charging DATSUN 210 1979 Owner's Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 512 of 548

Air

Conditioning

6

Loosen

the

connection

at

the

center

fitting

of

manifold

gauge

for

a

Clockwise

few

seconds

to

purge

air

inside

charg

ing

hose

See

Fig

AC

14

Counterclockwise

j

3

@

I

Can

tap

handle

2

ChlcginS

hose

3

Needle

4

Refrigerant

can

AC246

Fig

AC

13

Can

Top

Purging

air

R

12

To

L9w

pressure

service

valve

AC247

Fig

AC

14

Purging

Air

Ta

High

pressure

service

valve

f

r

AC181A

Fig

AC

15

Discharging

System

AC

ll

DISCHARGING

SYSTEM

The

pressurized

refrigerant

gas

in

side

system

must

be

discharged

to

a

pressure

approaching

atmospheric

pressure

prior

to

evacuating

refrigerant

inside

system

This

operation

should

be

also

made

to

pennit

safe

removal

when

replacing

system

components

A

Close

high

and

low

pressure

valves

of

manifold

gauge

fully

2

Connect

two

charging

hoses

of

manifold

gauge

to

their

respective

service

valves

WARNING

Securely

connect

high

pressure

dis

charge

service

valve

to

that

of

manifold

gauge

with

a

hose

also

connect

low

pressure

suction

serv

ice

valve

to

that

of

manifold

gauge

For

locations

of

high

and

low

pres

sure

discharge

and

suction

service

valves

see

Fig

AC

29

3

Open

both

manifold

gauge

valves

slightly

and

slowly

discharge

refriger

ant

from

system

See

Fig

AC

15

WARNING

Protect

fingers

with

cloth

against

frostbite

by

refrigerant

when

con

necting

the

charging

hose

to

the

service

valve

or

disconnecting

it

therefrom

Nole

Do

not

allow

refrigerant

to

rush

out

Otherwise

compressor

oil

will

be

discharged

along

with

refriger

ant

EVACUATING

SYSTEM

I

Connect

high

and

low

pressure

charging

hoses

of

manifold

gauge

to

their

respective

service

valves

of

sys

tem

and

discharge

refrigerant

from

system

Refer

to

Discharging

System

WARNING

Securely

connect

high

pressure

dis

charge

service

valve

to

that

of

manifold

gauge

with

a

hose

also

connect

low

pressure

suction

servo

ice

valve

to

that

of

manifold

gauge

For

locations

of

high

and

low

pres

sure

discharge

and

wction

service

valves

see

Fig

AC

29

Page 513 of 548

Air

COl

ditioning

2

When

refrigerant

has

been

dis

charged

to

a

pressure

approaching

at

mospheric

pressure

connect

center

charging

hose

to

a

vacuum

pump

3

Close

both

valves

of

manifold

gauge

fully

Then

start

vacuum

pump

4

Open

low

pressure

valve

and

suck

old

refrigerant

ftom

system

See

Fig

AC

16

5

When

low

pressure

gauge

reading

has

reached

to

approximately

500

nunHg

20

inHg

slowly

open

high

pressure

valve

First

step

To

Low

pressure

service

valve

To

High

pressure

service

valve

rtl

Second

step

To

Low

pressure

service

valve

To

High

pressure

service

valve

f

AC182A

Fig

AC

16

Evacuating

System

First

and

Second

Steps

AC

12

6

When

pressure

insill

system

h

as

dropped

to

710

mmHg

28

inHg

fully

close

both

of

valves

of

manifold

gauge

and

stop

vacuum

pump

Let

stand

it

for

5

to

10

minutes

in

this

state

and

confirm

that

the

reading

does

not

rise

Note

a

The

low

pressure

gauge

reads

lower

by

25

mmHg

I

inHg

per

a

300

m

1

000

ft

elevation

Perfonn

evacu

alion

according

to

the

following

table

Elevation

m

ft

0

0

300

1

000

600

2

000

900

3

000

Vacuum

of

system

nunHg

inHg

710

28

685

27

660

26

635

25

Note

Values

show

reading

of

the

low

pressure

gauge

b

The

rate

of

ascension

of

the

low

pressure

gauge

should

be

less

than

25

mmHg

I

inHg

in

five

min

utes

If

the

pressure

rises

or

the

specified

negative

pressure

can

not

be

obtained

lhere

is

a

leak

in

the

system

In

this

case

immediately

charge

system

with

refrigerant

and

repair

the

leak

de

scribed

in

the

following

J

Charge

system

with

a

can

of

refrigerant

about

0

4

kg

0

9Ib

Re

fer

to

Charging

Refrigerant

2

Check

for

refrigerant

leakige

with

a

leak

detector

Repair

any

leak

ages

found

Refer

to

Checking

for

Leaks

3

Discharge

refrigerant

again

and

then

evacuate

system

CHARGING

REFRIGERANT

I

Install

manifold

gauge

to

system

Refer

to

Handling

Manifold

Gauge

Page 514 of 548

WARNING

Securely

connect

high

pressure

dis

charge

service

valve

to

that

of

manifold

gauge

with

a

hose

also

connect

low

pressure

suction

serv

ice

valve

to

that

of

manifold

gauge

For

locations

of

high

and

low

pres

sure

discharge

and

suction

service

valves

see

Fig

AC

29

CAUTION

a

Be

sure

to

purge

air

from

the

high

and

low

pressure

charging

hoses

b

If

air

is

mixed

with

refrigerant

gas

in

system

evacuation

of

system

should

be

performed

Refer

to

Evacuating

System

2

Attach

center

charging

hose

of

manifold

gauge

to

refrigerant

can

through

can

tap

Break

seal

of

refriger

ant

can

to

allow

refrigerant

to

enter

manifold

gauge

Loo

en

charging

hose

at

the

center

fitting

of

manifold

gauge

and

purge

air

from

inside

charging

hose

Refer

to

Handling

Can

Tap

3

Open

high

and

low

pressure

valves

of

manifold

gauge

and

charge

refrigerant

into

system

See

Fig

AC

17

Note

When

refrigerant

charging

speed

is

slow

immerse

refrigerant

can

in

water

heated

to

a

temperature

of

about

400C

1

040

F

for

a

short

time

See

Fig

AC

18

WARNING

a

Under

any

circumstances

the

re

frigerant

can

must

not

be

warm

ed

in

water

heated

to

a

temper

ature

of

over

520C

1260F

b

A

blow

toreh

or

stove

must

never

be

used

to

warm

up

the

can

Air

Conditioning

To

Low

pressure

service

valve

t

R

12

t

@

I

J

To

High

pressure

service

valve

t

t

AC183A

Fig

AC

17

Charging

Refrigerant

p

CAUTION

When

charging

liquefied

refrigerant

into

the

system

with

the

can

turned

upside

down

to

reduce

charging

time

charge

it

only

through

high

pressure

discharge

service

valve

but

not

through

low

pressure

suction

service

valve

See

Fig

AC

19

After

comple

tion

of

charging

the

compressor

should

always

be

turned

several

times

manually

lmmene

in

water

heated

to

about

400C

1040F

for

a

hort

time

AC184A

Fig

AC

18

Charging

Refrigerant

To

Low

pressure

service

valve

To

High

pressure

service

valve

t

r

J

AC

13

Low

t

AC185A

Fig

AC

19

Chorging

Liquefied

Refrigerant

Page 515 of 548

4

Wfefrlgerant

charging

speed

slows

down

charge

it

while

running

the

compressor

for

ease

of

charging

After

having

taken

the

steps

up

to

3

above

proceed

with

charging

in

the

following

order

1

Shut

off

high

pressure

valve

of

manifold

gauge

2

Run

the

engine

at

idling

speeds

below

1

500

rpm

3

Set

the

Temperature

lever

and

Fan

switch

at

maximum

cool

and

maximum

speed

respectively

To

Lpw

pressure

service

valve

t

Air

Conditioning

4

Charge

efiigerani

while

con

trolling

low

pressure

gauge

reading

at

2

8

kg

cm2

40

psi

or

less

by

turning

in

or

out

low

pressure

valve

of

mani

fold

gauge

See

Fig

A

20

WARNING

Never

charge

refrigerant

through

high

pressure

side

discharge

side

of

system

since

this

will

force

re

frigerant

back

into

refrigerant

can

and

can

may

explode

To

High

pressure

service

valve

A

5

When

refrigerant

can

is

empty

fully

close

both

valves

of

manifold

gauge

and

replace

refrigerant

can

with

a

new

ot

e

Before

opening

manifold

gauge

valve

to

charge

refrigerant

from

new

can

be

sure

to

purge

air

from

inside

charging

hose

6

Charge

the

specified

amount

of

refrigerant

into

system

by

weighing

charged

refrigerant

with

scale

Over

charging

wiU

cause

discharge

pressure

to

rise

AC380A

Fig

AC

20

Charging

Refrigeront

Measure

the

amount

of

charged

refrigerant

with

a

scale

Make

a

note

of

the

amount

charged

from

can

AC252

Fig

AC

21

Chorging

Refrigeront

Refrigerant

capacity

Unit

kg

lb

Refrigerarit

Minimum

Maximum

R

12

0

8

1

8

1

0

2

2

AC14

Note

The

p

Ce

of

btibble

hi

sight

glass

of

receiver

drier

is

an

unsuitable

method

of

checking

the

amount

of

refrigerant

charged

in

system

The

state

of

the

bubbles

iJt

sight

glass

should

only

be

used

ior

checking

whether

the

amount

of

charged

refrigerant

is

small

or

not

The

amount

of

charged

refrigerani

can

be

correcdy

judged

by

means

of

discharge

pressure

Refer

to

Re

frigerant

Level

Check

7

After

the

specified

amount

of

refrigerant

has

been

charged

intosys

tern

close

manifold

gauge

valves

Then

detach

charging

hoses

from

service

valves

of

system

Be

sure

to

install

valve

cap

to

service

valve

8

Confirm

that

there

are

no

leaks

in

system

by

checking

with

a

leak

detec

tor

Refer

to

Checking

for

Leaks

Note

Conducting

8

performance

test

prior

to

removing

manifold

gauge

is

8

good

service

operation

Refer

to

Performance

Test

CHECKING

FOR

LEAKS

Conduct

a

leak

t

st

whenever

leak

age

of

refrigerant

is

suspected

and

when

conducting

service

operations

which

are

accompanied

by

disassembly

or

loosening

of

connection

fittings

Refrigerant

is

a

colorless

odorless

gas

and

leakage

from

system

is

diffi

cult

to

detect

Accordingly

the

use

of

a

leak

detector

facilitates

check

for

leaks

Two

methods

of

checking

are

available

one

employs

a

halide

leak

detector

which

bums

propane

gas

or

butane

gas

and

the

other

is

an

electric

type

leak

detector

If

any

trace

of

oil

is

noted

at

and

around

connection

fittings

it

is

a

sure

indication

that

refrigerant

is

leaking

This

condition

can

be

corrected

easily

by

retightening

the

joints

If

any

joint

on

line

is

suspected

of

small

amount

of

leakage

use

a

leak

detector

to

locate

leaking

points

Page 517 of 548

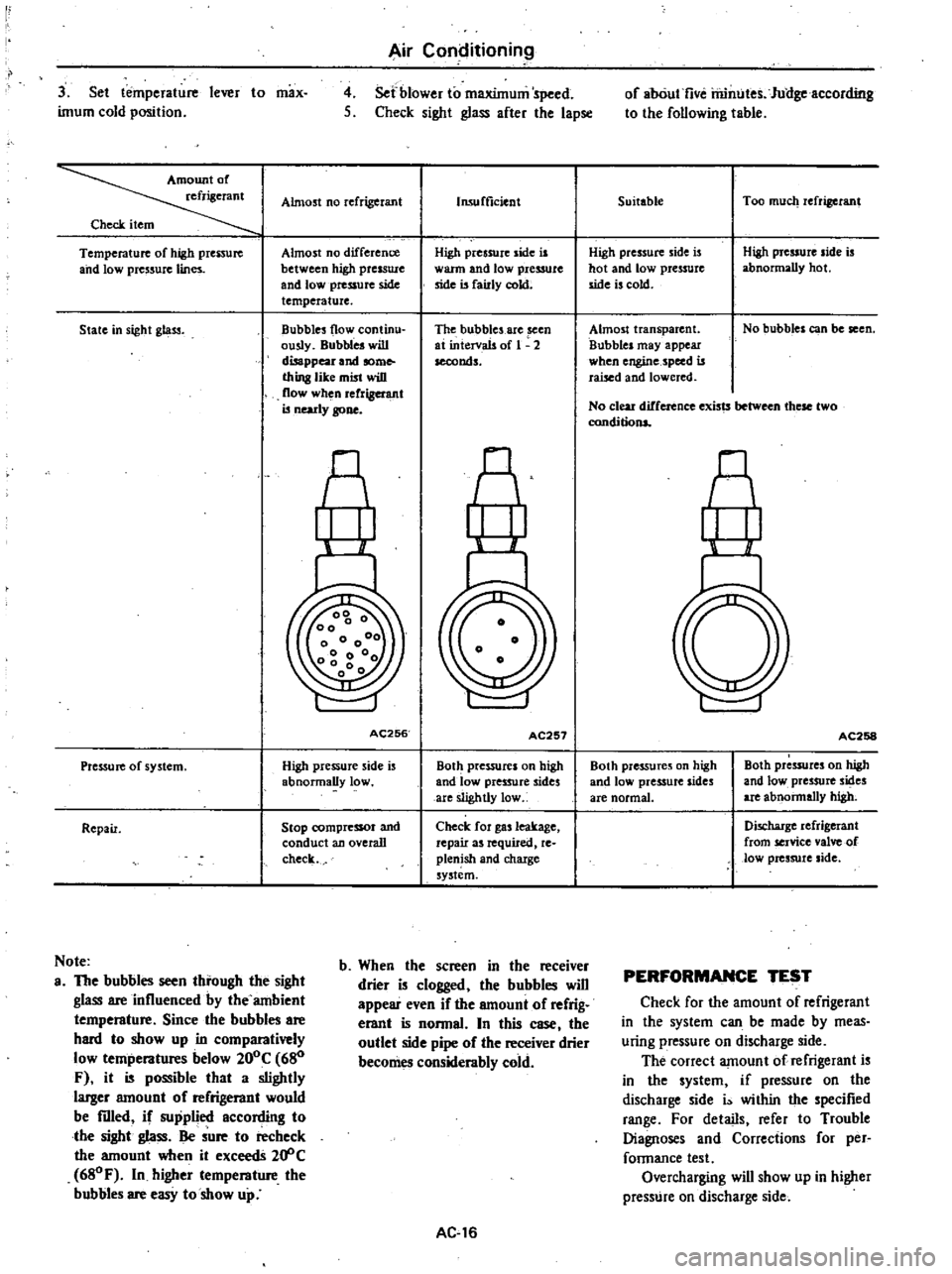

I

I

3

Set

temperature

lever

to

max

imum

cold

position

Air

Conditioning

4

Sefblower

to

maximum

speed

S

Check

sight

glass

after

the

lapse

Almost

no

refrigerant

Check

item

Temperature

of

high

prenure

and

low

pressure

lines

Almost

no

difference

between

high

presswc

and

lowpressufC

side

temperature

State

in

sight

gl

ltS3

Bubbles

flow

continu

ously

Bubbles

will

disappear

and

some

thing

like

mist

wiD

flow

when

rerrigel

l

llt

is

nearly

gone

AC256

Pressure

of

system

High

pressure

side

is

abnormally

low

Repair

Stop

compressor

and

conduct

an

overall

check

Note

a

The

bubbles

seen

tbrough

the

sight

glass

are

influenced

by

the

ambient

tempemture

Since

the

bubbles

are

bard

to

show

up

in

comparatively

low

tempemtures

below

200C

680

F

it

is

possible

that

a

slightly

larger

amouot

of

refrigemot

would

be

filled

if

supplied

according

to

tbe

sight

glass

Be

sure

to

recheck

the

amount

when

it

exceedS

20

C

680F

In

higher

tempemture

tbe

bubbles

are

easy

to

show

up

Insufficient

High

pressure

side

is

warm

and

low

pressure

side

is

fairly

cokt

The

bubbles

are

seen

at

intervals

of

1

2

seconds

AC257

Both

pressures

on

high

and

low

pressure

sides

are

slightly

low

Check

for

gas

leakage

repair

as

required

re

plenish

and

chaxge

system

b

Wben

the

screen

in

tbe

receiver

drier

is

clogged

tbe

bubbles

wiD

appear

even

if

the

amount

of

refrig

erant

is

nonnaL

In

this

case

tbe

outlet

side

pipe

of

tbe

receiver

drier

becomes

considembly

cold

AC

16

of

abOut

five

rilintJtes

Jullgeaccording

to

the

following

table

Suitable

Too

much

refrigerant

High

pressure

side

is

hot

and

low

pressure

side

is

cold

High

pressure

side

is

abnormally

hot

Almost

transparent

Bubbles

may

appear

when

engine

speed

is

raised

and

lowered

No

bubbles

can

be

seen

No

clear

difference

exists

these

two

conditions

nl

AC258

Both

pre55ures

on

high

and

low

pressure

sides

are

normal

Both

pressures

on

high

and

low

pressure

sides

are

abnonnally

high

Discharge

refrigerant

from

service

valve

of

low

pressure

side

PERFORMANCE

TEST

Check

for

the

amount

of

refrigerant

in

the

system

can

be

made

by

meas

uring

pressure

on

discharge

side

The

correct

amount

of

refrigerant

is

in

the

system

if

pressure

on

the

discharge

side

i

within

the

specified

range

For

details

refer

to

Trouble

Diagnoses

and

Corrections

for

per

fannance

test

Overcharging

will

show

up

in

higher

presstJre

on

discharge

side

Page 520 of 548

Air

Conditioning

IDLER

PULLEY

AND

COMPRESSOR

DRIVE

BELT

ADJ

USTMENT

OF

BELT

TENSION

Idler

pulley

Alternator

Crankshaft

pulley

Unit

mm

in

Idler

pulley

Fig

AC

25

Belt

Tension

Specified

compressor

belt

tension

is

8

to

12

mm

0

31

to

0

47

in

when

thumb

pressure

of

10

kg

22

Ib

is

applied

midway

between

idler

pulley

and

compressor

pulley

1

Loosen

idler

pulley

lock

nut

and

then

adjust

pulley

by

turning

adjusting

bolt

2

After

adjustment

tighten

idler

pulley

lock

nut

bolt

3

Remove

idler

pulley

4

Install

pulley

in

the

reverse

order

of

removal

5

Adjust

compressor

belt

tension

REMOVAL

AND

INSTALLATION

1

Jack

up

front

of

car

and

remove

under

cover

2

Remove

idler

pulley

lock

nut

and

loosen

belt

tension

adjusting

Fig

AC26

AC382A

Idler

Pulley

TIghtening

torque

@

3

7

to

5

1

kg

m

27

to

37

ft

lb

AC383A

Fig

AC

27

Compressor

and

Bracket

AC

19

REMOVAL

I

Operate

compressor

if

possible

at

engine

idling

speed

with

air

condi

tioner

controls

set

for

maximum

cool

ing

and

high

blower

speed

for20

to

30

minutes

with

all

windows

open

to

return

oil

into

compressor

2

Disconnect

battery

ground

cables

and

compressor

lead

wire

at

con

nector

3

Discharge

refrigerant

from

cool

ing

system

Refer

to

Discharging

Sys

tem

4

Jack

up

front

of

car

and

remove

under

cover

5

Loosen

idler

pulley

lock

nut

and

loosen

tension

adjusting

bolt

fully

Remove

compressor

drive

belt

See

Fig

AC

26

6

Remove

high

and

low

flexible

hoses

from

compressor

WARNING

Gradually

loosen

discharge

side

hose

fitting

and

remove

it

after

remaining

pressure

has

been

re

leased

CAUTION

Be

sure

to

immediately

put

plug

in

flexible

hose

and

compressor

open

ings

7

Remove

bolts

securing

lower

part

of

compressor

8

Remove

bolts

securing

upper

part

of

compressor

Hold

compressor

with

one

hand

when

removing

bolts

and

then

remove

compressor

With

compressor

clutch

up

lift

compressor

out

with

both

hands

CAUTION

00

not

attempt

to

leave

the

com

pressor

on

its

side

or

upside

down

for

more

than

10

minutes

as

the

compressor

oil

will

enter

the

low

pressure

chambers

If

under

that

condition

compressor

should

be

oper

ated

suddenly

internal

damage

would

result

To

expel

oil

from

chambers

hand

crank

compressor

several

times

in

its

installed

condition

Page 521 of 548

INSTA

L1ATION

InstaU

in

the

reverse

order

of

removal

observing

the

following

I

When

installing

add

required

amount

Of

compressor

oil

Refer

to

Compressor

Oil

Level

Check

2

Apply

a

coat

of

fresh

compressor

oil

to

sealing

surfaces

of

pipe

joints

3

Check

tightening

torque

of

com

pressor

mounting

bolts

compressor

mounting

bracket

mounting

bolts

and

refrigerant

line

See

Figs

AC

27

and

AC

29

4

DO

not

remove

plugs

from

com

pressor

and

flexible

hose

before

connecting

hoses

S

Turn

compressor

several

times

before

installing

6

Adjust

compressor

drive

belt

tension

See

Fig

AC

2S

7

Evacuate

and

recharge

system

Refer

to

General

Service

for

evacuating

system

and

charging

re

frigerant

8

Conduct

leak

test

and

make

sure

that

there

is

no

leak

from

connections

CONDE

NSER

REMOVAL

Disconnect

battery

ground

cable

2

Discharge

system

Refer

to

Gen

eral

Service

for

discharging

system

3

Remove

radiator

grille

4

Remove

center

stay

5

Disconnect

refrigerant

lines

from

condenser

CAUTION

8

Use

wrench

to

fix

union

on

con

denser

and

then

loosen

flare

nut

of

refrigerant

line

with

another

wrench

b

Plug

up

all

openings

in

condenser

and

system

Air

COl1ditioning

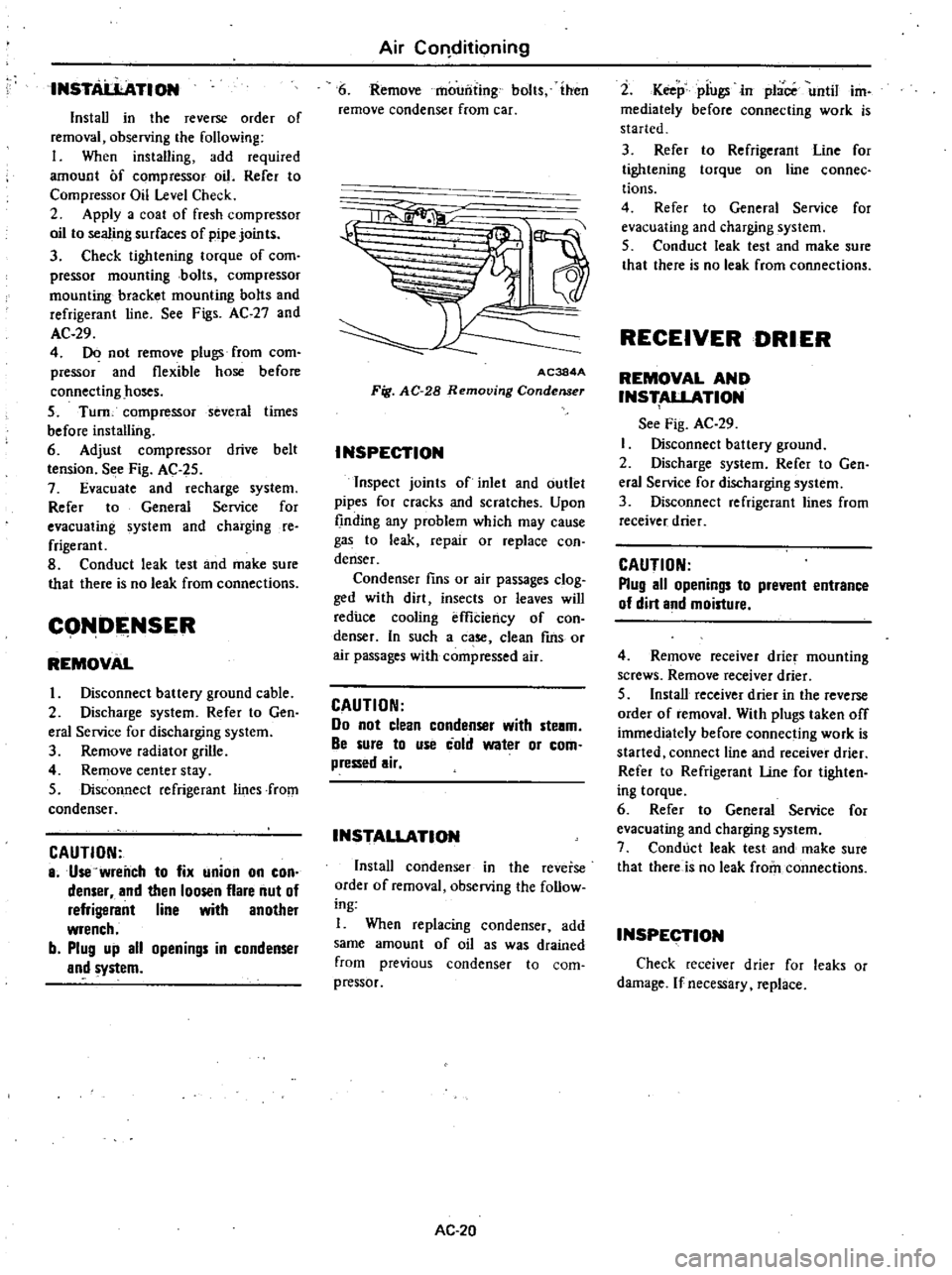

6

Remove

mounting

bolts

ihen

remove

condenser

from

car

1a

11

AC384A

Fig

AC

28

Removing

Condenser

INSPECTION

Inspect

joints

of

inlet

and

outlet

pipes

for

cracks

and

scratches

Upon

finding

any

problem

which

may

cause

gas

to

leak

repair

or

replace

con

denser

Condenser

fins

or

air

passages

clog

ged

with

dirt

insects

or

leaves

will

reduce

cooling

effiCiency

of

con

denser

In

such

a

case

clean

fms

or

air

passages

with

compressed

air

CAUTION

Do

not

clean

condenser

with

ste8m

Be

sure

to

use

cold

water

or

com

pressed

air

INSTALLATION

Install

condenser

in

the

reverse

order

of

removal

observing

Ihe

follow

ing

I

When

replacing

condenser

add

same

amount

of

oil

as

was

drained

from

previous

condenser

to

com

pressor

AC

20

2

Keep

piugsin

place

until

im

mediately

before

connecting

work

is

started

3

Refer

to

Refrigerant

Line

for

tightening

torque

on

line

connec

tions

4

Refer

to

General

Service

for

evacuating

and

charging

system

5

Conduct

leak

test

and

make

sure

that

there

is

no

leak

from

connections

RECEIVER

DRIER

REMOVAL

AND

INS

ALLATION

See

Fig

AC

29

Disconnect

battery

ground

2

Discharge

system

Refer

to

Gen

eral

Service

for

discharging

system

3

Disconnect

refrigerant

lines

from

receiver

drier

CAUTION

Plug

all

openings

to

prevent

entrance

of

dirt

and

moisture

4

Remove

receiver

drier

mounting

screws

Remove

receiver

drier

5

Install

receiver

drier

in

the

reverse

order

of

removal

With

plugs

taken

off

immediately

before

connecting

work

is

started

connect

line

and

receiver

drier

Refer

to

Refrigerant

Une

for

tighten

ing

torque

6

Refer

to

General

Service

for

evacuating

and

charging

system

7

Conduct

leak

test

and

make

sure

that

there

is

no

leak

from

connections

INSPECTION

Check

receiver

drier

for

leaks

or

damage

If

necessary

replace

Page 522 of 548

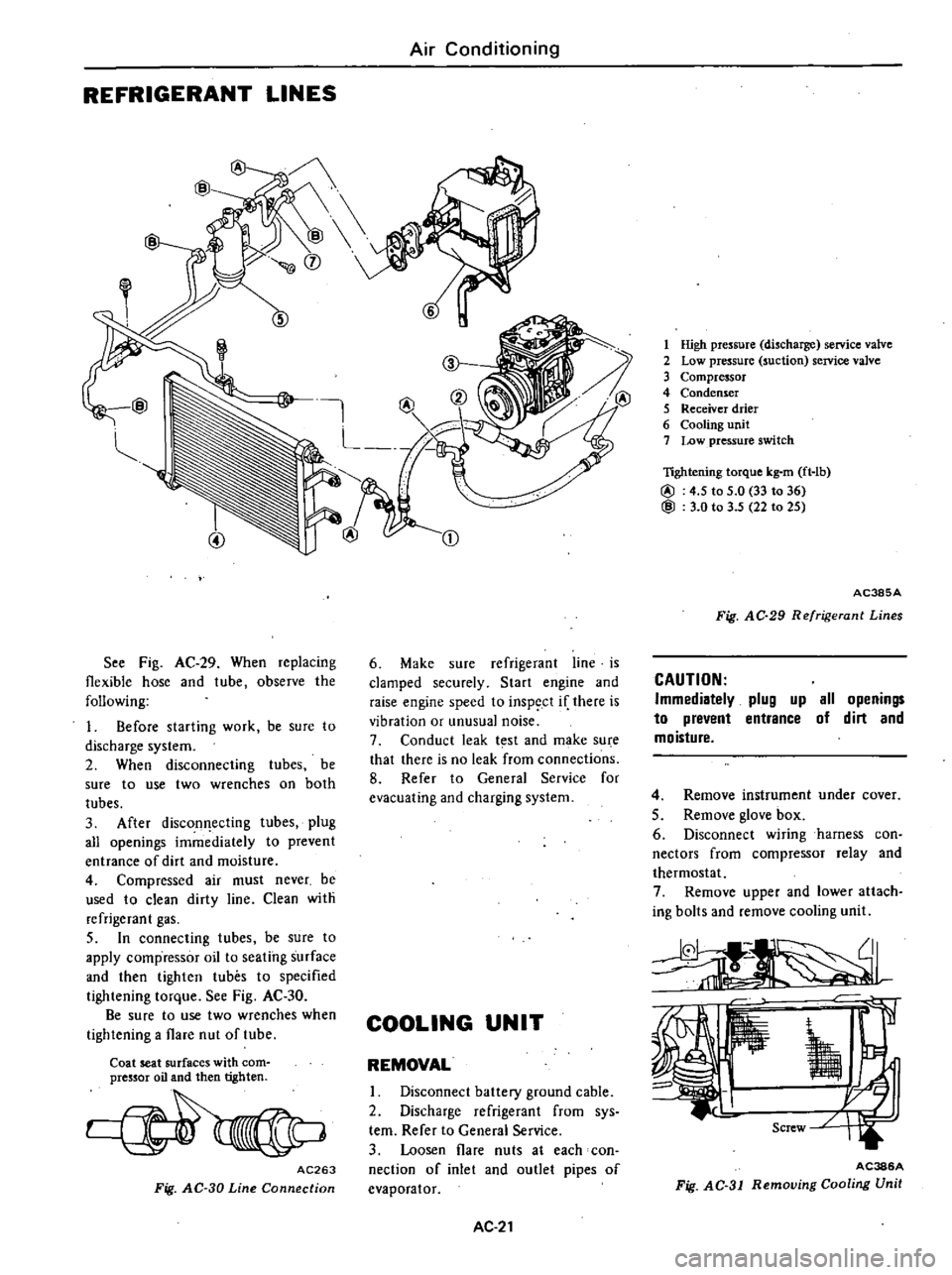

REFRIGERANT

LINES

Air

Conditioning

@

I

J

L

S

r

Z

S

t

@

See

Fig

AC

29

When

replacing

flexible

hose

and

tube

observe

the

following

1

Before

starting

work

be

sure

to

discharge

system

2

When

disconnecting

tubes

be

sure

to

use

two

wrenches

on

both

tubes

3

After

discon

ecting

tubes

plug

all

openings

immediately

to

prevent

entrance

of

dirt

and

moisture

4

Compressed

air

must

never

be

used

to

clean

dirty

line

Clean

with

refrigerant

gas

5

In

connecting

tubes

be

sure

to

apply

compressor

oil

to

seating

surface

and

then

tighten

tubes

to

specified

tightening

torque

See

Fig

AC

30

Be

sure

to

use

two

wrenches

when

tightening

a

flare

nut

of

tube

Coat

seat

surfaces

with

com

pressor

oil

and

then

tighten

AC263

Fig

AC

30

Line

Connection

CD

6

Make

sure

refrigerant

line

is

clamped

securely

Start

engine

and

raise

engine

speed

to

inspect

if

there

is

vibration

or

unusual

noise

7

Conduct

leak

t

st

and

make

su

e

that

there

is

no

leak

from

connections

8

Refer

to

General

Service

for

evacuating

and

charging

system

COOLING

UNIT

REMOVAL

I

Disconnect

battery

ground

cable

2

Discharge

refrigerant

from

sys

tern

Refer

to

General

Service

3

Loosen

flare

nuts

at

each

con

nection

of

inlet

and

outlet

pipes

of

evaporator

AC

21

1

High

pressure

discharge

service

valve

2

Low

pressure

suction

service

valve

3

Compressor

4

Condenser

5

Receiver

drier

6

Cooling

unit

7

Low

pressure

switch

lightening

torque

kg

m

ft

lb

@

4

5

to

5

0

33

to

36

@

3

0

to

3

5

22

to

25

AC385A

Fig

AC

29

Refrigerant

Lines

CAUTION

Immediatelv

plug

up

all

openings

to

prevent

entrance

of

dirt

and

moisture

4

Remove

instrument

under

cover

5

Remove

glove

box

6

Disconnect

wiring

harness

con

nectors

from

compressor

relay

and

thermostat

7

Remove

upper

and

lower

attach

ing

bolts

and

remove

cooling

unit

AC386A

Fig

AC

31

Removing

Cooling

Unit

Page 523 of 548

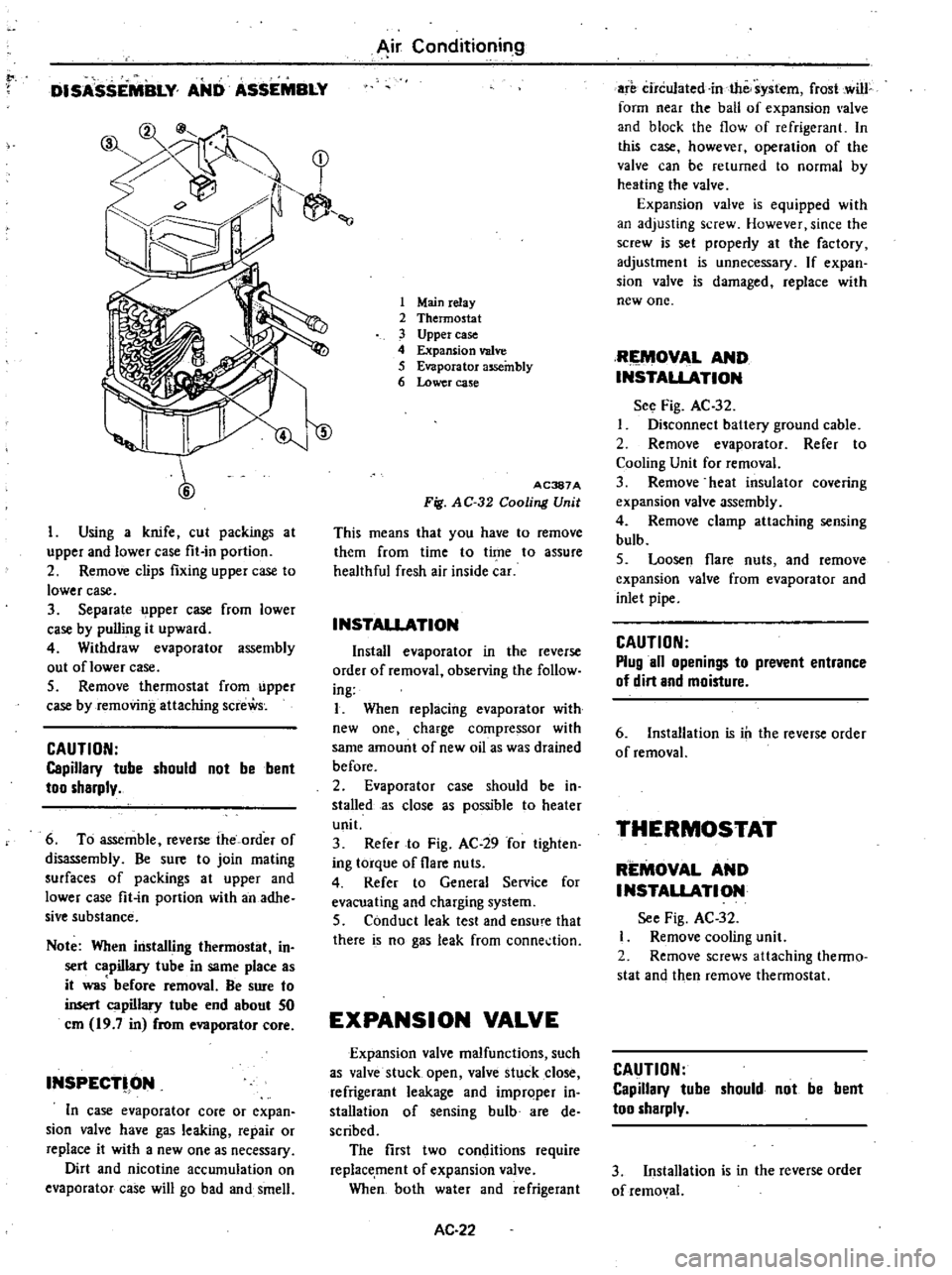

to

DISASSEMBLY

AND

ASSEMBLY

y

1

7

1

r

II

l

1

Using

a

knife

cut

packings

at

upper

and

lower

case

fit

in

portion

2

Remove

clips

fixing

upper

case

to

lower

case

3

Separate

upper

case

from

lower

case

by

pulling

it

upward

4

Withdraw

evaporator

assembly

out

oflower

case

5

Remove

thermostat

from

upper

case

by

removing

attaching

screWs

CAUTION

Capillary

tube

should

not

be

bent

too

sharply

6

To

assemble

reverse

the

order

of

disassembly

Be

sure

to

join

mating

surfaces

of

packings

at

upper

and

lower

case

fit

in

portion

with

an

adhe

sive

substance

Note

When

installing

thermostat

in

sert

capillary

tube

in

same

place

as

it

was

before

removal

Be

sure

to

insert

capillary

tube

end

about

50

em

19

7

in

from

evaporator

core

INSPECT

ON

In

case

evaporator

core

or

expan

sion

valve

have

gas

leaking

repair

or

replace

it

with

a

new

one

as

necessary

Dirt

and

nicotine

accumulation

on

evaporator

case

will

go

b

d

and

smell

Air

Conditioning

1

Mainrelay

2

Thermostat

3

Upper

case

4

Expansion

valve

5

Evaporator

assembly

6

Lower

case

ID

AC387A

Fig

AC

32

Cooling

Unit

This

means

that

you

have

to

remove

them

from

time

to

time

to

assure

healthful

fresh

air

inside

car

INSTAllATION

Install

evaporator

in

the

reverse

order

of

removal

observing

the

follow

ing

I

When

replacing

evaporator

with

new

one

charge

compressor

with

same

amount

of

new

oil

as

was

drained

before

2

Evaporator

case

should

be

in

stalled

as

close

s

possible

to

heater

unit

3

Refer

to

Fig

AC

29

for

tighten

ing

torque

of

flare

nuts

4

Refer

to

General

Service

for

evacuating

and

charging

system

5

Conduct

leak

test

and

ensu

e

that

there

is

no

gas

leak

from

conne

tion

EXPANSION

VALVE

Expansion

valve

malfunctions

such

as

valve

stuck

open

valve

stuck

close

refrigerant

leakage

and

improper

in

stall

tion

of

sensing

bulb

are

de

scribed

The

first

two

conditions

require

replacement

of

expansion

valve

When

both

water

and

refrigerant

AC

22

are

circulated

in

the

system

frost

cwill

form

near

the

ball

of

expansion

alve

and

block

the

flow

of

refrigerant

In

this

case

however

operation

of

the

valve

can

be

returned

to

normal

by

heating

the

valve

Expansion

valve

is

equipped

with

an

adjusting

screw

However

since

the

screw

is

set

properly

at

the

factory

adjustment

is

unnecessary

If

expan

sion

valve

is

damaged

replace

with

new

one

RIEMOV

L

AND

INSTALlATION

See

Fig

AC

32

Disconnect

baltery

ground

cable

2

Remove

ev

porator

Refer

to

Cooling

Unit

for

removal

3

Remove

heat

insulator

covering

expansion

valve

assembly

4

Remove

clamp

attaching

sensing

bulb

5

Loosen

flare

nuts

and

remove

expansion

valve

from

evaporator

and

inlet

pipe

CAUTION

Plug

all

openings

to

prevent

entrance

of

dirt

and

moisture

6

Installation

is

ill

the

reverse

order

of

removal

THERMOSTAT

REMOVAL

AND

INSTALlATION

See

Fig

AC

32

Remove

cooling

unit

2

Remove

screws

attaching

thenno

stat

and

then

remove

thermostat

CAUTION

Capillary

tube

should

not

be

bent

too

sharply

3

Installation

is

in

the

reverse

order

of

removal

Page 530 of 548

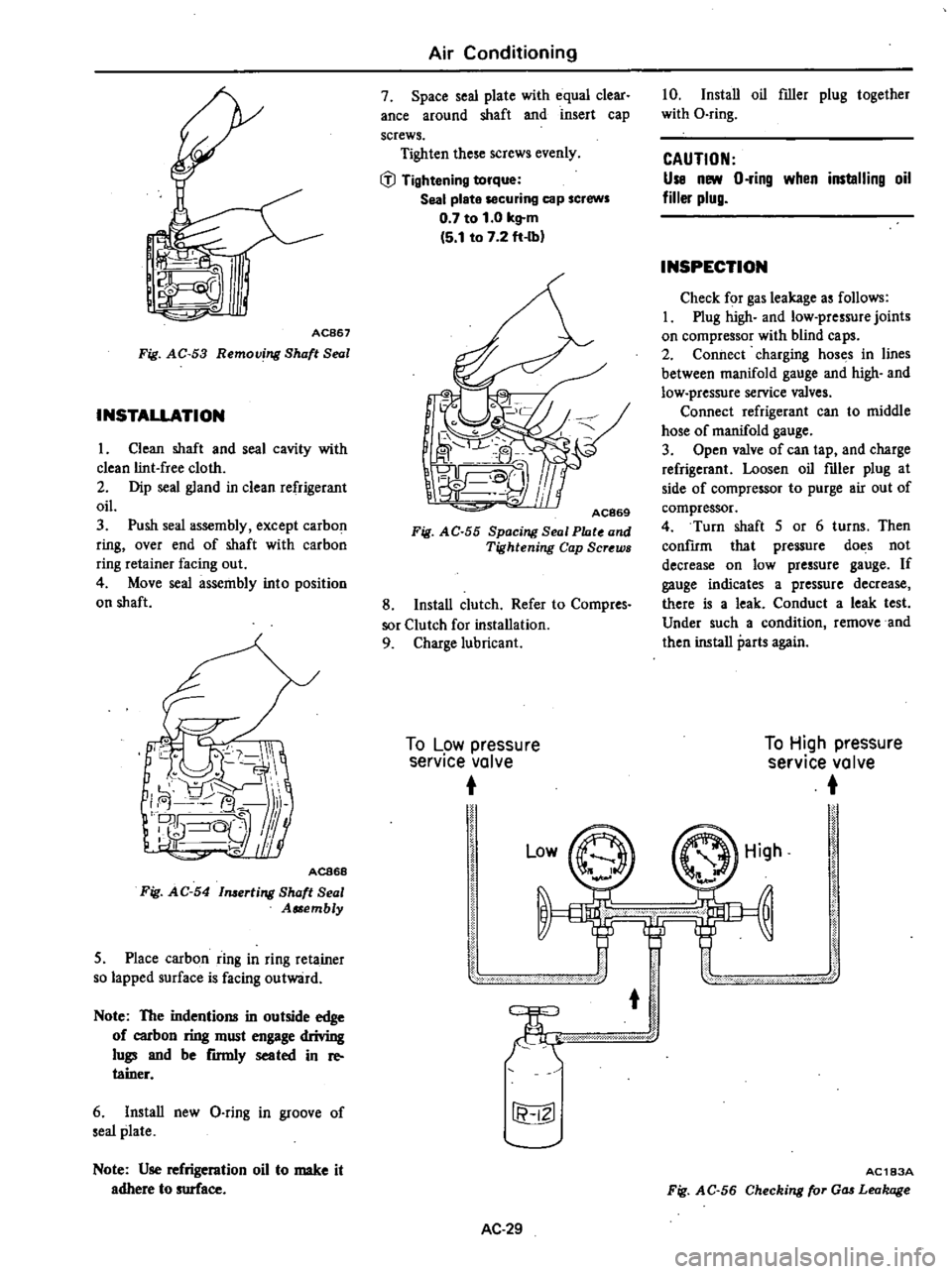

AC867

Fig

AC

53

Removing

Shaft

Seal

INSTALLATION

1

Clean

shaft

and

seal

cavity

with

clean

lint

free

cloth

2

Dip

seal

gland

in

clean

refrigerant

oil

3

Push

seal

assembly

except

carbon

ring

over

end

of

shaft

with

carbon

ring

retainer

facing

out

4

Move

seal

assembly

into

position

on

shaft

ACB68

Fig

AC

54

1merting

Shaft

Seal

Assembly

5

Place

carbon

ring

in

ring

reta

iner

so

lapped

surface

is

facing

outward

Note

The

indentions

in

outside

edge

of

carbon

ring

must

engage

driving

lugs

and

be

rmnly

seated

in

re

tainer

6

Install

new

Q

ring

in

groove

of

seal

plate

Note

Use

refrigeration

oil

to

make

it

adhere

to

surface

Air

Conditioning

7

Space

seal

plate

with

equal

clear

ance

around

shaft

and

insert

cap

screws

Tighten

these

screws

evenly

IiJ

Tightening

torque

Seal

plate

securing

cap

screws

0

7

to

1

0

kg

m

5

1

to

7

2

ft

Ibl

AC869

Fig

AC

55

Spacing

Seal

Plate

and

Tightening

Cap

Screws

8

Install

clutch

Refer

to

Compres

sor

Clutch

for

installation

9

Charge

lubricant

To

Low

pressure

service

valve

10

Install

oil

filler

plug

together

with

O

ring

CAUTION

Use

new

O

ring

when

installing

oil

filler

plug

INSPECTION

Check

for

gas

leakage

as

follows

I

Plug

high

and

low

pressure

joints

on

compressor

with

blind

caps

2

Connect

charging

hoses

in

lines

between

manifold

gauge

and

high

and

low

pressure

service

valves

Connect

refrigerant

can

to

middle

hose

of

manifold

gauge

3

Open

valve

of

can

tap

and

charge

refrigerant

Loosen

oil

filler

plug

at

side

of

compressor

to

purge

air

out

of

compressor

4

Turn

shaft

5

or

6

turns

Then

confIrm

that

pressure

does

not

decrease

on

low

pressure

gauge

If

gauge

indicates

a

pressure

decrease

there

is

a

leak

Conduct

a

leak

test

Under

such

a

condition

remove

and

then

install

parts

again

To

High

pressure

service

valve

Low

r

fi

IZl

AC

29

High

AC183A

Fig

AC

56

Checking

for

Gas

Leakage