jack points DATSUN 210 1979 Service Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 5 of 548

DATSUN

210

Model

8310

Series

SECTIONGI

GENERAL

INFORMATION

CONTENTS

MODEL

VARIATION

IDENTIFICATION

NUMBERS

CAR

IDENTIFICATION

PLATE

CAR

SERIAL

NUMBER

IDENTIFICATION

NUMBER

PLATE

ENGINE

SERIAL

NUMBER

COLOR

CODE

NUMBER

LABEL

M

V

S

S

CERTIFICATION

LABEL

EMISSION

CONTROL

INFORMATION

LABE

L

MANUAL

TRf

NSMISSION

NUMBER

AUTOMATIC

TRANSMISSION

NUMBER

APPROXIMATE

REFILL

CAPACITIES

GI

2

GI

3

GI

3

GI

3

GI

4

GI

4

GI

4

GI

4

GI

4

GI

4

GI

4

GI

5

RECOMMENDED

FuEL

RECOMMENDED

LUBRICANTS

RECOf

lMENDED

LUBRICANTS

RECOMMENDED

SAE

VISCOSITY

NUMBER

LUBRICATION

CHART

MAINTENANCE

SCHEDULE

LIFTING

POINTS

AND

TOWING

PANTOGRAPH

JACK

GARAGE

JA

CK

AND

SAFETY

STAND

TOWING

TIE

DOWN

SPECIAL

TOOLS

j

GI

5

GI

5

GI

5

GI

5

GI

6

Gill

j

9

GI

9

GI

eGI

9

p

G

I

O

Page 13 of 548

General

Information

LIFTING

POINTS

AND

TOWING

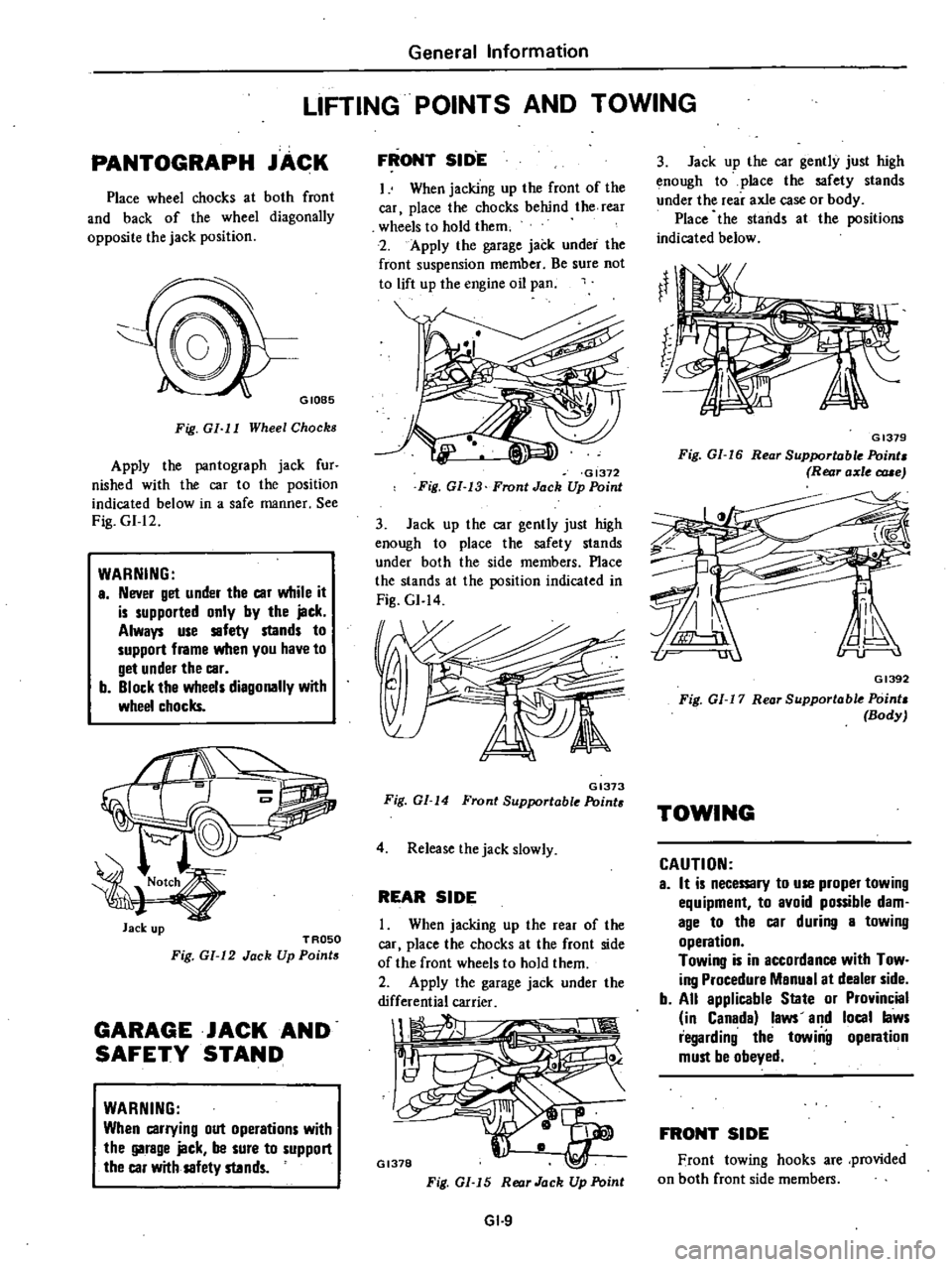

PANTOGRAPH

JACK

Place

wheel

chocks

at

both

front

and

back

of

the

wheel

diagonally

opposite

the

jack

position

GIOB5

Fig

GI

I

I

Wheel

Chocks

Apply

the

pantograph

jack

fur

nished

with

the

car

to

the

position

indicated

below

in

a

safe

manner

See

Fig

GI

12

WARNING

a

Never

get

under

the

car

while

it

is

supported

only

by

the

jack

Always

use

safety

stands

to

support

frame

when

you

have

to

get

under

the

car

b

Block

the

wheels

diagonally

with

wheel

chocks

Jack

up

TROSO

Fig

GI

12

Jack

Up

Points

GARAGE

JACK

AND

SAFETY

STAND

WARNING

When

carrying

out

operations

with

the

garage

jack

be

sure

to

support

the

car

with

safety

stands

FRONT

SID

E

I

When

jacking

up

the

front

of

the

car

place

the

chocks

behind

the

rear

wheels

to

hold

them

2

Apply

the

garage

jack

under

the

front

suspension

member

Be

sure

not

to

lift

up

the

engine

oil

pan

GI372

Fig

GI

13

Front

Jack

Up

Point

3

Jack

up

the

car

gently

just

high

enough

to

place

the

safety

stands

under

both

the

side

members

Place

the

stands

at

the

position

indicated

in

Fig

GI

14

GI373

Fig

GI

14

Front

Supportable

Point

4

Release

the

jack

slowly

REAR

SIDE

When

jacking

up

the

rear

of

the

car

place

the

chocks

at

the

front

side

of

the

front

wheels

to

hold

them

2

Apply

the

garage

jack

under

the

differential

carrier

1

1

Il

GI378

Fig

GI

15

Rear

Jack

Up

Point

GI

9

3

Jack

up

the

car

gently

just

high

enough

to

place

the

safety

stands

under

the

rear

axle

case

or

body

Place

the

stands

at

the

positions

indicated

below

GI379

Fig

GI

16

Rear

Supportable

Point

Rear

axle

c

rue

GI392

Fig

01

17

Rear

Supportable

Point

Body

TOWING

CAUTION

a

It

is

necemry

to

use

proper

towing

equipment

to

avoid

possible

dam

age

to

the

car

during

a

towing

operation

Towing

is

in

accordance

with

Tow

ing

Procedure

Manual

at

dealer

side

b

All

applicable

State

or

Provincial

in

Canada

laws

and

local

laws

regarding

the

towiilg

operation

must

be

obeyed

FRONT

SIDE

Front

towing

hooks

are

provided

on

both

front

side

members

Page 220 of 548

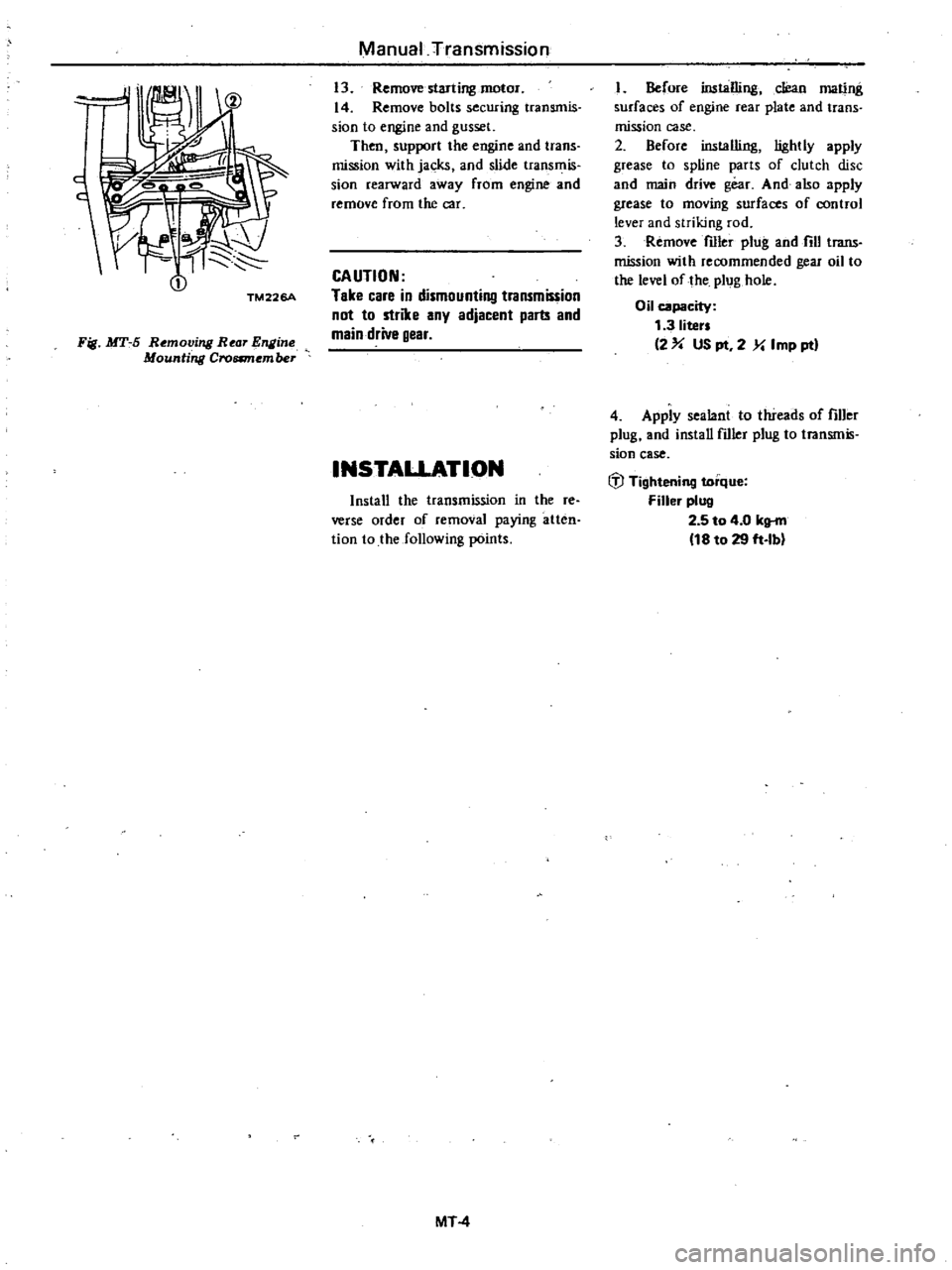

Fig

MT

5

Removing

Rear

1IIline

Mounting

Croamember

Manual

Transmission

13

Remove

starling

motor

14

Remove

bolts

securing

transmis

sion

to

engine

and

gusset

Then

support

the

engine

and

trans

mission

with

jacks

and

slide

trans

is

sion

rearward

away

from

engine

and

remove

from

the

car

CAUTION

Take

care

in

dismounting

trammission

not

to

strike

any

adjacent

parts

and

main

drive

gear

INSTAUATION

Install

the

transmission

in

the

re

verse

order

of

removal

paying

atten

tion

to

the

following

points

MT

4

I

Before

installing

cJean

mating

surfaces

of

engine

rear

plate

and

trans

mission

case

2

Before

installing

lightly

apply

grease

to

spline

parts

of

clutch

disc

and

main

drive

gear

And

also

apply

grease

to

moving

surfaces

of

control

lever

and

striking

rod

3

Remove

filler

plug

and

fill

trans

mission

with

recommended

gear

oil

to

the

level

of

the

plug

hole

Oil

capacity

1

3

liter

2

US

pt

2

Y

Imp

ptl

4

Apply

sealant

to

threads

of

filler

plug

and

install

fdler

plug

to

transmis

sion

case

IiJ

Tightening

torque

Filler

plug

2

5

to

4

0

klt

fll

18

to

29

ft

Ib

Page 234 of 548

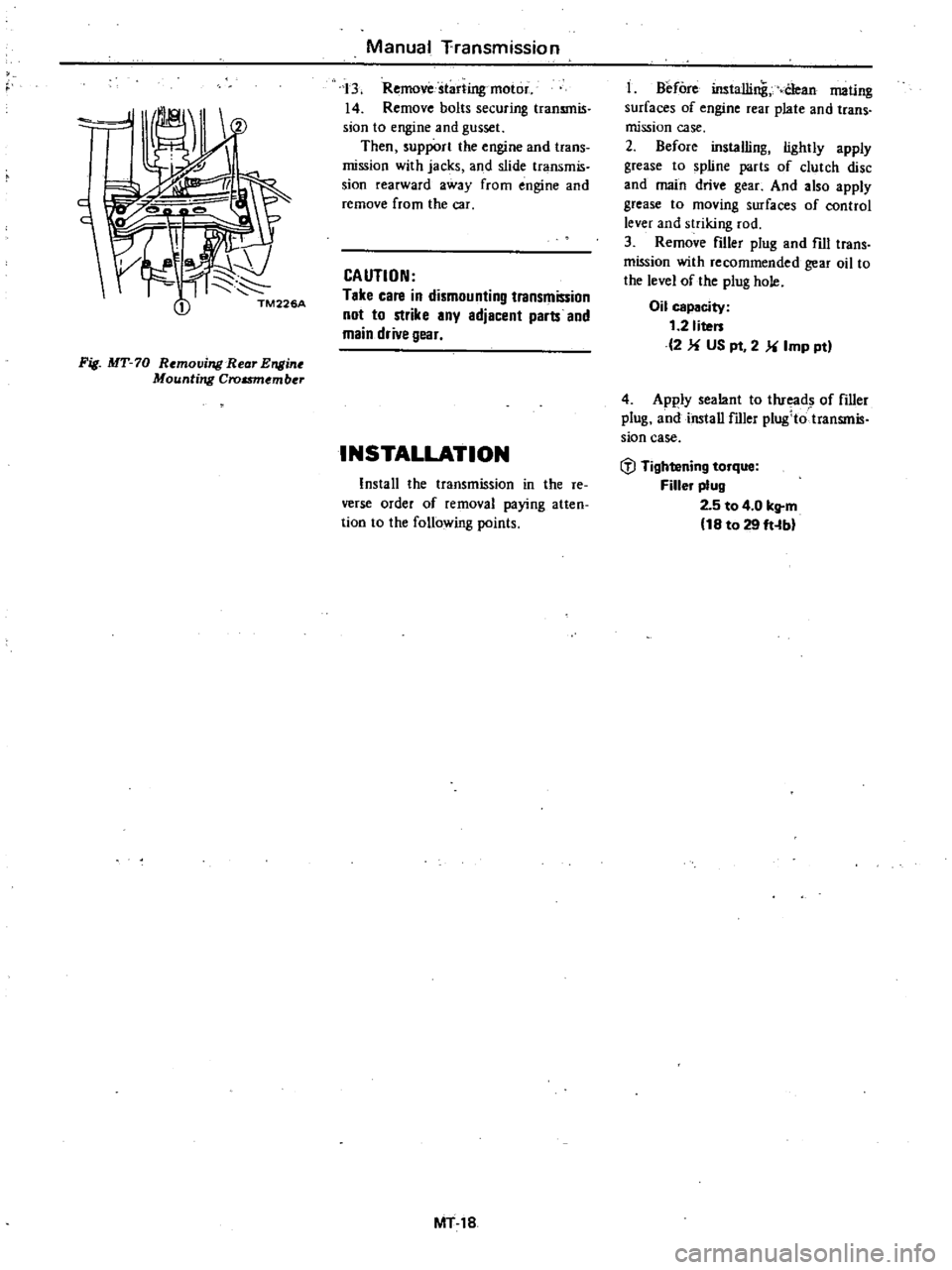

o

Fig

MT

70

R

movi7l

lB

ar

Ensi

Mounting

Croum

mber

Manual

Transmission

3

Remove

starting

motor

14

Remove

bolts

securing

transmis

sJon

to

engine

and

gusset

Then

support

the

engine

and

trans

mission

with

jacks

and

slide

transmis

sion

rearward

away

from

engine

and

remove

from

the

car

CAUTION

Take

cate

in

dismounting

transmission

not

to

strike

any

adjacenl

parts

and

main

drive

gear

INSTALLATION

Install

the

transmission

in

the

re

verse

order

of

removal

paying

atten

tion

to

the

following

points

MT18

t

Before

installing

Clean

mating

surfaces

of

engine

rear

plate

and

trans

mission

case

2

Before

installing

lightly

apply

grease

to

spline

parts

of

clutch

disc

and

main

drive

gear

And

also

apply

grease

to

moving

surfaces

of

control

lever

and

striking

rod

3

Remove

filler

plug

and

fill

trans

mission

with

recommended

gear

oil

to

the

level

of

the

plug

hole

Oil

capacity

t

2

liters

2

US

pt

2

Imp

ptl

4

Apply

sealant

to

thread

of

filler

plug

and

install

filler

plug

totransmis

sian

case

l

l

Tightening

torque

Filler

plug

2

5

to

4

0

kg

m

t8

to

29

ft

bl

Page 277 of 548

Automatic

Transmission

REMOVAL

AND

INSTALLATION

TRANSMISSION

ASSEMBLY

When

dismounting

the

automatic

transmission

from

a

car

pay

attention

to

the

following

points

I

Before

dismounting

the

trans

mission

rigidly

inspect

it

by

aid

of

the

Trouble

shooting

Chart

and

dis

mount

it

only

when

coll5idered

to

be

necessary

2

Dismount

the

transmission

with

utmost

care

and

when

mounting

observe

the

tightening

torque

indi

cated

on

another

table

not

to

exert

excessive

force

REMOVAL

In

dismounting

automatic

transmis

sion

from

car

proceed

as

follows

I

Disconnect

battery

ground

cable

from

terminal

2

Disengage

torsion

shaft

from

ac

eelerator

linkage

3

Jack

up

vehicle

and

support

its

weight

on

safety

stands

Recommend

a

hydraulic

hoist

or

open

pit

be

utilized

if

available

Make

sure

that

safety

is

insured

4

Remove

propeller

shaft

Note

Pl

ll

up

the

openina

in

the

rear

extension

to

prevent

oil

from

flow

ing

out

S

Disconnect

front

exhaust

tube

6

Disconnect

selector

ra

8e

lever

from

manual

shaft

7

Disconnect

wire

connections

at

inhibitor

switch

8

Disconnect

vacuum

lube

from

vacuum

diaphragm

and

wire

connee

tions

at

downshift

solenoid

9

Disconnect

speedometer

cable

from

rear

exlension

10

Disconnect

oil

charging

pipe

II

Disconnect

oil

cooler

inlet

and

outlet

tubes

al

transmission

case

12

Support

engine

by

locating

a

jack

under

oil

pan

with

a

wooden

block

used

between

oil

pan

and

jack

Support

transmission

by

means

of

a

transmission

jack

CAUTION

Do

not

plecs

the

jack

under

the

oil

pin

dnin

plug

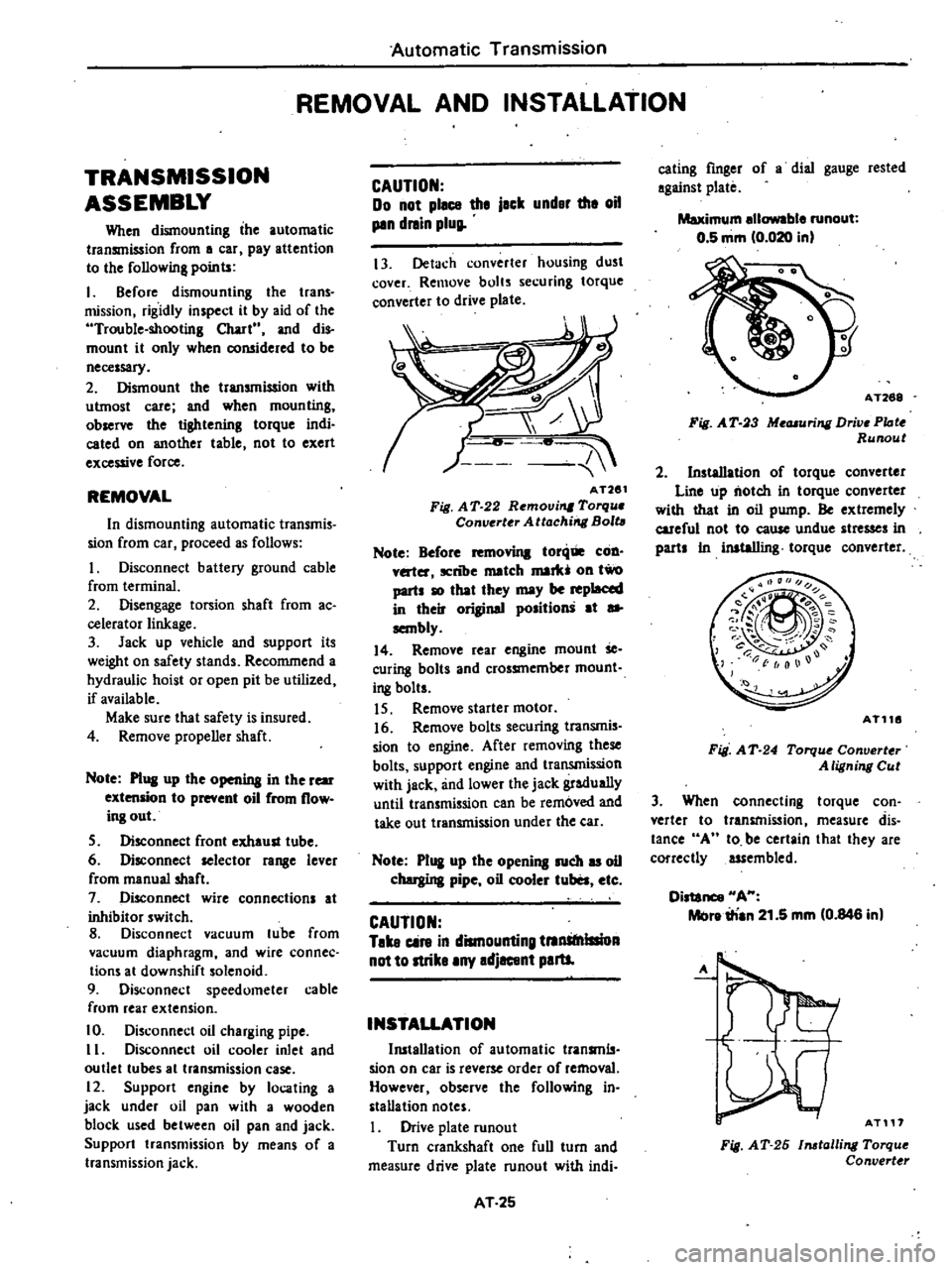

13

Detach

converter

housing

dust

cover

Remove

bolts

securing

torque

converter

to

drive

plate

AT261

Fig

A

T

22

Removi

Torqu

Converter

Attachirrg

Bolt

Note

Before

toni

COD

v

ter

ICnlJe

match

mark

011

two

parts

10

that

they

may

be

replaced

in

their

original

position

at

sa

sembly

14

Remove

rear

engine

mount

Se

curing

bolts

and

crossmember

mount

i

8

bolts

IS

Remove

starter

motor

16

Remove

bolts

securing

transmis

sion

to

engine

After

removing

these

bolts

support

engine

and

transmission

with

jack

and

lower

the

jack

gradually

until

transmission

can

be

removed

and

take

out

transmission

under

the

ear

Note

P1

I

up

the

opening

such

u

oil

chergina

pipe

oil

cooler

tuba

etc

CAUTION

Take

cin

in

dismounting

tnnStnlllioA

not

to

strike

any

adjacent

paru

INSTALLATION

Ill5tallation

of

automatic

transmls

sian

on

car

is

reverse

order

of

removal

However

observe

the

following

in

stallation

notes

Drive

plate

runout

Turn

crankshaft

one

full

turn

and

measure

drive

plate

runout

with

indi

AT

25

eating

finger

of

a

dial

gauge

rested

against

plate

Maximum

ellowable

runout

0

5

mm

0

020

in

AT268

Fig

A

T

3

Me

uring

Drive

PIote

Runout

2

Installation

of

torque

converter

Line

up

notch

in

torque

converter

with

that

in

oil

pump

Be

extremely

careful

not

to

eause

undue

stresses

in

parts

In

inataIIing

torque

converter

AT116

Fig

A

T

24

Torqu

Converter

A

ligning

Cut

3

When

connecting

torque

con

verter

to

transmission

measure

dis

tance

A

10

be

certain

that

they

are

correctly

assembled

Distance

HA

Melre

irian

21

5

mm

0

846

in

A

AT117

Fig

AT

26

1116talling

Torque

Convert

r

Page 309 of 548

Propeller

Shaft

Differential

Carrier

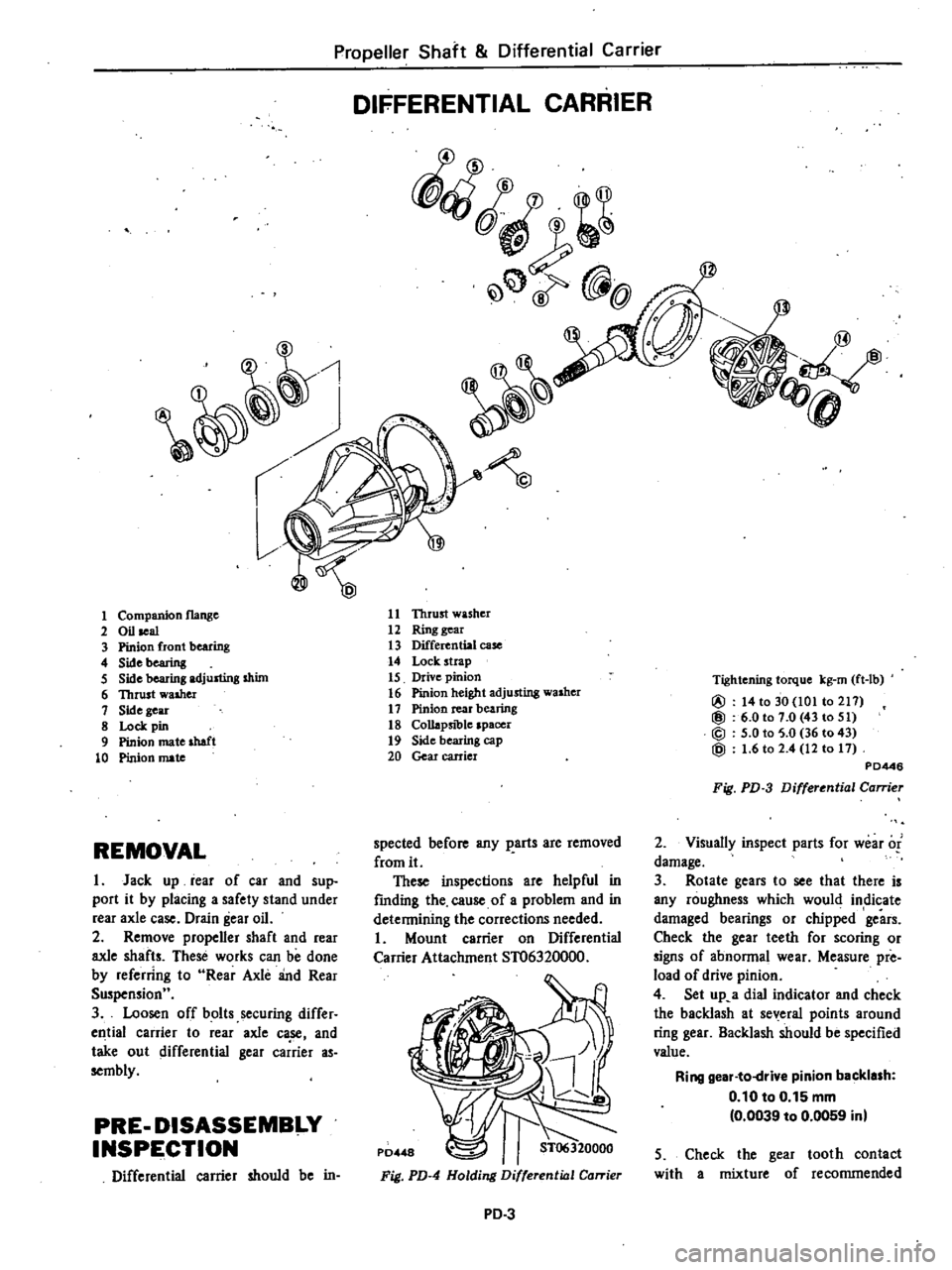

DIFFERENTIAL

CARRIER

fQ

@

1

11

Thrust

washer

12

Ring

gear

13

Differential

case

14

Lock

strap

15

Drive

pinion

16

Pinion

height

adjusting

washer

17

Pinion

rear

bearing

18

Collapsible

spacer

19

Side

bearing

cap

20

Gear

carrier

1

Companion

flange

2

Oil

seal

3

Pinion

front

bearing

4

Sidebearing

5

Side

bearing

adjusting

shim

6

Thrust

walher

1

Side

gear

8

Lock

pin

9

Pinion

mate

shaft

10

Pinion

mate

Tightening

torque

kg

rn

ft

lb

@

14

to

30

101

to

211

@

6

0101

0

43

to

51

@

5

0

to

5

0

36

to

43

@

1

6

to

2

4

12

to

11

PD446

Fig

PD

3

Differential

Carrier

2

Visuany

inspect

parts

for

wear

of

damage

3

Rotate

gears

to

see

that

there

is

any

roughness

which

would

indicate

damaged

bearings

or

chipped

gears

Check

the

gear

teeth

for

scoring

or

signs

of

abnonnal

wear

Measure

pre

load

of

drive

pinion

4

Set

up

a

dial

indicator

and

check

the

backlash

at

several

points

around

ring

gear

Backlash

should

be

specified

value

Ring

gear

to

drive

pinion

backlash

0

10

to

0

15

mm

0

0039

to

0

0059

inl

spected

before

any

parts

are

removed

from

it

These

inspections

are

helpful

in

fmding

the

cause

of

a

problem

and

in

detennining

the

corrections

needed

Mount

carrier

on

Differential

Carrier

Attachment

ST06320000

REMOVAL

I

Jack

up

rear

of

car

and

sup

port

it

by

placing

a

safety

stand

under

rear

axle

case

Drain

gear

oil

2

Remove

propener

shaft

and

rear

axle

shafts

These

works

can

be

done

by

referring

to

Rear

Axle

and

Rear

Suspensionu

3

Loosen

off

bolts

securing

differ

ell

tial

carrier

to

rear

axle

ca

se

and

take

out

differential

gear

carrier

as

sembly

PRE

DISASSEMBI

Y

INSPE

CTION

Differential

carrier

should

be

in

5

Check

the

gear

tooth

contact

with

a

mixture

of

recommended

Fig

PD

4

Holding

Differential

Carrier

PD

3

Page 324 of 548

Front

Axle

Front

Suspension

INSPECTION

AND

ADJUSTIVIENT

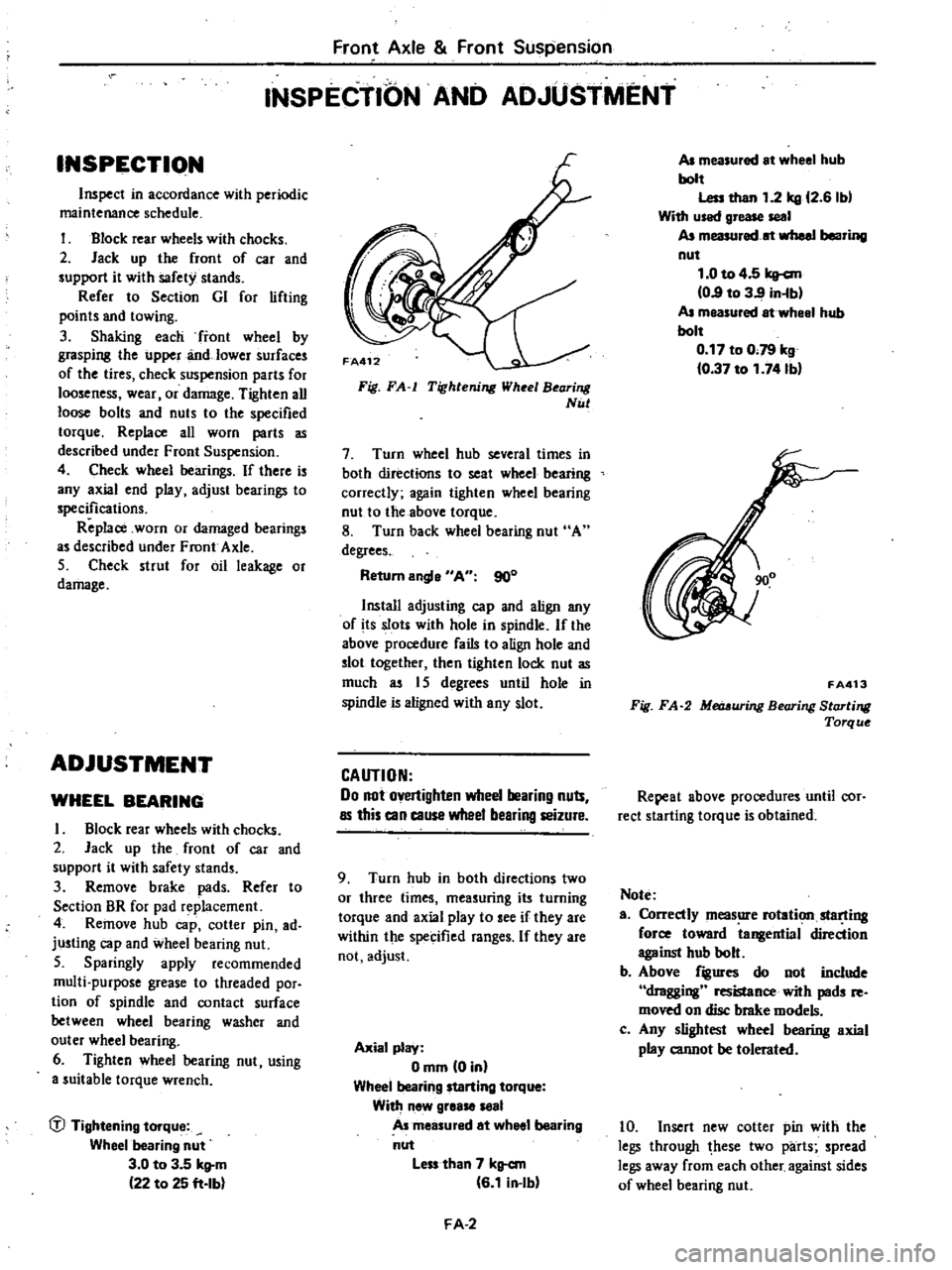

INSPECTION

Inspect

in

accordance

with

periodic

maintenance

schedule

Block

rear

wheels

with

chocks

2

Jack

up

the

front

of

car

and

support

it

with

safety

stands

Refer

to

Section

GI

for

lifting

points

and

towing

3

Shaking

each

fiont

wheel

by

grasping

the

upper

and

lower

surfaces

of

the

tires

check

suspension

parts

for

looseness

wear

or

damage

Tighten

aU

loose

bolts

and

nuts

to

the

specified

torque

Replace

all

worn

parts

as

described

under

Front

Suspension

4

Check

wheel

bearings

If

there

is

any

axial

end

play

adjust

bearings

to

specifications

Replace

worn

or

damaged

bearings

as

described

under

Front

Axle

S

Check

strut

for

oil

leakage

or

damage

ADJUSTMENT

WHEEL

BEARING

Block

rear

wheels

with

chocks

2

Jack

up

the

front

of

car

and

support

it

with

safety

stands

3

Remove

brake

pads

Refer

to

Section

BR

for

pad

replacement

4

Remove

hub

cap

cotter

pin

ad

justing

cap

and

wheel

bearing

nut

S

Sparingly

apply

recommended

multi

purpose

grease

to

threaded

por

tion

of

spindle

and

contact

surface

between

wheel

bearing

washer

and

outer

wheel

bearing

6

Tighten

wheel

bearing

nut

using

a

suitable

torque

wrench

P

Tightening

torque

Wheel

bearing

nut

3

0

to

3

5

kll

m

22

to

25

ft

Ibl

Fig

FA

Tighlening

Wheel

Bearing

Nul

7

Turn

wheel

hub

several

times

in

both

directions

to

seat

wheel

bearing

correctly

again

tighten

wheel

bearing

nut

to

the

above

torque

8

Turn

back

wheel

bearing

nut

A

degrees

Return

engle

AU

900

Install

adjusting

cap

and

align

any

of

its

slots

with

hole

in

spindle

If

the

above

procedure

fails

to

align

hole

and

slot

together

then

tighten

lock

nut

as

much

as

I

S

degrees

until

hole

in

spindle

is

aligned

with

eny

slot

CAUTION

00

not

overtighten

wheel

bearing

nuts

as

this

can

cause

wheel

bearing

seizure

9

Turn

hub

in

both

directions

two

or

three

times

measuring

its

turning

torque

and

axial

play

to

ee

if

they

are

within

the

specified

range

If

they

are

not

adjust

Axial

play

Omm

Din

Wheel

bealing

starting

torque

With

new

gleaS8

l8al

A

measured

et

wheel

bearing

nut

less

than

7

kg

cm

G

1

in

Ibl

FA

2

AJ

measuled

et

wheel

hub

bolt

Less

then

1

2

kg

12

G

Ibl

With

u

ed

gr

seal

AJ

measured

at

wheel

bealing

nut

1

0

to

4

5

kg

cm

0

9

to

3

9

in

b

AJ

measuled

at

wheel

hub

bolt

0

17

to

0

79

kg

0

37

to

1

741bl

FA413

Fig

FA

2

Metr

uring

Bearing

Starting

Torq

ue

Repeat

above

procedures

until

cor

rect

starting

torque

is

obtained

Note

a

Correctly

meas

e

rotation

slar

ting

force

toward

tangential

direction

against

hub

bolt

b

Above

figures

do

not

include

dragging

resistance

with

pads

re

moved

on

disc

brake

models

c

Any

slightest

wheel

bearing

axial

play

cannot

be

tolerated

10

Insert

new

cotter

pin

with

the

legs

through

hese

two

parts

spread

legs

away

from

each

other

against

sides

of

wheel

bearing

nut

Page 331 of 548

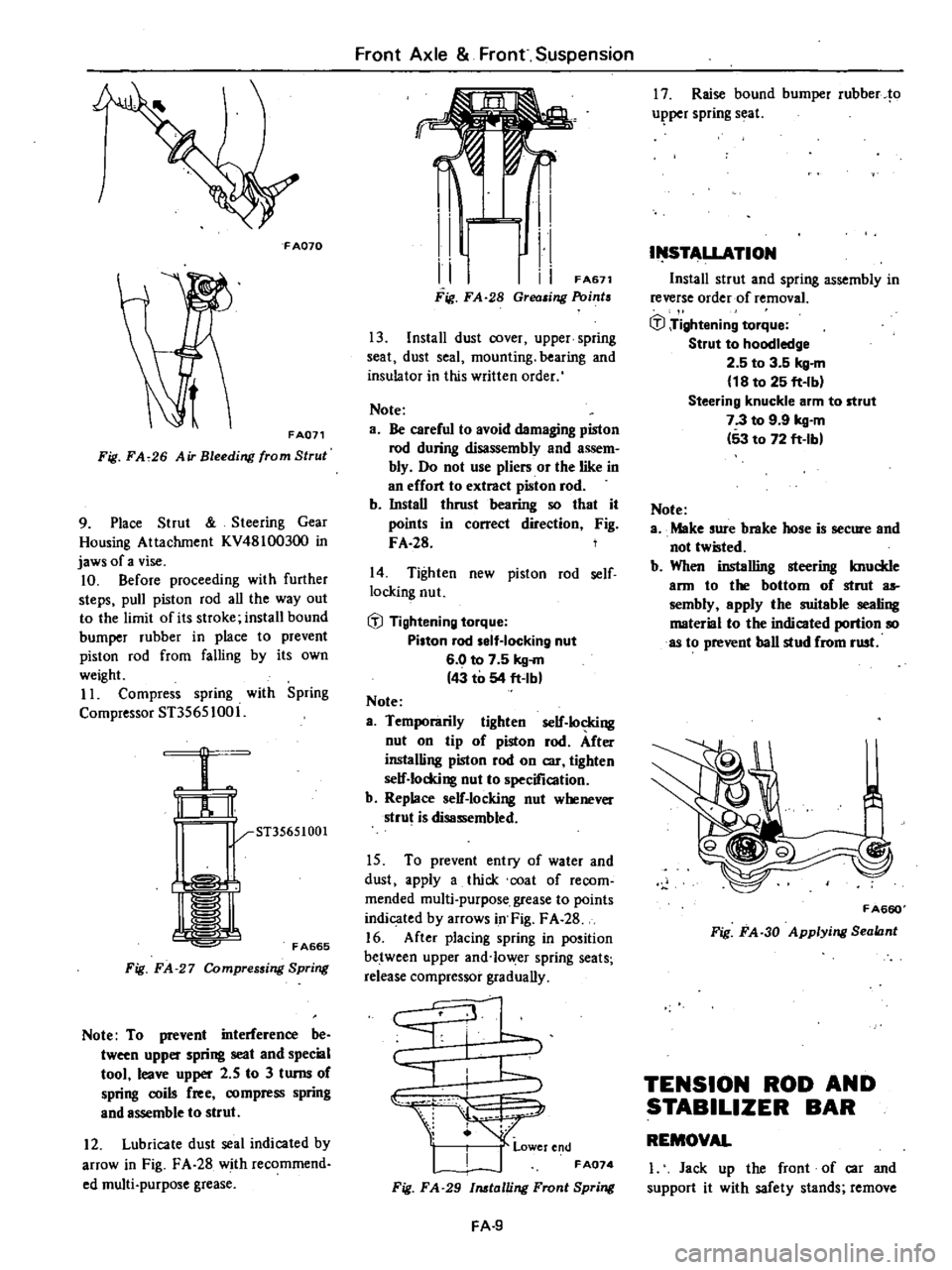

FA070

FA071

Fig

FA

26

Air

Bleeding

from

Strul

9

Place

Strut

Steering

Gear

Housing

Attachment

KV48100300

in

jaws

of

a

vise

10

Before

proceeding

with

further

steps

pull

piston

rod

all

the

way

out

to

the

limit

of

its

stroke

install

bound

bumper

rubber

in

place

to

prevent

piston

rod

from

falling

by

its

own

weight

11

Compress

spring

with

Spring

Compressor

ST35651001

ST35651001

r

l

I

FA665

Fig

FA

27

Compressing

Spring

Note

To

prevent

interference

be

tween

upper

spring

seat

and

special

tool

leave

upper

2

5

to

3

turns

of

spring

coils

free

compress

spring

and

assemble

to

strut

12

Lubricate

dust

seal

indicated

by

arrow

in

Fig

FA

28

with

recommend

ed

multi

purpose

grease

Front

Axle

Front

Suspension

I

1

i

I

FA671

Fig

FA

28

Grea

ing

Point

13

Install

dust

cover

upper

spring

seat

dust

seal

mounting

bearing

and

insulator

in

this

written

order

Note

a

Be

careful

to

avoid

damaging

piston

rod

during

disassembly

and

assem

bly

Do

not

use

pliers

or

the

like

in

an

effort

to

extract

piston

rod

b

InstaU

thrust

bearing

so

that

it

points

in

correct

direction

Fig

FA

28

14

Tighten

new

piston

rod

self

locking

nut

fil

Tightening

torque

Pi

ton

rod

elf

Iocking

nut

6

0

to

7

5

kg

m

43

to

54

ft

lbl

Note

a

Temporarily

tighten

self

locking

nut

on

tip

of

piston

rod

After

installing

piston

rod

on

car

tighten

self

locking

nut

to

specification

b

Replace

self

locking

nut

whenever

strut

is

disassembled

15

To

prevent

entry

of

water

and

dust

apply

a

thick

coat

of

recom

mended

multi

purpose

grease

to

points

indicated

by

arrows

in

Fig

F

A

28

16

After

placing

spring

in

position

between

upper

and

lo

er

spring

seats

release

compressor

graduaUy

I

J

k

1

jt

r

end

FA074

Fig

FA

29

talling

Front

Spring

FA

9

17

Raise

bound

bumper

rubber

10

u

per

spring

seal

I

STALLATION

Install

strut

and

spring

assembly

in

reverse

order

of

removaL

fil

Tightening

torque

Strut

to

hoodledge

2

5

to

3

5

kg

m

18

to

25

ft

Ib

Steering

knuckle

arm

to

strut

7

3

to

9

9

kg

m

53

to

72

ft

lb

Note

a

Make

sure

brake

hose

is

secure

and

not

tw

ted

b

When

installing

steering

knuckle

ann

to

the

bottom

of

strut

as

sembly

epply

the

suitable

sealing

material

to

the

indicated

portion

so

as

to

prevent

ball

stud

from

rust

FA660

Fig

FA

30

Applying

Sealant

TENSION

ROD

AND

STABILIZER

BAR

REMOVAL

I

Jack

up

the

front

of

car

and

support

it

with

safety

stands

remove

Page 378 of 548

t

MAINTEN

NCE

TIRE

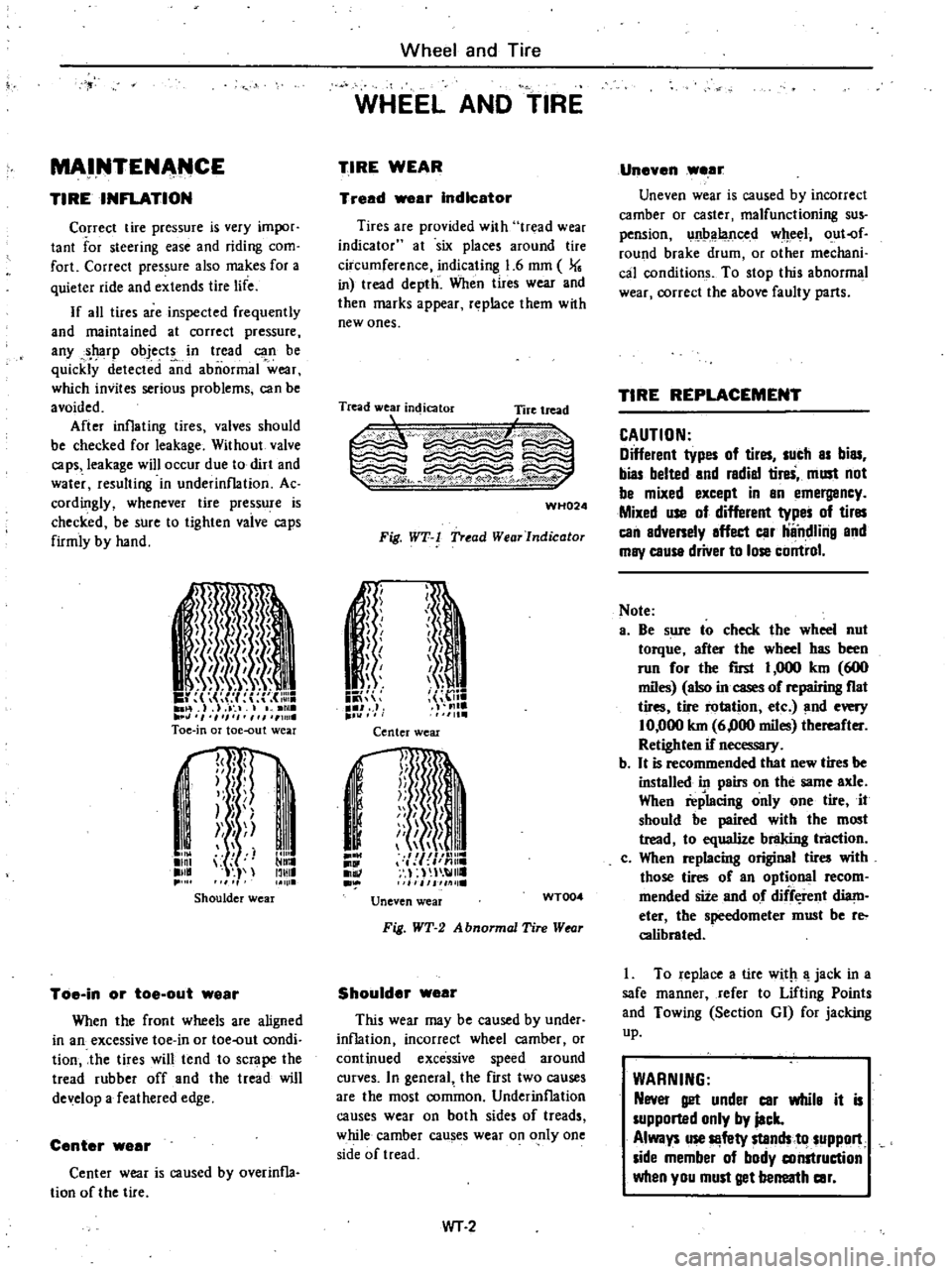

INFLATION

Correct

tire

pressure

is

very

impor

tant

for

steering

ease

and

riding

com

fort

Correct

pressure

also

makes

for

a

quieter

ride

and

extends

tire

life

If

all

tires

are

inspected

frequently

and

maintained

at

correct

pressure

any

sharp

objects

in

tread

can

be

quickiy

detected

nd

abnormal

wear

which

invites

serious

problems

can

be

avoided

After

inflating

tires

valves

should

be

checked

for

leakage

Without

valve

caps

leakage

will

occur

due

to

dirt

and

water

resulting

in

underinflation

Ac

cordingly

whenever

tire

pressure

is

checked

be

sure

to

tighten

vaive

caps

firmly

by

hand

JW

Sri

in

1

II

I

i

I

1

I

1

1

I

I

I

II

I

I

I

i

M

I

l

1

14

nl

01

I

II

Toe

in

or

toe

out

wear

I

J

I

I

p

rt

i

Ilnl

lll

11111

IllIlI

Shoulder

wear

Toe

in

or

toe

out

wear

When

the

front

wheels

are

aligned

in

an

excessive

toe

in

or

toe

out

condi

tion

the

tires

will

tend

to

scrape

the

tread

rubber

off

and

the

tread

will

de

elop

a

feathered

edge

Center

wear

Center

wear

is

caused

by

overinfla

tion

of

the

tire

Wheel

and

Tire

WHEEL

AND

TIRE

TIRE

WEAR

Tread

ar

Indicator

Tires

are

provided

with

tr

lad

wear

indicator

at

six

places

around

tire

circumference

indicating

1

6

mm

J

in

tread

depth

When

tires

wear

and

then

marks

appear

replace

them

wtth

new

ones

Tread

wear

indicator

Tire

tread

L

1

c

WH024

Fig

WT

l

Tread

WearJndicator

n

1

ii

J

J

f

J

I

h

I

me

1111

Center

wear

j

I

1II

mnr

I

j

n

Ii

Ii

i

I

Jil

111

lie

Uneven

wear

WT004

Fig

WT

2

A

bnormal

Tire

Wtor

Shoulder

wear

This

wear

may

be

caused

by

under

inflation

incorrect

wheel

camber

or

continued

excessive

speed

around

curves

In

general

the

first

two

causes

are

the

most

common

Underinflation

causes

wear

on

both

sides

of

treads

while

camber

causes

wear

on

only

one

side

of

tread

WT

2

Uneven

wear

Uneven

wear

is

caused

by

incorrect

camber

or

caster

malfunctioning

sus

pension

unbalanced

wheel

out

of

round

brake

drum

or

other

mechani

cal

conditions

To

stop

this

abnormal

wear

correct

the

above

faulty

parts

TIRE

REPLACEMENT

CAUTION

Different

types

of

tires

sucb

as

bias

bias

belted

and

radial

tireS

must

not

be

mixed

except

in

an

emergancy

Mixed

use

of

different

types

of

tires

can

adversely

affect

car

ilndlilig

and

may

cause

driver

to

lose

control

Note

a

Be

sure

to

check

the

wheel

nut

torque

after

the

wheel

has

been

run

for

the

rust

I

000

km

600

miles

also

in

cases

of

repairing

fiat

tires

tire

rotation

etc

and

every

10

000

km

6

000

miles

thereafter

Retighten

if

necessary

b

It

is

recommended

that

new

tires

be

installed

in

pairs

on

the

same

axle

When

replacing

only

one

tire

it

should

be

paired

with

the

most

tread

to

equalize

braking

tl1lction

c

When

replacing

original

tires

with

those

tires

of

an

optional

recom

mended

site

and

of

diff

rent

diam

eter

the

speedometer

must

be

reo

calibrated

I

To

replace

a

tire

with

a

jack

in

a

safe

manner

refer

to

Lifting

Points

and

Towing

Section

GI

for

jacking

up

WARNING

Never

get

under

car

whila

it

is

supported

only

by

jack

Always

use

Il

fety

stands

to

suppon

side

member

of

body

construction

when

you

must

get

berreatb

car