lock DATSUN 210 1979 Service Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 8 of 548

r

IDENY

iFICAYiON

NUMBER

PLATE

The

identification

number

plate

is

located

on

the

upper

surface

of

the

instrument

panel

and

can

be

seen

from

outside

through

the

windshield

glass

The

identification

number

consists

of

the

car

model

and

the

serial

number

LC024

Fig

GI

3

Identification

Number

Plate

JAJcation

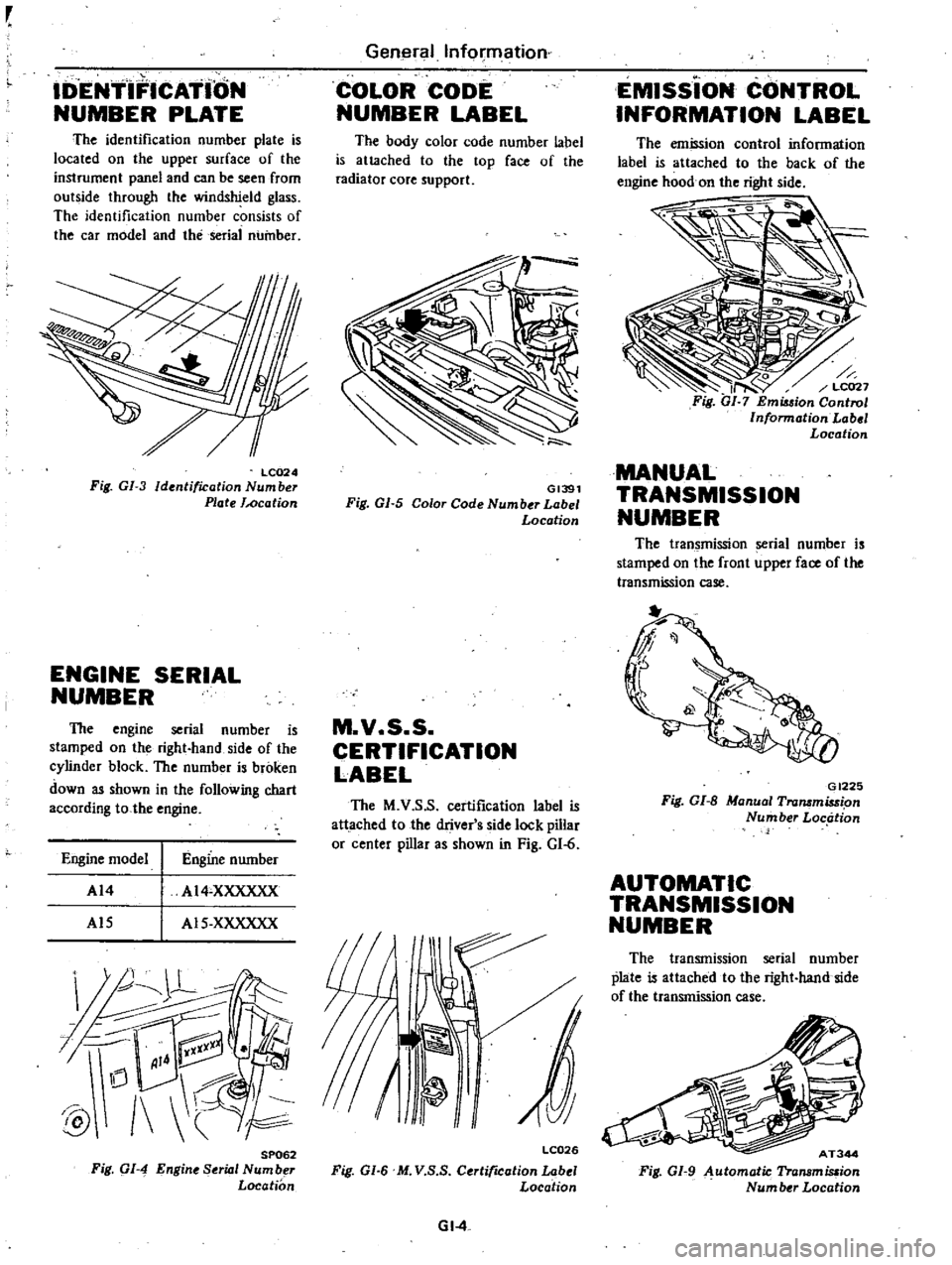

ENGINE

SERIAL

NUMBER

The

engine

serial

number

is

stamped

on

the

right

hand

side

of

the

cylinder

block

The

number

is

broken

down

as

shown

in

the

following

chart

according

tothe

engine

Engine

model

Engine

number

AI4

AIS

AI4

XXXXXX

AIS

XXXXXX

J

lL

@

1

C

SP062

Fig

C

1

4

Engine

Serial

Numbf

Location

General

Information

COLOR

CODt

NUMBER

LABEL

The

body

color

code

number

label

is

attached

to

the

top

face

of

the

radiator

core

support

GI391

Fig

GI

5

Color

Code

Number

Label

Location

M

V

5

S

CERTIFICATION

LABEL

The

M

V

S

S

certification

label

is

attached

to

the

driver

s

side

lock

pillar

or

center

pillar

as

shown

in

Fig

GI

6

s

I

p

LC026

Fig

GI

6

M

V

S

S

Certification

Label

Location

GI

4

EMISSION

CONTROL

INFORMATION

LABEL

The

emission

control

information

label

is

attached

to

the

back

of

the

engine

hood

on

the

right

side

MANUAL

TRANSMISSION

NUMBER

The

transmission

rial

number

is

stamped

on

the

front

upper

face

of

the

transmission

case

GI225

Fig

GI

B

Manual

Transmission

Number

Loc

zti

on

AUTOMATIC

TRANSMISSION

NUMBER

The

transmission

serial

number

plate

is

attached

to

the

right

hand

side

of

the

transmission

case

AT344

Fig

Gl

9

Automatic

Transmission

Num

ber

Location

Page 13 of 548

General

Information

LIFTING

POINTS

AND

TOWING

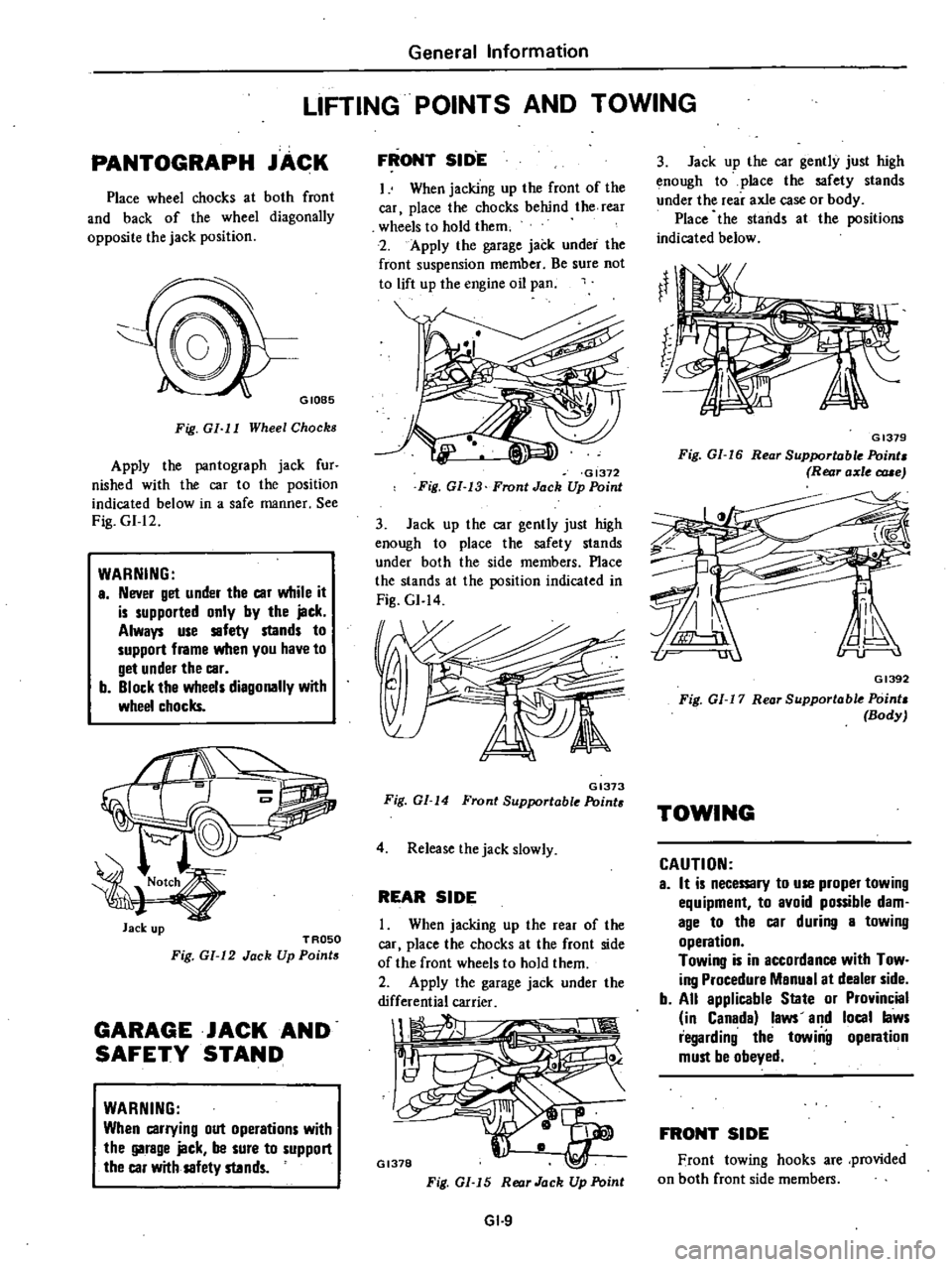

PANTOGRAPH

JACK

Place

wheel

chocks

at

both

front

and

back

of

the

wheel

diagonally

opposite

the

jack

position

GIOB5

Fig

GI

I

I

Wheel

Chocks

Apply

the

pantograph

jack

fur

nished

with

the

car

to

the

position

indicated

below

in

a

safe

manner

See

Fig

GI

12

WARNING

a

Never

get

under

the

car

while

it

is

supported

only

by

the

jack

Always

use

safety

stands

to

support

frame

when

you

have

to

get

under

the

car

b

Block

the

wheels

diagonally

with

wheel

chocks

Jack

up

TROSO

Fig

GI

12

Jack

Up

Points

GARAGE

JACK

AND

SAFETY

STAND

WARNING

When

carrying

out

operations

with

the

garage

jack

be

sure

to

support

the

car

with

safety

stands

FRONT

SID

E

I

When

jacking

up

the

front

of

the

car

place

the

chocks

behind

the

rear

wheels

to

hold

them

2

Apply

the

garage

jack

under

the

front

suspension

member

Be

sure

not

to

lift

up

the

engine

oil

pan

GI372

Fig

GI

13

Front

Jack

Up

Point

3

Jack

up

the

car

gently

just

high

enough

to

place

the

safety

stands

under

both

the

side

members

Place

the

stands

at

the

position

indicated

in

Fig

GI

14

GI373

Fig

GI

14

Front

Supportable

Point

4

Release

the

jack

slowly

REAR

SIDE

When

jacking

up

the

rear

of

the

car

place

the

chocks

at

the

front

side

of

the

front

wheels

to

hold

them

2

Apply

the

garage

jack

under

the

differential

carrier

1

1

Il

GI378

Fig

GI

15

Rear

Jack

Up

Point

GI

9

3

Jack

up

the

car

gently

just

high

enough

to

place

the

safety

stands

under

the

rear

axle

case

or

body

Place

the

stands

at

the

positions

indicated

below

GI379

Fig

GI

16

Rear

Supportable

Point

Rear

axle

c

rue

GI392

Fig

01

17

Rear

Supportable

Point

Body

TOWING

CAUTION

a

It

is

necemry

to

use

proper

towing

equipment

to

avoid

possible

dam

age

to

the

car

during

a

towing

operation

Towing

is

in

accordance

with

Tow

ing

Procedure

Manual

at

dealer

side

b

All

applicable

State

or

Provincial

in

Canada

laws

and

local

laws

regarding

the

towiilg

operation

must

be

obeyed

FRONT

SIDE

Front

towing

hooks

are

provided

on

both

front

side

members

Page 17 of 548

Engine

Tune

up

BASIC

MECHANICAL

SYSTEM

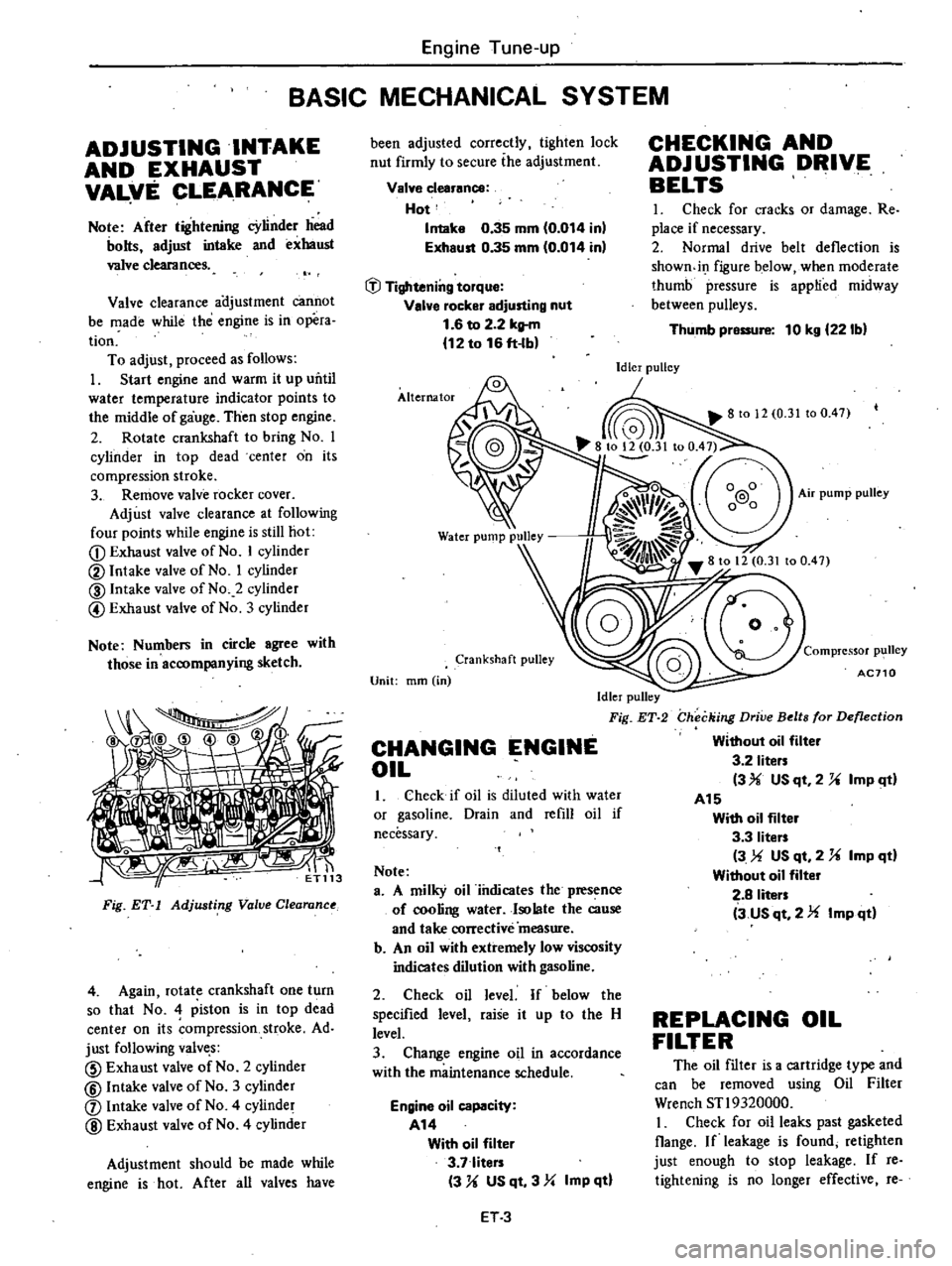

ADJUSTING

INTAKE

AND

EXHAUST

VAL

fE

CLEARANCE

Note

After

tightening

cYlinder

head

bolts

adjust

intake

and

exhaust

valve

clearances

Valve

clearance

ai

ljustment

cannot

be

made

while

the

engine

is

in

opera

tion

To

adjust

proceed

as

follows

I

Start

engine

and

warm

it

up

uritil

water

temperature

indicator

points

to

the

middle

of

gauge

Then

stop

engine

2

Rotate

crankshaft

to

bring

No

I

cylinder

in

top

dead

center

on

its

compression

stroke

3

Remove

valve

rocker

cover

Adjust

valve

clearance

at

following

four

points

while

engine

is

still

hot

CD

Exhaust

valve

of

No

I

cylinder

@

Intake

valve

of

No

I

cylinder

@

Intake

valve

of

No

2

cylinder

@

Exhaust

valve

of

No

3

cylinder

Note

Numbers

in

circle

agree

with

those

in

accompanying

sketch

tiri

Fig

ET

1

Adjusting

Value

Clearanu

4

Again

rotate

crankshaft

one

turn

so

that

No

4

piston

is

in

top

dead

center

on

its

ompression

stroke

Ad

just

following

valve

s

CID

Exhaust

valve

of

No

2

cylinder

@

Intake

valve

of

No

3

cylinder

j

Intake

valve

of

No

4

cylinder

@

Exhaust

valve

of

No

4

cylinder

Adjustment

should

be

made

while

engine

is

hot

After

all

valves

have

been

adjusted

correctly

tighten

lock

nut

firmly

to

secure

ihe

adjustment

Valve

clearance

Hot

Intake

0

35

mm

0

014

inl

Exhaust

0

35

mm

0

014

in

tJl

Tightening

torque

Valve

rocker

adjusting

nut

1

6

to

2

2

kltm

12

to

16

ft

lb

Alternator

Crankshaft

pulley

Unit

mm

in

Idler

pulley

Fig

ET

2

CHANGING

ENGINE

OIL

1

Check

if

oil

is

diluted

with

water

or

gasoline

Drain

and

refill

oil

if

necessary

Note

a

A

milky

oil

iiulicates

the

presence

of

cooling

water

Isolate

the

cause

and

take

corrective

measure

b

An

oil

with

extremely

low

viscosity

indicates

dilution

with

gasoline

2

Check

oil

level

If

below

the

specified

level

raise

it

up

to

the

H

level

3

Change

engine

oil

in

accordance

with

the

maintenance

schedule

Engine

oil

capacity

A14

With

oil

filter

3

7

liters

3

U

US

qt

3

Yo

Imp

qtl

ET3

CHECKING

AND

ADJUSTING

DRIVE

BELTS

I

Check

for

cracks

or

damage

Re

place

if

necessary

2

Normal

drive

belt

deflection

is

showndI

figure

below

when

moderate

thumb

pressure

is

applied

midway

between

pulleys

Thumb

pressure

10

kg

221bl

Idler

pulley

Compressor

p1

111ey

AC710

Checking

Drive

Belts

for

Deflection

Without

oil

filter

3

2

liters

3

USqt

2

U

ImP

ltl

A15

With

oil

filter

3

3

liters

3

US

qt

2

U

Imp

qd

Without

oil

filter

2

8

liters

3

us

qt

2

Imp

qd

REPLACING

OIL

FILTER

The

oil

filter

is

a

cartridge

type

and

can

be

removed

using

Oil

Filter

Wrench

STl9320000

I

Check

for

oil

leaks

past

gasketed

Oange

If

leakage

is

found

retighten

just

enough

to

stop

leakage

If

reo

tightening

is

no

longer

effective

re

Page 19 of 548

sion

pressure

chances

are

that

piston

rings

are

worn

or

damaged

2

If

pressure

stays

low

the

likeli

hood

is

that

valve

is

sticking

or

seating

Engine

Tune

up

improperly

3

If

cylinder

compression

in

any

two

adjacent

cylinders

is

low

and

if

adding

oil

does

not

help

the

compres

sion

there

is

leakage

past

the

gasketed

surface

Oil

and

water

in

combustion

cham

bers

can

result

from

this

problem

IGNITION

AND

FUEL

SYSTEM

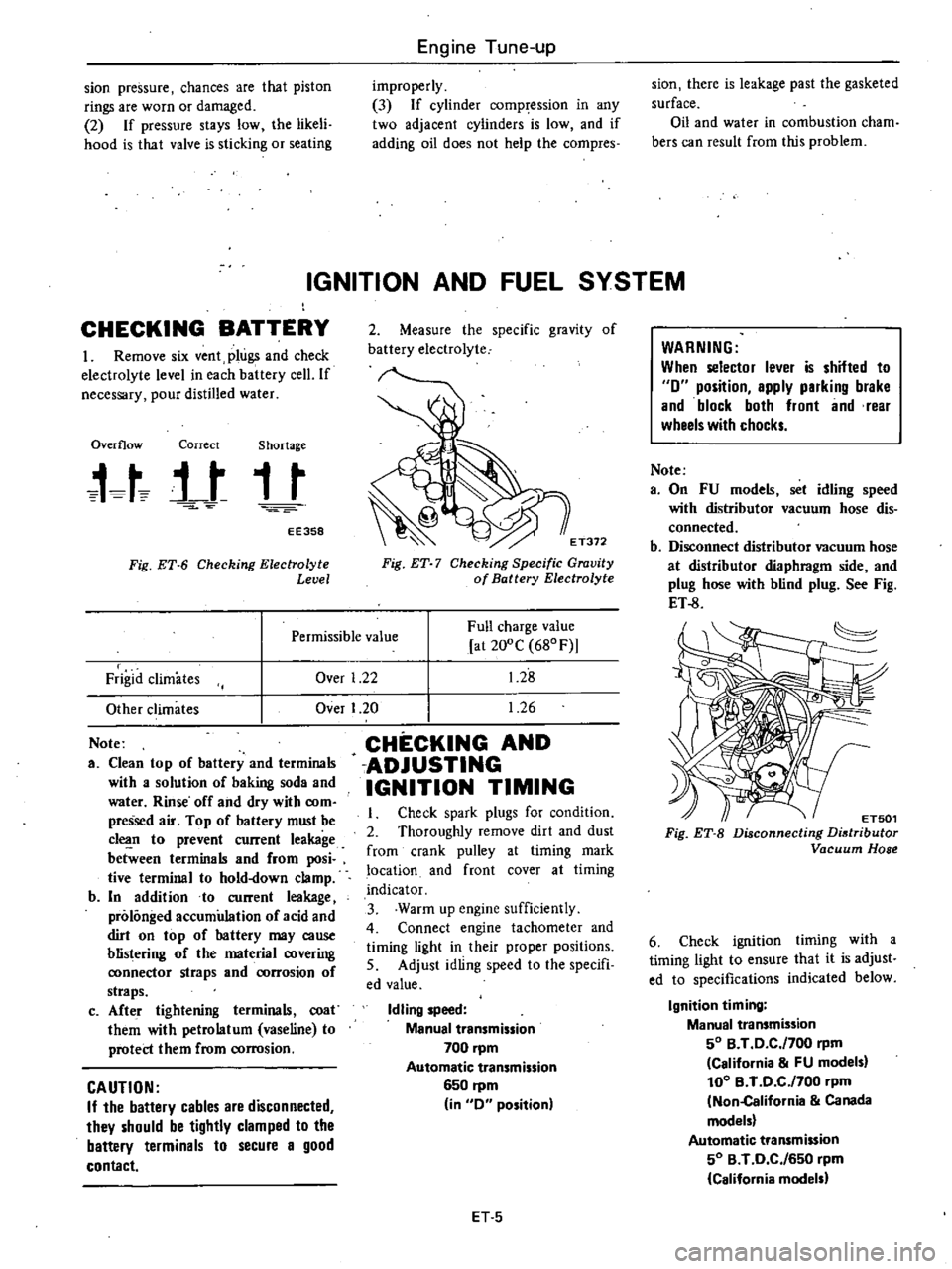

CHECKING

BATTERY

I

Remove

six

vent

plugs

and

check

electrolyte

level

in

each

battery

cell

If

necessary

pour

distilled

water

Overflow

Correct

Shortage

t

t

j

t

t

t

EE358

Fig

ET

6

Checking

Electrolyte

Level

2

Measure

the

specific

gravity

of

battery

electrolyte

E

T372

Fig

ET

7

Checking

Specific

Gravity

of

Battery

Electrolyte

Over

1

22

Full

charge

value

at

200C

680F

1

28

1

26

Permissible

value

Frigid

climates

Other

climates

Note

a

Clean

top

of

battery

and

terminals

with

a

solution

of

baking

soda

and

water

Rinse

off

and

dry

with

com

pressed

air

Top

of

battery

must

be

c1

n

to

prevent

current

leakage

between

terminals

and

from

posi

tive

terminal

to

hold

down

clamp

b

In

addition

to

current

leakage

prolonged

accumulation

of

acid

and

dirt

on

top

of

hattery

may

cause

blistering

of

the

material

covering

ronnector

straps

and

rorrosion

of

straps

c

Afte

r

tightening

terminals

coat

them

with

petrolatum

vaseline

to

protect

them

from

corrosion

CAUTION

If

the

battery

cables

are

disconnected

they

should

be

tightly

clamped

to

the

battery

terminals

to

secure

a

good

contact

Over

I

20

CHECKING

AND

ADJUSTING

IGNITION

TIMING

Check

spark

plugs

for

condition

2

Thoroughly

remove

dirt

and

dust

from

crank

pulley

at

timing

mark

location

and

front

cover

at

timing

indicator

3

Warm

up

engine

sufficiently

4

Connect

engine

tachometer

and

timing

light

in

their

proper

positions

5

Adjust

idling

speed

to

the

specifi

ed

value

Idling

speed

Manual

transmission

700

pm

Automatic

transmission

6S0

rpm

in

0

position

ET

S

WARNING

When

selector

lever

is

shifted

to

0

position

apply

parking

brake

and

block

both

front

and

rear

wheels

with

chocks

Note

a

On

FU

models

set

idling

speed

with

distributor

vacuum

hose

dis

connected

b

Disconnect

distributor

vacuum

hose

at

distributor

diaphragm

side

and

plug

hose

with

blind

plug

See

Fig

ET

8

ET501

Fig

ET

B

Disconnecting

Distributor

Vacuum

Hose

6

Check

ignition

timing

with

a

timing

light

to

ensure

that

it

is

adjust

ed

to

specifications

indicated

below

Ignition

timing

Manual

transmission

SO

B

T

0

C

f700

rpm

California

FU

models

100

B

T

0

C

f700

pm

Non

California

Canada

models

Automatic

transmission

SO

B

T

0

C

f6S0

rpm

California

models

Page 20 of 548

SO

B

T

D

C

l650

rpm

Non

California

models

except

Canada

100

B

T

D

C

650

rpm

Canada

models

Note

On

FU

models

ignition

timing

is

set

under

a

condition

where

distributor

vacuum

hose

is

discon

nected

If

necessary

adjust

ignition

timing

as

follows

I

Loosen

set

screw

until

dis

tributor

c

uJ

be

moved

by

hand

2

Adjust

ignition

timing

to

speci

fications

3

Lock

distributor

set

screw

and

make

sure

that

timing

is

correct

YJ

Fig

T

9

Adjusting

Ignition

Timing

7

On

FU

models

proceed

as

fol

lows

I

Remove

blind

plug

from

dis

tributor

vacuum

hose

and

connect

hose

to

distributor

diaphragm

2

If

engine

speed

varies

in

this

state

set

idling

speed

at

specified

value

with

throttle

adjusting

screw

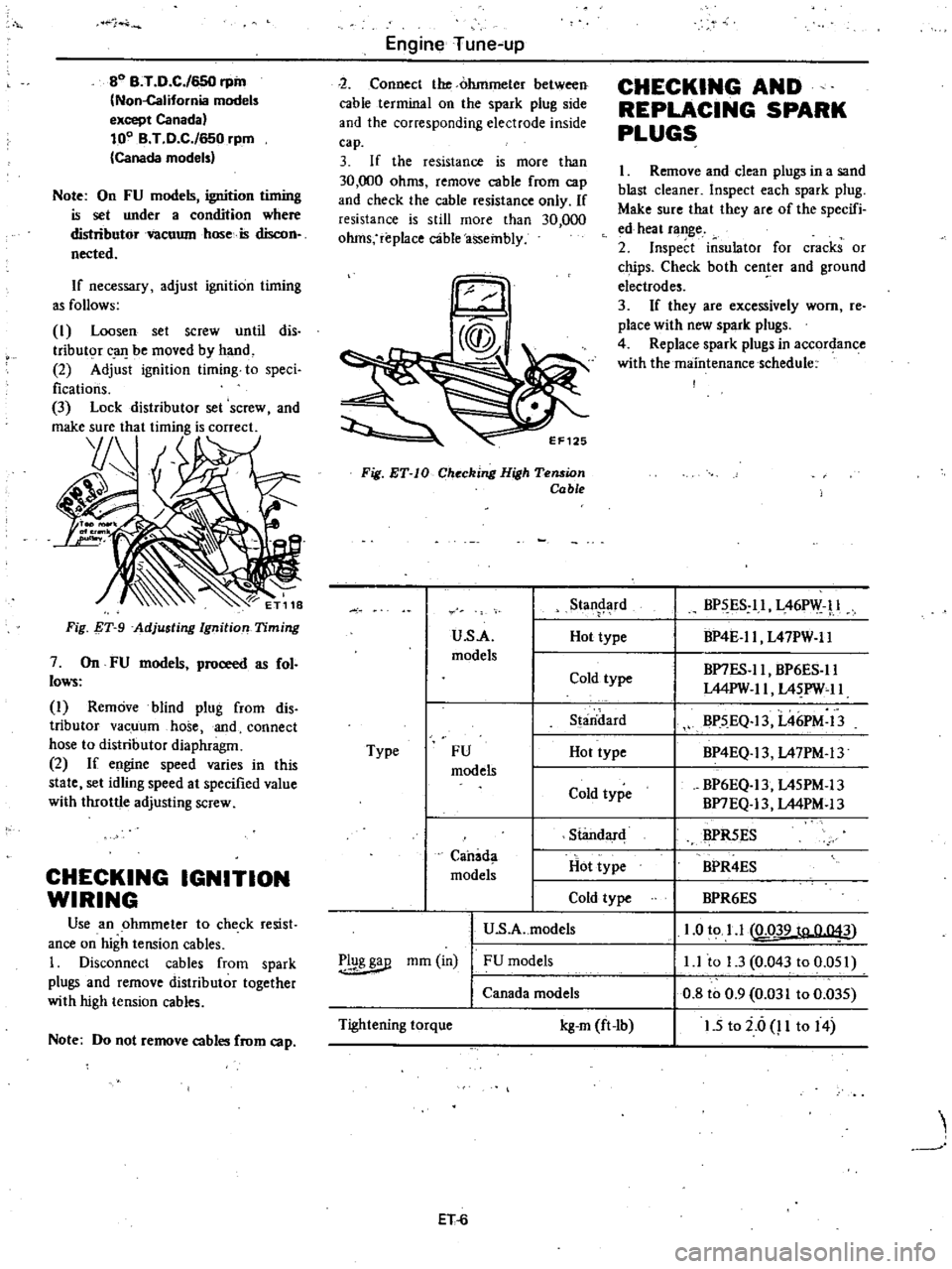

CHECKING

IGNITION

WIRING

Use

an

ohmmeter

to

check

resist

ance

on

high

tension

cables

1

Disconnect

cables

from

spark

plugs

and

remove

distributor

together

with

high

tension

cables

Note

Do

not

remove

cables

from

cap

Engine

Tune

up

2

Connect

the

ohmmeter

between

cable

terminal

on

the

spark

plug

side

and

the

corresponding

electrode

inside

cap

3

If

the

resistance

is

more

than

30

000

ohms

remove

cable

from

cap

and

check

the

cable

resistance

only

If

resistance

is

still

more

than

30

000

ohms

replace

c3ble

assembly

Fig

ET

IO

Checking

High

Tension

Cable

u

s

A

models

Type

FU

models

Standard

Hot

type

Cold

type

U

S

A

models

Canada

models

r

1g

mm

in

FU

models

Canada

models

Tightening

torque

kg

m

ft

lb

ET

6

Stan

rd

Hot

type

Cold

type

S

aridard

Hot

type

Cold

type

CHECKING

AND

REPLACING

SPARK

PLUGS

I

Remove

and

clean

plugs

in

a

sand

blast

cleaner

Inspect

each

spark

plug

Make

sure

that

they

are

of

the

specifi

ed

heat

range

2

Inspect

insulator

for

cracks

or

chips

Check

both

center

and

ground

electrodes

3

If

they

are

excessively

worn

re

place

with

new

spark

plugs

4

Replace

spark

plugs

in

accordance

with

the

maintenance

schedule

BP

ES

ll

L46PW

l

BP4E

ll

L47PW

ll

BP7ES

ll

BP6ES

ll

L44PW

II

L4

PW

11

BP5

EQ

13

L46PM

13

BP4EQ

13

L47PM

13

BP6EQ

13

L45PM

13

BP7EQ

13

L44PM

13

BPR5ES

BPR4ES

BPR6ES

1

0

to

1

1

LQ39

to

0

043

l

l

to

1

3

0

043

to

0

051

0

8

to

0

9

0

031

to

0

035

1

5

to

i

6

P

to

14

Page 21 of 548

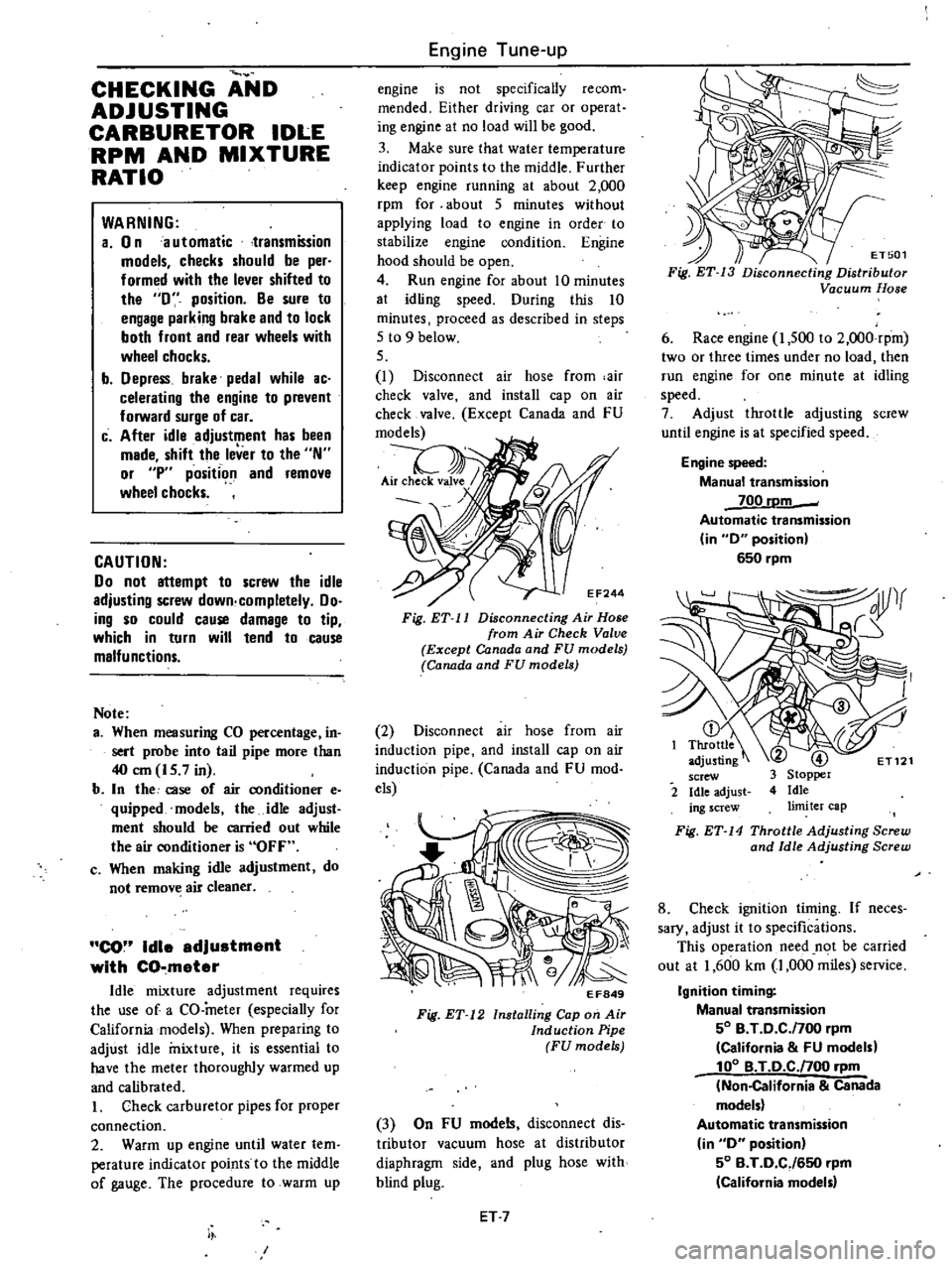

CHECKING

AND

ADJUSTING

CARBURETOR

IDLE

RPM

AND

MIXTURE

RATIO

WARNING

a

0

n

a

utomatic

transmission

models

checks

should

be

per

formed

with

the

lever

shifted

to

the

0

position

Be

sure

to

engage

parking

brake

and

to

lock

both

front

and

rear

wheels

with

wheel

chocks

b

Oepress

brake

pedal

while

ac

celerating

the

engine

to

prevent

forward

surge

of

car

c

After

idle

adjustment

has

been

made

shift

the

lever

to

the

N

or

P

positfon

and

remove

wheel

chocks

CAUTION

00

not

attempt

to

screw

the

idle

adjusting

screw

down

completely

00

ing

so

could

cause

damage

to

tip

which

in

turn

will

tend

to

cause

malfunctions

Note

a

When

measuring

CO

percentage

in

sert

probe

into

tail

pipe

more

than

40

cm

15

7

in

b

In

thee

case

of

air

conditioner

e

quipped

models

the

idle

adjust

ment

should

be

carried

out

while

the

air

conditioner

is

OFF

c

When

making

idle

adjustment

do

not

removt

air

cleaner

CO

Idle

adJustment

with

CO

meter

Idle

mixture

adjustment

requires

the

use

of

a

CO

meter

especially

for

California

models

When

preparing

to

adjust

idle

mixture

it

is

essential

to

have

the

meter

thoroughly

warmed

up

and

calibrated

1

Check

carburetor

pipes

for

proper

connection

2

Warm

up

engine

until

water

tern

perature

indicator

points

to

the

middle

of

gauge

The

procedure

to

warm

up

J

Engine

Tune

up

engine

is

not

specifically

recom

mended

Either

driving

car

or

operat

ing

engine

at

no

load

will

be

good

3

Make

sure

that

water

temperature

indicator

points

to

the

middle

Further

keep

engine

running

at

about

2

000

rpm

for

about

5

minutes

without

applying

load

to

engine

in

order

to

stabilize

engine

condition

Engine

hood

should

be

open

4

Run

engine

for

about

10

minutes

at

idling

speed

During

this

10

minutes

proceed

as

described

in

steps

5

to

9

below

5

I

Disconnect

air

hose

from

air

check

valve

and

install

cap

on

air

check

valve

Except

Canada

and

FU

models

EF244

Fig

ET

11

Disconnecting

Air

Hose

from

Air

Check

Valve

Except

Canada

and

FU

models

Canada

and

FU

models

2

Disconnect

air

hose

from

air

induction

pipe

and

install

cap

on

air

induction

pipe

Canada

and

FU

mod

els

EF849

Fig

ET

12

Installing

Cap

on

Air

Induction

Pipe

FU

models

3

On

FU

models

disconnect

dis

tributor

vacuum

hose

at

distributor

diaphragm

side

and

plug

hose

with

blind

plug

ET

7

ET501

Fig

ET

13

Disconnecting

Distributor

Vacuum

Hose

6

Race

engine

I

500

to

2

OOO

rpm

two

or

three

times

under

no

load

then

run

engine

for

one

minute

at

idling

speed

7

Adjust

throttle

adjusting

screw

until

engine

is

at

specified

speed

Engine

speed

Manual

transmission

700

rDm

Automatic

transmission

in

0

position

650

rpm

2

Fig

ET

14

Throttle

Adjusting

Screw

and

Idle

Adjusting

Screw

8

Check

ignition

timing

If

neces

sary

adjust

it

to

specifications

This

operation

need

n

t

be

carried

out

at

1

600

km

1

000

miles

service

Ignition

timing

Manual

transmission

50

B

T

0

C

f700

rpm

California

FU

models

100

B

T

O

C

noo

rpm

Non

California

Canada

models

Automatic

transmission

in

0

position

50

B

T

0

CJ650

rpm

California

model

Page 22 of 548

SO

B

T

D

C

650

rpm

Non

California

models

except

Canada

100

B

T

0

C

650

rpm

Canada

models

Note

On

FU

models

ignition

timing

t

under

a

con4ition

where

distnoutor

vacuum

hose

is

discon

nected

9

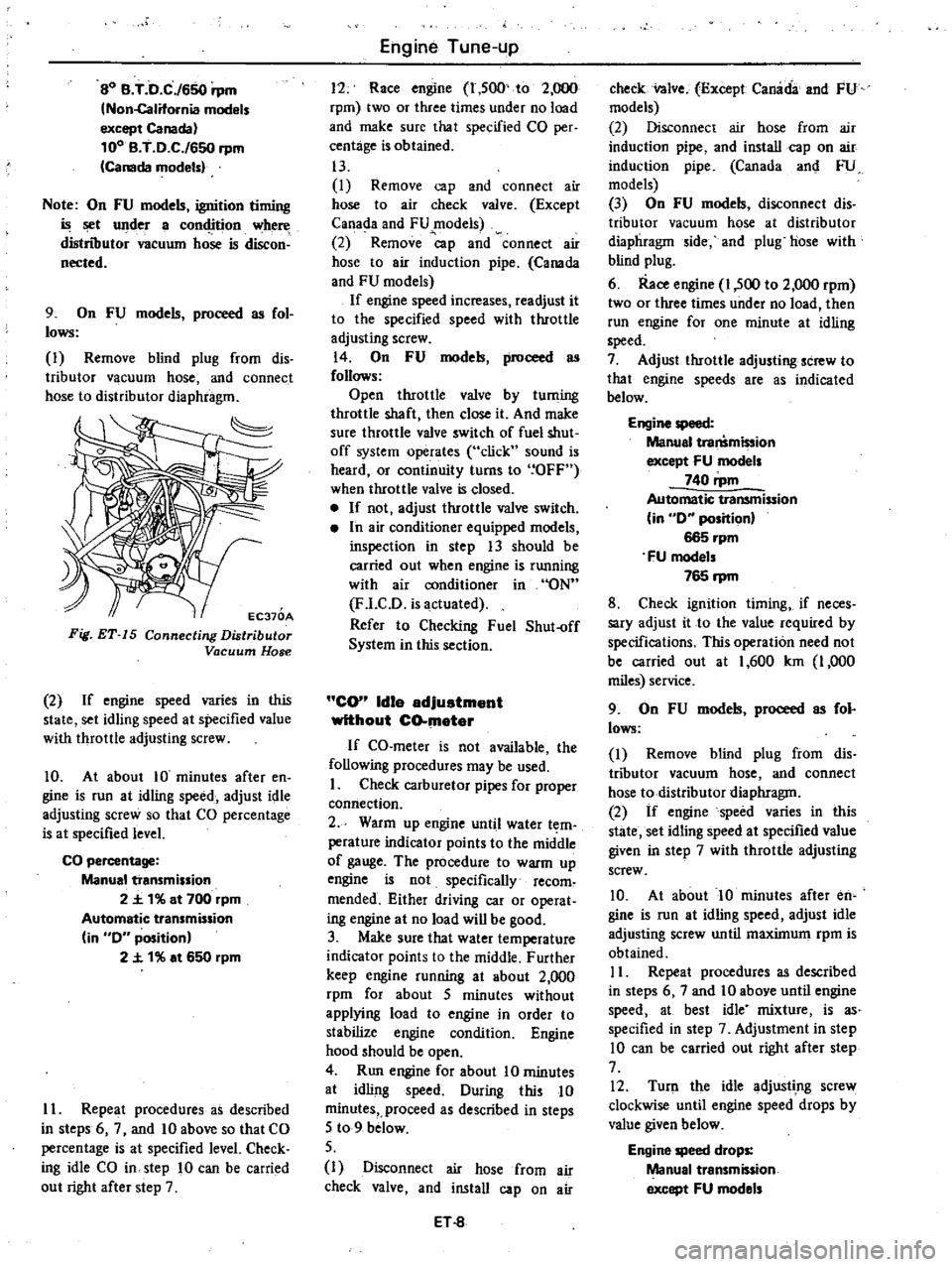

On

FU

models

proceed

as

fol

lows

I

Remove

blind

plug

from

dis

tributor

vacuum

hose

and

connect

hose

to

distributor

diaphragm

EC370A

Fig

ET

15

Connecting

Distributor

Vacuum

Hose

2

If

engine

speed

varies

in

this

state

set

idling

speed

at

specified

value

with

throttle

adjusting

screw

10

At

about

10

minutes

after

en

gine

is

run

at

idling

speed

adjust

idle

adjusting

screw

so

that

CO

percentage

is

at

specified

level

CO

percentage

Manual

transmission

2

t

1

at

700

rpm

Automatic

transmission

in

0

position

2

t

1

at

650

rpm

II

Repeat

procedures

as

described

in

steps

6

7

and

10

above

so

that

CO

percentage

is

at

specified

level

Check

ing

idle

CO

in

step

10

can

be

carried

out

right

after

step

7

Engine

Tune

up

11

Race

engine

1

500

to

2

000

rpm

two

or

three

times

under

no

load

and

make

sure

that

specified

CO

per

centage

is

obtained

13

I

Remove

cap

and

connect

air

hose

to

air

check

valve

Except

Canada

and

FU

models

2

Remove

p

and

connect

air

hose

to

air

induction

pipe

Canada

and

FU

models

If

engine

speed

increases

readjust

it

to

the

specified

speed

with

throttle

adjusting

screw

14

On

FU

models

proceed

as

follows

Open

throttle

valve

by

tuming

throttle

shaft

then

close

it

And

make

sure

throttle

valve

switch

of

fuel

shut

off

system

operates

click

sound

is

heard

or

continuity

turns

to

OFF

when

throttle

valve

is

closed

If

not

adjust

throttle

valve

switch

In

air

conditioner

equipped

models

inspection

in

step

13

should

be

carried

out

when

engine

is

running

with

air

conditioner

in

ON

F

l

CD

is

actuated

Refer

to

Checking

Fuel

Shut

off

System

in

this

section

CO

Idle

adjuatment

without

CO

mater

If

CO

meter

is

not

available

the

following

procedures

may

be

used

I

Check

carburetor

pipes

for

proper

comiection

2

Warm

up

engine

until

water

t

m

perature

indicator

points

to

the

middle

of

gauge

The

procedure

to

warm

up

engine

is

not

specifically

recom

mended

Either

driving

car

or

operat

ing

engine

at

no

load

will

be

good

3

Make

sure

that

water

temperature

indicator

points

to

the

middle

Further

keep

engine

running

at

about

2

000

rpm

for

about

5

minutes

without

applying

load

to

engine

in

order

to

stabilize

engine

condition

Engine

hood

should

be

open

4

Run

engine

for

about

10

minutes

at

idling

speed

During

this

10

minutes

proceed

as

described

in

steps

5

to

9

below

5

I

Disconnect

air

hose

from

air

check

valve

and

install

cap

on

air

ET

8

check

nlve

Except

Canada

and

FU

models

2

Disconnect

air

hose

from

air

induction

pipe

and

install

cap

on

air

induction

pipe

Canada

an

FU

models

3

On

FU

models

disconnect

dis

tributor

vacuum

hose

at

distributor

diaphragm

ide

and

plug

hose

with

blind

plug

6

Race

engine

1

500

to

2

000

rpm

two

or

three

times

under

no

load

then

run

engine

for

one

minute

at

idling

speed

7

Adjust

throttle

adjusting

screw

to

that

engine

speeds

are

as

indicated

below

Engine

speed

Manual

tra

mi

ion

except

FU

models

740

rpm

Automatic

transmission

in

0

position

665

rpm

FU

models

765

rpm

8

Check

ignition

timing

if

neces

sary

adjust

it

to

the

value

required

by

specifications

This

operation

need

not

be

carried

out

at

1

600

km

1

000

miles

service

9

On

FU

models

proceed

as

fol

lows

I

Remove

blind

plug

from

dis

tributor

vacuum

hose

and

connect

hose

to

distributor

diaphragm

2

If

engine

speed

varies

in

this

state

set

idling

speed

at

specified

value

given

in

step

7

with

throttle

adjusting

screw

10

At

about

10

minutes

after

en

gine

is

run

at

idling

speed

adjust

idle

adjusting

screw

until

maximum

rpm

is

obtained

II

Repeat

procedures

as

described

in

steps

6

7

and

10

above

until

engine

speed

at

best

idle

mixture

is

as

specified

in

step

7

Adjustment

in

step

10

can

be

carried

out

right

after

step

7

12

Turn

the

idle

adjustIng

screw

clockwise

until

engine

speed

drops

by

value

given

below

Engine

speed

drops

Manual

transmission

except

FU

models

Page 26 of 548

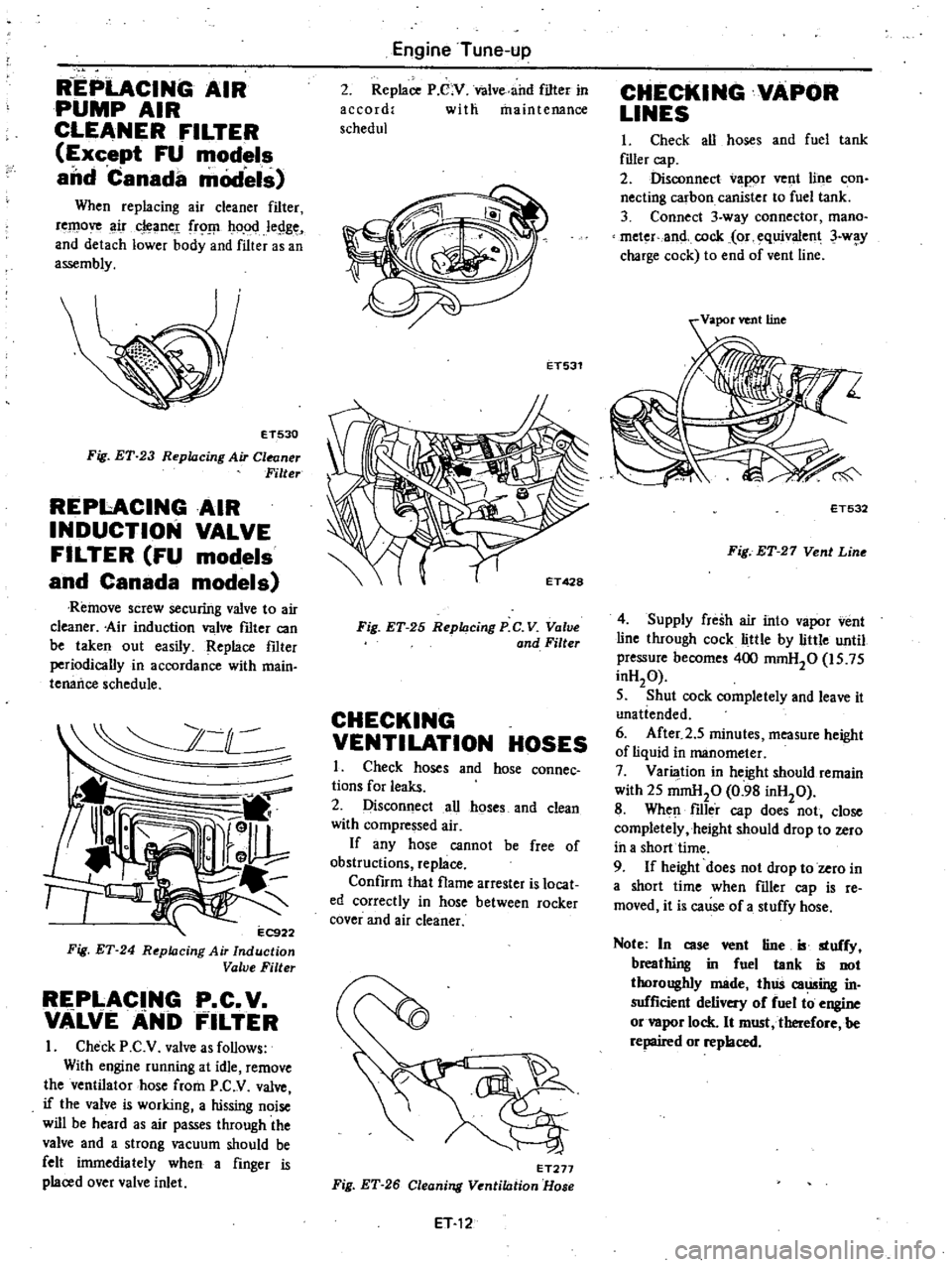

R

EPIACING

AIR

PUMP

AIR

CLEANER

FILTER

Except

FU

models

and

Canada

models

When

replacing

air

cleaner

filter

remove

ir

cleane

frO

ho

od

legge

and

detach

lower

body

and

filter

as

an

assembly

ET530

Fig

ET

23

Replacing

Air

Cleaner

Filter

REPI

ACINGAIR

INDUCTION

VALVE

FILTER

FU

models

and

Canada

models

Remove

screw

securirtg

valve

to

air

cleaner

Air

induction

valve

fIlter

can

be

taken

out

easily

Replace

fIlter

periodically

in

accordance

with

main

tenance

schedule

2

C

l

11

l

r

r

EC9

Fig

ET

24

R

pklcing

Air

Induction

Value

Filter

REPLACING

P

C

V

VALVEANb

FILTER

I

Check

P

C

V

valve

as

follows

With

engine

running

at

idle

remove

the

ventilator

hose

from

P

C

V

valve

if

the

valve

is

working

a

hissing

noise

will

be

heard

as

air

passes

through

the

valve

and

a

strong

vacuum

should

be

felt

inunediately

when

a

finger

is

placed

over

valve

inlet

Engine

Tune

up

2

Replace

P

C

V

Valve

and

filter

in

accord

with

maintenance

schedul

ET531

Fig

ET

25

Replacing

P

C

V

Value

and

Filter

CHECKING

VENTILATION

HOSES

I

Check

hoses

and

hose

connec

tions

for

leaks

2

Disconnect

all

hoses

and

clean

with

compressed

air

If

any

hose

cannot

be

free

of

obstructions

replace

Confirm

that

flame

arrester

is

locat

ed

correctly

in

hose

between

rocker

cover

and

air

cleaner

ET277

Fig

ET

26

Cleaning

Ventilation

Hose

ET

12

CHECKING

VAPOR

LINES

I

Check

all

hoses

and

fuel

tank

flller

cap

2

Disconnect

vapor

vent

line

con

necting

carbon

canister

to

fuel

tank

3

Connect

3

way

connector

mana

meter

and

cock

or

equivalent

3

w

y

charge

cock

to

end

of

vent

line

ET532

Fig

ET

27

Vent

Line

4

Supply

fresh

air

into

vapor

vent

line

through

cock

little

by

little

until

pressure

become

400

mmH20

is

75

inH20

5

Shut

cock

completely

and

leave

it

unatiended

6

After

2

5

minutes

measure

height

of

liquid

in

manometer

7

Varilllion

in

height

should

remain

with

25

mmHp

0

98

inH20

8

When

filler

cap

does

not

close

completely

height

should

drop

to

zero

ih

a

short

time

9

If

height

does

not

drop

to

zero

in

a

short

time

when

filler

cap

is

re

moved

it

is

cause

of

a

stuffy

hose

Note

In

case

vent

tine

B

stuffy

breathing

in

fuel

tank

is

not

thoroughly

made

thlis

caming

in

sufficient

delivery

of

fuel

to

engine

or

vapor

lock

It

must

tberefore

be

repaired

or

replaced

Page 35 of 548

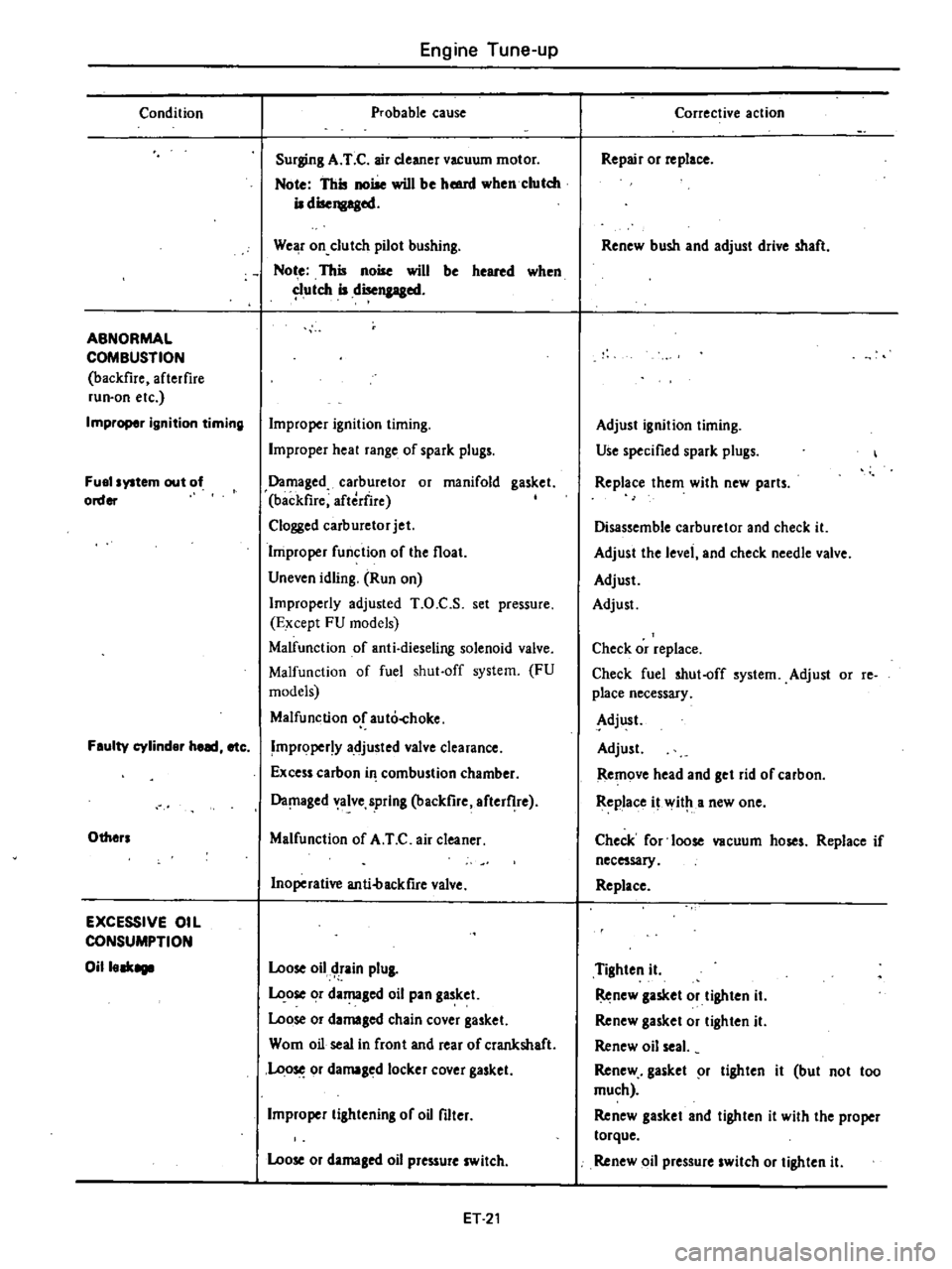

Condition

ABNORMAL

COMBUSTION

backfire

afterfire

run

on

etc

Improper

ignition

timing

Fuel

system

out

of

order

Feulty

cylinder

heed

etc

Others

EXCESSIVE

OIL

CONSUMPTION

Oilleek8111

Engine

Tune

up

Probable

cause

Surging

A

T

C

air

cleaner

vacuum

motor

Note

This

noise

will

be

hmnl

when

clutch

iI

disengaged

We

r

on

clutch

pilot

bushing

Not

e

This

noise

will

be

heared

when

utch

iI

disengaged

Improper

ignition

timing

Improper

heal

range

of

spark

plugs

Damaged

carburetor

or

manifold

gasket

backfire

aftedire

Clogged

carburetor

jet

Improper

function

of

the

float

Uneven

idling

Run

on

Improperly

adjusted

T

O

C

S

set

pressure

Except

FU

models

Malfunction

of

anti

dieseling

solenoid

valve

Malfunction

of

fuel

shut

off

system

FU

models

Malfunction

or

auto

hoke

Improper

y

adjusted

valve

clearance

Excess

carbon

in

combustion

chamber

Da

laged

alve

spring

backfire

after

he

Malfunction

of

A

T

C

air

cleaner

Inoperative

anti4lackfire

valve

Loose

oil

tain

plUI

ose

or

damaged

oil

pan

gasket

Loose

or

damaled

chain

cover

gasket

Wom

oil

seal

in

front

and

rear

of

crankshaft

Loo

or

damaged

locker

cover

gasket

Improper

lilhtening

of

oU

filter

Loose

or

damaled

oil

pressure

switch

ET

21

Corrective

action

Repair

or

replace

Renew

bush

and

adjust

drive

shaft

Adjust

ignition

liming

Use

specified

spark

plugs

Replace

them

with

new

parts

Disassemble

carburetor

and

check

it

Adjust

the

level

and

check

needle

valve

Adjust

Adjust

Check

or

replace

Check

fuel

shut

off

system

Adjust

or

re

place

necessary

Adjust

Adjust

Remove

head

and

get

rid

of

carbon

Replace

it

wit

a

new

one

Check

for

loose

vacuum

hoses

Replace

if

necessary

Replace

Tighten

it

Renew

lasket

or

tighten

iI

Renew

gasket

or

lighten

it

Renew

oil

seal

Renew

gasket

r

lighten

it

but

not

too

much

Renew

gasket

and

tighten

it

with

the

proper

torque

Renew

oil

pressure

switch

or

tighten

it

Page 36 of 548

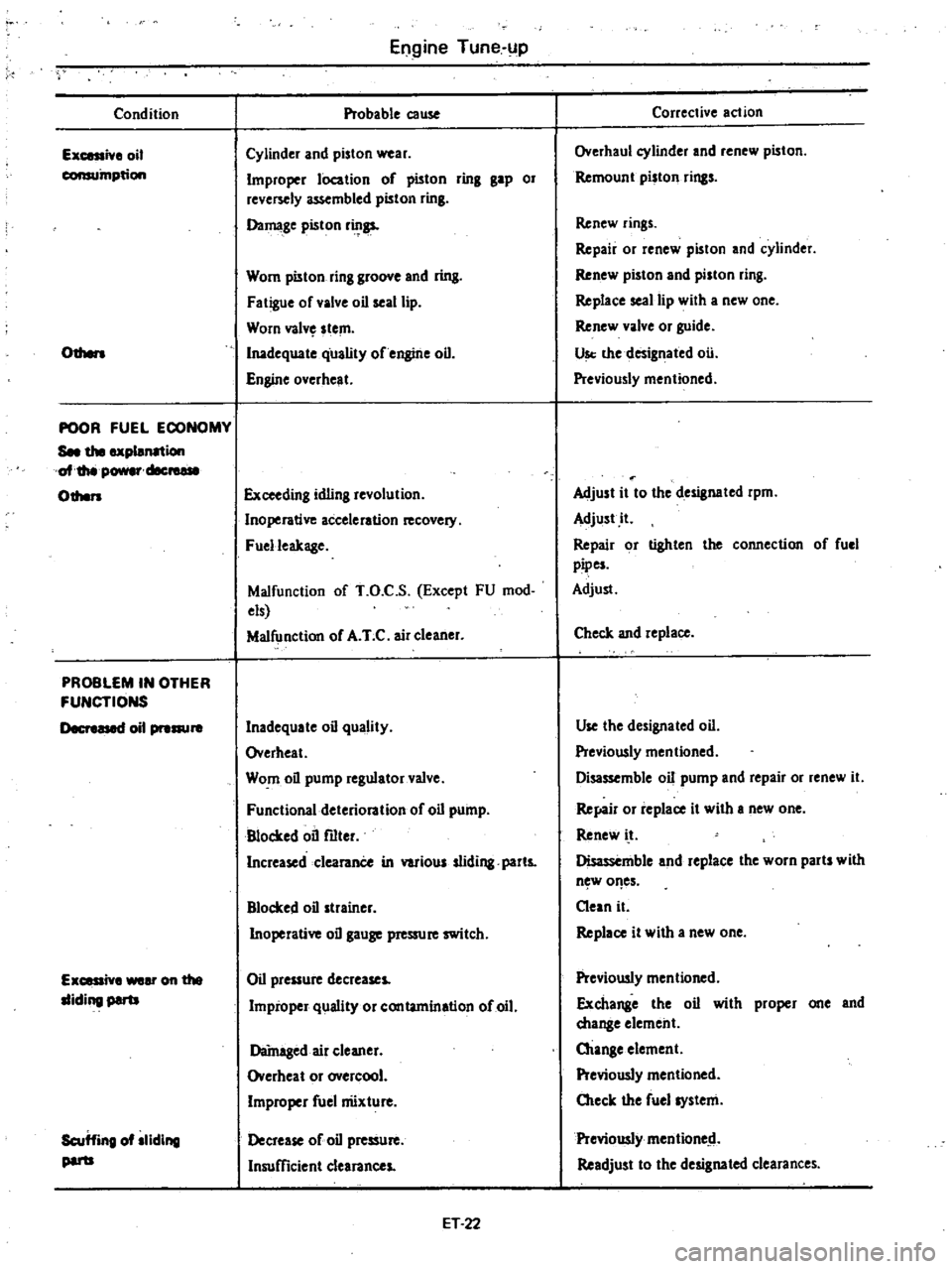

Condition

Ex

iv

oil

consumption

Odlen

POOR

FUEL

ECONOMY

See

the

explanation

oI

thtI

power

cIec

01hen

PROBLEM

IN

OTHER

FUNCTIONS

t

1

oil

pre

E

eronthe

lIiding

par1J

Scuffing

oIlliding

par1J

Engine

Tune

up

Probable

cause

Cylinder

and

piston

wear

Improper

lOcation

of

pi5ton

ring

gap

or

reversely

assembled

piston

ring

Damage

pi5ton

r

gs

Wom

pilton

ring

groove

and

ring

Fatigue

of

valve

oil

seal

lip

Worn

valv

stem

Inadequate

qUality

of

engine

oil

Engine

overheat

Exceeding

idling

revolution

Inoperative

acceleration

covel

Fuelleakage

Malfunction

of

T

O

C

S

Except

FU

mod

els

Malfunction

of

A

T

C

air

cleaner

Inadequate

oil

quality

Overheat

Worn

oil

pump

regulator

valve

Functional

deterioration

of

oil

pump

Blocked

oil

filter

Increased

clearanCe

in

various

sliding

parts

Blocked

oil

strainer

Inoperative

oil

gauge

pressure

switch

Oil

pressure

decreases

Improper

quality

or

contamination

of

oil

Damaged

air

cleaner

Overheat

or

overcool

Improper

fuel

nUxture

Decrease

of

oil

presSure

Insufficient

clearances

ET

22

Corrective

action

Overhaul

cylinder

and

renew

piston

Remount

piston

rings

Renew

rings

Repair

or

renew

piston

and

cylinder

Renew

piston

and

piston

ring

Replace

seal

lip

with

a

new

one

Renew

valve

or

guide

Us

the

designated

ou

Previously

mentioned

Adjust

it

to

the

designated

rpm

Adjust

it

Repair

or

lighten

the

connection

of

fuel

pipes

Adjust

Check

and

replace

Use

the

designated

oil

Previously

mentioned

Disassemble

oil

pump

and

repair

or

renew

it

Ref4ir

or

replace

it

with

I

new

one

Renew

i

t

Disassemble

and

replace

the

worn

parts

with

n

w

of

es

Clean

it

Replace

it

with

a

new

one

Previously

mentioned

Exchange

the

oil

with

proper

one

and

change

element

Otange

element

Previously

mentioned

Oteck

the

fuel

system

Previously

mentione

d

Readjust

to

the

designated

clearances