steering wheel DATSUN 210 1979 Service Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 3 of 548

DATSUN

210

SERVICE

MANUAL

Model

8310

Series

T

OfOUoW

lTY

INISSAN

N

OIlCOIIO

NISSAN

MOTOR

CO

LTD

17

1

Ginza

6

Chome

Chuo

ku

Tokyo

104

Japan

QUICK

REFERENCE

INDEX

GENERAL

INFORMATION

GI

ENGINE

TUNE

UP

ET

ENGINE

MECHANICAL

EM

ENGINE

LUBRICATION

SYSTEM

EL

COOLING

SYSTEM

CO

ENGI

NE

FUEL

EF

EMISSION

CONTROL

SYSTEM

EC

ENGINE

ELECTRICAL

SYSTEM

EE

ENGINE

REMOVAL

INSTALLATION

ER

CLUTCH

CL

lMr

MANUAL

TRANSMISSION

MT

AUTOMATIC

TRANSMISSION

AT

H

PROPELLER

SHAFT

OIFFERENTlAL

CARRIER

PO

FRONT

AXLE

FRONT

SUSPENSION

FA

10

REAR

AXLE

REAR

SUSPENSION

RA

BRAKE

SYSTEM

BR

WHEEL

A

NO

TI

RE

WT

0

STEERING

SYSTEM

ST

ENGINE

CONTROL

FUEL

EXHAUST

SYSTEMS

FE

BOOY

BF

BOOY

ELECTRICAL

SYSTEM

BE

AIR

CONOITIONING

AC

Page 14 of 548

GI417

Fig

GI

15

Front

Towing

Hook

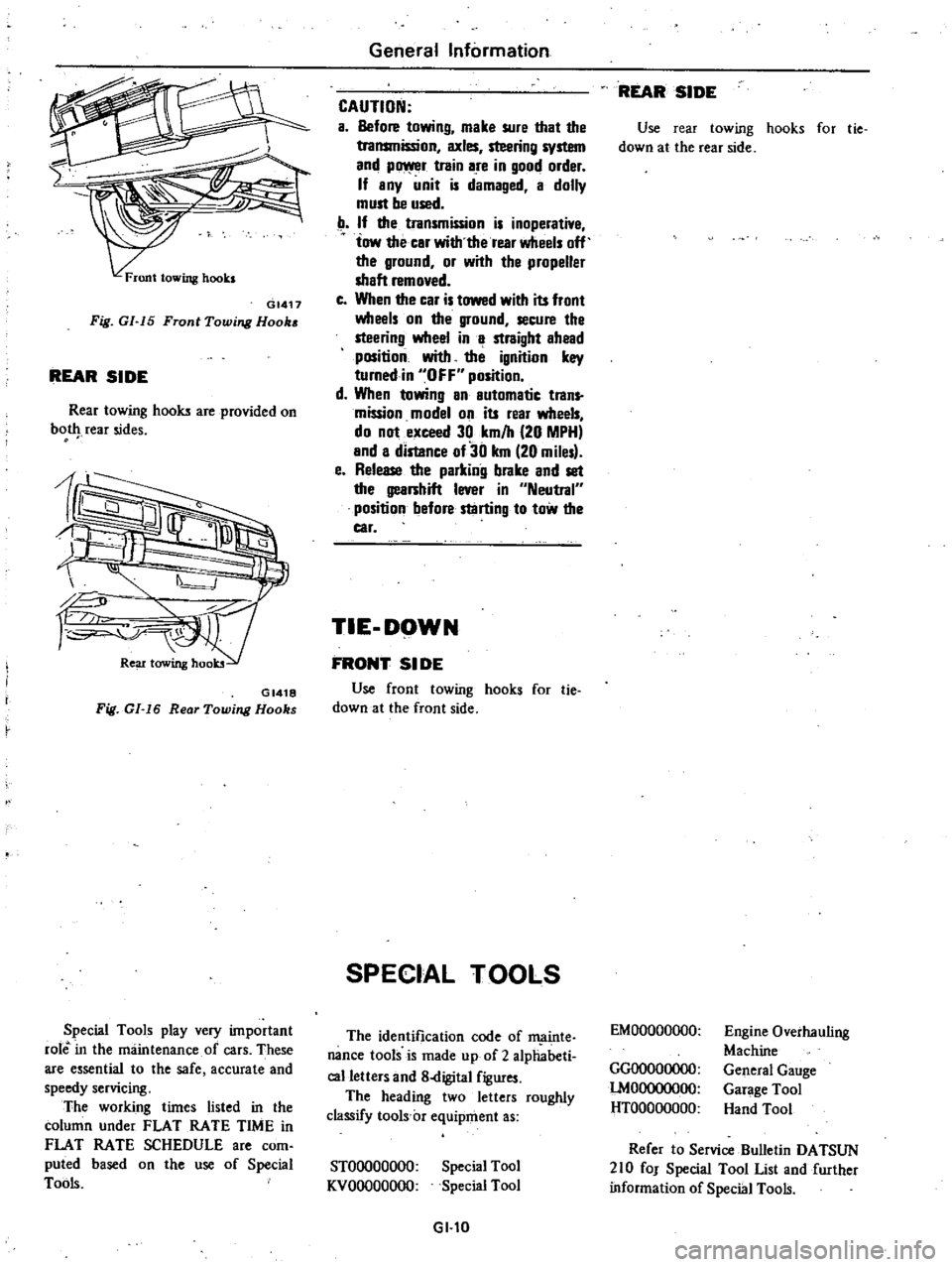

REAR

SIDE

Rear

towing

hooks

are

provided

on

bot

rear

sides

GI418

Fig

GI

16

Rear

Towing

Hooks

Special

Tools

play

very

important

role

in

the

maintenance

of

cars

These

are

essential

to

the

safe

accurate

and

speedy

servicing

The

working

times

listed

in

the

column

under

FLAT

RATE

TIME

in

FLAT

RATE

SCHEDULE

are

com

puted

based

on

the

use

of

Special

Tools

General

Information

CAUTION

a

Before

towing

make

sure

that

the

transmission

axles

steering

system

and

p

r

train

are

in

good

order

If

any

unit

is

damaged

a

dolly

must

be

used

If

the

transmission

is

inoperative

tow

the

car

with

the

rear

wheels

off

the

ground

or

with

the

propeller

shaft

removed

c

When

the

car

is

towed

with

its

front

wheels

on

the

ground

secure

the

steering

wheel

in

a

straight

ahead

position

with

the

ignition

key

turnedin

OFF

position

d

When

towing

an

automatic

trans

mission

model

on

its

rear

wheels

do

not

exceed

30

km

h

20

MPH

and

a

distance

of30

km

20

miles

e

Release

the

parking

brake

and

set

the

gearshift

lever

in

Neutral

position

before

starting

to

tow

the

car

TIE

DOWN

FRONT

51

DE

Use

front

towing

hooks

for

tie

down

at

the

front

side

SPECIAL

TOOLS

The

identification

code

of

ffi

linte

nance

tools

is

made

up

of

2

alphabeti

calletters

and

8

digital

figures

The

heading

two

letters

roughly

classify

tools

c

equipment

as

STOOOOOOOO

KVOOOOOOOO

Special

Tool

Special

Tool

GI

l0

REAR

SIDE

Use

rear

towing

hooks

for

tie

down

at

the

rear

side

EMOOOOOOOO

GGOOOOOOOO

lMOOOOOOOO

HTOOOOOOOO

Engine

Overhauling

Machine

General

Gauge

Garage

Tool

Hand

Tool

Refer

to

Service

Bulletin

DATSUN

210

fOJ

Special

Tool

List

and

further

information

of

Special

Tools

Page 325 of 548

Fig

FA

3

Installing

Coller

Pin

II

Install

hub

cap

with

new

Q

ring

and

wheel

WHEEL

ALIGNMENT

Correct

front

wheel

alignment

as

sures

proper

car

handling

characteris

tics

and

minimum

steering

effort

with

the

least

amount

of

tire

wear

Before

adjusting

front

wheel

alignment

be

sure

to

make

preliminary

inspection

of

front

end

parts

Tire

pressure

and

balance

Wheel

bearings

and

wheel

bearing

nuts

Steering

gear

play

Steering

gear

housing

loose

at

frame

Steering

linkage

and

connections

Shock

absorber

operation

If

wrong

repair

or

replace

the

damaged

portion

or

parts

When

using

equipment

for

front

wheel

alignment

inspection

follow

the

instructions

furnished

with

equipment

Note

Inspection

should

be

made

with

the

car

set

Ievel

and

at

curb

weight

Cember

end

caster

Camber

and

caster

are

preset

at

factory

and

cannot

be

adjusted

The

car

requires

only

toe

in

and

car

posture

adjustment

Note

If

camber

or

caster

alignment

is

not

within

specifications

check

as

sociated

parts

Repair

or

replace

as

necessary

Front

Axle

Front

Suspension

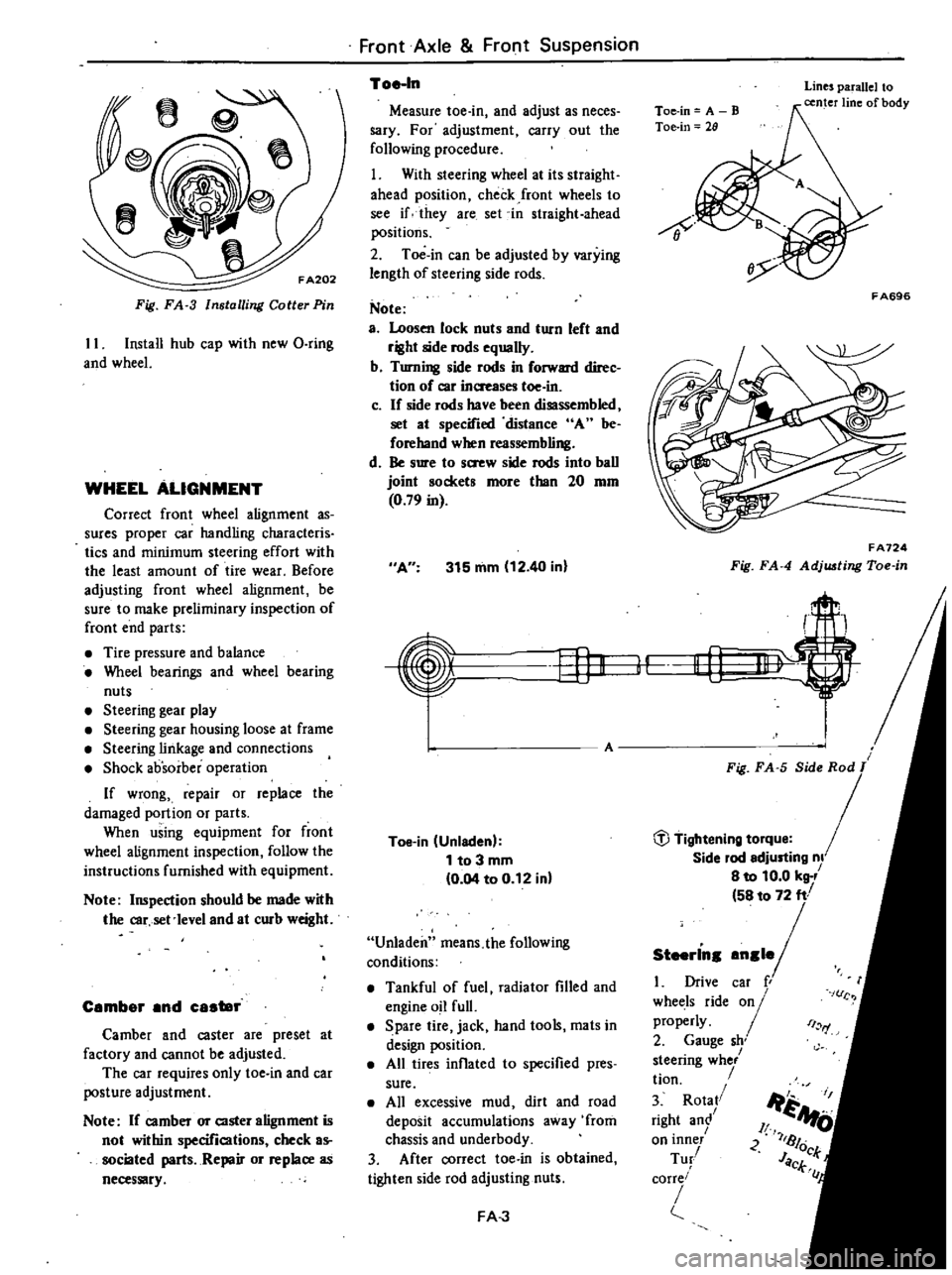

Toe

In

Measure

toe

in

and

adjust

as

neces

sary

For

adjustment

carry

out

the

following

procedure

1

With

steering

wheel

at

its

straight

ahead

position

check

front

wheels

to

see

if

they

are

set

in

straight

ahead

positions

2

Toe

in

can

be

adjusted

by

varying

length

of

steering

side

rods

Note

a

Loosen

lock

nuts

and

turn

left

and

right

side

rods

equally

b

Turning

side

rods

in

forward

direc

tion

of

car

inaeases

toe

in

c

If

side

rods

have

been

disassembled

set

at

specified

distance

A

be

forehand

when

reassembling

d

Be

sure

to

s

w

side

rods

into

ball

joint

sockets

more

than

20

mm

0

79

in

A

315

mm

12

40

in

EfJK

Toe

in

Unladen

1

to

3

mm

0

04

to

0

12

in

Unladen

means

the

following

conditions

Tankful

of

fuel

radiator

filled

and

engine

oil

full

Spare

tire

jack

hand

tools

mats

in

design

position

All

tires

inflated

to

specified

pres

sure

All

excessive

mud

dirt

and

road

deposit

accumulations

away

from

chassis

and

underbody

3

After

correct

toe

in

is

obtained

tighten

side

rod

adjusting

nuts

FA

J

Toe

in

A

B

Toe

in

28

Lines

parallel

to

center

line

of

body

8

F

A696

FA724

Fig

FA

4

Adj

ting

Toe

in

r

II

Li

1

t

Fig

FA

5

Side

Rod

T

Side

lod

edjusting

nl

8

to

10

0

kg

58

to

72

ft

1

Drive

caf

r

whet

ls

ride

01

properly

2

Gauge

sh

steenng

whe

tion

3

Rota

right

an

on

lOner

Tu

corre

i

I

rf

c

Ji

1

A

JI

U

2

7181

JOck

CL

C

Page 326 of 548

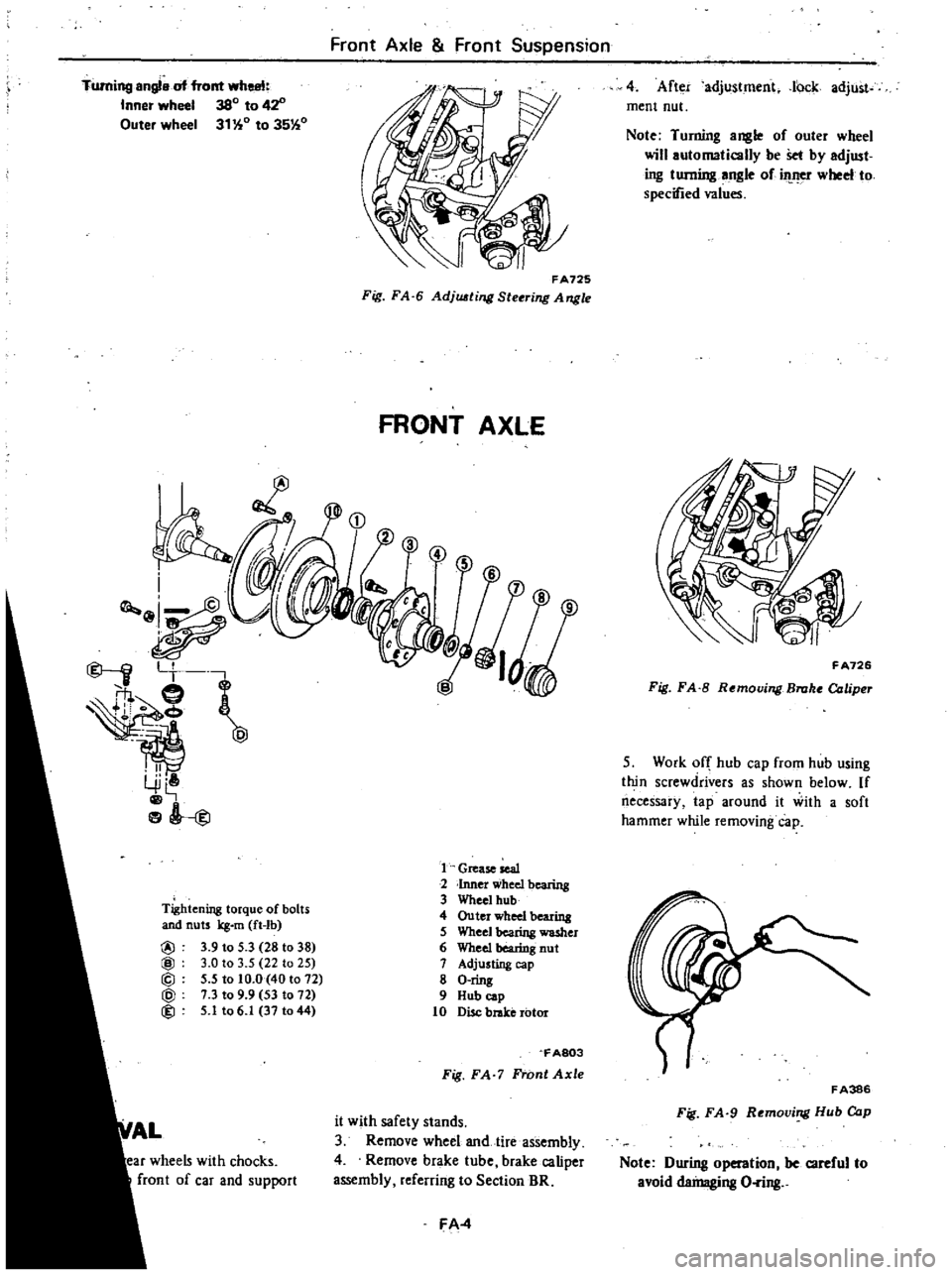

Turning

engie

of

front

wheel

Inner

wheel

380

to

42

Outel

wheel

31

0

to

35

0

Tightening

torque

of

bolts

and

nuts

kg

m

ft

lb

@

3

9

to

5

3

28

to

38

@

3

0

to

3

5

22

to

25

@

5

5

to

10

0

40

to

72

@

7

3

to

9

9

53

to

72

@

5

1

to

6

1

371044

ear

wheels

with

chocks

fron

t

of

car

and

support

Front

Axle

Front

Suspension

FA125

Fig

FA

6

AdjU

ting

Steering

Angle

FRONT

AXLE

1

Grease

seal

2

Inner

wbeel

bearin

3

Wheel

hub

4

Outer

wheel

bearins

5

Wheel

bearing

washer

6

Wheel

bearing

nut

7

Adjusting

cap

8

O

ring

9

Hub

cap

10

Disc

brake

rotor

FA803

Fig

FA

7

Front

Axle

it

with

safety

stands

3

Remove

wheel

and

tire

assembly

4

Remove

brake

tube

brake

caliper

assembly

referring

to

Section

DR

FA

4

4

After

adjustment

l

ck

adju

ment

nut

Note

Turning

angle

of

outer

wheel

will

automatically

be

Set

by

adjust

ing

turning

angle

ofin

f

U

wheel

to

specified

values

FA726

Fig

FA

8

RemouingBroke

Caliper

5

Work

off

hub

cap

from

hub

using

t

n

screwdrivers

as

shown

below

If

necessary

tap

around

it

with

a

soft

hammer

while

removing

cap

F

A386

Fig

FA

9

Remouing

Hub

Cap

Note

During

operation

be

careful

to

avoid

deinaging

O

ring

Page 336 of 548

WHEEL

BEARING

Wheel

bearing

axial

play

Wheel

bearing

nut

tightening

torque

Return

angle

Rotation

starting

torque

With

new

grease

seal

With

used

grease

seal

At

wheel

hub

bolt

With

new

grease

seal

With

used

grease

seal

SUSPENSIONBA

JOINT

Turning

torque

New

parts

Used

parts

TIGHTENIN

TORQUE

LOWERBAl

L

JOINT

Ball

joint

socket

to

lower

arm

Ball

joint

to

knuckle

arm

Stud

nut

STRUT

Steering

knuckle

arm

to

strut

Strut

to

hoodledge

Piston

rod

self

locking

nut

Gland

packing

DISC

BRAKE

Rotor

to

hub

SIDE

ROD

Side

rod

ball

jOIDt

to

knuckle

arm

LOWER

ARM

Lower

arm

bolt

nut

Side

rod

adjusting

nut

TENSION

ROD

Tension

rod

bushing

installation

nut

Tension

rod

to

lower

arm

Tension

rod

bracket

to

body

Frpn

Axle

Front

Suspension

mm

in

0

0

kg

m

ft

lb

degree

3

0

to

3

5

22

to

25

900

kg

cm

in

lbr

kg

em

in

Ib

Less

than

7

0

6

1

1

0

to

4

5

0

9

to

3

9

kg

lb

kg

lb

Less

than

1

2

2

6

0

1

7

to

0

79

0

37

to

1

74

kg

cm

in

Ib

kg

cm

in

Ib

40

to

100

35

to

87

More

than

20

17

kg

m

ft

Ib

5

1

to

6

1

37

to

44

5

5

to

10

0

40

to

72

7

3

to

9

9

53

to

72

2

5

to

3

5

18

to

25

6

0

to

7

5

43

to

54

8

0

to

11

0

58

to

80

3

9

to

5

3

28

to

38

3

0

to

7

0

22

to

51

3

9

to

5

0

2810

36

8

0

to

10

0

58

to

72

4

5

to

5

1

33

to

37

5

1

to

6

1

37

to

44

3

2

to

4

3

23

to

31

FA

14

Page 338 of 548

Front

Axle

Front

Suspension

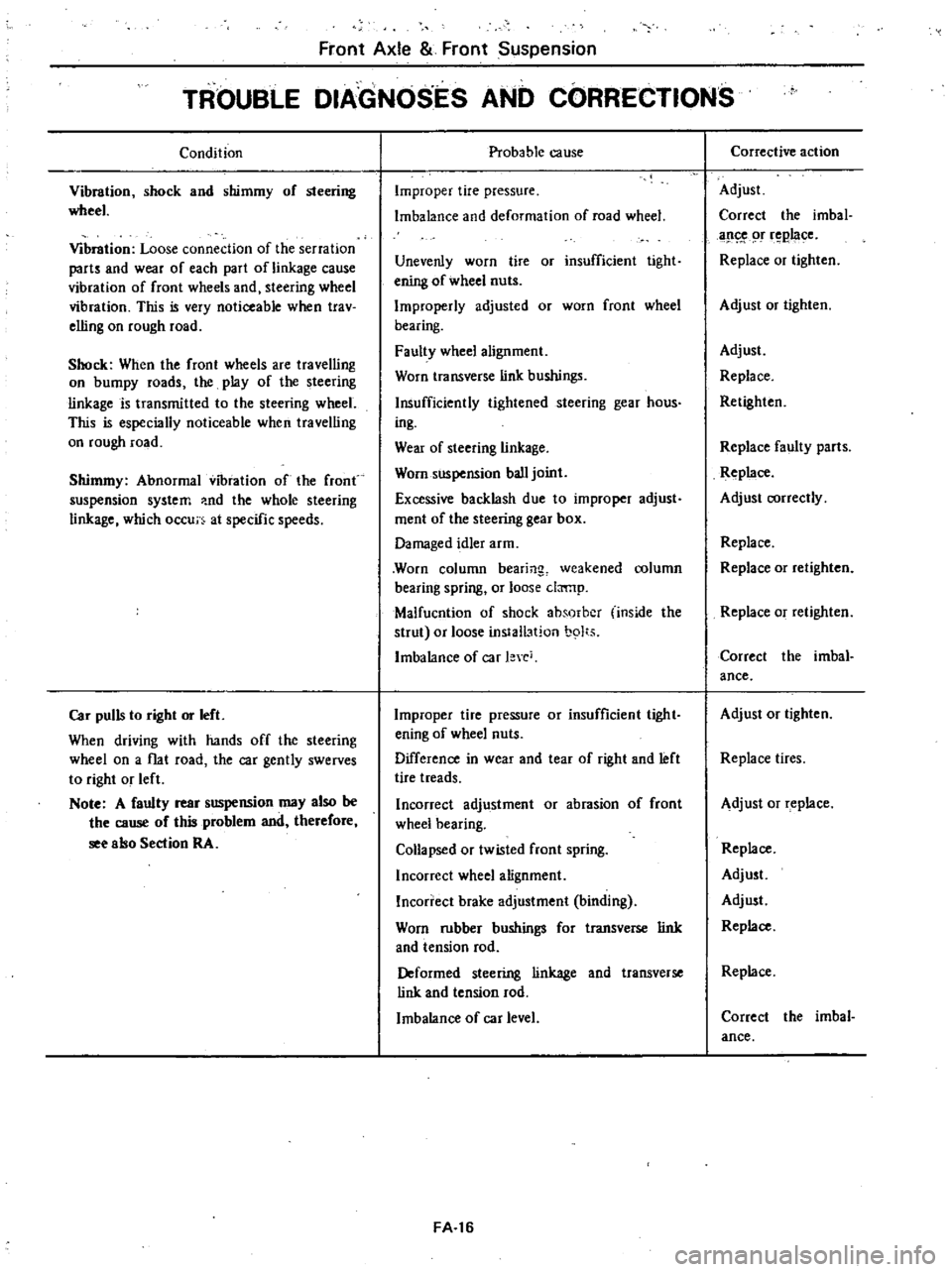

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Condition

Vibration

shock

and

shimmy

of

steering

wheel

Vibration

Loose

connection

of

the

serration

parts

and

wear

of

each

part

of

linkage

cause

vibration

of

front

wheels

and

steering

wheel

vibration

This

is

very

noticeable

when

trav

elling

on

rough

road

Shock

When

the

front

wheels

are

travelling

on

bumpy

roads

the

play

of

the

steering

linkage

is

transmitted

to

the

steering

wheel

This

is

especially

noticeable

when

travelling

on

rough

road

Shimmy

Abnormal

vibration

of

the

front

suspension

system

nd

the

whole

steering

linkage

which

occu

at

specific

speeds

Car

pulls

to

right

or

left

When

driving

with

hands

off

the

steering

wheel

on

a

flat

road

the

car

gently

swerves

to

right

or

left

Note

A

faulty

rear

suspension

may

also

be

the

cause

of

this

problem

and

therefore

see

ebo

Section

RA

Proba

b

Ie

ca

use

Improper

tire

pressure

Imbalance

and

deformation

of

road

wheel

Unevenly

worn

tire

or

insufficient

tight

ening

of

wheel

nuts

Improperly

adjusted

or

worn

front

wheel

bearing

Faulty

wheel

alignment

Worn

transverse

link

bushings

Insufficiently

tightened

steering

gear

hous

ing

Wear

of

steering

linkage

Worn

suspension

ball

joint

Excessive

backlash

due

to

improper

adjust

ment

of

the

steering

gear

box

Damaged

idler

arm

Worn

column

bearing

weakened

column

bearing

spring

or

loose

drmp

Malfucntion

of

shock

absorber

inside

the

strut

or

loose

install3t

on

b9

t5

Imbalance

of

car

l

e

Improper

tire

pressure

or

insufficient

tight

ening

of

wheel

nuts

Difference

in

wear

and

tear

of

right

and

left

tire

treads

Incorrect

adjustment

or

abrasion

of

front

wheel

bearing

Collapsed

or

twisted

front

spring

Incorrect

wheel

alignment

Incorrect

brake

adjustment

binding

Worn

rubber

bushings

for

transverse

link

and

tension

rod

Deformed

steering

linkage

and

transverse

link

and

tension

rod

Imbalance

of

car

level

FA

16

Corrective

action

Adjust

Correct

the

imbal

ap

9f

r

B4I

e

Replace

or

tighten

Adjust

or

tighten

Adjust

Replace

Retighten

Replace

faulty

parts

Replace

Adjust

correctly

Replace

Replace

or

retighten

Replace

or

retighten

Correct

the

imbal

ance

Adjust

or

tighten

Replace

tires

Adjust

or

replace

Replace

Adjust

Adjust

Replace

Replace

Correct

the

imbal

ance

Page 339 of 548

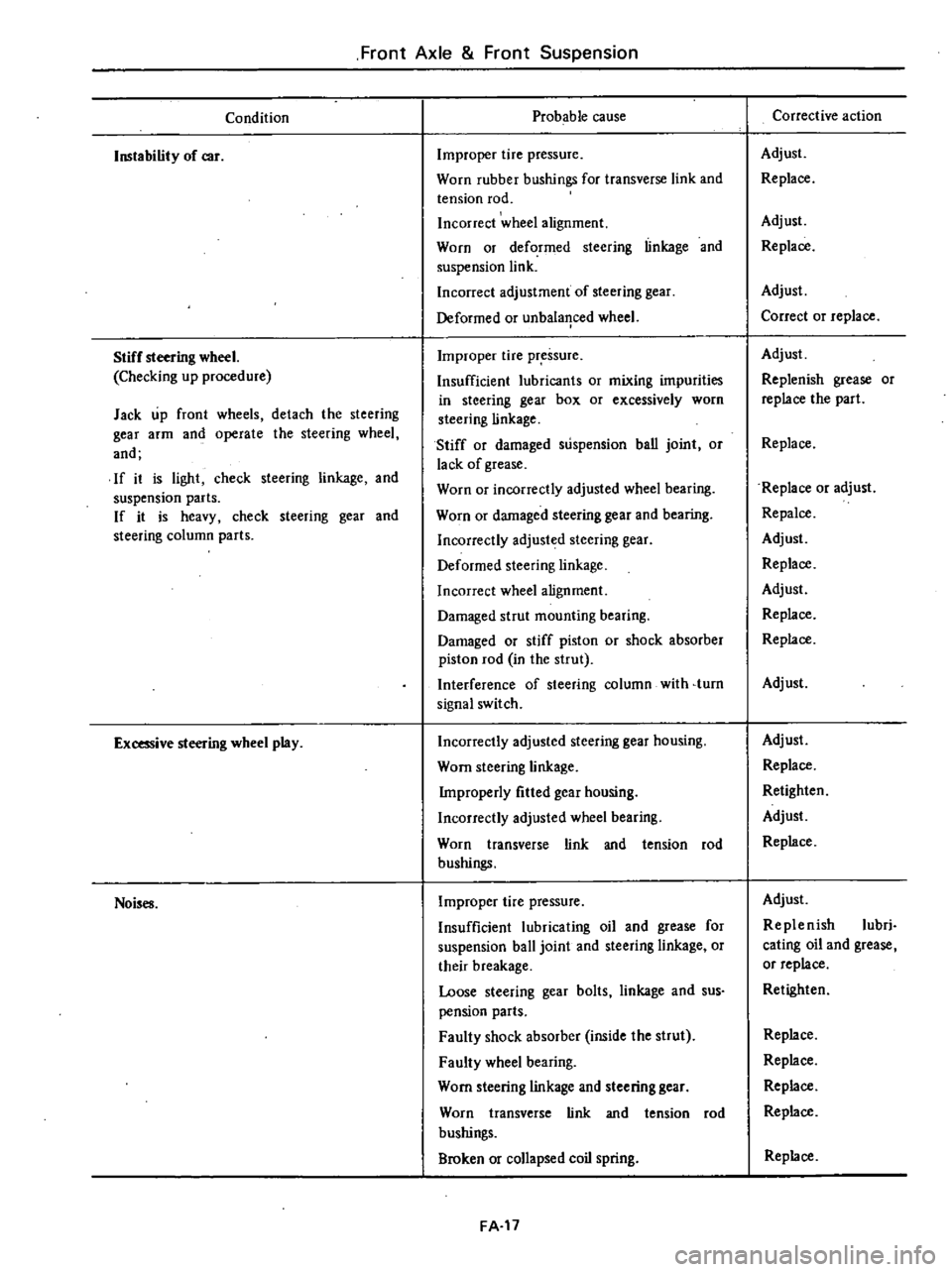

Front

Axle

Front

Suspension

Condition

Instability

of

car

Stiff

steering

wheel

Checking

up

procedure

Jack

up

front

wheels

detach

the

steering

gear

arm

and

operate

the

steering

wheel

and

If

it

is

light

check

steering

linkage

and

suspension

parts

If

it

is

heavy

check

steering

gear

and

steering

column

parts

Excessive

steering

wheel

play

Noises

Probable

cause

Improper

tire

pressure

Worn

rubber

bushings

for

transverse

link

and

tension

rod

Incorrect

wheel

alignment

Worn

or

deformed

steering

linkage

and

suspension

link

Incorrect

adjustment

of

steering

gear

Deformed

or

unbala

1ced

wheel

Improper

tire

pressure

Insufficient

lubricants

or

mixing

impurities

in

steering

gear

box

or

excessively

worn

steering

linkage

Stiff

or

damaged

suspension

ban

joint

or

lack

of

grease

Worn

or

incorrectly

adjusted

wheel

bearing

Worn

or

damaged

steering

gear

and

bearing

Incorrectly

adjusted

steering

gear

Deformed

steering

linkage

Incorrect

wheel

alignment

Damaged

strut

mounting

bearing

Damaged

or

stiff

piston

or

shock

absorber

piston

rod

in

the

strut

Interference

of

steering

column

with

turn

signal

switch

Incorrectly

adjusted

steering

gear

housing

Worn

steering

linkage

Improperly

fitted

gear

housing

Incorrectly

adjusted

wheel

bearing

Worn

transverse

link

and

tension

rod

bushings

Improper

tire

pressure

Insufficient

lubricating

oil

and

grease

for

suspension

ball

joint

and

steering

linkage

or

their

breakage

Loose

steering

gear

bolts

linkage

and

sus

pension

parts

Faulty

shock

absorber

inside

the

strut

Faulty

wheel

bearing

Worn

steering

linkage

and

steering

gear

Worn

transverse

link

and

tension

rod

bushings

Broken

or

collapsed

coil

spring

FA

17

Corrective

action

Adjust

Replace

Adjust

Replace

Adjust

Correct

or

replace

Adjust

Replenish

grease

or

replace

the

part

Replace

Replace

or

adjust

Repalce

Adjust

Replace

Adjust

Replace

Replace

Adjust

Adjust

Replace

Retighten

Adjust

Replace

Adjust

Replenish

lubri

cating

oil

and

grease

or

replace

Retighten

Replace

Replace

Replace

Replace

Replace

Page 341 of 548

Front

Axle

Front

Suspension

SPECIAL

SERVICE

TOOLS

Tool

number

tool

name

CD

S13532

I

000

@

S135322000

ID

ST35325000

Front

wheel

bearing

drift

Inner

Front

wheel

bearing

drift

Outer

Drift

bar

@

GJ

KV48

100300

Strut

and

steering

gear

housing

attachment

ST3565S001

CD

ST35651001

@

S135652000

I

Coil

spring

compressor

set

Coil

spring

compressor

Clamp

Kent

Moore

No

Reference

page

or

Fig

No

Page

F

A

5

J

25729

Fig

FA

18

Fig

F

A

20

PageFA

8

Page

FA

9

Fig

FA

IS

Fig

FA

19

Fig

F

A

27

Tool

number

tool

name

S135500001

G

land

packing

wrench

KV

40

I

0

1900

G

land

packing

guide

CI

HT72520000

ilalljoinl

remover

S136720000

Transverse

link

bushing

replacer

set

t9

11

FA

19

Kent

Moore

No

Reference

page

or

Fig

No

J

25825

Fig

F

A

20

Fig

FA

25

Fig

FA

24

Page

FA

IO

J

25847

Fig

FA

37

Fig

F

A

39

Page 373 of 548

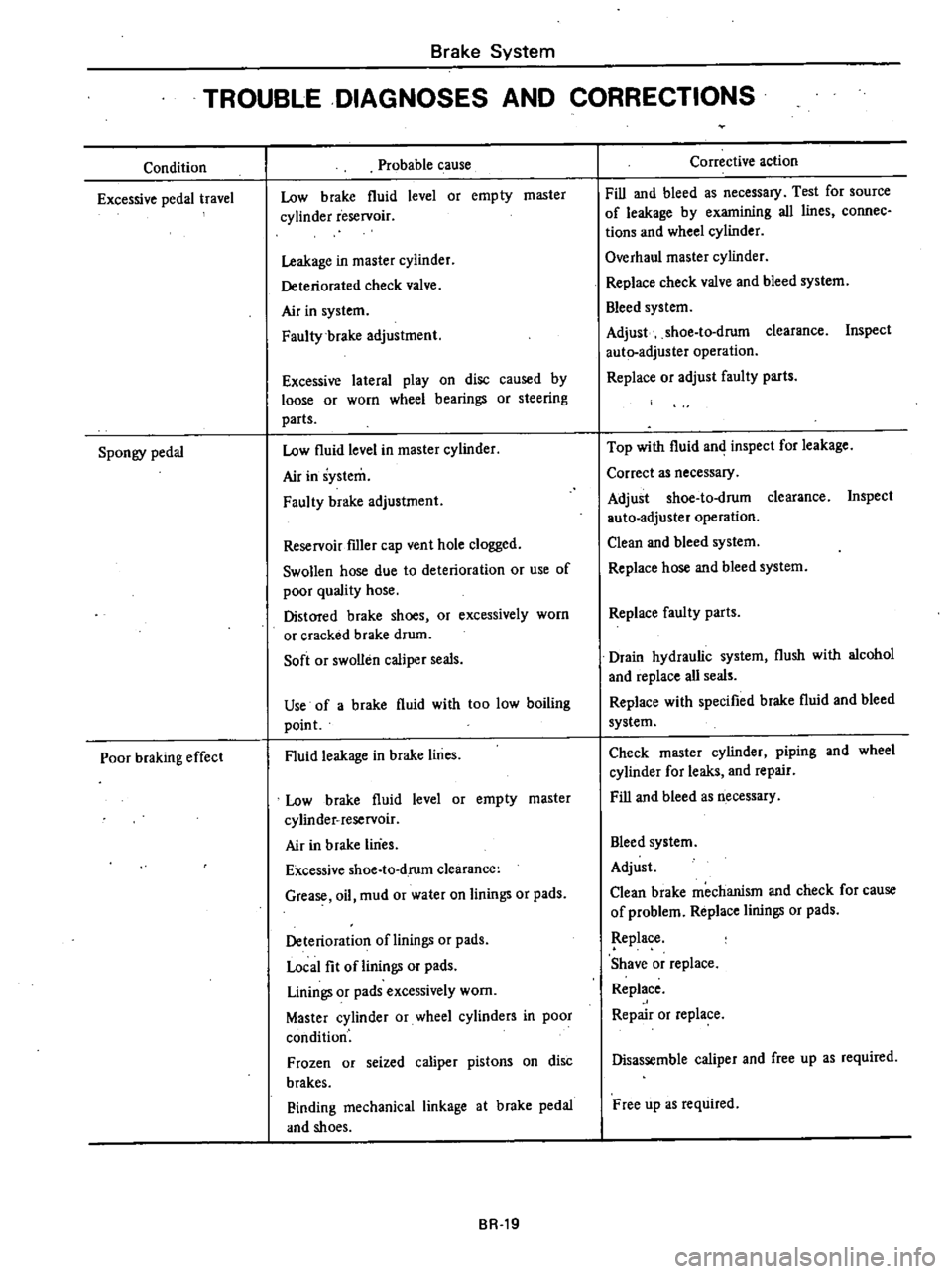

Brake

System

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Condition

Excessive

pedal

travel

Spongy

pedal

Poor

braking

effect

Probable

cause

Low

brake

fluid

level

or

empty

master

cyUnder

reservoir

Leakage

in

master

cylinder

Deteriorated

check

valve

Air

in

system

Faulty

brake

adjustment

Excessive

lateral

play

on

disc

caused

by

loose

or

worn

wheel

bearings

or

steering

parts

Low

fluid

level

in

master

cylinder

Air

in

system

Faulty

brake

adjustment

Reservoir

fIller

cap

vent

hole

clogged

Swollen

hose

due

to

deterioration

or

use

of

poor

quality

hose

Distored

brake

shoes

or

excessively

worn

or

cracked

brake

drum

Soft

or

swollen

caliper

seals

Use

of

a

brake

fluid

with

too

low

boiling

point

Fluid

leakage

in

brake

lines

Low

brake

fluid

level

or

empty

master

cylinder

reservoir

Air

in

brake

lines

Excessive

shoe

to

d

rum

clearance

Grease

oil

mud

or

water

on

linings

or

pads

Deterioration

of

linings

or

pads

Local

fit

of

linings

or

pads

Linings

or

pads

excessively

worn

Master

cylinder

or

wheel

cylinders

in

poor

condition

Frozen

or

seized

caliper

pistons

on

disc

brakes

Finding

mechanical

linkage

at

brake

pedal

and

shoes

BR

19

Corrective

action

Fill

and

bleed

as

necessary

Test

for

source

of

leakage

by

examining

all

lines

connec

tions

and

wheel

cylinder

Overhaul

master

cylinder

Replace

check

valve

and

bleed

system

Bleed

system

Adjust

shoe

to

drum

clearance

Inspect

auto

adjuster

operation

Replace

or

adjust

faulty

parts

Top

with

fluid

and

inspect

for

leakage

Correct

as

necessary

Adjust

shoe

to

drum

clearance

Inspect

auto

adjuster

operation

Clean

and

bleed

system

Replace

hose

and

bleed

system

Replace

faul

ty

parts

Drain

hydraulic

system

flush

with

alcohol

and

replace

all

seals

Replace

with

specified

brake

fluid

and

bleed

system

Check

master

cylinder

p

pmg

and

wheel

cylinder

for

leaks

and

repair

Fill

and

bleed

as

necessary

Bleed

system

Adjust

Clean

brake

mechanism

and

check

for

cause

of

problem

Replace

linings

or

pads

Replace

Shave

or

replace

Replace

Repair

or

replace

Disassemble

caliper

and

free

up

as

required

Free

up

as

required

Page 378 of 548

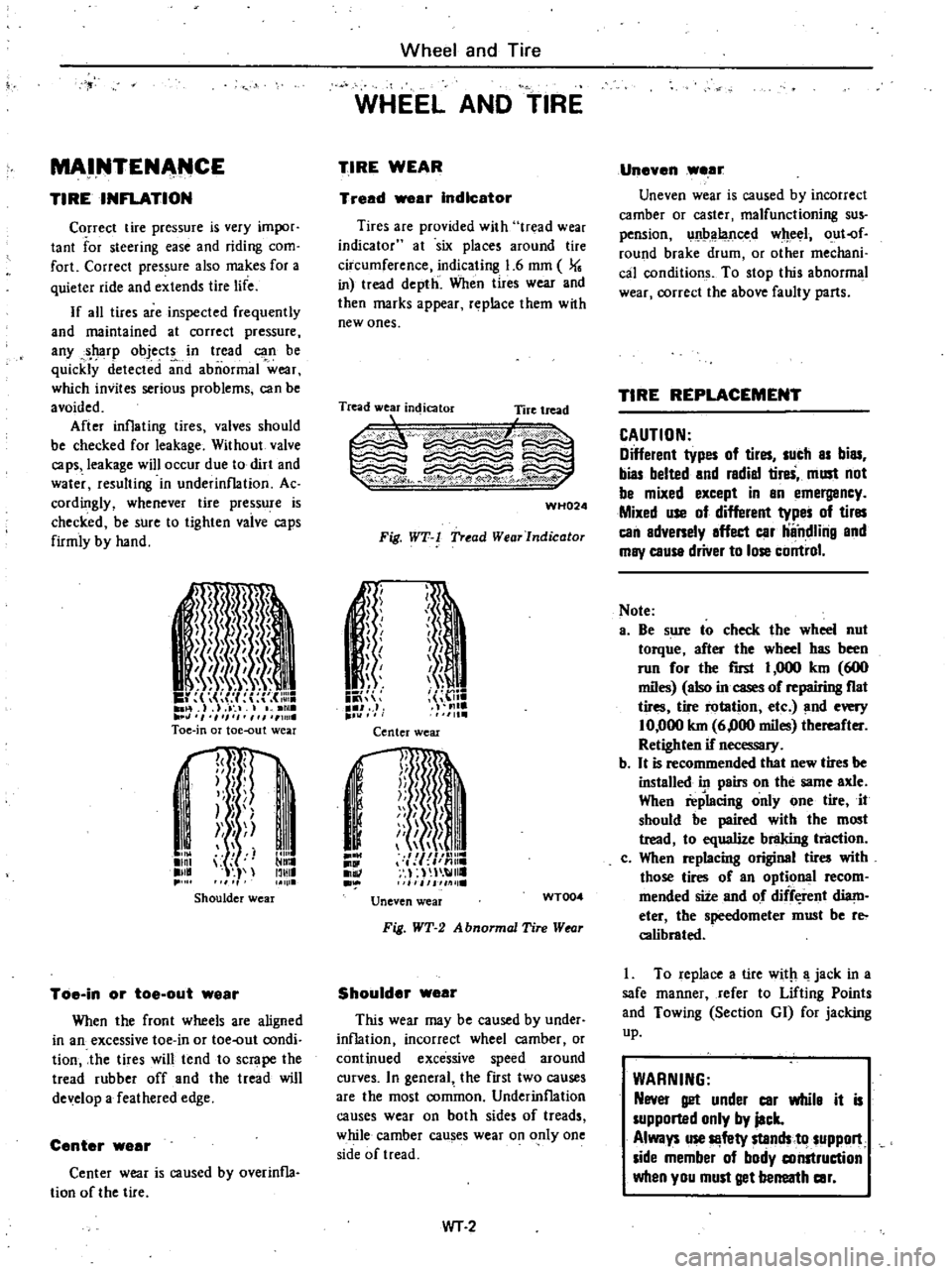

t

MAINTEN

NCE

TIRE

INFLATION

Correct

tire

pressure

is

very

impor

tant

for

steering

ease

and

riding

com

fort

Correct

pressure

also

makes

for

a

quieter

ride

and

extends

tire

life

If

all

tires

are

inspected

frequently

and

maintained

at

correct

pressure

any

sharp

objects

in

tread

can

be

quickiy

detected

nd

abnormal

wear

which

invites

serious

problems

can

be

avoided

After

inflating

tires

valves

should

be

checked

for

leakage

Without

valve

caps

leakage

will

occur

due

to

dirt

and

water

resulting

in

underinflation

Ac

cordingly

whenever

tire

pressure

is

checked

be

sure

to

tighten

vaive

caps

firmly

by

hand

JW

Sri

in

1

II

I

i

I

1

I

1

1

I

I

I

II

I

I

I

i

M

I

l

1

14

nl

01

I

II

Toe

in

or

toe

out

wear

I

J

I

I

p

rt

i

Ilnl

lll

11111

IllIlI

Shoulder

wear

Toe

in

or

toe

out

wear

When

the

front

wheels

are

aligned

in

an

excessive

toe

in

or

toe

out

condi

tion

the

tires

will

tend

to

scrape

the

tread

rubber

off

and

the

tread

will

de

elop

a

feathered

edge

Center

wear

Center

wear

is

caused

by

overinfla

tion

of

the

tire

Wheel

and

Tire

WHEEL

AND

TIRE

TIRE

WEAR

Tread

ar

Indicator

Tires

are

provided

with

tr

lad

wear

indicator

at

six

places

around

tire

circumference

indicating

1

6

mm

J

in

tread

depth

When

tires

wear

and

then

marks

appear

replace

them

wtth

new

ones

Tread

wear

indicator

Tire

tread

L

1

c

WH024

Fig

WT

l

Tread

WearJndicator

n

1

ii

J

J

f

J

I

h

I

me

1111

Center

wear

j

I

1II

mnr

I

j

n

Ii

Ii

i

I

Jil

111

lie

Uneven

wear

WT004

Fig

WT

2

A

bnormal

Tire

Wtor

Shoulder

wear

This

wear

may

be

caused

by

under

inflation

incorrect

wheel

camber

or

continued

excessive

speed

around

curves

In

general

the

first

two

causes

are

the

most

common

Underinflation

causes

wear

on

both

sides

of

treads

while

camber

causes

wear

on

only

one

side

of

tread

WT

2

Uneven

wear

Uneven

wear

is

caused

by

incorrect

camber

or

caster

malfunctioning

sus

pension

unbalanced

wheel

out

of

round

brake

drum

or

other

mechani

cal

conditions

To

stop

this

abnormal

wear

correct

the

above

faulty

parts

TIRE

REPLACEMENT

CAUTION

Different

types

of

tires

sucb

as

bias

bias

belted

and

radial

tireS

must

not

be

mixed

except

in

an

emergancy

Mixed

use

of

different

types

of

tires

can

adversely

affect

car

ilndlilig

and

may

cause

driver

to

lose

control

Note

a

Be

sure

to

check

the

wheel

nut

torque

after

the

wheel

has

been

run

for

the

rust

I

000

km

600

miles

also

in

cases

of

repairing

fiat

tires

tire

rotation

etc

and

every

10

000

km

6

000

miles

thereafter

Retighten

if

necessary

b

It

is

recommended

that

new

tires

be

installed

in

pairs

on

the

same

axle

When

replacing

only

one

tire

it

should

be

paired

with

the

most

tread

to

equalize

braking

tl1lction

c

When

replacing

original

tires

with

those

tires

of

an

optional

recom

mended

site

and

of

diff

rent

diam

eter

the

speedometer

must

be

reo

calibrated

I

To

replace

a

tire

with

a

jack

in

a

safe

manner

refer

to

Lifting

Points

and

Towing

Section

GI

for

jacking

up

WARNING

Never

get

under

car

whila

it

is

supported

only

by

jack

Always

use

Il

fety

stands

to

suppon

side

member

of

body

construction

when

you

must

get

berreatb

car