engine DATSUN 510 1968 Service Workshop Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1968, Model line: 510, Model: DATSUN 510 1968Pages: 252, PDF Size: 12.2 MB

Page 106 of 252

ENGINE

ELECTRICAL

SYSTEM

101

8

To

separate

the

stator

from

the

dIode

end

housmg

assembly

unsolder

the

three

negatIve

dIodes

from

the

three

co1l1ead

WIres

The

nega

tIve

dIodes

are

marked

WIth

black

figures

and

the

posItIve

ones

With

red

figures

CAUTION

Use

extreme

care

when

unsoldenng

the

diodes

to

prevent

excessive

heat

from

damagmg

thi

m

Use

a

100

to

200

watt

soldermg

Iron

for

no

more

than

two

seconds

at

the

dIOde

Junction

9

Remove

the

brush

cover

by

unscreWIng

the

two

set

screws

10

Unsolder

the

negatIve

terminal

lead

wire

Separate

dIOde

end

from

stator

Figure

33

@

11

Remove

the

heat

smk

and

the

brush

holder

from

the

rear

cover

by

unscrewmg

the

setscrews

as

shown

m

Figure

34

@

12

DIsassemble

the

brush

holder

by

unsolder

ing

the

F

lead

WIre

black

whIte

E

lead

WIre

black

and

the

negatIve

and

pOSItIve

brush

holder

Wires

Figure

35

shows

the

brush

holder

dIsassembled

O

tlII

I

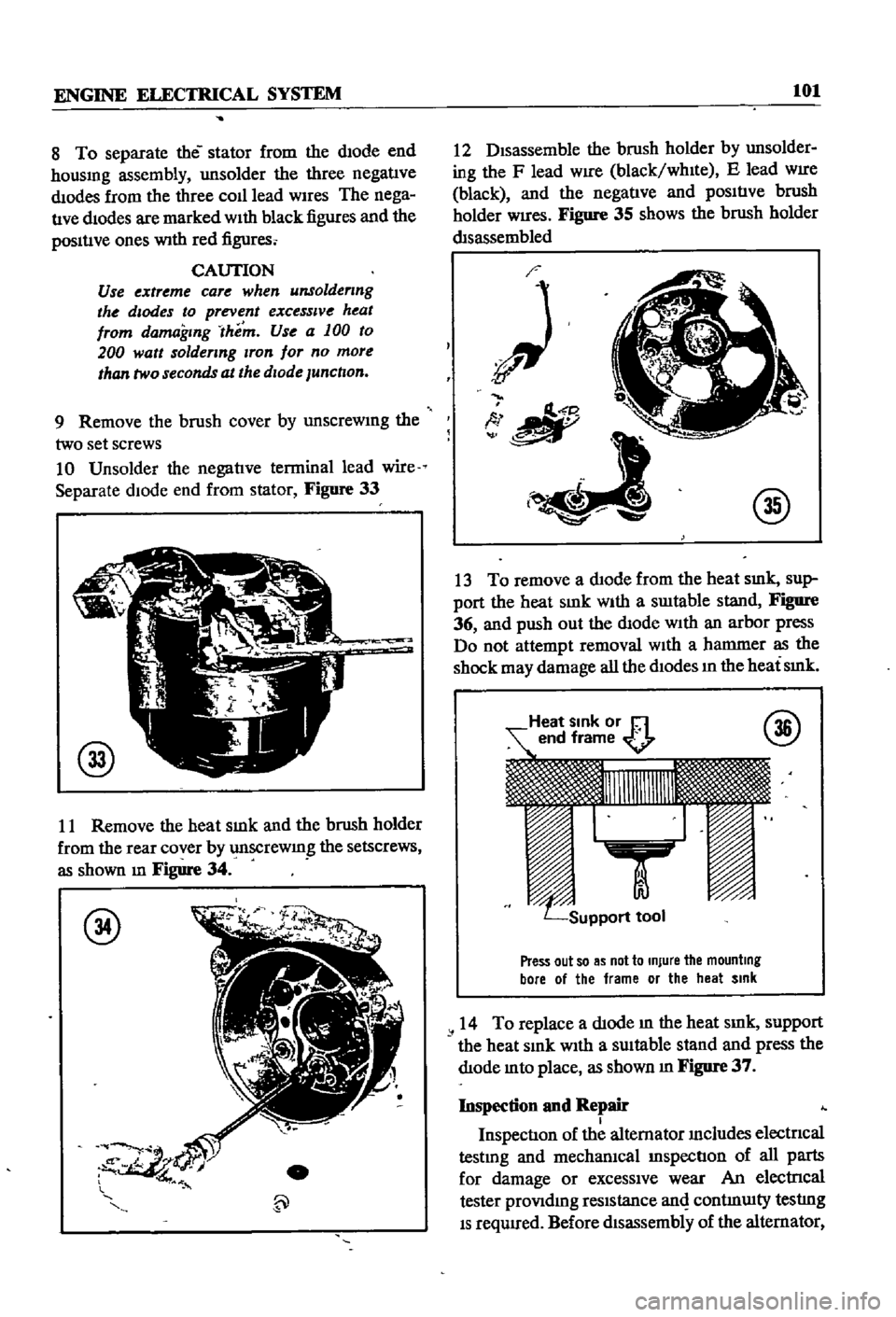

@

13

To

remove

a

dIode

from

the

heat

smk

sup

port

the

heat

SInk

WIth

a

swtable

stand

Figure

36

and

push

out

the

dIode

With

an

arbor

press

Do

not

attempt

removal

WIth

a

hammer

as

the

shock

may

damage

all

the

dIodes

ill

the

heat

SInk

Press

out

so

as

not

to

Injure

the

mounting

bore

01

the

frame

or

the

heat

Sink

14

To

replace

a

dIode

m

the

heat

smk

support

the

heat

SInk

With

a

SUItable

stand

and

press

the

dIode

mto

place

as

shown

m

Figure

37

Inspection

and

Repair

I

InspectIon

of

the

alternator

Includes

electncal

testmg

and

mechanIcal

InspectIon

of

all

parts

for

damage

or

exceSSIve

wear

An

electrIcal

tester

proVIdmg

reSIstance

anI

contmUlty

testlng

IS

requIred

Before

dIsassembly

of

the

alternator

Page 108 of 252

ENGINE

ELECTRICAL

SYSTEM

103

2

Check

the

lead

Wires

of

the

armature

coil

Includmg

the

neutral

wire

for

ground

as

shown

In

Figure

42

HIgh

reSIStance

no

current

flow

indicates

gqod

condItion

If

not

the

stator

must

be

replaced

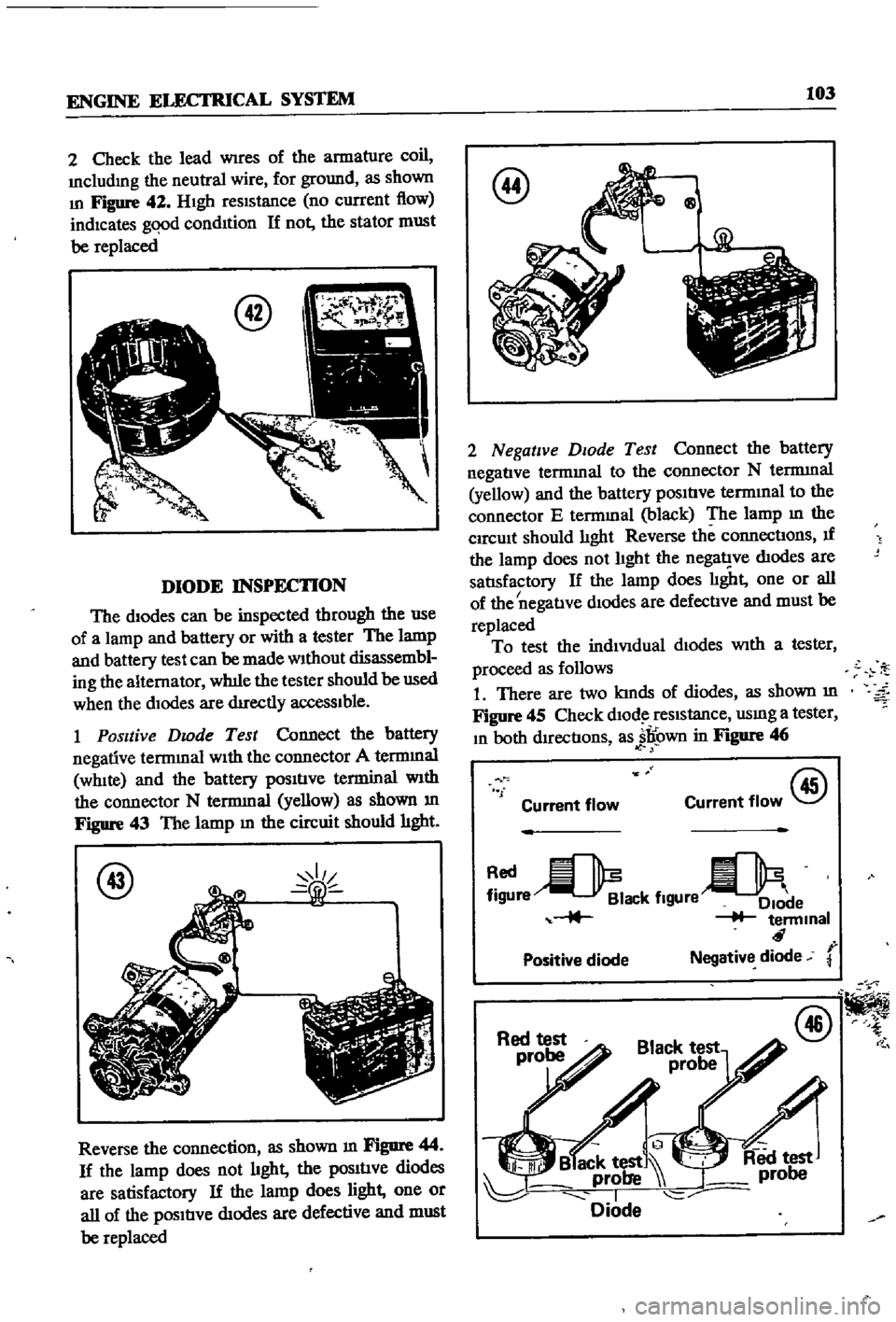

DIODE

INSPECTION

The

diodes

can

be

inspected

through

the

use

of

a

lamp

and

battery

or

with

a

tester

The

lamp

and

battery

test

can

be

made

Without

disassembl

ing

the

alternator

wh1le

the

tester

should

be

used

when

the

dIodes

are

dIrectly

acceSSIble

1

Positive

Dwde

Test

Connect

the

battery

negative

terrmnal

WIth

the

connector

A

terrmnal

WhIte

and

the

battery

pOSItIve

terminal

With

the

connector

N

terrmnal

yellow

as

shown

m

Figure

43

The

lamp

m

the

circuit

should

hght

@

Reverse

the

connection

as

shown

m

Figure

44

If

the

lamp

does

not

hght

the

pOSItIve

diodes

are

satisfactory

If

the

lamp

does

light

one

or

all

of

the

pOSItIve

dIodes

are

defective

and

must

be

replaced

@

Qg

2

Negative

DIOde

Test

Connect

the

battery

negatIve

termmal

to

the

connector

N

terrmnal

yellow

and

the

battery

pOSItIve

termInal

to

the

connector

E

termmal

black

The

lamp

m

the

CIrcUit

should

lIght

Reverse

the

connectIons

If

the

lamp

does

not

lIght

the

nega1

ve

dIodes

are

satlsfactory

If

the

lamp

does

lIght

one

or

all

I

of

the

negatIve

dIodes

are

defectIve

and

must

be

replaced

To

test

the

indiVIdual

dIodes

With

a

tester

proceed

as

follows

1

There

are

two

kInds

of

diodes

as

shown

m

Figure

45

Check

dlOd

reSIstance

usmg

a

tester

In

both

dIrectIons

as

jl

own

in

Figure

46

f

Current

flow

@

Current

flow

re

ack

flgUre

e

terminal

r

Positive

diode

Negative

diode

@

Page 110 of 252

ENGINE

ELECTRICAL

SYSTEM

105

VOLTAGE

REGULATOR

REMOVAL

To

remove

the

voltage

regulator

dISconnect

the

6

way

multIple

electrIcal

COlInector

and

the

screws

holdmg

the

regulator

to

the

SIde

wall

lJ

R

ftl5

C

Wt

Str

Ii

DISTRIBUTOR

W

I

vE

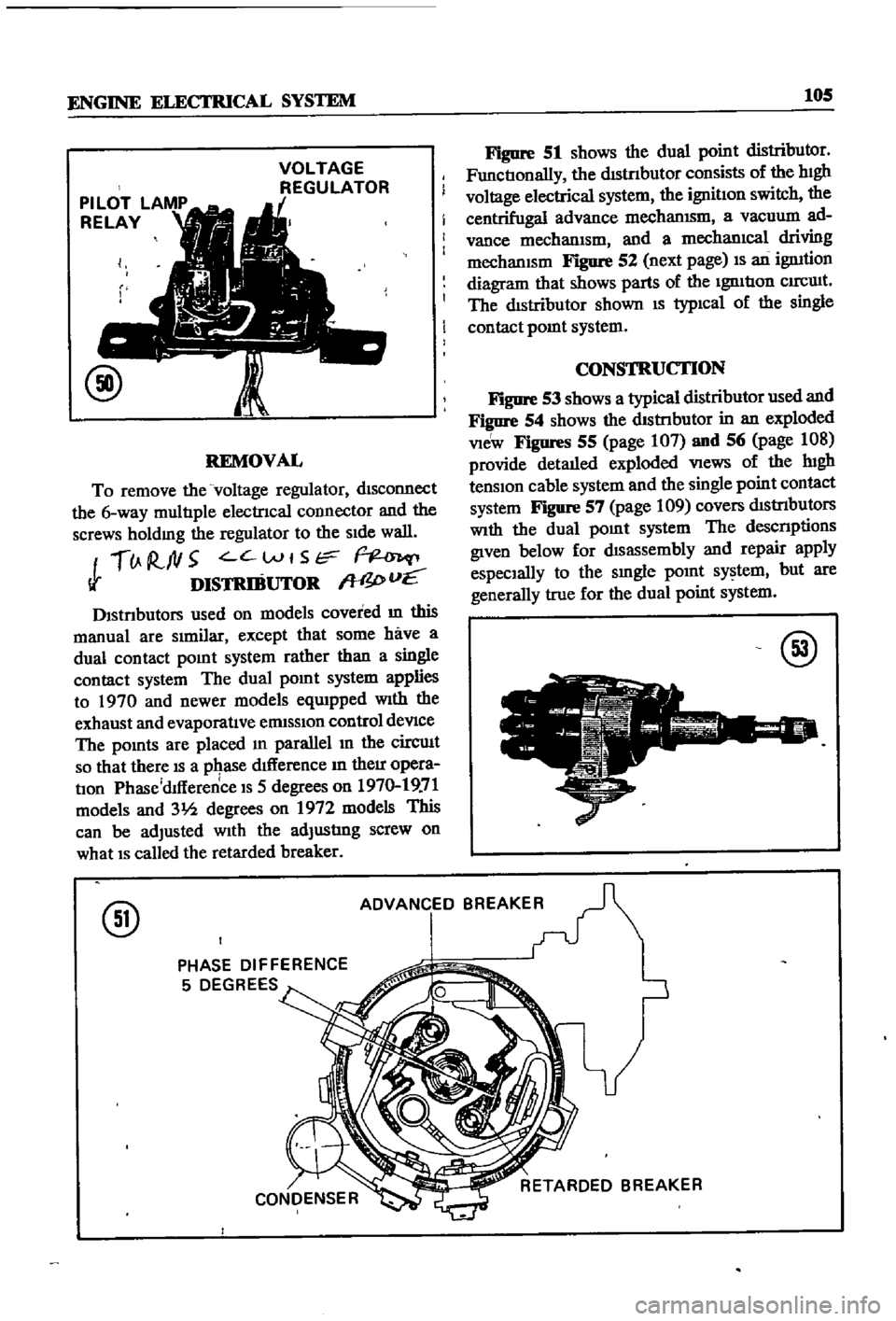

Dlstnbutors

used

on

models

covered

m

this

manual

are

SImilar

except

that

some

have

a

dual

contact

pomt

system

rather

than

a

single

contact

system

The

dual

pomt

system

applies

to

1970

and

newer

models

eqUIpped

With

the

exhaust

and

evaporatIve

ermsslOn

control

deVIce

The

pomts

are

placed

m

parallel

In

the

circuIt

so

that

there

IS

a

pqase

dIfference

In

their

opera

tIon

Phase

dlfference

IS

5

degrees

on

1970

19

71

models

and

31h

degrees

on

1972

models

This

can

be

adjusted

With

the

adjustIng

screw

on

what

IS

called

the

retarded

breaker

Figure

51

shows

the

dual

point

distributor

FunctIonally

the

dIStnbutor

consists

of

the

hIgh

voltage

electrical

system

the

ignitIon

switch

the

centrifugal

advance

mechanISm

a

vacuum

ad

vance

mechanIsm

and

a

mechanIcal

driving

mechanISm

Figure

52

next

page

IS

an

ignItion

diagram

that

shows

parts

of

the

IgnItIon

CIrCUIt

The

dIstributor

shown

IS

typIcal

of

the

single

contact

pomt

system

CONSTRUCTION

Figure

53

shows

a

typical

distributor

used

and

Figure

54

shows

the

dIStnbutor

in

an

exploded

VIeW

Figures

55

page

107

and

56

page

108

provide

detaIled

exploded

VIews

of

the

lugh

tenSIon

cable

system

and

the

single

point

contact

system

Figure

57

page

109

covers

dIStrIbutors

With

the

dual

pOInt

system

The

descnptions

given

below

for

dIsassembly

and

repair

apply

espeCIally

to

the

smgle

pOInt

system

but

are

generally

true

for

the

dual

point

system

@

@

ADVANCED

BREAKER

PHASE

DIFFERENCE

5

DEGREES

Page 111 of 252

106

CHAPTER

NINE

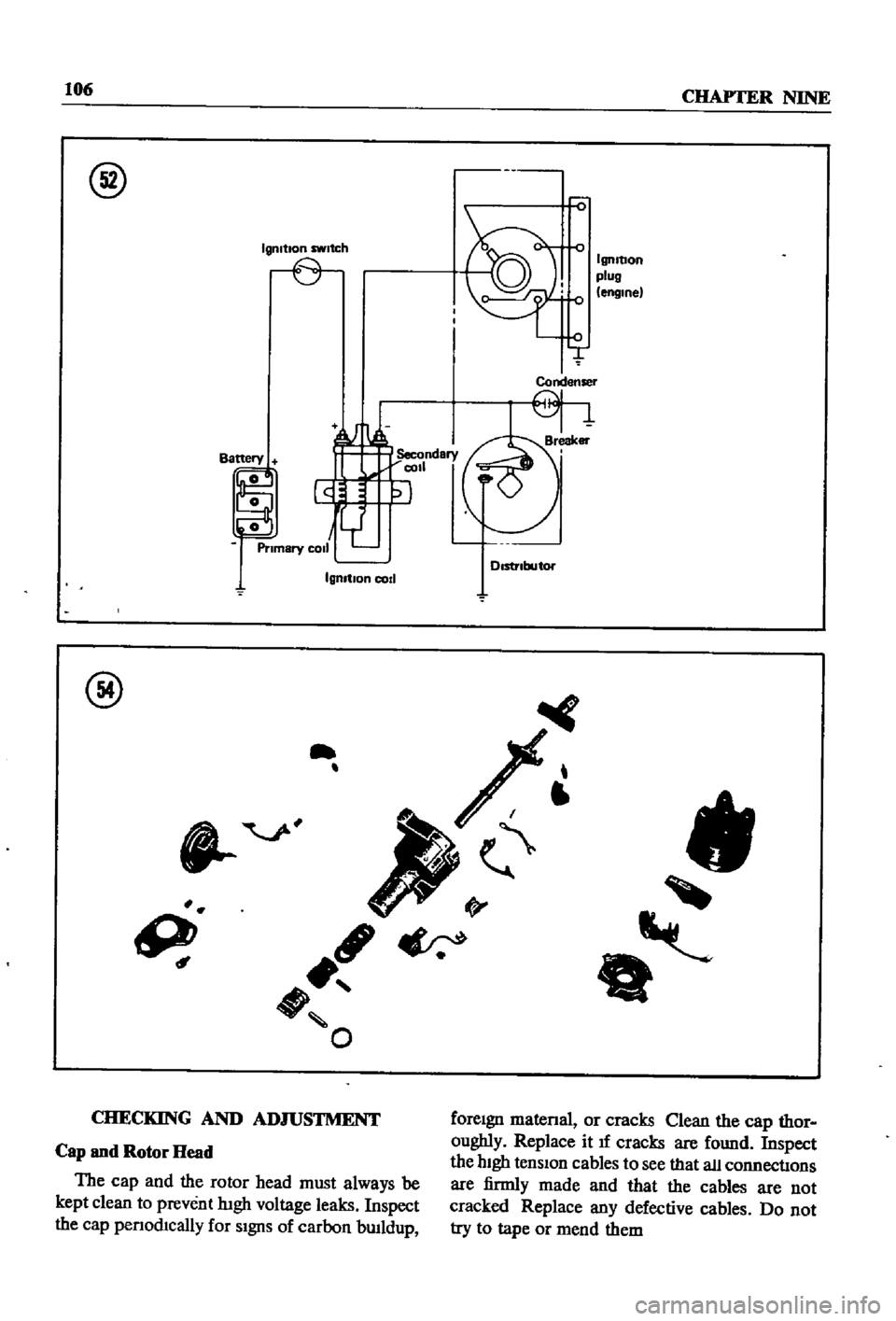

@

Igmtlon

switch

IgnItion

plug

engine

Condenser

IgnItIon

cod

@

II

9

ft

O

CHECKING

AND

ADJUSTMENT

foreIgn

matenal

or

cracks

Qean

the

cap

thor

oughly

Replace

it

If

cracks

are

found

Inspect

the

hIgh

tensIon

cables

to

see

that

all

connectIons

are

firmly

made

and

that

the

cables

are

not

cracked

Replace

any

defective

cables

Do

not

try

to

tape

or

mend

them

Cap

and

Rotor

Head

The

cap

and

the

rotor

head

must

always

be

kept

clean

to

prevent

lugh

voltage

leaks

Inspect

the

cap

penod1cally

for

SIgnS

of

carbon

bwldup

Page 116 of 252

ENGINE

ELECTRICAL

SYSTEM

111

@

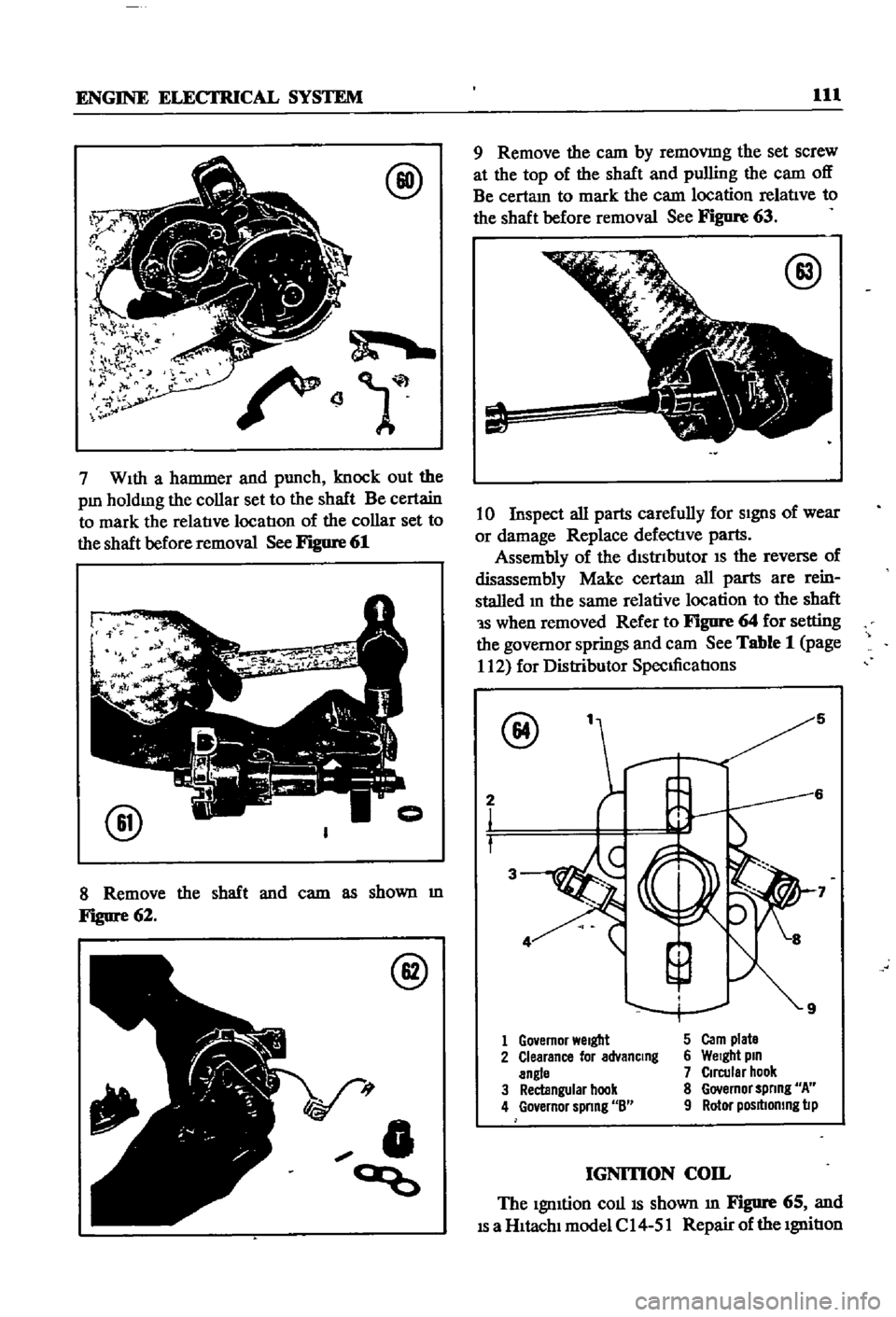

7

WIth

a

hammer

and

punch

knock

out

the

pm

holdmg

the

collar

set

to

the

shaft

Be

certain

to

mark

the

relatIve

locatIon

of

the

collar

set

to

the

shaft

before

removal

See

Figure

61

@

8

Remove

the

shaft

and

cam

as

shown

m

Figure

62

@

V

t

0

ao

9

Remove

the

cam

by

removmg

the

set

screw

at

the

top

of

the

shaft

and

pulling

the

cam

off

Be

certam

to

mark

the

cam

location

relatIve

to

the

shaft

before

removal

See

Figure

63

@

10

Inspect

all

parts

carefully

for

SIgnS

of

wear

or

damage

Replace

defectIve

parts

Assembly

of

the

dIStrIbutor

IS

the

reverse

of

disassembly

Make

certam

all

parts

are

rein

stalled

m

the

same

relative

location

to

the

shaft

1S

when

removed

Refer

to

Figure

64

for

setting

the

governor

springs

and

cam

See

Table

1

page

112

for

Distributor

SpecIficatIons

@

5

2

3

1

Go

emor

Welgbt

5

Carn

plate

2

Clearance

lor

advanCing

6

Welgbt

pin

angle

7

Circular

hook

3

Rectangular

hook

8

Governor

spnng

A

4

Go

ernor

spnng

8

9

Rotor

posltlomng

lip

IGNITION

COIL

The

IgnItion

COllIS

shown

m

Figure

65

and

IS

a

HItachI

model

C

14

51

Repair

of

the

IgnitIon

Page 118 of 252

ENGINE

ELECI

RICAL

SYSTEM

113

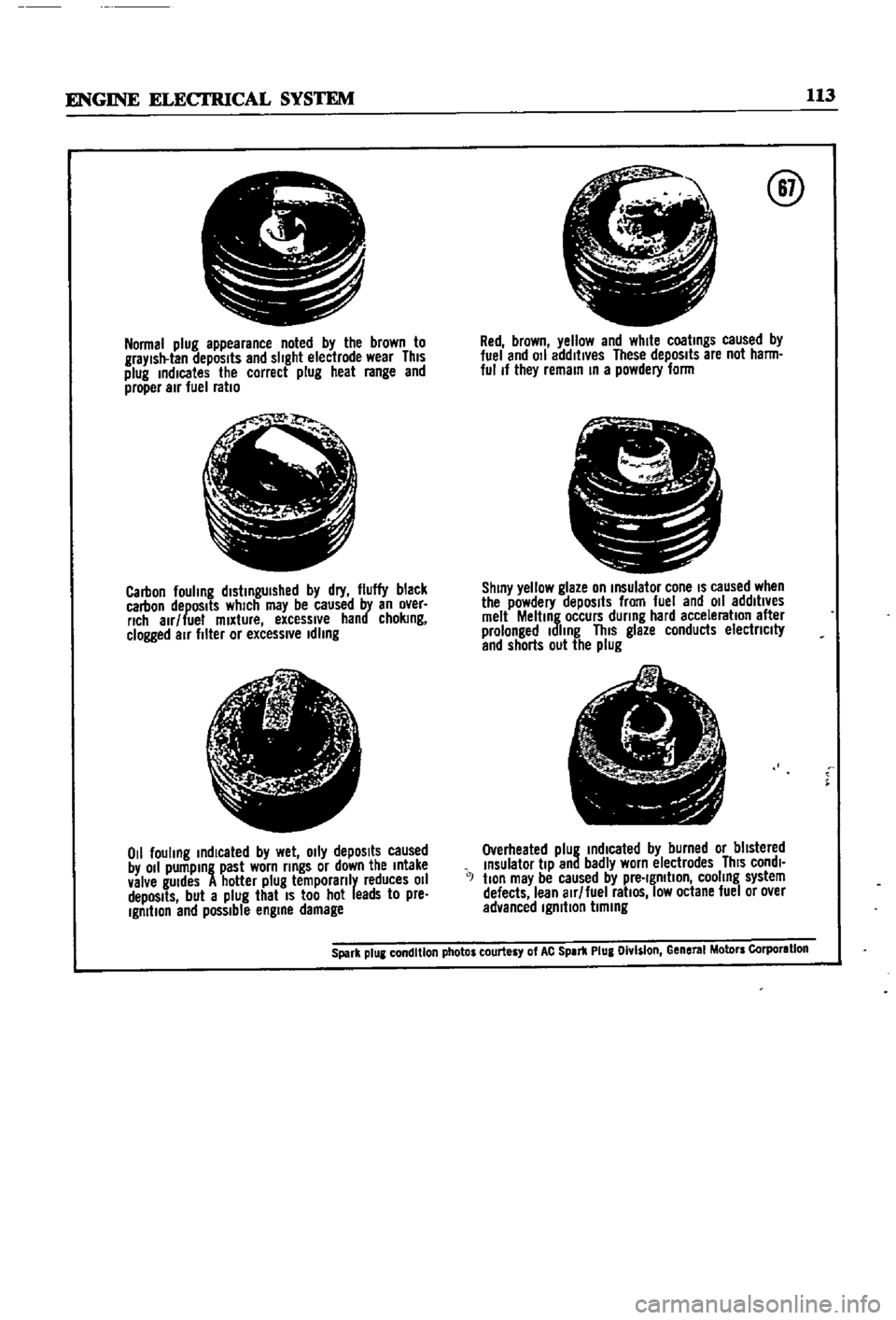

i

Normal

plug

appearance

noted

by

the

brown

to

graYlsll

lan

depOSits

and

slight

eleclrode

wear

This

plug

indicates

the

correct

plug

heal

range

and

proper

air

fuel

ratio

jI

Jo

t

Ql

i

Carbon

fouhng

distinguished

by

dry

fluffy

black

carbon

depOSits

which

may

be

caused

by

an

over

rich

alr

lue

mixture

excessive

hand

choking

clogged

air

filler

or

excessl

e

Idling

t

I

j

if

r

l

1

tfc

ji

0

1

fouling

indicated

by

wet

o

ly

depOSits

caused

by

011

pumping

past

worn

rings

or

down

the

Intake

valve

gUIdes

A

hotter

plug

temporanly

reduces

011

depOSits

but

a

plug

that

IS

too

hot

leads

to

pre

Ignition

end

possible

engine

damage

@

Red

brown

yellow

and

white

coatings

caused

by

luel

and

011

addltl

es

These

depOSits

are

not

harm

ful

If

they

remain

In

a

powdery

lorm

pr

11

L

J

J

S

C

ShinY

yellow

glaze

on

Insulalor

cone

IS

caused

when

the

powdery

depOSits

from

fuel

and

011

addltl

es

melt

Melting

occurs

during

hard

acceleration

alter

prolonged

Idling

This

glaze

conducts

electnclty

and

shorts

out

the

plug

e

1

A

I

A

I

7

Overheated

plug

indIcated

by

burned

or

blistered

Insulator

tiP

and

badly

worn

electrodes

ThiS

condl

J

tlon

may

be

caused

by

pre

Ignition

cooling

system

defects

lean

alr

luel

ratiOS

low

octane

luel

or

o

er

advanced

Ignition

timing

Spark

plUI

condition

photos

courtesy

of

AC

SPIr1l

Plug

Olv

s

on

Gene

MolDrs

Corporlllon

Page 119 of 252

CHAPTER

TEN

EMISSION

CONTROL

SYSTEM

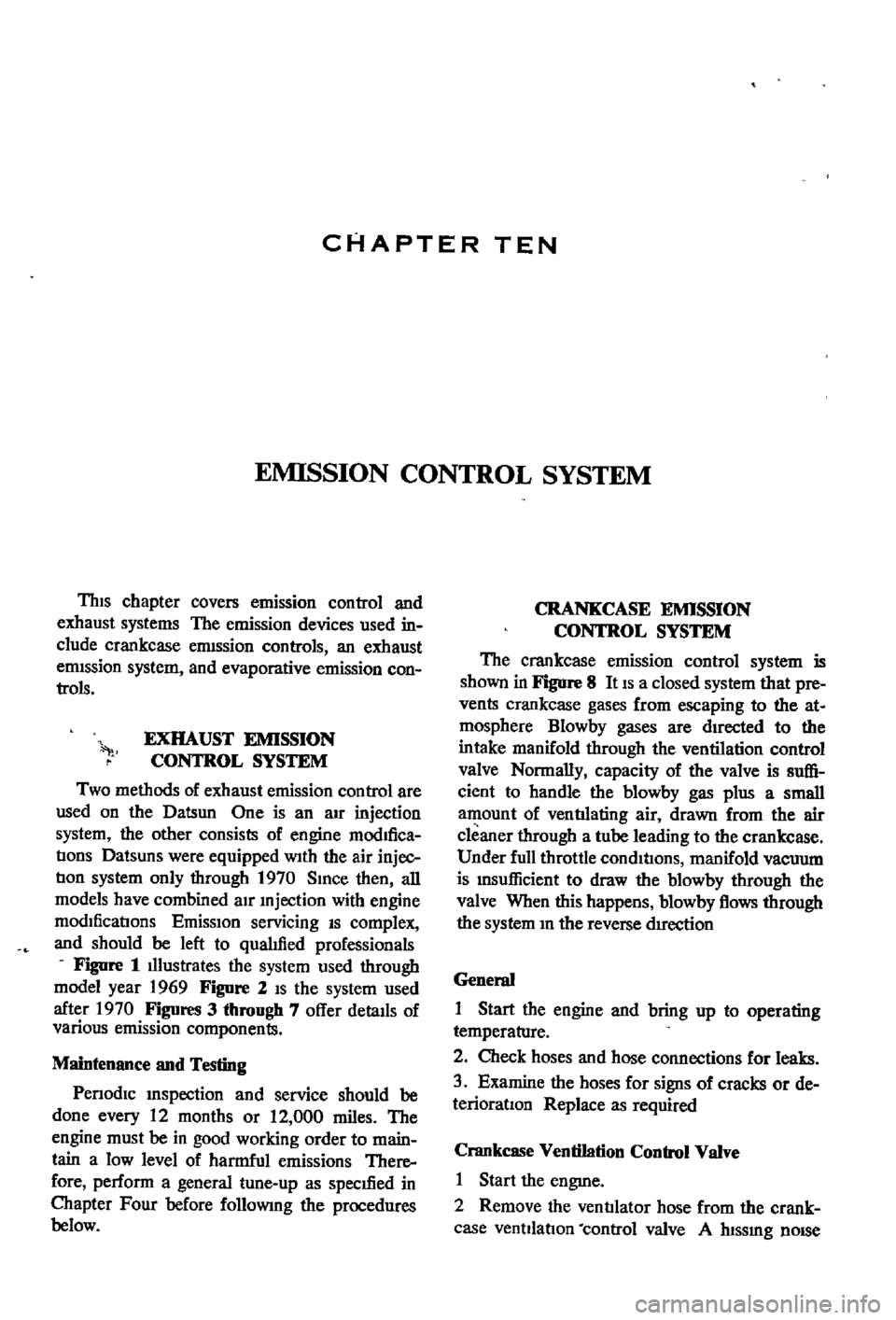

ThIs

chapter

covers

emission

control

and

exhaust

systems

The

emission

devices

used

in

clude

crankcase

ermssion

controls

an

exhaust

ermssion

system

and

evaporative

emission

con

trols

EXHAUST

EMISSION

CONTROL

SYSTEM

Two

methods

of

exhaust

emission

control

are

used

on

the

Datsun

One

is

an

aIr

injection

system

the

other

consists

of

engine

modifica

tIons

Datsuns

were

equipped

With

the

air

injec

tIon

system

only

through

1970

SInce

then

all

models

have

combined

aIr

mjection

with

engine

modIficatIons

EmisSIon

servicing

IS

complex

and

should

be

left

to

qualIfied

professionals

Figure

1

Illustrates

the

system

used

through

model

year

1969

Figure

2

IS

the

system

used

after

1970

Figures

3

through

7

offer

detaIls

of

various

emission

components

Maintenance

and

Testing

Penodlc

mspection

and

service

should

be

done

every

12

months

or

12

000

miles

The

engine

must

be

in

good

working

order

to

main

tain

a

low

level

of

harmful

emissions

There

fore

perform

a

general

tune

up

as

spec1fied

in

Chapter

Four

before

followmg

the

procedures

below

CRANKCASE

EMISSION

CONTROL

SYSTEM

The

crankcase

emission

control

system

is

shown

in

FlgDre

8

It

IS

a

closed

system

that

pre

vents

crankcase

gases

from

escaping

to

the

at

mosphere

Blowby

gases

are

dIrected

to

the

intake

manifold

through

the

ventilation

control

valve

Normally

capacity

of

the

valve

is

suffi

cient

to

handle

the

blowby

gas

plus

a

small

amount

of

ventIlating

air

drawn

from

the

air

cleaner

through

a

tube

leading

to

the

crankcase

Under

fun

throttle

condItIons

manifold

vacuum

is

Insufficient

to

draw

the

blowby

through

the

valve

When

this

happens

b10wby

flows

through

the

system

In

the

reverse

dIrection

General

1

Start

the

engine

and

bring

up

to

operating

temperature

2

Check

hoses

and

hose

connections

for

leaks

3

Examine

the

hoses

for

signs

of

cracks

or

de

terioraoon

Replace

as

required

Crankcase

Ventilation

Control

Valve

1

Start

the

engme

2

Remove

the

ventIlator

hose

from

the

crank

case

ventilatIon

control

valve

A

htssmg

nOISe

Page 122 of 252

EMISSION

CONTROL

SYSTEM

117

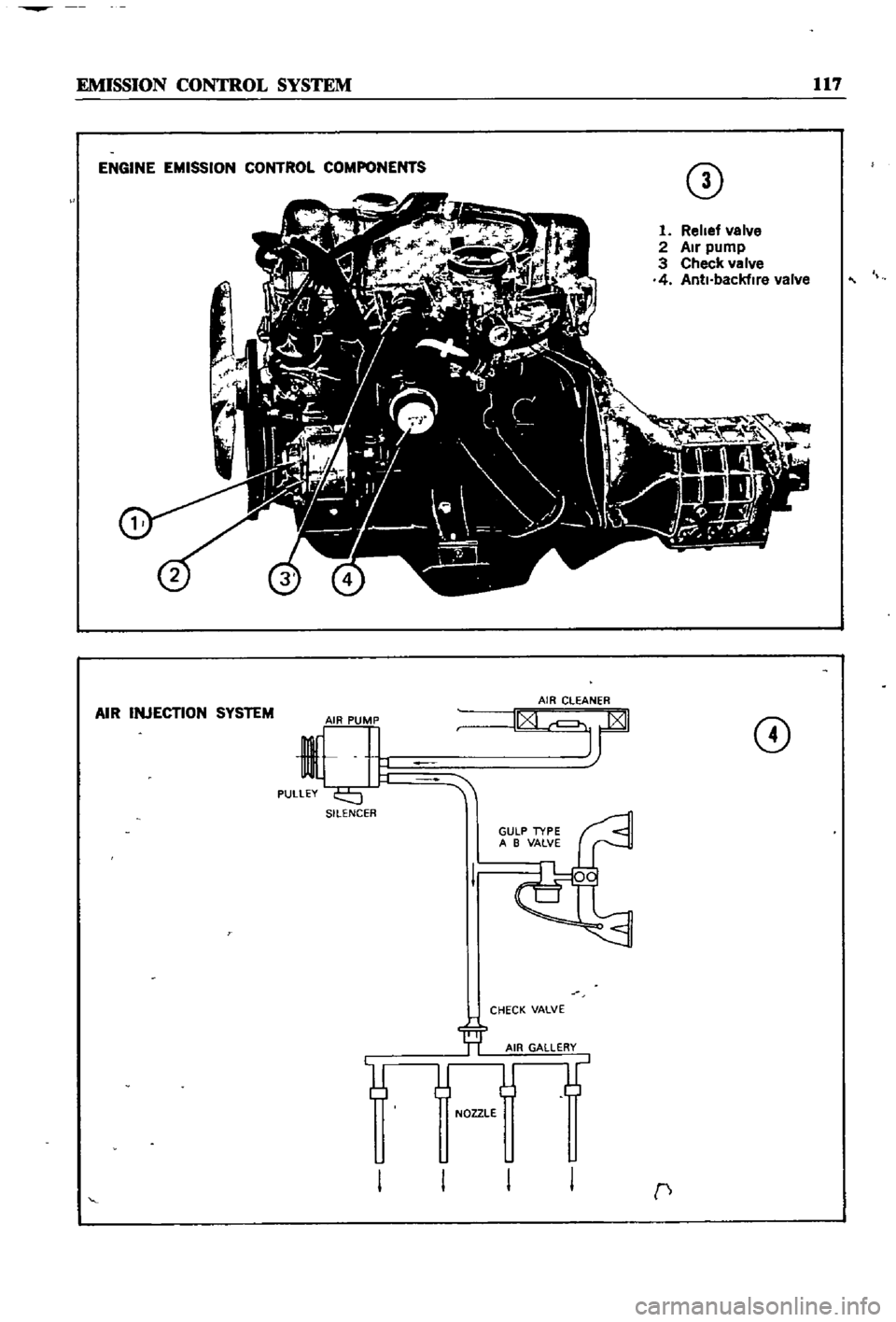

ENGINE

EMISSION

CONTROL

COMPONENTS

CD

1

Relief

valve

2

Air

pump

3

Check

valve

4

Anti

backfire

valve

AIR

INJECTION

SYSTEM

CD

SILENCER

CHECK

VALVE

NOZZLE

c

Page 127 of 252

122

CHAPTER

TEN

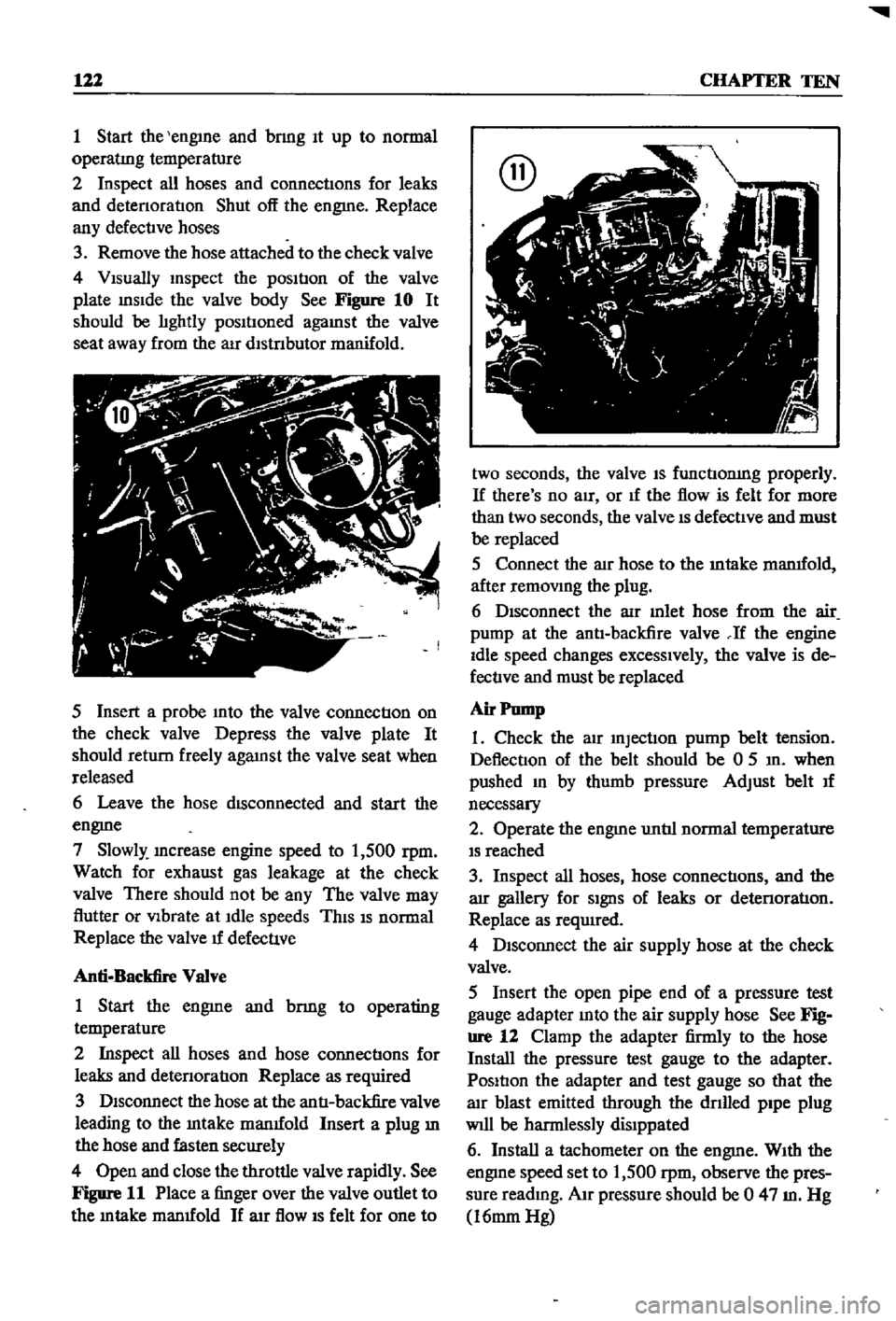

1

Start

the

engIne

and

bnng

It

up

to

normal

operatIng

temperature

2

Inspect

all

hoses

and

connectIons

for

leaks

and

detenoratIon

Shut

off

the

engme

Replace

any

defectIve

hoses

3

Remove

the

hose

attached

to

the

check

valve

4

VIsually

Inspect

the

posItIon

of

the

valve

plate

InsIde

the

valve

body

See

Figure

10

It

should

be

lIghtly

posItIoned

agaInst

the

valve

seat

away

from

the

aIr

dlstnbutor

manifold

5

Insert

a

probe

Into

the

valve

connectIon

on

the

check

valve

Depress

the

valve

plate

It

should

return

freely

agaInst

the

valve

seat

when

released

6

Leave

the

hose

dISconnected

and

start

the

engme

7

Slowly

Increase

engine

speed

to

1

500

rpm

Watch

for

exhaust

gas

leakage

at

the

check

valve

There

should

not

be

any

The

valve

may

flutter

or

VIbrate

at

Idle

speeds

ThIS

IS

normal

Replace

the

valve

u

defecuve

Anti

Backfire

Valve

1

Start

the

engme

and

bnng

to

operating

temperature

2

Inspect

all

hoses

and

hose

connectIons

for

leaks

and

detenoratIon

Replace

as

required

3

DIsconnect

the

hose

at

the

antI

backfire

valve

leading

to

the

Intake

manuold

Insert

a

plug

ill

the

hose

and

fasten

securely

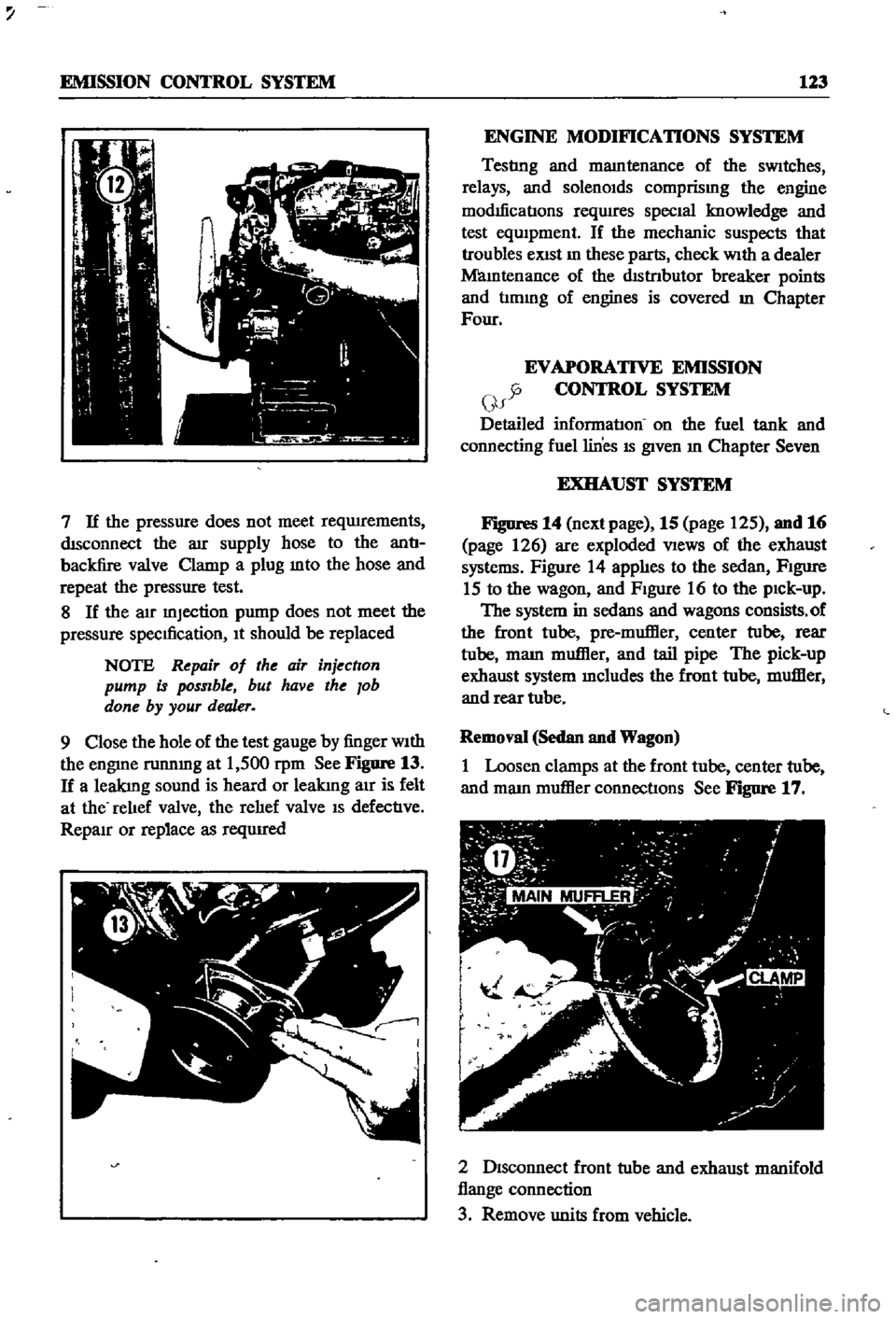

4

Open

and

close

the

throttle

valve

rapidly

See

Figure

11

Place

a

finger

over

the

valve

outlet

to

the

m

take

manuold

If

arr

flow

IS

felt

for

one

to

two

seconds

the

valve

IS

functIonIng

properly

If

there

s

no

aIr

or

If

the

flow

is

felt

for

more

than

two

seconds

the

valve

IS

defectIve

and

must

be

replaced

5

Connect

the

alr

hose

to

the

mtake

manuold

after

remOVIng

the

plug

6

DIsconnect

the

aIr

mlet

hose

from

the

air

pump

at

the

antI

backfire

valve

If

the

engine

Idle

speed

changes

excessIvely

the

valve

is

de

fectIve

and

must

be

replaced

Air

Pump

1

Check

the

atr

InjectIon

pump

belt

tension

DeflectIon

of

the

belt

should

be

0

5

In

when

pushed

In

by

thumb

pressure

Adjust

belt

u

necessary

2

Operate

the

engme

untIl

normal

temperature

IS

reached

3

Inspect

all

hoses

hose

connectIons

and

the

arr

gallery

for

SIgnS

of

leaks

or

detenoratIon

Replace

as

required

4

DIsconnect

the

air

supply

hose

at

the

check

valve

5

Insert

the

open

pipe

end

of

a

pressure

test

gauge

adapter

Into

the

air

supply

hose

See

Fig

ure

12

Clamp

the

adapter

firmly

to

the

hose

Install

the

pressure

test

gauge

to

the

adapter

PosItIon

the

adapter

and

test

gauge

so

that

the

alr

blast

emitted

through

the

dnlled

pipe

plug

Will

be

harmlessly

dislppated

6

Install

a

tachometer

on

the

engme

WIth

the

engIne

speed

set

to

1

500

rpm

observe

the

pres

sure

readmg

AIr

pressure

should

be

0

47

m

Hg

16mm

Hg

Page 128 of 252

EMISSION

CONTROL

SYSTEM

123

7

If

the

pressure

does

not

meet

reqwrements

dISconnect

the

aIr

supply

hose

to

the

antI

backfire

valve

Clamp

a

plug

mto

the

hose

and

repeat

the

pressure

test

8

If

the

air

mJection

pump

does

not

meet

the

pressure

specIfication

It

should

be

replaced

NOTE

Repair

of

the

air

injection

pump

is

possible

but

have

the

lob

done

by

your

dealer

9

Close

the

hole

of

the

test

gauge

by

finger

With

the

engme

runnmg

at

1

500

rpm

See

Figure

13

If

a

leakIng

sound

is

heard

or

leakIng

air

is

felt

at

the

relIef

valve

the

relIef

valve

IS

defectIve

RepaIr

or

replace

as

reqUIred

ENGINE

MODIFICATIONS

SYSTEM

Testlng

and

mamtenance

of

the

sWitches

relays

and

solenOIds

comprismg

the

engine

modIficatIons

reqwres

SpecIal

knowledge

and

test

eqUIpment

If

the

mechanic

suspects

that

troubles

eXist

In

these

parts

check

With

a

dealer

Mamtenance

of

the

dIstrIbutor

breaker

points

and

tImmg

of

engines

is

covered

m

Chapter

Four

EVAPORATIVE

EMISSION

y

CONTROL

SYSTEM

f

Detailed

informatIon

on

the

fuel

tank

and

connecting

fuel

lines

IS

given

In

Chapter

Seven

EXHAUST

SYSTEM

Figures

14

next

page

15

page

125

and

16

page

126

are

exploded

VIews

of

the

exhaust

systems

Figure

14

applIes

to

the

sedan

FIgure

15

to

the

wagon

and

FIgure

16

to

the

pIck

up

The

system

in

sedans

and

wagons

consists

of

the

front

tube

pre

muffier

center

tube

rear

tube

mam

muffier

and

tail

pipe

The

pick

up

exhaust

system

mcludes

the

front

tube

muffier

and

rear

tube

Removal

Sedan

and

Wagon

1

Loosen

clamps

at

the

front

tube

center

tube

and

mam

muffier

connectIons

See

Figure

17

2

DIsconnect

front

tube

and

exhaust

manifold

flange

connection

3

Remove

units

from

vehicle