fuse DAEWOO NUBIRA 2004 Service Workshop Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: NUBIRA, Model: DAEWOO NUBIRA 2004Pages: 2643, PDF Size: 80.54 MB

Page 352 of 2643

1F – 106IENGINE CONTROLS

DAEWOO V–121 BL4

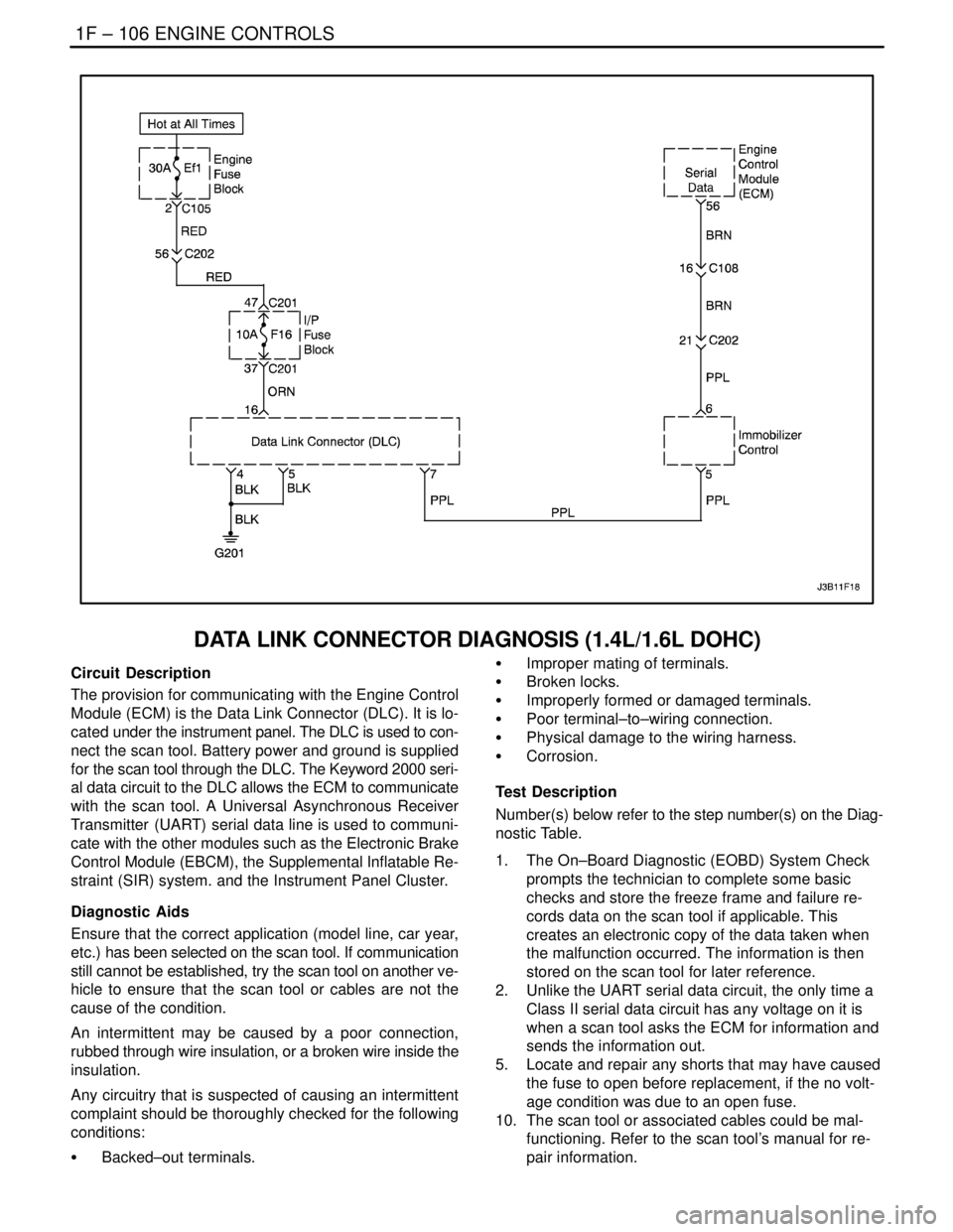

DATA LINK CONNECTOR DIAGNOSIS (1.4L/1.6L DOHC)

Circuit Description

The provision for communicating with the Engine Control

Module (ECM) is the Data Link Connector (DLC). It is lo-

cated under the instrument panel. The DLC is used to con-

nect the scan tool. Battery power and ground is supplied

for the scan tool through the DLC. The Keyword 2000 seri-

al data circuit to the DLC allows the ECM to communicate

with the scan tool. A Universal Asynchronous Receiver

Transmitter (UART) serial data line is used to communi-

cate with the other modules such as the Electronic Brake

Control Module (EBCM), the Supplemental Inflatable Re-

straint (SIR) system. and the Instrument Panel Cluster.

Diagnostic Aids

Ensure that the correct application (model line, car year,

etc.) has been selected on the scan tool. If communication

still cannot be established, try the scan tool on another ve-

hicle to ensure that the scan tool or cables are not the

cause of the condition.

An intermittent may be caused by a poor connection,

rubbed through wire insulation, or a broken wire inside the

insulation.

Any circuitry that is suspected of causing an intermittent

complaint should be thoroughly checked for the following

conditions:

S Backed–out terminals.S Improper mating of terminals.

S Broken locks.

S Improperly formed or damaged terminals.

S Poor terminal–to–wiring connection.

S Physical damage to the wiring harness.

S Corrosion.

Test Description

Number(s) below refer to the step number(s) on the Diag-

nostic Table.

1. The On–Board Diagnostic (EOBD) System Check

prompts the technician to complete some basic

checks and store the freeze frame and failure re-

cords data on the scan tool if applicable. This

creates an electronic copy of the data taken when

the malfunction occurred. The information is then

stored on the scan tool for later reference.

2. Unlike the UART serial data circuit, the only time a

Class II serial data circuit has any voltage on it is

when a scan tool asks the ECM for information and

sends the information out.

5. Locate and repair any shorts that may have caused

the fuse to open before replacement, if the no volt-

age condition was due to an open fuse.

10. The scan tool or associated cables could be mal-

functioning. Refer to the scan tool’s manual for re-

pair information.

Page 354 of 2643

1F – 108IENGINE CONTROLS

DAEWOO V–121 BL4

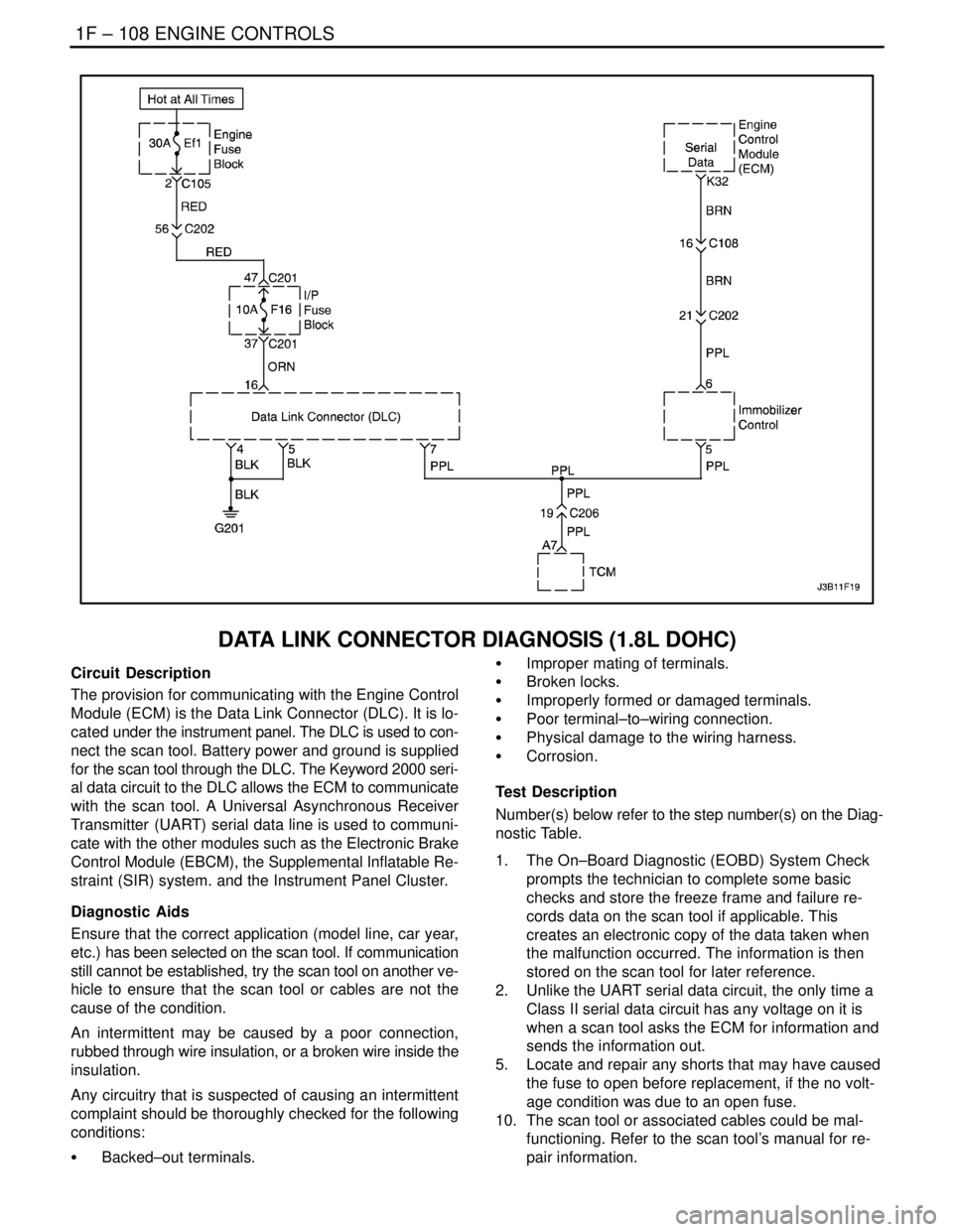

DATA LINK CONNECTOR DIAGNOSIS (1.8L DOHC)

Circuit Description

The provision for communicating with the Engine Control

Module (ECM) is the Data Link Connector (DLC). It is lo-

cated under the instrument panel. The DLC is used to con-

nect the scan tool. Battery power and ground is supplied

for the scan tool through the DLC. The Keyword 2000 seri-

al data circuit to the DLC allows the ECM to communicate

with the scan tool. A Universal Asynchronous Receiver

Transmitter (UART) serial data line is used to communi-

cate with the other modules such as the Electronic Brake

Control Module (EBCM), the Supplemental Inflatable Re-

straint (SIR) system. and the Instrument Panel Cluster.

Diagnostic Aids

Ensure that the correct application (model line, car year,

etc.) has been selected on the scan tool. If communication

still cannot be established, try the scan tool on another ve-

hicle to ensure that the scan tool or cables are not the

cause of the condition.

An intermittent may be caused by a poor connection,

rubbed through wire insulation, or a broken wire inside the

insulation.

Any circuitry that is suspected of causing an intermittent

complaint should be thoroughly checked for the following

conditions:

S Backed–out terminals.S Improper mating of terminals.

S Broken locks.

S Improperly formed or damaged terminals.

S Poor terminal–to–wiring connection.

S Physical damage to the wiring harness.

S Corrosion.

Test Description

Number(s) below refer to the step number(s) on the Diag-

nostic Table.

1. The On–Board Diagnostic (EOBD) System Check

prompts the technician to complete some basic

checks and store the freeze frame and failure re-

cords data on the scan tool if applicable. This

creates an electronic copy of the data taken when

the malfunction occurred. The information is then

stored on the scan tool for later reference.

2. Unlike the UART serial data circuit, the only time a

Class II serial data circuit has any voltage on it is

when a scan tool asks the ECM for information and

sends the information out.

5. Locate and repair any shorts that may have caused

the fuse to open before replacement, if the no volt-

age condition was due to an open fuse.

10. The scan tool or associated cables could be mal-

functioning. Refer to the scan tool’s manual for re-

pair information.

Page 357 of 2643

ENGINE CONTROLS 1F – 111

DAEWOO V–121 BL4

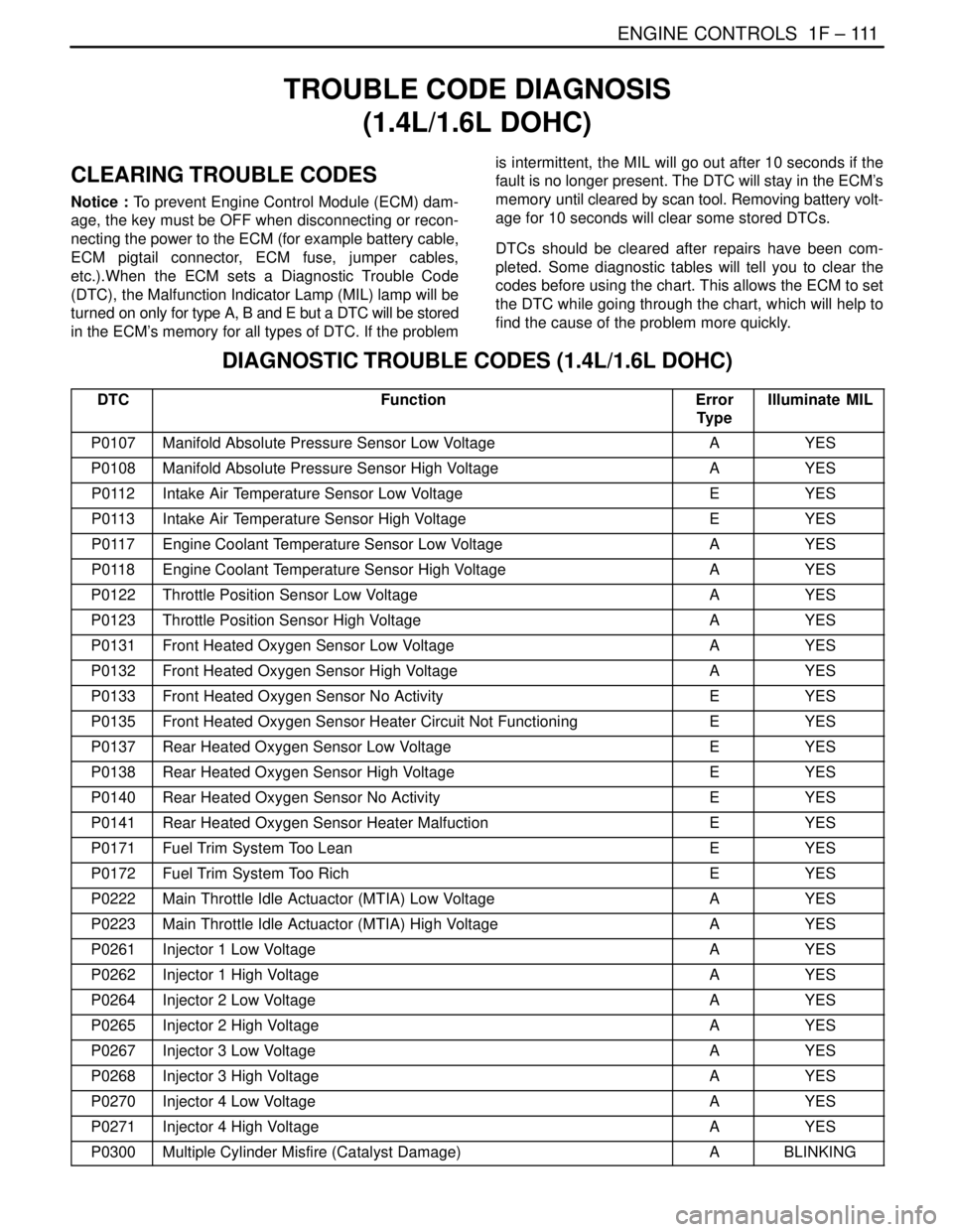

TROUBLE CODE DIAGNOSIS

(1.4L/1.6L DOHC)

CLEARING TROUBLE CODES

Notice : To prevent Engine Control Module (ECM) dam-

age, the key must be OFF when disconnecting or recon-

necting the power to the ECM (for example battery cable,

ECM pigtail connector, ECM fuse, jumper cables,

etc.).When the ECM sets a Diagnostic Trouble Code

(DTC), the Malfunction Indicator Lamp (MIL) lamp will be

turned on only for type A, B and E but a DTC will be stored

in the ECM’s memory for all types of DTC. If the problemis intermittent, the MIL will go out after 10 seconds if the

fault is no longer present. The DTC will stay in the ECM’s

memory until cleared by scan tool. Removing battery volt-

age for 10 seconds will clear some stored DTCs.

DTCs should be cleared after repairs have been com-

pleted. Some diagnostic tables will tell you to clear the

codes before using the chart. This allows the ECM to set

the DTC while going through the chart, which will help to

find the cause of the problem more quickly.

DIAGNOSTIC TROUBLE CODES (1.4L/1.6L DOHC)

DTCFunctionError

TypeIlluminate MIL

P0107Manifold Absolute Pressure Sensor Low VoltageAYES

P0108Manifold Absolute Pressure Sensor High VoltageAYES

P0112Intake Air Temperature Sensor Low VoltageEYES

P0113Intake Air Temperature Sensor High VoltageEYES

P0117Engine Coolant Temperature Sensor Low VoltageAYES

P0118Engine Coolant Temperature Sensor High VoltageAYES

P0122Throttle Position Sensor Low VoltageAYES

P0123Throttle Position Sensor High VoltageAYES

P0131Front Heated Oxygen Sensor Low VoltageAYES

P0132Front Heated Oxygen Sensor High VoltageAYES

P0133Front Heated Oxygen Sensor No ActivityEYES

P0135Front Heated Oxygen Sensor Heater Circuit Not FunctioningEYES

P0137Rear Heated Oxygen Sensor Low VoltageEYES

P0138Rear Heated Oxygen Sensor High VoltageEYES

P0140Rear Heated Oxygen Sensor No ActivityEYES

P0141Rear Heated Oxygen Sensor Heater MalfuctionEYES

P0171Fuel Trim System Too LeanEYES

P0172Fuel Trim System Too RichEYES

P0222Main Throttle Idle Actuactor (MTIA) Low VoltageAYES

P0223Main Throttle Idle Actuactor (MTIA) High VoltageAYES

P0261Injector 1 Low VoltageAYES

P0262Injector 1 High VoltageAYES

P0264Injector 2 Low VoltageAYES

P0265Injector 2 High VoltageAYES

P0267Injector 3 Low VoltageAYES

P0268Injector 3 High VoltageAYES

P0270Injector 4 Low VoltageAYES

P0271Injector 4 High VoltageAYES

P0300Multiple Cylinder Misfire (Catalyst Damage)ABLINKING

Page 361 of 2643

ENGINE CONTROLS 1F – 115

DAEWOO V–121 BL4

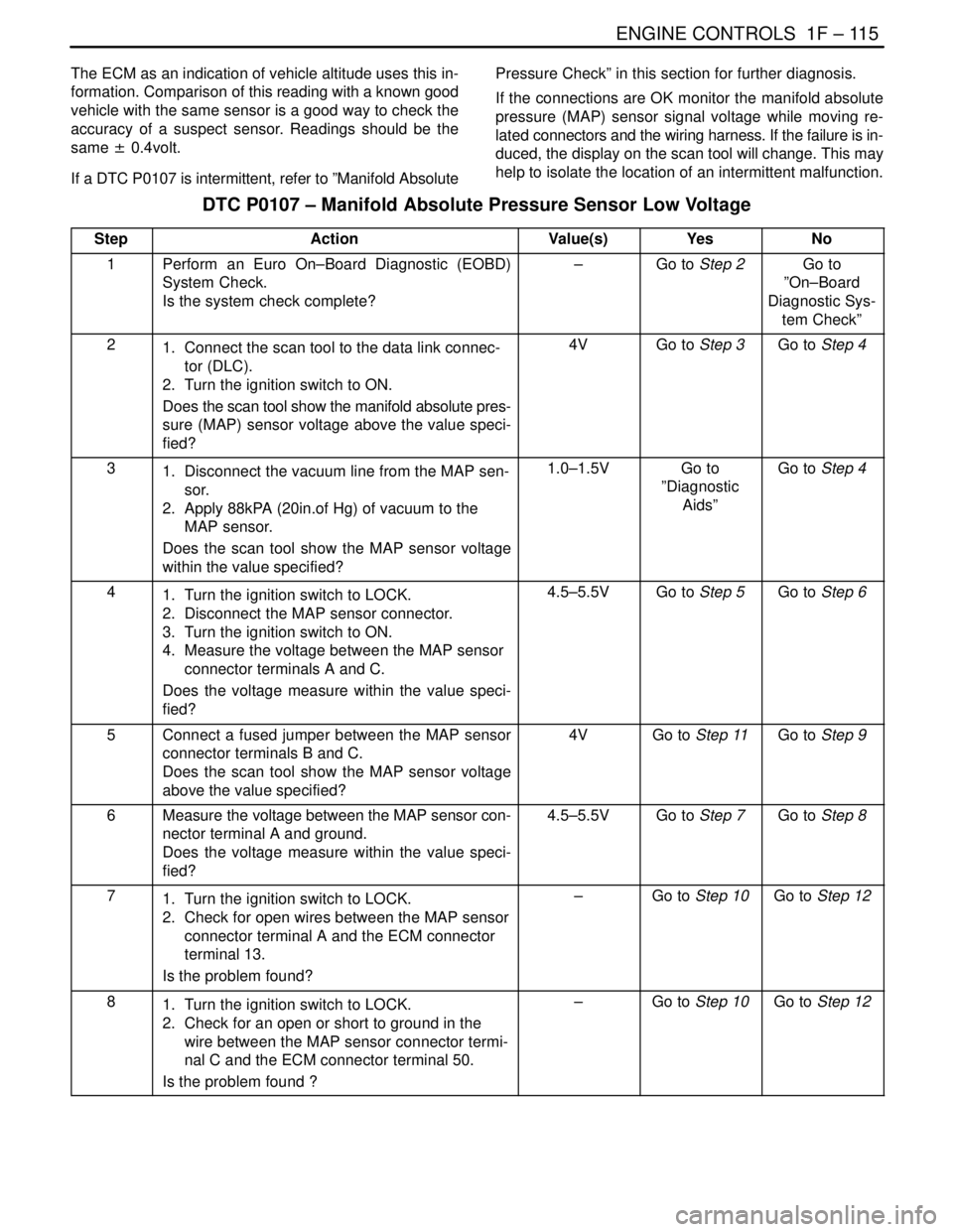

The ECM as an indication of vehicle altitude uses this in-

formation. Comparison of this reading with a known good

vehicle with the same sensor is a good way to check the

accuracy of a suspect sensor. Readings should be the

same ± 0.4volt.

If a DTC P0107 is intermittent, refer to ”Manifold AbsolutePressure Check” in this section for further diagnosis.

If the connections are OK monitor the manifold absolute

pressure (MAP) sensor signal voltage while moving re-

lated connectors and the wiring harness. If the failure is in-

duced, the display on the scan tool will change. This may

help to isolate the location of an intermittent malfunction.

DTC P0107 – Manifold Absolute Pressure Sensor Low Voltage

StepActionValue(s)YesNo

1Perform an Euro On–Board Diagnostic (EOBD)

System Check.

Is the system check complete?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Connect the scan tool to the data link connec-

tor (DLC).

2. Turn the ignition switch to ON.

Does the scan tool show the manifold absolute pres-

sure (MAP) sensor voltage above the value speci-

fied?4VGo to Step 3Go to Step 4

31. Disconnect the vacuum line from the MAP sen-

sor.

2. Apply 88kPA (20in.of Hg) of vacuum to the

MAP sensor.

Does the scan tool show the MAP sensor voltage

within the value specified?1.0–1.5VGo to

”Diagnostic

Aids”Go to Step 4

41. Turn the ignition switch to LOCK.

2. Disconnect the MAP sensor connector.

3. Turn the ignition switch to ON.

4. Measure the voltage between the MAP sensor

connector terminals A and C.

Does the voltage measure within the value speci-

fied?4.5–5.5VGo to Step 5Go to Step 6

5Connect a fused jumper between the MAP sensor

connector terminals B and C.

Does the scan tool show the MAP sensor voltage

above the value specified?4VGo to Step 11Go to Step 9

6Measure the voltage between the MAP sensor con-

nector terminal A and ground.

Does the voltage measure within the value speci-

fied?4.5–5.5VGo to Step 7Go to Step 8

71. Turn the ignition switch to LOCK.

2. Check for open wires between the MAP sensor

connector terminal A and the ECM connector

terminal 13.

Is the problem found?–Go to Step 10Go to Step 12

81. Turn the ignition switch to LOCK.

2. Check for an open or short to ground in the

wire between the MAP sensor connector termi-

nal C and the ECM connector terminal 50.

Is the problem found ?–Go to Step 10Go to Step 12

Page 364 of 2643

1F – 118IENGINE CONTROLS

DAEWOO V–121 BL4

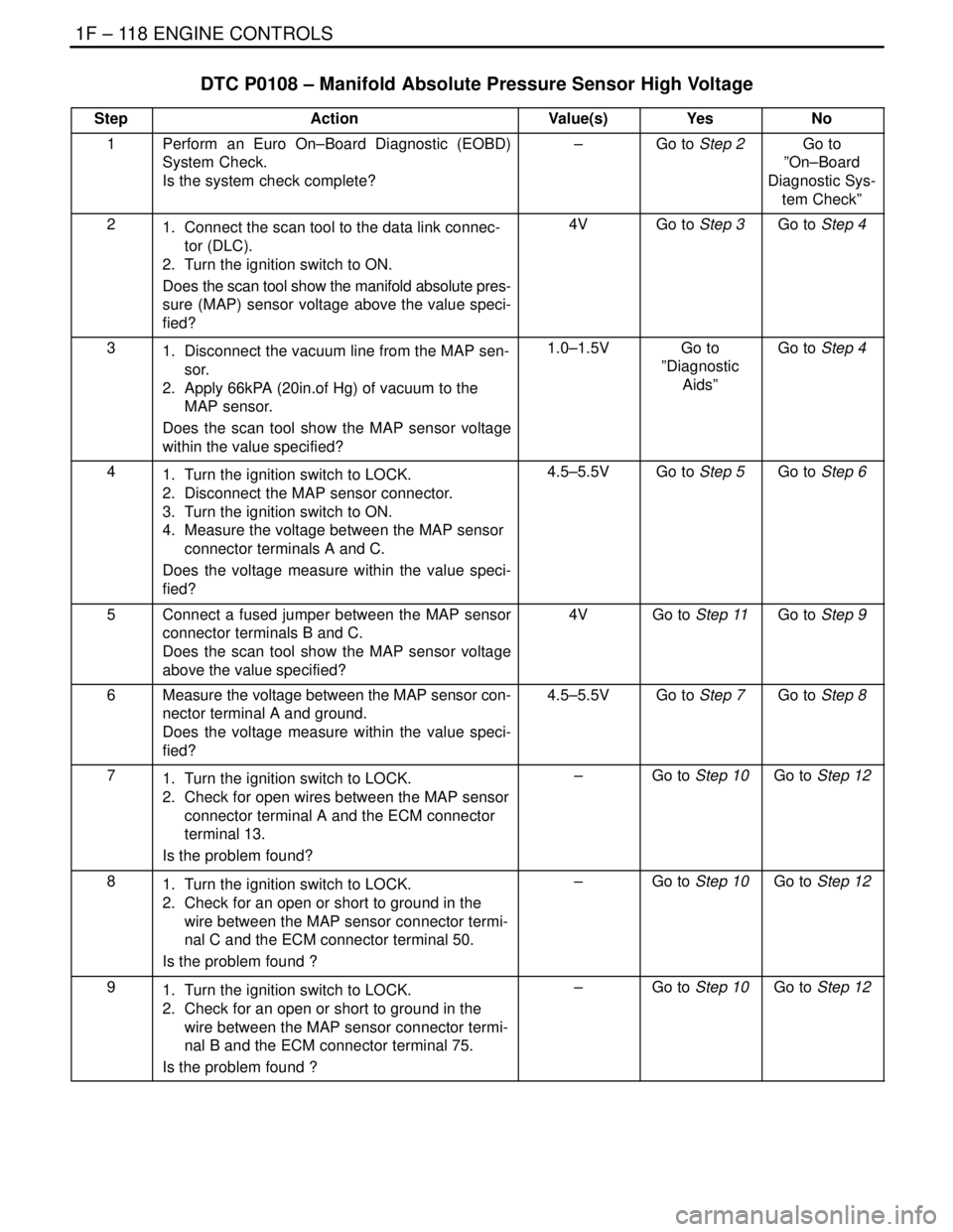

DTC P0108 – Manifold Absolute Pressure Sensor High Voltage

StepActionValue(s)YesNo

1Perform an Euro On–Board Diagnostic (EOBD)

System Check.

Is the system check complete?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Connect the scan tool to the data link connec-

tor (DLC).

2. Turn the ignition switch to ON.

Does the scan tool show the manifold absolute pres-

sure (MAP) sensor voltage above the value speci-

fied?4VGo to Step 3Go to Step 4

31. Disconnect the vacuum line from the MAP sen-

sor.

2. Apply 66kPA (20in.of Hg) of vacuum to the

MAP sensor.

Does the scan tool show the MAP sensor voltage

within the value specified?1.0–1.5VGo to

”Diagnostic

Aids”Go to Step 4

41. Turn the ignition switch to LOCK.

2. Disconnect the MAP sensor connector.

3. Turn the ignition switch to ON.

4. Measure the voltage between the MAP sensor

connector terminals A and C.

Does the voltage measure within the value speci-

fied?4.5–5.5VGo to Step 5Go to Step 6

5Connect a fused jumper between the MAP sensor

connector terminals B and C.

Does the scan tool show the MAP sensor voltage

above the value specified?4VGo to Step 11Go to Step 9

6Measure the voltage between the MAP sensor con-

nector terminal A and ground.

Does the voltage measure within the value speci-

fied?4.5–5.5VGo to Step 7Go to Step 8

71. Turn the ignition switch to LOCK.

2. Check for open wires between the MAP sensor

connector terminal A and the ECM connector

terminal 13.

Is the problem found?–Go to Step 10Go to Step 12

81. Turn the ignition switch to LOCK.

2. Check for an open or short to ground in the

wire between the MAP sensor connector termi-

nal C and the ECM connector terminal 50.

Is the problem found ?–Go to Step 10Go to Step 12

91. Turn the ignition switch to LOCK.

2. Check for an open or short to ground in the

wire between the MAP sensor connector termi-

nal B and the ECM connector terminal 75.

Is the problem found ?–Go to Step 10Go to Step 12

Page 378 of 2643

1F – 132IENGINE CONTROLS

DAEWOO V–121 BL4

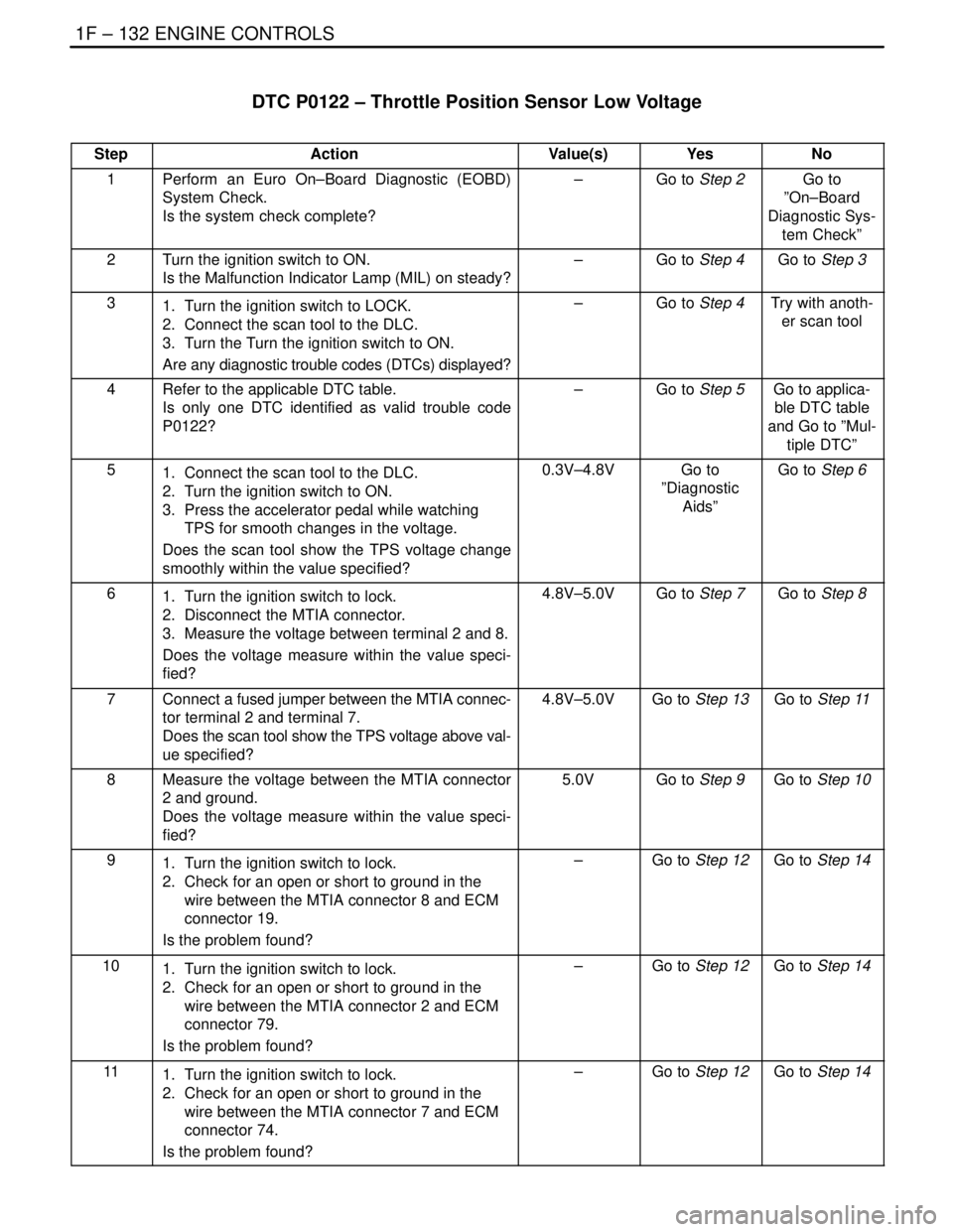

DTC P0122 – Throttle Position Sensor Low Voltage

StepActionValue(s)YesNo

1Perform an Euro On–Board Diagnostic (EOBD)

System Check.

Is the system check complete?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

2Turn the ignition switch to ON.

Is the Malfunction Indicator Lamp (MIL) on steady?–Go to Step 4Go to Step 3

31. Turn the ignition switch to LOCK.

2. Connect the scan tool to the DLC.

3. Turn the Turn the ignition switch to ON.

Are any diagnostic trouble codes (DTCs) displayed?–Go to Step 4Try with anoth-

er scan tool

4Refer to the applicable DTC table.

Is only one DTC identified as valid trouble code

P0122?–Go to Step 5Go to applica-

ble DTC table

and Go to ”Mul-

tiple DTC”

51. Connect the scan tool to the DLC.

2. Turn the ignition switch to ON.

3. Press the accelerator pedal while watching

TPS for smooth changes in the voltage.

Does the scan tool show the TPS voltage change

smoothly within the value specified?0.3V–4.8VGo to

”Diagnostic

Aids”Go to Step 6

61. Turn the ignition switch to lock.

2. Disconnect the MTIA connector.

3. Measure the voltage between terminal 2 and 8.

Does the voltage measure within the value speci-

fied?4.8V–5.0VGo to Step 7Go to Step 8

7Connect a fused jumper between the MTIA connec-

tor terminal 2 and terminal 7.

Does the scan tool show the TPS voltage above val-

ue specified?4.8V–5.0VGo to Step 13Go to Step 11

8Measure the voltage between the MTIA connector

2 and ground.

Does the voltage measure within the value speci-

fied?5.0VGo to Step 9Go to Step 10

91. Turn the ignition switch to lock.

2. Check for an open or short to ground in the

wire between the MTIA connector 8 and ECM

connector 19.

Is the problem found?–Go to Step 12Go to Step 14

101. Turn the ignition switch to lock.

2. Check for an open or short to ground in the

wire between the MTIA connector 2 and ECM

connector 79.

Is the problem found?–Go to Step 12Go to Step 14

111. Turn the ignition switch to lock.

2. Check for an open or short to ground in the

wire between the MTIA connector 7 and ECM

connector 74.

Is the problem found?–Go to Step 12Go to Step 14

Page 381 of 2643

ENGINE CONTROLS 1F – 135

DAEWOO V–121 BL4

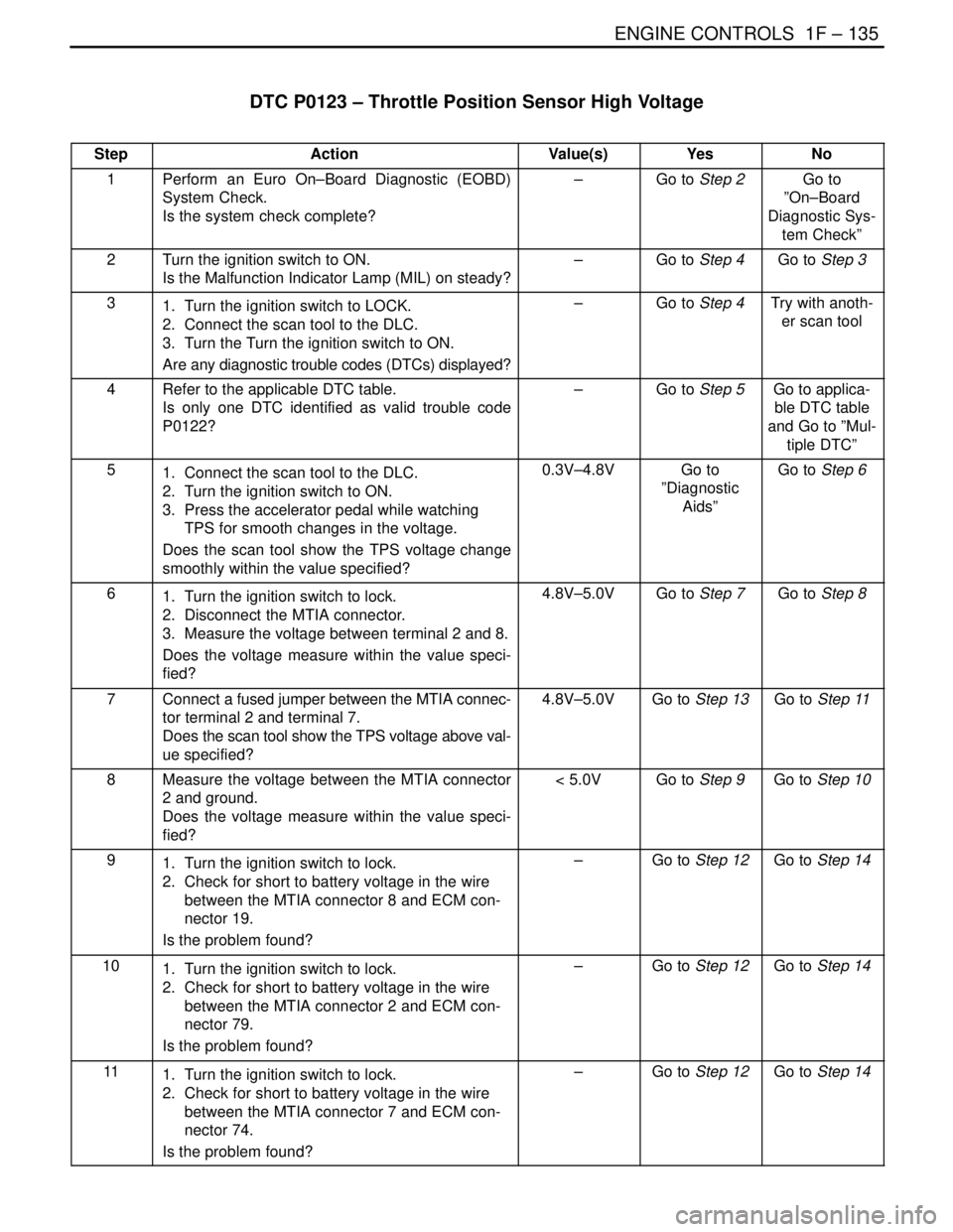

DTC P0123 – Throttle Position Sensor High Voltage

StepActionValue(s)YesNo

1Perform an Euro On–Board Diagnostic (EOBD)

System Check.

Is the system check complete?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

2Turn the ignition switch to ON.

Is the Malfunction Indicator Lamp (MIL) on steady?–Go to Step 4Go to Step 3

31. Turn the ignition switch to LOCK.

2. Connect the scan tool to the DLC.

3. Turn the Turn the ignition switch to ON.

Are any diagnostic trouble codes (DTCs) displayed?–Go to Step 4Try with anoth-

er scan tool

4Refer to the applicable DTC table.

Is only one DTC identified as valid trouble code

P0122?–Go to Step 5Go to applica-

ble DTC table

and Go to ”Mul-

tiple DTC”

51. Connect the scan tool to the DLC.

2. Turn the ignition switch to ON.

3. Press the accelerator pedal while watching

TPS for smooth changes in the voltage.

Does the scan tool show the TPS voltage change

smoothly within the value specified?0.3V–4.8VGo to

”Diagnostic

Aids”Go to Step 6

61. Turn the ignition switch to lock.

2. Disconnect the MTIA connector.

3. Measure the voltage between terminal 2 and 8.

Does the voltage measure within the value speci-

fied?4.8V–5.0VGo to Step 7Go to Step 8

7Connect a fused jumper between the MTIA connec-

tor terminal 2 and terminal 7.

Does the scan tool show the TPS voltage above val-

ue specified?4.8V–5.0VGo to Step 13Go to Step 11

8Measure the voltage between the MTIA connector

2 and ground.

Does the voltage measure within the value speci-

fied?< 5.0VGo to Step 9Go to Step 10

91. Turn the ignition switch to lock.

2. Check for short to battery voltage in the wire

between the MTIA connector 8 and ECM con-

nector 19.

Is the problem found?–Go to Step 12Go to Step 14

101. Turn the ignition switch to lock.

2. Check for short to battery voltage in the wire

between the MTIA connector 2 and ECM con-

nector 79.

Is the problem found?–Go to Step 12Go to Step 14

111. Turn the ignition switch to lock.

2. Check for short to battery voltage in the wire

between the MTIA connector 7 and ECM con-

nector 74.

Is the problem found?–Go to Step 12Go to Step 14

Page 391 of 2643

ENGINE CONTROLS 1F – 145

DAEWOO V–121 BL4

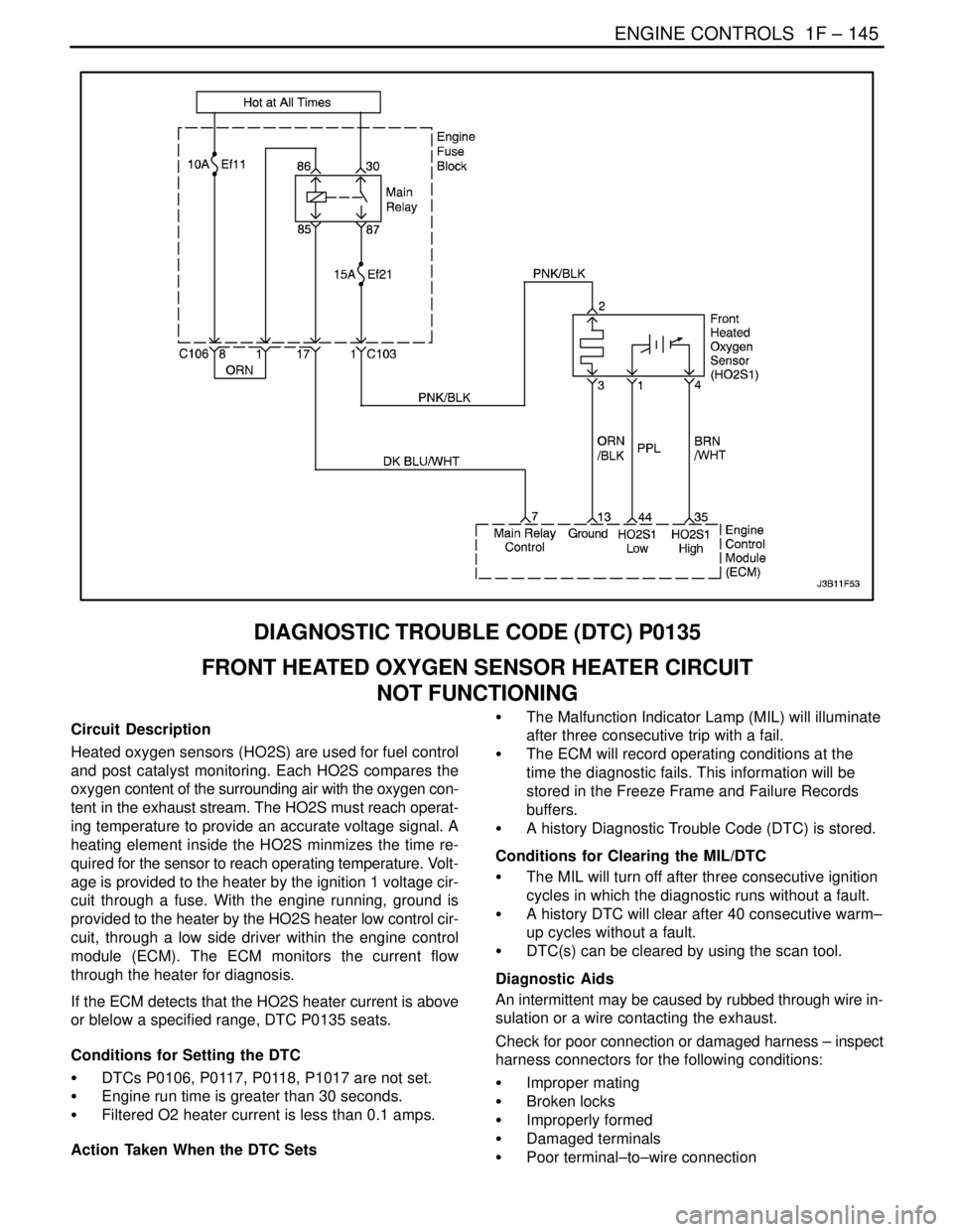

DIAGNOSTIC TROUBLE CODE (DTC) P0135

FRONT HEATED OXYGEN SENSOR HEATER CIRCUIT

NOT FUNCTIONING

Circuit Description

Heated oxygen sensors (HO2S) are used for fuel control

and post catalyst monitoring. Each HO2S compares the

oxygen content of the surrounding air with the oxygen con-

tent in the exhaust stream. The HO2S must reach operat-

ing temperature to provide an accurate voltage signal. A

heating element inside the HO2S minmizes the time re-

quired for the sensor to reach operating temperature. Volt-

age is provided to the heater by the ignition 1 voltage cir-

cuit through a fuse. With the engine running, ground is

provided to the heater by the HO2S heater low control cir-

cuit, through a low side driver within the engine control

module (ECM). The ECM monitors the current flow

through the heater for diagnosis.

If the ECM detects that the HO2S heater current is above

or blelow a specified range, DTC P0135 seats.

Conditions for Setting the DTC

S DTCs P0106, P0117, P0118, P1017 are not set.

S Engine run time is greater than 30 seconds.

S Filtered O2 heater current is less than 0.1 amps.

Action Taken When the DTC SetsS The Malfunction Indicator Lamp (MIL) will illuminate

after three consecutive trip with a fail.

S The ECM will record operating conditions at the

time the diagnostic fails. This information will be

stored in the Freeze Frame and Failure Records

buffers.

S A history Diagnostic Trouble Code (DTC) is stored.

Conditions for Clearing the MIL/DTC

S The MIL will turn off after three consecutive ignition

cycles in which the diagnostic runs without a fault.

S A history DTC will clear after 40 consecutive warm–

up cycles without a fault.

S DTC(s) can be cleared by using the scan tool.

Diagnostic Aids

An intermittent may be caused by rubbed through wire in-

sulation or a wire contacting the exhaust.

Check for poor connection or damaged harness – inspect

harness connectors for the following conditions:

S Improper mating

S Broken locks

S Improperly formed

S Damaged terminals

S Poor terminal–to–wire connection

Page 392 of 2643

1F – 146IENGINE CONTROLS

DAEWOO V–121 BL4

S Damaged harness

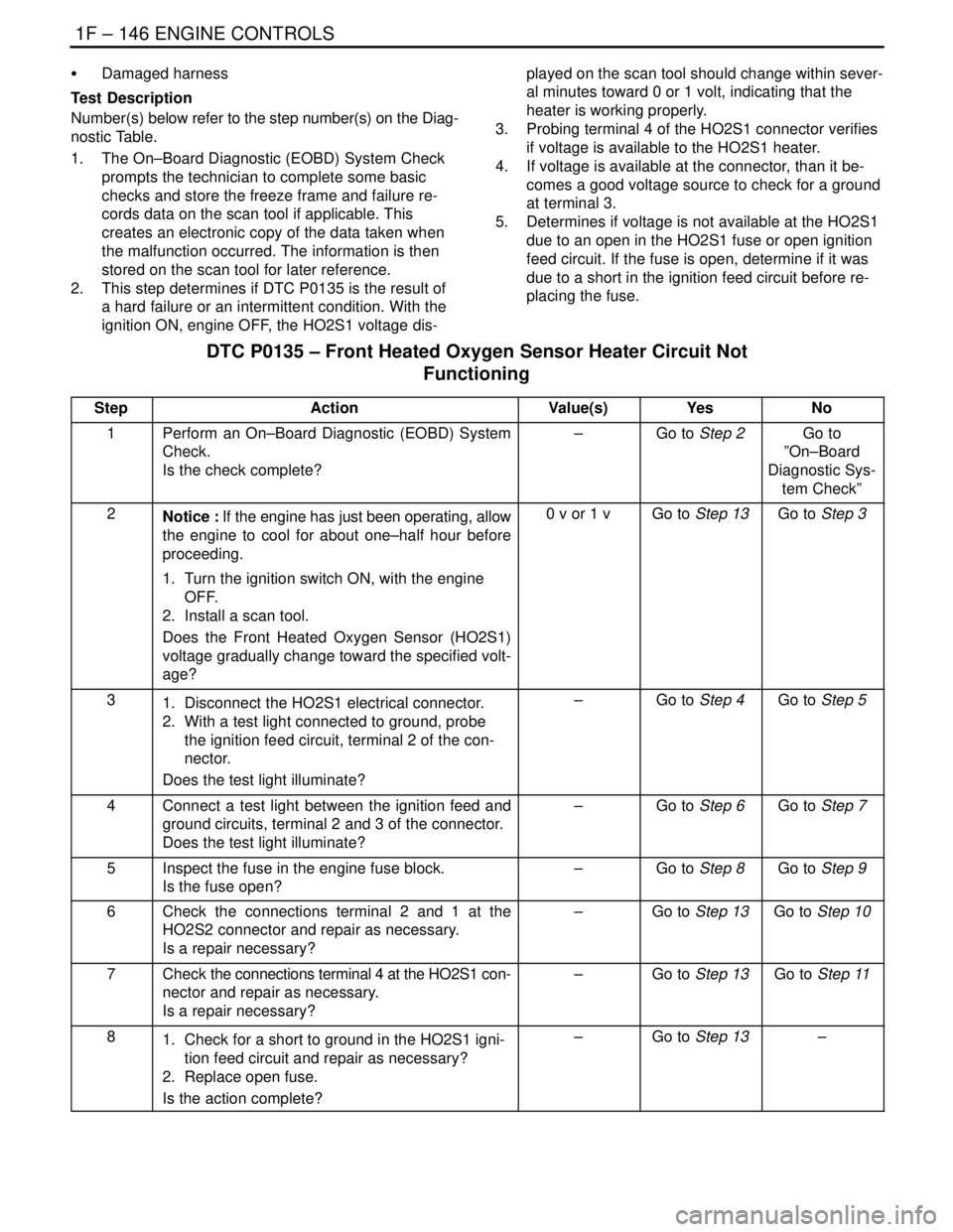

Test Description

Number(s) below refer to the step number(s) on the Diag-

nostic Table.

1. The On–Board Diagnostic (EOBD) System Check

prompts the technician to complete some basic

checks and store the freeze frame and failure re-

cords data on the scan tool if applicable. This

creates an electronic copy of the data taken when

the malfunction occurred. The information is then

stored on the scan tool for later reference.

2. This step determines if DTC P0135 is the result of

a hard failure or an intermittent condition. With the

ignition ON, engine OFF, the HO2S1 voltage dis-played on the scan tool should change within sever-

al minutes toward 0 or 1 volt, indicating that the

heater is working properly.

3. Probing terminal 4 of the HO2S1 connector verifies

if voltage is available to the HO2S1 heater.

4. If voltage is available at the connector, than it be-

comes a good voltage source to check for a ground

at terminal 3.

5. Determines if voltage is not available at the HO2S1

due to an open in the HO2S1 fuse or open ignition

feed circuit. If the fuse is open, determine if it was

due to a short in the ignition feed circuit before re-

placing the fuse.

DTC P0135 – Front Heated Oxygen Sensor Heater Circuit Not

Functioning

StepActionValue(s)YesNo

1Perform an On–Board Diagnostic (EOBD) System

Check.

Is the check complete?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

2Notice : If the engine has just been operating, allow

the engine to cool for about one–half hour before

proceeding.

1. Turn the ignition switch ON, with the engine

OFF.

2. Install a scan tool.

Does the Front Heated Oxygen Sensor (HO2S1)

voltage gradually change toward the specified volt-

age?0 v or 1 vGo to Step 13Go to Step 3

31. Disconnect the HO2S1 electrical connector.

2. With a test light connected to ground, probe

the ignition feed circuit, terminal 2 of the con-

nector.

Does the test light illuminate?–Go to Step 4Go to Step 5

4Connect a test light between the ignition feed and

ground circuits, terminal 2 and 3 of the connector.

Does the test light illuminate?–Go to Step 6Go to Step 7

5Inspect the fuse in the engine fuse block.

Is the fuse open?–Go to Step 8Go to Step 9

6Check the connections terminal 2 and 1 at the

HO2S2 connector and repair as necessary.

Is a repair necessary?–Go to Step 13Go to Step 10

7Check the connections terminal 4 at the HO2S1 con-

nector and repair as necessary.

Is a repair necessary?–Go to Step 13Go to Step 11

81. Check for a short to ground in the HO2S1 igni-

tion feed circuit and repair as necessary?

2. Replace open fuse.

Is the action complete?–Go to Step 13–

Page 412 of 2643

1F – 166IENGINE CONTROLS

DAEWOO V–121 BL4

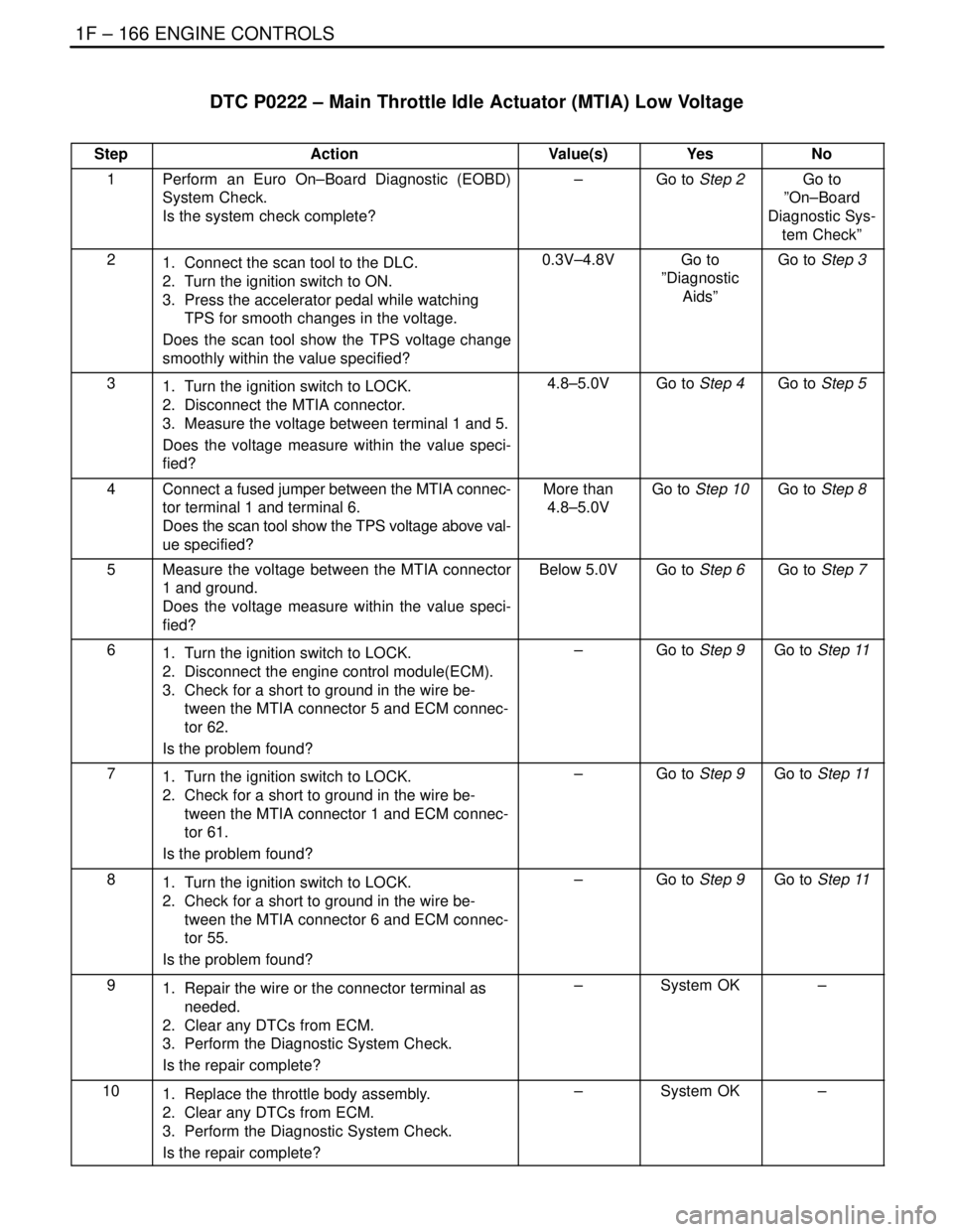

DTC P0222 – Main Throttle Idle Actuator (MTIA) Low Voltage

StepActionValue(s)YesNo

1Perform an Euro On–Board Diagnostic (EOBD)

System Check.

Is the system check complete?–Go to Step 2Go to

”On–Board

Diagnostic Sys-

tem Check”

21. Connect the scan tool to the DLC.

2. Turn the ignition switch to ON.

3. Press the accelerator pedal while watching

TPS for smooth changes in the voltage.

Does the scan tool show the TPS voltage change

smoothly within the value specified?0.3V–4.8VGo to

”Diagnostic

Aids”Go to Step 3

31. Turn the ignition switch to LOCK.

2. Disconnect the MTIA connector.

3. Measure the voltage between terminal 1 and 5.

Does the voltage measure within the value speci-

fied?4.8–5.0VGo to Step 4Go to Step 5

4Connect a fused jumper between the MTIA connec-

tor terminal 1 and terminal 6.

Does the scan tool show the TPS voltage above val-

ue specified?More than

4.8–5.0VGo to Step 10Go to Step 8

5Measure the voltage between the MTIA connector

1 and ground.

Does the voltage measure within the value speci-

fied?Below 5.0VGo to Step 6Go to Step 7

61. Turn the ignition switch to LOCK.

2. Disconnect the engine control module(ECM).

3. Check for a short to ground in the wire be-

tween the MTIA connector 5 and ECM connec-

tor 62.

Is the problem found?–Go to Step 9Go to Step 11

71. Turn the ignition switch to LOCK.

2. Check for a short to ground in the wire be-

tween the MTIA connector 1 and ECM connec-

tor 61.

Is the problem found?–Go to Step 9Go to Step 11

81. Turn the ignition switch to LOCK.

2. Check for a short to ground in the wire be-

tween the MTIA connector 6 and ECM connec-

tor 55.

Is the problem found?–Go to Step 9Go to Step 11

91. Repair the wire or the connector terminal as

needed.

2. Clear any DTCs from ECM.

3. Perform the Diagnostic System Check.

Is the repair complete?–System OK–

101. Replace the throttle body assembly.

2. Clear any DTCs from ECM.

3. Perform the Diagnostic System Check.

Is the repair complete?–System OK–