radio antenna DATSUN 210 1979 Service Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 440 of 548

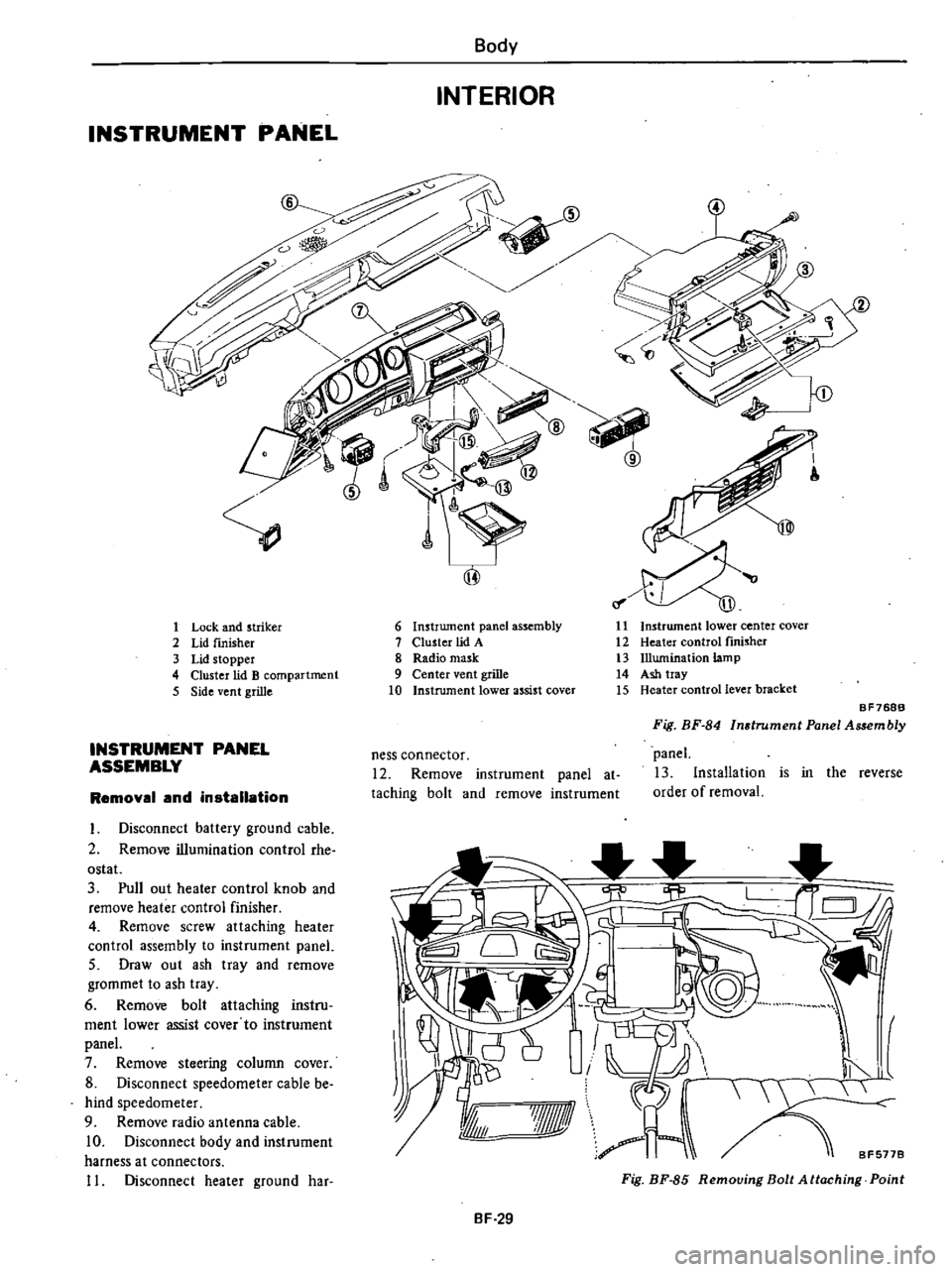

INSTRUMENT

PANEL

Body

INTERIOR

1

Lock

and

striker

2

Lid

fInisher

3

Lid

stopper

4

Cluster

lid

B

compartment

5

Side

vent

grille

INSTRUMENT

PANEL

ASSEMBLY

Removal

and

installation

I

Disconnect

battery

ground

cable

2

Remove

illumination

control

rhe

ostat

3

Pull

out

heater

control

knob

and

remove

heater

control

finisher

4

Remove

screw

attaching

heater

control

assembly

to

instrument

panel

5

Draw

out

ash

tray

and

remove

grommet

to

ash

tray

6

Remove

bolt

attaching

instru

ment

lower

assist

cover

to

instrument

panel

7

Remove

steering

column

cover

8

Disconnect

speedometer

cable

be

hind

speedometer

9

Remove

radio

antenna

cable

10

Disconnect

body

and

instrument

harness

at

connectors

11

Disconnect

heater

ground

har

6

Instrument

panel

assembly

7

Cluster

lid

A

8

Radio

mask

9

Center

vent

grille

10

Instrument

lower

assist

cover

11

Instrument

lower

center

cover

12

Heater

control

fInisher

13

Illumination

lamp

14

Ash

tray

15

Heater

control

lever

bracket

ness

connector

12

Remove

instrument

panel

at

taching

bolt

and

remove

instrument

BF768B

Fig

BF

84

Instrument

Panel

Assembly

panel

13

Installation

is

in

the

reverse

order

of

removal

I

I

I

8F5778

7Jf1ll

A

Fig

BF

85

Removing

Bolt

Attaching

Point

BF

29

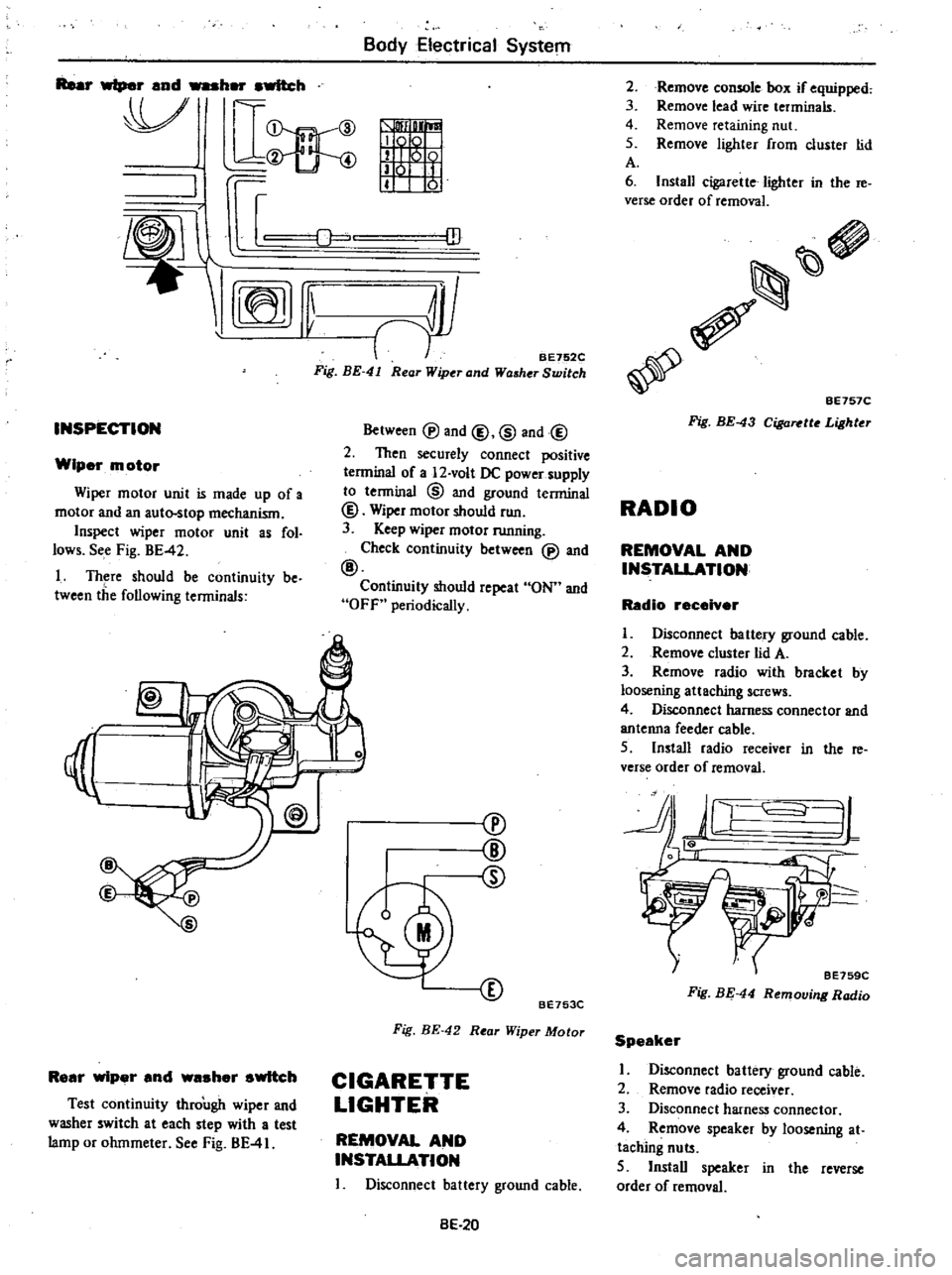

Page 465 of 548

Rear

wiper

and

her

awltch

V

D

mn

ID

I

INSPECTION

Wiper

motor

Wiper

motor

unit

is

made

up

of

a

motor

and

an

auto

stop

mechanism

Inspect

wiper

motor

unit

as

fol

lows

See

Fig

BE

42

I

Th

re

should

be

continuity

be

tween

the

following

terminals

Body

Electrical

System

ill

BE752C

Fig

BE

41

Rear

Wiper

and

Washer

Switch

Between

@

and

@

@

and@

2

Then

securely

connect

positive

terminal

of

a

12

volt

DC

power

supply

to

tenninal

@

and

ground

terminal

@

Wiper

motor

should

run

3

Keep

wiper

motor

running

Check

continuity

between

@

and

@

Continuity

should

repeat

ON

and

OFf

periodically

I

Rear

wiper

and

waaher

switch

Test

continuity

through

wiper

and

washer

switch

at

each

step

with

a

test

lamp

or

ohmmeter

See

Fig

BE

41

cv

@

CD

BE753C

Fig

BE

42

Rear

Wiper

Motor

CIGARETTE

LIGHTER

REMOVAL

AND

INSTALLATION

I

Disconnect

battery

ground

cable

BE

20

Remove

comole

box

if

equipped

Remove

lead

wire

terminals

Remove

retaining

nut

Remove

lighter

from

cluster

lid

2

3

4

5

A

6

Install

cigarette

lighter

in

the

re

verse

order

of

removal

BE757C

Fig

BE

43

CiI

a

tto

Lighter

RADIO

REMOVAL

AND

INSTALLATION

Radio

receiver

I

Disconnect

battery

ground

cable

2

Remove

cluster

lid

A

3

Remove

radio

with

bracket

by

loosening

attaching

screws

4

DiscOnnect

harness

connector

and

antenna

feeder

cable

5

Install

radio

receiver

in

the

re

verse

order

of

removal

JL

J

tf

BE759C

Fig

BE

44

Removing

Radio

Speaker

I

Disconnect

battery

ground

cable

2

Remove

radio

receiver

3

Disconnect

harness

connector

4

Remove

speaker

by

loosening

at

taching

nuts

5

Install

speaker

in

the

reverse

order

of

removal

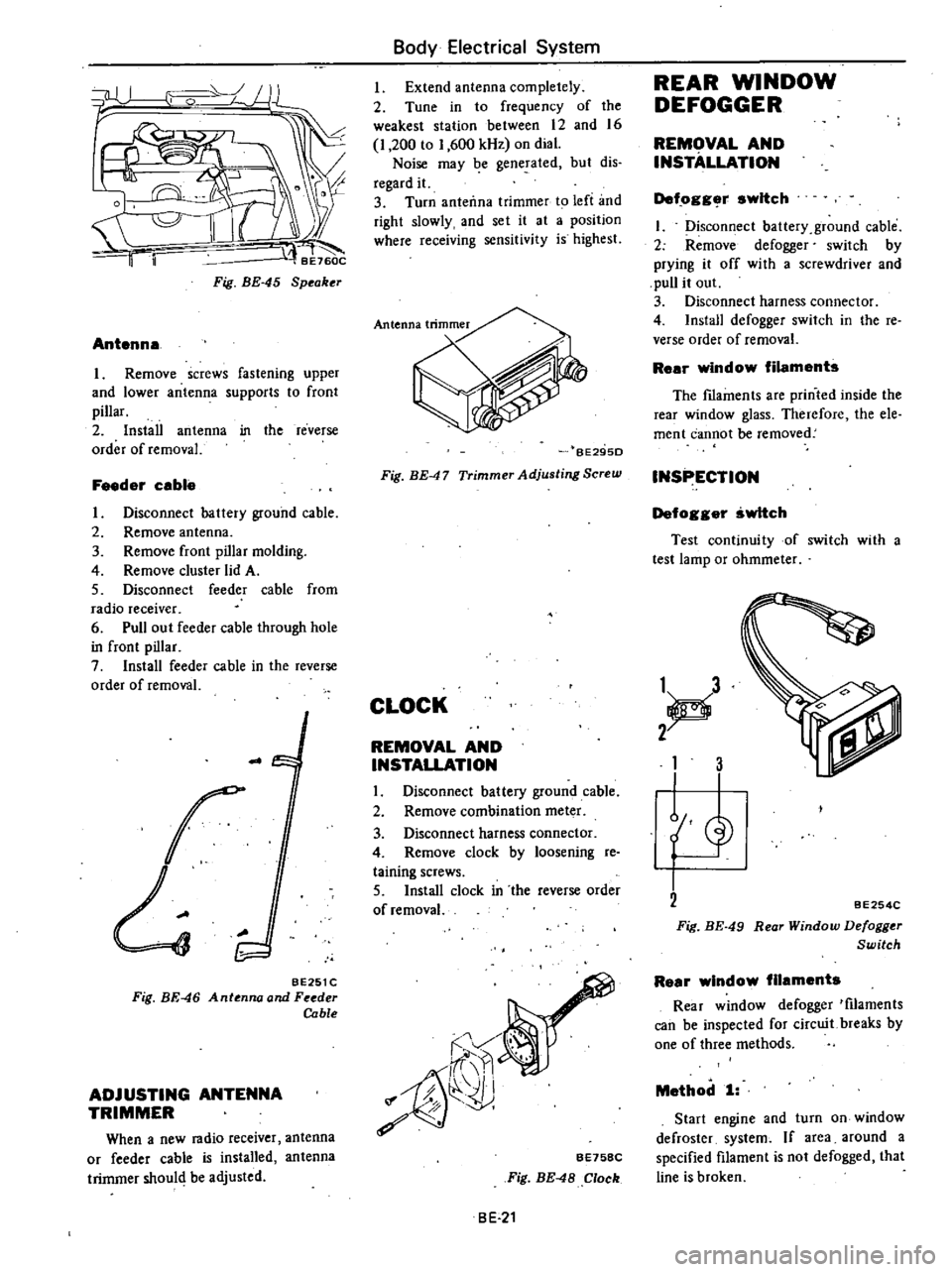

Page 466 of 548

t

Fig

BE

45

Speaker

Antenna

Remove

screws

fastening

upper

and

lower

antenna

supports

to

front

pillar

2

Install

antenna

in

the

reverse

order

of

removal

Feeder

cable

I

Disconnect

battery

ground

cable

2

Remove

antenna

3

Remove

front

pillar

molding

4

Remove

cluster

lid

A

5

Disconnect

feeder

cable

from

radio

receiver

6

Pull

out

feeder

cable

through

hole

in

front

pillar

7

Install

feeder

cable

in

the

reverse

order

of

removal

r

BE251C

Fig

BE

46

Antenna

and

Feeder

Cable

ADJUSTING

ANTENNA

TRIMMER

When

a

new

radio

receiver

antenna

or

feeder

cable

is

installed

antenna

trimmer

shoul

be

adjusted

Body

Electrical

System

Extend

antenna

completely

2

Tune

in

to

frequency

of

the

weakest

station

between

12

and

16

I

200

to

1

600

kHz

on

dial

Noise

may

be

generated

but

dis

regard

it

3

Turn

anteiln3

trimmer

to

left

and

right

slowly

and

set

it

at

a

position

where

receiving

sensitivity

is

highest

BE29SD

Fig

BE

47

Trimmer

Adjusting

Screw

CLOCK

REMOVAL

AND

INSTALLATION

I

Disconnect

battery

ground

cable

2

Remove

combination

meter

3

Disconnect

harness

connector

4

Remove

clock

by

loosening

re

taining

screws

5

Install

clock

in

the

reverse

order

of

removal

r

Jf

rr

i1

b

Ii

f

7

8

eE758C

Fig

BE

48

Clock

BE

21

REAR

WINDOW

DEFOGGER

REMOVAL

AND

INSTALLATION

Def

ogg

r

switch

I

Disconfi

ect

battery

ground

cable

2

Remove

defogger

switch

by

prying

it

off

with

a

screwdriver

and

pull

it

out

3

Disconnect

harness

connector

4

Install

defogger

switch

in

the

reo

verse

order

of

removal

Rear

window

filaments

The

fIlaments

are

printed

inside

the

rear

window

glass

Therefore

the

ele

ment

cannot

be

removed

INSPECTION

Defogger

switch

Test

continuity

of

switch

with

a

test

lamp

or

ohmmeter

1

d

2

1

3

L

BE254C

Fig

BE

49

Rear

Window

Defogger

Switch

Rear

window

filaments

Rear

window

defogger

tfilaments

can

be

inspected

for

circuit

breaks

by

one

of

three

methods

Method

1

Start

engine

and

turn

on

window

defroster

system

If

area

around

a

specified

filament

is

not

defogged

that

line

is

broken

Page 499 of 548

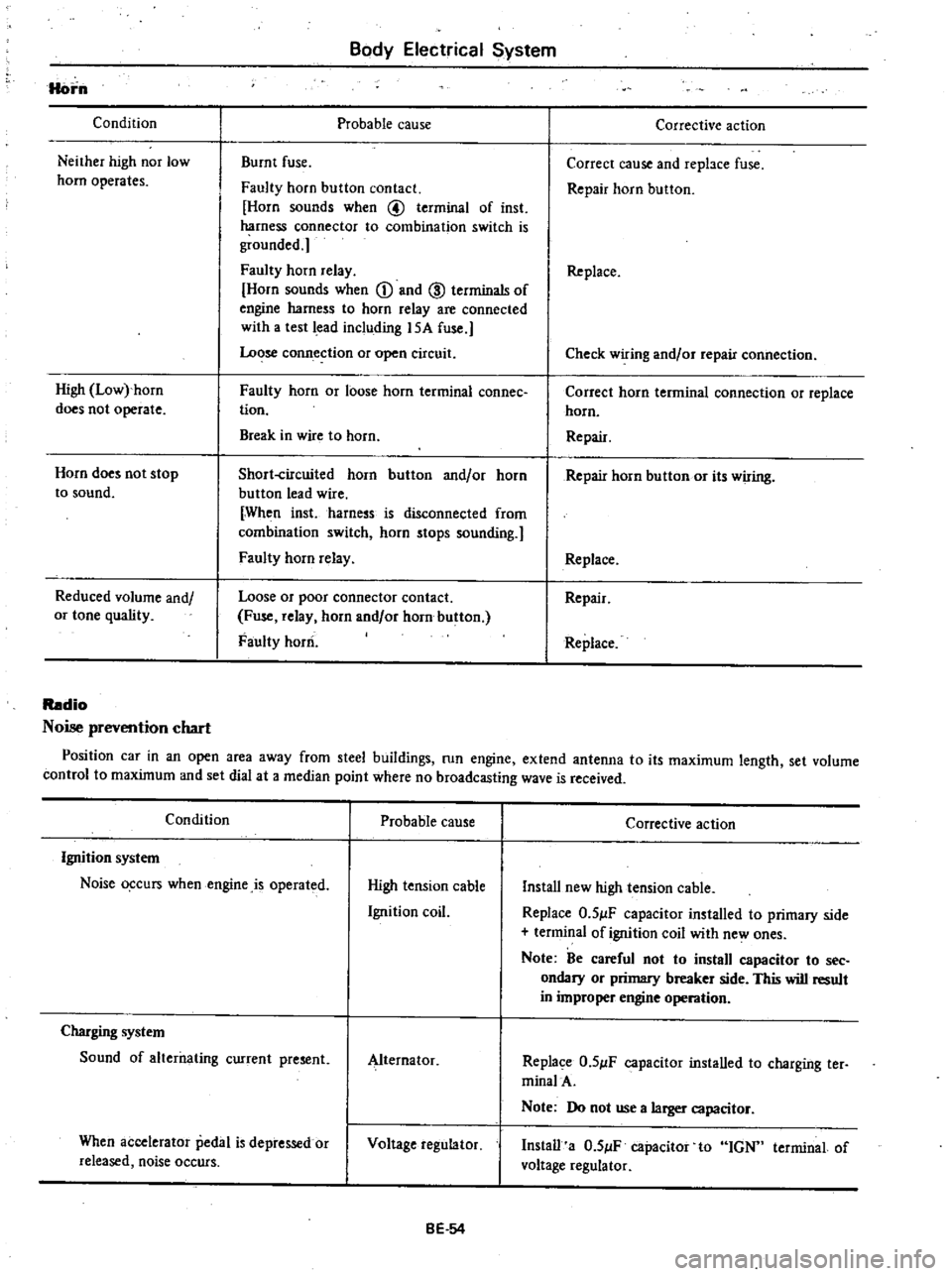

Horn

Condition

Neither

high

nor

low

horn

operates

High

Low

horn

does

not

operate

Horn

does

not

stop

to

sound

Reduced

volume

and

or

tone

quality

Body

Electrical

System

Probable

cause

Burnt

fuse

Faulty

horn

button

contact

Horn

sounds

when

@

terminal

of

inst

harness

connector

to

combination

switch

is

grounded

Faulty

horn

relay

Horn

sounds

when

CD

and

ID

terminals

of

engine

harness

to

horn

relay

are

connected

with

a

test

lead

including

15A

fuse

Lo

se

conn

ection

or

open

circuit

Faulty

horn

or

loose

horn

terminal

connee

tion

Break

in

wire

to

horn

Short

circuited

horn

button

and

or

horn

button

lead

wire

When

inst

harness

is

disconnected

from

combination

switch

horn

stops

sounding

Faulty

horn

relay

Loose

or

poor

connector

contact

Fuse

relay

horn

and

or

horn

button

Faulty

horn

Corrective

action

Correct

cause

and

repbce

fuse

Repair

horn

button

Replace

Check

wiring

and

or

repair

connection

Correct

horn

terminal

connection

or

replace

horn

Repair

Repair

horn

button

or

its

wiring

Replace

Repair

Replace

Radio

Noise

prevention

chart

Position

car

in

an

open

area

away

from

steel

buildings

run

engine

extend

antenna

to

its

maximum

length

set

volume

control

to

maximum

and

set

dial

at

a

median

point

where

no

broadcasting

wave

is

received

Condition

Probable

cause

Ignition

system

Noise

o

curs

when

engine

is

operated

High

tension

cable

Ignition

coil

Charging

system

Sound

of

alterilating

current

present

Alternator

When

accelerator

pedal

is

depressed

or

released

noise

occurs

Voltage

regulator

BE

54

Corrective

action

Install

new

high

tension

cable

Replace

O

5

lF

capacitor

installed

to

primary

side

terminal

of

ignition

coil

with

ne

ones

Note

Be

careful

not

to

install

capacitor

to

see

ondary

or

primary

breaker

side

This

will

result

in

improper

engine

operation

Replace

O

5

lF

capacitor

installed

to

charging

ter

minalA

Note

Do

not

use

a

larger

capacitor

Install

a

O

5

lF

capacitor

to

IGN

terminal

of

voltage

regulator