fuel DATSUN 210 1979 Owners Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 452 of 548

Body

Electrical

System

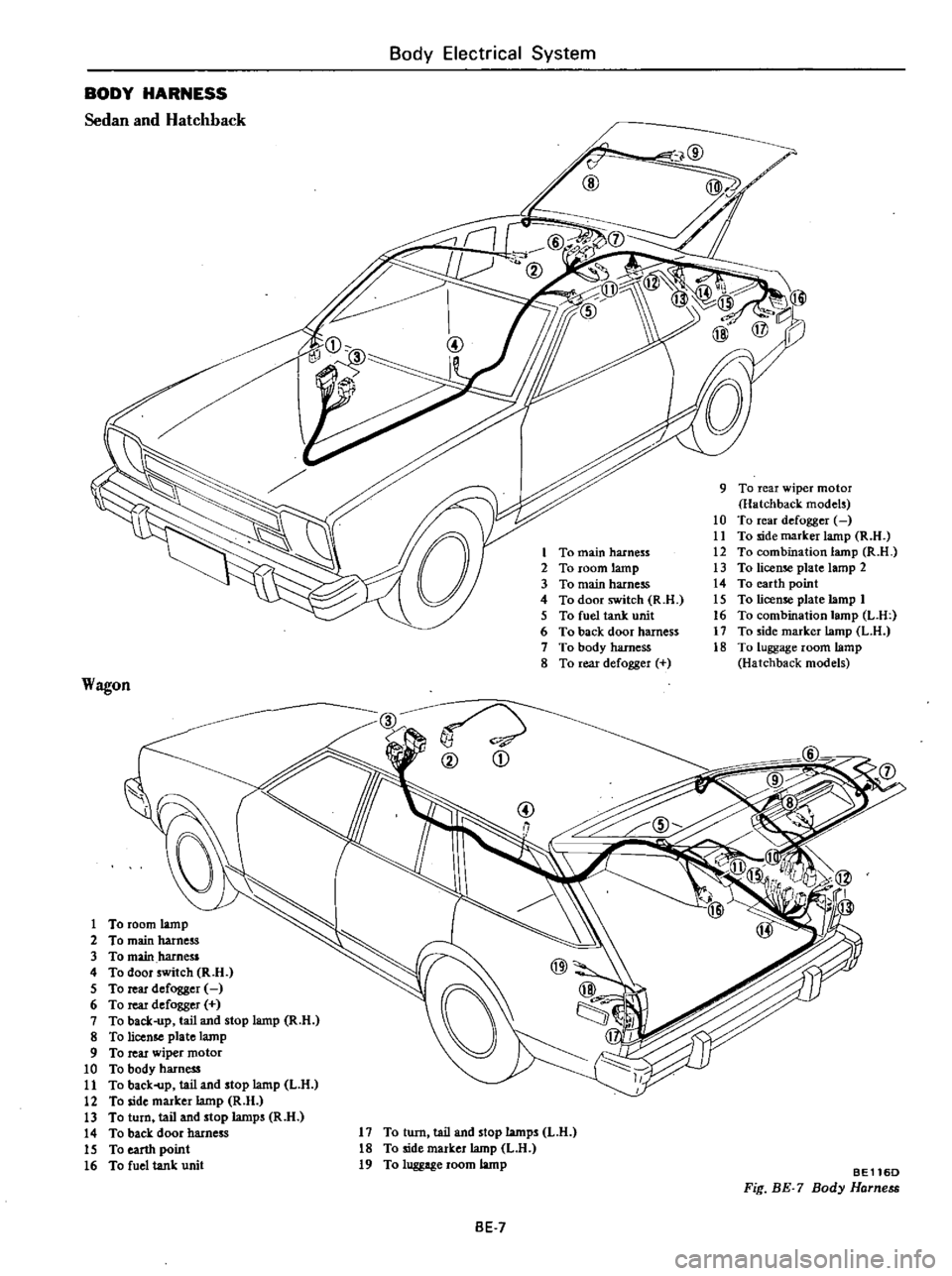

BODY

HARNESS

Sedan

and

Hatchback

9

To

rear

wiper

motor

Hatchback

models

10

To

rear

defogger

11

To

side

marker

lamp

R

H

12

To

combination

lamp

R

n

13

To

license

plate

lamp

2

14

To

earth

point

15

To

license

plate

lamp

1

16

To

combination

lamp

L

U

17

To

side

marker

lamp

L

H

18

To

luggage

room

lamp

Hatchback

models

Wagon

D

S

3

To

main

hamess

4

To

door

switch

R

n

5

To

rear

defogger

6

To

rear

defogger

7

To

back

up

tail

and

stop

lamp

R

H

8

To

license

plate

lamp

9

To

rear

wiper

motor

10

To

body

harness

11

To

baek

p

tail

and

stop

lamp

L

H

12

To

side

marker

lamp

R

H

13

To

turn

tail

and

stop

lamps

R

n

14

To

back

door

harness

15

To

earth

point

16

To

fuel

tank

unit

@

Yj

qr

@

D

17

To

turn

tail

and

stop

lamps

L

H

18

To

side

marker

lamp

L

U

19

To

luggage

room

lamp

BE116D

Fig

BE

7

Body

Harness

BE

7

Page 456 of 548

ILLUMINATION

CONTROL

UNIT

Body

Electrical

System

8

GY

GW

AIMING

ADJUSTMENT

To

adjust

vertical

aim

use

adjusting

screw

on

upper

side

of

headlamp

and

to

adjust

horizontal

ailn

use

adjusting

screw

on

side

of

headlamp

BE1200

Fig

BE

I3

Illumination

Control

Unit

1

Vertical

adjustment

2

Horizontal

adjustment

BE1210

Fig

BE

14

Aiming

Ad

iusting

Screws

Note

Before

makiiIg

headlamp

aim

ing

adjustment

observe

the

follow

ing

instructions

a

Keep

all

tires

inflated

to

correct

pressures

b

Place

car

and

tester

on

one

and

BE

11

same

flat

surface

c

See

that

there

is

no

load

in

car

coolant

engine

oil

fIlled

up

to

correct

level

and

full

fuel

tank

other

than

the

driver

or

equivalent

weight

placed

in

driver

s

position

d

For

details

refer

to

SAE

J599d

When

performing

headlamp

aiming

adjustment

use

an

aiming

machine

aiming

wall

screen

or

headlamp

tester

For

operating

instructions

of

any

almer

it

should

be

in

good

repair

calibrated

and

used

accordi

g

to

respective

operation

manuals

supplied

with

the

unit

If

any

aimer

is

not

available

aiming

adjustment

can

be

done

as

follqws

Turn

headlamp

low

beam

on

H

Horizontal

center

line

of

headlamps

BE297D

Fig

BE

I5

Aiming

Adjustment

Unit

mm

in

Note

a

Adjust

headlamps

so

that

upper

edge

of

hot

spot

is

equal

in

height

to

headlamp

height

and

left

edge

of

hot

spot

is

equal

in

height

to

each

center

line

of

headlamps

b

Dotted

lines

in

illustration

show

center

of

headlamp

Page 458 of 548

Body

Electrical

System

INSPECTION

4

Installation

is

in

the

reverse

order

of

removal

Test

continuity

through

door

switch

with

a

test

lamp

or

ohmmeter

When

plunger

is

pressed

into

switch

assembly

door

switch

contacts

are

open

Contacts

are

closed

when

plung

er

is

projected

METERS

AND

GAUGES

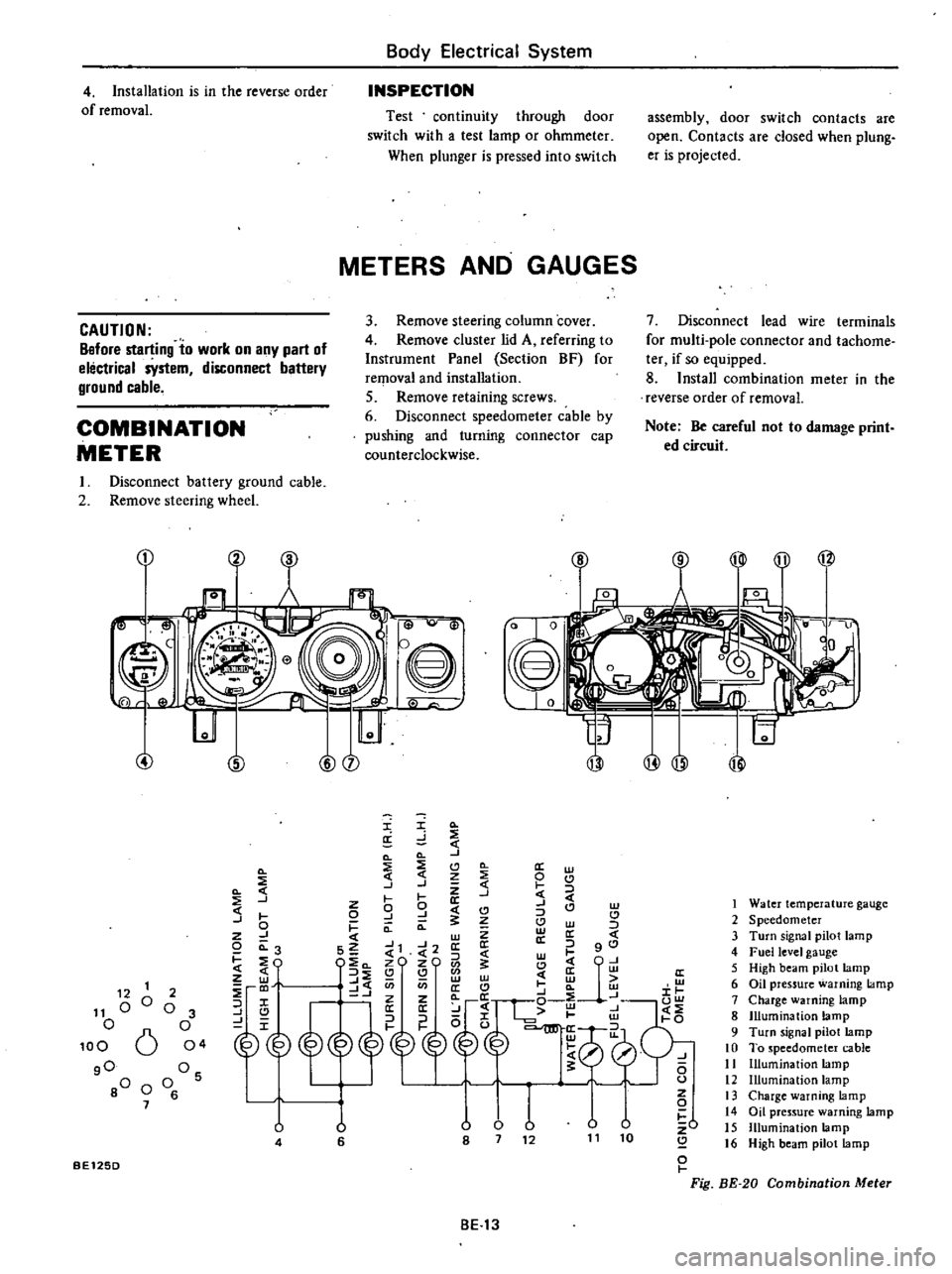

3

Remove

steering

column

cover

4

Remove

cluster

lid

A

referring

to

Instrument

Panel

Section

BF

for

reqlOval

and

installation

5

Remove

retaining

screws

6

Disconnect

speedometer

cable

by

pushing

and

turning

connector

cap

counterclockwise

7

Disconnect

lead

wire

terminals

for

multi

pole

connector

and

tachome

ter

if

so

equipped

8

Install

combination

meter

in

the

reverse

order

of

removal

CAUTION

Before

starting

to

work

on

any

part

of

electrical

sYstem

disconnect

battery

ground

cable

COMBINATION

METER

Note

Be

careful

not

to

damage

print

ed

circuit

I

Disconnect

battery

ground

cable

2

Remove

steering

wheel

CD

Cl

B

i

lJ

Q

@

8

0

I

0

w

@

@

I

Q

a

d

Q

Q

J

Q

2

Cl

0

a

w

Q

3

j

J

Z

t

0

J

W

C

I

0

9

J

CI

C

CI

J

0

I

Q

a

Cl

w

z

J

w

Z

a

c

o

0

3

S2

J1

J2

a

a

l

gO

C

4

l

w

I

EO

l

c

zO

zO

1

Cl

CjU

z

3

Q

Q

w

c

ffi

ffi

to

J

C

U

en

a

C

a

w

i

r

@

p

g10

l

0

U

lJ

v

v

zO

8

7

12

11

10

Q

o

I

Fig

BE

20

Combination

Meter

1

Water

temperature

gauge

2

Speedometer

3

Turn

signal

pilot

lamp

4

Fuel

level

gauge

5

High

beam

pilot

lamp

6

Oil

pressure

warning

lamp

7

Charge

warning

lamp

8

Illumination

lamp

9

Turn

signal

pilot

lamp

10

To

speedometer

cable

11

Illumination

lamp

12

Illumination

lamp

13

Charge

warning

lamp

14

Oil

pressure

warning

lamp

15

Illumination

lamp

16

High

beam

pilot

lamp

12

1

11

00

o

100

6

gO

80

0

7

2

o

3

o

04

Os

o

6

U

4

u

6

BE125D

BE13

Page 459 of 548

Body

Electrical

System

DISASsEMlU

Y

AND

ASSEI

t18LV

BE126D

Fig

BE

21

Combination

Meter

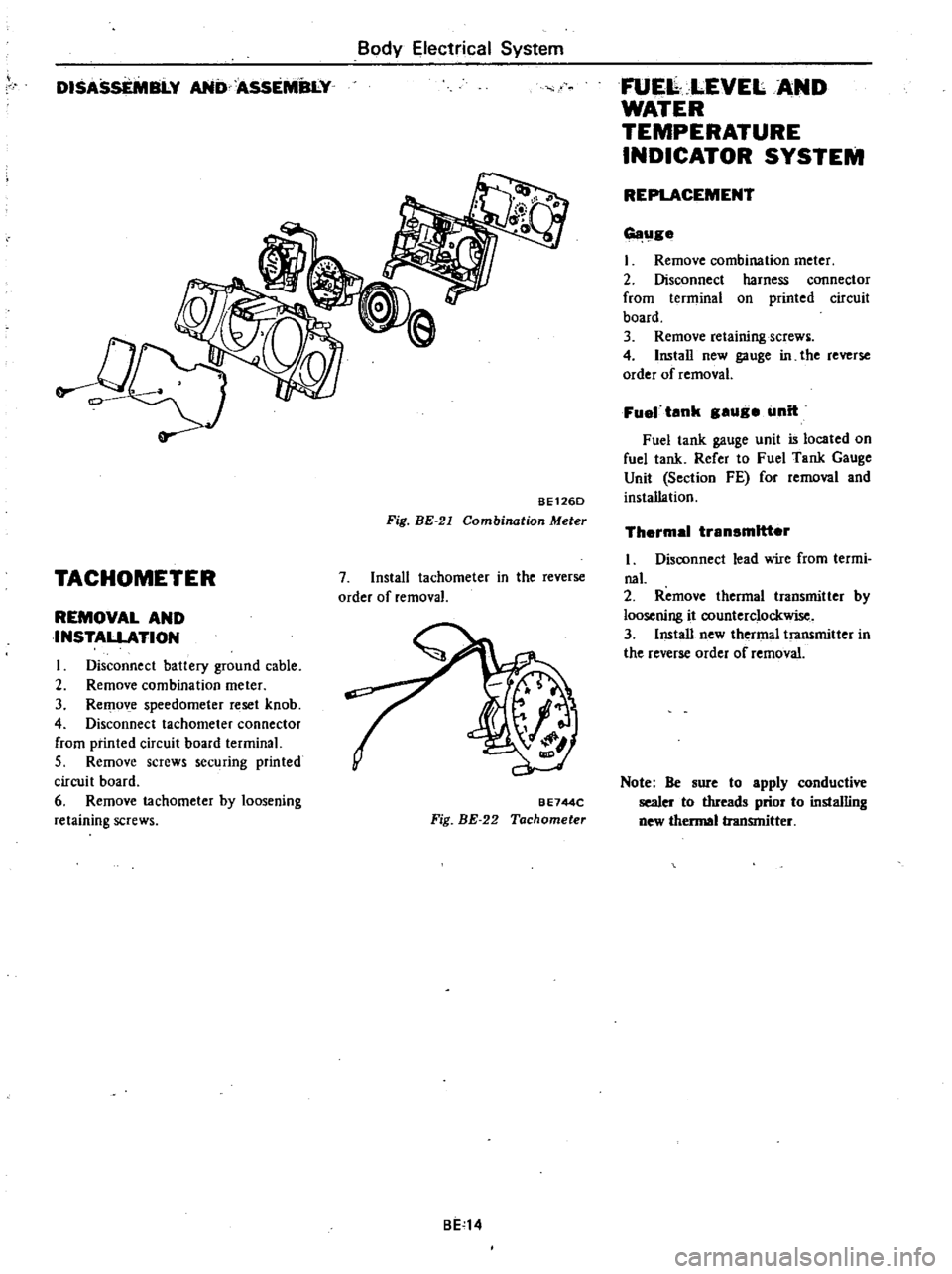

TACHOMETER

7

Install

tachometer

in

the

reverse

order

of

removal

REMOVAL

AND

INSTALLATION

I

Disconnect

battery

ground

cable

2

Remove

combination

meter

3

RemO

e

speedometer

reset

knob

4

Disconnect

tachometer

connector

from

printed

circuit

board

terminal

5

Remove

screws

securing

printed

circui

t

board

6

Remove

tachometer

by

loosening

retaining

screws

BE744C

Fig

BE

22

Tachometer

BE

14

FUE

LEVELAND

WATER

TEMPERATURE

INDICATOR

SYSTEM

REPLACEMENT

G11l1ge

I

Remove

combination

meter

2

Disconnect

harness

connector

from

terminal

on

printed

circuit

board

3

Remove

retaining

screws

4

Install

new

gauge

in

the

reverse

order

of

removal

Fuel

tank

gauge

unit

Fuel

tank

gauge

unit

is

located

on

fuel

tank

Refer

to

Fuel

Tank

Gauge

Unit

Section

FE

for

removal

and

installation

Thermal

transmitter

I

Disconnect

lead

wire

from

termi

naL

2

Remove

thermal

transmitter

by

loosening

it

oountercIockwise

3

Install

new

thermal

transmitter

in

the

reverse

order

of

removal

Note

Be

aure

to

apply

conductive

sealer

to

threads

prior

to

installing

new

hennal

transmitter

Page 475 of 548

WIPER

MOTOR

WINDSHIELD

WASHER

MOTOR

REAR

WIPER

MOTOR

REAR

WINDOW

WASHER

MOTOR

m

w

o

HORN

CIGARETTE

LIGHTER

CLOCK

HAZARD

FLASHER

LAMP

STOP

LAMP

ROOM

LAMP

LUGGAGE

ROOM

LAMP

TAIL

LAMP

CLEARANCE

LAMP

LICENSE

PLATE

LAMP

COMBINATION

METER

LAMP

l

I

ll

6

C

l

ii

en

g

0

o

m

till

oill

l

I

t1

l

CO

l

m

l

m

0

z

t

15A

10A

14

fA

20A

16

T

r

t1

l

t1

l

CO

CO

CJ

CJ

1

1

m

m

0

0

z

z

HEATER

lAIR

CONDITIONER

ENGINE

REVOLUTION

SWITCH

FUEL

CUT

SOLENOID

VACUUM

CUT

SOLENOID

AUTO

CHOKE

HEATER

THROTTLE

OPENER

SOLENOID

TURN

SIGNAL

LAMP

GAUGE

I

FUEL

L

WATER

TEMPERATURE

WARNING

LAMP

BRAKE

CHARGE

OIL

PRESSURE

SEAT

BELT

WARNING

BUZZER

BACK

UP

LAMP

KICKDOWN

SOLENOID

TACHOMETER

REAR

DEFOGGER

f

c

It

1

1

m

g

II

n

a

n

c

It

c

1J

c

CIl

z

G

S

3

OJ

o

Cl

m

CD

In

Ql

Page 486 of 548

Body

Electrical

System

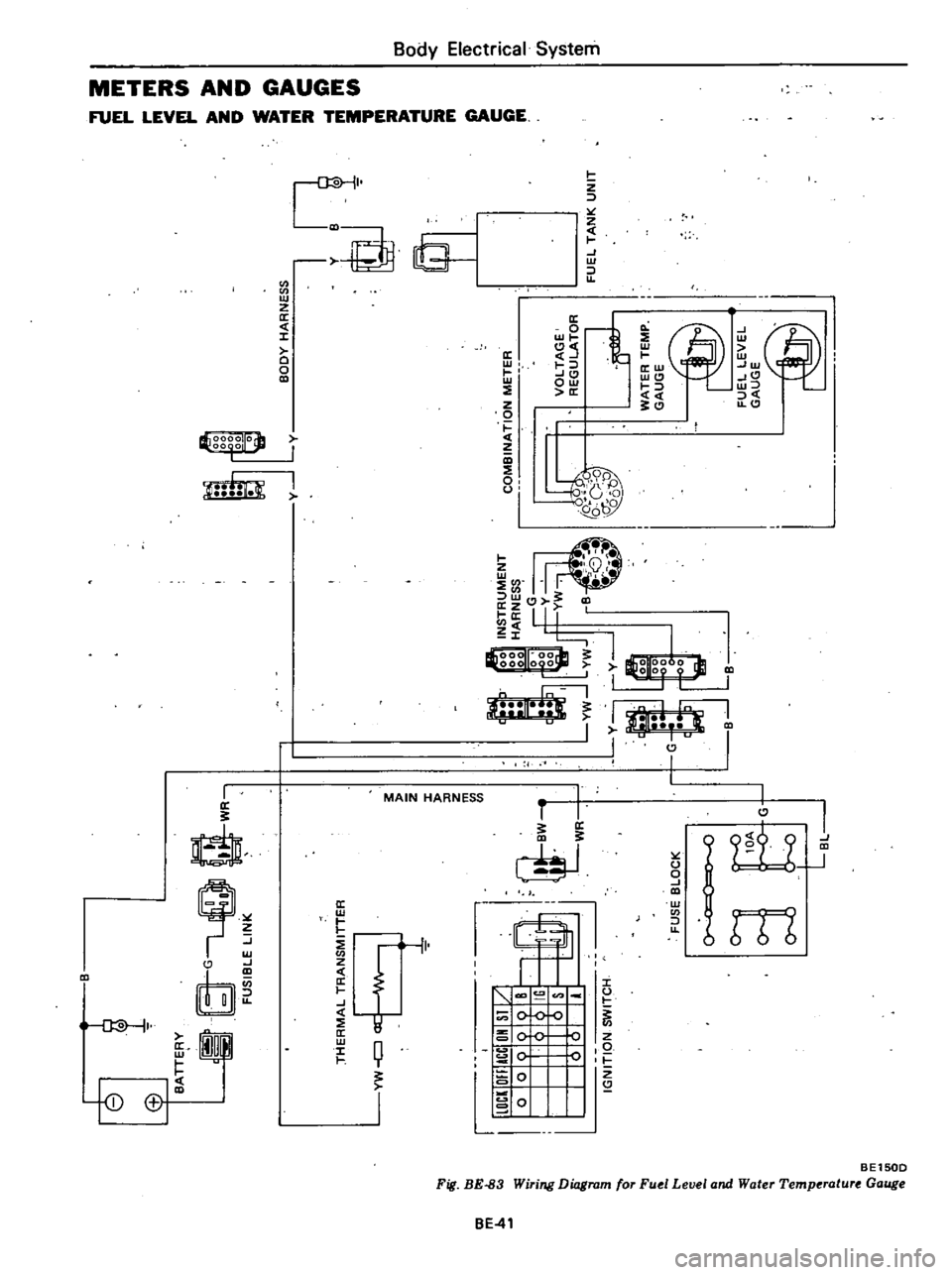

METERS

AND

GAUGES

FUEL

LEVEL

AND

WATER

TEMPERATURE

GAUGE

riiOOOOIIO

OO

OI

J

II

I

0

riJn

C

J

1

1

ffi

QM

fD

01

II

z

z

J

W

u

Q

lb

en

en

w

Z

0

J

o

o

wg

l

JC

Ow

0

0

w

w

z

o

z

o

0

6

Pp

J

1

t6

0

0

0

co

2

Q

I

z

w

E

w

C1

CD

0

Z

L

I

L

0

I

c

J

1

0

fggglr

gg

i

J

MAIN

HARNESS

T

I

0

0

w

c

r

t

f

Tf

i1

en

Z

0

J

f

l

J

J

0

0

0

0

010

01

w

Q

Z

J

u

0

lC

a

to

IE

a

Z

S

I

t

0

L

L

wC1

1CJ

w

cct

0

3

CJ

LLO

f

I

I

CD

1

I

O

Z

Q

1

J

J

o

J

W

en

u

m

BE150D

Fig

BE

83

Wiring

Diagram

for

Fu

l

Leuel

and

Water

Temperature

Gauge

BE

41

Page 487 of 548

Fuel

level

gauge

Condition

Fuel

level

gauge

does

not

operate

Pointer

indicates

only

F

10

position

Fuel

level

gauge

does

not

operate

accurately

Body

Electrical

System

Probable

cause

Faulty

fuel

gauge

tank

unit

or

loose

unit

terminal

connection

pointer

deflects

when

fuel

gauge

tank

unit

yellow

wire

isgrounded

Faulty

fuel

level

gauge

Loose

connection

or

open

circuit

Faulty

fuel

gauge

tank

unit

Pointer

drops

below

E

0

mark

when

ignition

switch

is

turned

off

Faulty

fuellevel

gauge

pointer

still

indicates

F

10

position

when

ignition

switch

is

turned

off

Faulty

fuel

gauge

tank

unit

Faulty

fuel

level

gauge

Poor

or

loose

connection

Faulty

gauge

voltage

regulator

Gauge

pointer

fluctuates

excessively

Condition

Water

temperature

gauge

Probable

cause

Water

temperature

gauge

does

not

operate

Gauge

indicates

only

maximum

temperature

Water

temperature

gauge

does

not

operate

accurately

Faulty

therrruiJ

transmitter

or

loose

terminal

connection

When

yellow

white

wire

to

thermal

trans

mitter

is

grounded

gauge

pointer

fluctuates

Faulty

water

temperature

gauge

Open

circuit

Faulty

thermal

transmitter

Gauge

pointer

returns

to

original

position

when

ignition

switch

is

turned

off

Faulty

water

temperature

gauge

Gauge

pointer

indicates

maximum

tempera

ture

even

after

ignition

switch

is

turned

off

Faulty

water

temperature

gauge

Loose

or

poor

connection

BE

42

Corrective

action

Replace

fuel

gauge

tank

unit

or

correct

terminal

connection

Replace

Check

wiring

and

or

repair

connection

Replace

Replace

Replace

Replace

fuel

level

gauge

Correct

connector

terminal

contact

Replace

fuel

level

gauge

Main

or

water

temperature

gauge

Sub

Corrective

action

Replace

thermal

transmitter

or

correct

ter

minal

connection

Replace

water

temperature

gauge

Replace

thermal

transmitter

Replace

water

temperature

gauge

Replace

water

temperature

gauge

Correct

connector

terminal

contact

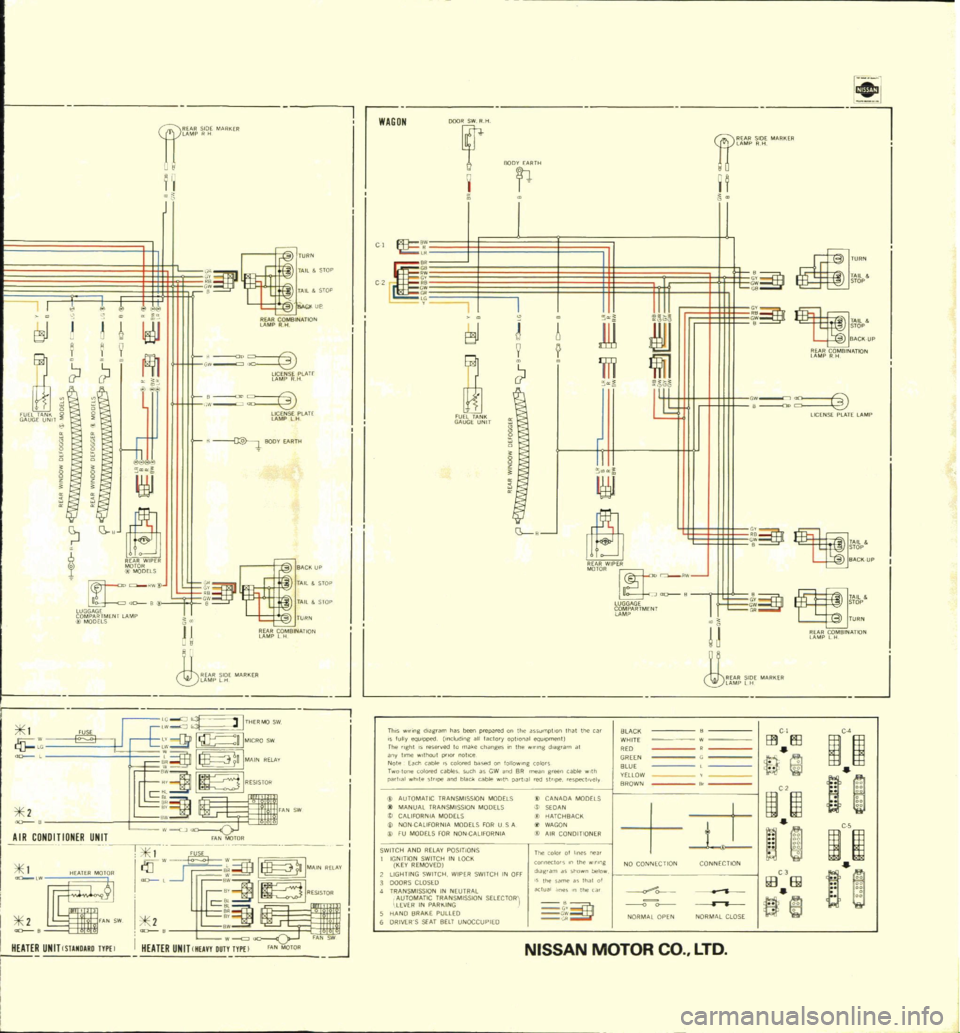

Page 547 of 548

C

E3J

i

I

u

r

o

alNATIO

1

9

fl

l

w

tif

S

lATr

u

N

T

i

0

lf

5f

lAH

8

g

llOOY

AIITI

0

BI

b

RWIPER

IoOODELS

a

RW

LUGGAGf

aD

B

iO

b

n

rNr

lAMP

1

FUSE

1

AIR

CONDnION

R

UNIT

1

lii

I

I

N

UNITCSlAMD

UOTYPEl

I

LAMP

lH

ARKER

Th

ng

diagram

ha

been

fullyeqU1pped

nclod

p

wredontheas

The

ght

IS

e

erv

l

og

all

factory

optIonal

SUmQtron

tllat

the

car

BLACK

any

tme

II

1aut

to

make

chang

s

In

the

eQU

Omefll

Note

EaCh

cao

ro

notICe

l

d

g

am

at

WHITE

D

CI

r

olon

colO

E

d

Ca

Iore

l

ba

ed

on

1011010

ffi

El3

C4

pa

l

a

wh

te

Sl

l

bles

Suel

as

GW

n

8R

g

colors

GREEN

1m

o11Id

blaCk

cao

th

pa

l

I

n

5

at

l@

Il

BLUE

C

AUTOMATIC

fRAN

pe

l

tely

YlilOW

I

MANUAL

TRAN

M

MISSION

MODUS

BROWN

1

CALIFORNIA

MOD

ION

MODELS

A

MODELS

w

w

B

j

NONCAUroRNIA

I

HATCHBACK

It

it

FU

MODEtS

FOR

tS

FOR

USA

WAGON

AllFORN

A

t

AIR

CONDITIONER

SWITCH

AND

RE

J

IGNITION

SWI

Y

POSITIONS

KEY

REMOVEO

IN

lOCII

n

co

o

011

@

1

1

LIGHTING

SWITCH

W

P

con

10

lhe

w

n

g

DOORS

CtoSlO

ER

SWITCH

IN

OFF

TRANSMISSION

m

hown

be

w

NO

CONNECTION

CONNECTION

AUtOMATIC

T

EUTRAl

I

me

th

of

lEVER

IN

PAIU

IN

SSIDN

SlLECfORi

oKlualhne

nthec

HANOBRAIIEPUllEO

t

ffi

III

fi

ORIVEWS

SEAT

BELT

UNOCCUPIED

@

C

JiOR

lOPEN

NORMAL

CLOSE

NISSAN

MOTOR

tl

J

w

iJ

j

II

C

TA

l

SfOP

t

o

L

SlOP

fUPN

lj

ro

elNA

TI

N

JbtJ

1

G

J

W

1

J

ITHERMO

sw

B

H

IMICRO

sw

1

l

n

MA

IN

RELA

V

c

1W231

rAN

SW

I

A

NMOTOR

of

l

I

rr

I

I

I

c

1m231

i

11

II

i

HEATER

UNIT

Mun

DUT

FA

N

J

WAGON

t

o

a

ijE

c

r

g

E3J

FUEl

Tjl

NII

GA

LJGE

UNIT

JL

OODfi

11

tl

DJ

H

t

ow

J

TA

l

BA

CII

UP

rI

O

BlNjl

TIOf

l

J

9

111

fi

l

JID

l

6

o

o

c

II

LICENSE

PLA

TE

LAMP

ijf

I

LUGGAGE

R

r2

ARTMENI

C

ow

Tjl

ll

STOP

IIA

CIIUP

t

C

co

STOP

fURN

n

ro

fBINA

TION

I

J

CO

LTD