air suspension DATSUN 210 1979 Service Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 3 of 548

DATSUN

210

SERVICE

MANUAL

Model

8310

Series

T

OfOUoW

lTY

INISSAN

N

OIlCOIIO

NISSAN

MOTOR

CO

LTD

17

1

Ginza

6

Chome

Chuo

ku

Tokyo

104

Japan

QUICK

REFERENCE

INDEX

GENERAL

INFORMATION

GI

ENGINE

TUNE

UP

ET

ENGINE

MECHANICAL

EM

ENGINE

LUBRICATION

SYSTEM

EL

COOLING

SYSTEM

CO

ENGI

NE

FUEL

EF

EMISSION

CONTROL

SYSTEM

EC

ENGINE

ELECTRICAL

SYSTEM

EE

ENGINE

REMOVAL

INSTALLATION

ER

CLUTCH

CL

lMr

MANUAL

TRANSMISSION

MT

AUTOMATIC

TRANSMISSION

AT

H

PROPELLER

SHAFT

OIFFERENTlAL

CARRIER

PO

FRONT

AXLE

FRONT

SUSPENSION

FA

10

REAR

AXLE

REAR

SUSPENSION

RA

BRAKE

SYSTEM

BR

WHEEL

A

NO

TI

RE

WT

0

STEERING

SYSTEM

ST

ENGINE

CONTROL

FUEL

EXHAUST

SYSTEMS

FE

BOOY

BF

BOOY

ELECTRICAL

SYSTEM

BE

AIR

CONOITIONING

AC

Page 325 of 548

Fig

FA

3

Installing

Coller

Pin

II

Install

hub

cap

with

new

Q

ring

and

wheel

WHEEL

ALIGNMENT

Correct

front

wheel

alignment

as

sures

proper

car

handling

characteris

tics

and

minimum

steering

effort

with

the

least

amount

of

tire

wear

Before

adjusting

front

wheel

alignment

be

sure

to

make

preliminary

inspection

of

front

end

parts

Tire

pressure

and

balance

Wheel

bearings

and

wheel

bearing

nuts

Steering

gear

play

Steering

gear

housing

loose

at

frame

Steering

linkage

and

connections

Shock

absorber

operation

If

wrong

repair

or

replace

the

damaged

portion

or

parts

When

using

equipment

for

front

wheel

alignment

inspection

follow

the

instructions

furnished

with

equipment

Note

Inspection

should

be

made

with

the

car

set

Ievel

and

at

curb

weight

Cember

end

caster

Camber

and

caster

are

preset

at

factory

and

cannot

be

adjusted

The

car

requires

only

toe

in

and

car

posture

adjustment

Note

If

camber

or

caster

alignment

is

not

within

specifications

check

as

sociated

parts

Repair

or

replace

as

necessary

Front

Axle

Front

Suspension

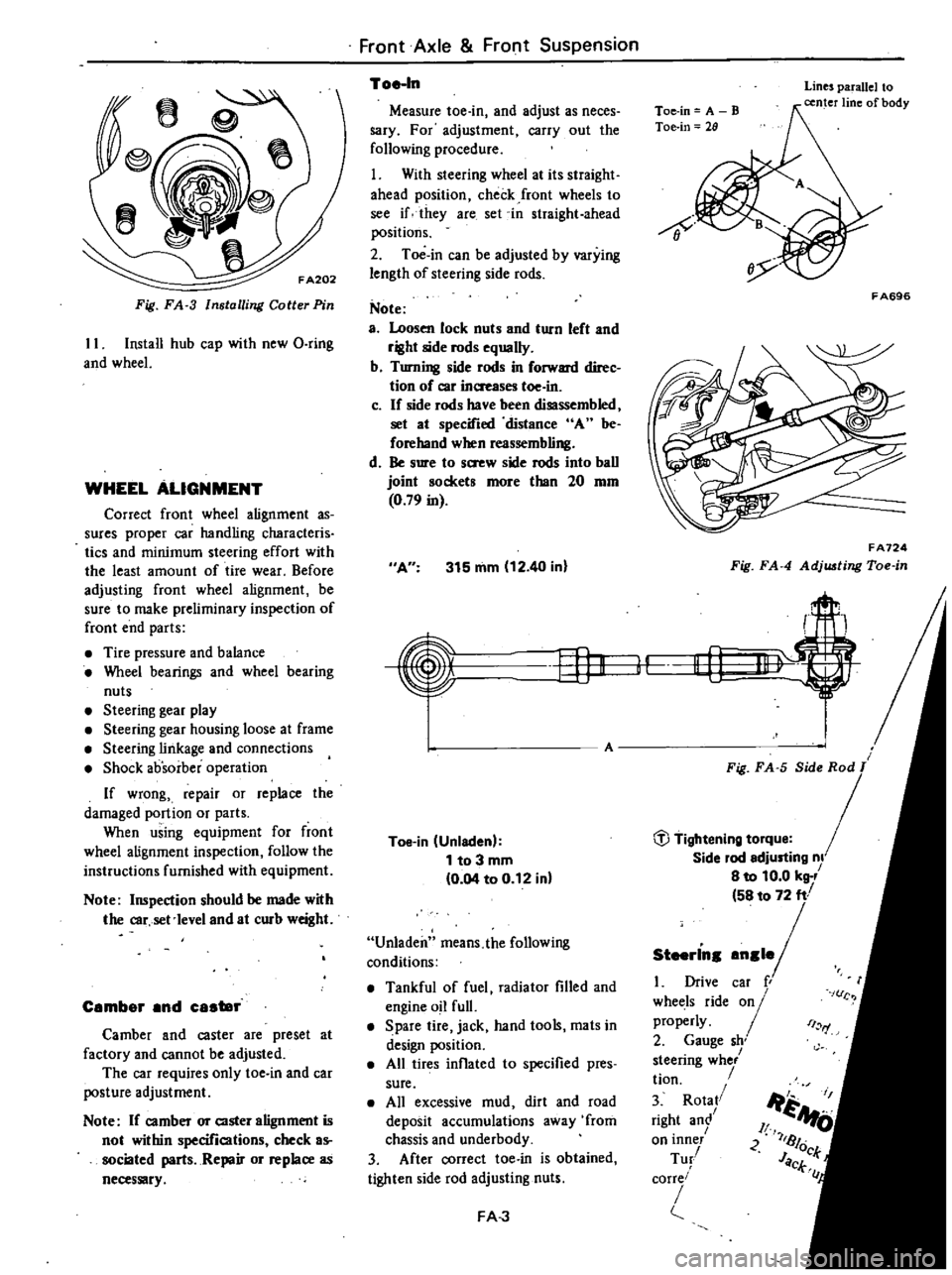

Toe

In

Measure

toe

in

and

adjust

as

neces

sary

For

adjustment

carry

out

the

following

procedure

1

With

steering

wheel

at

its

straight

ahead

position

check

front

wheels

to

see

if

they

are

set

in

straight

ahead

positions

2

Toe

in

can

be

adjusted

by

varying

length

of

steering

side

rods

Note

a

Loosen

lock

nuts

and

turn

left

and

right

side

rods

equally

b

Turning

side

rods

in

forward

direc

tion

of

car

inaeases

toe

in

c

If

side

rods

have

been

disassembled

set

at

specified

distance

A

be

forehand

when

reassembling

d

Be

sure

to

s

w

side

rods

into

ball

joint

sockets

more

than

20

mm

0

79

in

A

315

mm

12

40

in

EfJK

Toe

in

Unladen

1

to

3

mm

0

04

to

0

12

in

Unladen

means

the

following

conditions

Tankful

of

fuel

radiator

filled

and

engine

oil

full

Spare

tire

jack

hand

tools

mats

in

design

position

All

tires

inflated

to

specified

pres

sure

All

excessive

mud

dirt

and

road

deposit

accumulations

away

from

chassis

and

underbody

3

After

correct

toe

in

is

obtained

tighten

side

rod

adjusting

nuts

FA

J

Toe

in

A

B

Toe

in

28

Lines

parallel

to

center

line

of

body

8

F

A696

FA724

Fig

FA

4

Adj

ting

Toe

in

r

II

Li

1

t

Fig

FA

5

Side

Rod

T

Side

lod

edjusting

nl

8

to

10

0

kg

58

to

72

ft

1

Drive

caf

r

whet

ls

ride

01

properly

2

Gauge

sh

steenng

whe

tion

3

Rota

right

an

on

lOner

Tu

corre

i

I

rf

c

Ji

1

A

JI

U

2

7181

JOck

CL

C

Page 327 of 548

6

Pry

off

cotter

pin

take

out

ad

justing

cap

and

wheel

bearing

lock

nut

7

Remove

wheel

hub

with

disc

brake

rotor

from

spindle

with

bearing

installed

FA199

Fig

FA

10

Removing

Wheel

Hub

Note

Be

careful

not

to

drop

outer

bearing

DOne

out

of

hub

when

removing

hub

from

knuckle

spin

dle

8

Remove

outer

bearing

cone

9

Loosen

four

bolts

securing

brake

disc

remove

disc

brake

rotor

from

wheel

hub

assembly

Fig

FA

11

Removing

Due

Broke

Rotor

Loosen

screws

securing

baffle

plate

take

out

baffle

plate

10

Remove

inner

earing

cone

after

prying

out

grease

seaL

Discard

grease

seaL

11

If

it

is

necessary

to

replace

earing

outer

race

drive

it

out

from

hub

with

a

brass

drift

and

mallet

Evenly

tap

bearing

outer

race

through

two

grooves

inside

hub

Front

Axle

Front

Suspension

Fig

FA

12

Removing

Bearing

Outer

Race

INSPECTION

WHEEL

BEARING

Thoroughly

clean

grease

and

dirt

from

wheel

bearing

with

cleaning

sol

vent

and

dry

with

compressed

air

free

from

moisture

Check

wheel

bearing

to

see

that

it

rolls

freely

and

is

free

from

noise

crack

pitting

or

wear

WHEEL

HUB

Check

wheel

hub

for

crack

by

means

of

a

magnetic

exploration

or

dyeing

test

and

replace

if

cracked

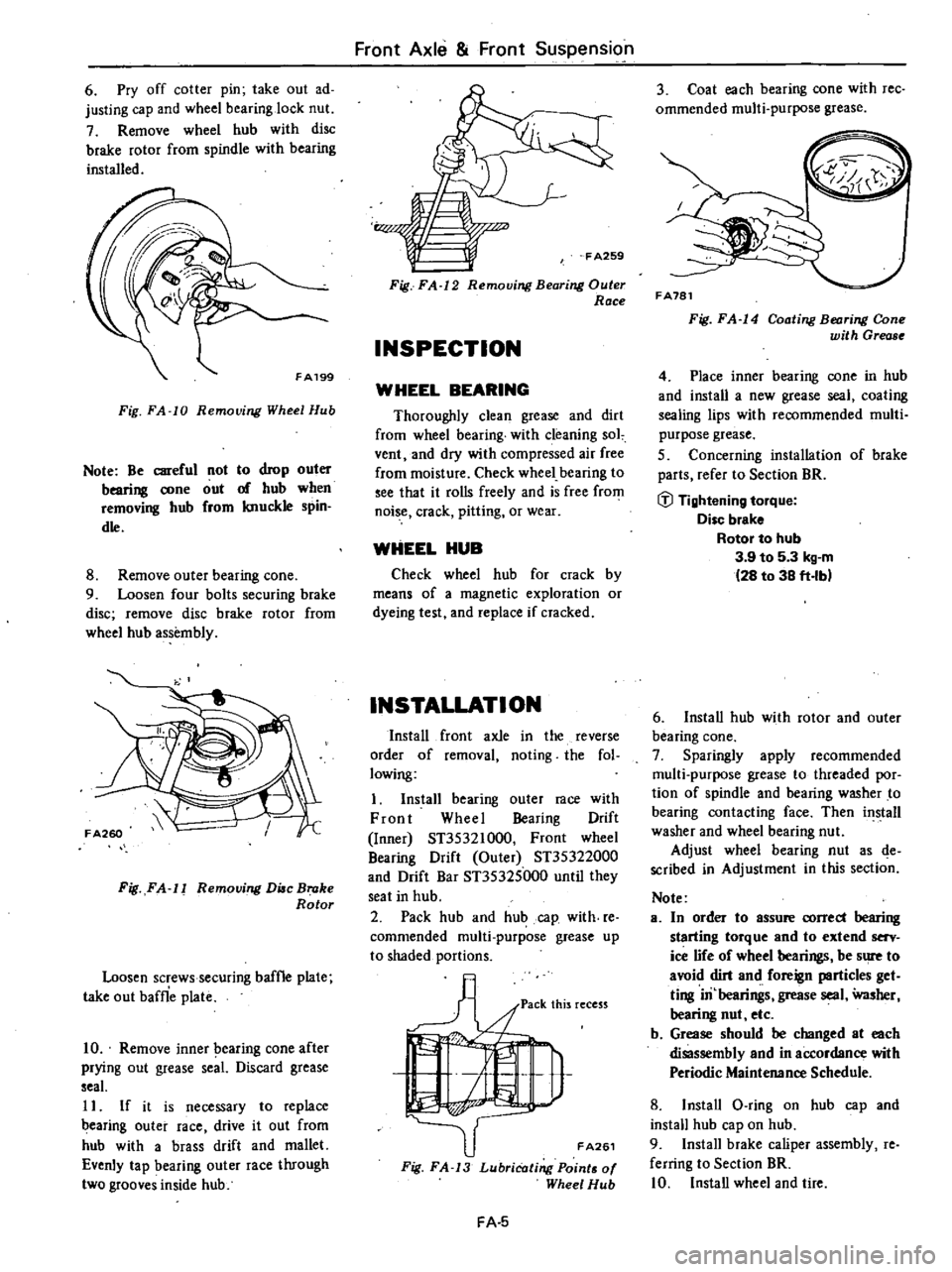

INSTALLATION

Install

front

axle

in

the

reverse

order

of

removal

noting

the

fol

lowing

I

Install

bearing

outer

race

with

Front

Wheel

Bearing

Drift

Inner

ST35321000

Front

wheel

Bearing

Drift

Outer

ST35322000

and

Drift

Bar

ST35325000

until

they

seat

in

hub

2

Pack

hub

and

hub

cap

with

re

commended

multi

purpose

grease

up

to

shaded

portions

fA261

Fig

FA

13

LubriCating

Points

of

Wheel

Hub

FA

5

3

Coat

each

bearing

DOne

with

rec

ommended

multi

purpose

grease

FA781

Fig

FA

14

Coating

Bearing

Cone

with

Grease

4

Place

inner

bearing

cone

in

hub

and

install

a

new

grease

seal

coating

sealing

lips

with

recommended

multi

purpose

grease

5

Concerning

installation

of

brake

parts

refer

to

Section

BR

i

l

Tightening

tOlque

Disc

brake

Rotor

to

hub

3

9

to

5

3

kg

m

28

to

38

ft

lbl

6

Install

hub

with

rotor

and

outer

bearing

cone

7

Sparingly

apply

recommended

multi

purpose

grease

to

threaded

por

tion

of

spindle

and

bearing

washer

to

bearing

contacting

face

Then

install

washer

and

wheel

bearing

nut

Adjust

wheel

bearing

nut

as

de

scribed

in

Adjustment

in

this

section

Note

a

In

order

to

assure

DOrrect

bearing

starting

torque

and

to

extend

serv

ice

nfe

of

wheel

bearings

be

sure

to

avoid

dirt

and

foreign

particles

get

ting

iIi

bearings

grease

seal

Washer

bearing

nut

etc

b

Grease

should

be

changed

at

each

disassembly

end

in

aa

ordance

with

Periodic

Maintenance

Schedule

8

Install

O

ring

on

hub

cap

and

install

hub

cap

on

hub

9

Install

brake

caliper

assembly

re

ferring

to

Section

BR

10

Install

wheel

and

lire

Page 329 of 548

S

Support

strut

assembly

with

a

jack

or

suitable

stand

and

remove

three

nuts

securing

strut

to

hoodledge

Strut

assembly

and

spring

can

then

be

removed

as

a

unit

DISASSEMBLY

When

disassembling

a

strut

extra

caution

should

be

exercised

to

avoid

dirt

and

dust

getting

inside

strut

This

dirt

and

dust

is

loaded

with

abrasive

which

if

enters

strut

causes

internal

leak

and

premature

wear

of

moving

parts

I

Secure

Strut

Steering

Gear

Housing

Attachment

KV48100300

in

a

vise

and

install

strut

on

attachment

2

Set

up

Spring

Compressor

ST3S6S

100

I

on

spring

Compress

spring

just

far

enough

to

permit

turn

ing

of

strut

mounting

insulator

by

hand

Remove

self

locking

nut

FA658

Fig

FA

18

Comprt

ingSpring

3

Remove

lock

nut

on

top

of

piston

rod

remove

mounting

insulator

strut

mounting

bearing

dust

seal

spring

seat

spring

and

bumper

rubber

CAUTION

Be

sure

to

hook

special

tool

8135651001

evenly

on

a

minimum

of

three

coils

Paying

attention

not

to

damage

piston

lod

Front

Axle

Front

Suspension

AJ

r

ST3565S001

F

A059

k

j

h

Fig

FA

19

Removing

Mounting

Insulator

4

Retract

piston

rod

by

pushing

it

down

until

it

bottoms

Remove

gland

packing

with

Gland

Packing

Wrench

ST3SS00001

A

ST35500001

1J

FA209

KV48

100300

Fig

FA

20

Removing

Gland

Packing

Note

Clean

gland

pecking

of

mud

and

other

foreign

perticles

accumu

lated

5

Remove

O

ring

from

top

of

pis

ton

rod

guide

bushing

6

Lift

out

piston

rod

together

with

cylinder

Note

Do

not

remove

pistion

rod

quickly

as

this

will

cause

oil

to

spurt

out

FA275

Fig

FA

21

Removing

Pi

ton

Rod

and

Cyliilder

FA

7

Note

Piston

rod

piston

rod

guide

and

cylinder

are

adjusted

to

provide

precision

mating

sutfeces

and

should

be

handled

as

a

matched

set

7

Drain

fluid

thoroughly

from

inner

cylinder

and

discard

8

Wash

aU

parts

in

suitable

solvent

9

Drain

fluid

thoroughly

from

outer

casing

Note

This

operation

is

very

im

portant

since

performance

of

strut

varies

with

amount

of

fluid

filled

within

strut

INSPECTION

I

Replace

gland

packing

O

ring

and

fluid

whenever

strut

is

disassembled

2

Wash

aU

perts

except

for

non

metallic

parts

with

suitable

solvent

and

dry

with

compressed

air

3

Blow

dirt

and

dust

off

of

non

metallic

parts

using

compressed

air

Note

a

Oil

oozing

out

at

and

around

gland

pecking

does

not

call

for

strut

maintenance

If

oil

leaks

past

pring

sest

check

piston

rod

and

gland

pecking

to

cxirrect

the

cause

of

problem

If

oil

leakage

occurs

on

welded

portion

of

outer

strut

casing

replace

strut

outer

casing

essembly

b

If

hock

absorber

itself

is

malfunc

tioning

replace

as

an

assembly

in

cluding

piston

rod

cylinder

bot

tom

valve

and

guide

bushing

Outer

ce

in

Check

outer

casing

for

evidences

of

deformation

cracking

or

other

dam

age

If

necessary

discard

Strut

mountln

In

uletor

Replace

if

cemented

rubber

to

metal

joints

are

melted

or

cracked

Rubber

parts

should

also

be

replaced

if

deteriorated

Strut

mountln

beerln

Replace

if

inspection

reveals

abnor

mal

noise

or

excessive

rattle

in

axial

direction

Page 330 of 548

Note

CbedI

dust

seal

forsaatcbes

or

aacb

on

lips

end

replace

if

neces

sary

ASSEMBLY

When

assembling

strut

be

careful

not

to

drop

or

scratch

parts

since

they

are

precisely

machined

to

very

close

tolerances

Before

assembly

clean

away

all

dirt

to

prevent

any

possible

entry

of

dirt

into

strut

Note

If

replacement

of

any

strut

compooent

parts

is

found

to

be

neoesaery

make

sure

tlllt

parta

ere

the

same

brand

as

thoee

used

in

the

strot

essemhly

I

Install

strut

outer

casing

on

Strut

Steering

Gear

Housing

Attachment

KV48

100300

See

Fig

FA

20

2

Install

cylinder

and

piston

rod

assembly

shock

absorber

kit

in

outer

casing

3

Remove

pistoo

rod

guide

from

cylinder

and

Pour

correct

amount

of

new

fluid

into

ylinder

and

strut

outer

casing

Amount

of

oil

325

cc

19

83

cu

in

1

FA065

Fig

FA

22

FillingShoelt

Absorber

Fluid

Note

e

It

i

important

that

correct

emount

of

fluid

be

poured

into

strut

to

assure

correct

damping

force

of

Front

Axle

Front

Suspension

mock

absorber

b

U

GENUINE

NISSAN

STRUT

OIL

or

equivalent

every

after

over

11101

4

Securely

install

piston

rod

guide

in

cylinder

Note

Be

c

aref

1l

t

to

damage

gujde

with

thread

portion

of

pistoo

rod

5

Install

new

O

ring

over

rod

guide

6

Lubricate

sealing

lips

of

gland

packing

uterisked

in

Fig

F

A

23

with

lithium

base

grease

containing

molyb

denum

disulphide

and

install

gland

packing

with

Gland

Packing

Guide

KV40101900

FA659

Grease

V

1

1

0

I

FA464

Fig

FA

23

Grea

ing

Point

of

Gland

lbelting

KV40101900

F

A276

Fig

F

A

24

t

lung

Gland

lbelting

FA

8

7

Tighten

gland

packing

fl

Tightening

torque

8

0

to

11

0

kg

m

58

to

80

ft

lb

Note

a

When

tightening

gland

packing

it

i

POrl

t

J

It

d

he

ttJI

teoded

epproximately

120

IDID

4

72

in

from

upper

surfece

of

gland

packing

to

faclli18te

spring

iosteIlatioo

b

Gland

packing

should

be

tighteoed

to

specified

torque

with

the

aid

of

Gland

Packing

Wreoch

ST35500001

When

doing

so

the

amouot

of

torque

to

be

read

be

neath

wrench

oeedle

should

be

modified

eccording

to

the

following

formula

L

Ckg

m

8x

L

O

IO

or

L

Cft

Ib

58x

L

0

33

where

C

Value

to

he

reed

on

the

torque

wrench

kg

m

ft

Ib

L

Effective

length

of

torque

wrench

m

ft

Gland

packing

WIcoch

Torque

C

Lm

ft

I

0

1

m

0

33

ft

FA278

Fig

FA

25

Gland

lbeltill

l

Wrench

8

Bleed

air

out

of

shock

absorber

as

follows

I

Holding

strut

by

hand

with

its

spindle

side

facing

down

pull

out

piston

f

d

completely

Then

turn

strut

upside

down

so

that

spindle

side

is

now

facing

up

Under

this

condition

retract

piston

rod

all

the

way

in

2

Repeat

the

above

procedure

several

times

so

that

air

will

be

bled

out

from

strut

th

oroughiy

3

If

during

the

above

step

en

equal

pressure

is

felt

through

the

hand

grippitig

piston

rod

on

both

strokes

it

is

an

indication

that

air

is

expelled

from

strut

thoroughly

Page 331 of 548

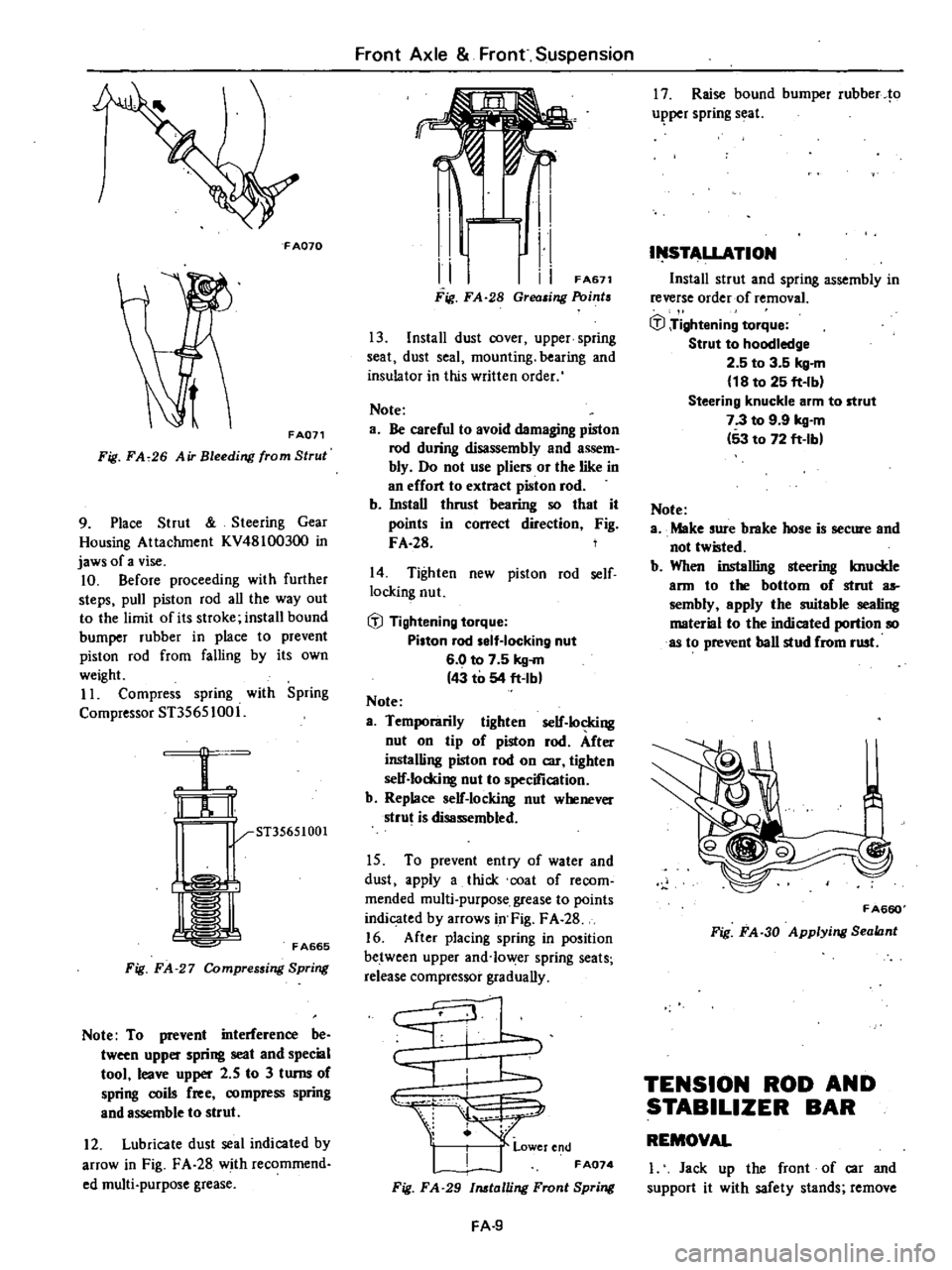

FA070

FA071

Fig

FA

26

Air

Bleeding

from

Strul

9

Place

Strut

Steering

Gear

Housing

Attachment

KV48100300

in

jaws

of

a

vise

10

Before

proceeding

with

further

steps

pull

piston

rod

all

the

way

out

to

the

limit

of

its

stroke

install

bound

bumper

rubber

in

place

to

prevent

piston

rod

from

falling

by

its

own

weight

11

Compress

spring

with

Spring

Compressor

ST35651001

ST35651001

r

l

I

FA665

Fig

FA

27

Compressing

Spring

Note

To

prevent

interference

be

tween

upper

spring

seat

and

special

tool

leave

upper

2

5

to

3

turns

of

spring

coils

free

compress

spring

and

assemble

to

strut

12

Lubricate

dust

seal

indicated

by

arrow

in

Fig

FA

28

with

recommend

ed

multi

purpose

grease

Front

Axle

Front

Suspension

I

1

i

I

FA671

Fig

FA

28

Grea

ing

Point

13

Install

dust

cover

upper

spring

seat

dust

seal

mounting

bearing

and

insulator

in

this

written

order

Note

a

Be

careful

to

avoid

damaging

piston

rod

during

disassembly

and

assem

bly

Do

not

use

pliers

or

the

like

in

an

effort

to

extract

piston

rod

b

InstaU

thrust

bearing

so

that

it

points

in

correct

direction

Fig

FA

28

14

Tighten

new

piston

rod

self

locking

nut

fil

Tightening

torque

Pi

ton

rod

elf

Iocking

nut

6

0

to

7

5

kg

m

43

to

54

ft

lbl

Note

a

Temporarily

tighten

self

locking

nut

on

tip

of

piston

rod

After

installing

piston

rod

on

car

tighten

self

locking

nut

to

specification

b

Replace

self

locking

nut

whenever

strut

is

disassembled

15

To

prevent

entry

of

water

and

dust

apply

a

thick

coat

of

recom

mended

multi

purpose

grease

to

points

indicated

by

arrows

in

Fig

F

A

28

16

After

placing

spring

in

position

between

upper

and

lo

er

spring

seats

release

compressor

graduaUy

I

J

k

1

jt

r

end

FA074

Fig

FA

29

talling

Front

Spring

FA

9

17

Raise

bound

bumper

rubber

10

u

per

spring

seal

I

STALLATION

Install

strut

and

spring

assembly

in

reverse

order

of

removaL

fil

Tightening

torque

Strut

to

hoodledge

2

5

to

3

5

kg

m

18

to

25

ft

Ib

Steering

knuckle

arm

to

strut

7

3

to

9

9

kg

m

53

to

72

ft

lb

Note

a

Make

sure

brake

hose

is

secure

and

not

tw

ted

b

When

installing

steering

knuckle

ann

to

the

bottom

of

strut

as

sembly

epply

the

suitable

sealing

material

to

the

indicated

portion

so

as

to

prevent

ball

stud

from

rust

FA660

Fig

FA

30

Applying

Sealant

TENSION

ROD

AND

STABILIZER

BAR

REMOVAL

I

Jack

up

the

front

of

car

and

support

it

with

safety

stands

remove

Page 333 of 548

FA731

Fig

FA

35

Removing

Wwer

Arm

8

Remove

suspension

ball

joint

from

lower

arm

9

Place

knuckle

arm

in

a

vise

Re

move

suspension

ball

joint

from

knuckle

arm

using

a

press

@

I

r

662

Fig

FA

36

Remouing

Suspension

Ball

Joint

10

Withdraw

lower

arm

bushing

from

transverse

link

using

Front

Lower

Arm

Bushing

Replacer

Set

ST36720000

and

a

press

Mrl

o

o

o

0

F

A669

Fig

FA

37

Removing

Wwer

Am

BuNUng

INSPECTION

Lower

arm

I

Repair

or

replace

lower

arm

if

deformed

cracked

or

damaged

Front

Axle

Front

Suspension

2

Replace

bushing

if

excessively

worn

or

cracked

3

Make

sure

mating

surface

of

bush

ing

is

clean

and

free

from

oil

or

grease

apply

soapy

water

to

bushing

to

facili

tate

installation

Lower

bell

Joint

I

Ball

joint

is

assembled

at

factory

and

cannot

be

disassembled

Check

ball

stud

turning

torque

with

nut

in

place

on

ball

stud

If

it

is

far

from

specifications

replace

liJ

Turning

torque

New

parts

40

to

100

kg

cm

35

to

87

in

Ibl

Used

parts

More

than

20

kg

cm

117

in

Ibl

lUJ

F

A333

Fig

FA

38

Lower

Ball

Joint

2

Check

condition

of

dust

cover

If

it

is

cracked

excessively

replace

ball

joint

3

Lubricate

ball

joint

with

recorn

mended

multi

purpose

grease

To

lubricate

remove

plug

and

in

stall

grease

nipple

Pump

grease

slowly

until

old

grease

is

completely

forced

out

After

greasing

reinstall

plug

Note

When

a

high

pressure

grease

gun

used

operate

it

carefully

so

that

grease

is

injected

slowly

and

new

grease

does

not

DOme

out

from

clamp

portion

INSTALLATION

Install

lower

arm

and

suspension

ball

joint

in

reverse

order

of

removal

FA

l

Lower

erm

buahln

I

Before

installing

bushing

rub

off

rust

or

paint

drops

from

insi

e

collar

on

lower

arm

with

emery

paper

2

Using

Replacer

Set

ST36720000

insert

bushing

with

a

press

until

end

face

of

bushing

is

aligned

with

collar

on

lower

arm

ST36720000

I

I

HA734

Fig

FA

39

Installiff

l

Wwer

Ami

Bu

hi1f

I

Lower

erm

end

atebIllzer

ber

To

install

lower

arm

and

stabilizer

bar

temporarily

tighten

securing

bolts

Then

tighten

bolts

to

specifications

at

curb

weight

with

tires

on

ground

liJ

Tightening

torque

Bell

joint

socket

to

lower

arm

5

1

to

6

1

kg

m

37

to

44

ft

Ibl

Bell

joint

socket

to

lowel

arm

with

tension

rod

5

1

to

6

1

kg

m

37

to

44

ft

Ibl

Bell

joint

to

knuck

le

arm

5

5

to

10

0

kg

m

140

to

72

ft

Ibl

Lower

IIrm

bolt

nut

3

9

to

5

0

kg

m

28

to

36

ft

Ibl

Side

lod

ball

joint

to

knuckle

arm

3

0

to

7

0

kg

m

122

to

51

ft

lbl

Steering

knuckle

erm

to

stlut

7

3

to

9

9

kg

m

53

to

72

ft

Ibl

Page 335 of 548

Front

Axle

Front

Suspension

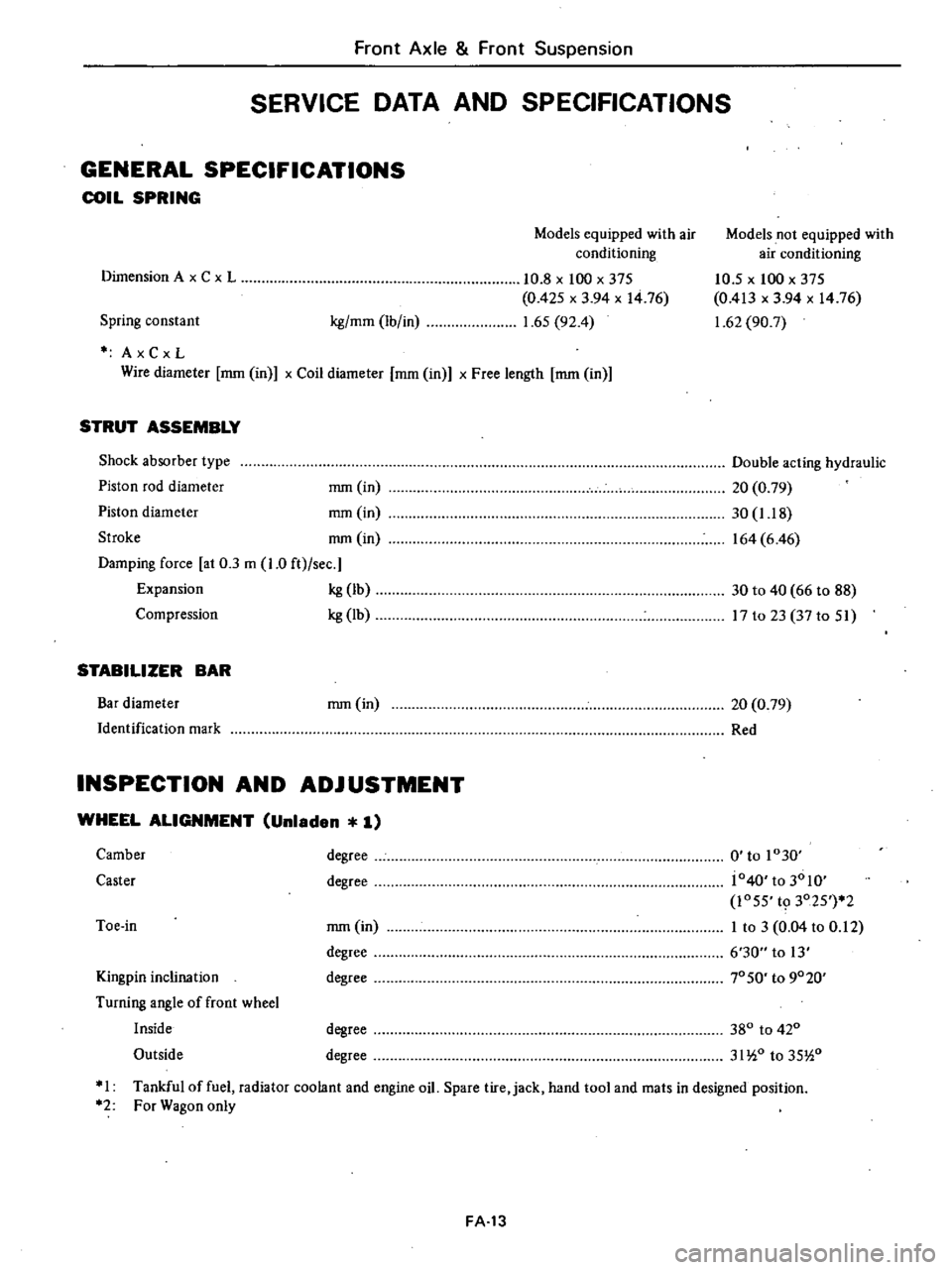

SERVICE

DATA

AND

SPECIFICATIONS

GENERAL

SPECIFICATIONS

COIL

SPRING

Models

equipped

with

air

conditioning

Models

not

equipped

with

air

conditioning

10

5

x

100

x

375

0

413

x

3

94

x

1476

1

62

90

7

Spring

constant

kg

mm

Ib

in

10

8

x

100

x

375

0

425

x

3

94

x

1476

1

65

92

4

Dimension

A

x

C

x

L

AxCxL

Wire

diameter

mm

in

x

Coil

diameter

mm

in

x

Free

length

mm

in

STRUT

ASSEMBLY

Shock

absorber

type

Piston

rod

diameter

mm

in

Piston

diameter

mm

in

Stroke

nun

in

Damping

force

at

0

3

m

1

0

ft

sec

Expansion

kg

Ib

Compression

kg

Ib

Double

acting

hydraulic

20

0

79

30

1

18

164

6

46

30

to

40

66

to

88

17

to

23

37

to

51

STABILIZER

BAR

Bar

diameter

Identification

mark

mm

in

20

0

79

Red

INSPECTION

AND

ADJUSTMENT

WHEEL

ALIGNMENT

Unladen

1

Kingpin

inclination

Turning

angle

of

front

wheel

Inside

Outside

mm

in

degree

degree

0

to

1030

j040

to

3010

1055

t9

3025

2

I

to

3

0

04

to

0

12

6

30

to

13

70

SO

to

9020

Camber

Caster

degree

degree

Toe

in

degree

degree

380

to

420

31

io

to

35

i0

I

Tankful

of

fuel

radiator

coolant

and

engine

oil

Spare

tire

jack

hand

tool

and

mats

in

designed

position

2

For

Wagon

only

FA

13

Page 348 of 548

Rear

Axle

Rear

Suspension

Inspection

I

Check

for

signs

of

cracks

distor

tion

or

other

damage

Replace

if

beyond

repair

2

If

rubber

bushing

shows

evidence

of

cracks

replace

it

using

Link

Rubber

Bushing

Drift

KV4010l6S0

See

Fig

RA

24

to

rubber

bushing

inserting

surface

oflink

CAUTION

a

00

not

tap

end

face

of

bushing

directly

with

a

hammer

as

deforma

tion

may

result

in

loose

bolt

b

When

installing

rubber

bushing

on

link

never

apply

mineral

oil

Note

Before

instelling

rubber

bushing

on

link

apply

an

ample

amount

of

soapsuds

to

link

bushing

guide

and

Removal

1

1

KV401016S0

1

1

j

KV40101610

Lower

link

upper

KV40101440

I

link

KV40101430

14

t4

l

Installation

KV401016S0

KV4010161O

KV40101620

KV40101630

r

KV40101440

upper

link

KV40101430

I

h

r

RA572

Fig

RA

24

Replacing

Link

Rubber

B

hing

RA

7

Instellation

Install

upper

or

lower

link

assembly

in

reverse

order

of

removal

Note

3

Securing

bolts

for

use

with

lower

link

differ

in

length

from

those

for

upper

link

If

used

wrong

securing

bolts

cannot

be

tightened

securely

b

Before

tightening

link

bushing

bolts

and

nuts

temporarily

attach

both

ends

of

upper

and

lower

links

to

axle

case

and

body

After

jacking

up

center

of

differential

carrier

until

upper

and

lower

links

are

almost

horizontal

securely

tighten

link

bushing

bolts

a

d

nuts

c

When

supporting

car

weight

at

center

of

differential

carrier

do

not

put

a

load

in

car

j

Tightening

torque

Upper

link

fixing

bolt

and

nut

7

0

to

8

0

kg

m

5t

0

58

ft

lbl

Lower

link

fixing

nut

7

0

to

8

0

kg

m

51

to

58

ft

lbl

Page 383 of 548

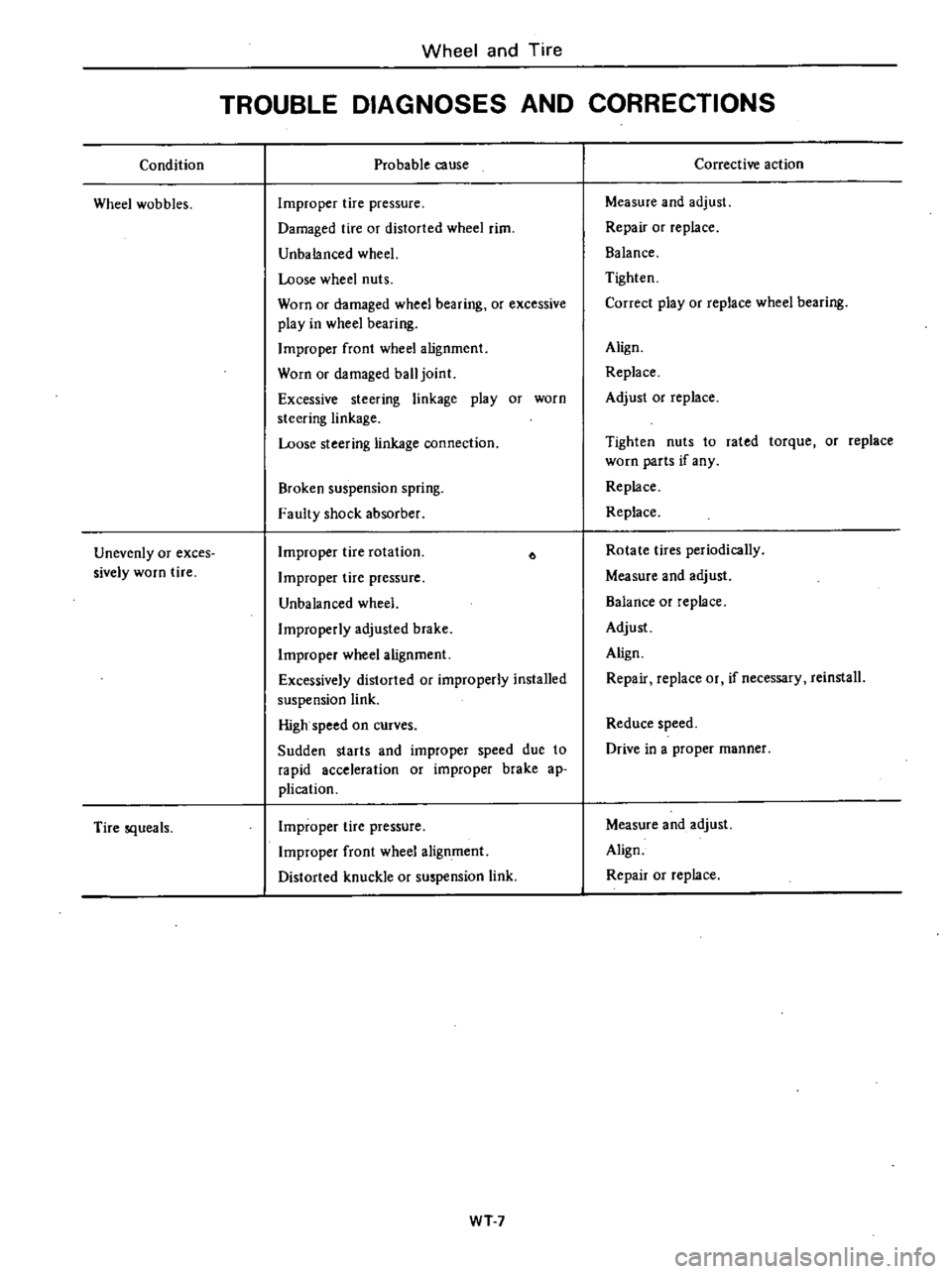

Condition

Wheel

wobbles

Unevenly

or

exces

sively

worn

tire

Tire

squeals

Wheel

and

Tire

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Probable

cause

Improper

tire

pressure

Damaged

tire

or

distorted

wheel

rim

Unbalanced

wheel

Loose

wheel

nuts

Worn

or

damaged

wheel

bearing

or

excessive

play

in

wheel

bearing

Improper

front

wheel

alignment

Worn

or

damaged

ball

joint

Excessive

steering

linkage

play

or

worn

steering

linkage

Loose

steering

linkage

connection

Broken

suspension

spring

Faulty

shock

absorber

Improper

tire

rotation

Improper

tire

pressure

Unbalanced

wheel

Improperly

adjusted

brake

Improper

wheel

alignment

Excessively

distorted

or

improperly

installed

suspension

link

High

speed

on

curves

Sudden

starts

and

improper

speed

due

to

rapid

acceleration

or

improper

brake

ap

plication

Improper

tire

pressure

Improper

front

wheel

alignment

Distorted

knuckle

or

suspension

link

WT7

Corrective

action

Measure

and

adjust

Repair

or

replace

Balance

Tighten

Correct

play

or

replace

wheel

bearing

Align

Replace

Adjust

or

replace

Tighten

nuts

to

rated

torque

or

replace

worn

parts

if

any

Replace

Replace

Rotate

tires

periodically

Measure

and

adjust

Balance

or

replace

Adjust

Align

Repair

replace

or

if

necessary

reinstall

Reduce

speed

Drive

in

a

proper

manner

Measure

and

adjust

Align

Repair

or

replace