Solenoid 1 Output Shorted To

Power 5A1–148. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P1852 – Solenoid 1 Output Open 5A1–150. . . .

DTC P1853 – Solenoid 2 Output Shorted To

Ground 5A1–152. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P1854 – Solenoid 2 Output Shorted To

Power 5A1–154. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P1855 – Solenoid 2 Output Open 5A1–156. . . .

DTC P1861 – EDS 4 Output Shorted To

Ground 5A1–158. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P1862 – EDS 4 Output Shorted To

Power 5A1–160. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P1863 – EDS 4 Output Open 5A1–162. . . . . . . .

DTC P1864 – EDS 5 Output Shorted To

Ground 5A1–164. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P1865 – EDS 5 Output Shorted To

Power 5A1–166. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P1866 – EDS 5 Output Open 5A1–168. . . . . . . .

DTC P1867 – EDS 6 Output Shorted To

Ground 5A1–170. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . DTC P1868 – EDS 6 Output Shorted To

Power 5A1–172. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P1869 – EDS 6 Output Open 5A1–174. . . . . . . .

DTC P1871 – EDS Valve Power Supply

Circuit Shorted to Power 5A1–176. . . . . . . . . . . . . . .

DTC P1874 – Solenoid Valve Power Supply

Circuit Shorted to Power 5A1–178. . . . . . . . . . . . . . .

DTC P1881 – 2–1 Shift Malfunction 5A1–180. . . . . . .

DTC P1883 – 3–2 Shift Malfunction 5A1–182. . . . . . .

DTC P1884 – 4–3 Shift Malfunction 5A1–184. . . . . . .

DTC P1885 – 3–1 Shift Malfunction 5A1–186. . . . . . .

DTC P1886 – 4–2 Shift Malfunction 5A1–188. . . . . . .

MAINTENANCE AND REPAIR5A1–190 . . . . . . . . . . . .

ON–VEHICLE SERVICE 5A1–190. . . . . . . . . . . . . . . . . .

Transaxle Fluid Level Checking Procedure 5A1–190.

Changing the Fluid 5A1–191. . . . . . . . . . . . . . . . . . . . . .

Fluid Level Set After Service 5A1–192. . . . . . . . . . . . .

Repairing Fluid Leaks 5A1–192. . . . . . . . . . . . . . . . . . .

Case Porosity Repair 5A1–193. . . . . . . . . . . . . . . . . . . .

Shift Control Lever Assembly 5A1–193. . . . . . . . . . . . .

Shift Control Cable 5A1–195. . . . . . . . . . . . . . . . . . . . . .

Shift Control Cable Adjustment 5A1–196. . . . . . . . . . .

Transaxle Control Module(TCM) 5A1–197. . . . . . . . . .

Park/Neutral Start Switch 5A1–198. . . . . . . . . . . . . . . .

Oil Cooler Pipes/Hoses 5A1–199. . . . . . . . . . . . . . . . . .

Drive Axle Oil Seal 5A1–201. . . . . . . . . . . . . . . . . . . . . .

Oil Pan, Oil Pan Gasket 5A1–201. . . . . . . . . . . . . . . . .

Control Valve Body Assembly 5A1–203. . . . . . . . . . . .

Left Transaxle Mounting Bracket 5A1–205. . . . . . . . . .

Transaxle Assembly 5A1–206. . . . . . . . . . . . . . . . . . . . .

UNIT REPAIR 5A1–212. . . . . . . . . . . . . . . . . . . . . . . . . . .

Torque Converter 5A1–212. . . . . . . . . . . . . . . . . . . . . . .

Transaxle Holding Fixture Assembly 5A1–212. . . . . . .

Valve Body 5A1–212. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear Cover 5A1–213. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Clutch B/E 5A1–214. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Clutch B/E Measurement Procedure 5A1–217. . . . . .

Planetary Gear Set 5A1–220. . . . . . . . . . . . . . . . . . . . .

Brake C/D 5A1–221. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Differential 5A1–224. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Side Shaft 5A1–224. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Brake F, Slotted Nut 5A1–225. . . . . . . . . . . . . . . . . . . . .

Torque Converter Housing 5A1–227. . . . . . . . . . . . . . .

Shift Mechanism 5A1–228. . . . . . . . . . . . . . . . . . . . . . . .

Parking Lock System 5A1–229. . . . . . . . . . . . . . . . . . . .

Bearing Plate(With Spur Gear) Assembly 5A1–229. .

Oil Pump Assembly 5A1–229. . . . . . . . . . . . . . . . . . . . .

Differential/Side Shaft Outer Race, Bearing

Shim 5A1–230. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 1352 of 2643

ZF 4 HP 16 AUTOMATIC TRANSAXLE 5A1 – 3

DAEWOO V–121 BL4

Important Measurement/Adjustment 5A1–230. . . . . . .

GENERAL DESCRIPTION AND SYSTEM

OPERATION5A1–232 . . . . . . . . . . . . . . . . . . . . . . . . . . . Mechanical Components 5A1–232. . . . . . . . . . . . . . . . .

Electronical Components 5A1–236. . . . . . . . . . . . . . . .

TCM Inputs That Affect the 4HP 16

Transaxle 5A1–241. . . . . . . . . . . . . . . . . . . . . . . . . . .

INTRODUCTION

ZF 4HP 16 AUTOMATIC TRANSAXLE

The ZF 4 HP 16 is a four–speed automatic transaxle de-

signed for cars with front–wheel drive and a transversely

mounted engine.

The transaxle has a hydrodynamic torque converter with

a controlled slip lock–up clutch.

A planetary gear train establishes the mechanical gear ra-

tios. The integral constant ratio can be adapted to the en-

gine’s power output and the vehicle’s weight. The elec-

tronic–hydraulic control makes controlled power shifts and

various shift programs possible. In selector lever position

”P”, the output is locked mechanically.The special feature of this transaxle is that it operates with-

out freewheels. Shifting between individual gears takes

place by means of overlapping clutch engagement and re-

lease.

The advantage of overlap shifting is as follows:

– The transaxle can be of more compact design

and is lighter on account of the absence of free-

wheels and the lower number of shift elements

– Lower drag losses, i.e. higher efficiency

– Lower peak torques acting on the components

and driveline.

However, overlap shifting necessitates high–performance

hardware and software, and precision engine signals.

Page 1353 of 2643

5A1 – 4IZF 4 HP 16 AUTOMATIC TRANSAXLE

DAEWOO V–121 BL4

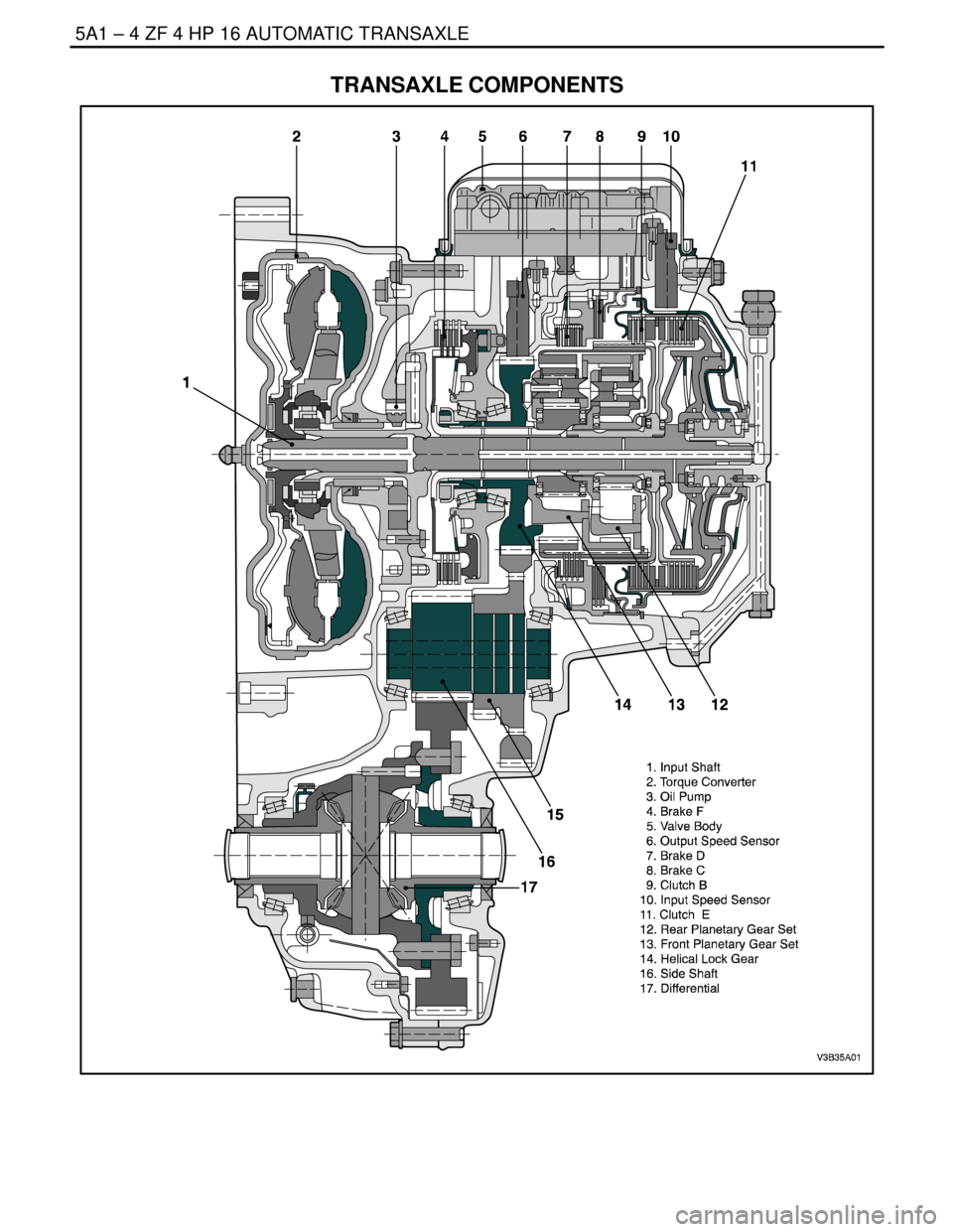

TRANSAXLE COMPONENTS

Page 1354 of 2643

ZF 4 HP 16 AUTOMATIC TRANSAXLE 5A1 – 5

DAEWOO V–121 BL4

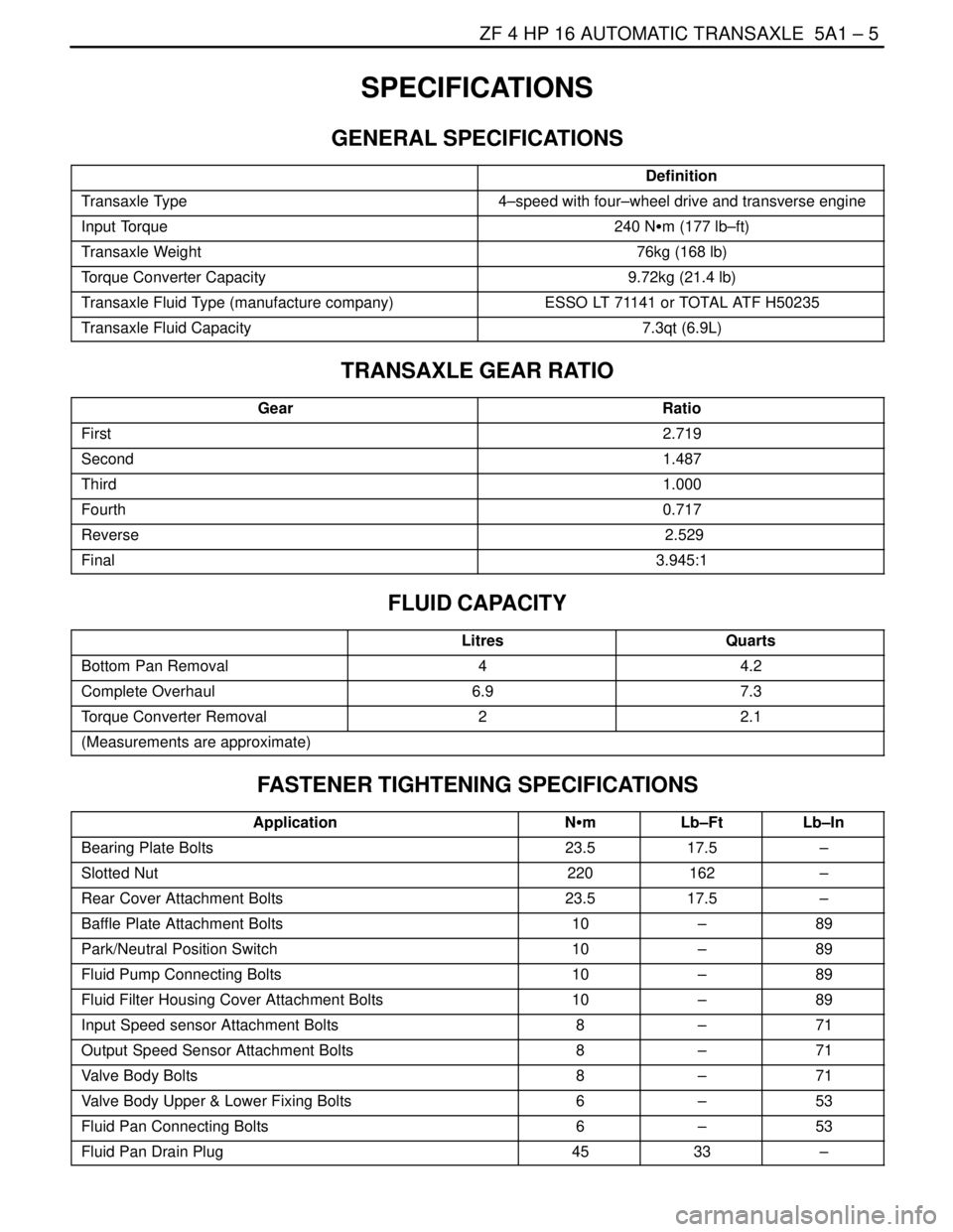

SPECIFICATIONS

GENERAL SPECIFICATIONS

Definition

Transaxle Type4–speed with four–wheel drive and transverse engine

Input Torque240 NSm (177 lb–ft)

Transaxle Weight76kg (168 lb)

Torque Converter Capacity9.72kg (21.4 lb)

Transaxle Fluid Type (manufacture company)ESSO LT 71141 or TOTAL ATF H50235

Transaxle Fluid Capacity7.3qt (6.9L)

TRANSAXLE GEAR RATIO

GearRatio

First2.719

Second1.487

Third1.000

Fourth0.717

Reverse 2.529

Final3.945:1

FLUID CAPACITY

LitresQuarts

Bottom Pan Removal44.2

Complete Overhaul6.97.3

Torque Converter Removal22.1

(Measurements are approximate)

FASTENER TIGHTENING SPECIFICATIONS

ApplicationNSmLb–FtLb–In

Bearing Plate Bolts23.517.5–

Slotted Nut220162–

Rear Cover Attachment Bolts23.517.5–

Baffle Plate Attachment Bolts10–89

Park/Neutral Position Switch10–89

Fluid Pump Connecting Bolts10–89

Fluid Filter Housing Cover Attachment Bolts10–89

Input Speed sensor Attachment Bolts8–71

Output Speed Sensor Attachment Bolts8–71

Valve Body Bolts8–71

Valve Body Upper & Lower Fixing Bolts6–53

Fluid Pan Connecting Bolts6–53

Fluid Pan Drain Plug4533–