check engine DAEWOO NUBIRA 2004 Service Repair Manual

[x] Cancel search | Manufacturer: DAEWOO, Model Year: 2004, Model line: NUBIRA, Model: DAEWOO NUBIRA 2004Pages: 2643, PDF Size: 80.54 MB

Page 1950 of 2643

POWER STEERING GEAR 6C – 33

DAEWOO V–121 BL4

GENERAL DESCRIPTION

AND SYSTEM OPERATION

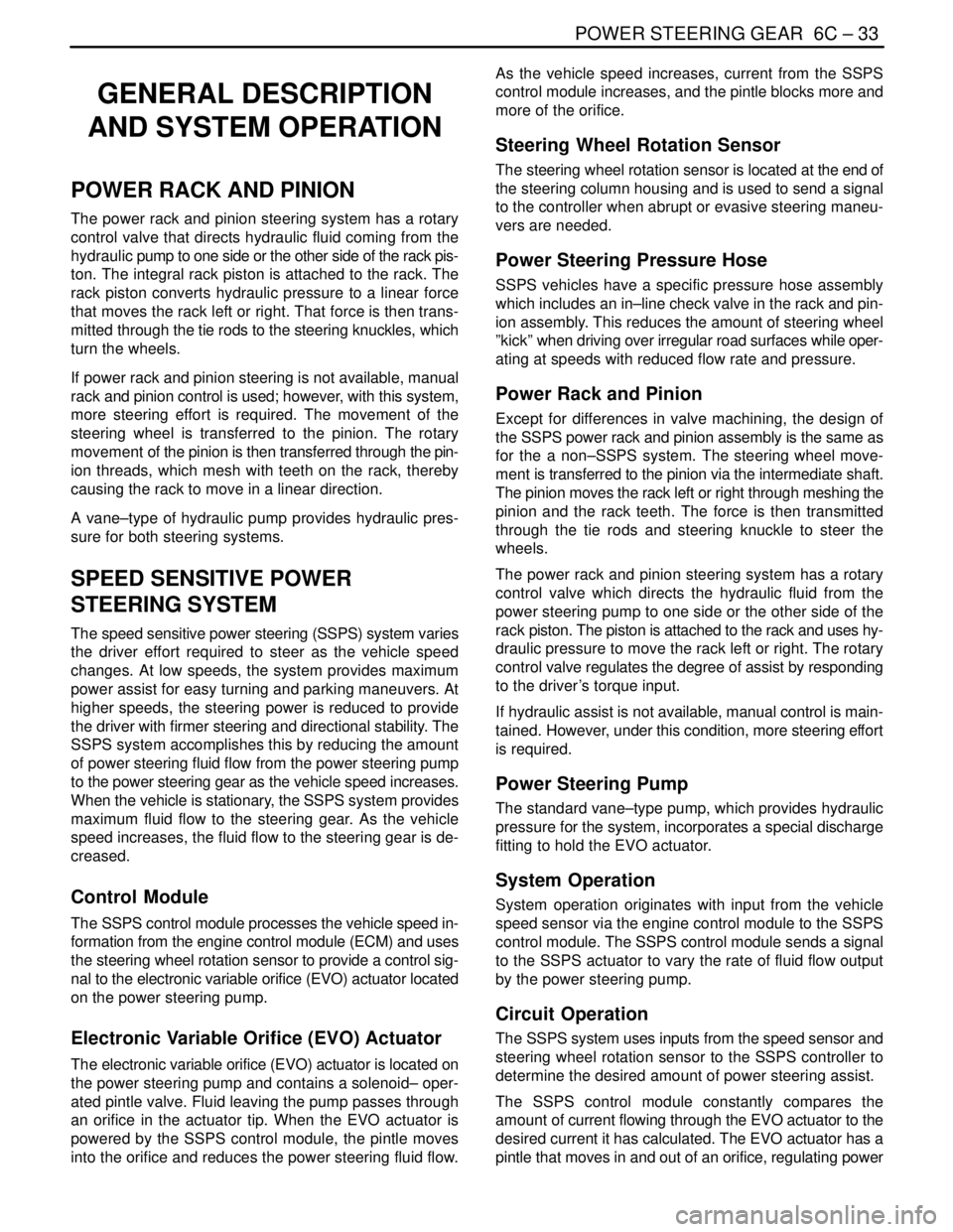

POWER RACK AND PINION

The power rack and pinion steering system has a rotary

control valve that directs hydraulic fluid coming from the

hydraulic pump to one side or the other side of the rack pis-

ton. The integral rack piston is attached to the rack. The

rack piston converts hydraulic pressure to a linear force

that moves the rack left or right. That force is then trans-

mitted through the tie rods to the steering knuckles, which

turn the wheels.

If power rack and pinion steering is not available, manual

rack and pinion control is used; however, with this system,

more steering effort is required. The movement of the

steering wheel is transferred to the pinion. The rotary

movement of the pinion is then transferred through the pin-

ion threads, which mesh with teeth on the rack, thereby

causing the rack to move in a linear direction.

A vane–type of hydraulic pump provides hydraulic pres-

sure for both steering systems.

SPEED SENSITIVE POWER

STEERING SYSTEM

The speed sensitive power steering (SSPS) system varies

the driver effort required to steer as the vehicle speed

changes. At low speeds, the system provides maximum

power assist for easy turning and parking maneuvers. At

higher speeds, the steering power is reduced to provide

the driver with firmer steering and directional stability. The

SSPS system accomplishes this by reducing the amount

of power steering fluid flow from the power steering pump

to the power steering gear as the vehicle speed increases.

When the vehicle is stationary, the SSPS system provides

maximum fluid flow to the steering gear. As the vehicle

speed increases, the fluid flow to the steering gear is de-

creased.

Control Module

The SSPS control module processes the vehicle speed in-

formation from the engine control module (ECM) and uses

the steering wheel rotation sensor to provide a control sig-

nal to the electronic variable orifice (EVO) actuator located

on the power steering pump.

Electronic Variable Orifice (EVO) Actuator

The electronic variable orifice (EVO) actuator is located on

the power steering pump and contains a solenoid– oper-

ated pintle valve. Fluid leaving the pump passes through

an orifice in the actuator tip. When the EVO actuator is

powered by the SSPS control module, the pintle moves

into the orifice and reduces the power steering fluid flow.As the vehicle speed increases, current from the SSPS

control module increases, and the pintle blocks more and

more of the orifice.

Steering Wheel Rotation Sensor

The steering wheel rotation sensor is located at the end of

the steering column housing and is used to send a signal

to the controller when abrupt or evasive steering maneu-

vers are needed.

Power Steering Pressure Hose

SSPS vehicles have a specific pressure hose assembly

which includes an in–line check valve in the rack and pin-

ion assembly. This reduces the amount of steering wheel

”kick” when driving over irregular road surfaces while oper-

ating at speeds with reduced flow rate and pressure.

Power Rack and Pinion

Except for differences in valve machining, the design of

the SSPS power rack and pinion assembly is the same as

for the a non–SSPS system. The steering wheel move-

ment is transferred to the pinion via the intermediate shaft.

The pinion moves the rack left or right through meshing the

pinion and the rack teeth. The force is then transmitted

through the tie rods and steering knuckle to steer the

wheels.

The power rack and pinion steering system has a rotary

control valve which directs the hydraulic fluid from the

power steering pump to one side or the other side of the

rack piston. The piston is attached to the rack and uses hy-

draulic pressure to move the rack left or right. The rotary

control valve regulates the degree of assist by responding

to the driver’s torque input.

If hydraulic assist is not available, manual control is main-

tained. However, under this condition, more steering effort

is required.

Power Steering Pump

The standard vane–type pump, which provides hydraulic

pressure for the system, incorporates a special discharge

fitting to hold the EVO actuator.

System Operation

System operation originates with input from the vehicle

speed sensor via the engine control module to the SSPS

control module. The SSPS control module sends a signal

to the SSPS actuator to vary the rate of fluid flow output

by the power steering pump.

Circuit Operation

The SSPS system uses inputs from the speed sensor and

steering wheel rotation sensor to the SSPS controller to

determine the desired amount of power steering assist.

The SSPS control module constantly compares the

amount of current flowing through the EVO actuator to the

desired current it has calculated. The EVO actuator has a

pintle that moves in and out of an orifice, regulating power

Page 1980 of 2643

7A – 6IHEATING AND VENTILATION SYSTEM

DAEWOO V–121 BL4

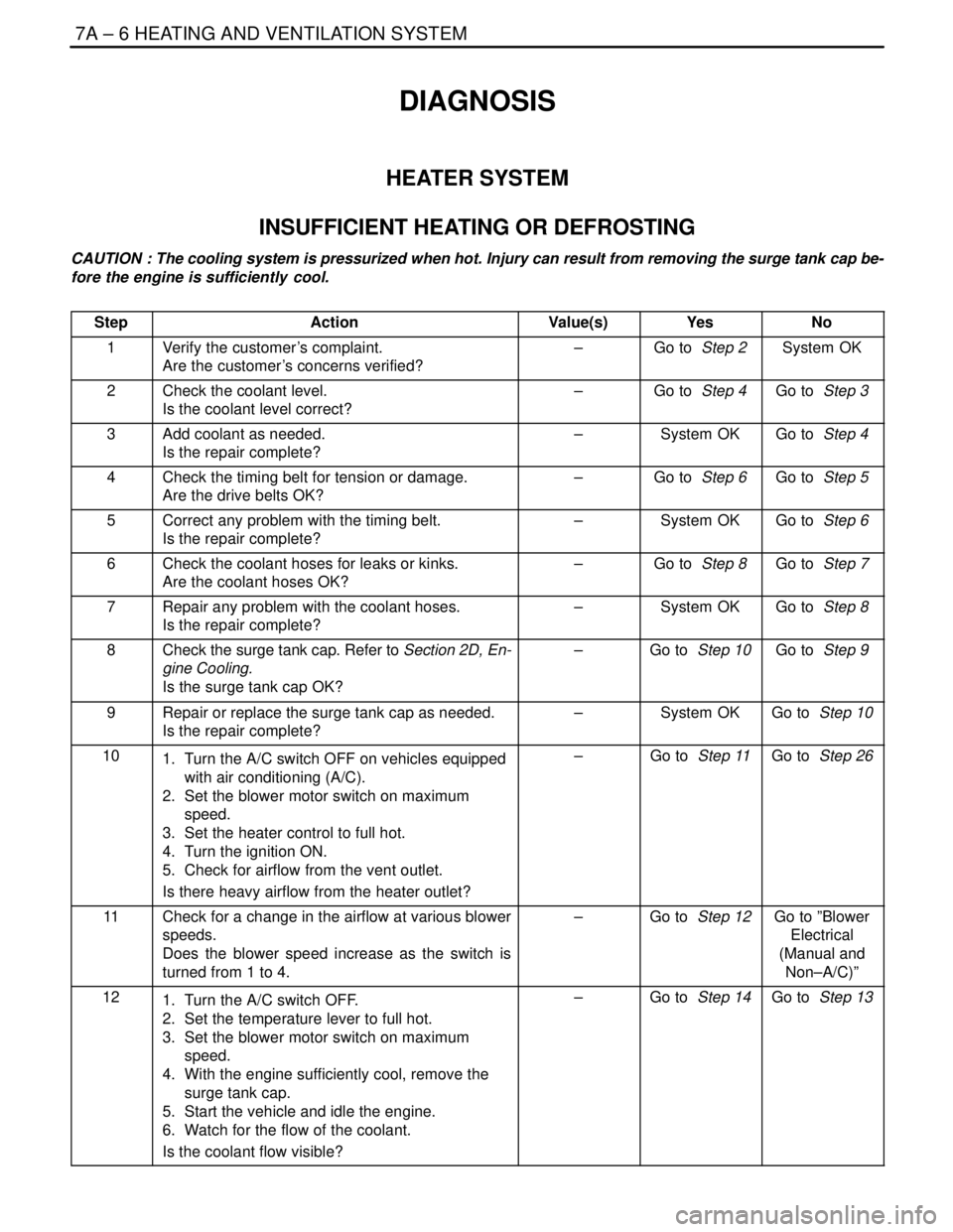

DIAGNOSIS

HEATER SYSTEM

INSUFFICIENT HEATING OR DEFROSTING

CAUTION : The cooling system is pressurized when hot. Injury can result from removing the surge tank cap be-

fore the engine is sufficiently cool.

Step

ActionValue(s)YesNo

1Verify the customer’s complaint.

Are the customer’s concerns verified?–Go to Step 2System OK

2Check the coolant level.

Is the coolant level correct?–Go to Step 4Go to Step 3

3Add coolant as needed.

Is the repair complete?–System OKGo to Step 4

4Check the timing belt for tension or damage.

Are the drive belts OK?–Go to Step 6Go to Step 5

5Correct any problem with the timing belt.

Is the repair complete?–System OKGo to Step 6

6Check the coolant hoses for leaks or kinks.

Are the coolant hoses OK?–Go to Step 8Go to Step 7

7Repair any problem with the coolant hoses.

Is the repair complete?–System OKGo to Step 8

8Check the surge tank cap. Refer to Section 2D, En-

gine Cooling.

Is the surge tank cap OK?–Go to Step 10Go to Step 9

9Repair or replace the surge tank cap as needed.

Is the repair complete?–System OKGo to Step 10

101. Turn the A/C switch OFF on vehicles equipped

with air conditioning (A/C).

2. Set the blower motor switch on maximum

speed.

3. Set the heater control to full hot.

4. Turn the ignition ON.

5. Check for airflow from the vent outlet.

Is there heavy airflow from the heater outlet?–Go to Step 11Go to Step 26

11Check for a change in the airflow at various blower

speeds.

Does the blower speed increase as the switch is

turned from 1 to 4.–Go to Step 12Go to ”Blower

Electrical

(Manual and

Non–A/C)”

121. Turn the A/C switch OFF.

2. Set the temperature lever to full hot.

3. Set the blower motor switch on maximum

speed.

4. With the engine sufficiently cool, remove the

surge tank cap.

5. Start the vehicle and idle the engine.

6. Watch for the flow of the coolant.

Is the coolant flow visible?–Go to Step 14Go to Step 13

Page 1981 of 2643

HEATING AND VENTILATION SYSTEM 7A – 7

DAEWOO V–121 BL4

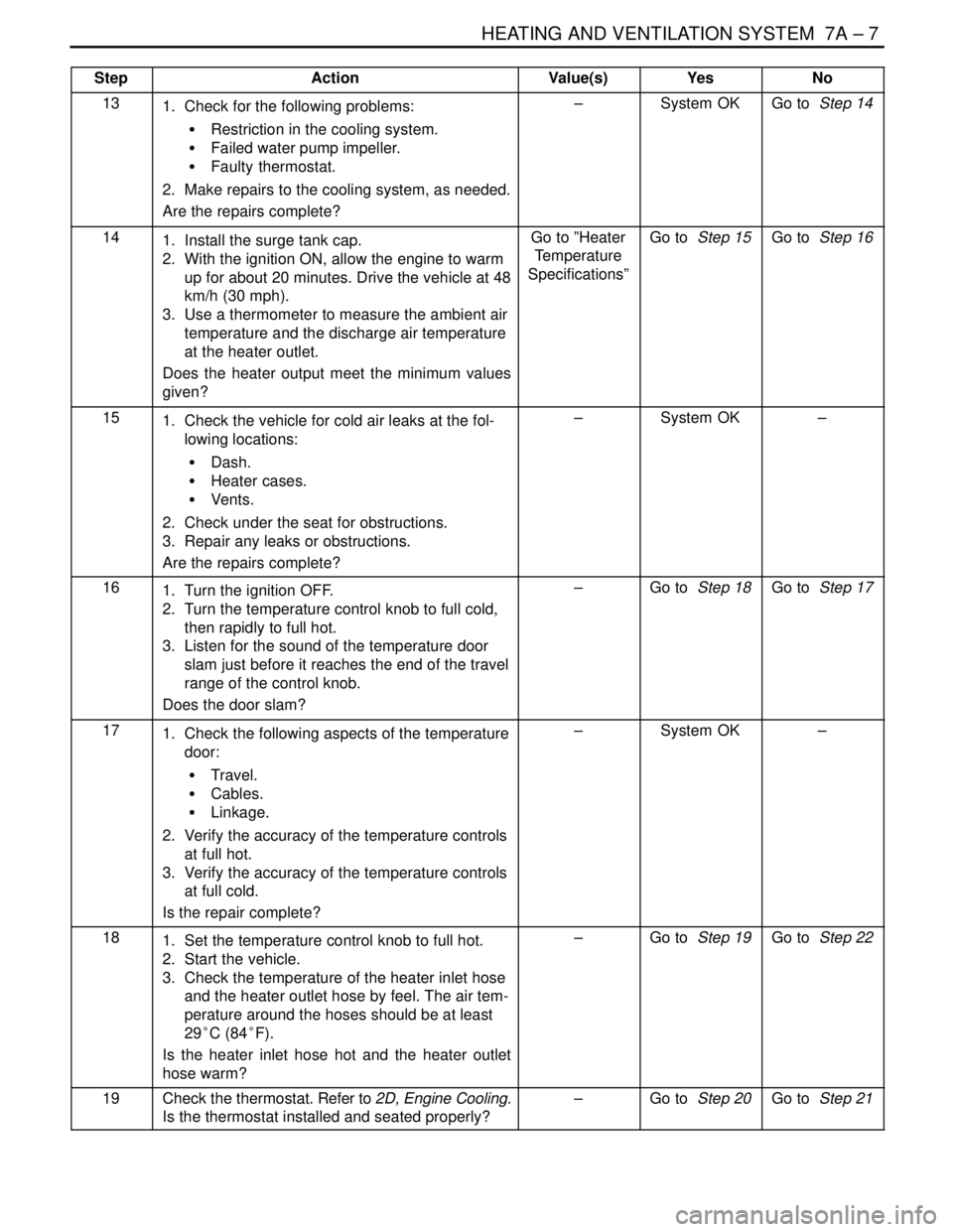

StepNo Yes Value(s) Action

131. Check for the following problems:

S Restriction in the cooling system.

S Failed water pump impeller.

S Faulty thermostat.

2. Make repairs to the cooling system, as needed.

Are the repairs complete?–System OKGo to Step 14

141. Install the surge tank cap.

2. With the ignition ON, allow the engine to warm

up for about 20 minutes. Drive the vehicle at 48

km/h (30 mph).

3. Use a thermometer to measure the ambient air

temperature and the discharge air temperature

at the heater outlet.

Does the heater output meet the minimum values

given?Go to ”Heater

Temperature

Specifications”Go to Step 15Go to Step 16

151. Check the vehicle for cold air leaks at the fol-

lowing locations:

S Dash.

S Heater cases.

S Vents.

2. Check under the seat for obstructions.

3. Repair any leaks or obstructions.

Are the repairs complete?–System OK–

161. Turn the ignition OFF.

2. Turn the temperature control knob to full cold,

then rapidly to full hot.

3. Listen for the sound of the temperature door

slam just before it reaches the end of the travel

range of the control knob.

Does the door slam?–Go to Step 18Go to Step 17

171. Check the following aspects of the temperature

door:

S Travel.

S Cables.

S Linkage.

2. Verify the accuracy of the temperature controls

at full hot.

3. Verify the accuracy of the temperature controls

at full cold.

Is the repair complete?–System OK–

181. Set the temperature control knob to full hot.

2. Start the vehicle.

3. Check the temperature of the heater inlet hose

and the heater outlet hose by feel. The air tem-

perature around the hoses should be at least

29°C (84°F).

Is the heater inlet hose hot and the heater outlet

hose warm?–Go to Step 19Go to Step 22

19Check the thermostat. Refer to 2D, Engine Cooling.

Is the thermostat installed and seated properly?–Go to Step 20Go to Step 21

Page 1982 of 2643

7A – 8IHEATING AND VENTILATION SYSTEM

DAEWOO V–121 BL4

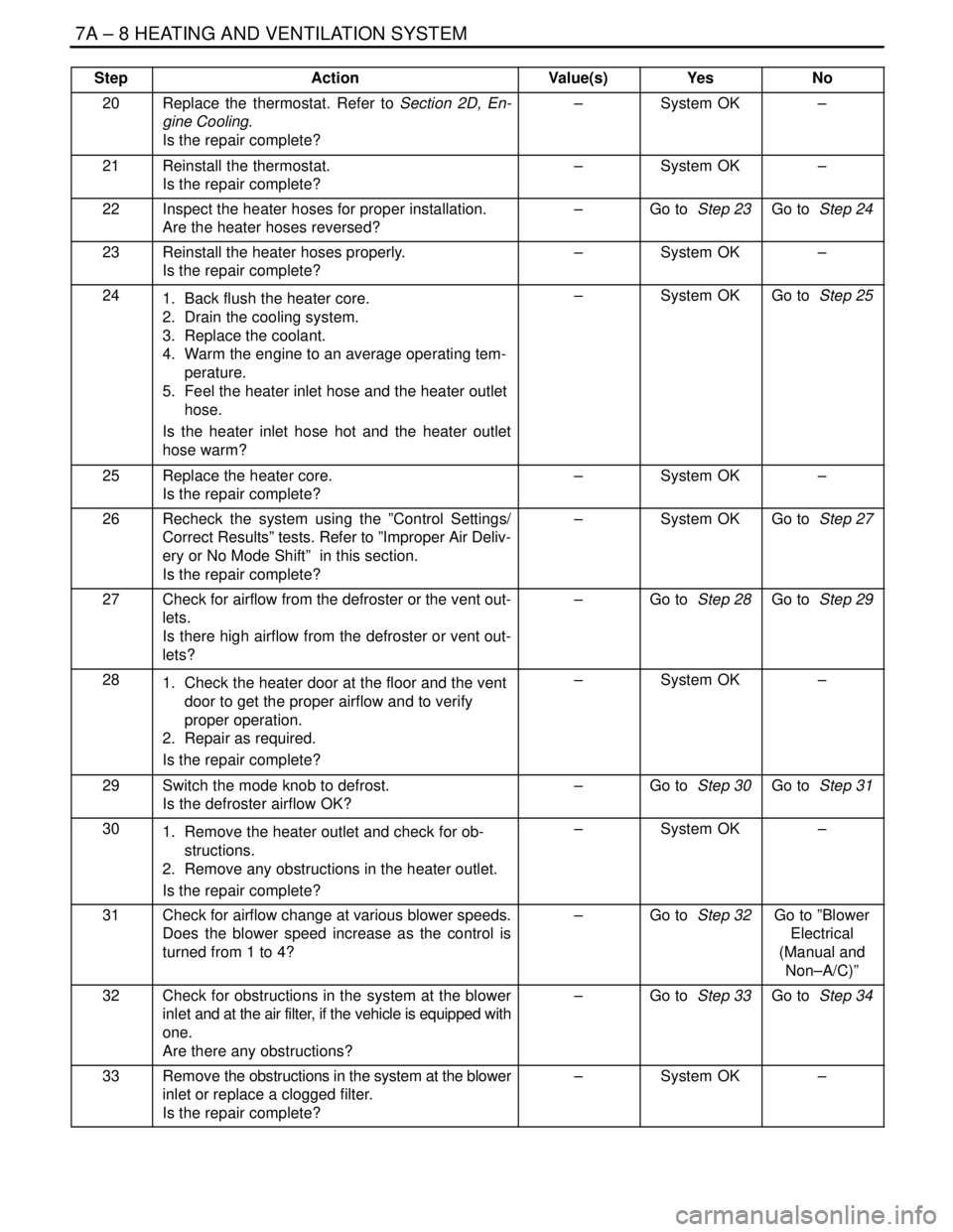

StepNo Yes Value(s) Action

20Replace the thermostat. Refer to Section 2D, En-

gine Cooling.

Is the repair complete?–System OK–

21Reinstall the thermostat.

Is the repair complete?–System OK–

22Inspect the heater hoses for proper installation.

Are the heater hoses reversed?–Go to Step 23Go to Step 24

23Reinstall the heater hoses properly.

Is the repair complete?–System OK–

241. Back flush the heater core.

2. Drain the cooling system.

3. Replace the coolant.

4. Warm the engine to an average operating tem-

perature.

5. Feel the heater inlet hose and the heater outlet

hose.

Is the heater inlet hose hot and the heater outlet

hose warm?–System OKGo to Step 25

25Replace the heater core.

Is the repair complete?–System OK–

26Recheck the system using the ”Control Settings/

Correct Results” tests. Refer to ”Improper Air Deliv-

ery or No Mode Shift” in this section.

Is the repair complete?–System OKGo to Step 27

27Check for airflow from the defroster or the vent out-

lets.

Is there high airflow from the defroster or vent out-

lets?–Go to Step 28Go to Step 29

281. Check the heater door at the floor and the vent

door to get the proper airflow and to verify

proper operation.

2. Repair as required.

Is the repair complete?–System OK–

29Switch the mode knob to defrost.

Is the defroster airflow OK?–Go to Step 30Go to Step 31

301. Remove the heater outlet and check for ob-

structions.

2. Remove any obstructions in the heater outlet.

Is the repair complete?–System OK–

31Check for airflow change at various blower speeds.

Does the blower speed increase as the control is

turned from 1 to 4?–Go to Step 32Go to ”Blower

Electrical

(Manual and

Non–A/C)”

32Check for obstructions in the system at the blower

inlet and at the air filter, if the vehicle is equipped with

one.

Are there any obstructions?–Go to Step 33Go to Step 34

33Remove the obstructions in the system at the blower

inlet or replace a clogged filter.

Is the repair complete?–System OK–

Page 1983 of 2643

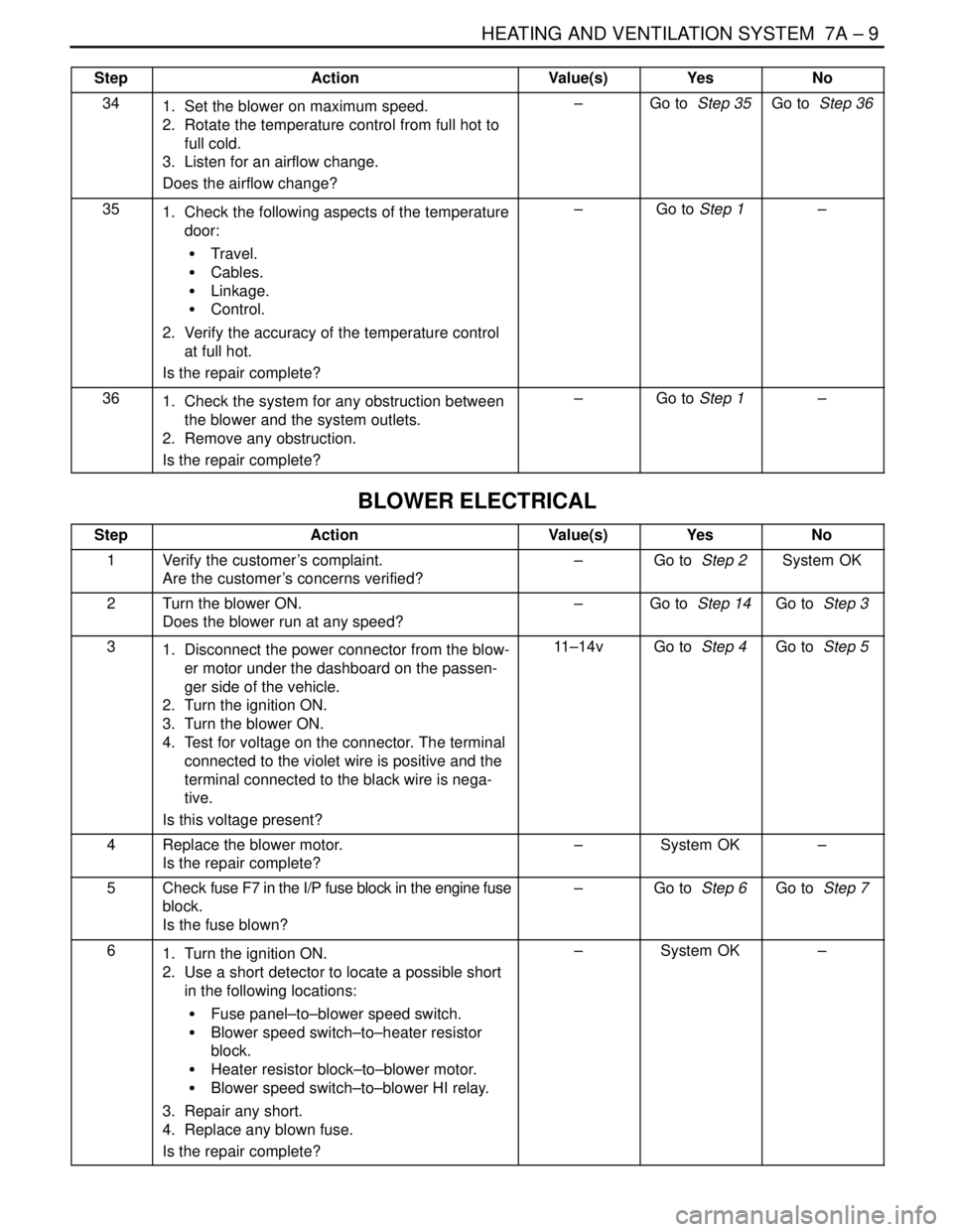

HEATING AND VENTILATION SYSTEM 7A – 9

DAEWOO V–121 BL4

StepNo Yes Value(s) Action

341. Set the blower on maximum speed.

2. Rotate the temperature control from full hot to

full cold.

3. Listen for an airflow change.

Does the airflow change?–Go to Step 35Go to Step 36

351. Check the following aspects of the temperature

door:

S Travel.

S Cables.

S Linkage.

S Control.

2. Verify the accuracy of the temperature control

at full hot.

Is the repair complete?–Go to Step 1–

361. Check the system for any obstruction between

the blower and the system outlets.

2. Remove any obstruction.

Is the repair complete?–Go to Step 1–

BLOWER ELECTRICAL

StepActionValue(s)YesNo

1Verify the customer’s complaint.

Are the customer’s concerns verified?–Go to Step 2System OK

2Turn the blower ON.

Does the blower run at any speed?–Go to Step 14Go to Step 3

31. Disconnect the power connector from the blow-

er motor under the dashboard on the passen-

ger side of the vehicle.

2. Turn the ignition ON.

3. Turn the blower ON.

4. Test for voltage on the connector. The terminal

connected to the violet wire is positive and the

terminal connected to the black wire is nega-

tive.

Is this voltage present?11–14vGo to Step 4Go to Step 5

4Replace the blower motor.

Is the repair complete?–System OK–

5Check fuse F7 in the I/P fuse block in the engine fuse

block.

Is the fuse blown?–Go to Step 6Go to Step 7

61. Turn the ignition ON.

2. Use a short detector to locate a possible short

in the following locations:

S Fuse panel–to–blower speed switch.

S Blower speed switch–to–heater resistor

block.

S Heater resistor block–to–blower motor.

S Blower speed switch–to–blower HI relay.

3. Repair any short.

4. Replace any blown fuse.

Is the repair complete?–System OK–

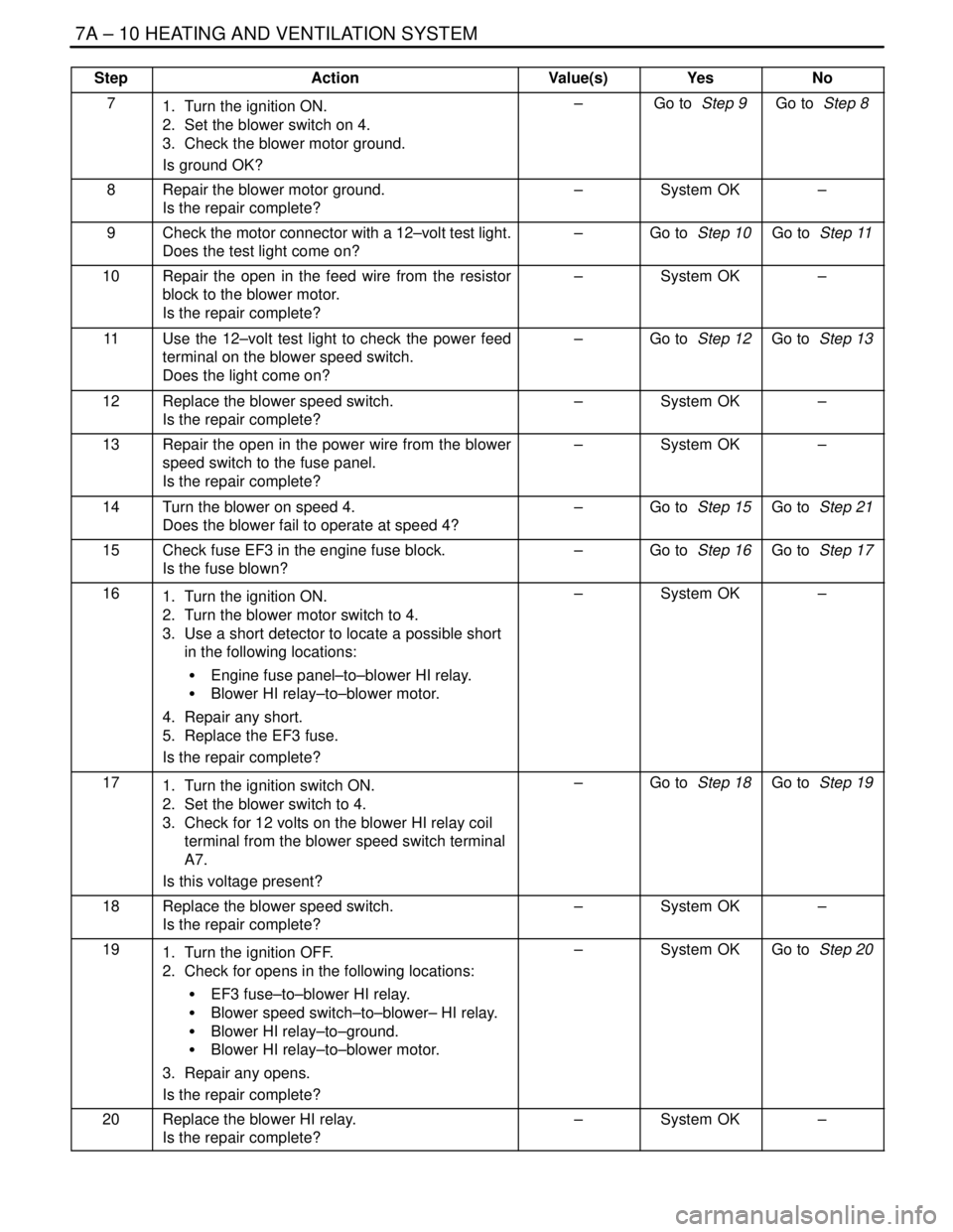

Page 1984 of 2643

7A – 10IHEATING AND VENTILATION SYSTEM

DAEWOO V–121 BL4

StepNo Yes Value(s) Action

71. Turn the ignition ON.

2. Set the blower switch on 4.

3. Check the blower motor ground.

Is ground OK?–Go to Step 9Go to Step 8

8Repair the blower motor ground.

Is the repair complete?–System OK–

9Check the motor connector with a 12–volt test light.

Does the test light come on?–Go to Step 10Go to Step 11

10Repair the open in the feed wire from the resistor

block to the blower motor.

Is the repair complete?–System OK–

11Use the 12–volt test light to check the power feed

terminal on the blower speed switch.

Does the light come on?–Go to Step 12Go to Step 13

12Replace the blower speed switch.

Is the repair complete?–System OK–

13Repair the open in the power wire from the blower

speed switch to the fuse panel.

Is the repair complete?–System OK–

14Turn the blower on speed 4.

Does the blower fail to operate at speed 4?–Go to Step 15Go to Step 21

15Check fuse EF3 in the engine fuse block.

Is the fuse blown?–Go to Step 16Go to Step 17

161. Turn the ignition ON.

2. Turn the blower motor switch to 4.

3. Use a short detector to locate a possible short

in the following locations:

S Engine fuse panel–to–blower HI relay.

S Blower HI relay–to–blower motor.

4. Repair any short.

5. Replace the EF3 fuse.

Is the repair complete?–System OK–

171. Turn the ignition switch ON.

2. Set the blower switch to 4.

3. Check for 12 volts on the blower HI relay coil

terminal from the blower speed switch terminal

A7.

Is this voltage present?–Go to Step 18Go to Step 19

18Replace the blower speed switch.

Is the repair complete?–System OK–

191. Turn the ignition OFF.

2. Check for opens in the following locations:

S EF3 fuse–to–blower HI relay.

S Blower speed switch–to–blower– HI relay.

S Blower HI relay–to–ground.

S Blower HI relay–to–blower motor.

3. Repair any opens.

Is the repair complete?–System OKGo to Step 20

20Replace the blower HI relay.

Is the repair complete?–System OK–

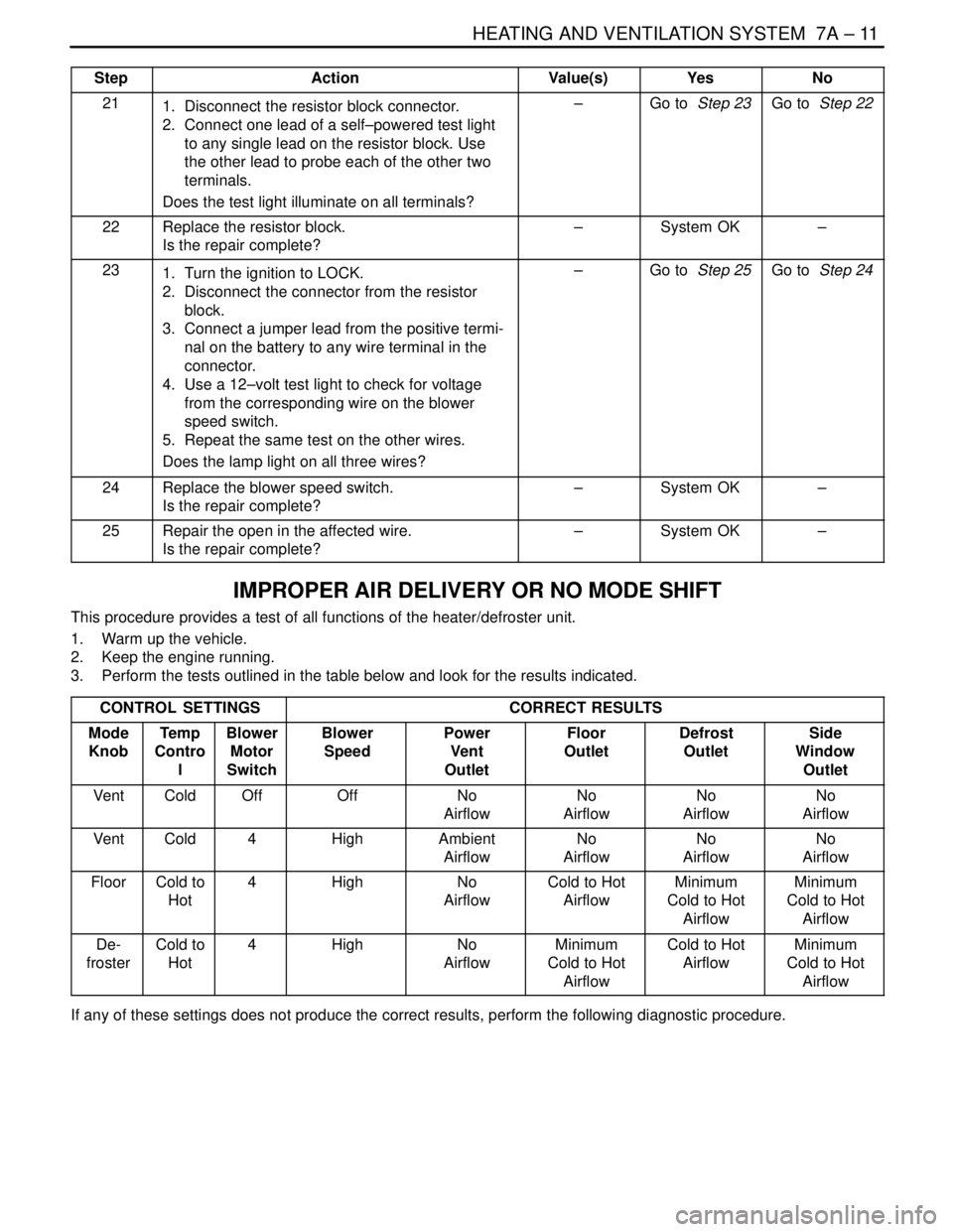

Page 1985 of 2643

HEATING AND VENTILATION SYSTEM 7A – 11

DAEWOO V–121 BL4

StepNo Yes Value(s) Action

211. Disconnect the resistor block connector.

2. Connect one lead of a self–powered test light

to any single lead on the resistor block. Use

the other lead to probe each of the other two

terminals.

Does the test light illuminate on all terminals?–Go to Step 23Go to Step 22

22Replace the resistor block.

Is the repair complete?–System OK–

231. Turn the ignition to LOCK.

2. Disconnect the connector from the resistor

block.

3. Connect a jumper lead from the positive termi-

nal on the battery to any wire terminal in the

connector.

4. Use a 12–volt test light to check for voltage

from the corresponding wire on the blower

speed switch.

5. Repeat the same test on the other wires.

Does the lamp light on all three wires?–Go to Step 25Go to Step 24

24Replace the blower speed switch.

Is the repair complete?–System OK–

25Repair the open in the affected wire.

Is the repair complete?–System OK–

IMPROPER AIR DELIVERY OR NO MODE SHIFT

This procedure provides a test of all functions of the heater/defroster unit.

1. Warm up the vehicle.

2. Keep the engine running.

3. Perform the tests outlined in the table below and look for the results indicated.

CONTROL SETTINGS

CORRECT RESULTS

Mode

KnobTe m p

Contro

lBlower

Motor

SwitchBlower

SpeedPower

Vent

OutletFloor

OutletDefrost

OutletSide

Window

Outlet

VentColdOffOffNo

AirflowNo

AirflowNo

AirflowNo

Airflow

VentCold4HighAmbient

AirflowNo

AirflowNo

AirflowNo

Airflow

FloorCold to

Hot4HighNo

AirflowCold to Hot

AirflowMinimum

Cold to Hot

AirflowMinimum

Cold to Hot

Airflow

De-

frosterCold to

Hot4HighNo

AirflowMinimum

Cold to Hot

AirflowCold to Hot

AirflowMinimum

Cold to Hot

Airflow

If any of these settings does not produce the correct results, perform the following diagnostic procedure.

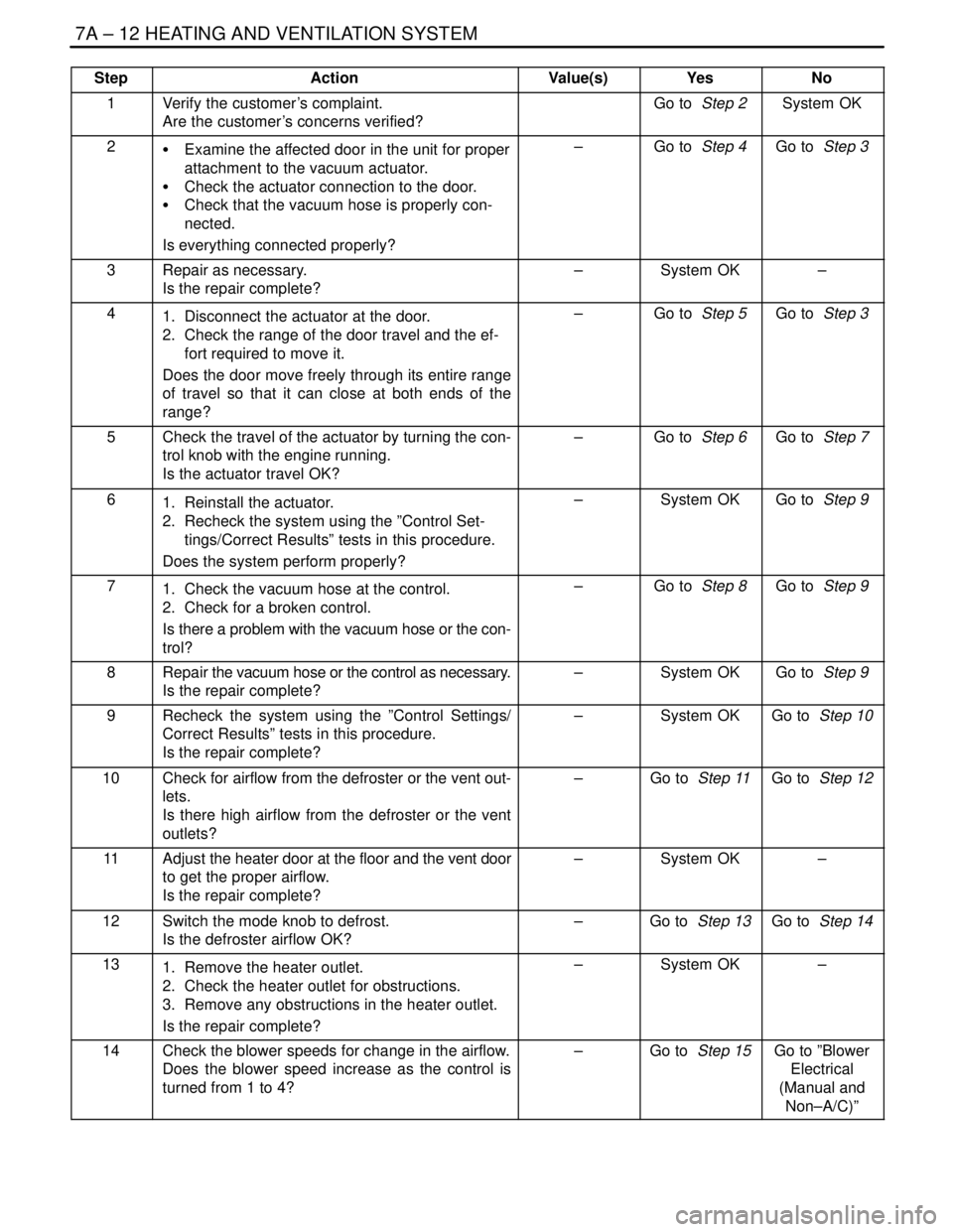

Page 1986 of 2643

7A – 12IHEATING AND VENTILATION SYSTEM

DAEWOO V–121 BL4

StepActionValue(s)YesNo

1Verify the customer’s complaint.

Are the customer’s concerns verified?Go to Step 2System OK

2S Examine the affected door in the unit for proper

attachment to the vacuum actuator.

S Check the actuator connection to the door.

S Check that the vacuum hose is properly con-

nected.

Is everything connected properly?–Go to Step 4Go to Step 3

3Repair as necessary.

Is the repair complete?–System OK–

41. Disconnect the actuator at the door.

2. Check the range of the door travel and the ef-

fort required to move it.

Does the door move freely through its entire range

of travel so that it can close at both ends of the

range?–Go to Step 5Go to Step 3

5Check the travel of the actuator by turning the con-

trol knob with the engine running.

Is the actuator travel OK?–Go to Step 6Go to Step 7

61. Reinstall the actuator.

2. Recheck the system using the ”Control Set-

tings/Correct Results” tests in this procedure.

Does the system perform properly?–System OKGo to Step 9

71. Check the vacuum hose at the control.

2. Check for a broken control.

Is there a problem with the vacuum hose or the con-

trol?–Go to Step 8Go to Step 9

8Repair the vacuum hose or the control as necessary.

Is the repair complete?–System OKGo to Step 9

9Recheck the system using the ”Control Settings/

Correct Results” tests in this procedure.

Is the repair complete?–System OKGo to Step 10

10Check for airflow from the defroster or the vent out-

lets.

Is there high airflow from the defroster or the vent

outlets?–Go to Step 11Go to Step 12

11Adjust the heater door at the floor and the vent door

to get the proper airflow.

Is the repair complete?–System OK–

12Switch the mode knob to defrost.

Is the defroster airflow OK?–Go to Step 13Go to Step 14

131. Remove the heater outlet.

2. Check the heater outlet for obstructions.

3. Remove any obstructions in the heater outlet.

Is the repair complete?–System OK–

14Check the blower speeds for change in the airflow.

Does the blower speed increase as the control is

turned from 1 to 4?–Go to Step 15Go to ”Blower

Electrical

(Manual and

Non–A/C)”

Page 1988 of 2643

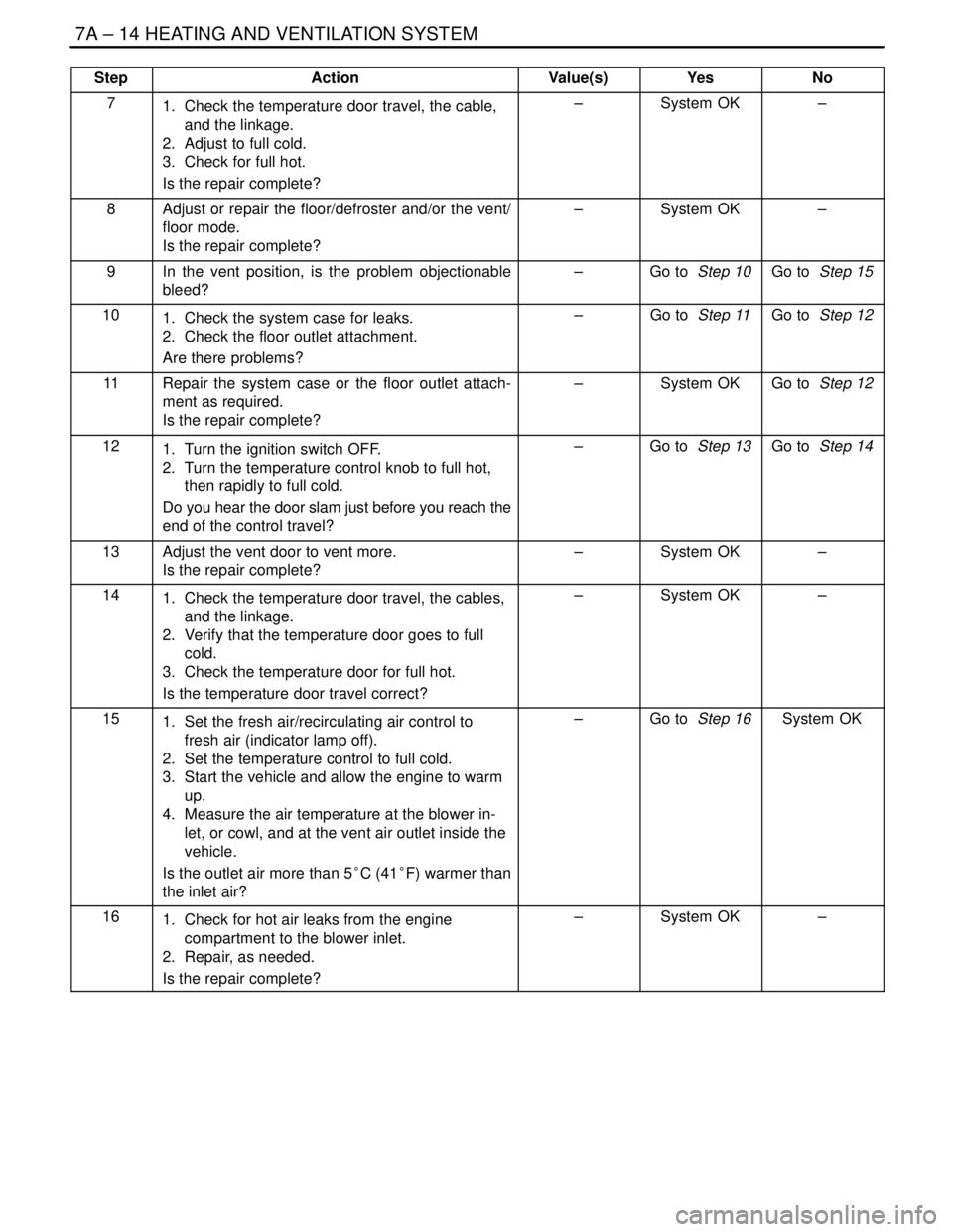

7A – 14IHEATING AND VENTILATION SYSTEM

DAEWOO V–121 BL4

StepNo Yes Value(s) Action

71. Check the temperature door travel, the cable,

and the linkage.

2. Adjust to full cold.

3. Check for full hot.

Is the repair complete?–System OK–

8Adjust or repair the floor/defroster and/or the vent/

floor mode.

Is the repair complete?–System OK–

9In the vent position, is the problem objectionable

bleed?–Go to Step 10Go to Step 15

101. Check the system case for leaks.

2. Check the floor outlet attachment.

Are there problems?–Go to Step 11Go to Step 12

11Repair the system case or the floor outlet attach-

ment as required.

Is the repair complete?–System OKGo to Step 12

121. Turn the ignition switch OFF.

2. Turn the temperature control knob to full hot,

then rapidly to full cold.

Do you hear the door slam just before you reach the

end of the control travel?–Go to Step 13Go to Step 14

13Adjust the vent door to vent more.

Is the repair complete?–System OK–

141. Check the temperature door travel, the cables,

and the linkage.

2. Verify that the temperature door goes to full

cold.

3. Check the temperature door for full hot.

Is the temperature door travel correct?–System OK–

151. Set the fresh air/recirculating air control to

fresh air (indicator lamp off).

2. Set the temperature control to full cold.

3. Start the vehicle and allow the engine to warm

up.

4. Measure the air temperature at the blower in-

let, or cowl, and at the vent air outlet inside the

vehicle.

Is the outlet air more than 5°C (41°F) warmer than

the inlet air?–Go to Step 16System OK

161. Check for hot air leaks from the engine

compartment to the blower inlet.

2. Repair, as needed.

Is the repair complete?–System OK–

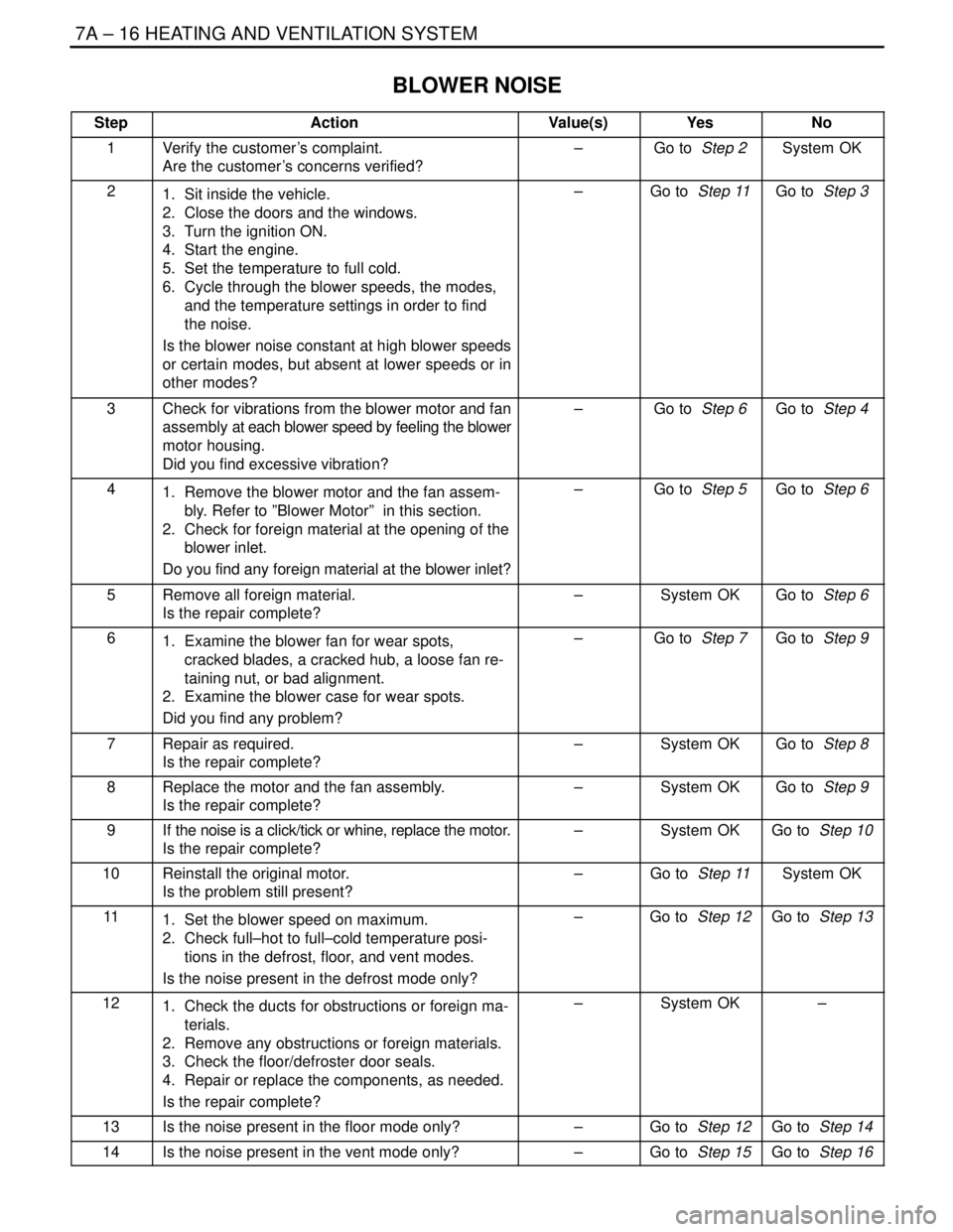

Page 1990 of 2643

7A – 16IHEATING AND VENTILATION SYSTEM

DAEWOO V–121 BL4

BLOWER NOISE

StepActionValue(s)YesNo

1Verify the customer’s complaint.

Are the customer’s concerns verified?–Go to Step 2System OK

21. Sit inside the vehicle.

2. Close the doors and the windows.

3. Turn the ignition ON.

4. Start the engine.

5. Set the temperature to full cold.

6. Cycle through the blower speeds, the modes,

and the temperature settings in order to find

the noise.

Is the blower noise constant at high blower speeds

or certain modes, but absent at lower speeds or in

other modes?–Go to Step 11Go to Step 3

3Check for vibrations from the blower motor and fan

assembly at each blower speed by feeling the blower

motor housing.

Did you find excessive vibration?–Go to Step 6Go to Step 4

41. Remove the blower motor and the fan assem-

bly. Refer to ”Blower Motor” in this section.

2. Check for foreign material at the opening of the

blower inlet.

Do you find any foreign material at the blower inlet?–Go to Step 5Go to Step 6

5Remove all foreign material.

Is the repair complete?–System OKGo to Step 6

61. Examine the blower fan for wear spots,

cracked blades, a cracked hub, a loose fan re-

taining nut, or bad alignment.

2. Examine the blower case for wear spots.

Did you find any problem?–Go to Step 7Go to Step 9

7Repair as required.

Is the repair complete?–System OKGo to Step 8

8Replace the motor and the fan assembly.

Is the repair complete?–System OKGo to Step 9

9If the noise is a click/tick or whine, replace the motor.

Is the repair complete?–System OKGo to Step 10

10Reinstall the original motor.

Is the problem still present?–Go to Step 11System OK

111. Set the blower speed on maximum.

2. Check full–hot to full–cold temperature posi-

tions in the defrost, floor, and vent modes.

Is the noise present in the defrost mode only?–Go to Step 12Go to Step 13

121. Check the ducts for obstructions or foreign ma-

terials.

2. Remove any obstructions or foreign materials.

3. Check the floor/defroster door seals.

4. Repair or replace the components, as needed.

Is the repair complete?–System OK–

13Is the noise present in the floor mode only?–Go to Step 12Go to Step 14

14Is the noise present in the vent mode only?–Go to Step 15Go to Step 16