engine DATSUN 510 1968 Service Owner's Guide

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1968, Model line: 510, Model: DATSUN 510 1968Pages: 252, PDF Size: 12.2 MB

Page 51 of 252

46

CHAPTER

SIX

CAUTION

When

removing

camshaft

use

ex

treme

care

not

to

scratch

the

cam

bushings

Be

certam

to

leave

the

cam

shaft

bushings

Intact

so

as

not

to

get

them

out

of

al

gnment

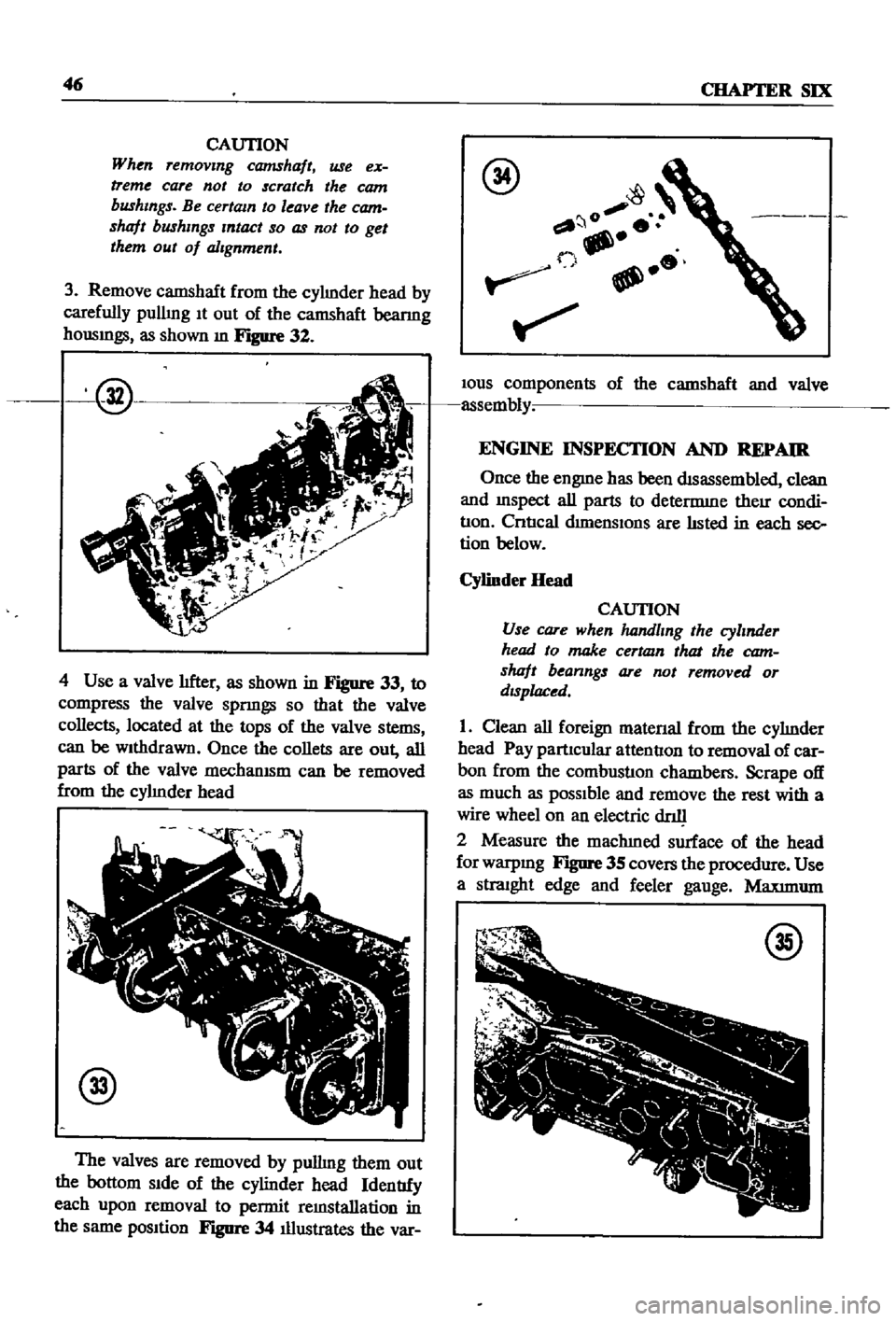

3

Remove

camshaft

from

the

cylmder

head

by

carefully

pullmg

It

out

of

the

camshaft

beanng

housmgs

as

shown

m

Figure

32

@

4

Use

a

valve

hfter

as

shown

in

Figure

33

to

compress

the

valve

spnngs

so

that

the

valve

collects

located

at

the

tops

of

the

valve

stems

can

be

wIthdrawn

Once

the

collets

are

out

all

parts

of

the

valve

mechamsm

can

be

removed

from

the

cylmder

head

@

The

valves

are

removed

by

pullmg

them

out

the

bottom

SIde

of

the

cylinder

head

IdentIfy

each

upon

removal

to

permit

remstallation

in

the

same

posItion

Figure

34

Illustrates

the

var

@

o

o

IOUS

components

of

the

camshaft

and

valve

assembly

ENGINE

INSPECTION

AND

REPAIR

Once

the

engme

has

been

dIsassembled

clean

and

mspect

all

parts

to

determme

theIr

condi

tIon

CntIcal

dunenslOns

are

hsted

in

each

sec

tion

below

Cylinder

Head

CAUTION

Use

care

when

handling

the

cylinder

head

to

make

certam

that

the

cam

shaft

beanngs

are

not

removed

or

dIsplaced

1

Clean

all

foreign

matenal

from

the

cylmder

head

Pay

partIcular

attentIon

to

removal

of

car

bon

from

the

combustIon

chambers

Scrape

off

as

much

as

pOSSIble

and

remove

the

rest

with

a

wire

wheel

on

an

electric

dn11

2

Measure

the

machIned

surface

of

the

head

for

warpmg

FIgUre

35

covers

the

procedure

Use

a

StraIght

edge

and

feeler

gauge

Maxunum

@

Page 52 of 252

ENGINE

47

allowable

warpage

IS

0

0039

in

0

I

mm

Standard

should

be

less

than

0

0012

in

O

03mm

In

the

event

the

measurements

are

out

of

tolerance

the

cylmder

head

surface

should

be

milled

or

resurfaced

3

Verify

that

all

water

and

011

passages

are

free

of

foreign

matena

Use

compressed

aIr

to

clean

passages

after

scraping

4

Note

the

condition

of

all

studs

in

the

cylinder

head

Replace

damaged

ones

Valve

Assembly

I

Check

intake

and

exhaust

valve

assembhes

for

worn

damaged

or

deformed

valve

caps

and

stems

Correct

or

replace

the

valve

If

excessive

defects

exist

2

Measure

valve

stem

diameter

WIth

a

micro

meter

as

shown

in

Fignre

36

Figure

37

gives

cnncal

drmensions

@

@

Y

lm

1

0

515

r

3

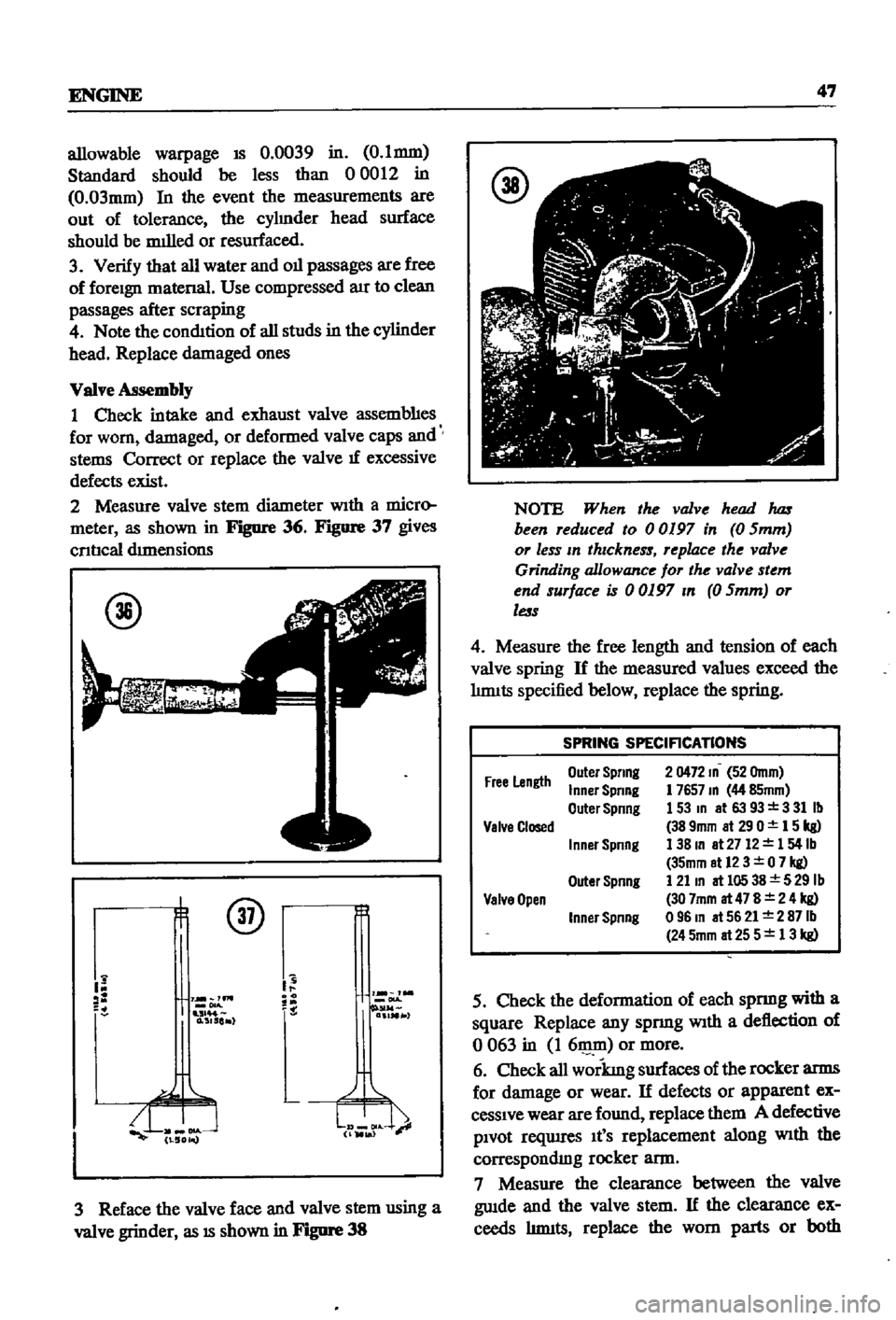

Reface

the

valve

face

and

valve

stem

using

a

valve

grinder

as

18

shown

in

Fignre

38

NOTE

When

the

valve

head

1uzs

been

reduced

to

00197

in

0

Smm

or

less

In

thIckness

replace

the

valve

Grinding

allowance

for

the

valve

stem

end

surface

is

00197

In

0

Smm

or

less

4

Measure

the

free

length

and

tension

of

each

valve

spring

If

the

measured

values

exceed

the

hnuts

specified

below

replace

the

spring

SPRING

SPECIFICATIONS

Free

Length

Outel

Spring

Inner

Spring

Outer

Spring

2

0472

10

52

Omm

1

765710

44

85mm

153m

at6393

331Ib

389mm

at290

15kg

138m

at

2712

154lb

35mm

at12

3

0

7

kg

121

10

at

105

38

5

29

Ib

30

7mm

at

47

8

2

4

kg

09610

at5621

2871b

245mm

at

25

5

13

kg

Valve

Closed

I

nner

Spring

Outer

Spnng

Valve

Open

Inner

Spnng

5

Check

the

deformation

of

each

spnng

with

a

square

Replace

any

spnng

WIth

a

deflection

of

o

063

in

I

611lID

or

more

6

Check

all

workmg

surfaces

of

the

rocker

arms

for

damage

or

wear

If

defects

or

apparent

ex

cessIve

wear

are

found

replace

them

A

defective

PIvot

reqwres

It

S

replacement

along

WIth

the

correspondIng

rocker

ann

7

Measure

the

clearance

between

the

valve

gwde

and

the

valve

stem

If

the

clearance

ex

ceeds

hnuts

replace

the

worn

parts

or

both

Page 54 of 252

ENGINE

49

Cylinder

Block

1

Check

the

cylmder

block

for

defects

such

as

cracks

leaky

soft

plugs

and

blocked

water

pass

ages

Blowout

all

passages

With

compressed

air

2

Measure

the

surface

of

the

cylinder

block

that

mates

with

the

cyhnder

head

for

warpage

Use

a

straight

edge

and

feeler

gauge

to

measure

clearance

as

shown

m

Figure

42

Surface

flat

ness

clearance

should

be

less

than

0

0020

m

0

05mm

Maxunum

allowable

is

0

0039

in

010mm

Resurface

the

cyhnder

block

if

beyond

hnnts

@

3

Use

a

bore

gauge

as

shown

m

Figure

43

to

measure

the

bore

of

each

cyhnder

Measure

near

the

top

at

the

center

and

near

the

bottom

If

excessive

wear

taper

or

out

of

round

exists

rebore

the

cyhnders

or

replace

the

cylinder

hners

Maxunum

wear

hnnt

of

a

cyhnder

bore

IS

o

0079

m

0

2mm

Standard

bore

IS

3

2677

0

0020

m

83

000

0

050mm

The

al

@

lowable

error

m

the

cyhnder

bore

taper

is

0

0006

in

0015mm

The

difference

between

the

four

cyhnder

bores

should

not

exceed

0

0020

in

0

05mm

NOTE

When

any

cylmder

needs

re

boring

all

foUT

must

be

rebored

4

If

the

cyhnder

bores

are

Wlthm

tolerances

use

a

ndge

reamer

to

remove

the

ndge

at

the

top

of

the

cyhnder

bores

and

then

hone

the

cyhnder

walls

to

complete

the

recolllhuonmg

Measure

the

cyhnder

bores

when

honmg

has

been

finished

to

venfy

that

allowable

tolerances

have

not

been

exceeded

Measuring

Bore

Below

is

a

method

for

checking

cntical

clear

ance

between

piston

and

cylinder

wall

Unless

you

are

familiar

With

such

work

call

m

an

expert

Clearance

should

be

between

0

0010

and

0

0018

m

0025

thrQugh

0

045mm

1

Insert

the

pISton

without

rings

upside

down

in

the

cyhnder

bore

2

Use

a

feeler

gauge

between

0

0010

and

00018

mches

thick

Insert

It

between

the

pISton

and

the

cylinder

wall

as

shown

m

Figure

and

attach

a

spring

gauge

as

illustrated

@

Page 56 of 252

ENGINE

51

8

Figure

48

shows

the

pm

bemg

mserted

to

make

certam

that

It

can

be

pressed

m

at

room

temperature

by

hand

Piston

pm

clearance

to

piston

pm

should

be

between

0

0003

and

0

0004

m

0008

and

0

01Omm

NOTE

The

piston

pin

IS

fitted

to

the

connecting

rod

with

a

fitting

force

of

from

1

to

3

tons

of

pressure

Connecting

Rod

1

Inspect

all

connectmg

rods

for

flaws

or

obVIOUS

damage

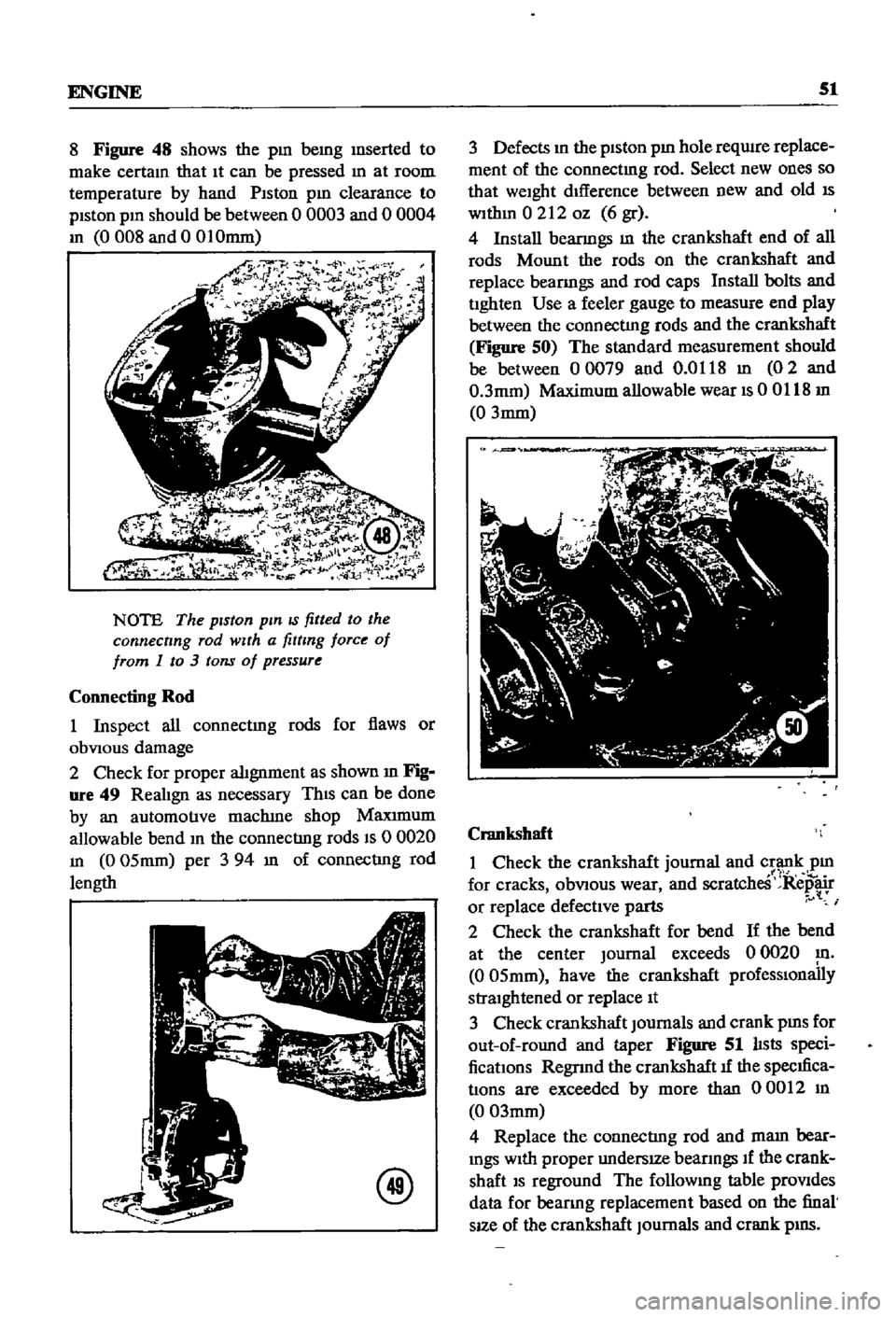

2

Check

for

proper

alignment

as

shown

m

Fig

ure

49

RealIgn

as

necessary

ThIS

can

be

done

by

an

automotive

maclune

shop

Maxrmum

allowable

bend

m

the

connecting

rods

IS

0

0020

m

0

05mm

per

3

94

m

of

connecting

rod

length

@

3

Defects

m

the

piston

pm

hole

reqwre

replace

ment

of

the

connectmg

rod

Select

new

ones

so

that

weight

dIfference

between

new

and

old

IS

wlthm

0212

oz

6

gr

4

Install

beanngs

m

the

crankshaft

end

of

all

rods

Mount

the

rods

on

the

crankshaft

and

replace

beanngs

and

rod

caps

Install

bolts

and

tighten

Use

a

feeler

gauge

to

measure

end

play

between

the

connecting

rods

and

the

crankshaft

Figure

50

The

standard

measurement

should

be

between

00079

and

0

0118

m

02

and

0

3mm

Maximum

allowable

wear

IS

00118

m

0

3mm

Crankshaft

1

Check

the

crankshaft

journal

and

crank

pm

1

1

for

cracks

obVIOUS

wear

and

scratcheS

Repair

or

replace

defective

parts

I

2

Check

the

crankshaft

for

bend

If

the

bend

at

the

center

Journal

exceeds

0

0020

m

0

05mm

have

the

crankshaft

prOfeSSIOnally

straightened

or

replace

It

3

Check

crankshaft

Journals

and

crank

pms

for

out

of

round

and

taper

Figure

51

lIsts

speci

fications

Regnnd

the

crankshaft

1f

the

specIfica

tions

are

exceeded

by

more

than

00012

m

0

03mm

4

Replace

the

connecting

rod

and

mam

bear

mgs

With

proper

undersIZe

beanngs

If

the

crank

shaft

IS

reground

The

followmg

table

prOVides

data

for

beanng

replacement

based

on

the

final

sIZe

of

the

crankshaft

Journals

and

crank

pIllS

Page 58 of 252

ENGINE

53

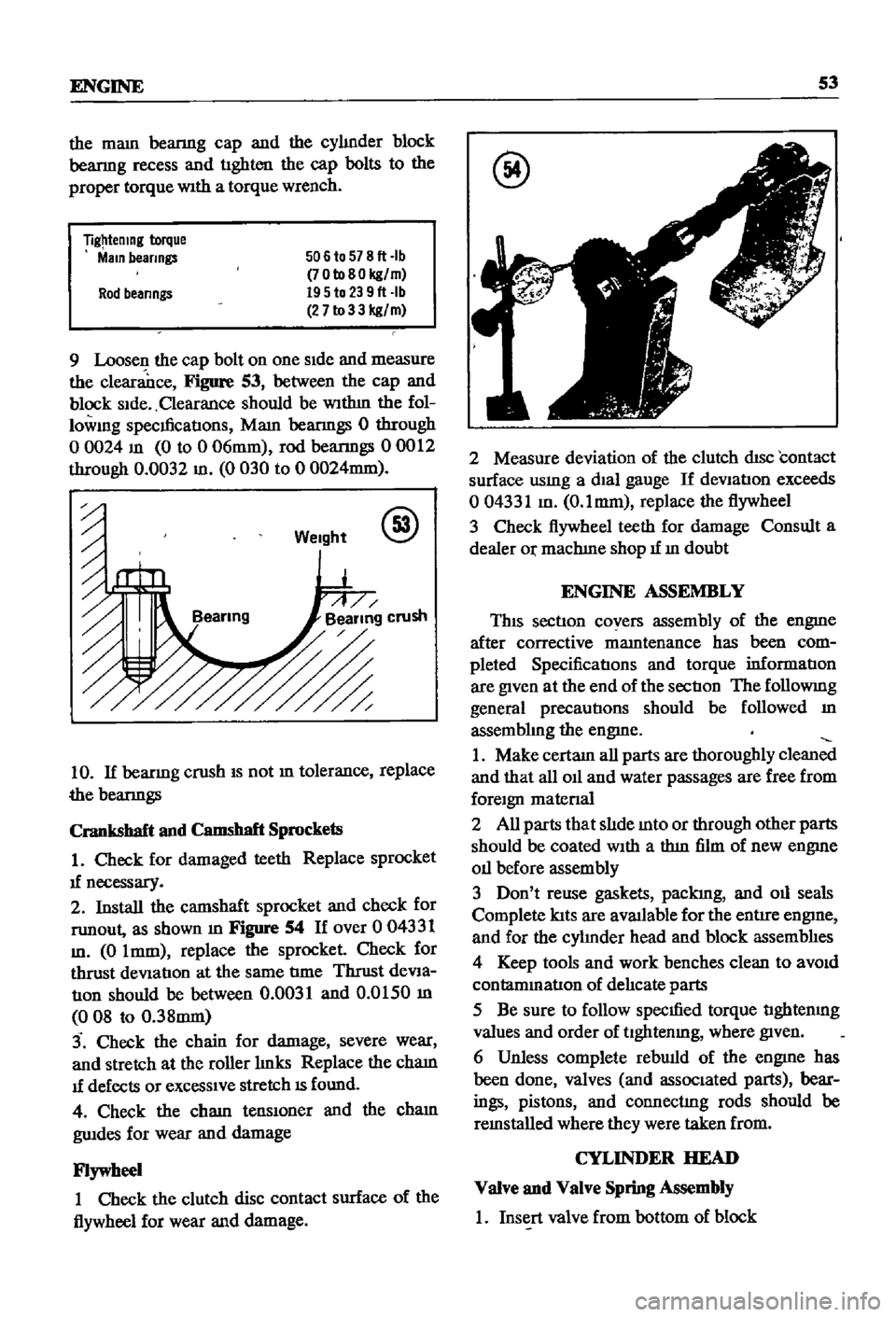

the

mam

beanng

cap

and

the

cyhnder

block

beanng

recess

and

tighten

the

cap

bolts

to

the

proper

torque

WIth

a

torque

wrench

Tig

temng

torque

Main

bearings

506

to

57

8

It

Ib

70to80kg

m

195

to

23

9

It

Ib

27

to3

3

kg

m

Rod

beanngs

9

Loosen

the

cap

bolt

on

one

Side

and

measure

the

clearance

Figure

53

between

the

cap

and

block

Side

Clearance

should

be

WIthm

the

fol

lowmg

specmcatIons

Mam

beanngs

0

through

o

0024

m

0

to

0

06mm

rod

beanngs

00012

through

0

0032

m

0

030

to

0

0024mm

Weight

@

10

If

beanng

crush

IS

not

m

tolerance

replace

the

beanngs

Crankshaft

and

Camshaft

Sprockets

1

Check

for

damaged

teeth

Replace

sprocket

1f

necessary

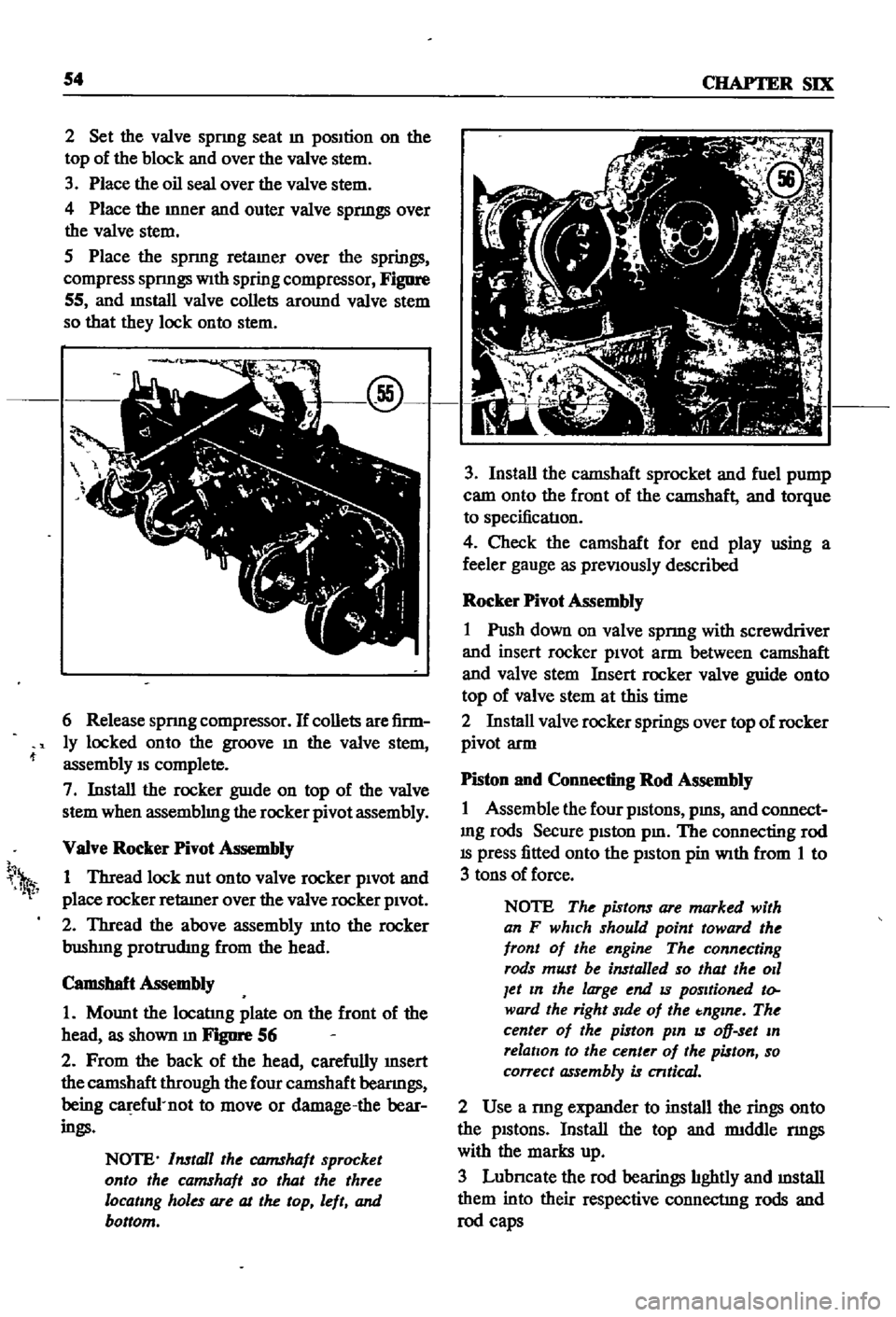

2

Install

the

camshaft

sprocket

and

check

for

runout

as

shown

m

Figure

54

If

over

0

04331

m

0

Imm

replace

the

sprocket

Check

for

thrust

deViation

at

the

same

tIme

Thrust

deVia

tIOn

should

be

between

0

0031

and

0

0150

m

008

to

0

38mm

3

Check

the

chain

for

damage

severe

wear

and

stretch

at

the

roller

hnks

Replace

the

cham

1f

defects

or

exceSSIve

stretch

IS

found

4

Check

the

cham

tenslOner

and

the

cham

gwdes

for

wear

and

damage

Flywheel

1

Check

the

clutch

disc

contact

surface

of

the

flywheel

for

wear

and

damage

@

2

Measure

deviation

of

the

clutch

disc

contact

surface

usmg

a

dial

gauge

If

deVIation

exceeds

004331

m

O

lmm

replace

the

flywheel

3

Check

flywheel

teeth

for

damage

Consult

a

dealer

Or

machIne

shop

1f

m

doubt

ENGINE

ASSEMBLY

This

section

covers

assembly

of

the

engme

after

corrective

mamtenance

has

been

com

pleted

SpecificatIons

and

torque

informatIon

are

given

at

the

end

of

the

sectIon

The

followmg

general

precautions

should

be

followed

m

assembhng

the

engme

1

Make

certam

all

parts

are

thoroughly

clean

and

that

all

011

and

water

passages

are

free

from

foreign

matenal

2

All

parts

that

slIde

mto

or

through

other

parts

should

be

coated

With

a

thm

film

of

new

engme

011

before

assembly

3

Don

t

reuse

gaskets

packIng

and

011

seals

Complete

lats

are

aVlUlable

for

the

entire

engme

and

for

the

cyhnder

head

and

block

assemblIes

4

Keep

tools

and

work

benches

clean

to

aVOid

contammatlon

of

delIcate

parts

5

Be

sure

to

follow

specmed

torque

tIghtenmg

values

and

order

of

tlghtenmg

where

given

6

Unless

complete

rebwld

of

the

engme

has

been

done

valves

and

associated

parts

bear

ings

pistons

and

connectIng

rods

should

be

remstalled

where

they

were

taken

from

CYLINDER

HEAD

Valve

and

Valve

Spring

Assembly

1

Insert

valve

from

bottom

of

block

Page 59 of 252

54

CHAP1ER

SIX

2

Set

the

valve

spnng

seat

m

position

on

the

top

of

the

block

and

over

the

valve

stem

3

Place

the

oil

seal

over

the

valve

stem

4

Place

the

mner

and

outer

valve

spnngs

over

the

valve

stem

S

Place

the

spnng

retamer

over

the

springs

compress

spnngs

With

spring

compressor

Figure

55

and

mstall

valve

collets

around

valve

stem

so

that

they

lock

onto

stem

6

Release

spnng

compressor

If

collets

are

firm

ly

locked

onto

the

groove

m

the

valve

stem

assembly

IS

complete

7

Install

the

rocker

guIde

on

top

of

the

valve

stem

when

assemblmg

the

rocker

pivot

assembly

VaIve

Rocker

Pivot

Assembly

1

Thread

lock

nut

onto

valve

rocker

pivOt

and

place

rocker

retaIner

over

the

valve

rocker

pivOt

2

Thread

the

above

assembly

mto

the

rocker

bushIng

protrudIng

from

the

head

Camshaft

Assembly

1

Mount

the

locatIng

plate

on

the

front

of

the

head

as

shown

m

FJgIlI

1

56

2

From

the

back

of

the

head

carefully

InSert

the

camshaft

through

the

four

camshaft

beanngs

being

ca

efu1

not

to

move

or

damage

the

bear

ings

NOTE

Install

the

CQJ7IShaft

sprocket

onto

the

camshaft

so

that

the

three

locating

holes

are

at

the

top

left

and

bottom

h

1

3

Install

the

camshaft

sprocket

and

fuel

pump

cam

onto

the

front

of

the

camshaft

and

torque

to

specificatIon

4

Check

the

camshaft

for

end

play

using

a

feeler

gauge

as

preViously

described

Rocker

Pivot

Assembly

1

Push

down

on

valve

spnng

with

screwdriver

and

insert

rocker

piVOt

arm

between

camshaft

and

valve

stem

Insert

rocker

valve

guide

onto

top

of

valve

stem

at

this

time

2

Install

valve

rocker

springs

over

top

of

rocker

pivot

arm

Piston

and

Connecting

Rod

Assembly

1

Assemble

the

four

pistons

pms

and

connect

mg

rods

Secure

piston

pm

The

connecting

rod

IS

press

fitted

onto

the

pISton

pin

With

from

1

to

3

tons

of

force

NOTE

The

pistons

are

marked

with

an

F

which

should

point

toward

the

front

of

the

engine

The

connecting

rods

must

be

installed

so

that

the

011

Jet

In

the

large

end

IS

positioned

to

ward

the

right

Side

of

the

tnglne

The

center

of

the

piston

pin

IS

oD

set

In

relation

to

the

center

of

the

piston

so

correct

assembly

is

cntical

2

Use

a

nng

expander

to

install

the

rings

onto

the

pistons

Install

the

top

and

rmddle

nngs

with

the

marks

up

3

Lubncate

the

rod

bearings

hghtly

and

mstall

them

into

their

respective

connectIng

rods

and

rod

caps

Page 60 of 252

ENGINE

55

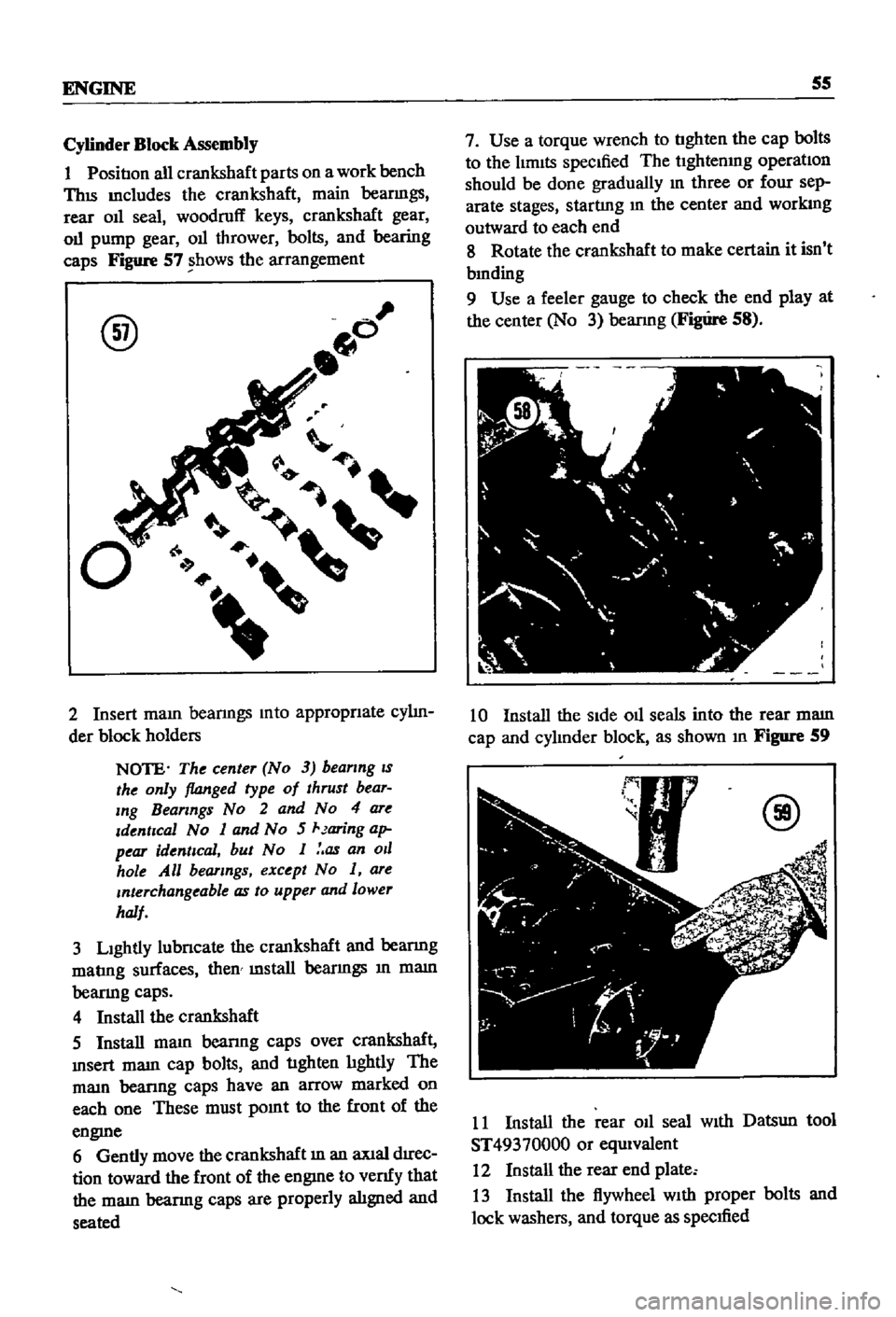

Cylinder

Block

Assembly

1

PositIon

all

crankshaft

parts

on

a

work

bench

ThIS

mcludes

the

crankshaft

main

beanngs

rear

011

seal

woodruff

keys

crankshaft

gear

011

pump

gear

011

thrower

bolts

and

bearing

caps

Figure

57

shows

the

arrangement

@

2

Insert

maIO

beanngs

mto

appropnate

cy1m

der

block

holders

NOTE

The

center

No

3

beanng

IS

the

only

flanged

type

of

thrust

bear

Ing

Bearings

No

2

and

No

4

are

Identical

No

1

and

No

5

Jaring

ap

pear

identical

but

No

1

as

an

011

hole

All

bearings

except

No

1

are

Interchangeable

as

to

upper

and

lower

half

3

LIghtly

lubncate

the

crankshaft

and

beanng

matmg

surfaces

then

mstall

beanngs

10

mam

beanng

caps

4

Install

the

crankshaft

5

Install

mam

beanng

caps

over

crankshaft

msert

mam

cap

bolts

and

tighten

hghtly

The

mam

beanng

caps

have

an

arrow

marked

on

each

one

These

must

pomt

to

the

front

of

the

engme

6

Gently

move

the

crankshaft

10

an

aXIal

drrec

don

toward

the

front

of

the

engme

to

venfy

that

the

mam

beanng

caps

are

properly

alIgned

and

seated

7

Use

a

torque

wrench

to

tighten

the

cap

bolts

to

the

hmlts

speCIfied

The

t1ghtenmg

operatIon

should

be

done

gradually

10

three

or

four

sep

arate

stages

starting

10

the

center

and

workmg

outward

to

each

end

8

Rotate

the

crankshaft

to

make

certain

it

isn

t

bmding

9

Use

a

feeler

gauge

to

check

the

end

play

at

the

center

No

3

beanng

Figure

58

10

Install

the

SIde

oll

seals

into

the

rear

mam

cap

and

cy1mder

block

as

shown

10

Figure

59

@

11

Install

the

rear

011

seal

WIth

Datsun

tool

ST49370000

or

equIvalent

12

Install

the

rear

end

plate

13

Install

the

flywheel

WIth

proper

bolts

and

lock

washers

and

torque

as

specified

Page 61 of 252

56

CHAPTER

SIX

NOTE

Lubncate

the

cylinder

walls

with

new

engine

oil

prior

to

insertIOn

of

pistOns

Make

certain

that

the

ring

gaps

are

not

In

line

wIth

one

another

Place

the

gaps

180

degrees

from

each

other

and

not

posltloned

either

front

to

back

or

dIrectly

in

line

with

the

piston

pIns

CAUTION

Use

extreme

care

when

Inserting

pzs

tons

so

as

to

avoId

crankshaft

damage

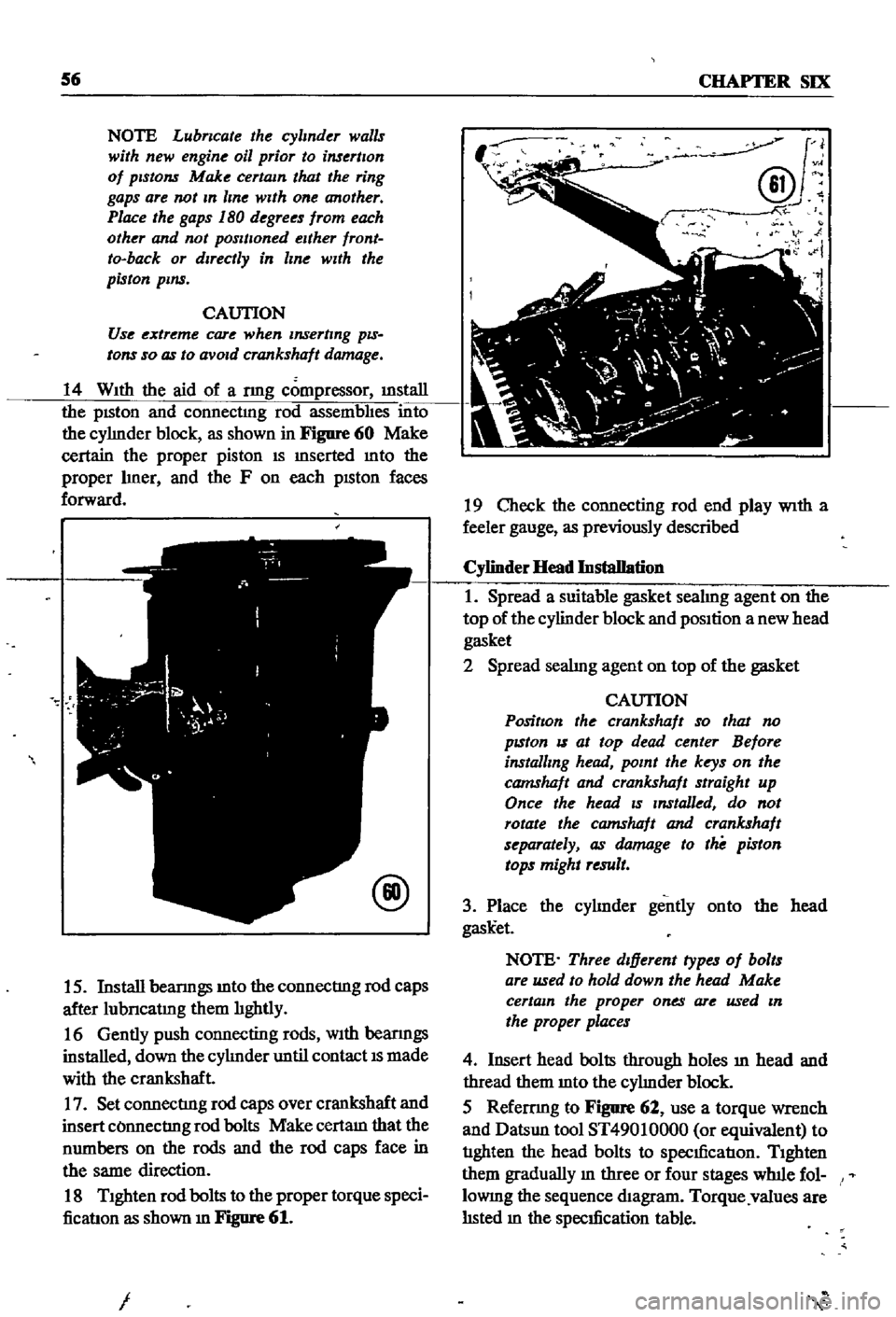

14

With

the

aid

of

a

nng

compressor

illStaIl

the

pISton

and

connectmg

rod

assembhes

into

the

cyhnder

block

as

shown

in

Figure

60

Make

certain

the

proper

piston

IS

mserted

mto

the

proper

hner

and

the

F

on

each

pISton

faces

forward

@

15

Install

beanngs

mto

the

connectIng

rod

caps

after

lubncatmg

them

hghtly

16

Gently

push

connecting

rods

With

beanngs

installed

down

the

cyhnder

until

contact

IS

made

with

the

crankshaft

17

Set

connectIng

rod

caps

over

crankshaft

and

insert

COnnectIng

rod

bolts

Make

certam

that

the

numbers

on

the

rods

and

the

rod

caps

face

in

the

same

direction

18

Tighten

rod

bolts

to

the

proper

torque

speci

ficatIon

as

shown

m

Figure

61

I

J

@v

N

i

19

Check

the

connecting

rod

end

play

With

a

feeler

gauge

as

previously

described

Cylinder

Head

Installation

1

Spread

a

suitable

gasket

seahng

agent

on

the

top

of

the

cylinder

block

and

position

a

new

head

gasket

2

Spread

seahng

agent

on

top

of

the

gasket

CAUTION

PositIon

the

crankshaft

so

that

no

pzston

IS

at

top

dead

center

Before

installing

head

point

the

keys

on

the

camshaft

and

crankshaft

straight

up

Once

the

head

zs

Installed

do

not

rotate

the

camshaft

and

crankshaft

separately

as

damage

to

the

piston

tops

might

result

3

Place

the

cyhnder

gently

onto

the

head

gask

et

NOTE

Three

dIfferent

types

of

bolts

are

used

to

hold

down

the

head

Make

certain

the

proper

ones

are

used

In

the

proper

places

4

Insert

head

bolts

through

holes

ill

head

and

thread

them

mto

the

cyhnder

block

5

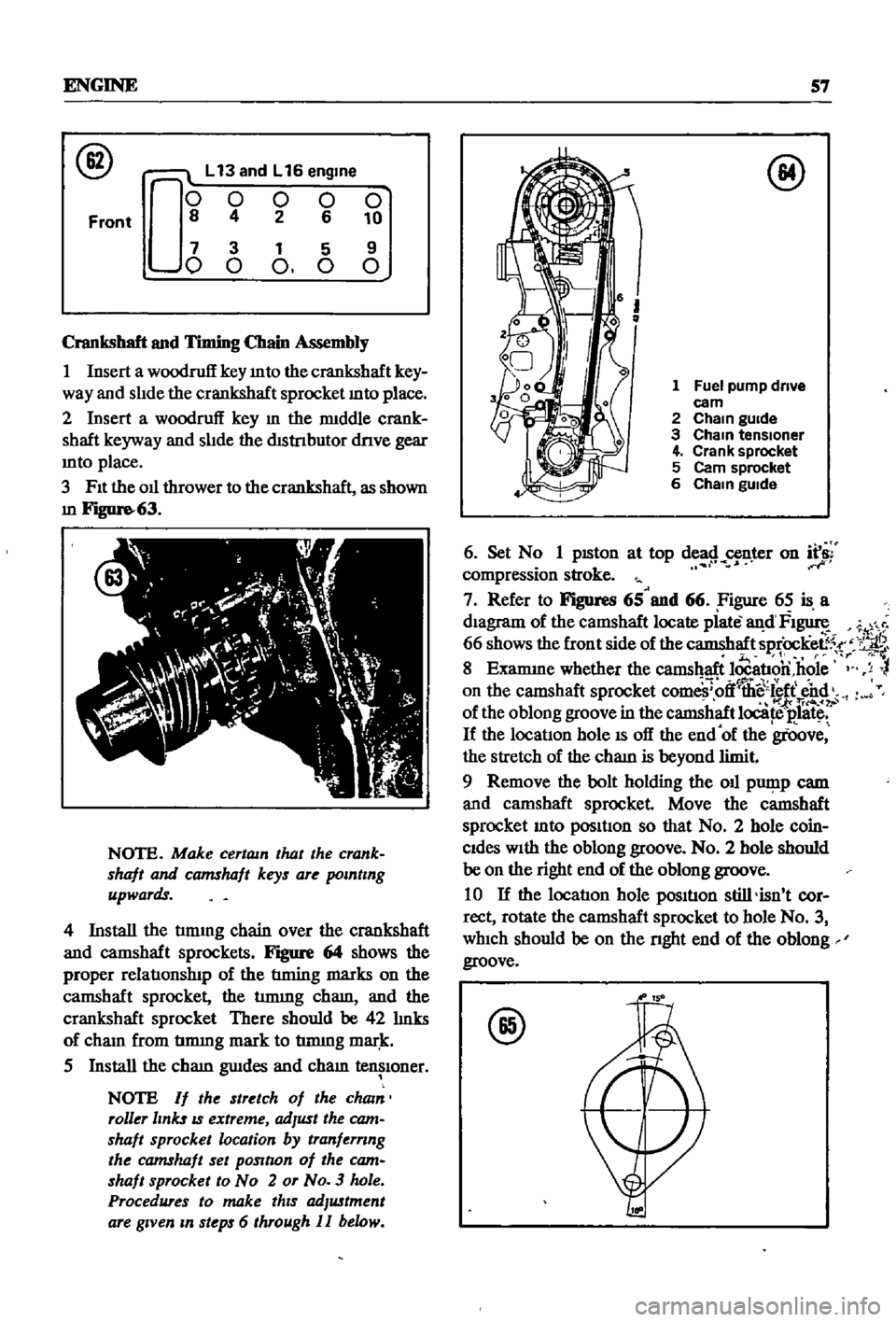

Refemng

to

Figure

62

use

a

torque

wrench

and

Datsun

tool

ST49010000

or

equivalent

to

tIghten

the

head

bolts

to

specIficatIon

Tighten

them

gradually

m

three

or

four

stages

wlnle

fol

lOWIng

the

sequence

diagram

Torque

values

are

hsted

m

the

specIfication

table

Page 62 of 252

ENGINE

57

@

L

13

and

L

16

engme

000000

8

4

2

6

10

7

3

1

5

9

o

0

0

0

0

Front

Crankshaft

and

Timing

Chain

Assembly

1

Insert

a

woodruff

key

mto

the

crankshaft

key

way

and

slide

the

crankshaft

sprocket

mto

place

2

Insert

a

woodruff

key

m

the

Illiddle

crank

shaft

keyway

and

slide

the

dIstnbutor

dnve

gear

mto

place

3

FIt

the

oil

thrower

to

the

crankshaft

as

shown

m

Figure

63

NOTE

Make

certam

that

the

crank

shaft

and

camshaft

keys

are

polntlng

upwards

4

Install

the

tmung

chain

over

the

crankshaft

and

camshaft

sprockets

Figure

64

shows

the

proper

relatIonslnp

of

the

tIming

marks

on

the

camshaft

sprocket

the

tmung

cham

and

the

crankshaft

sprocket

There

should

be

42

hnks

of

cham

from

tmung

mark

to

tmung

mar

k

5

Install

the

cham

gwdes

and

cham

tensIoner

NOTE

If

the

stretch

of

the

cham

roller

links

IS

extreme

adJust

the

cam

shaft

sprocket

location

by

tranfernng

the

camshaft

set

pOSltlon

of

the

cam

shaft

sprocket

to

No

2

or

No

3

hole

Procedures

to

make

thIS

adJustment

are

gIVen

m

steps

6

through

II

below

@

1

Fuel

pump

drive

eam

2

Cham

gUide

3

Cham

tensloner

4

Crank

sprocket

5

Cam

sprocket

6

Cham

gUide

6

Set

N

1

pISton

at

top

de

8

n

r

on

f

compressIon

stroke

7

Refer

to

Figures

65

and

66

Figure

65

is

a

dIagram

of

the

camshaft

locate

piate

an

d

FI

1

66

shows

the

front

side

of

the

camshaft

sprOcKee5

r

11

r

If

8

Examme

whether

the

camshaft

locatIon

hole

y

on

the

camshaft

sprocket

com

ff

llii

sl

ff

end

foI

tri4o

of

the

oblong

groove

in

the

camshaft

locate

E

1litc

If

the

locatIon

hole

IS

off

the

end

of

the

groove

the

stretch

of

the

cham

is

beyond

limit

9

Remove

the

bolt

holding

the

oil

pwp

p

cam

and

camshaft

sprocket

Move

the

camshaft

sprocket

mto

posItIon

so

that

No

2

hole

coin

Cides

With

the

oblong

groove

No

2

hole

should

be

on

the

right

end

of

the

oblong

groove

10

If

the

locatIon

hole

posItIon

still

isn

t

cor

rect

rotate

the

camshaft

sprocket

to

hole

No

3

which

should

be

on

the

nght

end

of

the

oblong

groove

@

Page 64 of 252

ENGINE

59

2

Coat

the

pan

gasket

on

both

sides

With

gasket

compound

and

attach

the

oil

pan

to

the

cyhnder

block

Torque

as

specIfied

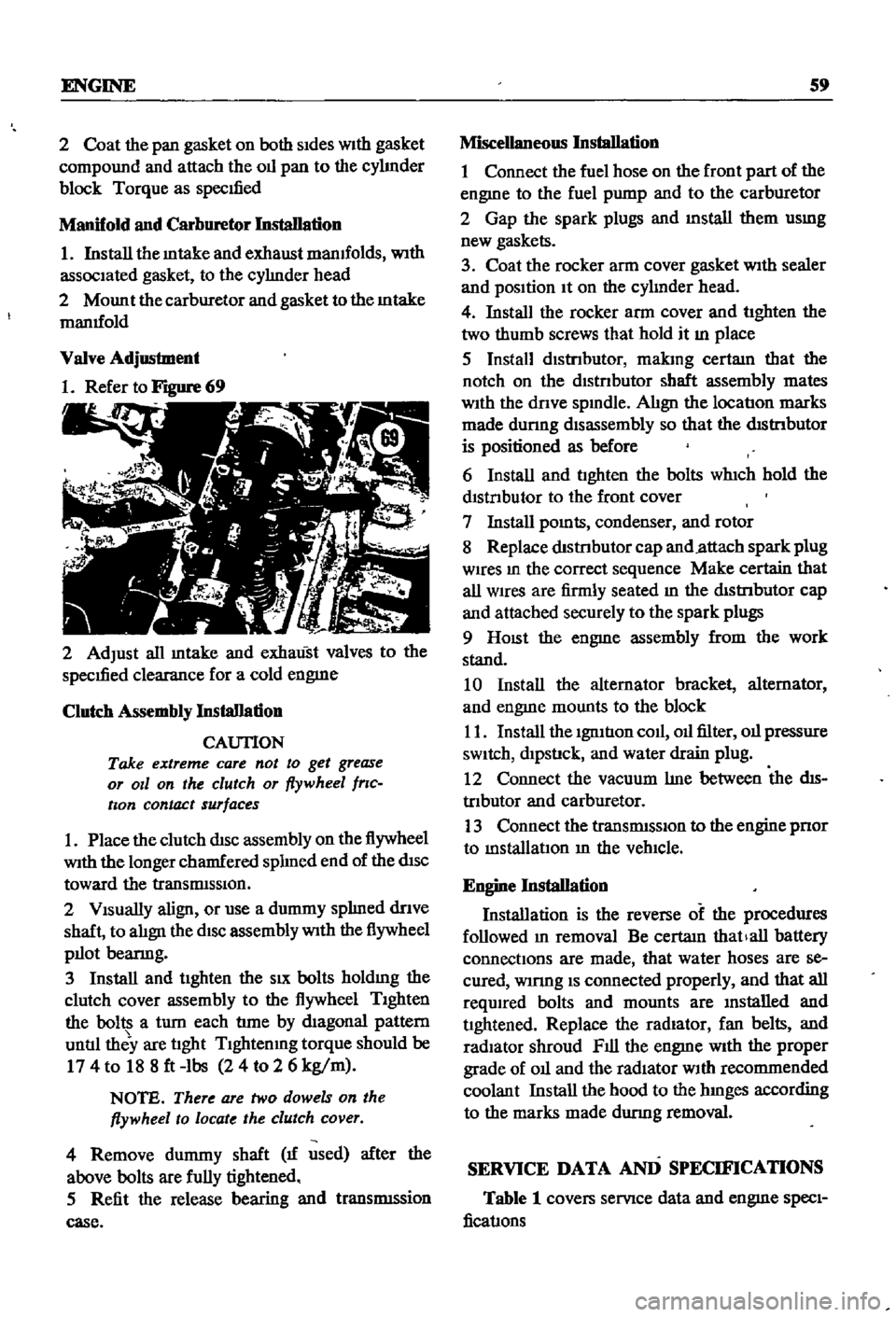

Manifold

and

Carburetor

Installation

1

Install

the

mtake

and

exhaust

manIfolds

WIth

associated

gasket

to

the

cylmder

head

2

Mount

the

carburetor

and

gasket

to

the

mtake

manIfold

2

Adjust

all

mtake

and

exhaust

valves

to

the

specIfied

clearance

for

a

cold

engme

Clutch

Assembly

Installation

CAUTION

Take

extreme

care

not

to

get

grease

or

011

on

the

clutch

or

flywheel

frlc

hon

contact

surfaces

1

Place

the

clutch

disc

assembly

on

the

flywheel

With

the

longer

chamfered

splmed

end

of

the

dISC

toward

the

transmISSion

2

Visually

align

or

use

a

dummy

splmed

dnve

shaft

to

ahgn

the

diSC

assembly

With

the

flywheel

pilot

beanng

3

Install

and

tighten

the

SIX

bolts

holdmg

the

clutch

cover

assembly

to

the

flywheel

Tighten

the

bolts

a

turn

each

tune

by

diagonal

pattern

until

they

are

tight

Tlghtenmg

torque

should

be

174

to

188ft

lbs

24

to

2

6

kg

m

NOTE

There

are

two

dowels

on

the

flywheel

to

locate

the

clutch

cover

4

Remove

dummy

shaft

If

used

after

the

above

bolts

are

fully

tightened

5

Refit

the

release

bearing

and

translI11Ssion

case

Miscellaneous

Installation

1

Connect

the

fuel

hose

on

the

front

part

of

the

engme

to

the

fuel

pump

and

to

the

carburetor

2

Gap

the

spark

plugs

and

mstall

them

usmg

new

gaskets

3

Coat

the

rocker

arm

cover

gasket

With

sealer

and

position

It

on

the

cylmder

head

4

Install

the

rocker

arm

cover

and

tighten

the

two

thumb

screws

that

hold

it

m

place

5

Install

distrIbutor

makmg

certam

that

the

notch

on

the

distributor

shaft

assembly

mates

With

the

drive

spmdle

Ahgn

the

location

marks

made

dunng

disassembly

so

that

the

distrIbutor

is

positioned

as

before

6

Install

and

tighten

the

bolts

which

hold

the

dIStributor

to

the

front

cover

7

Install

pomts

condenser

and

rotor

8

Replace

distrIbutor

cap

and

attach

spark

plug

Wires

m

the

correct

sequence

Make

certain

that

all

wires

are

firmly

seated

m

the

distrIbutor

cap

and

attached

securely

to

the

spark

plugs

9

HOISt

the

engme

assembly

from

the

work

stand

10

Install

the

alternator

bracket

alternator

and

engme

mounts

to

the

block

11

Install

the

IgnItIon

coil

oil

filter

oil

pressure

SWitch

dipstick

and

water

drain

plug

12

Connect

the

vacuum

Ime

between

the

dis

trIbutor

and

carburetor

13

Connect

the

transIDlSSlOn

to

the

engine

prior

to

mstallatIon

m

the

vehicle

Engine

Installation

Installation

is

the

reverse

of

the

procedures

followed

m

removal

Be

certaIn

thatlall

battery

connections

are

made

that

water

hoses

are

se

cured

wmng

IS

connected

properly

and

that

all

required

bolts

and

mounts

are

mstalled

and

tightened

Replace

the

radiator

fan

belts

and

radiator

shroud

Fill

the

engme

With

the

proper

grade

of

oil

and

the

radiator

With

recommended

coolant

Install

the

hood

to

the

hInges

according

to

the

marks

made

dUrIng

removal

SERVICE

DATA

AND

SPECIFICATIONS

Table

1

covers

servIce

data

and

engme

Speci

fications