reset DATSUN 210 1979 Service Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 187 of 548

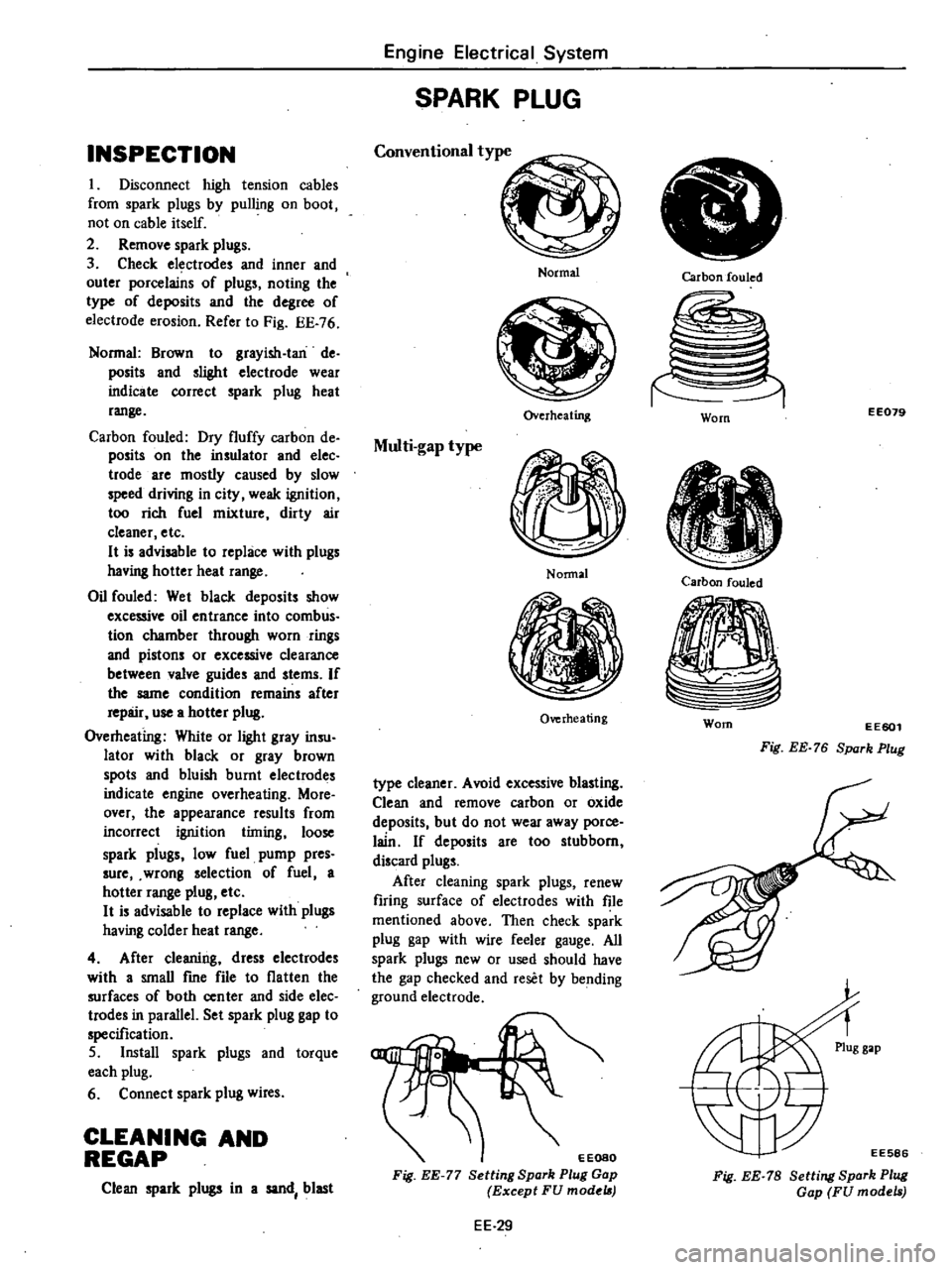

INSPECTION

I

Disconnect

high

tension

cables

from

spark

plugs

by

pulling

on

boot

not

on

cable

itself

2

Remove

spark

plugs

3

Check

electrodes

and

inner

and

outer

porcelains

of

plugs

noting

the

type

of

deposits

and

the

degree

of

electrode

erosion

Refer

to

Fig

EE

76

Normal

Brown

to

grayish

Ian

de

posits

and

slighl

electrode

wear

indicate

correct

spark

plug

heat

range

Carbon

fouled

Dry

fluffy

carbon

de

posits

on

the

insulator

and

elec

trode

are

mostly

caused

by

slow

speed

driving

in

city

weak

ignition

too

rich

fuel

mixture

dirty

air

cleaner

etc

H

is

advisable

to

replace

with

plugs

having

hotter

heat

range

Oil

fouled

Wet

black

deposits

show

excessive

oil

entrance

into

comb

us

tion

chamber

through

worn

rings

and

pistons

or

excessive

clearance

between

valve

guides

and

stems

If

the

same

condition

remains

after

repair

use

a

hotter

plug

Overheating

White

or

light

gray

insu

lator

with

black

or

gray

brown

spots

and

bluish

burnt

electrodes

indicate

engine

overheating

More

over

the

appearance

results

from

incorrect

ignition

timing

loose

spark

plugs

low

fuel

pump

pres

sure

wrong

selection

of

fuel

a

hotter

range

plug

etc

H

is

advisable

to

replace

with

plugs

having

colder

heat

range

4

After

cleaning

dress

electrodes

with

a

smaU

fme

file

to

flatten

the

surfaces

of

both

center

and

side

elec

trodes

in

parallel

Set

spark

plug

gap

to

specification

5

Install

spark

plugs

and

torque

each

plug

6

Connect

spark

plug

wires

CLEANING

AND

REGAP

Clean

spark

plugs

in

a

sand

blast

Engine

Electrical

System

SPARK

PLUG

Conventional

type

Normal

Overheating

Multi

gap

type

Nonnal

Overheating

type

cleaner

Avoid

excessive

blasting

Clean

and

remove

carbon

or

oxide

deposits

but

do

not

wear

away

porce

lain

If

deposits

are

too

stubborn

discard

plugs

After

cleaning

spark

plugs

renew

firing

surface

of

electrodes

with

file

mentioned

above

Then

check

spark

plug

gap

with

wire

feeler

gauge

All

spark

plugs

new

or

used

should

have

the

gap

checked

and

reset

by

bending

ground

electrode

EEOSO

Fig

EE

77

Setting

Spark

Plug

Gap

Except

FU

model

EE

29

Carbon

fouled

EE079

Worn

Carbon

fouled

Worn

EE601

Fig

EE

76

Spark

Plug

EE586

Fig

EE

78

Setting

Spark

Plug

Gap

FU

models

Page 325 of 548

Fig

FA

3

Installing

Coller

Pin

II

Install

hub

cap

with

new

Q

ring

and

wheel

WHEEL

ALIGNMENT

Correct

front

wheel

alignment

as

sures

proper

car

handling

characteris

tics

and

minimum

steering

effort

with

the

least

amount

of

tire

wear

Before

adjusting

front

wheel

alignment

be

sure

to

make

preliminary

inspection

of

front

end

parts

Tire

pressure

and

balance

Wheel

bearings

and

wheel

bearing

nuts

Steering

gear

play

Steering

gear

housing

loose

at

frame

Steering

linkage

and

connections

Shock

absorber

operation

If

wrong

repair

or

replace

the

damaged

portion

or

parts

When

using

equipment

for

front

wheel

alignment

inspection

follow

the

instructions

furnished

with

equipment

Note

Inspection

should

be

made

with

the

car

set

Ievel

and

at

curb

weight

Cember

end

caster

Camber

and

caster

are

preset

at

factory

and

cannot

be

adjusted

The

car

requires

only

toe

in

and

car

posture

adjustment

Note

If

camber

or

caster

alignment

is

not

within

specifications

check

as

sociated

parts

Repair

or

replace

as

necessary

Front

Axle

Front

Suspension

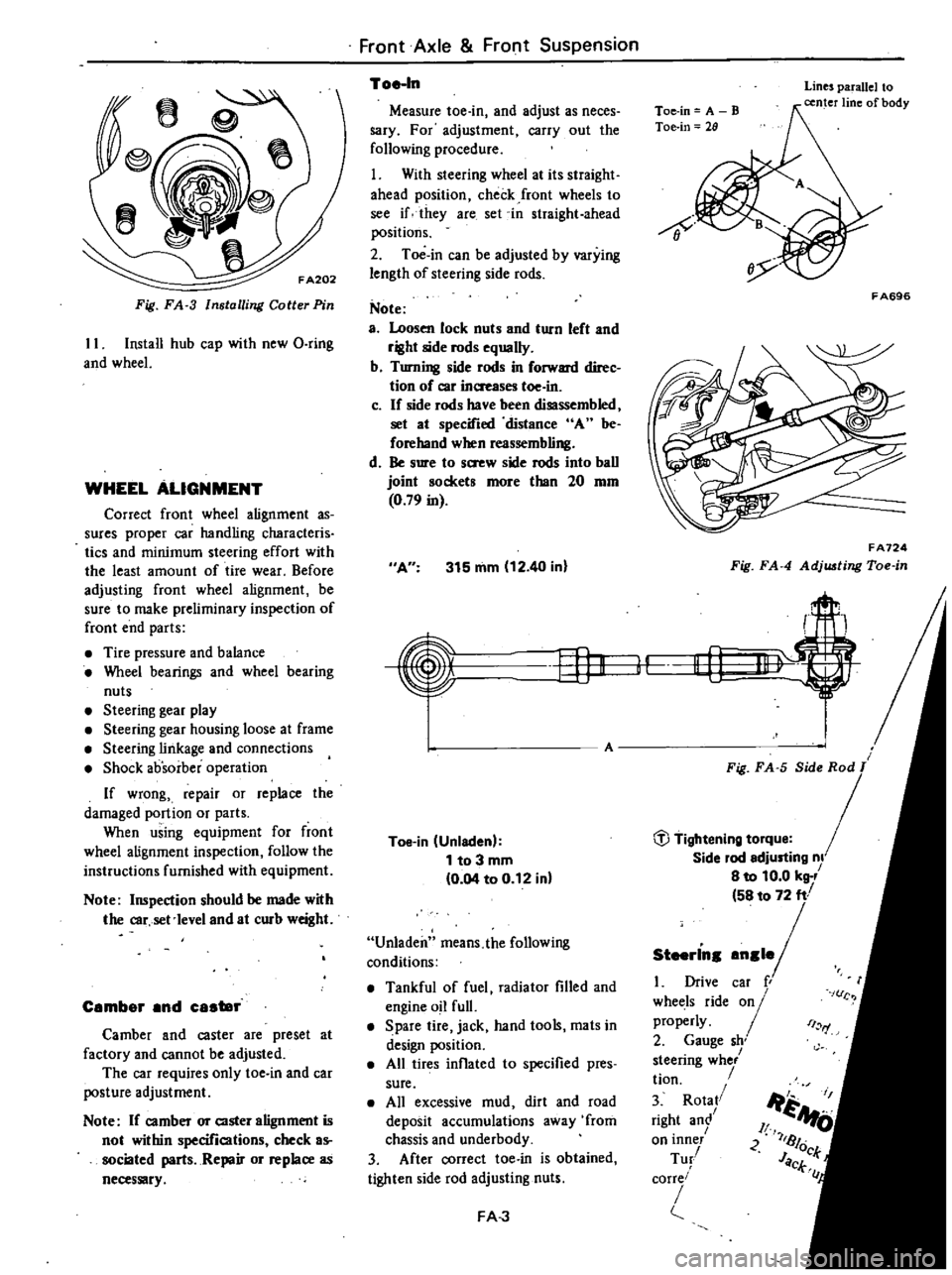

Toe

In

Measure

toe

in

and

adjust

as

neces

sary

For

adjustment

carry

out

the

following

procedure

1

With

steering

wheel

at

its

straight

ahead

position

check

front

wheels

to

see

if

they

are

set

in

straight

ahead

positions

2

Toe

in

can

be

adjusted

by

varying

length

of

steering

side

rods

Note

a

Loosen

lock

nuts

and

turn

left

and

right

side

rods

equally

b

Turning

side

rods

in

forward

direc

tion

of

car

inaeases

toe

in

c

If

side

rods

have

been

disassembled

set

at

specified

distance

A

be

forehand

when

reassembling

d

Be

sure

to

s

w

side

rods

into

ball

joint

sockets

more

than

20

mm

0

79

in

A

315

mm

12

40

in

EfJK

Toe

in

Unladen

1

to

3

mm

0

04

to

0

12

in

Unladen

means

the

following

conditions

Tankful

of

fuel

radiator

filled

and

engine

oil

full

Spare

tire

jack

hand

tools

mats

in

design

position

All

tires

inflated

to

specified

pres

sure

All

excessive

mud

dirt

and

road

deposit

accumulations

away

from

chassis

and

underbody

3

After

correct

toe

in

is

obtained

tighten

side

rod

adjusting

nuts

FA

J

Toe

in

A

B

Toe

in

28

Lines

parallel

to

center

line

of

body

8

F

A696

FA724

Fig

FA

4

Adj

ting

Toe

in

r

II

Li

1

t

Fig

FA

5

Side

Rod

T

Side

lod

edjusting

nl

8

to

10

0

kg

58

to

72

ft

1

Drive

caf

r

whet

ls

ride

01

properly

2

Gauge

sh

steenng

whe

tion

3

Rota

right

an

on

lOner

Tu

corre

i

I

rf

c

Ji

1

A

JI

U

2

7181

JOck

CL

C

Page 459 of 548

Body

Electrical

System

DISASsEMlU

Y

AND

ASSEI

t18LV

BE126D

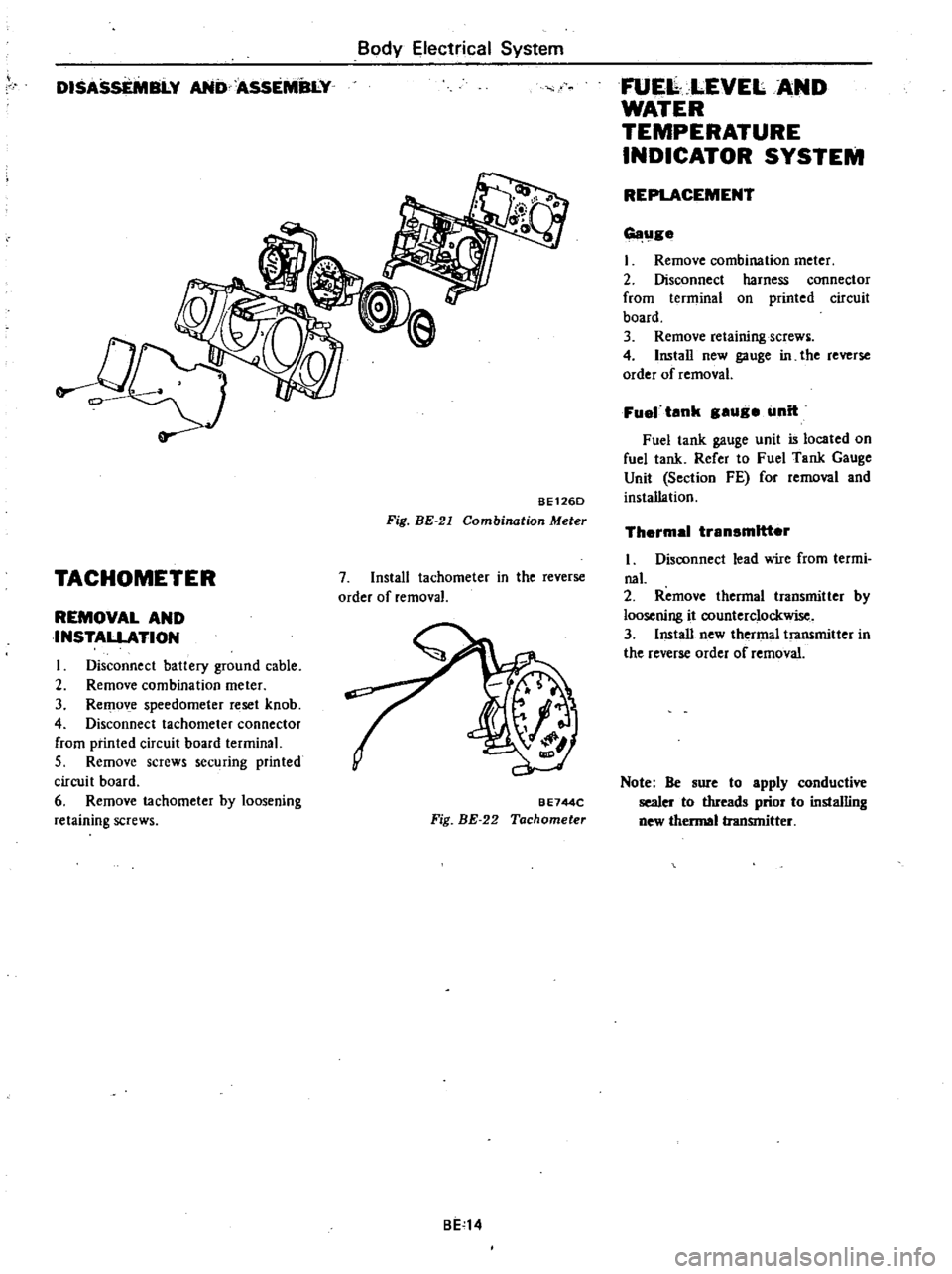

Fig

BE

21

Combination

Meter

TACHOMETER

7

Install

tachometer

in

the

reverse

order

of

removal

REMOVAL

AND

INSTALLATION

I

Disconnect

battery

ground

cable

2

Remove

combination

meter

3

RemO

e

speedometer

reset

knob

4

Disconnect

tachometer

connector

from

printed

circuit

board

terminal

5

Remove

screws

securing

printed

circui

t

board

6

Remove

tachometer

by

loosening

retaining

screws

BE744C

Fig

BE

22

Tachometer

BE

14

FUE

LEVELAND

WATER

TEMPERATURE

INDICATOR

SYSTEM

REPLACEMENT

G11l1ge

I

Remove

combination

meter

2

Disconnect

harness

connector

from

terminal

on

printed

circuit

board

3

Remove

retaining

screws

4

Install

new

gauge

in

the

reverse

order

of

removal

Fuel

tank

gauge

unit

Fuel

tank

gauge

unit

is

located

on

fuel

tank

Refer

to

Fuel

Tank

Gauge

Unit

Section

FE

for

removal

and

installation

Thermal

transmitter

I

Disconnect

lead

wire

from

termi

naL

2

Remove

thermal

transmitter

by

loosening

it

oountercIockwise

3

Install

new

thermal

transmitter

in

the

reverse

order

of

removal

Note

Be

aure

to

apply

conductive

sealer

to

threads

prior

to

installing

new

hennal

transmitter