window DATSUN 210 1979 Service Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 99 of 548

DASH

POT

SYSTEM

These

carburetors

are

equipped

with

a

dash

pot

interlocked

with

the

primary

thrott

Ie

valve

through

a

link

mechanism

The

dash

pot

prevents

the

throttle

valve

from

closing

abruptly

thereby

reducing

He

emissions

during

deceleia

tion

or

gear

shifting

In

automatic

transmissi9fi

models

it

also

prevents

engine

stall

resulting

from

quick

application

of

the

brake

or

from

quick

release

of

the

accelerator

pedal

after

it

s

been

tread

upon

slightly

INSPECTION

AND

ADJUSTMENT

CARBURETOR

IDLE

R

P

M

AND

MIXTURE

RATIO

CO

idle

adjustment

with

CO

meter

Refer

to

Carburetor

Idle

rpm

and

Mixture

Ratio

Section

ET

for

check

ing

and

a

justment

CO

idle

adjustment

without

CO

meter

Non

California

models

Refer

to

Carburetor

Idle

rpm

and

Mixture

Ratio

Section

ETl

fot

check

ing

and

adjustment

Idle

limiter

cap

Refer

to

Idle

Limiter

Cap

SeCtio

ET

for

checking

and

adjustment

FUEL

LEVEL

I

With

engine

idling

visually

check

fuel

level

through

sight

window

of

float

chamber

Fuel

level

is

correct

if

it

is

at

the

indicator

point

Note

Fuel

level

indicator

point

is

located

IS

mm

0

59

in

below

top

of

carburetor

body

H

as

shown

in

Figure

below

Engine

Fuel

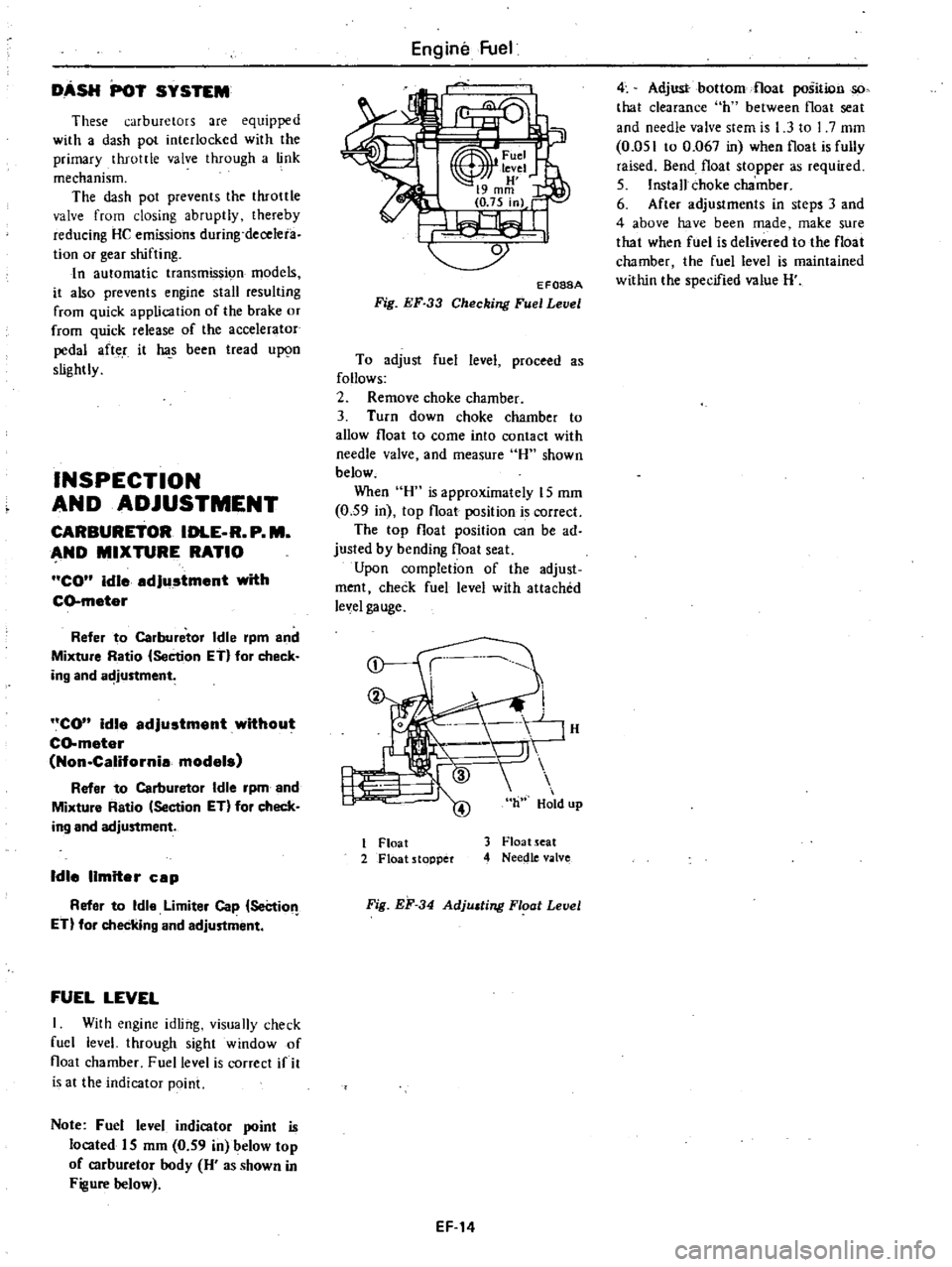

EF088A

Fig

EF

33

Checking

Fuel

Level

To

adjust

fuel

level

proceed

as

follows

2

Remove

choke

chamber

3

Turn

down

choke

chamber

to

allow

float

to

come

into

contact

with

needle

valve

and

measure

H

shown

below

When

H

is

approximately

15

mm

0

59

in

top

float

position

is

correct

The

top

float

position

can

be

ad

justed

by

bending

float

seat

Upon

completion

of

the

adjust

ment

check

fuel

level

with

attached

level

gauge

nhH

J

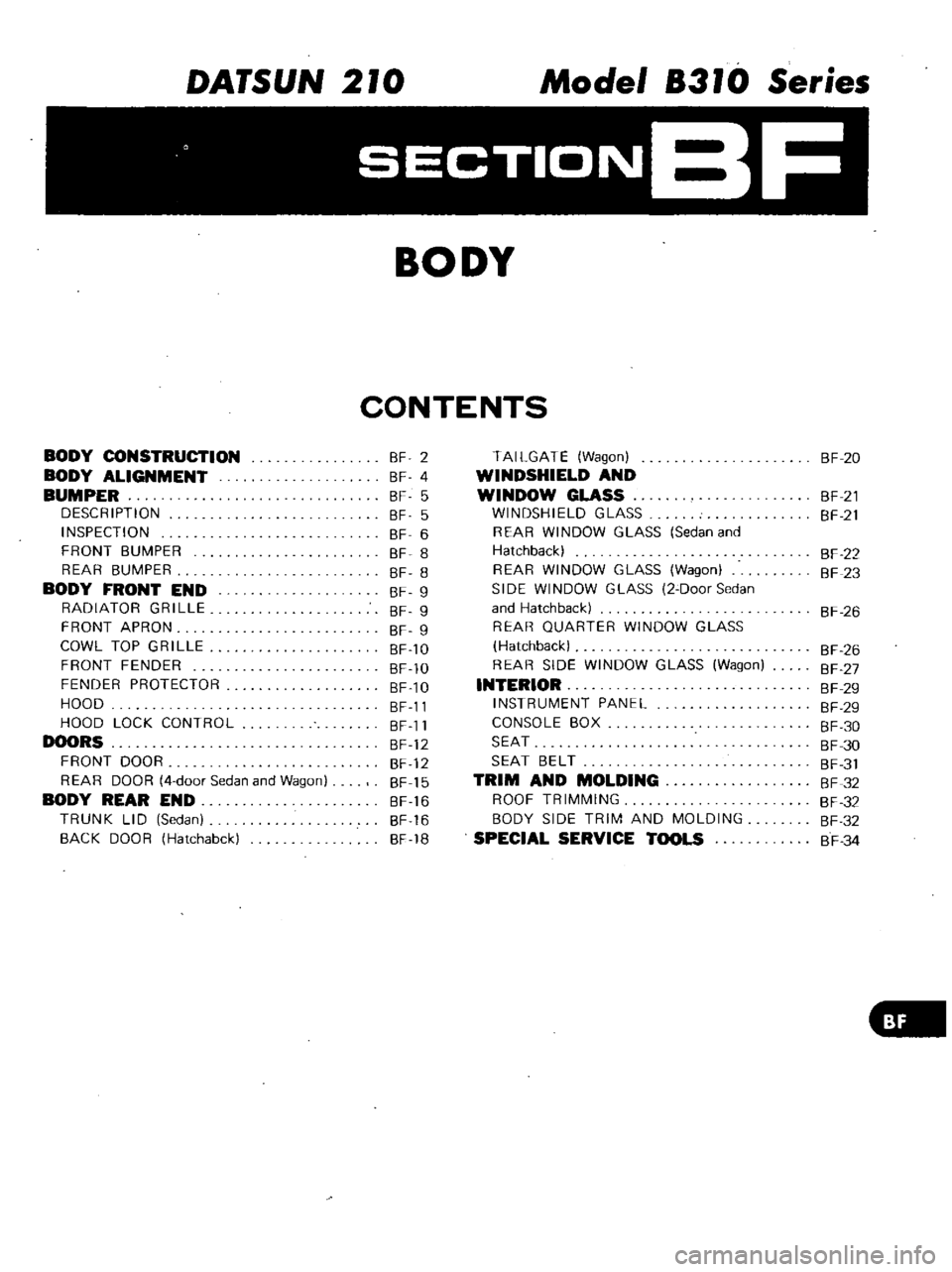

1

Float

2

Float

stopper

3

Float

seat

4

Needle

valve

Fig

EF

34

Adjusting

Floot

Level

EF

14

4

Adjust

bottom

float

position

so

that

clearance

hl

between

float

seat

and

needle

valve

stem

is

1

3

to

I

7

mm

0

051

to

0

067

in

when

float

is

fully

raised

Bend

float

stopper

as

required

5

Install

choke

chamber

6

After

adjustments

in

steps

3

and

4

above

have

been

made

make

sure

that

when

fuel

is

delivered

to

the

float

chamber

the

fuel

level

is

maintained

within

the

specified

value

H

Page 412 of 548

DATSUN

210

Model

8310

Series

F

BODY

CONSTRUCTION

BODY

ALIGNMENT

BUMPER

DESCRIPTION

INSPECTION

FRONT

BUMPER

REAR

BUMPER

BODY

FRONT

END

RADIATOR

GRILLE

FRONT

APRON

COWL

TOP

GRILLE

FRONT

FENDER

FENDER

PROTECTOR

HOOD

HOOD

LOCK

CONTROL

DOORS

FRONT

DOOR

REAR

DOOR

4

door

Sedan

and

Wagon

BODY

REAR

END

TRUNK

LID

Sedan

SAC

K

000

R

Hatchabck

BODY

CONTENTS

BF

2

BF

4

BF

5

BF

5

BF

6

BF

8

SF

8

BF

9

BF

9

BF

9

BF

10

BF

10

BF

10

BF

11

BF

11

BF

12

BF

12

BF

15

BF

16

BF

16

BF

18

TAILGATE

Wagon

WINDSHIELD

AND

WINDOW

GLASS

WINDSHIELD

GLASS

REAR

WINDOW

GLASS

Sedan

and

Hatchback

REAR

WINDOW

GLASS

Wagon

SIDE

WINDOW

GLASS

2

Door

Sedan

and

Hatchback

REAR

QUARTER

WINDOW

GLASS

Hatchback

REAR

SIDE

WINDOW

GLASS

Wagon

INTERIOR

INSTRUMENT

PANEL

CONSOLE

BOX

SEAT

SEAT

BELT

TRIM

AND

MOLDING

ROOF

TRIMMING

BODY

SIDE

TRIM

AND

MOLDING

SPECIAL

SERVICE

TOOLS

BF

20

8F

21

SF

21

BF

22

SF

23

BF

26

BF

26

BF

27

SF

29

BF

29

SF

30

BF

30

BF

31

SF

32

BF

32

BF

32

BF

34

Page 424 of 548

FRONT

DOOR

ASSEMBLY

Adjustment

Proper

door

alignment

can

be

ob

tained

by

adjusting

door

hinge

and

door

lock

striker

Front

door

hinge

can

be

adjusted

without

removing

front

fender

Door

hinge

can

be

moved

up

and

down

and

fore

and

aft

in

enlarged

holes

by

loosening

attaching

bolts

Striker

can

be

moved

up

and

down

and

from

side

to

side

in

enlarged

holes

by

loosening

attaching

bolts

Door

should

be

adjusted

for

an

even

and

parallel

fit

with

the

door

opening

and

surrounding

body

panels

Be

careful

not

to

distort

or

mar

door

and

surrounding

body

panels

when

adjusting

II

I

J

BF163A

Fig

BF

20

Adjusting

Door

Lock

Striker

Removal

and

installation

I

Open

door

fully

and

support

it

with

a

stand

or

jack

Note

Place

a

rag

between

door

and

stand

or

jack

to

protect

door

panel

from

being

sCaRed

2

Remove

door

to

hinge

attaching

bolts

and

remove

door

from

hinges

BF529B

Fig

BF

21

Removing

Front

Door

3

Installation

is

in

the

reverse

order

of

removal

Body

Note

Apply

grease

to

sliding

surfaces

of

levers

and

springs

FRONT

DOOR

GLASS

AND

REGULATOR

Adjustment

Door

window

glass

alignment

can

be

performed

by

adjusting

guide

chan

nel

A

guide

channel

B

I

Partially

tighten

guide

channel

A

and

guide

channel

B

attaching

screws

2

With

glass

in

down

position

move

guide

channel

A

from

side

to

side

and

move

guide

channel

B

up

and

down

to

obtain

proper

alignment

of

window

glass

to

door

sash

glass

3

Cycle

window

glass

up

and

down

to

assure

a

good

window

fit

4

After

proper

glass

alignment

is

obtained

tighten

guide

channel

A

and

guide

channel

B

attaching

bolts

I

I

b

G

O

J

V

moC

BF541B

Fig

BF

22

Adjusting

Guide

Channel

Removal

and

installation

I

Remove

reguiator

handle

by

pry

ing

out

set

pin

Fig

BF

23

shows

set

pin

assembled

to

regulator

handle

and

regulator

handle

to

regulator

with

door

glass

raised

fully

Front

600

Set

pin

Pring

BF285B

Fig

BF

23

Regulator

Handle

and

Set

Pin

BF

13

2

Remove

arm

rest

door

inside

handle

escutcheon

and

door

lock

3

Remove

door

finisher

and

sealing

screen

4

Remove

door

outer

molding

Except

Hatchback

fT

BF530B

Fig

BF

24

Removing

Door

Outer

Molding

5

Lower

door

glass

with

regulator

handle

until

regulator

to

glass

attach

ing

bolts

appear

at

access

holes

in

door

inside

panel

6

Supporting

door

glass

by

hand

remove

regulator

to

glass

attaching

bolts

b

a8

BF531B

Fig

BF

25

Removing

Bolt

Attaching

Glass

7

Raise

door

glass

and

draw

it

upwards

9

o

BF532B

Fig

BF

26

Removing

Door

Gla

8

Page 432 of 548

Body

WINDSHIELD

AND

WINDOW

GLASS

WINDSHIELD

GLASS

00

REMOVAL

I

Place

a

protective

cover

over

hood

front

fenders

instrument

panel

and

front

seats

2

Remove

windshield

wiper

arm

as

semblies

3

Remove

windshield

moldings

4

On

inside

of

body

loosen

lip

of

weatherstrip

from

body

flange

along

top

and

sides

of

windshield

opening

Use

a

conventional

screwdriver

and

carefully

put

weatherstrip

over

body

flange

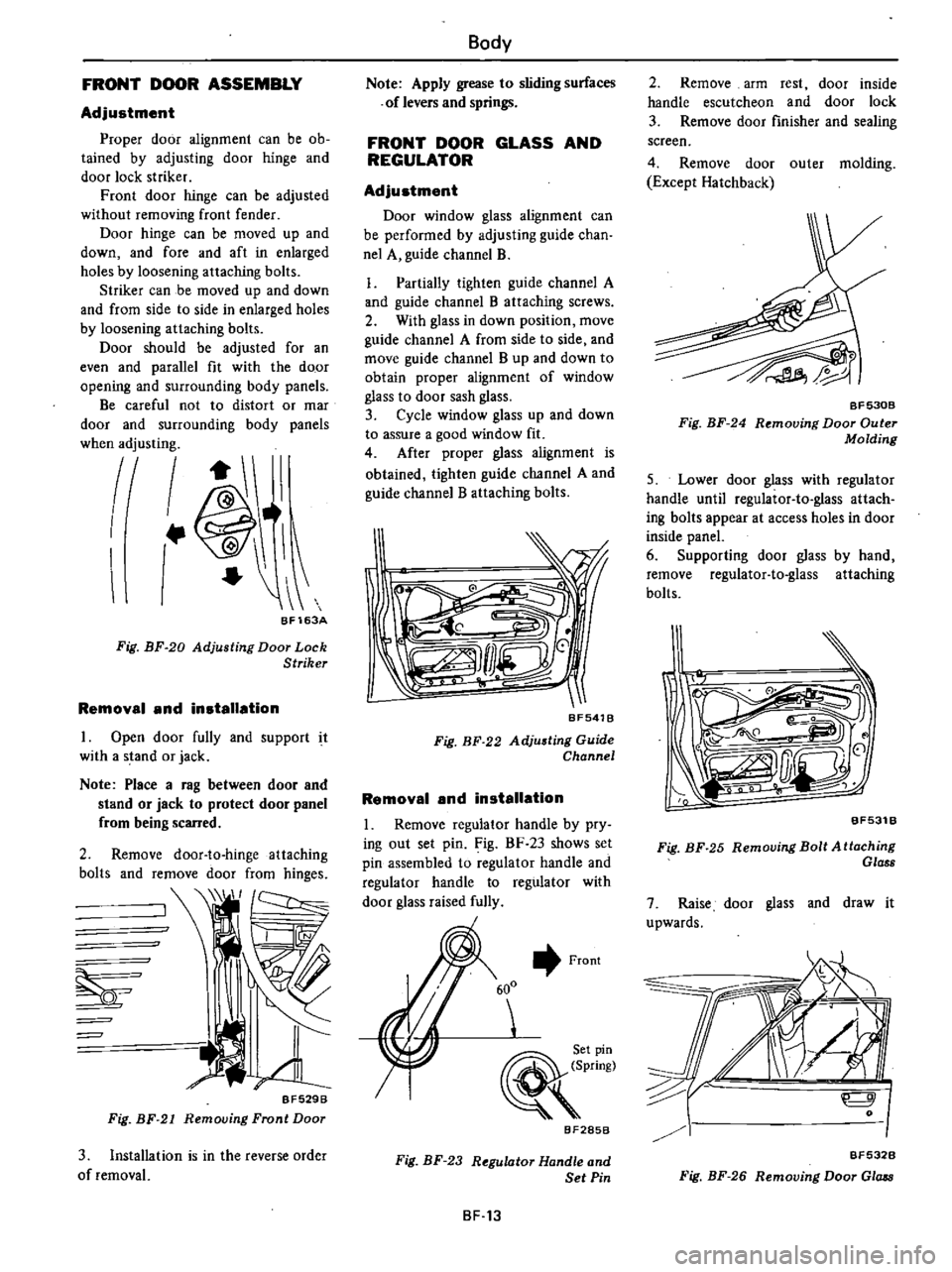

BF5618

Fig

BF

54

Removing

Wind

hield

D

1

Front

windshield

weatherstrip

2

Windshield

glass

3

Windshield

molding

set

4

Roof

panel

5

Roof

headlining

BF5608

Fig

BF

53

Winct

hield

Ol

5

After

windshield

weatherstrip

is

free

from

body

flange

with

aid

of

helper

carefully

lift

windshield

from

opening

Attach

two

Suckers

ST08800000

to

glass

surface

beforehand

to

facili

tate

lifting

out

windshield

glass

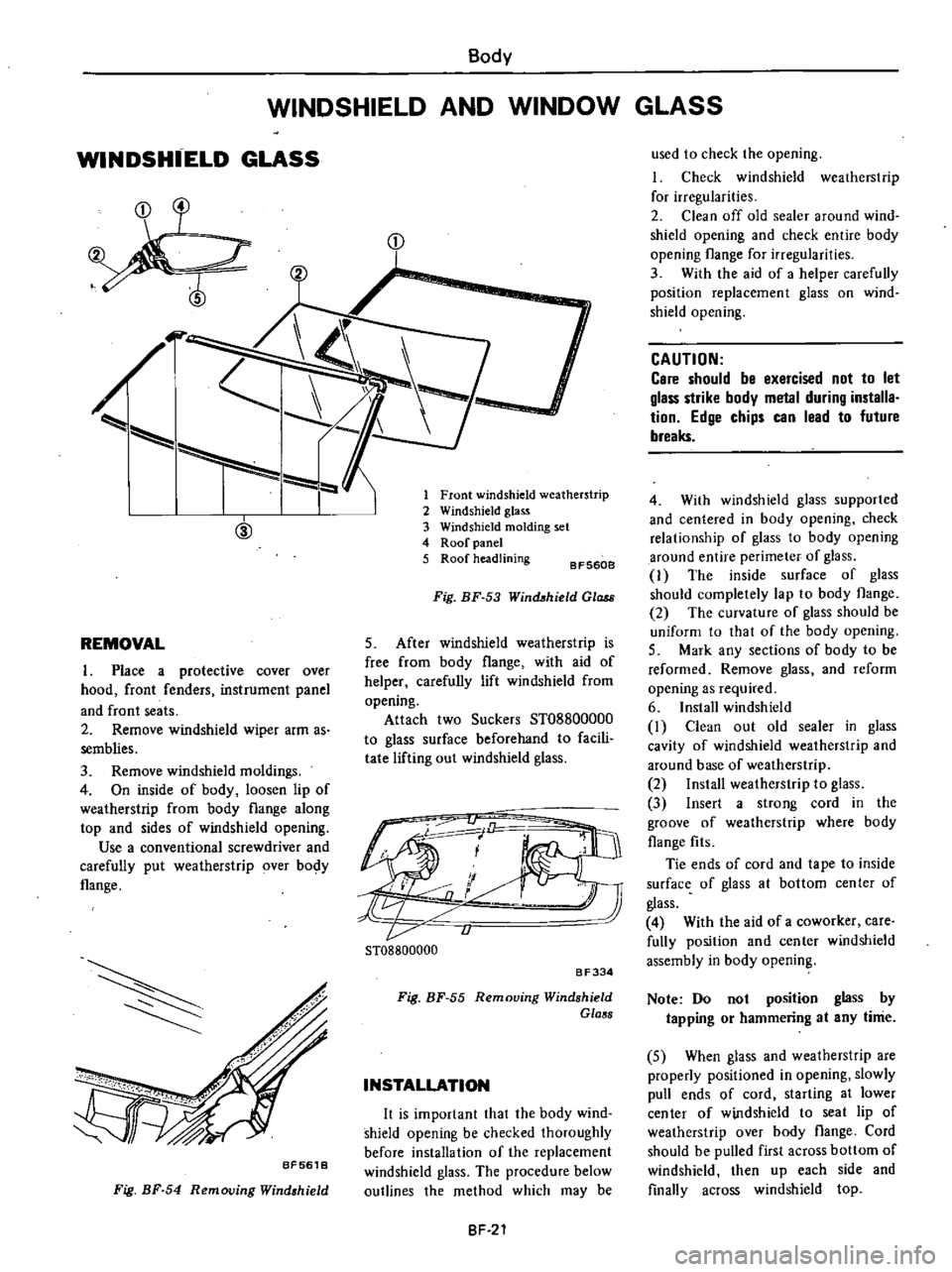

Li

ST08800000

BF334

Fig

BF

55

Removing

Windshield

Glass

INSTALLATION

It

is

important

that

the

body

wind

shield

opening

be

checked

thoroughly

before

installation

of

the

replacement

windshield

glass

The

procedure

below

outlines

the

method

which

may

be

BF

21

used

to

check

the

opening

I

Check

windshield

weatherstrip

for

irregularities

2

Clean

off

old

sealer

around

wind

shield

opening

and

check

entire

body

opening

flange

for

irregularities

3

With

the

aid

of

a

helper

carefully

position

replacement

glass

on

wind

shield

opening

CAUTION

Care

should

be

exercised

not

to

let

glass

strike

body

metal

during

installa

tion

Edge

chips

can

lead

to

future

breaks

4

With

windshield

glass

supported

and

centered

in

body

opening

check

relationship

of

glass

to

body

opening

around

entire

perimeter

of

glass

I

The

inside

surface

of

glass

should

completely

lap

to

body

flange

2

The

curvature

of

glass

should

be

uniform

to

that

of

the

body

opening

5

Mark

any

sections

of

body

to

be

reformed

Remove

glass

and

reform

opening

as

required

6

Install

windshield

I

Clean

out

old

sealer

in

glass

cavity

of

windshield

weatherstrip

and

around

base

of

weatherstrip

2

Install

weatherstrip

to

glass

3

Insert

a

strong

cord

in

the

groove

of

weatherstrip

where

body

flange

fits

Tie

ends

of

cord

and

tape

to

inside

surface

of

glass

at

bottom

center

of

glass

4

With

the

aid

of

a

coworker

care

fully

position

and

center

windshield

assembly

in

body

opening

Note

Do

not

position

glass

by

tapping

or

hammering

at

any

time

5

When

glass

and

weatherstrip

are

properly

positioned

in

opening

slowly

pull

ends

of

cord

starting

at

lower

center

of

windshield

to

seat

lip

of

weatherstrip

over

body

flange

Cord

should

be

pulled

first

across

bottom

of

windshield

then

up

each

side

and

finally

across

windshield

top

Page 433 of 548

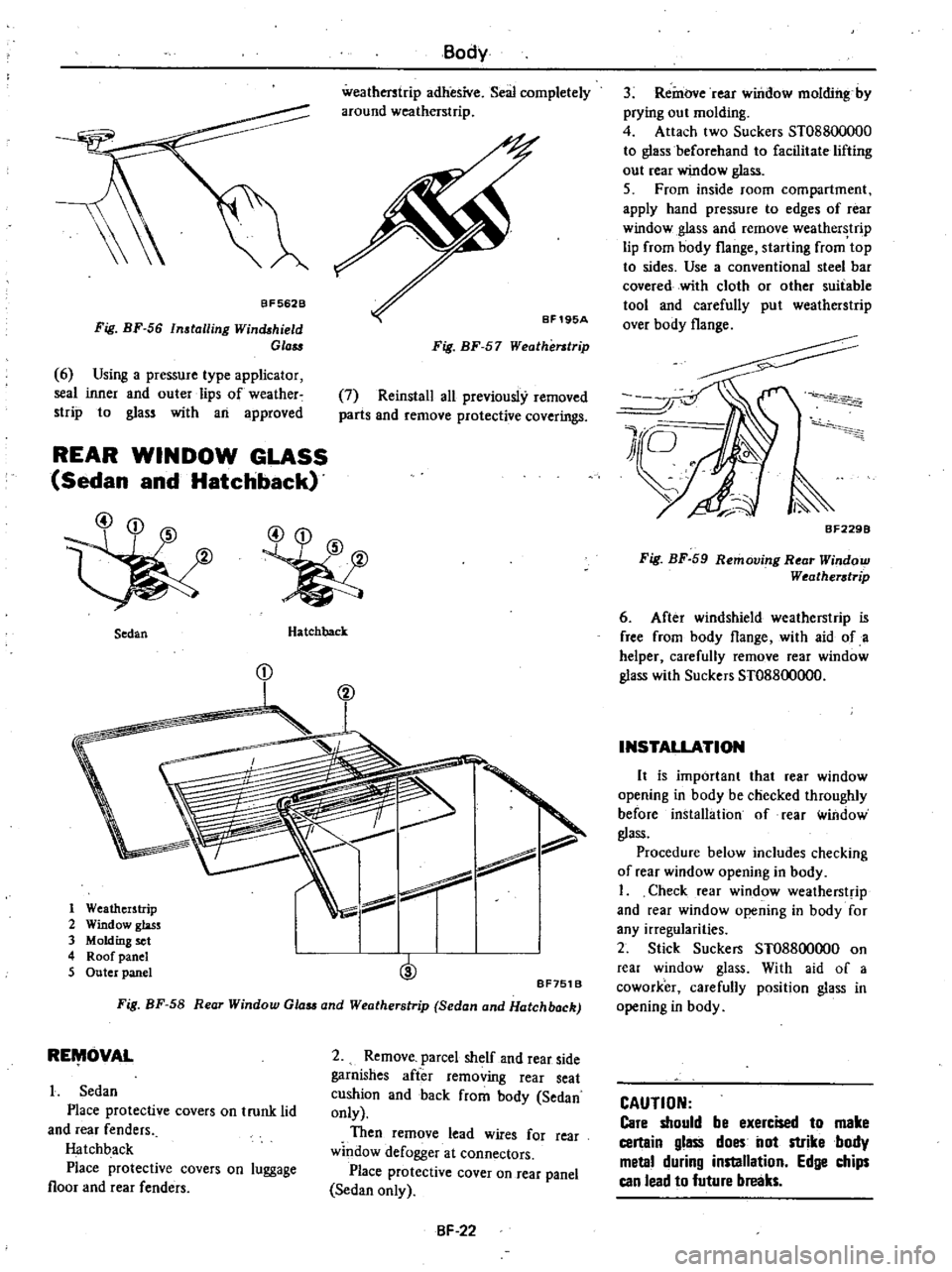

BF562B

Fig

BF

56

Installing

Winchhield

Gla

6

Using

a

pressure

type

applicator

seal

inner

and

outer

lips

of

weather

strip

to

glass

with

an

approved

REAR

WINDOW

GLASS

Sedan

and

Hatchback

Body

weatherstrip

adhesive

Seal

completely

around

weatherstrip

Bf195A

Fig

BF

57

Weatherstrip

7

Reinstall

all

previously

removed

parts

and

remove

protective

coverings

Sedan

Hatchback

1

Weatherstrip

2

Window

glass

3

Molding

set

4

Roof

panel

@

5

Outer

panel

BF751

B

Fig

BF

58

Rear

Window

Glau

and

Weatherstrip

Sedan

and

Hatchback

RE

OVAL

l

Sedan

Place

protective

covers

on

trunk

lid

and

rear

fenders

Hatchback

Place

protective

covers

on

luggage

floor

and

rear

fenders

2

Remove

parcel

shelf

and

rear

side

garnishes

after

removing

rear

seat

cushion

and

back

from

body

Sedan

only

Then

remove

lead

wires

for

rear

willdow

defogger

at

connectors

Place

protective

cover

on

rear

panel

Sedan

only

BF

22

3

Remove

rear

window

molding

by

prying

out

molding

4

Attach

two

Suckers

ST088oo000

to

glass

beforehand

to

facilitate

lifting

out

rear

window

glass

5

From

inside

room

compartment

apply

hand

pressure

to

edges

of

rear

window

glass

and

remove

weather

trip

lip

from

body

flange

starting

from

top

to

sides

Use

a

conventional

steel

bar

covered

with

cloth

or

other

suitable

tool

and

carefully

put

weatherstrip

over

body

flange

BF229B

Fig

BF

59

Removing

Rear

Window

Weatheratrip

6

After

windshield

weatherstrip

is

free

from

body

flange

with

aid

of

a

helper

carefully

remove

rear

window

glass

with

Suckers

ST08800000

INSTALLATION

It

is

important

that

rear

window

opening

in

body

be

checked

throughly

before

installation

of

rear

window

glass

Procedure

below

includes

checking

of

rear

window

opening

in

body

1

Check

rear

window

weatherstrip

and

rear

window

opening

in

body

for

any

irregularities

2

Stick

Suckers

ST08800000

on

rear

window

glass

With

aid

of

a

coworker

carefuUy

position

glass

in

opening

in

body

CAUTION

Care

should

be

exercised

to

make

certain

glass

does

not

strike

body

metal

during

installation

Edge

chips

can

lead

to

future

breaks

Page 434 of 548

Body

2

Insert

a

strong

cord

in

groove

of

weatherstrip

where

opening

flange

fits

Note

Insert

cord

so

that

its

ends

are

at

bottom

center

of

glass

from

lower

center

of

rear

window

glass

to

seal

lip

of

weatherstrip

on

opening

flange

Cord

should

be

pulled

first

across

bottom

of

glass

then

up

each

side

and

finally

across

top

5

Carefully

tap

around

rear

window

glass

to

assist

in

seating

weatherstrip

on

flange

Note

Never

tap

or

hammer

at

glass

to

position

3

With

rear

window

glass

supported

and

centered

in

opening

in

body

check

relationship

between

glass

and

9pening

around

entire

perimeter

of

glass

I

Entire

inside

surface

of

glass

should

be

in

contact

with

opening

2

Curvature

of

glass

should

con

form

to

that

of

opening

3

Mark

any

section

of

opening

to

be

refonned

Remove

glass

and

reform

opening

as

required

4

Install

rear

window

glass

as

follows

I

Install

rear

window

weatherstrip

to

glass

n

I

Ii

V

i

I

1

j

CD

I

CV

ID

1

Rear

window

glass

2

Cord

3

Weatherstrip

BF648

Fig

BF

61

In5talling

Cord

in

Weatherstrip

3

With

aid

of

a

coworker

carefully

position

and

center

rear

window

glass

in

opening

in

body

supporting

it

with

SuckerST08800000

4

When

glass

and

weatherstrip

are

properly

positioned

in

opening

slowly

pull

ends

of

cord

with

a

coworker

pushing

glass

from

outside

starting

Fig

BF

62

Installing

Rear

Window

Glass

5

Install

all

previously

removed

parts

8F647

Fig

BF

60

Installing

Weatherstrip

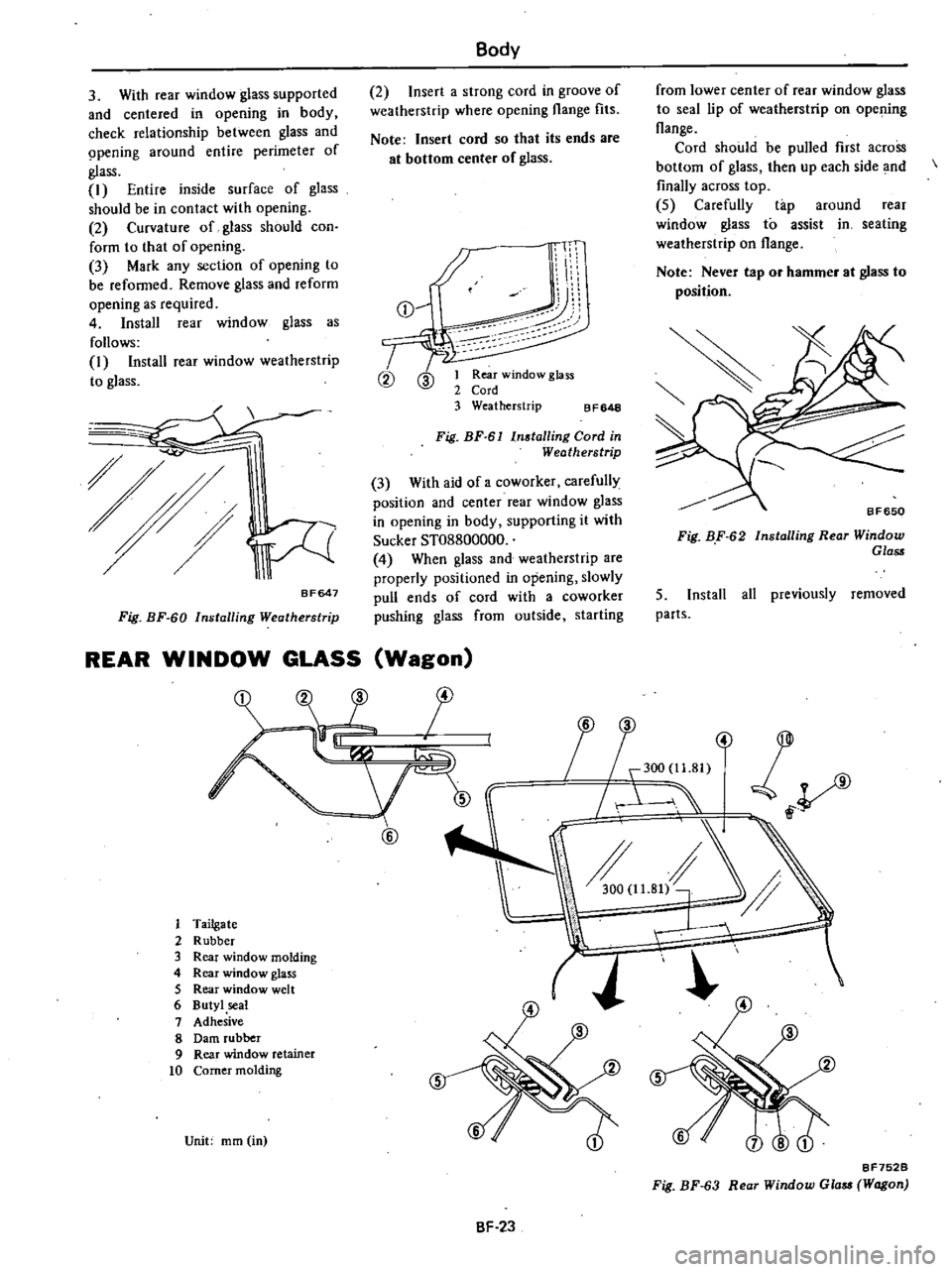

REAR

WINDOW

GLASS

Wagon

ll3

eOO

l1

81

fJ

1

2

wV

6pf

@

1

Tailgate

2

Rubber

3

Rear

window

molding

4

Rear

window

glass

5

Rear

window

welt

6

Butyl

seal

7

Adhesive

8

Dam

rubber

9

Rear

window

retainer

10

Corner

molding

Unit

mm

in

BF752B

Fig

BF

63

Rear

Window

Gla

Wagon

BF

23

Page 435 of 548

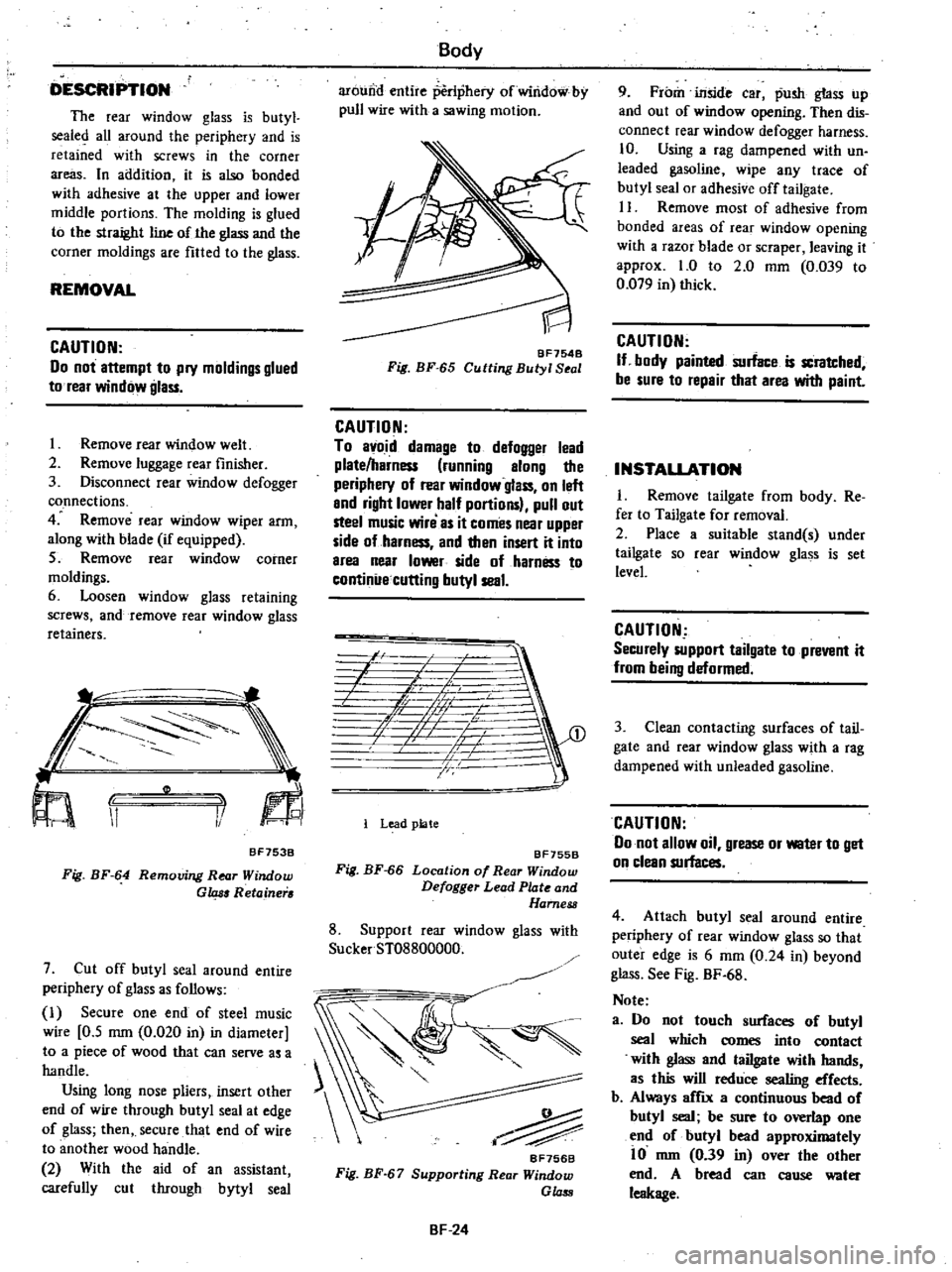

DESCRIPTION

The

rear

window

glass

is

butyl

sealed

aU

around

the

periphery

and

is

retained

with

screws

in

the

corner

areas

In

addition

it

is

also

bonded

with

adhesive

at

the

upper

and

lower

middle

portions

The

molding

is

glued

to

the

straight

line

of

the

glass

and

the

corner

moldings

are

fitted

to

the

glass

REMOVAL

CAUTION

00

not

attempt

to

pry

moldings

glued

to

rear

window

glass

1

Remove

rear

window

welt

2

Remove

luggage

rear

finisher

3

Disconnect

rear

window

defogger

connections

4

Remove

rear

window

wiper

arm

along

with

blade

if

equipped

5

Remove

rear

window

comer

moldings

6

Loosen

window

glass

retaining

screws

and

remove

rear

window

glass

retainers

II

1

BF753B

Fig

BF

64

Removing

RNr

Window

G

Retainer

7

Cut

off

butyl

seal

around

entire

periphery

of

glass

as

follows

I

Secure

one

end

of

steel

music

wire

0

5

mm

0

020

in

in

diameter

to

a

piece

of

wood

that

can

serve

as

a

handle

Using

long

nose

pliers

insert

other

end

of

wire

through

butyl

seal

at

edge

of

glass

then

secure

that

end

of

wire

to

another

wood

handle

2

With

the

aid

of

an

assistant

carefully

cut

through

bytyl

seal

Body

arDUna

entire

periphery

ofwirid6

by

pull

wire

with

a

sawing

motion

BF754B

Fig

BF

65

Cutting

Butyl

S

I

CAUTION

To

avoid

damage

to

defogger

lead

plate

harness

running

along

the

periphery

of

rear

window

glass

on

left

and

right

lower

half

portions

pull

out

steel

music

willi

as

it

comes

near

upper

side

of

harness

and

then

insert

it

into

area

near

lower

side

of

harness

to

continue

cutting

butyl

seal

71

A

L

0

fr

f

1

Lead

plate

BF755B

Fig

BF

66

Location

of

Rear

Window

Defogger

Lead

Plate

and

Harness

8

Support

rear

window

glass

with

SuckerST08800000

BF756B

Fig

BF

67

Supporting

Rear

Window

GLus

BF

24

9

From

inside

car

push

glass

up

and

out

of

window

opening

Then

dis

connect

rear

window

defogger

harness

10

Using

a

rag

dampened

with

un

leaded

gasoline

wipe

any

trace

of

butyl

seal

or

adhesive

off

tailgate

II

Remove

most

of

adhesive

from

bonded

areas

of

rear

window

opening

with

a

razor

blade

or

scraper

leaving

it

approx

1

0

to

2

0

mm

0

039

to

0

079

in

thick

CAUTION

If

body

painted

surtin

e

is

scratched

be

sure

to

repair

that

area

with

paint

INSTALLATION

I

Remove

tailgate

from

body

Re

fer

to

Tailgate

for

removal

2

Place

a

suitable

stand

s

under

tailgate

so

rear

window

gla

s

is

set

level

CAUTION

Securely

support

tailgate

to

prevent

it

from

being

deformed

3

Clean

contacting

surfaces

of

tail

gate

and

rear

window

glass

with

a

rag

dampened

with

unleaded

gasoline

CAUTION

00

not

allow

oil

grease

or

water

to

get

on

clean

surfaces

4

Attach

butyl

seal

around

entire

periphery

of

rear

window

glass

so

that

outer

edge

is

6

mm

0

24

in

beyond

glass

See

Fig

BF

68

Note

a

Do

not

touch

surfaces

of

butyl

seal

which

comes

into

contact

with

glass

and

tailgate

with

hands

as

this

will

reduce

sealing

effects

b

Always

amx

a

continuous

bead

of

butyl

seal

be

sure

to

overlap

one

end

of

butyl

bead

approximately

i

0

mm

0

39

in

over

the

other

end

A

bread

can

cause

water

leakage

Page 436 of 548

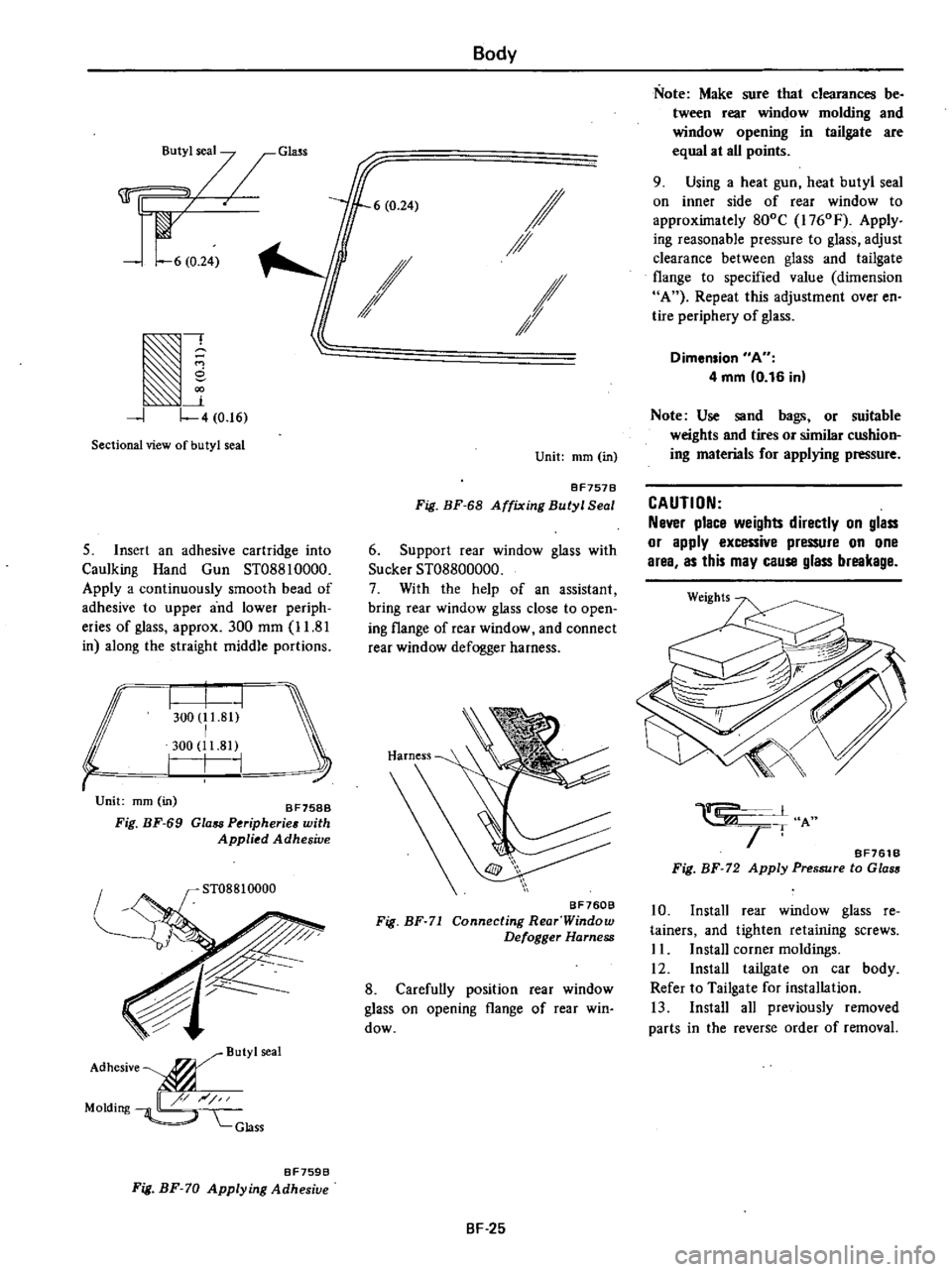

r

t

s7

Glm

I

6

0

24

k

IJ

4

0

16

Sectional

view

of

butyl

seal

5

Insert

an

adhesive

cartridge

into

Caulking

Hand

Gun

ST08810000

Apply

a

continuously

smooth

bead

of

adhesive

to

upper

and

lower

periph

eries

of

glass

approx

300

mm

11

81

in

along

the

straight

middle

portions

r

300

1

S

300

11

81

I

I

Unit

mm

in

Fig

BF

69

aF7SaB

Glass

Puipherie

with

Applied

Adhesive

ST08810000

ButYlseal

Adhesive

P

Molding

GlaSS

BF759B

Fig

BF

70

Applying

Adhesiue

Body

6

0

24

If

I

Unit

mm

in

BF7578

Fig

BF

68

Affixing

Butyl

Seal

6

Support

rear

window

glass

with

SuckerST08800000

7

With

the

help

of

an

assistant

bring

rear

window

glass

close

to

open

iog

flange

of

rear

window

and

connect

rear

window

defogger

harness

BF760B

Fig

BF

71

Connecting

Rear

Window

Defogger

Harness

8

Carefully

position

rear

window

glass

on

opening

flange

of

rear

win

dow

BF

25

Note

Make

sure

that

clearances

be

tween

rear

window

molding

and

window

opening

in

tailgate

are

equal

at

all

points

9

Using

a

heat

gun

heat

butyl

seal

on

inner

side

of

rear

window

to

approxilnately

800C

l760F

Apply

ing

reasonable

pressure

to

glass

adjust

clearance

between

glass

and

tailgate

flange

to

specified

value

dimension

A

Repeat

this

adjustment

over

en

tire

periphery

of

glass

Dimension

A

4

mm

0

16

in

Note

Use

sand

bags

or

suitable

weights

and

tires

or

similar

cushion

ing

materials

for

applying

pressure

CAUTION

Never

place

weights

directly

on

glass

or

apply

excessive

pressure

on

one

area

as

this

may

cause

glass

breakage

1

I

I

A

1T

BF761B

Fig

BF

72

Apply

Pressure

to

Glass

10

Install

rear

window

glass

re

tainers

and

tighten

retaining

screws

II

Install

corner

moldings

12

Install

tailgate

on

car

body

Refer

to

Tailgate

for

installation

13

Install

all

previously

removed

parts

in

the

reverse

order

of

removal

Page 437 of 548

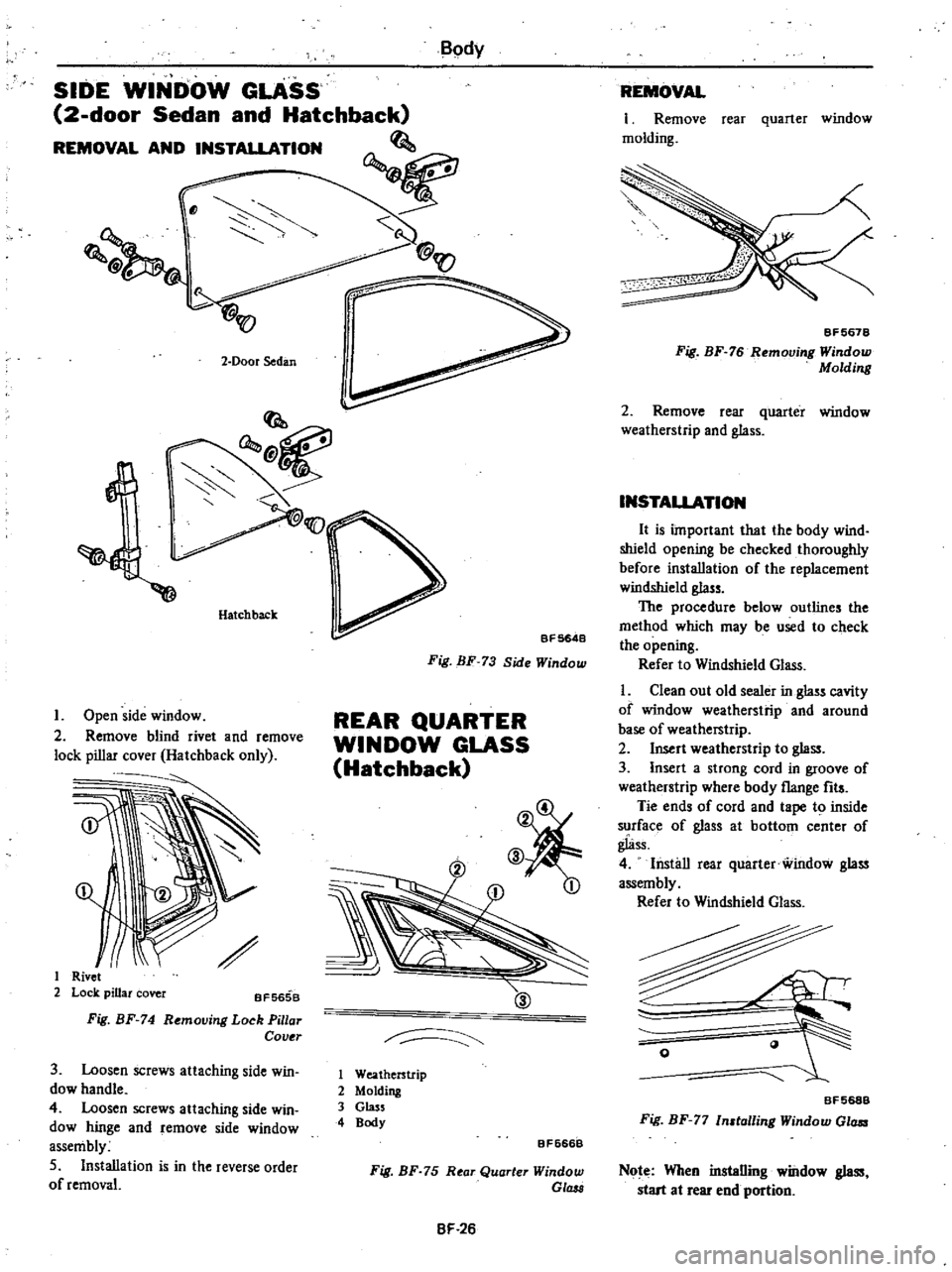

B

dy

SIDE

WINIJOW

GLASS

2

door

Sedan

and

Hatchback

REMOVAL

AND

INSTALLATION

@V

2

Door

Sedan

l

Hatchback

I

Open

side

window

2

Remove

blind

rivet

and

remove

lock

pillar

cover

Hatchback

only

1

Rivet

2

Lock

piUar

cover

BF5658

Fig

BF

74

Removing

Lock

Pillar

Caller

3

Loosen

screws

attaching

side

win

dow

handle

4

Loosen

screws

attaching

side

win

dow

hinge

and

remove

side

window

assembly

5

Installation

is

in

the

reverse

order

of

removal

SF

5648

Fig

BF

73

Side

Window

REAR

QUARTER

WINDOW

GLASS

Hatchback

@

ID

1

Weatherstrip

2

Molding

3

Glass

4

Body

BF666B

Fig

BF

75

Rear

Quarter

Window

GI

BF

26

REMOVAL

I

Remove

rear

quarter

window

molding

BF5678

Fig

BF

76

Removing

Window

Molding

2

Remove

rear

quarter

window

weatherstrip

and

glass

INSTAUATION

It

is

ilnportant

that

the

body

wind

shield

opening

be

checked

thoroughly

before

installation

of

the

replacement

windshield

glass

The

procedure

below

outlines

the

method

which

may

be

used

to

check

the

opening

Refer

to

Windshield

Glass

I

Clean

out

old

sealer

in

glass

cavity

of

window

weatherstrip

and

around

base

of

weatherstrip

2

Insert

weatherstrip

to

glass

3

Insert

a

strong

cord

in

groove

of

weatherstrip

where

body

flange

fits

Tie

ends

of

cord

and

tape

to

inside

surface

of

glass

at

bottom

center

of

gliss

4

Install

rear

quarter

window

glass

assembly

Refer

to

Windshield

Glass

A

r

BF568B

Fig

BF

77

In

talling

Window

GltlII

Note

When

installing

window

glass

start

at

rear

end

portion

Page 438 of 548

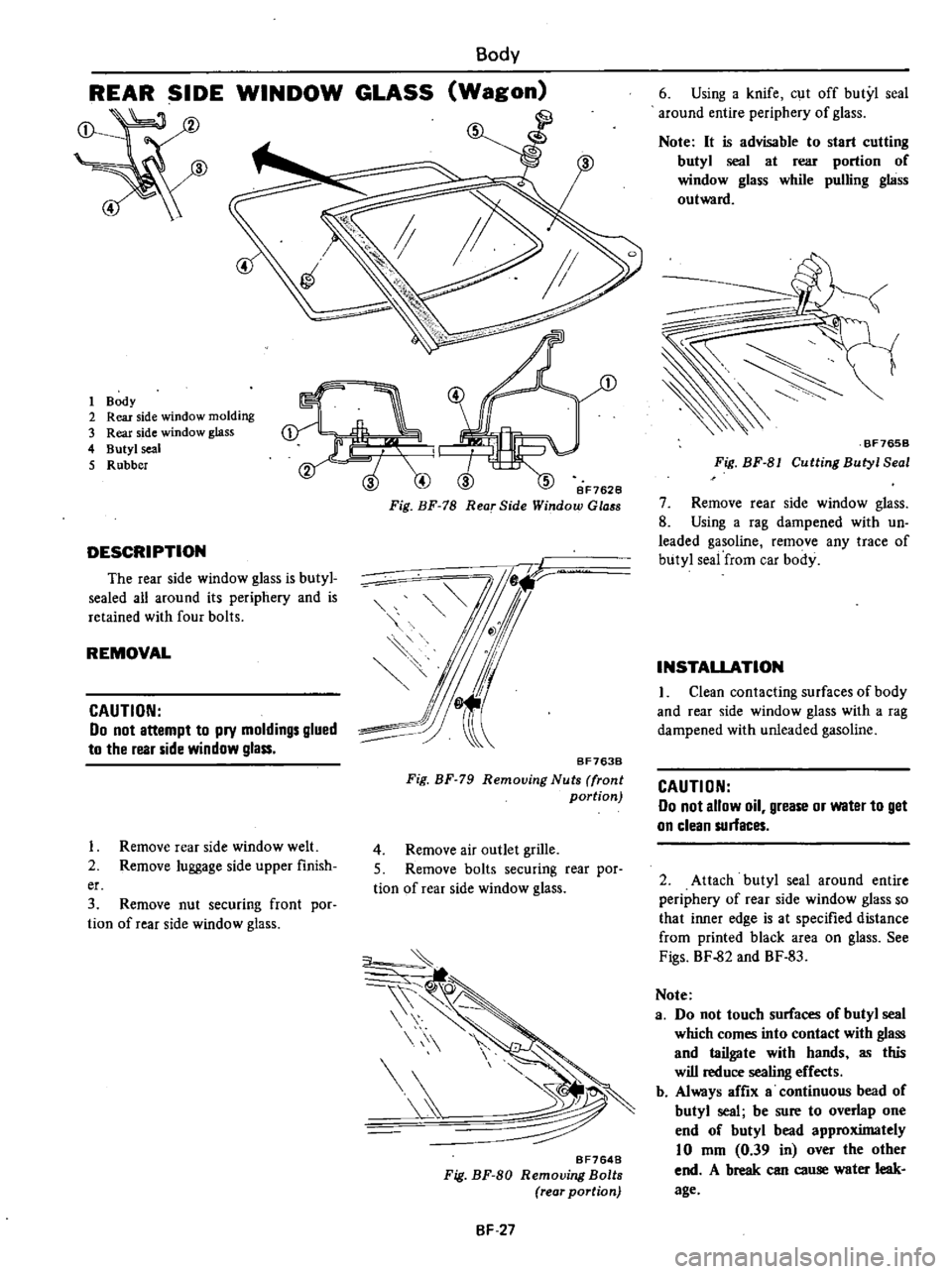

Body

REAR

SIDE

WINDOW

GLASS

Wagon

4

1

Body

2

Rear

side

window

molding

3

Rear

side

window

glass

4

Butyl

seal

5

Rubber

Bf7628

Fig

BF

78

Rear

Side

Window

Glo

8

DESCRIPTION

The

rear

side

window

glass

is

butyl

sealed

all

around

its

periphery

and

is

retained

with

four

bolts

REMOVAL

CAUTION

Do

not

attempt

to

pry

moldings

glued

to

the

rear

side

window

glass

BF763B

Fig

BF

79

Removing

Nuts

front

portion

1

Remove

rear

side

window

welt

2

Remove

luggage

side

upper

finish

4

Remove

air

outlet

grille

S

Remove

bolts

securing

rear

por

tion

of

rear

side

window

glass

er

3

Remove

nut

securing

front

por

tion

of

rear

side

window

glass

lt

BF7648

Fig

BF

80

Removing

Bolts

rear

portion

BF

27

6

Using

a

knife

cut

off

butyl

seal

around

entire

periphery

of

glass

Note

It

is

advisable

to

start

cutting

butyl

seal

at

rear

portion

of

window

glass

while

pulling

glass

outward

BF765B

Fig

BF

81

Cutting

Butyl

Seal

7

Remove

rear

side

window

glass

8

Using

a

rag

dampened

with

un

leaded

gasoline

remove

any

trace

of

butyl

seai

from

car

body

INSTALLATION

I

Clean

contacting

surfaces

of

body

and

rear

side

window

glass

with

a

rag

dampened

with

unleaded

gasoline

CAUTION

Do

not

allow

oil

grease

or

water

to

get

on

clean

surfaces

2

Attach

butyl

seal

around

entire

periphery

of

rear

side

window

glass

so

that

inner

edge

is

at

specified

distance

from

printed

black

area

on

glass

See

Figs

BF

82

and

BF

83

Note

a

Do

not

touch

surfaces

of

butyl

seal

which

comes

into

contact

with

glass

and

tailgate

with

hands

as

this

will

reduce

sealing

effects

b

Always

affix

a

continuous

bead

of

butyl

seal

be

sure

to

overlap

one

end

of

butyl

bead

approximately

10

mm

0

39

in

over

the

other

end

A

break

can

cause

water

leak

age