tow DATSUN 210 1979 Owner's Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 292 of 548

Place

the

vehicle

in

a

pit

and

by

sampling

the

lealeed

oil

deiermine

if

it

is

the

torque

converter

oil

The

torque

converter

oil

has

a

color

like

red

wine

so

it

is

easily

distinguished

from

engine

oil

or

gear

oil

Wipe

off

the

lealeing

oil

and

dust

and

detect

the

spot

of

ill

lell8e

nonflammable

organic

solvent

such

as

carbon

tetrachloride

for

wiping

Raise

the

oil

tcmperature

by

op

erating

the

engine

and

shift

the

lever

to

D

to

increase

the

oil

pressure

The

sp

Q

of

o

1

1I8

u

J1en

be

found

more

easily

Note

As

oil

leakage

from

the

breath

er

does

not

talee

place

except

when

running

at

high

peed

it

iSimpos

sible

to

ate

this

lealcage

with

vehicle

stationary

CHECKING

ENGINE

IDLING

REVOLunON

The

engine

idling

revolution

should

be

properly

adjusted

If

the

engine

revolution

is

too

low

the

e

gine

does

not

operate

smoothly

and

if

too

high

a

strong

shocle

or

creep

develops

when

changing

over

from

ON

to

Dn

or

R

CHECKING

AND

ADJUSTING

KICK

WN

SWITCH

AND

DOWNSH

FT

SOLENOID

When

the

Ieickdown

operation

is

not

made

properly

or

the

speed

chang

ingpoint

is

too

high

check

the

kick

down

switch

downshift

solenoid

and

wiring

between

them

When

the

igni

tion

Ieey

is

po

iti

ned

at

the

1st

stage

and

the

accelerator

pedal

is

depressed

deeply

the

switch

contact

hould

be

closed

and

the

solenoid

should

clicle

If

it

does

not

click

it

indicates

a

defect

Then

check

each

part

with

the

testing

inatrumen15

Auto

lT1atic

Transmissiqn

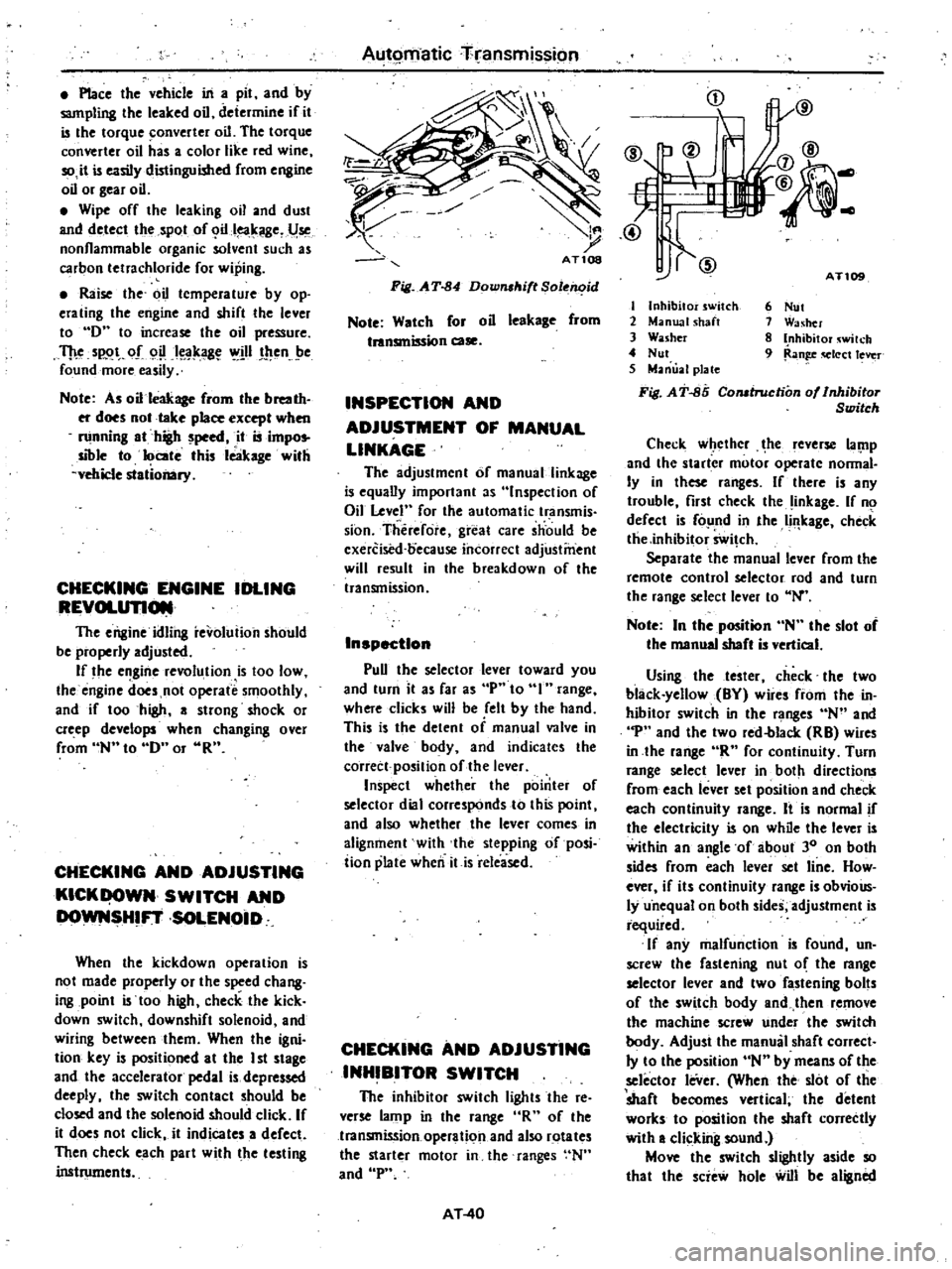

Fi

J

A

T

84

Down

ltift

Sole

id

Note

Watch

for

oil

leekage

from

tnnsmission

case

INSPECTION

AND

ADJUSTMENT

OF

MANUAL

LINKAGE

The

adjustmcnt

of

manual

linkage

i

equany

important

as

Inspection

of

Oil

Level

for

the

automatic

transmis

sion

Therefore

great

care

should

be

cxercised

oecause

incorrect

adjustment

will

result

in

the

breakdown

of

the

transmission

Inspection

pun

the

selector

lever

toward

you

and

turn

it

as

far

as

p

to

range

where

clicks

will

be

ell

by

the

hand

This

is

the

detent

of

manual

valve

in

the

valve

body

and

indicates

the

corrett

position

of

the

lever

Inspect

whether

the

pointer

of

selector

dial

corresponds

to

this

point

and

also

whether

the

lever

comes

in

alignment

with

the

stepping

of

posi

iion

plate

when

itis

released

CHECKING

AND

ADJUSTING

INHIBITOR

SWITCH

The

inhibitor

switch

lights

the

re

verse

lamp

in

the

range

R

of

the

transmission

operation

and

also

rotates

the

starter

motor

in

the

ranges

N

and

P

AT

40

i

j

tI

IlV

@

@

AT

I

Inhibitor

switch

2

Manual

shaft

3

Washer

4

Nut

5

Manual

plate

Fi

J

AT

85

Comtruction

of

Inhibitor

Switch

6

Nut

1

Washer

8

Inhibitor

wilch

9

Ran

q

Iect

lever

Check

w

ethcr

he

leverse

lal

1p

and

the

starter

motor

operate

nonnal

Iy

in

these

ranges

If

there

is

any

trouble

first

check

the

inkage

If

no

defect

is

fo

nd

in

the

Ii

leage

check

tlie

inhibitor

Swi

ch

Separate

the

manual

lever

from

the

remote

control

selector

rod

and

turn

the

range

select

lever

to

N

Note

In

the

position

N

the

slot

of

the

manual

shaft

is

vertical

Using

the

tester

check

the

two

black

yellow

BY

wire

from

the

in

hibitor

switch

in

the

ranges

N

and

p

and

the

two

red

blacle

RB

wires

in

the

lange

R

for

continuity

Turn

range

select

lever

in

both

directions

from

each

lever

set

position

and

check

each

continuity

range

It

is

normal

if

the

electricity

is

on

while

the

lever

is

within

an

angle

of

about

30

on

both

sides

from

each

lever

set

line

How

ever

if

its

continuity

range

is

obvioUs

ly

u

nequal

on

both

sides

adjustment

is

required

If

any

malfunction

is

found

un

screw

the

fastening

nut

o

the

range

selector

lever

and

two

fastening

bolts

of

the

switch

body

and

then

remove

the

machine

screw

under

the

switch

body

Adjust

the

manual

shaft

correct

Iy

to

the

position

N

by

means

of

the

selector

leVer

When

the

slot

of

the

shaft

becomes

vertical

the

detent

worles

to

position

the

shaft

correctly

with

a

clicking

sound

Move

the

switch

slightly

aside

so

that

the

scie

hole

will

be

aligned

Page 324 of 548

Front

Axle

Front

Suspension

INSPECTION

AND

ADJUSTIVIENT

INSPECTION

Inspect

in

accordance

with

periodic

maintenance

schedule

Block

rear

wheels

with

chocks

2

Jack

up

the

front

of

car

and

support

it

with

safety

stands

Refer

to

Section

GI

for

lifting

points

and

towing

3

Shaking

each

fiont

wheel

by

grasping

the

upper

and

lower

surfaces

of

the

tires

check

suspension

parts

for

looseness

wear

or

damage

Tighten

aU

loose

bolts

and

nuts

to

the

specified

torque

Replace

all

worn

parts

as

described

under

Front

Suspension

4

Check

wheel

bearings

If

there

is

any

axial

end

play

adjust

bearings

to

specifications

Replace

worn

or

damaged

bearings

as

described

under

Front

Axle

S

Check

strut

for

oil

leakage

or

damage

ADJUSTMENT

WHEEL

BEARING

Block

rear

wheels

with

chocks

2

Jack

up

the

front

of

car

and

support

it

with

safety

stands

3

Remove

brake

pads

Refer

to

Section

BR

for

pad

replacement

4

Remove

hub

cap

cotter

pin

ad

justing

cap

and

wheel

bearing

nut

S

Sparingly

apply

recommended

multi

purpose

grease

to

threaded

por

tion

of

spindle

and

contact

surface

between

wheel

bearing

washer

and

outer

wheel

bearing

6

Tighten

wheel

bearing

nut

using

a

suitable

torque

wrench

P

Tightening

torque

Wheel

bearing

nut

3

0

to

3

5

kll

m

22

to

25

ft

Ibl

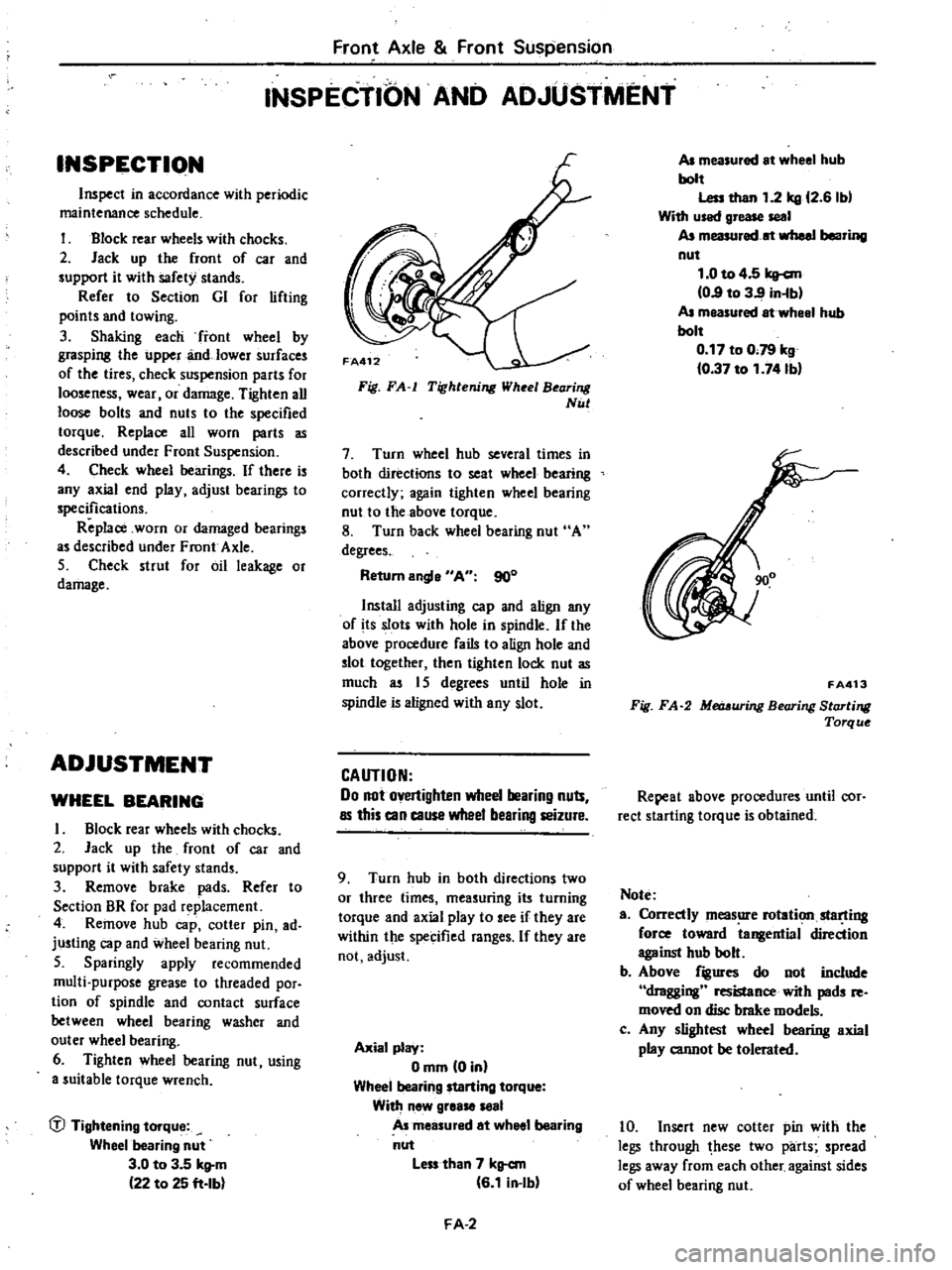

Fig

FA

Tighlening

Wheel

Bearing

Nul

7

Turn

wheel

hub

several

times

in

both

directions

to

seat

wheel

bearing

correctly

again

tighten

wheel

bearing

nut

to

the

above

torque

8

Turn

back

wheel

bearing

nut

A

degrees

Return

engle

AU

900

Install

adjusting

cap

and

align

any

of

its

slots

with

hole

in

spindle

If

the

above

procedure

fails

to

align

hole

and

slot

together

then

tighten

lock

nut

as

much

as

I

S

degrees

until

hole

in

spindle

is

aligned

with

eny

slot

CAUTION

00

not

overtighten

wheel

bearing

nuts

as

this

can

cause

wheel

bearing

seizure

9

Turn

hub

in

both

directions

two

or

three

times

measuring

its

turning

torque

and

axial

play

to

ee

if

they

are

within

the

specified

range

If

they

are

not

adjust

Axial

play

Omm

Din

Wheel

bealing

starting

torque

With

new

gleaS8

l8al

A

measured

et

wheel

bearing

nut

less

than

7

kg

cm

G

1

in

Ibl

FA

2

AJ

measuled

et

wheel

hub

bolt

Less

then

1

2

kg

12

G

Ibl

With

u

ed

gr

seal

AJ

measured

at

wheel

bealing

nut

1

0

to

4

5

kg

cm

0

9

to

3

9

in

b

AJ

measuled

at

wheel

hub

bolt

0

17

to

0

79

kg

0

37

to

1

741bl

FA413

Fig

FA

2

Metr

uring

Bearing

Starting

Torq

ue

Repeat

above

procedures

until

cor

rect

starting

torque

is

obtained

Note

a

Correctly

meas

e

rotation

slar

ting

force

toward

tangential

direction

against

hub

bolt

b

Above

figures

do

not

include

dragging

resistance

with

pads

re

moved

on

disc

brake

models

c

Any

slightest

wheel

bearing

axial

play

cannot

be

tolerated

10

Insert

new

cotter

pin

with

the

legs

through

hese

two

parts

spread

legs

away

from

each

other

against

sides

of

wheel

bearing

nut

Page 332 of 548

wheels

2

Remove

splaahboard

if

necessary

3

Back

off

nut

securing

tension

rod

to

bracket

and

remove

bolts

which

secure

tension

rod

to

lower

arm

Tension

rod

can

then

be

taken

out

4

Remove

nuts

securing

stabilizer

bar

to

connecting

rod

Note

Two

wrenches

are

n

1

in

this

B

5

Remove

bolts

and

nuts

securing

stabilizer

bar

bracket

in

position

Stabilizer

bar

can

then

be

iaken

o

t

CV

3

@

I

Lower

ann

5

Tension

rod

2

Stabilizer

bar

bracket

connecting

rod

6

Tension

rod

3

Stabilizer

bar

4

Stabilizer

bar

bracket

FA129

Fig

FA

31

Removing

Tension

Rod

and

Stabilizer

Bar

INSPECTION

I

Check

tension

rod

and

stabilizer

bar

for

evidence

of

deformation

or

cracks

if

necessary

replace

2

Check

rubber

parts

such

as

ten

sion

rod

and

stabilizer

bar

bushings

to

be

sure

they

are

not

deteriorated

or

cracked

if

1ecessary

replace

INSTAllATION

Install

tension

rod

and

stabilizer

bar

in

tJ

1e

reverse

order

of

removal

noting

the

following

I

Be

sure

stabilizer

bar

is

not

closer

to

either

side

but

is

located

at

the

middle

If

stabilizer

bar

is

new

use

the

following

procedure

to

center

the

stabilizer

bar

Position

arm

with

white

paipt

mark

toward

left

side

of

car

Front

Axle

Front

Suspension

Set

slabillz

rliar

mount

bushingS

So

that

outer

side

of

stabilizer

bar

bushing

is

brought

into

inner

side

of

marking

e

o

I

19

e

1

Marking

2

Bushing

3

Marking

4

While

painting

5

Marking

0

A

F

A667

Fig

FA

32

Centering

8lDbilize

Bar

2

Chec

to

be

sure

that

tension

rod

bushing

is

propelly

centered

in

its

seat

3

Be

sure

that

tension

rod

bracket

bolt

is

correctly

torqued

Note

a

Noting

direction

of

tension

rod

bushing

properly

center

bushing

in

tension

rod

bushing

washer

Fig

FA

33

Direclion

of

Tension

Rod

BUlhing

b

After

installation

make

sure

mini

mum

clearances

between

tension

rods

end

stabilizer

bar

are

equal

on

both

sides

c

Closely

observe

torq

ue

specification

when

tightening

tension

rod

bracket

retaining

bolts

d

First

tighten

tension

rod

on

bracket

side

to

specified

torque

setting

then

install

the

other

end

on

lower

arm

fJ

Tightening

tOlque

Tension

rod

bushing

installation

nut

4

5

to

5

11rg

33

to

37

ft

lbl

FA

10

Tension

rOd

to

Lower

ann

5

1

to

6

1

kg

m

137

to

44

ft

Ibl

Tension

rod

bracket

to

body

3

2

to

4

3

kg

m

23

to

31

ft

Ibl

Stabilizer

bar

bleck

t

1

6to2

11rg

112

to

15

ft

lbl

Stabilizel

bel

connecting

rod

1

6

to

2

1

kg

m

12

to

15

ft

lbl

LOWER

ARM

AND

LOWER

BALL

JOINT

The

lower

ann

is

connected

to

the

suspension

member

through

a

rubber

bwhing

end

to

the

strut

through

a

ball

joint

The

lower

ball

joint

is

assembled

at

the

factory

and

cannot

be

disassem

bled

REMOVAL

1

Block

rear

wheels

with

chocks

2

Jack

up

front

of

car

and

support

it

with

safety

stands

remove

wheel

3

Remove

splashboard

4

Separate

knuckle

arm

from

strut

5

Pry

colter

pin

off

and

separate

side

rod

fromknilckle

arm

using

Ball

Joint

Remover

HT72520000

FA661

Fig

FA

34

Remoliing8ideRod

Ball

Joint

6

Remove

tension

rod

and

stabilizer

bar

from

lower

ann

7

Remove

bolt

connecting

lower

ann

to

suspension

crossmember

Page 344 of 548

REAR

AXLE

REAR

AXLE

ASSEMBLY

Remove

L

Block

front

wheels

with

chocks

2

Raise

rear

of

car

high

enough

to

pennit

working

underneath

and

place

stands

solidly

under

body

member

on

both

sides

RA544

Fig

RA

2

Supporting

Point

3

Support

under

center

of

dif

ferential

carrier

with

a

garage

jack

4

Remove

rear

wheels

5

Disconnect

propeller

shaft

by

re

moving

bolts

CD

securing

propeller

shaft

flange

to

companion

flange

of

differential

carrier

6

Disconnect

brake

hose

from

brake

tube

at

body

@

and

rear

cable

adjuster

@

Fig

RA

3

Removing

Propeller

Shaft

and

Brohe

Hose

CAUTION

e

When

disconnecting

brake

tube

use

suitable

tube

wrench

Never

use

open

end

or

adjustable

wrench

b

Cover

brake

hose

end

pipe

open

ings

to

prevent

entrance

of

dirt

Rear

Axle

Rear

Suspension

7

Remove

bolts

securing

shock

absorber

lower

ends

on

each

side

RA485

Fig

RA

4

Removing

Bolt

Securing

Shock

Absorber

Lower

End

Note

When

removing

shock

absorber

lower

end

from

bracket

squeeze

shock

absorber

and

lift

it

out

right

above

to

accommodate

em

bossment

inside

bracket

C

AA486

Fig

RA

5

Shock

Absorber

Lower

End

8

Lower

jack

slowly

and

remove

cojI

springs

on

each

side

after

they

are

fully

extended

AA546

Fig

RA

6

Removing

Coil

Spring

9

Raise

jack

to

its

original

position

10

Remove

bolts

CD

and

@

se

curing

upper

and

lower

links

at

axle

case

side

RA

3

Fig

RA

7

Disconnecting

Upper

Link

and

Lower

Link

II

Release

garage

jack

slowly

and

pull

it

out

toward

rear

of

car

In

tenetlon

Install

rear

axle

in

the

reverse

order

of

removal

CAUTION

a

When

installing

brake

tubes

use

Flare

Nut

Torque

Wrench

GG94310000

b

Before

tightening

link

bushing

nuts

temporarily

attach

upper

and

lower

links

to

axle

case

Alter

jacking

up

center

of

differential

carrier

until

upper

Bnd

lower

links

are

almost

horizontal

securely

tighten

link

bushing

nuts

c

When

supporting

car

weight

at

Cl

nter

of

differential

carrier

do

not

put

a

load

in

car

j

Tightening

torque

Brake

tube

flare

nut

1

5

to

1

8

kg

m

11

to

13

ft

lb

Propeller

shaft

to

companion

flange

connecting

nut

2

4

to

3

3

kg

m

17

to

24

ft

Ibl

Shock

absorber

lower

end

nut

7

0

to

8

0

kg

m

51

to

58

ft

Ibl

lower

link

fixing

nut

7

0

to

8

0

kg

m

51

to

58

ft

Ib

Upper

link

fixing

nut

7

0

to

8

0

kg

m

51

to

58

ft

lb

Page 378 of 548

t

MAINTEN

NCE

TIRE

INFLATION

Correct

tire

pressure

is

very

impor

tant

for

steering

ease

and

riding

com

fort

Correct

pressure

also

makes

for

a

quieter

ride

and

extends

tire

life

If

all

tires

are

inspected

frequently

and

maintained

at

correct

pressure

any

sharp

objects

in

tread

can

be

quickiy

detected

nd

abnormal

wear

which

invites

serious

problems

can

be

avoided

After

inflating

tires

valves

should

be

checked

for

leakage

Without

valve

caps

leakage

will

occur

due

to

dirt

and

water

resulting

in

underinflation

Ac

cordingly

whenever

tire

pressure

is

checked

be

sure

to

tighten

vaive

caps

firmly

by

hand

JW

Sri

in

1

II

I

i

I

1

I

1

1

I

I

I

II

I

I

I

i

M

I

l

1

14

nl

01

I

II

Toe

in

or

toe

out

wear

I

J

I

I

p

rt

i

Ilnl

lll

11111

IllIlI

Shoulder

wear

Toe

in

or

toe

out

wear

When

the

front

wheels

are

aligned

in

an

excessive

toe

in

or

toe

out

condi

tion

the

tires

will

tend

to

scrape

the

tread

rubber

off

and

the

tread

will

de

elop

a

feathered

edge

Center

wear

Center

wear

is

caused

by

overinfla

tion

of

the

tire

Wheel

and

Tire

WHEEL

AND

TIRE

TIRE

WEAR

Tread

ar

Indicator

Tires

are

provided

with

tr

lad

wear

indicator

at

six

places

around

tire

circumference

indicating

1

6

mm

J

in

tread

depth

When

tires

wear

and

then

marks

appear

replace

them

wtth

new

ones

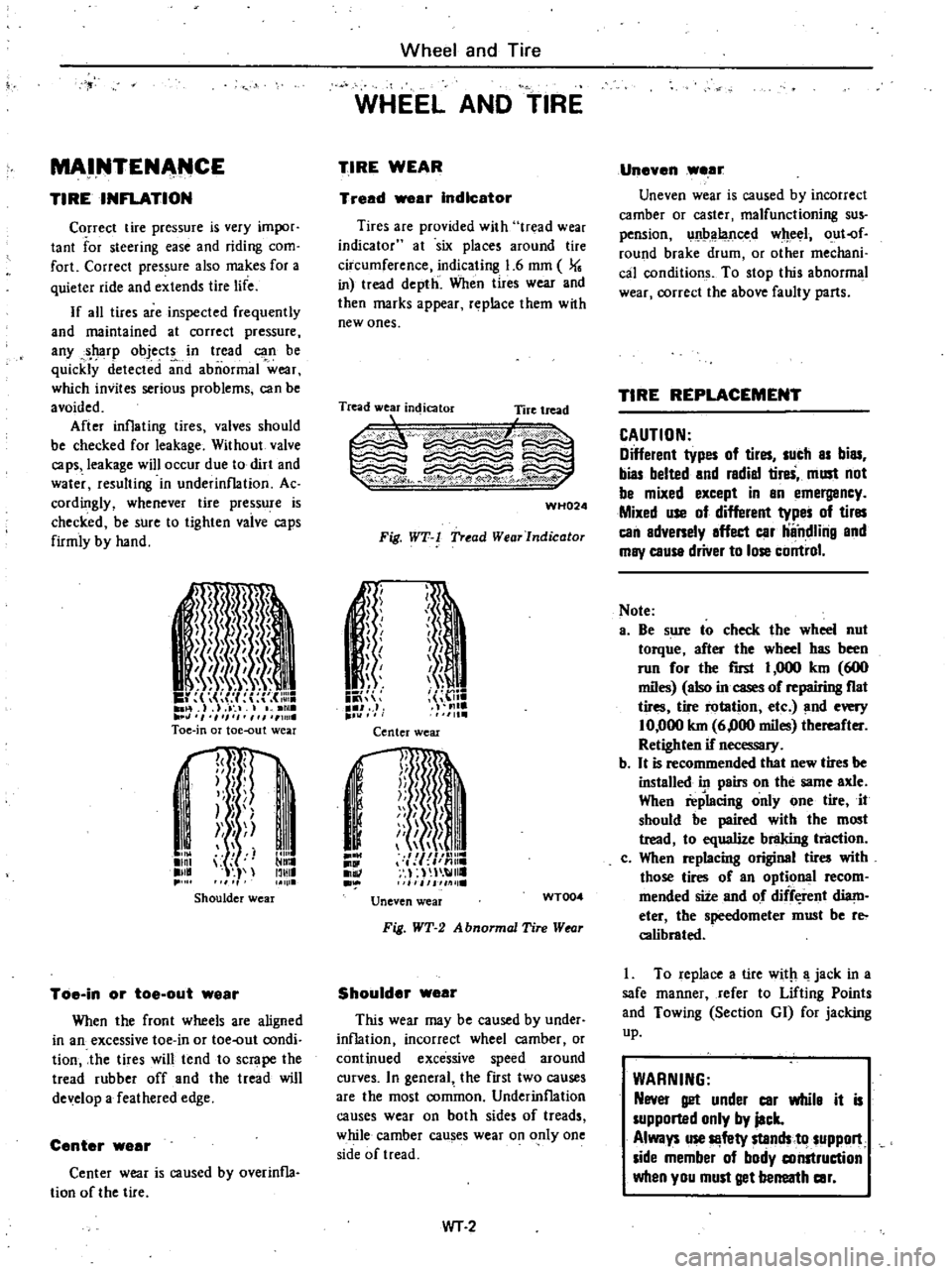

Tread

wear

indicator

Tire

tread

L

1

c

WH024

Fig

WT

l

Tread

WearJndicator

n

1

ii

J

J

f

J

I

h

I

me

1111

Center

wear

j

I

1II

mnr

I

j

n

Ii

Ii

i

I

Jil

111

lie

Uneven

wear

WT004

Fig

WT

2

A

bnormal

Tire

Wtor

Shoulder

wear

This

wear

may

be

caused

by

under

inflation

incorrect

wheel

camber

or

continued

excessive

speed

around

curves

In

general

the

first

two

causes

are

the

most

common

Underinflation

causes

wear

on

both

sides

of

treads

while

camber

causes

wear

on

only

one

side

of

tread

WT

2

Uneven

wear

Uneven

wear

is

caused

by

incorrect

camber

or

caster

malfunctioning

sus

pension

unbalanced

wheel

out

of

round

brake

drum

or

other

mechani

cal

conditions

To

stop

this

abnormal

wear

correct

the

above

faulty

parts

TIRE

REPLACEMENT

CAUTION

Different

types

of

tires

sucb

as

bias

bias

belted

and

radial

tireS

must

not

be

mixed

except

in

an

emergancy

Mixed

use

of

different

types

of

tires

can

adversely

affect

car

ilndlilig

and

may

cause

driver

to

lose

control

Note

a

Be

sure

to

check

the

wheel

nut

torque

after

the

wheel

has

been

run

for

the

rust

I

000

km

600

miles

also

in

cases

of

repairing

fiat

tires

tire

rotation

etc

and

every

10

000

km

6

000

miles

thereafter

Retighten

if

necessary

b

It

is

recommended

that

new

tires

be

installed

in

pairs

on

the

same

axle

When

replacing

only

one

tire

it

should

be

paired

with

the

most

tread

to

equalize

braking

tl1lction

c

When

replacing

original

tires

with

those

tires

of

an

optional

recom

mended

site

and

of

diff

rent

diam

eter

the

speedometer

must

be

reo

calibrated

I

To

replace

a

tire

with

a

jack

in

a

safe

manner

refer

to

Lifting

Points

and

Towing

Section

GI

for

jacking

up

WARNING

Never

get

under

car

whila

it

is

supported

only

by

jack

Always

use

Il

fety

stands

to

suppon

side

member

of

body

construction

when

you

must

get

berreatb

car

Page 391 of 548

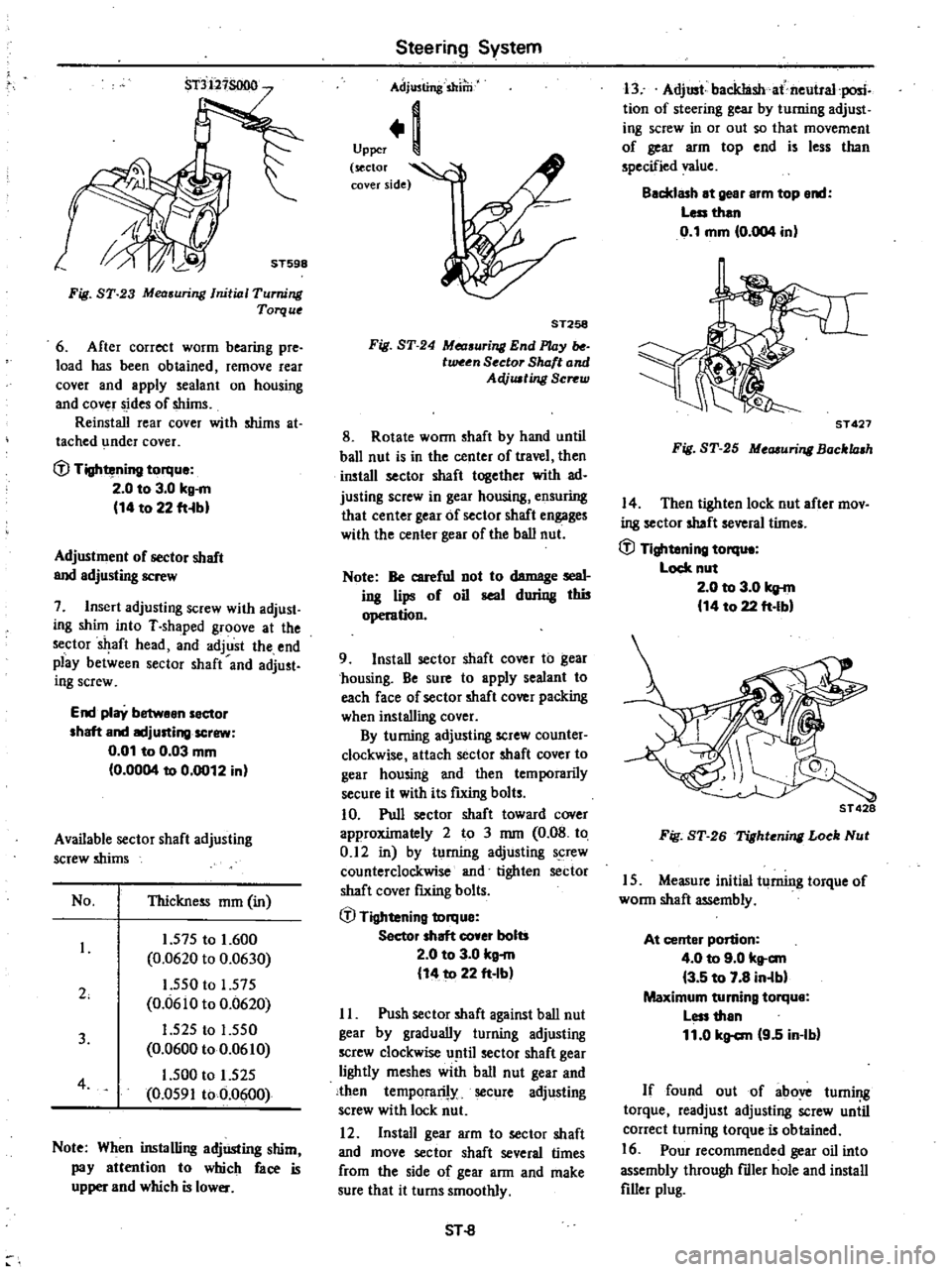

Fig

ST

23

Mea

uring

Initial

Turning

Torque

6

After

correct

worm

bearing

pre

load

has

been

obtained

remove

rear

cover

and

apply

sealant

on

housing

and

cover

sides

of

shims

Reinstall

rear

cover

with

shims

at

tached

under

cover

fJ

Tightening

torque

2

0

to

3

0

kg

m

14

to

22

fHbl

Adjustment

of

sector

shaft

and

adjusting

screw

7

Insert

adjusting

screw

with

adjust

ing

shUn

into

T

shaped

groove

at

the

sector

aft

head

and

adjust

the

end

play

between

sector

shaft

and

adjust

ing

screw

End

play

betwean

sector

shaft

and

IKljusting

screw

0

01

to

0

03

mm

0

0004

to

0

0012

in

Available

sector

shaft

adjusting

screw

shims

No

Thickness

mm

in

2

1

575

to

1

600

0

0620

to

0

0630

1

550

to

1

575

0

0610

to

0

0620

1

525

to

1

550

0

0600

to

0

0610

1

500

to

1

525

0

0591

to

0

0600

3

4

Note

When

installing

adjUsting

shim

pay

attention

to

which

face

is

upper

and

which

is

lower

Steering

System

Adjusting

shilli

Upper

1

sector

l

cover

side

ST258

Fig

ST

24

Measuri

End

l

UJy

tween

Sector

Shaft

and

AeVusting

Screw

8

Rotate

wonn

shaft

by

hand

until

ball

nut

is

in

the

center

of

travel

then

install

sector

shaft

together

with

ad

justing

screw

in

gear

housing

ensuring

that

center

gear

of

sector

shaft

engages

with

the

center

gear

of

the

ball

nut

Note

Be

careful

not

to

damage

seal

ing

lips

of

oil

seal

during

thi5

operation

9

Install

sector

shaft

cover

to

gear

chousing

Be

sure

to

apply

sealant

to

each

face

of

sector

shaft

cover

packing

when

installing

cover

By

turning

adjusting

screw

counter

clockwise

attach

sector

shaft

cover

to

gear

housing

and

then

temporarily

secure

it

with

its

futing

bolts

10

Pull

sector

shaft

toward

cover

approxUnately

2

to

3

mm

0

08

to

0

12

in

by

turning

adjusting

screw

counterclockwise

and

tighten

sector

shaft

cover

fIXing

bolts

fJ

Tightening

torque

Sector

shaft

co

er

bolts

2

0

to

3

0

kg

m

14

to

22

ft

Ib

II

Push

sector

shaft

against

ball

nut

gear

by

gradually

turning

adjusting

screw

clockwise

until

sector

shaft

gear

lightly

meshes

with

ball

nut

gear

and

then

temporarily

secure

adjusting

screw

with

lock

nut

12

Install

gear

arm

to

sector

shaft

and

move

sector

shaft

several

times

from

the

side

of

gear

ann

and

make

sure

that

it

turns

smoothly

SHl

13

Adjust

backIashat

neutral

posic

tion

of

steering

gear

by

turning

adjust

iog

screw

in

or

out

so

that

movement

of

gear

arm

top

end

is

less

than

specified

value

Backlash

at

gear

arm

top

end

Less

than

0

1

mm

0

004

in

ST

427

Fig

ST

25

Measuri

Bocklash

14

Then

tighten

lock

nut

after

mov

ing

sector

shaft

several

tUnes

fJ

Tightening

torqu

Lock

nut

2

0

to

3

0

kg

m

14

to

22

ft

Ibl

ST

428

Fig

ST

26

Tighteni

Loek

Nut

15

Measure

initial

turning

torque

of

wonn

shaft

assembly

At

center

portion

4

0

to

9

0

kt

c

m

3

5

to

7

8

in

lbl

Maximum

turning

torque

Less

than

11

0

kg

c

m

9

5

in

Ib

If

found

out

of

above

turning

torque

readjust

adjusting

screw

uniil

correct

turning

torque

is

obtained

16

Pour

recommended

gear

oil

into

assembly

through

fdler

hole

and

install

filler

plug

Page 404 of 548

Engine

Control

f1lel

Exhaust

Systems

flow

be

directed

toward

atmosphere

side

2

Blow

air

tluough

connector

on

atmosphere

side

Air

flow

should

be

smoothly

directed

toward

fuel

tank

3

If

cbeck

valve

is

suspected

of

not

being

properly

functioning

in

steps

I

and

2

above

replace

To

fuel

tank

FE477

Pressure

valve

Vacuum

valve

Return

spring

Fig

FE

6

Checking

Check

Valve

INSTALLATION

Install

any

parts

of

the

fuel

system

in

the

reverse

order

of

removal

Ob

serve

the

following

notes

Note

a

Install

hose

clamps

securely

Do

not

tighten

excessively

to

avoid

dam

aging

hoses

b

Fasten

clips

holding

fuel

tube

on

underbody

securely

Failure

to

fol

low

this

caution

could

result

in

damage

to

the

surface

of

fuel

tube

c

Do

not

kink

or

twist

hOse

and

tube

when

they

are

routed

d

Run

the

engine

and

check

for

leaks

at

connections

FUEL

TANK

Not

InstaU

fuel

filler

hose

after

fuel

tank

has

been

mounted

in

place

Failure

to

foUow

this

rule

could

result

in

leakage

from

around

hose

connections

Do

not

twist

or

smash

vent

hoses

when

they

are

routed

Be

sure

to

retain

them

with

clips

securely

FE

6

@

Tightening

torque

Drain

plug

1

6

to

2

4

kg

m

112

tn

17

ft

bl

Fuel

tank

0

8

to

1

2

kll

m

15

8

to

8

7

ft

Ibl

FUEL

TANK

GAUGE

UNIT

Note

When

installing

fuel

tank

gauge

unit

aJign

the

projection

of

tank

gauge

unit

with

the

notch

in

fuel

tank

and

tighten

it

securely

Be

sure

to

instaU

tank

gauge

unit

with

O

ring

in

place

CHECK

VALVE

Note

When

installing

check

valve

be

careful

of

its

designated

direction

See

Fig

FE

Page 407 of 548

Engine

Control

Fuel

Exhaust

Systems

8

Remove

front

exhaust

tube

from

exhaust

manifold

NON

CALIFORNIA

MODELS

EXCEPT

FU

MODEL

I

Temporarily

loosen

nuts

securing

front

exhaust

tube

assembly

to

ex

haust

manifold

2

Remove

front

exhaust

tube

as

sembly

from

exhaust

mounting

brack

et

3

Temporarily

loosen

bolts

securing

exhaust

mounting

insulator

to

body

and

remove

bolts

securing

muffler

lower

clamp

and

muffler

to

muffler

upper

clamp

4

Remove

exhaust

tube

clip

5

Break

sealant

off

the

front

tube

to

rear

tube

connection

Note

A

sealant

is

applied

to

the

tube

connections

to

eliminate

the

leak

age

of

exhaust

gases

Observe

the

procedures

outlined

later

in

this

section

as

a

guide

6

Remove

front

tube

from

exhaust

manifold

then

remove

rear

tube

from

car

Refer

to

California

Models

and

FU

Model

for

removal

When

disconnecting

the

exhaust

tube

connections

observe

the

follow

ing

parts

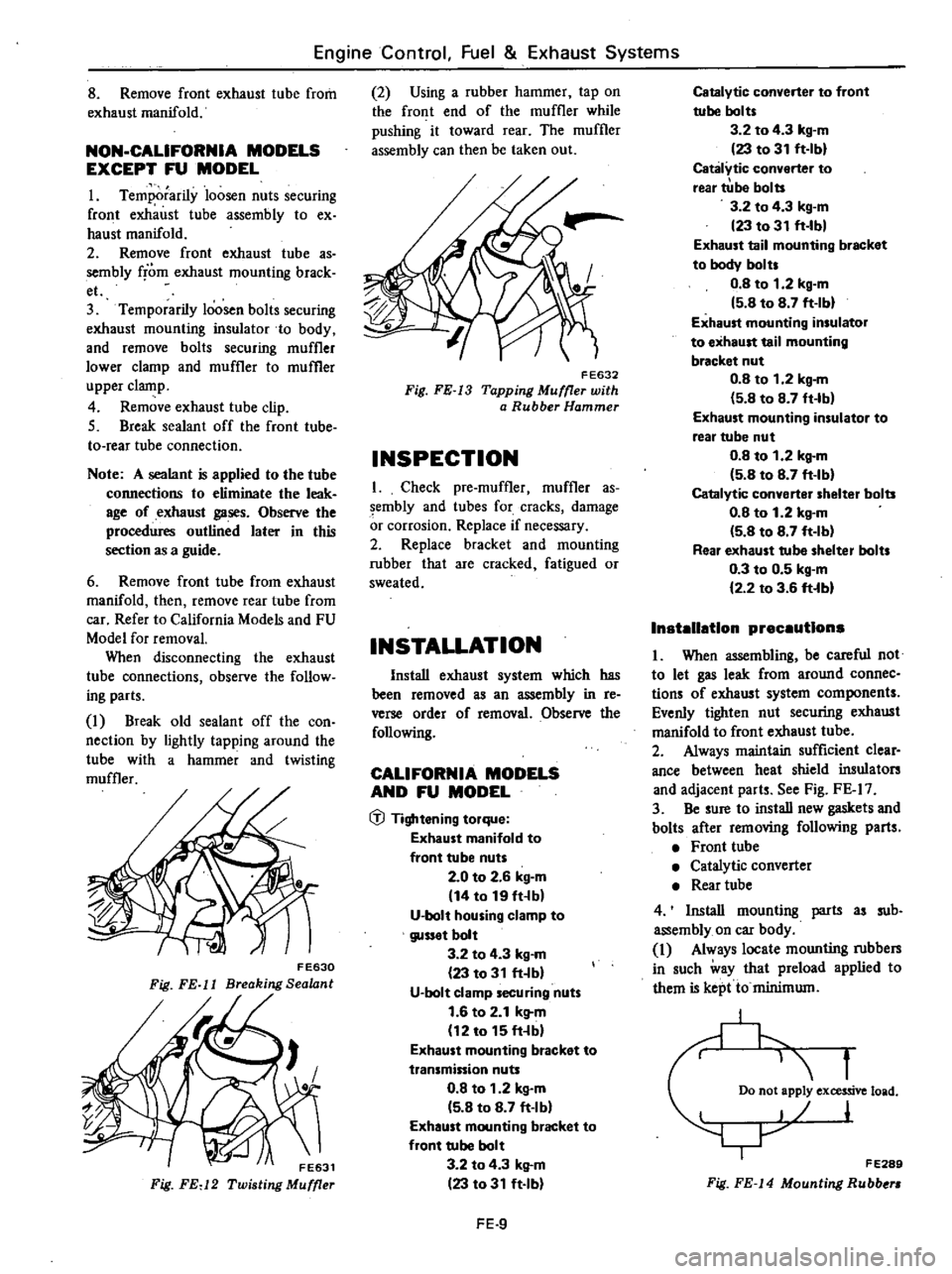

I

Break

old

sealant

off

the

con

nection

by

lightly

tapping

around

the

tube

with

a

hammer

and

twisting

muffler

F

E630

Fig

FE

11

Breaking

Sealant

Fig

FEd

2

2

Using

a

rubber

hammer

tap

on

the

front

end

of

the

muffler

while

pushing

it

toward

rear

The

muffler

assembly

can

then

be

taken

out

FE632

Fig

FE

13

Tapping

Muffler

with

a

Rubber

Hammer

INSPECTION

I

Check

pre

muffler

muffler

as

sembly

and

tubes

for

cracks

damage

or

corrosion

Replace

if

necessary

2

Replace

bracket

and

mounting

rubber

that

are

cracked

fatigued

or

sweated

INSTALLATION

Install

exhaust

system

which

has

been

removed

as

an

assembly

in

re

verse

order

of

removal

Observe

the

following

CALIFORNIA

MODELS

AND

FU

MODEL

1Jl

Tightening

torque

Exhaust

manifold

to

front

tube

nuts

2

0

to

2

6

kg

m

14

to

19

fHb

U

bolt

housing

clamp

to

gusset

bolt

3

2

to

4

3

kg

m

23

to

31

ft

bl

U

bolt

clamp

securing

nuts

1

6

to

2

1

k

l

m

12

to

15

ft

bl

Exhaust

mounting

bracket

to

transmission

nuts

0

8

to

1

2

kg

m

5

8

to

8

7

ft

Ibl

Exhaust

mounting

bracket

to

front

tube

bolt

3

2

to

4

3

k

l

m

23

to

31

ft

Ib

FE

9

CatalytiC

converter

to

front

tube

bolts

3

2

to

4

3

kg

m

23

to

31

ft

Ibl

Catalytic

converter

to

rear

tUbe

bolts

3

2

to

4

3

kg

m

23

to

31

ft

Ibl

Exhaust

tail

mounting

bracket

to

body

bolts

0

8

to

1

2

kg

m

5

B

to

8

7

ft

Ibl

Exhaust

mounting

insulator

to

exhaust

tail

mounting

bracket

nut

0

8

to

1

2

kg

m

5

8

to

8

7

ft

Ib

Exhaust

mounting

insulator

to

rear

tube

nut

O

B

to

1

2

kg

m

5

8

to

8

7

ft

Ib

Catalytic

converter

shelter

bolts

O

B

to

1

2

kg

m

5

8

to

B

7

ft

Ib

Rear

exhaust

tube

shelter

bolts

0

3

to

0

5

kg

m

2

2

to

3

6

ft

bl

Installation

precautions

I

When

assembling

be

careful

not

to

let

gas

leak

from

around

connec

tions

of

exhaust

system

components

Evenly

tighten

nut

securing

exhaust

manifold

to

front

exhaust

tube

2

Always

maintain

sufficient

clear

ance

between

heat

shield

insulators

and

adjacent

parts

See

Fig

FE

I7

3

Be

sure

to

install

new

gaskets

and

bolts

after

removing

following

parts

Front

tube

Catalytic

converter

Rear

tube

4

Install

mounting

parts

as

sub

assembly

on

car

body

I

Always

locate

mounting

rubbers

in

such

way

that

preload

applied

to

them

is

kept

to

minimum

f

Do

not

apply

excessive

load

I

F

E289

Fig

FE

J4

Mounting

Rubbe