carb DATSUN 210 1979 Service Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 11 of 548

I

I

w

I

w

ID

P

u

f

t

600

rlI

000

mile

ser

ce

one

0

e

lUe

US

1

d

l

erfol1

ance

and

ol

tirrlUlll

engine

con

Itlon

1

Ip

lE

P

CE

OPEl

P

lI0

hId

formed

at

numbef

ot

periodic

roll

tero

l

OU

k

l

lllele

Ie

0

onlhO

h

chOVe

co

e

1000

efS

j

es

l

Month

1

6

P

1

1E

P

CE

lEI

VP

L

1

2

24

36

48

60

72

7

5

15

2

2

5

301

37

5

45

6

1

2

18

24

30

36

G

l

1

Ip

lE

A

CE

OPEl

P

lI0

periodic

roll

ten

should

be

l

i

ometert

TIlles

ot

onth

Month

EMISSION

CONll

O

MMN1ENJl

NCE

P

P

P

P

I

ota

l

e

8t

exhaust

a

NEt

c

ear1lf

C

P

l

l

l

l

On

belU

11

l

l

I

EnQltltl

0

11

0

filter

I

engine

COO

Brot

I

Coo

n

v

te

hO

conne

on

P

P

P

laC

1

lrn

titt1ng

hOleS

8l

eof

ect

Ql1

P

IdlG

rpm

I

ca

elo

dIe

p

t

M

I

I

fl

1

turu

ra

IO

P

P

P

ChO

0

h8

chOke

pl

ink

1

1

de

th

ca

IV

e

conv

I

I

t

f

NOf

call

QP

2

I

f

1

h

t

olt

v

t

on

dec

0

iF

vel

filter

f

net

hO

p

p

nO

eonn

t

on

tc

2

l

p

cl

ner

It

ca

bU

tO

P

ode

h

e

ra

V

e

conv

rto

V

S

P

d

caP

cal

O

n

2

l

0

cI

n

tnte

on

C

M

n

od

rh

c

ralV

e

con

t8

carburetor

a

f

and

CB

3da

ff

lodels

P

P

p

o

e

p

r

control

o

n

P

f

l

I

grtltlOfl

tll1U

Spal

plIJQ

l

nltIOfl

Iflng

2

po

cr

nkca

i

ion

P

C

v

8

1

Vtoti

tlOll

r10lCS

e

pol

ln

l

F

nk

c

liel

v

iI

SO

pped

l

1

Calilorn

odO

h

ca

V

p

nd

c

on

e

I

t

on

It

i

J

r

a

g

q

c

C

l

l

l

5

o

3

Q

o

o

l

Page 15 of 548

DATSUN

210

Model

8310

Series

SECTIONET

ET

ENGINE

TUNE

UP

CONTENTS

EMISSION

CONTROL

DEVICES

BASIC

MECHANICAL

SYSTEM

ADJUSTING

INTAKE

AND

EXHAUST

VALVE

CLEARANCE

CHECKING

AND

ADJUSTING

DRIVE

BELTS

CHANGING

ENGINE

OIL

REPLACING

01

L

FI

L

TER

CHANGING

ENGINE

COOLANT

CHECKING

COOLING

SYSTEM

HOSES

AND

CONNECTIONS

CHECKING

ENGINE

COMPRESSION

IGNITION

AND

FUEL

SYSTEM

CHECKING

BATTERY

CHECKING

AND

ADJUSTING

IGNITION

TIMING

CHECKING

IGNITION

WIRING

CHECKING

AND

REPLACING

SPARK

PLUGS

CHECKING

AND

ADJUSTING

CARBURETOR

IDLE

RPM

AND

MIXTURE

RATIO

CHECKING

CHOKE

MECHANISM

Choke

plate

and

linkage

CHECKING

FUEL

SHUT

OFF

SYSTEM

FU

models

ET

2

ET

3

ET

3

ET

3

ET

3

ET

3

ET

4

ET

4

ET

4

ET

5

ET

5

ET

5

ET

6

ET

6

ET

7

ET

9

ET

9

REPLACING

FUEL

FILTER

ET

10

CHECKING

FUEL

LINES

Hoses

piping

connections

etc

ET

10

REPLACING

AIR

CLEANER

FILTER

ETlO

CHECKING

AUTOMATIC

TEMPERATURE

CONTROL

AIR

CLEANER

ET

10

EMISSION

CONTROL

SYSTEM

ET

11

CHECKING

VACUUM

FITTING

HOSES

AND

CONNECTIONS

ET

11

REPLACING

AIR

PUMP

AIR

CLEANER

FILTER

Except

FU

models

and

Canada

models

E

1122i

REPLACING

AIR

INDUCTION

VALVE

FILTER

FU

models

and

Canada

models

E

tlil1r2

C

REPLACING

PCV

VALVE

AND

FILTER

ETf

CHECKING

VENTI

LATION

HOSES

E1P12

CHECKING

VAPOR

LINES

Eli

J2

CHECKING

FUEL

TANK

VACUUM

RELIEF

I

f

III

VALVE

ET

13

REPLACING

CARBON

CANISTER

W

FILTER

ET

d

SERVICE

DATA

AND

SPECIFICATIONS

ET

14

TROUBLE

DIAGNOSES

AND

CORRECTIONS

ET

16

SPECIAL

SERVICE

TOOL

ET

23

Page 16 of 548

f

EMISSION

CONTROL

DEVICES

En

ine

model

I

AI4

I

A1S

B310

Non

CaliCor

Non

California

models

Califor

nia

Car

model

California

models

E

cept

for

C

nada

Canada

nia

modeb

models

Except

for

Canada

M

T

M

T

A

T

Ti

ansmiuion

M

T

A

T

Except

A

T

FU

M

T

A

T

Station

Wagon

FU

models

models

models

AIR

CLEAN

I

A

T

C

air

cleaner

I

X

I

X

X

I

X

I

X

I

X

I

X

I

X

X

ER

Idle

compensator

Dual

type

X

I

X

X

I

X

I

X

I

X

I

X

I

X

X

Fresh

air

duct

X

I

X

X

I

X

I

X

I

I

I

X

X

ENGINE

I

Early

fuel

evaporative

system

X

I

X

X

xl

X

I

X

I

X

I

X

X

BASE

Exhaust

gas

type

CARBV

I

P

T

C

auto

choke

X

I

X

X

X

I

X

I

X

I

X

I

X

X

m

RETOR

I

l

Thr

ttle

opener

X

X

X

X

I

I

X

I

X

I

X

X

Q

I

Fuel

shut

off

system

I

X

I

I

I

3

m

ll

i

Dash

po

t

X

X

X

X

I

X

I

X

I

X

I

X

X

N

l

IGNITION

I

H

I

C

ignitor

X

X

X

X

I

X

I

X

I

X

I

X

X

c

SYSTEM

Spark

timing

contra

system

T

e

S

X

X

X

I

I

I

I

l

X

X

I

X

ll

Thermal

vacuum

valve

X

X

X

I

X

I

I

I

I

X

X

c

Vacuum

delay

valve

X

I

X

I

I

I

X

I

0

X

A

I

S

I

Air

pump

Air

pump

air

cleaner

check

valve

I

X

X

I

X

I

X

I

I

I

I

x

X

A

B

valve

Combined

air

control

C

A

C

valve

I

X

X

I

I

I

I

I

I

X

Relief

valve

I

I

X

I

X

I

I

I

I

X

Air

induction

valve

Filter

A

B

valve

I

I

I

I

X

I

X

I

X

E

G

R

I

Exhaust

gas

recirculation

E

G

R

valve

I

X

I

X

I

X

I

X

I

X

I

X

I

X

I

X

X

SYSTEM

Thetmalvacuum

valve

I

X

I

X

I

X

I

X

I

X

I

X

I

X

I

X

X

Back

pressure

transducer

B

P

T

valve

I

X

I

X

I

X

I

X

I

X

I

I

I

X

X

CATALYZER

I

CatalytJc

converter

I

X

I

X

I

I

I

X

I

I

I

X

Newly

equipped

unit

on

1979

models

M

T

Manual

transmission

Remarks

X

Available

A

T

Automatic

transmission

Not

available

A

T

C

Aute

matic

tempeJ

ature

control

P

T

C

POlitive

temperature

coefficient

A

I

S

Air

injection

system

or

Air

induction

system

A

B

valve

Anti

backfire

valve

Page 21 of 548

CHECKING

AND

ADJUSTING

CARBURETOR

IDLE

RPM

AND

MIXTURE

RATIO

WARNING

a

0

n

a

utomatic

transmission

models

checks

should

be

per

formed

with

the

lever

shifted

to

the

0

position

Be

sure

to

engage

parking

brake

and

to

lock

both

front

and

rear

wheels

with

wheel

chocks

b

Oepress

brake

pedal

while

ac

celerating

the

engine

to

prevent

forward

surge

of

car

c

After

idle

adjustment

has

been

made

shift

the

lever

to

the

N

or

P

positfon

and

remove

wheel

chocks

CAUTION

00

not

attempt

to

screw

the

idle

adjusting

screw

down

completely

00

ing

so

could

cause

damage

to

tip

which

in

turn

will

tend

to

cause

malfunctions

Note

a

When

measuring

CO

percentage

in

sert

probe

into

tail

pipe

more

than

40

cm

15

7

in

b

In

thee

case

of

air

conditioner

e

quipped

models

the

idle

adjust

ment

should

be

carried

out

while

the

air

conditioner

is

OFF

c

When

making

idle

adjustment

do

not

removt

air

cleaner

CO

Idle

adJustment

with

CO

meter

Idle

mixture

adjustment

requires

the

use

of

a

CO

meter

especially

for

California

models

When

preparing

to

adjust

idle

mixture

it

is

essential

to

have

the

meter

thoroughly

warmed

up

and

calibrated

1

Check

carburetor

pipes

for

proper

connection

2

Warm

up

engine

until

water

tern

perature

indicator

points

to

the

middle

of

gauge

The

procedure

to

warm

up

J

Engine

Tune

up

engine

is

not

specifically

recom

mended

Either

driving

car

or

operat

ing

engine

at

no

load

will

be

good

3

Make

sure

that

water

temperature

indicator

points

to

the

middle

Further

keep

engine

running

at

about

2

000

rpm

for

about

5

minutes

without

applying

load

to

engine

in

order

to

stabilize

engine

condition

Engine

hood

should

be

open

4

Run

engine

for

about

10

minutes

at

idling

speed

During

this

10

minutes

proceed

as

described

in

steps

5

to

9

below

5

I

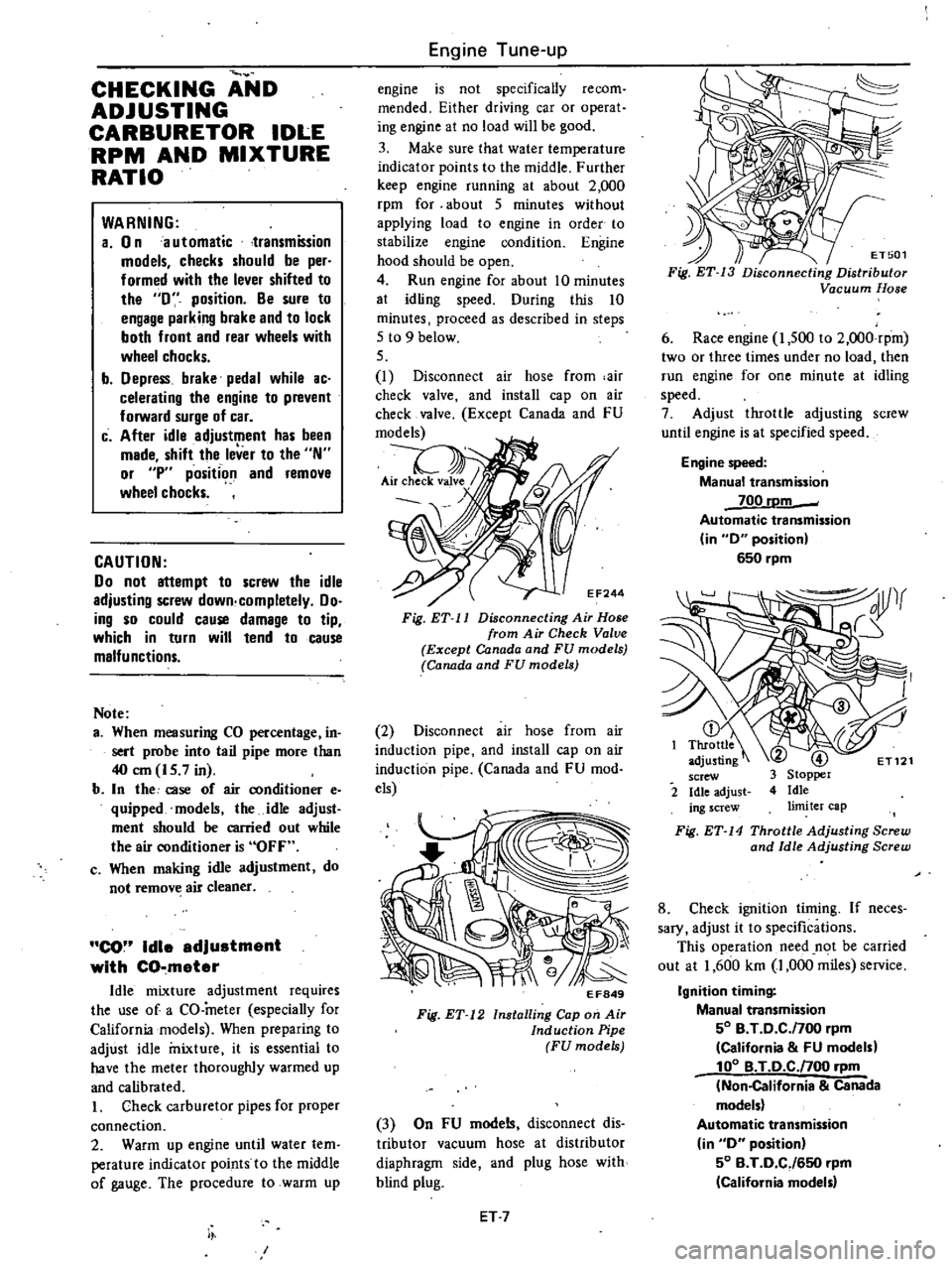

Disconnect

air

hose

from

air

check

valve

and

install

cap

on

air

check

valve

Except

Canada

and

FU

models

EF244

Fig

ET

11

Disconnecting

Air

Hose

from

Air

Check

Valve

Except

Canada

and

FU

models

Canada

and

FU

models

2

Disconnect

air

hose

from

air

induction

pipe

and

install

cap

on

air

induction

pipe

Canada

and

FU

mod

els

EF849

Fig

ET

12

Installing

Cap

on

Air

Induction

Pipe

FU

models

3

On

FU

models

disconnect

dis

tributor

vacuum

hose

at

distributor

diaphragm

side

and

plug

hose

with

blind

plug

ET

7

ET501

Fig

ET

13

Disconnecting

Distributor

Vacuum

Hose

6

Race

engine

I

500

to

2

OOO

rpm

two

or

three

times

under

no

load

then

run

engine

for

one

minute

at

idling

speed

7

Adjust

throttle

adjusting

screw

until

engine

is

at

specified

speed

Engine

speed

Manual

transmission

700

rDm

Automatic

transmission

in

0

position

650

rpm

2

Fig

ET

14

Throttle

Adjusting

Screw

and

Idle

Adjusting

Screw

8

Check

ignition

timing

If

neces

sary

adjust

it

to

specifications

This

operation

need

n

t

be

carried

out

at

1

600

km

1

000

miles

service

Ignition

timing

Manual

transmission

50

B

T

0

C

f700

rpm

California

FU

models

100

B

T

O

C

noo

rpm

Non

California

Canada

models

Automatic

transmission

in

0

position

50

B

T

0

CJ650

rpm

California

model

Page 22 of 548

SO

B

T

D

C

650

rpm

Non

California

models

except

Canada

100

B

T

0

C

650

rpm

Canada

models

Note

On

FU

models

ignition

timing

t

under

a

con4ition

where

distnoutor

vacuum

hose

is

discon

nected

9

On

FU

models

proceed

as

fol

lows

I

Remove

blind

plug

from

dis

tributor

vacuum

hose

and

connect

hose

to

distributor

diaphragm

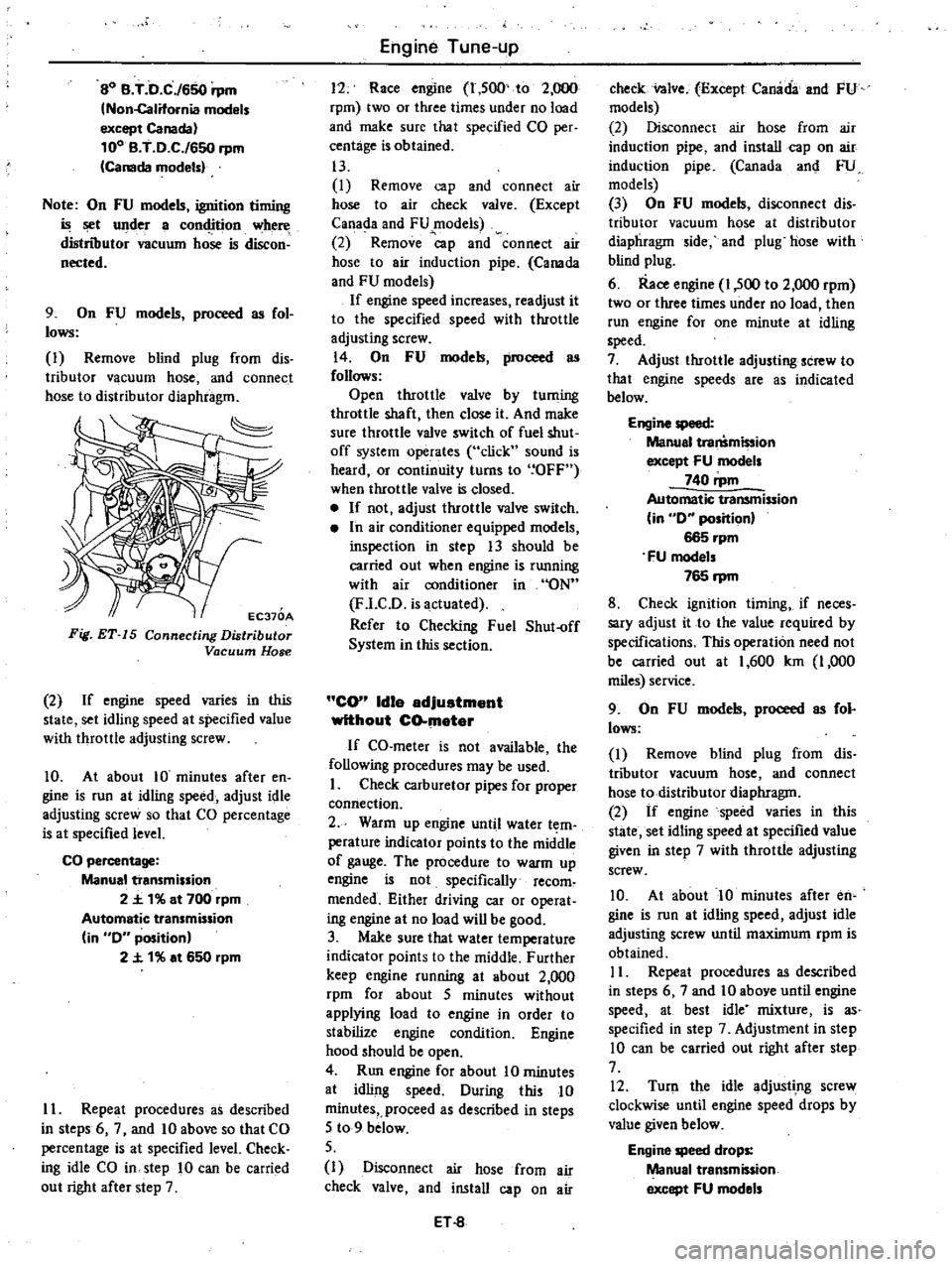

EC370A

Fig

ET

15

Connecting

Distributor

Vacuum

Hose

2

If

engine

speed

varies

in

this

state

set

idling

speed

at

specified

value

with

throttle

adjusting

screw

10

At

about

10

minutes

after

en

gine

is

run

at

idling

speed

adjust

idle

adjusting

screw

so

that

CO

percentage

is

at

specified

level

CO

percentage

Manual

transmission

2

t

1

at

700

rpm

Automatic

transmission

in

0

position

2

t

1

at

650

rpm

II

Repeat

procedures

as

described

in

steps

6

7

and

10

above

so

that

CO

percentage

is

at

specified

level

Check

ing

idle

CO

in

step

10

can

be

carried

out

right

after

step

7

Engine

Tune

up

11

Race

engine

1

500

to

2

000

rpm

two

or

three

times

under

no

load

and

make

sure

that

specified

CO

per

centage

is

obtained

13

I

Remove

cap

and

connect

air

hose

to

air

check

valve

Except

Canada

and

FU

models

2

Remove

p

and

connect

air

hose

to

air

induction

pipe

Canada

and

FU

models

If

engine

speed

increases

readjust

it

to

the

specified

speed

with

throttle

adjusting

screw

14

On

FU

models

proceed

as

follows

Open

throttle

valve

by

tuming

throttle

shaft

then

close

it

And

make

sure

throttle

valve

switch

of

fuel

shut

off

system

operates

click

sound

is

heard

or

continuity

turns

to

OFF

when

throttle

valve

is

closed

If

not

adjust

throttle

valve

switch

In

air

conditioner

equipped

models

inspection

in

step

13

should

be

carried

out

when

engine

is

running

with

air

conditioner

in

ON

F

l

CD

is

actuated

Refer

to

Checking

Fuel

Shut

off

System

in

this

section

CO

Idle

adjuatment

without

CO

mater

If

CO

meter

is

not

available

the

following

procedures

may

be

used

I

Check

carburetor

pipes

for

proper

comiection

2

Warm

up

engine

until

water

t

m

perature

indicator

points

to

the

middle

of

gauge

The

procedure

to

warm

up

engine

is

not

specifically

recom

mended

Either

driving

car

or

operat

ing

engine

at

no

load

will

be

good

3

Make

sure

that

water

temperature

indicator

points

to

the

middle

Further

keep

engine

running

at

about

2

000

rpm

for

about

5

minutes

without

applying

load

to

engine

in

order

to

stabilize

engine

condition

Engine

hood

should

be

open

4

Run

engine

for

about

10

minutes

at

idling

speed

During

this

10

minutes

proceed

as

described

in

steps

5

to

9

below

5

I

Disconnect

air

hose

from

air

check

valve

and

install

cap

on

air

ET

8

check

nlve

Except

Canada

and

FU

models

2

Disconnect

air

hose

from

air

induction

pipe

and

install

cap

on

air

induction

pipe

Canada

an

FU

models

3

On

FU

models

disconnect

dis

tributor

vacuum

hose

at

distributor

diaphragm

ide

and

plug

hose

with

blind

plug

6

Race

engine

1

500

to

2

000

rpm

two

or

three

times

under

no

load

then

run

engine

for

one

minute

at

idling

speed

7

Adjust

throttle

adjusting

screw

to

that

engine

speeds

are

as

indicated

below

Engine

speed

Manual

tra

mi

ion

except

FU

models

740

rpm

Automatic

transmission

in

0

position

665

rpm

FU

models

765

rpm

8

Check

ignition

timing

if

neces

sary

adjust

it

to

the

value

required

by

specifications

This

operation

need

not

be

carried

out

at

1

600

km

1

000

miles

service

9

On

FU

models

proceed

as

fol

lows

I

Remove

blind

plug

from

dis

tributor

vacuum

hose

and

connect

hose

to

distributor

diaphragm

2

If

engine

speed

varies

in

this

state

set

idling

speed

at

specified

value

given

in

step

7

with

throttle

adjusting

screw

10

At

about

10

minutes

after

en

gine

is

run

at

idling

speed

adjust

idle

adjusting

screw

until

maximum

rpm

is

obtained

II

Repeat

procedures

as

described

in

steps

6

7

and

10

above

until

engine

speed

at

best

idle

mixture

is

as

specified

in

step

7

Adjustment

in

step

10

can

be

carried

out

right

after

step

7

12

Turn

the

idle

adjustIng

screw

clockwise

until

engine

speed

drops

by

value

given

below

Engine

speed

drops

Manual

transmission

except

FU

models

Page 24 of 548

make

sure

throttle

valve

operates

click

sound

is

heard

or

continuity

turns

to

OFF

when

engine

speed

decrease

to

idling

If

not

adjust

throttle

valve

switch

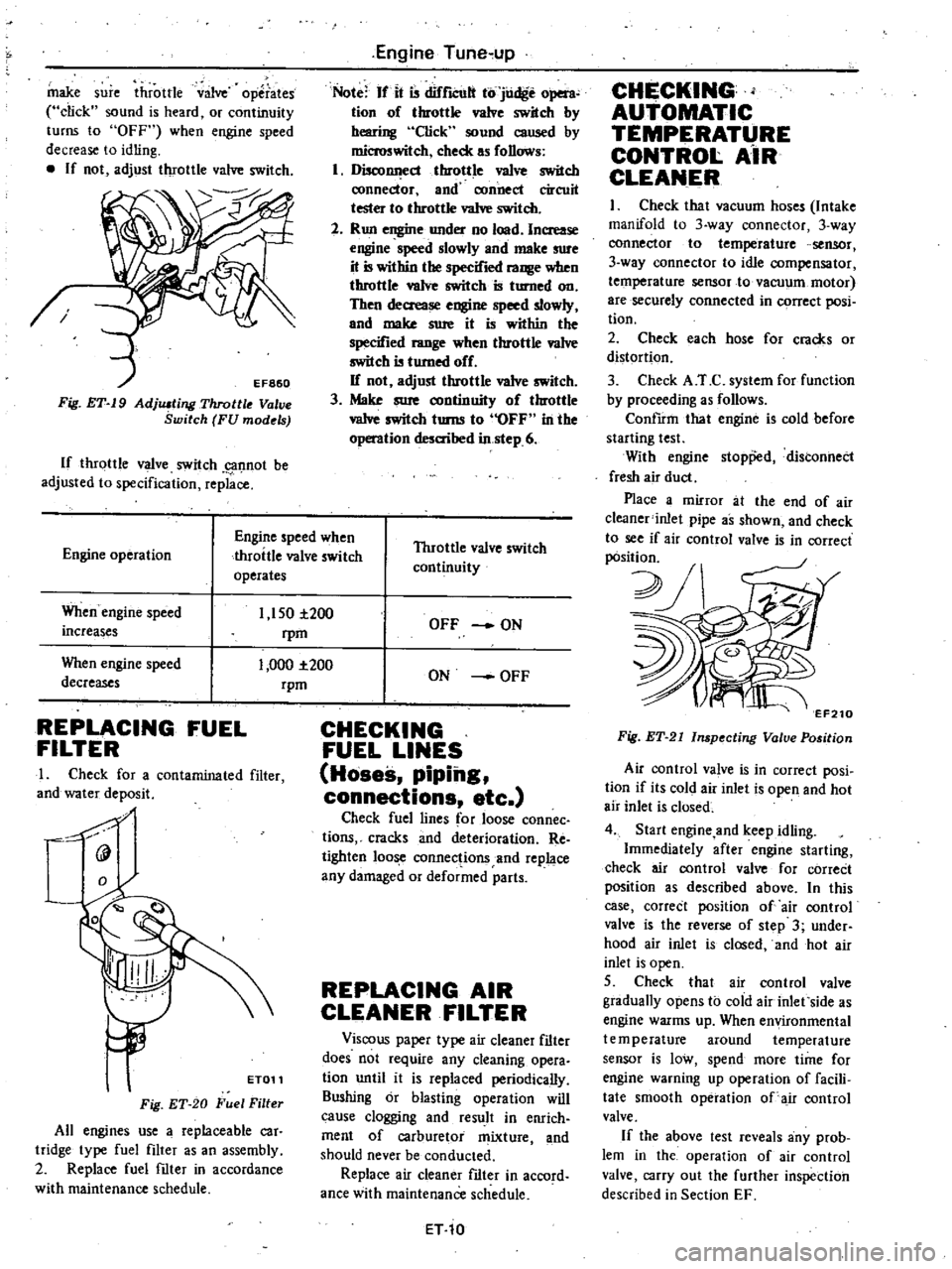

Fig

ET

19

AdjlUting

Throttle

V

ve

Switch

FU

models

If

throttle

valve

switch

g1f1not

be

adjusted

to

specification

replace

Engine

Tune

up

Note

If

it

is

difrlCUlt

to

judge

open

tion

of

throttle

valve

switch

by

hearing

Click

sound

caused

by

microswitch

check

as

follows

1

DiscollI

ecl

throttle

va1ve

switch

ronnector

and

connect

circuit

tester

to

throttle

va1ve

switch

2

Run

engine

under

no

load

Increase

engine

speed

slowly

and

make

sure

it

is

within

the

specified

range

when

throttle

valve

switch

is

turned

on

Then

decrease

engine

speed

slowly

and

make

sure

it

is

within

the

specified

range

when

throttle

va1ve

switch

is

turned

off

If

not

adjust

throttle

valve

switch

3

Make

sure

continuity

of

throttle

vaIve

switch

turns

to

OFF

in

the

operation

desaihed

in

step

6

Engine

operation

Engine

speed

when

throttle

valve

switch

operates

Throttle

valve

switch

continuity

When

engine

speed

increases

1

150

i200

rpm

1

000

1

200

rpm

When

engine

speed

decreases

REPLACING

FUEL

FILTER

I

Check

for

a

contaminated

filter

and

water

deposit

0

9

ET011

Fig

ET

20

Fuel

Filter

All

engines

use

a

replaceable

car

tridge

type

fuel

filter

as

an

assembly

2

Replace

fuel

filter

in

accordance

with

maintenance

schedule

OFF

ON

ON

OFF

CHECKING

FUEL

LINES

Hoses

piping

connections

etc

Check

fuel

lines

for

loose

connec

tions

cracks

and

deterioration

Re

tighten

loose

connections

and

replace

any

damaged

or

deformed

parts

REPLACING

AIR

CLEANER

FILTER

Viscous

paper

type

air

cleaner

filter

does

not

require

any

cleaning

opera

tion

until

it

is

replaced

periodically

Sushing

or

blasting

operation

will

cause

clogging

and

result

in

enrich

ment

of

carburetor

mixture

and

should

never

be

conducted

Replace

air

cleaner

filter

in

accord

ance

with

maintenance

schedule

ET

10

CHECKING

AUTOMATIC

TEMPERATURE

CONTROl

AiR

CLEANER

I

Check

that

vacuum

hoses

Intake

manifold

to

3

way

connector

3

way

connector

to

temperature

sensor

3

way

connector

to

idle

compensator

temperature

sensor

to

vacuum

motor

are

securely

connected

in

C9rrect

posi

tion

2

Check

each

hose

for

cracks

or

distortion

3

Check

A

T

C

system

for

function

by

proceeding

as

follows

ConfIrm

that

engine

is

cold

before

starting

test

With

engine

stopp

d

distonnect

fresh

air

duct

Place

a

mirror

at

the

end

of

air

c1eaner

inlet

pipe

as

shown

and

check

to

see

if

air

control

valve

is

in

correct

pOsition

2J

v

7

EF210

Fig

ET

21

Inspecting

Valve

Position

Air

control

va

ve

is

in

correct

posi

tion

if

its

cold

air

inlet

is

open

and

hot

air

inlet

is

closed

4

Start

engine

and

keep

idling

Immediately

after

engine

starting

check

air

control

valve

for

correCt

position

as

described

above

In

this

case

correct

position

of

air

control

valve

is

the

reverse

of

step

3

under

hood

air

inlet

is

closed

and

hot

air

inlet

is

open

5

Check

that

air

control

valve

gradually

opens

to

cold

air

inlet

side

as

engine

warms

up

When

environmental

temperature

around

temperature

sensor

is

low

spend

more

time

for

engine

warning

up

operation

of

facili

tate

smooth

operation

of

air

control

valve

If

the

above

test

reveals

any

prob

lem

in

the

operation

of

air

control

valve

carry

out

the

further

inspection

described

in

Section

EF

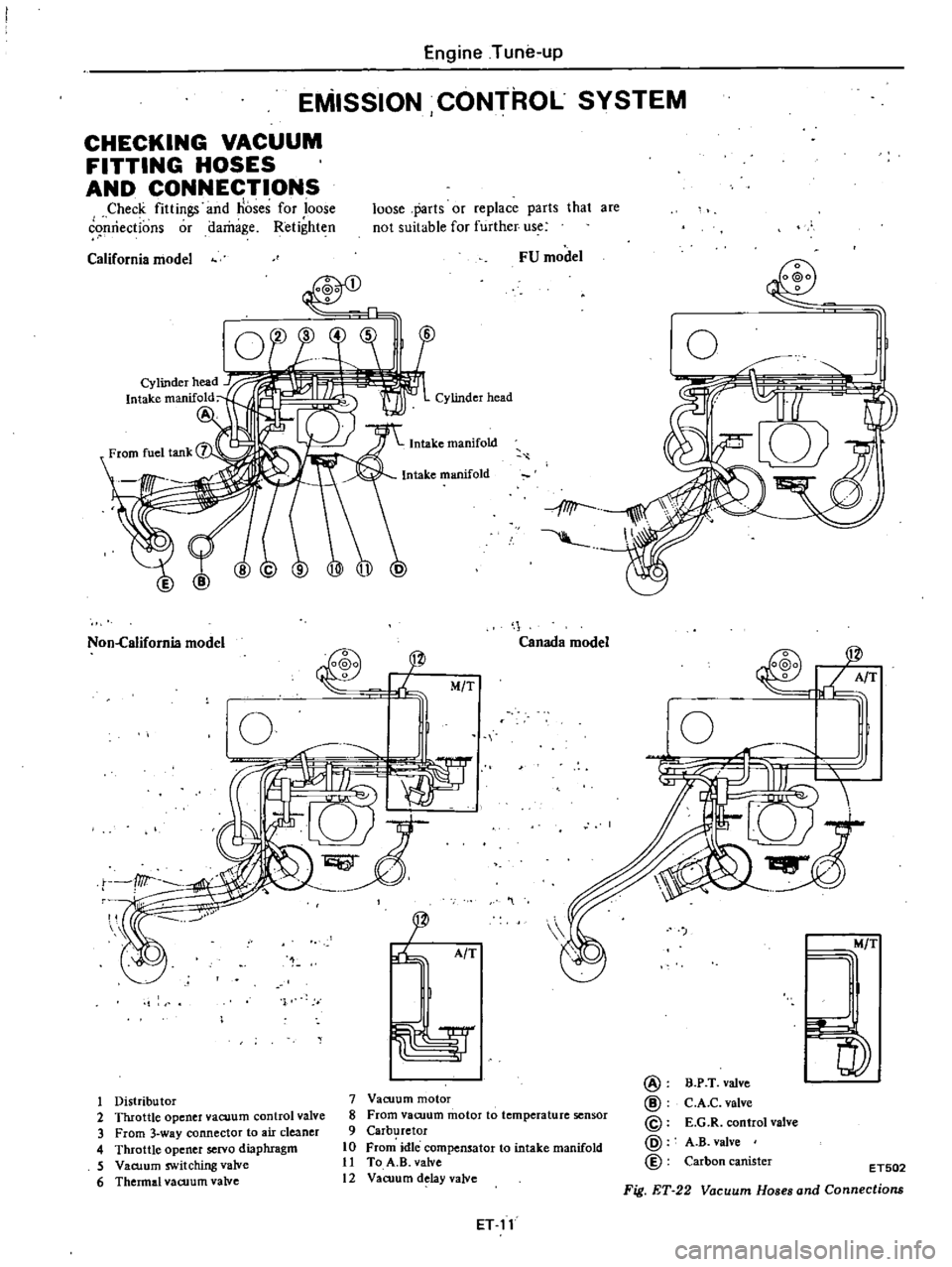

Page 25 of 548

Engine

Tune

up

EMISSION

CONTROL

SYSTEM

CHECKING

VACUUM

FITTING

HOSES

AND

CONNECTIONS

Check

fittings

and

hoses

for

ioose

cqnriections

or

damage

Retighten

loose

parts

or

replace

parts

that

are

not

suitable

for

further

use

California

model

FU

model

w

fl11r

o

Intake

manifold

Non

California

model

q

Canada

model

@

T

J

I

M

T

r

T

r

o

p

1

o

1

J

1

Distributor

2

Throttle

opener

vaaJ

um

control

valve

3

From

3

way

connector

to

air

cleaner

4

Throttle

opener

servo

diaphragm

5

Vacuum

switching

valve

6

Thermal

v3roum

valve

7

Vacuum

motor

8

From

vacuum

motor

to

temperature

sensor

9

Carburetor

10

From

idle

compensator

to

intake

manifold

11

To

A

B

valve

12

Vacuum

d

lay

valve

@

@

@

@

@

B

P

T

valve

C

A

C

valve

E

G

R

control

valve

A

B

valve

Carbon

canister

M

T

l

Q2

A

T

ET502

Fig

ET

22

Vacuum

Hoses

and

Connections

ET

11

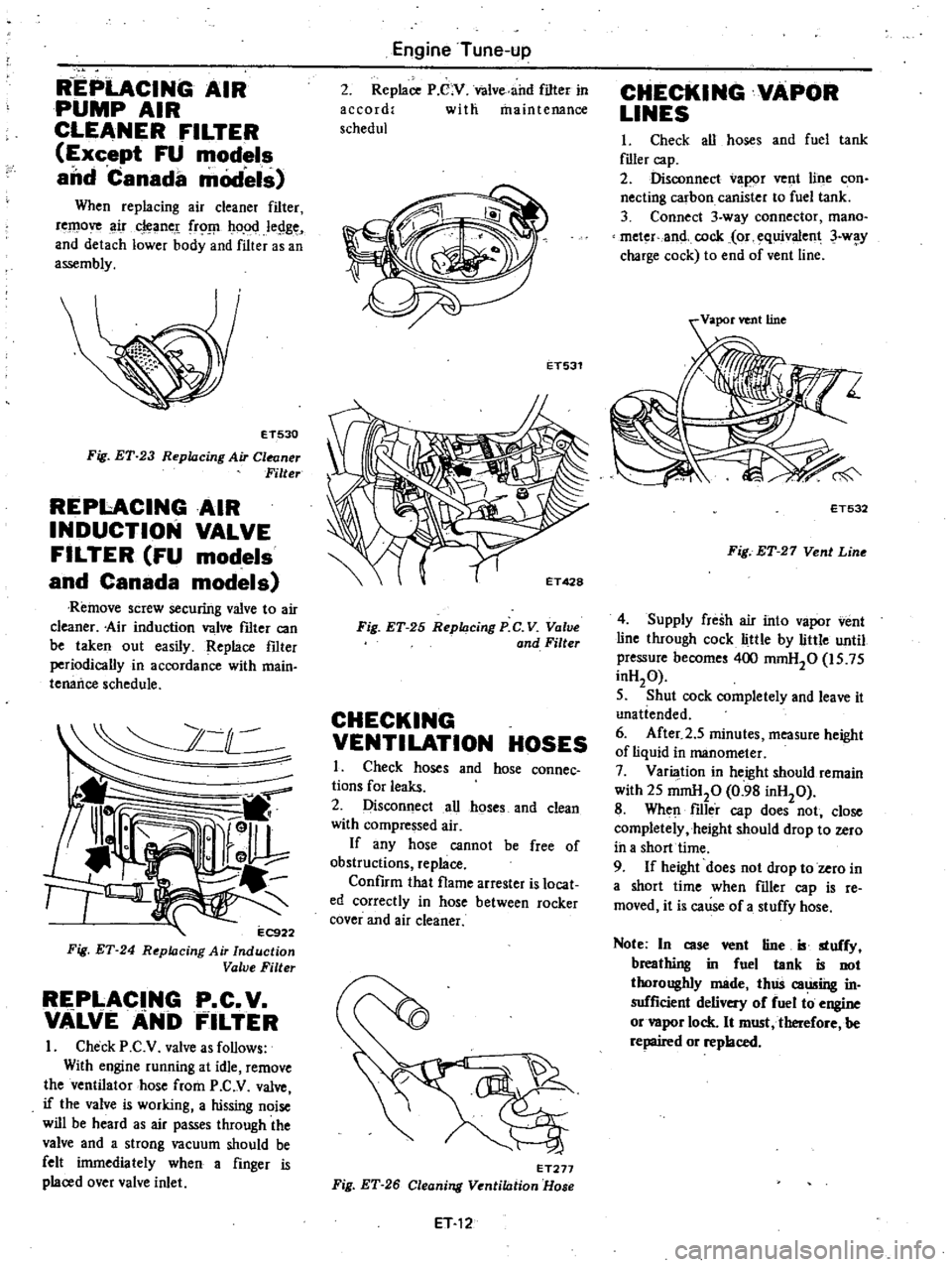

Page 26 of 548

R

EPIACING

AIR

PUMP

AIR

CLEANER

FILTER

Except

FU

models

and

Canada

models

When

replacing

air

cleaner

filter

remove

ir

cleane

frO

ho

od

legge

and

detach

lower

body

and

filter

as

an

assembly

ET530

Fig

ET

23

Replacing

Air

Cleaner

Filter

REPI

ACINGAIR

INDUCTION

VALVE

FILTER

FU

models

and

Canada

models

Remove

screw

securirtg

valve

to

air

cleaner

Air

induction

valve

fIlter

can

be

taken

out

easily

Replace

fIlter

periodically

in

accordance

with

main

tenance

schedule

2

C

l

11

l

r

r

EC9

Fig

ET

24

R

pklcing

Air

Induction

Value

Filter

REPLACING

P

C

V

VALVEANb

FILTER

I

Check

P

C

V

valve

as

follows

With

engine

running

at

idle

remove

the

ventilator

hose

from

P

C

V

valve

if

the

valve

is

working

a

hissing

noise

will

be

heard

as

air

passes

through

the

valve

and

a

strong

vacuum

should

be

felt

inunediately

when

a

finger

is

placed

over

valve

inlet

Engine

Tune

up

2

Replace

P

C

V

Valve

and

filter

in

accord

with

maintenance

schedul

ET531

Fig

ET

25

Replacing

P

C

V

Value

and

Filter

CHECKING

VENTILATION

HOSES

I

Check

hoses

and

hose

connec

tions

for

leaks

2

Disconnect

all

hoses

and

clean

with

compressed

air

If

any

hose

cannot

be

free

of

obstructions

replace

Confirm

that

flame

arrester

is

locat

ed

correctly

in

hose

between

rocker

cover

and

air

cleaner

ET277

Fig

ET

26

Cleaning

Ventilation

Hose

ET

12

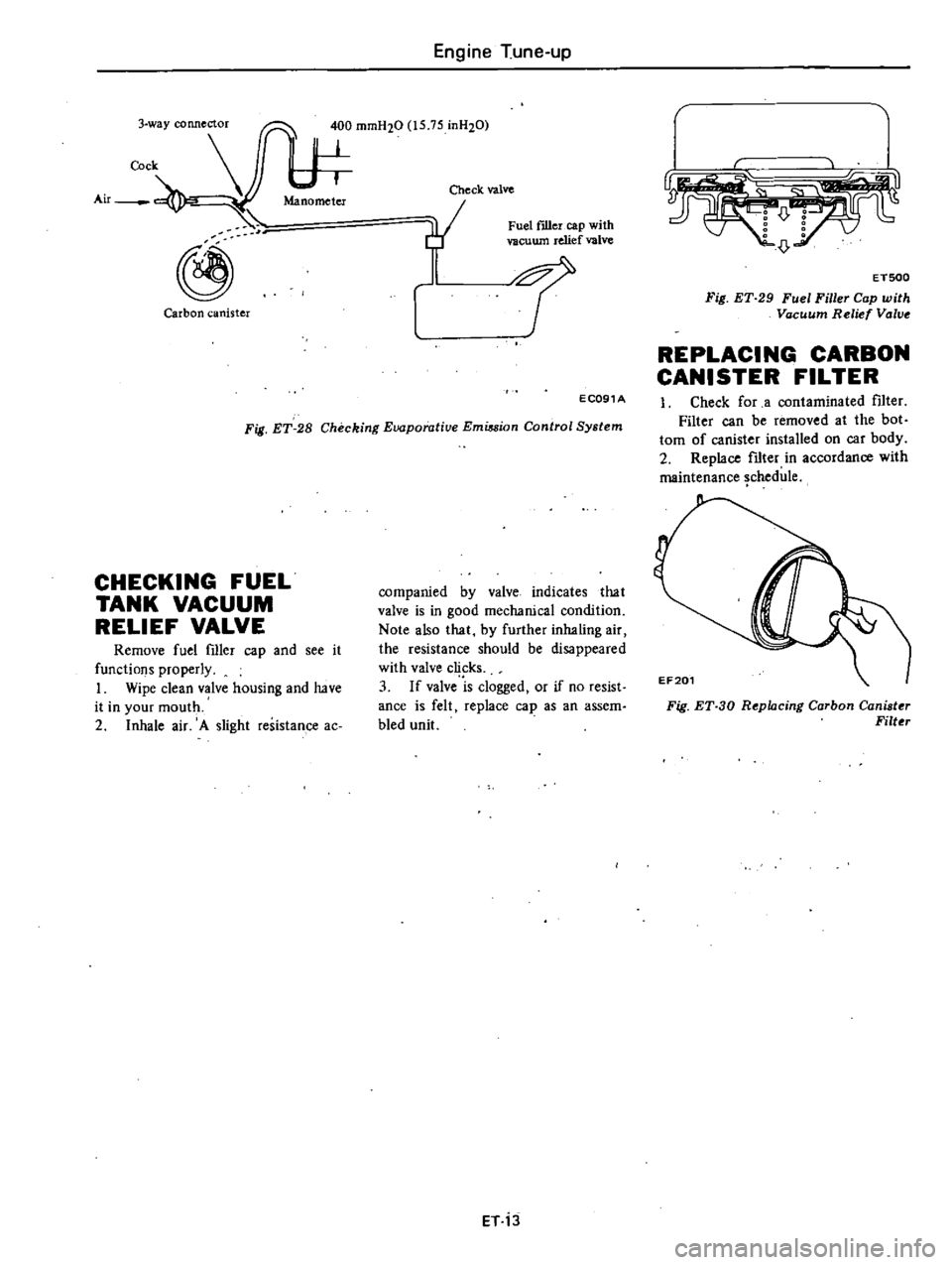

CHECKING

VAPOR

LINES

I

Check

all

hoses

and

fuel

tank

flller

cap

2

Disconnect

vapor

vent

line

con

necting

carbon

canister

to

fuel

tank

3

Connect

3

way

connector

mana

meter

and

cock

or

equivalent

3

w

y

charge

cock

to

end

of

vent

line

ET532

Fig

ET

27

Vent

Line

4

Supply

fresh

air

into

vapor

vent

line

through

cock

little

by

little

until

pressure

become

400

mmH20

is

75

inH20

5

Shut

cock

completely

and

leave

it

unatiended

6

After

2

5

minutes

measure

height

of

liquid

in

manometer

7

Varilllion

in

height

should

remain

with

25

mmHp

0

98

inH20

8

When

filler

cap

does

not

close

completely

height

should

drop

to

zero

ih

a

short

time

9

If

height

does

not

drop

to

zero

in

a

short

time

when

filler

cap

is

re

moved

it

is

cause

of

a

stuffy

hose

Note

In

case

vent

tine

B

stuffy

breathing

in

fuel

tank

is

not

thoroughly

made

thlis

caming

in

sufficient

delivery

of

fuel

to

engine

or

vapor

lock

It

must

tberefore

be

repaired

or

replaced

Page 27 of 548

3

way

connector

ck

Air

Manometer

@

Carbon

canister

Engine

Tune

up

400

mmH20

15

75

in

H20

Check

valve

r

F

uel

filler

cap

with

vacuum

relief

valve

1

Fig

ET

28

Checking

Evaporatiue

Emiuion

Control

System

EC091A

CHECKING

FUEL

TANK

VACUUM

RELIEF

VALVE

Remove

fuel

filler

cap

and

see

it

functions

properly

I

Wipe

clean

valve

housing

and

have

it

in

your

mouth

2

Inhale

air

A

slight

resistance

ac

companied

by

valve

indicates

that

valve

is

in

good

mechanical

condition

Note

also

that

by

further

inhaling

air

the

resistance

should

be

disappeared

with

valve

c

ks

3

If

valve

is

clogged

or

if

no

resist

ance

is

felt

replace

cap

as

an

assem

bled

unit

ET

j3

D

o

0

o

0

o

0

ET500

Fig

ET

29

Fuel

Filler

Cap

with

Vacuum

Relief

Value

REPLACING

CARBON

CANISTER

FILTER

Check

for

a

contaminated

fJlter

Filter

can

be

removed

at

the

bot

tom

of

canister

installed

on

car

body

2

Replace

fJlter

in

accordance

with

maintenance

chedule

EF201

Fig

ET

30

Repfucing

Carbon

Canister

Filter

Page 31 of 548

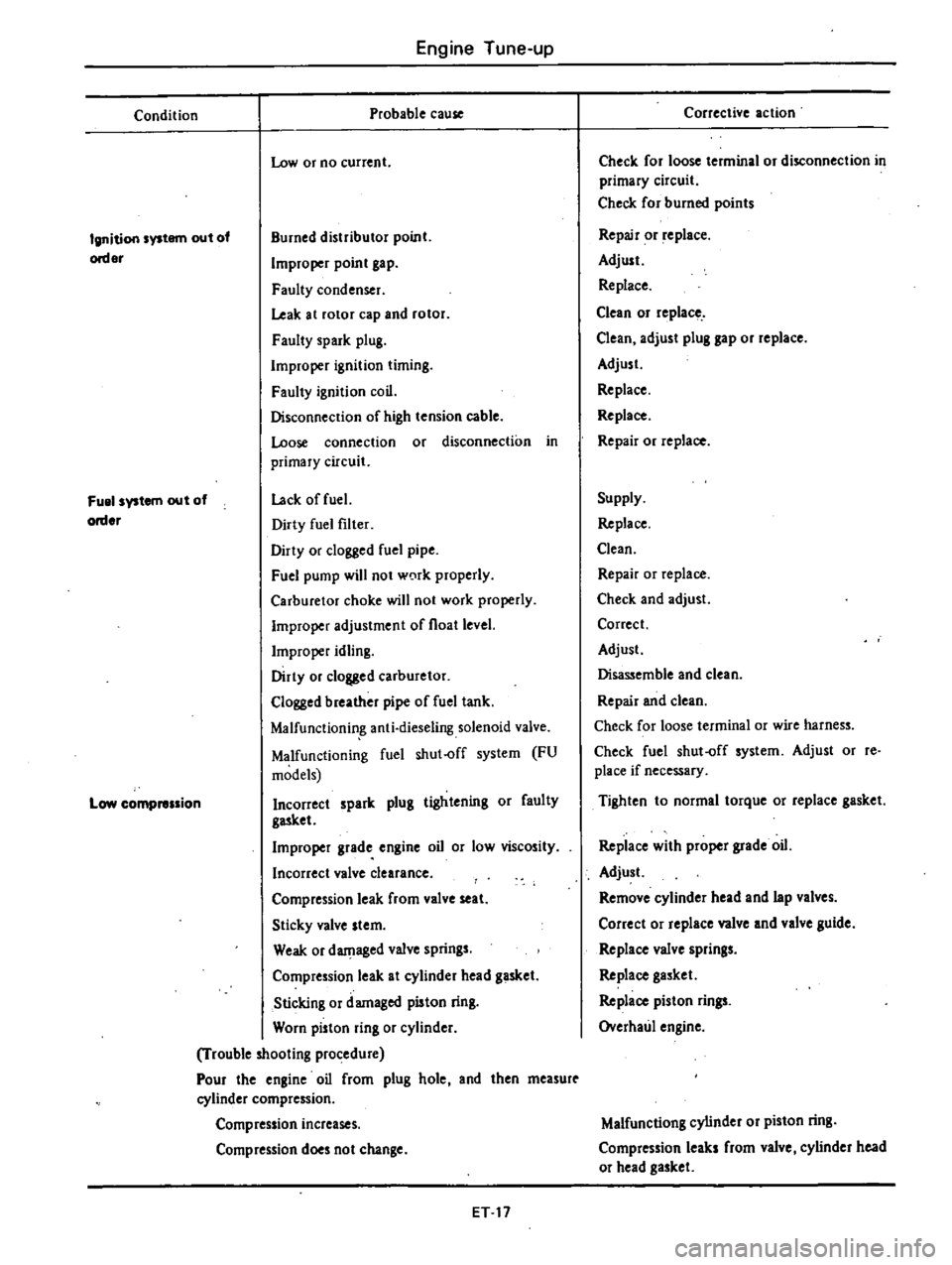

Engine

Tune

up

Condition

Probable

cause

Low

or

no

current

Ignition

system

out

of

order

Burned

distributor

point

Improper

point

gap

Faulty

condenser

Leak

at

rotor

cap

and

rotor

Faulty

spark

plug

Improper

ignition

timing

Faulty

ignition

coil

Disconnecrion

of

high

tension

cable

Loose

connection

or

disconnection

in

primary

circuit

Lack

offuel

Dirty

fuel

filter

Dirty

or

clogged

fuel

pipe

Fuel

pump

will

not

w0rk

properly

Carburetor

choke

will

not

work

properly

Improper

adjustment

of

float

level

Improper

idling

Dirty

or

clogged

carburetor

Clogged

breather

pipe

of

fuel

tank

Malfunctionin

g

anti

dieseling

solenoid

valve

Malfunctioning

fuel

shut

off

system

FU

models

Incorrect

spark

plug

tightening

or

faulty

gasket

Improper

grade

engine

oil

or

low

viscosity

Incorrect

valve

clearance

Compression

leak

from

valve

seat

Sticky

valve

stem

Weak

or

damaged

valve

springs

Compression

leak

at

cylinder

head

gasket

Sticking

or

damaged

piston

ring

Worn

piston

ring

or

cylinder

Trouble

looting

procedure

Pour

the

engine

oil

from

plug

hole

and

then

measurt

cylinder

compression

Fuel

system

out

of

order

Low

compression

Compression

increases

Compression

does

not

change

ET

17

Corrective

action

Check

for

loose

terminal

or

disconnection

in

primary

circuit

Check

for

burned

points

Repair

or

replace

Adjust

Replace

Clean

or

replace

Clean

adjust

plug

gap

or

replace

Adjust

Replace

Replace

Repair

or

replace

Supply

Replace

Clean

Repair

or

replace

Check

and

adjust

Correct

Adjust

Disassemble

and

clean

Repair

and

clean

Check

for

loose

terminal

or

wire

harness

Check

fuel

shut

off

system

Adjust

or

re

place

if

necessary

Tighten

to

normal

torque

or

replace

gasket

Replace

with

proper

grade

oil

Adjust

Remove

cylinder

head

and

lap

valves

Correct

or

replace

valve

and

valve

guide

Replace

valve

springs

Replace

gasket

Replace

piston

rings

Overhaul

engine

Malfunctiong

cylinder

or

piston

ring

Compression

leaks

from

valve

cylinder

head

or

head

gasket