engine oil DATSUN 210 1979 Owner's Guide

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 65 of 548

Engine

Mechanical

CRANKSHAFT

1

Q

I

j

s

l

s

A

B

AI4

AI5

Unit

mm

in

Journal

diameter

A

c

r

49

951

to

49

964

h9666

to

1

967

1

Pin

diameter

8

44

961

to

44

974

I

7701

to

1

7706

EM777

8

38

45

to

38

55

1

5138

to

1

5177

Standard

Out

of

round

X

Y

Taper

A

B

Taper

and

out

of

round

of

Less

than

A

B

journal

and

crank

pin

0

005

0

0002

0

A

B

X

Y

Crankshaft

bend

Less

than

0

025

0

0010

Crankshaft

free

end

play

0

05

to

0

15

EM715

0

0020

to

0

0059

BEARING

Bearing

oil

clearance

Unit

mm

in

Standard

Wear

limit

Main

bearing

clearance

0

026

to

0

090

0

0010

to

0

035

0

10

0

0039

CO

llecting

rod

bearing

clearance

0

030

to

0

079

0

0012

to

0

0031

EM

28

40

95

to

41

05

1

6122

to

1

6161

Unit

mm

in

Wear

limit

0

03

0

0012

0

05

0

0020

0

30

0

0118

Page 67 of 548

t

IGHTENING

TORQUE

Cylinder

head

bolt

Rocker

shaft

bracket

bolt

ain

bearing

cap

bolt

Flywheel

fixing

bolt

Drive

plate

fixing

bolt

Al4

AlS

Connecting

rod

cap

nut

Camshaft

sprocket

bolt

Locating

plate

bolt

Valve

rocker

adjusting

nut

Oil

strainer

bolt

Oil

pan

bolt

Oil

pan

drain

plug

Timing

chain

cover

bolt

Crank

pulley

bolt

Water

pump

bolt

Fuel

pump

bolt

Spark

plug

Engine

mounting

securing

bolt

Engine

Mechanical

Unit

kg

iii

ft

lb

7

0

to

7

5

51

to

54

2

0t02

5

14to

18

5

0

to

6

0

36

to

43

8

0

to

9

0

58

to

65

8

0

to

9

0

58

to

65

8

5

to

9

5

61

to

69

3

2

to

3

8

23

to

27

4

0

to

4

8

29

to

35

0

5

to

0

8

3

6

to

5

8

1

6

to

2

2

12to

16

0

9

to

I

4

6

5

to

10

1

0

4

to

0

6

2

9

to

4

3

2

0

to

3

0

14

to

22

0

5

to

0

7

3

6

to

5

1

15to

20

l08

to

145

0

9

to

I

4

6

5

to

1O

l

0

9

to

I

4

6

5

to

10

1

1

5

to

2

0

11

to

14

1

9

to

2

5

14to

18

EM

30

Page 68 of 548

Engine

Mechanical

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Condition

I

Noill

f

onglno

Knocking

of

crank

shaft

and

bearing

Piston

and

connecting

rod

knocking

Camshaft

knocking

Timilli

chain

noise

Camshaft

and

valve

mechanism

knock

ing

Probable

cause

Loose

main

bearing

Seized

bearing

Ben

crankshaft

Excessive

crankshaft

end

play

Loose

bearing

Seized

bearing

Loose

piston

pin

Loose

piston

in

cylinder

Broken

piston

ring

Improper

connecting

rod

alignment

Loose

bearing

Exc

essive

axial

play

Rough

ge

r

teeth

8roken

cam

gear

Improper

chain

tension

Worn

and

or

damaged

chain

I

Wom

sprocket

Worn

and

or

broken

tension

adjusting

mecha

nism

Excessive

camshaft

and

bearing

clearance

Improper

valve

clearance

Worn

adjusting

screw

Worn

rocker

face

Loose

valve

stem

in

guide

Weakened

valve

pring

Seized

valve

EM

31

Corrective

action

Replace

Replac

Repair

or

replace

Peplace

center

thrust

bearing

l

Replace

Replace

Replace

pin

or

bushing

Recondition

cylinder

Replace

Realign

Replace

Replace

bearing

thrust

plate

Repair

Replace

Adjust

Replace

Replace

Replace

Replace

AdjUst

Replace

Replace

Replace

guide

Replace

Repair

or

replace

Page 69 of 548

Condition

Waterpurnp

knocking

II

Othw

mllChani

troubl

Stuck

valve

Seized

valve

seat

Excessively

wom

cylinder

and

piston

Engine

Mechanical

Probab

Ie

cause

Improper

shaft

end

play

Broken

impeller

Improper

valve

clearance

Insufficient

clearance

between

valve

stem

and

guide

Weakened

or

broken

valve

pring

Biting

or

damage

of

valve

stem

Poor

fuel

quality

Il1

prop

r

valve

clearance

Weakened

valve

pring

Thin

valve

head

edge

Narrow

valve

seat

Overheating

Over

speeding

Sticked

valve

guide

Shortage

ofengine

oil

Dirty

engine

oil

Poor

oil

quality

Overheat

Wrong

assembly

of

piston

with

connecting

rod

Improper

piston

ring

clearance

Dirty

air

cleaner

Too

rich

mixture

Engine

over

run

Stuck

choke

valve

Over

choking

EM

32

Corrective

action

Replace

Replace

Adjust

Clean

stem

or

ream

the

guide

Replace

Repil

ce

or

clean

Use

good

fuel

Adjust

Replace

Replace

valve

Reface

Repair

or

replace

Drive

at

proper

speed

Repair

Add

or

replace

oil

Check

oil

level

on

daily

basis

Clean

crankcase

replace

oil

and

re

place

oil

ftIter

element

Use

proper

oil

Repair

or

replace

Repair

or

replace

Adjust

Clean

periodically

Adju

t

Drive

correctly

Clean

and

adjust

Start

in

correct

way

Page 70 of 548

Condition

Faulty

connecting

rod

Faulty

crankshaft

bearing

Engine

Mechanical

Probable

cause

Shortage

of

engine

oil

Low

oil

pressure

Poor

engine

oil

quality

Rough

crankshaft

surface

Clogged

oil

passage

Bearing

worn

or

eccentric

Bearing

improperly

assembled

Loose

bearing

Incorrect

connecting

rod

alignment

Shortage

of

engine

oil

Low

oil

pressure

Poor

quality

engine

oil

Worn

or

out

of

round

crankshaft

journal

Clogged

oil

passage

in

crankshaft

Bearing

worn

or

eccentric

Bearing

inproperly

assembled

Non

co

centric

crankshaft

or

bearing

EM

33

Corrective

action

Add

or

replace

oil

Check

oil

level

on

daily

basis

Correct

Use

proper

oil

Grind

and

replace

bearing

Clean

Replace

Repair

Replace

Repair

or

replace

Add

or

replace

Check

oil

level

on

daily

basis

Adjust

Use

proper

oil

Repair

Clean

Replace

Repair

Replace

Page 73 of 548

DATSUN

210

Model

8310

Series

SECTIONEL

ENGINE

LUBRICATION

SYSTEM

CONTENTS

ENGINE

LUBRICATION

SYSTEM

LUBRICATION

CIRCUIT

01

L

PUMP

OIL

PRESSURE

REGULATOR

VALVE

OIL

PRESSURE

RELIEF

VALVE

OIL

FILTER

OIL

PRESSURE

WARNING

SWITCH

EL

2

EL

2

EL

3

EL

4

EL

4

EL

4

EL

4

SERVICE

DATA

AND

SPECIFICATIONS

TROUBLE

DIAGNOSES

AND

CORRECTIONS

SPECIAL

SERVICE

TOOL

EL

5

EL

5

EL

6

Page 74 of 548

Engine

Lubrication

System

ENGINE

LUBRICATION

SYSTEM

LUBRICATION

CIRCUIT

EL

ll2

Fig

EL

l

Lubrication

Circuit

Oil

pump

Oilf1lter

I

I

Main

bearing

I

I

Crankshaft

I

Connecting

rod

I

bearing

l

Oil

trainer

I

Camshaft

bearing

I

Rocker

shaft

Chain

tensioner

Rocker

arm

Camshaft

Valve

lifter

Piston

Cylinder

wall

OiIpan

EL

2

Page 75 of 548

OIL

PUMP

The

oil

pump

and

filter

assembly

is

bolted

to

the

right

side

of

the

cylinder

block

and

can

be

removed

with

the

engine

in

pl

c

The

oil

pump

which

is

driven

by

a

gear

on

the

camshaft

has

the

full

flow

element

type

filter

in

stalled

to

the

oil

pump

cover

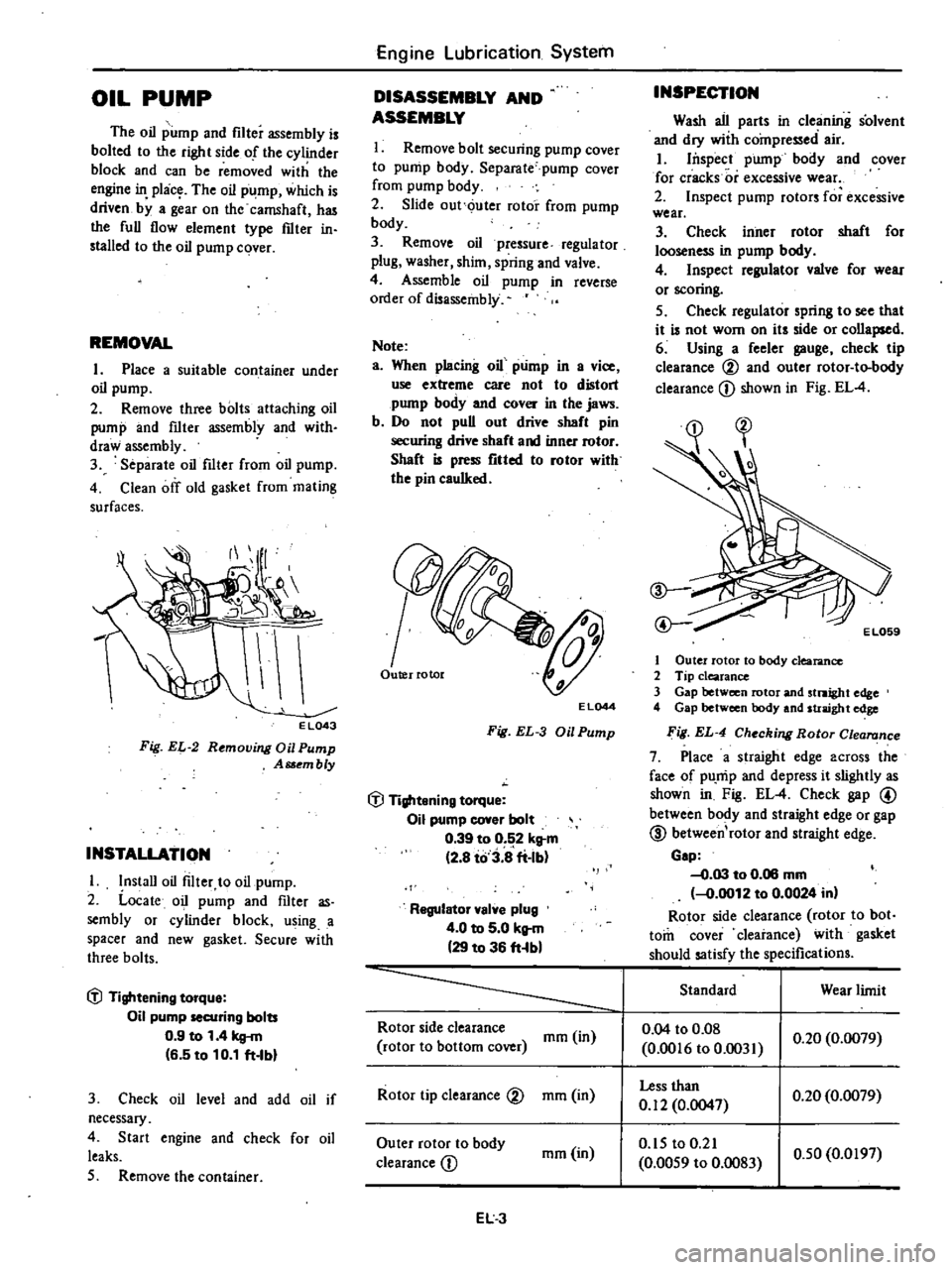

REMOVAL

I

Place

a

suitable

container

under

oil

pump

2

Remove

three

bolts

attaching

oil

pump

and

filter

assembly

and

with

draw

assembly

3

Separate

oil

filter

from

oil

pump

4

Ciean

off

old

gasket

from

mating

surfaces

i

E

L043

F

EL

2

R

moving

Oil

Pump

Asso

mbly

INSTALLATION

I

Install

oil

filter

to

oil

pump

2

Locate

oil

pump

and

filter

as

sembly

or

cylinder

block

using

a

spacer

and

new

gasket

Secure

with

three

bolts

l

l

Tightening

torque

Oil

pump

securing

bolts

0

9

to

1

4

kg

m

6

5

to

10

1

ft

lbl

3

Check

oil

level

and

add

oil

if

necessary

4

Start

engine

and

check

for

oil

leaks

5

Remove

the

container

Engine

Lubrication

System

DISASSEMBLY

AND

ASSEMBLY

I

Remove

bolt

securing

pump

cover

to

pump

body

Separate

pump

cover

from

pump

body

2

Slide

out

outer

rotor

from

pump

body

3

Remove

oil

pressure

regulator

plug

washer

shim

spring

and

valve

4

Assemble

oil

pump

in

reverse

order

of

disassembly

Note

a

When

placing

oil

pump

in

a

vice

use

extreme

care

not

to

distort

pump

body

and

cover

in

the

jaws

b

Do

not

pull

out

drive

shaft

pin

securing

drive

shaft

and

inner

rotor

Shaft

is

press

fitted

to

rotor

with

the

pin

caulked

EL044

Fig

EL

3

Oil

Pump

l

l

Tightening

torque

Oil

pump

cove

bolt

0

39

to

0

5

2

kltm

2

8

to

3

8

ti

Ib

Regulator

valve

plug

4

0

to

5

0

kltm

29

to

36

ft

bl

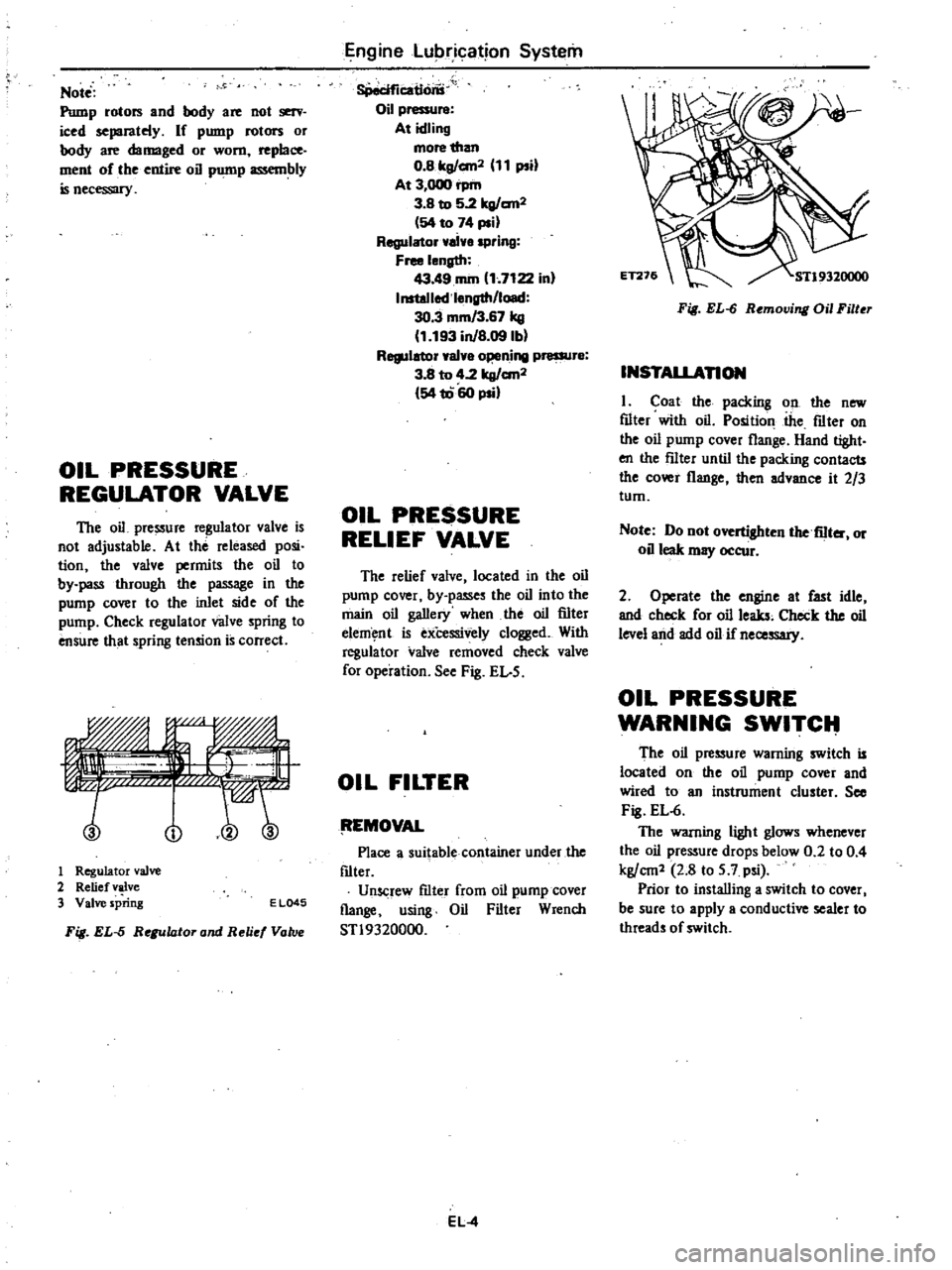

INSPECTION

Wash

all

parts

in

cleaning

solvent

and

dry

wiih

compressed

air

I

hispect

pump

body

and

cover

for

cracks

or

excessive

wear

2

Inspect

pump

rotors

for

excessive

wear

3

Check

inner

rotor

shaft

for

looseness

in

pump

body

4

Inspect

regulator

valve

for

wear

or

scoring

5

Check

regulator

spring

to

see

that

it

is

not

worn

on

its

side

or

collapsed

6

Using

a

feeler

gauge

check

tip

clearance

00

and

outer

rotor

to

body

clearance

CD

shown

in

Fig

EL

4

EL059

1

Outer

rotor

to

body

clearance

2

Tip

clearance

3

Gap

between

rotor

and

stnight

edge

4

Gap

between

body

and

straight

edge

ig

EL

4

Checking

Rotor

Clea

nce

7

Place

a

straight

edge

across

the

face

of

pU

mp

and

depress

it

slightly

as

shown

in

Fig

EL

4

Check

gap

@

between

body

and

straight

edge

or

gap

@

between

rotor

and

straight

edge

Gap

0

03

to

0

06

mm

0

0012

to

0

0024

in

Rotor

side

clearance

rotor

to

bot

tom

cover

clearance

with

gasket

should

satisfy

the

specifications

Standard

Wear

limit

Rotor

side

clearance

mm

in

0

04

to

0

08

rotor

to

bottom

cover

0

0016

to

0

031

0

20

0

0079

Rotor

tip

clearance

V

mm

in

Less

than

0

20

0

0079

0

12

0

0047

Outer

rotor

to

body

mm

in

0

15

to

0

21

0

50

0

0197

clearance

CD

0

0059

to

0

083

EL3

Page 76 of 548

Not

Pump

rotors

and

body

are

not

serv

iced

separatdy

If

pump

rotors

or

body

are

damaged

or

worn

replace

ment

of

the

entire

oil

pump

assembly

isnecessary

OIL

PRESSURE

REGULATOR

VALVE

The

oil

pressure

regulator

valve

is

not

adjustable

At

the

released

posi

tion

the

valve

permits

the

oil

to

by

pass

through

the

passage

in

the

pump

cover

to

the

inlet

side

of

the

pump

Check

regulator

valve

spring

to

ensure

that

spring

tension

is

correct

no

1

Regulator

valve

2

Relief

valve

3

Valve

spring

E

L045

Fig

EL

5

Regulator

and

Reli

Vatv

Engine

Lubrication

System

8Peciflcatlons

Oil

pressure

At

idling

more

than

O

Blrg

an2

11

psi

At

3

000

rpm

3

B

to

5

2lrg

an2

54

to

74

psi

Regulator

ai

spring

Free

length

43

49

rom

1

7122

in

InstoJlod

l

ngth

load

30

3

mm

3

67

kg

1

193

inJB

09lbl

Regulator

val

o

ning

pressur

3

8

to

4

2

lrg

an2

54

1060

psi

OIL

PRESSURE

RELIEF

VALVE

The

relief

valve

located

in

the

oil

pump

cover

by

passes

the

oil

into

the

main

oil

gallery

when

the

oil

filter

elem

nt

is

exCessively

clogged

With

regula

tor

valve

removed

check

valve

for

operation

See

Fig

EL

5

OIL

FILTER

tEMOVAL

Place

a

suitable

container

under

the

f1lter

Unscrew

f1lter

from

oil

pump

cover

flange

using

Oil

Filter

Wrench

STl9320000

EL

4

Fig

EL

6

Removing

Oil

Filter

INSTALLAnON

I

Coat

the

packing

on

the

new

f1lter

with

oil

Position

the

f1lter

on

the

oil

pump

cover

flange

Hand

tight

en

the

f11ter

until

the

packing

contacts

the

cover

flange

then

advance

it

2

3

tum

Note

Do

not

overtighten

the

fiIter

or

oil

leak

may

occur

2

Operate

the

engine

at

fast

idle

and

check

for

oil

leaks

Check

the

oil

level

and

add

oil

if

necessary

OIL

PRESSURE

WARNING

SWITCIt

The

oil

pressure

warning

switch

is

located

on

the

oil

pump

cover

and

wired

to

an

instrument

cluster

See

Fig

EL

6

The

warning

light

glows

whenever

the

oil

pressure

drops

below

0

2

to

0

4

kg

cm1

2

8

to

5

7

psi

Prior

to

installing

a

switch

to

cover

I

be

sure

to

apply

a

conductive

sealer

to

threads

of

switch

Page 77 of 548

Engine

Lubrication

System

SERVICE

DATA

AND

SPECIFICATIONS

Oil

pump

Standard

Wear

limit

Rotor

side

clearance

nun

in

0

04

to

0

08

0

20

0

0079

Rotor

to

bottom

cover

0

0016

to

0

0031

Rotor

tip

clearance

mm

in

less

than

0

20

0

0079

0

12

0

0047

Outer

rotor

to

body

clearance

nun

in

0

15

to

0

21

0

50

0

0197

0

0059

to

0

0083

Oil

pressure

regulator

valve

Oil

pressure

a

t

idling

Oil

pressure

at

3

000

rpm

Regulator

valve

spring

Free

length

Installed

length

load

kg

cm2

psi

kg

cm2

psi

more

than

0

8

II

3

8

to

5

2

54

to

74

nun

in

nun

kg

in

lb

43

49

I

7122

30

3

3

67

1

193

8

09

Tightening

torque

Oil

pump

securing

bolts

Oil

pump

cover

bolt

Regulator

valve

cap

nut

kg

m

ft

lb

kg

m

ft

lb

kg

m

ft

lb

0

9

to

I

4

6

5

to

10

1

0

39

to

0

52

2

8

to

3

8

4

0

to

5

0

29

to

36

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Condition

Probable

cause

Corrective

action

Oil

leakage

Damaged

or

cracked

body

cover

Oil

leakage

from

gasket

Oil

leakage

from

regulator

valve

Oil

leakage

from

blind

plug

Replace

Replace

Tighten

or

replace

Replace

Decreased

oil

pressure

Leak

of

oil

in

engine

oil

pan

Dirty

oil

strainer

Damaged

or

worn

pump

rotors

Faulty

regulator

Used

of

poor

quality

engine

oil

Correct

Clean

or

replace

Replace

Adjust

or

replace

Replace

Noise

Excessive

backlash

in

pump

rotors

Replace

EL

5