engine DATSUN 510 1968 Service Service Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1968, Model line: 510, Model: DATSUN 510 1968Pages: 252, PDF Size: 12.2 MB

Page 65 of 252

60

SIX

Table

1

ENGINE

SERVICE

DATA

AND

SPECIFICATIONS

GENERAL

SPECIFICATIONS

Cylinder

Arrangement

DIsplacement

Bore

and

Stroke

Valve

Arrangement

MaxImum

Brake

Horsepower

MaxImum

Gross

Torque

Firing

Order

Engme

dle

Smgle

POint

Dual

Pomt

CompressIon

RatIo

Engme

Idle

Mamfold

at

Idle

rpm

011

Pressure

hot

@

2

000

rpm

i

TIGHTENING

TORQUE

ft

Ib

kg

m

Cylinder

Head

Bolts

1st

turn

2nd

turn

Flywheel

Flxmg

Bolts

M

In

Beanng

Cap

Bolts

Camshaft

Gear

Bolt

I

011

Pan

1

1

fF

I

011

Pump

QII

Stramer

F

I

Crank

Pulley

Bolt

SPECIFICATIONS

In

mm

Valve

Mechamsm

Valve

Clearance

Hot

Valve

Clearance

Cold

Valve

Head

DIameter

Intake

Valve

Head

DIameter

Exhaust

Valve

Stem

DIameter

Intake

Valve

Stem

DIameter

Exhaust

Valve

Length

Intake

Valve

Length

Exhaust

Valve

LIft

Valve

Spring

Free

Length

Outer

Valve

Sprmg

Free

Length

Inner

Vaiv

Spnng

Loaded

Length

Outer

Valve

Spring

Loaded

Length

Inner

Valve

Sprmg

Assembllld

HeIght

Outer

Valve

Spnng

Assembled

Helght

Inner

Valve

Spnng

Effective

Turns

Outer

Valve

Sprmg

EffectIve

Turns

Inner

Valve

GUIde

Length

Intake

Valve

GUIde

Length

Exhaust

Valve

GUIde

HeIght

from

Head

Surface

Valve

GUIde

Inner

DIameter

Intake

Valve

GUIde

Inner

DIameter

Exhaust

Va

Ive

GUIde

Outer

Dlam

eter

Intake

Valve

GUIde

Outer

DIameter

Exhaust

Valve

GUIde

to

Stem

Clearance

Intake

Valve

GUIde

to

Stem

Clearance

Exhaust

Valve

eat

W

dth

Intake

Valve

SEtat

WIdth

Exhaust

4

m

Ilnil

97

3

cu

m

1595cc

3

2677

x

2

9016

In

83

x

73

7mm

Overhead

Camshaft

96

@

5

600

rpm

110

ft

Ib

13

8

kg

m

@

3

600

rpm

1

3

4

2

r

600

rpm

700

pm

85

1

i7

7

In

Hg

450mm

Hg

54

to

60

Ib

m

2

3

8

tQ

4

2

Iig

cm

325

4

5

39

8

5

5

68

No

75

9

9

50

to

1039

325

to

39

8

4

5

to

5

5

362

to

43

4

50

to

60

2

9

to

5

1

0

4

to

0

7

108

to

15

2

1

5

to

2

1

58t087

08to

12

1157

to

130

1

160

to

180

o

118

0

30

o

0C

98

0

25

1

50

38

0

1

30

33

0

031

80

031

80

456

1159

4

57

116

O

03937

100

2

05

52

0

1

77

44

96

1

21

@

1054

Ib

3

07

@

47

8

kg

o

96

@

56

Ib

24

5

@

25

5

kg

1

53

@

63

9

Ib

38

9

@

29

0

kg

1

38

@

27

1

Ib

35

@

123

kg

45

I

55

2

32

59

0

2

32

59

0

0409

to

0

417

104

to

106

0315

to

03154

80

to

8018

0315

to

03154

80

to

8

Oi8

04718

to

04723

11

985

to

11

996

04718

to

04723

11

985

to

11

996

00006

to

00018

0

015

to

0

045

00016

to

00028

0040

to

0070

o

055

to

0

071

1

4

to

1

8

0063

to

0079

1

6

to

20

Page 66 of 252

ENGINE

61

SPECIFICATIONS

In

mm

continued

Valve

Seat

Interference

Fit

Intake

Valve

Seat

Interference

Flt

Exh

ust

Valve

GUide

Interference

fit

I

Camshaft

and

Timing

Chain

Ca

mshaft

End

Play

Camshaft

Lobe

LIft

Camshaft

Journal

Diameter

Camshaft

Bend

Camshaft

Bearing

Inner

Diameter

Camshaft

Journal

to

B

arlng

Clearance

Rocker

Arm

Lever

Ratio

Connecting

Rod

Center

Distance

Standard

Bearing

Thickness

Big

End

Play

Connectmg

Rod

Beanng

Clearance

Connecting

Rod

Bend

per

3

937

In

100mm

Crankshaft

and

Main

Beanng

Journal

Diameter

Journal

Taper

and

Out

ot

Round

Crankshaft

Free

End

Play

Crank

Pin

Diameter

Crank

Pin

Taper

and

Out

ot

Round

Main

Bearing

Thickness

Main

Beanng

Clearance

Crankshaft

Bend

Piston

Standard

Diameter

Ellipse

Difference

Ring

Groove

Top

Second

011

Piston

to

Bore

Clearance

Piston

Pm

Hole

Offset

Piston

Pin

Piston

Pin

Diameter

Piston

Pin

Length

Piston

Pin

to

Piston

Clearance

Interference

Fit

ot

Piston

Pin

to

Connecting

Rod

Bushing

Piston

Ring

Ring

Height

Top

Second

011

Side

Clearance

Top

Second

011

Ring

Gap

Top

Second

011

Table

1

ENGINE

SERVICE

DATA

AND

SPECIFicATIONS

continued

00031

to

0

0043

0

OB

to

0

11

00024

to

0

0039

006

to

0

10

00011

to

00019

0027

to

0049

00031

to

0

0150

0

08

to

0

38

o

261

6

63

18877

to

1

8883

47

949

to

47

962

o

0020

0

05

1

8898

to

1

8904

48

0

to

48

016

00015

to

0

0026

0038

to

0

076

15

5

507

to

5

509

139

87

to

139

93

o

0588

to

0

0593

1

493

to

1

506

00079

to

0

0118

0

20

to

030

o

0006

to

0

0022

0

014

to

0

056

o

0012

003

2

1631

to

2

1636

54

942

to

54

955

less

than

00012

003

o

002

to

0

0059

0

05

to

0

15

1

9670

to

1

9675

49961

to

49

975

less

than

0

0012

0

03

o

0717

to

0

0722

1

822

to

1

835

o

0008

to

0

0028

0

020

to

0

072

00019

005

3267

to

3

269

8299

to

83

04

0013

to

0014

032

to

035

008

20

o

08

2

0

o

16

4

0

00010

to

0

0018

0

025

to

0

045

00394

0

0020

1

O

0

05

o

8266

to

0

8268

20

995

to

21

0

0

2

8346

to

2

8445

72

00

to

72

251

o

0003

to

0

0004

0

OOS

to

0

OlD

00006

to

0

0013

0015

to

0

033

o

0787

2

0

o

0787

2

0

o

1575

40

00018

to

00031

0

045

to

0

078

00012

to

0

0025

0030

to

0

063

00010

to

00025

0025

to

0

063

i

J

I

n

T

00091

to

0

0150

023

to

038

00059

to

0

0118

0

15

to

0

30

00059

to

0

0118

0

15

to

0

30

Page 70 of 252

FUEL

SYSTEM

6S

CD

2

Remove

the

fuel

stramer

from

Its

mountlng

clIp

3

Replace

the

fuel

stramer

as

reqUIred

4

Reconnect

the

mtake

and

outlet

fuellmes

FUEL

PUMP

The

fuel

pump

conSISts

of

a

body

rocker

arm

and

lmk

assembly

dIaphragm

dIaphragm

spring

seal

and

mlet

and

outlet

valves

The

l

r

t

1

9

l

F

r

fl

rocker

arm

IS

dnven

by

a

pump

cam

mounted

on

the

catnShaft

In

the

front

part

of

the

rocker

arm

front

cover

assembly

Figure

S

shows

the

fuel

pump

for

all

models

through

1970

Figure

6

illustrates

the

fuel

pump

for

1971

and

later

models

Fuel

pump

Testing

Fuel

pump

pressure

and

fuel

pump

capacity

testlng

are

performed

m

tests

descnbed

below

Both

tests

are

performed

With

the

fuel

pump

mounted

to

the

engme

Static

Pressure

Test

1

DIsconnect

the

carburetor

fuel

lme

at

the

carburetor

2

Install

an

adapter

and

a

tee

fittmg

to

the

fuel

lIne

and

attach

a

SUItable

pressure

gauge

3

Connect

adapter

to

carburetor

4

Start

and

run

engine

at

varymg

speeds

5

The

gauge

reading

IS

static

fuel

pressure

It

should

remam

between

256

and

341

Ib

m

2

018

to

0

24

kg

cm2

Pressure

below

thelower

lImIt

mdlcates

extreme

wear

on

one

part

or

gen

eral

wear

on

several

pump

parts

Pressure

above

the

upper

hrmt

indIcates

an

excessIvely

strong

diaphragm

spnng

or

a

dIaphragm

that

is

too

tIght

Both

condItIons

require

the

removal

of

the

fuel

pump

for

necessary

repaIr

or

replacement

Page 76 of 252

FUEL

SYSTEM

71

Dash

Pot

Adjustment

The

adjustment

of

the

dash

pot

IS

done

by

warmmg

up

the

engme

properly

and

checkIng

If

the

throttle

lever

touches

th

dash

pot

stem

as

the

engine

reaches

1

800

and

2

000

rpm

under

no

load

conditIons

Proper

contact

between

the

throttle

lever

and

the

dash

pot

stem

produces

a

normal

dash

pot

performance

Should

a

normal

mcrease

m

engme

speed

not

occur

adjust

the

dash

pot

as

follows

1

Loosen

the

dash

pot

locknuts

2

Rotate

the

dash

pot

nght

and

then

left

3

Adjust

the

dash

pot

so

that

the

throttle

lever

hIts

the

stem

between

1

800

and

2

000

rpm

4

Fasten

the

lock

nuts

securely

5

The

clearance

between

the

throttle

valve

and

the

throttle

chamber

wall

should

be

0

0709

m

0

8mm

or

10

degrees

In

throttle

valve

angle

MAJOR

CARBURETOR

SERVICE

PROCEDURES

A

carburetor

m

good

operatIng

condition

will

delIver

the

pr

per

gasolme

and

aIr

ratIos

for

all

engme

runnmg

speeds

A

gradual

declme

In

smoothness

response

and

power

Will

occur

as

the

carburetor

slIps

from

adjustment

and

Its

delI

cate

parts

become

dirty

and

worn

Overhaul

should

only

be

attempted

by

an

expenenced

mechanic

Accurate

calIbratIon

of

passages

and

dIS

charge

hole

reqUIre

that

extreme

care

be

taken

In

dISassembly

cleanmg

and

reassembly

Use

only

a

hIgh

grade

carburetor

cleaner

and

com

pressed

arr

to

clean

parts

and

passages

Never

use

wire

or

other

pOInted

Instruments

for

clean

ing

CalIbratIon

of

the

carburetor

will

be

af

fected

The

procedures

below

are

generally

true

for

all

models

As

an

aId

Figures

13

and

14

are

typIcal

examples

of

the

carburetors

used

Carburetor

Removal

1

Remove

the

au

cleaner

by

dIsconnectIng

all

hoses

attached

to

It

remoVmg

the

two

bolts

holdmg

the

aIr

cleaner

to

the

support

and

loos

enmg

the

band

bolt

at

the

base

of

the

aIr

cleaner

2

DIsconnect

fuellme

vacuum

Ime

and

choke

wire

u

eqUIpped

from

the

carburetor

3

Remove

the

throttle

lever

4

Remove

four

nuts

and

washers

holdmg

car

buretor

to

manIfold

5

Lift

carburetor

off

of

manuold

6

Remove

and

dIscard

carburetor

to

manuold

gasket

7

Place

carburetor

on

clean

workbench

Carburetor

Disassembly

1

The

maIn

Jets

slow

Jets

and

needle

valves

on

both

the

pnmary

and

secondary

systenIS

are

accessIble

from

outsIde

the

carburetor

Refer

to

FIgures

13

and

14

for

locatI

n

2

The

choke

chamber

can

be

detached

by

re

mOVIng

the

connectIng

rod

pump

connectIng

rod

return

sprmg

stop

pm

and

the

set

screws

I

that

hold

It

in

place

3

The

pnmary

and

secondary

emulSIon

tubes

can

be

disassembled

by

remOVIng

the

mam

air

bleeds

on

the

respectIve

SIdes

4

To

check

the

accelerator

pump

remove

the

cylInder

cover

Be

careful

not

to

lose

the

return

spnng

and

Inlet

valve

at

the

lower

part

of

the

pIston

durmg

dIsassembly

5

Detach

the

throttle

chamber

from

the

float

chamber

by

remOVIng

the

rod

lInkIng

the

dia

phragm

WIth

the

secondary

throttle

valve

and

the

four

screws

that

hold

It

However

It

IS

preferable

to

leave

the

throttle

valve

mtact

unless

absolutely

reqUired

If

It

IS

necessary

to

dlS

assemble

the

valve

It

should

be

Installed

so

that

the

secondary

throttle

valve

will

be

gap

free

OtherwIse

stable

Idle

and

good

slow

speed

performance

will

suffer

is

To

check

the

float

the

float

chamber

cover

must

be

removed

I

7

The

dIaphragm

IS

dIsassembled

by

removing

the

set

screws

holdmg

the

dIaphragm

chamber

cover

In

reassemblIng

the

diaphragm

be

careful

not

to

turn

the

edge

of

the

dIaphragm

up

8

In

dlsassemblmg

and

reassembling

the

mter

lockIng

lInks

take

care

so

that

each

lInkage

has

a

smooth

actIon

and

that

parts

are

not

forced

mto

pOSItIon

9

For

vehIcles

equipped

With

an

automatIc

choke

remove

the

brmetal

case

by

releasmg

the

set

screws

The

bimetal

1l

extremely

senSItIve

Page 90 of 252

COOLING

SYSTEM

8S

and

In

those

with

exhaust

and

evaporatIve

emIS

sion

control

devIces

a

fan

clutch

IS

combIned

WIth

the

thermostat

to

detect

temperature

m

the

engme

compartlnent

When

the

temperature

nses

the

thermostat

detects

the

change

an

the

fan

clutch

engages

thereby

helpmg

to

cool

the

engme

WATER

PUMP

Figure

2

page

86

IS

an

exploded

drawmg

of

the

water

pump

and

fan

assembly

for

1970

to

1971

The

top

half

of

the

IllustratIon

applIes

to

those

models

WIth

exhaust

and

evaporatIve

emiSSIOn

control

systems

The

bottom

half

covers

models

WIth

a

crankcase

emiSSIon

control

deVIce

only

Figure

3

page

87

IS

an

exploded

drawmg

of

the

water

pump

and

fan

assembly

for

1968

models

Without

exhaust

or

evaporatIve

controls

Figure

4

page

88

shows

the

1968

model

With

emISSIon

control

deVIce

As

can

be

seen

from

the

illustratIons

most

dIfferences

eXISt

withIn

the

fan

clutch

assembly

Water

Pump

Removal

1

Remove

upper

and

lower

radIator

hoses

from

the

thermostat

housmg

and

cylmder

block

re

spectIvely

Dram

coolant

from

rad1ator

and

cylInder

block

2

Loosen

the

alternator

mountlng

bolt

and

the

adjustIng

bolt

on

the

alternator

mountIng

bracket

3

Move

the

alternator

toward

the

cylinder

block

untIl

slack

IS

eVIdent

10

the

fan

belt

Re

move

fa

belt

fro

alternator

water

pump

and

crankshaft

pulley

4

It

IS

difficult

to

remove

the

water

pump

from

the

front

housmg

With

the

radiator

and

top

shroud

10

place

so

remove

them

5

Remove

the

bolts

holdmg

the

fan

assembly

to

the

water

pump

and

remove

the

fan

assembly

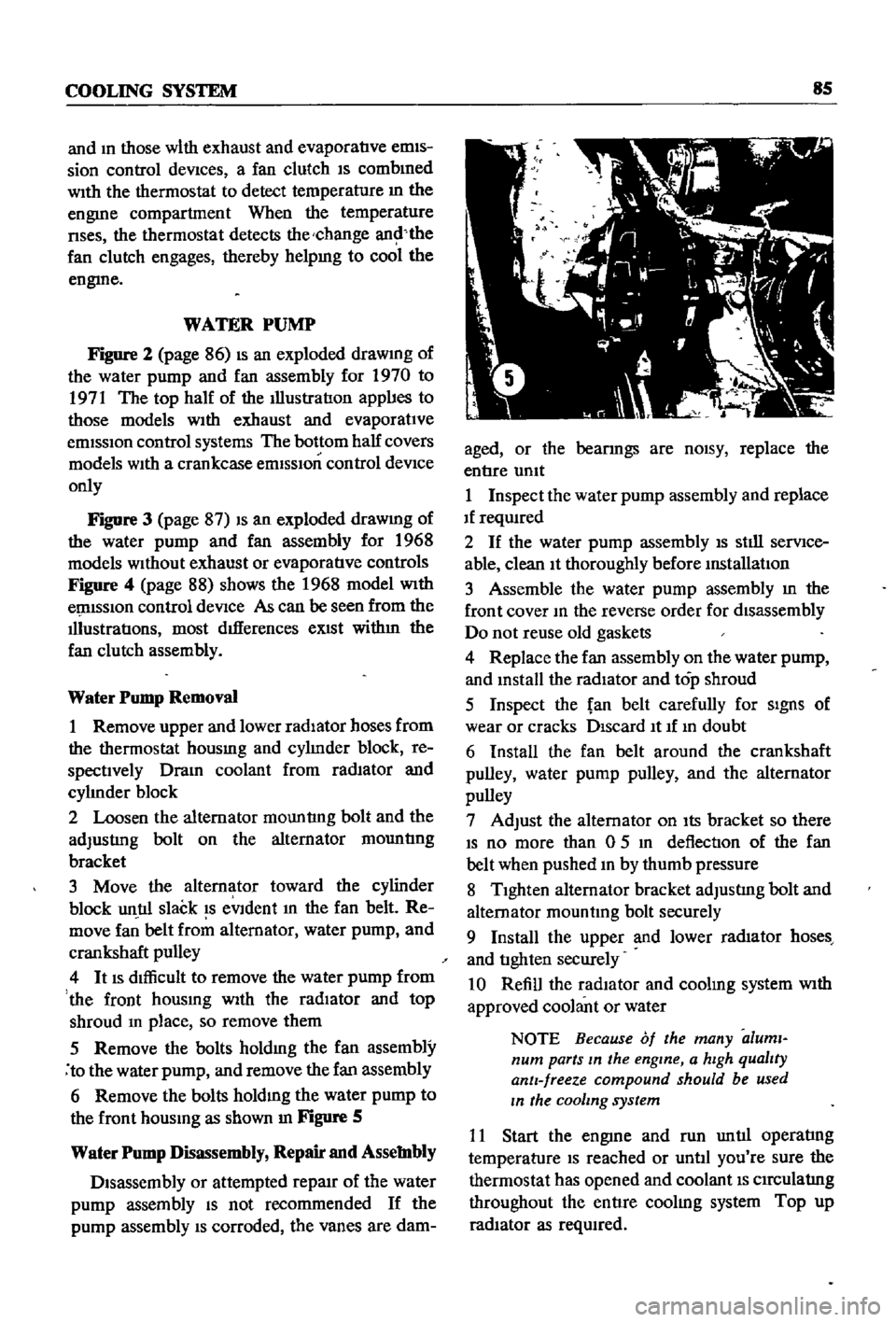

6

Remove

the

bolts

holdmg

the

water

pump

to

the

front

housmg

as

shown

In

Figure

S

Water

Pump

Disassembly

Repair

and

Assembly

Disassembly

or

attempted

repaIr

of

the

water

pump

assembly

IS

not

recommended

If

the

pump

assembly

IS

corroded

the

vanes

are

dam

aged

or

the

bearmgs

are

nOISY

replace

the

entIre

umt

1

Inspect

the

water

pump

assembly

and

replace

If

reqUIred

2

If

the

water

pump

assembly

IS

stIll

serVIce

able

clean

It

thoroughly

before

mstallatIon

3

Assemble

the

water

pump

assembly

m

the

front

cover

10

the

reverse

order

for

disassembly

Do

not

reuse

old

gaskets

4

Replace

the

fan

assembly

on

the

water

pump

and

mstall

the

radiator

and

top

shroud

5

Inspect

the

fan

belt

carefully

for

SIgnS

of

wear

or

cracks

DIscard

It

If

10

doubt

6

Install

the

fan

belt

around

the

crankshaft

pulley

water

pump

pulley

and

the

alternator

pulley

7

Adjust

the

alternator

on

Its

bracket

so

there

IS

no

more

than

0

5

10

deflection

of

the

fan

belt

when

pushed

10

by

thumb

pressure

8

TIghten

alternator

bracket

adjustIng

bolt

and

alternator

mountmg

bolt

securely

9

Install

the

upper

and

lower

rad1ator

hoses

and

tIghten

securely

10

Refill

the

radIator

and

coolmg

system

With

approved

coolant

or

water

NOTE

Because

of

the

many

aluml

num

parts

In

the

engine

a

hIgh

qualIty

antI

freeze

compound

should

be

used

In

the

cooling

system

11

Start

the

engme

and

run

untIl

operatIng

temperature

IS

reached

or

untIl

you

re

sure

the

thermostat

has

opened

and

coolant

IS

CIrCulatIng

throughout

the

entIre

coolIng

system

Top

up

radIator

as

reqUIred

Page 94 of 252

COOLING

SYSTEM

89

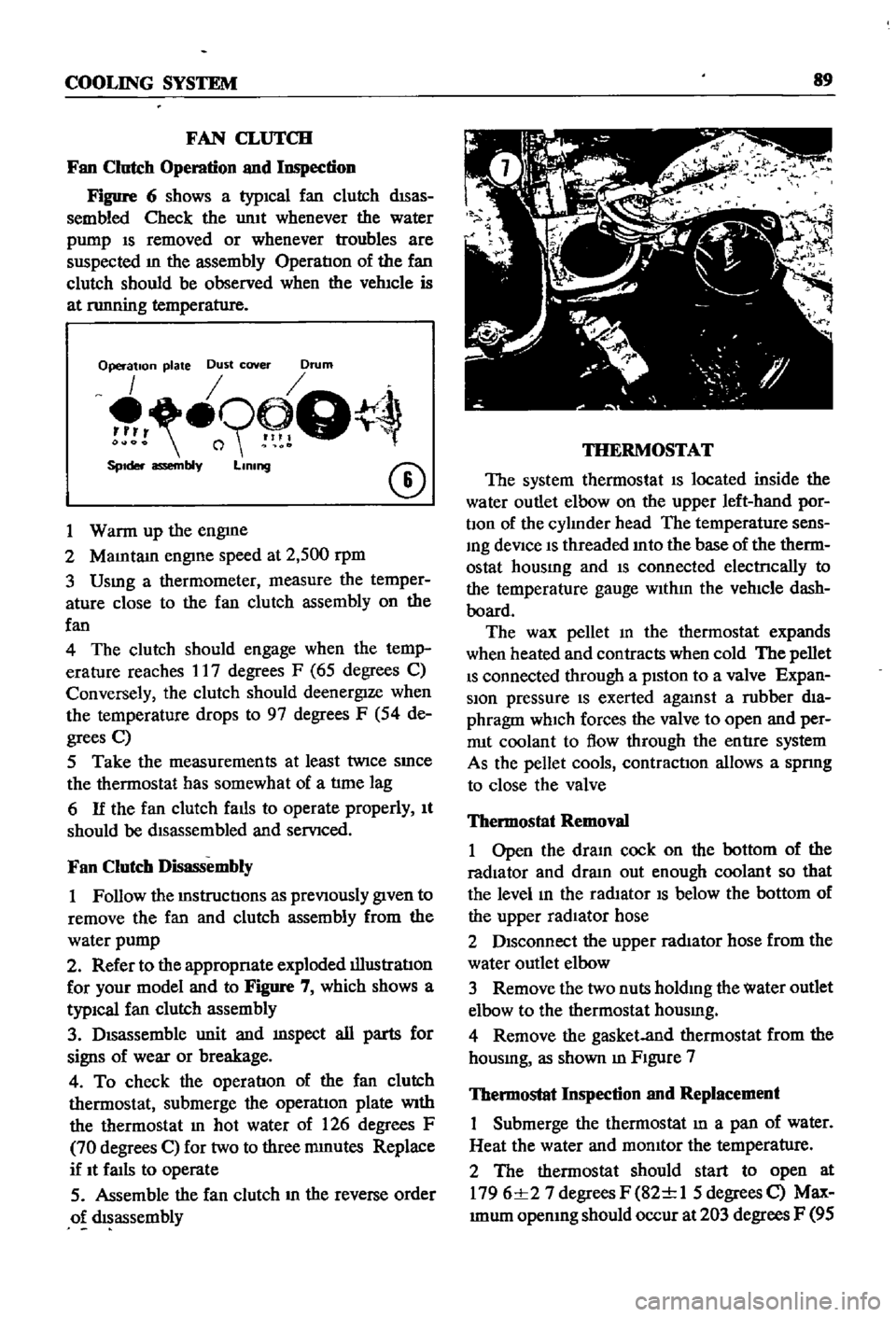

FAN

CLUTCH

Fan

Clutch

Operation

and

Inspection

Figure

6

shows

a

typICal

fan

clutch

dISas

sembled

Check

the

umt

whenever

the

water

pump

IS

removed

or

whenever

troubles

are

suspected

m

the

assembly

OperatIon

of

the

fan

clutch

should

be

observed

when

the

vehIcle

is

at

nmning

temperature

Operation

plate

Dust

cover

Drum

o9

Q

SpIder

assembly

LIning

CD

1

Warm

up

the

engme

2

MaIntam

engIne

speed

at

2

500

rpm

3

Usmg

a

thermometer

measure

the

temper

ature

close

to

the

fan

clutch

assembly

on

the

fan

4

The

clutch

should

engage

when

the

temp

erature

reaches

17

degrees

F

65

degrees

C

Conversely

the

clutch

should

deenergIze

when

the

temperature

drops

to

97

degrees

F

54

de

grees

C

5

Take

the

measurements

at

least

twice

SInce

the

thermostat

has

somewhat

of

a

tlme

lag

6

If

the

fan

clutch

falls

to

operate

properly

It

should

be

dIsassembled

and

servIced

Fan

Clutch

Disassembly

1

Follow

the

mstructIons

as

prevIOusly

gIven

to

remove

the

fan

and

clutch

assembly

from

the

water

pump

2

Refer

to

the

appropnate

exploded

illustratIon

for

your

model

and

to

Figure

7

which

shows

a

typiCal

fan

clutch

assembly

3

DIsassemble

unit

and

mspect

all

parts

for

signs

of

wear

or

breakage

4

To

check

the

operatIon

of

the

fan

clutch

thermostat

submerge

the

operatIon

plate

With

the

thermostat

In

hot

water

of

126

degrees

F

70

degrees

C

for

two

to

three

mmutes

Replace

if

It

faIls

to

operate

5

Assemble

the

fan

clutch

m

the

reverse

order

o

dIsassembly

THERMOSTAT

The

system

thermostat

IS

located

inside

the

water

outlet

elbow

on

the

upper

left

hand

por

bon

of

the

cylInder

head

The

temperature

sens

Ing

deVice

IS

threaded

Into

the

base

of

the

therm

ostat

housmg

and

IS

connected

electrlcally

to

the

temperature

gauge

WIthIn

the

vehIcle

dash

board

The

wax

pellet

m

the

thermostat

expands

when

heated

and

contracts

when

cold

The

pellet

IS

connected

through

a

pIston

to

a

valve

Expan

sion

pressure

IS

exerted

agalUst

a

rubber

dIa

phragm

which

forces

the

valve

to

open

and

per

rrut

coolant

to

flow

through

the

entIre

system

As

the

pellet

cools

contractIOn

allows

a

spnng

to

close

the

valve

Thermostat

Removal

1

Open

the

draIn

cock

on

the

bottom

of

the

radiator

and

dram

out

enough

coolant

so

that

the

level

In

the

radIator

IS

below

the

bottom

of

the

upper

radIator

hose

2

DIsconnect

the

upper

radIator

hose

from

the

water

outlet

elbow

3

Remove

the

two

nuts

holdIng

the

water

outlet

elbow

to

the

thermostat

housmg

4

Remove

the

gasket

and

thermostat

from

the

housmg

as

shown

m

FIgure

7

Thermostat

Inspection

and

Replacement

Submerge

the

thermostat

In

a

pan

of

water

Heat

the

water

and

momtor

the

temperature

2

The

thermostat

should

start

to

open

at

1796

1

27

degrees

F

82

1

1

5

degrees

C

Max

Imum

opemng

should

occur

at

203

degrees

F

95

Page 96 of 252

CHAPTER

NINE

ENGINE

ELECTRICAL

SYSTEM

The

electrIcal

system

has

undergone

slIght

yearly

changes

the

most

SignIficant

being

ill

the

distrIbutor

Some

models

have

a

smgle

contact

pomt

whIle

others

have

a

dual

pomt

system

De

talls

are

covered

m

the

dIstrIbutor

sectlon

The

electrIcal

system

IS

a

12

volt

negatIve

type

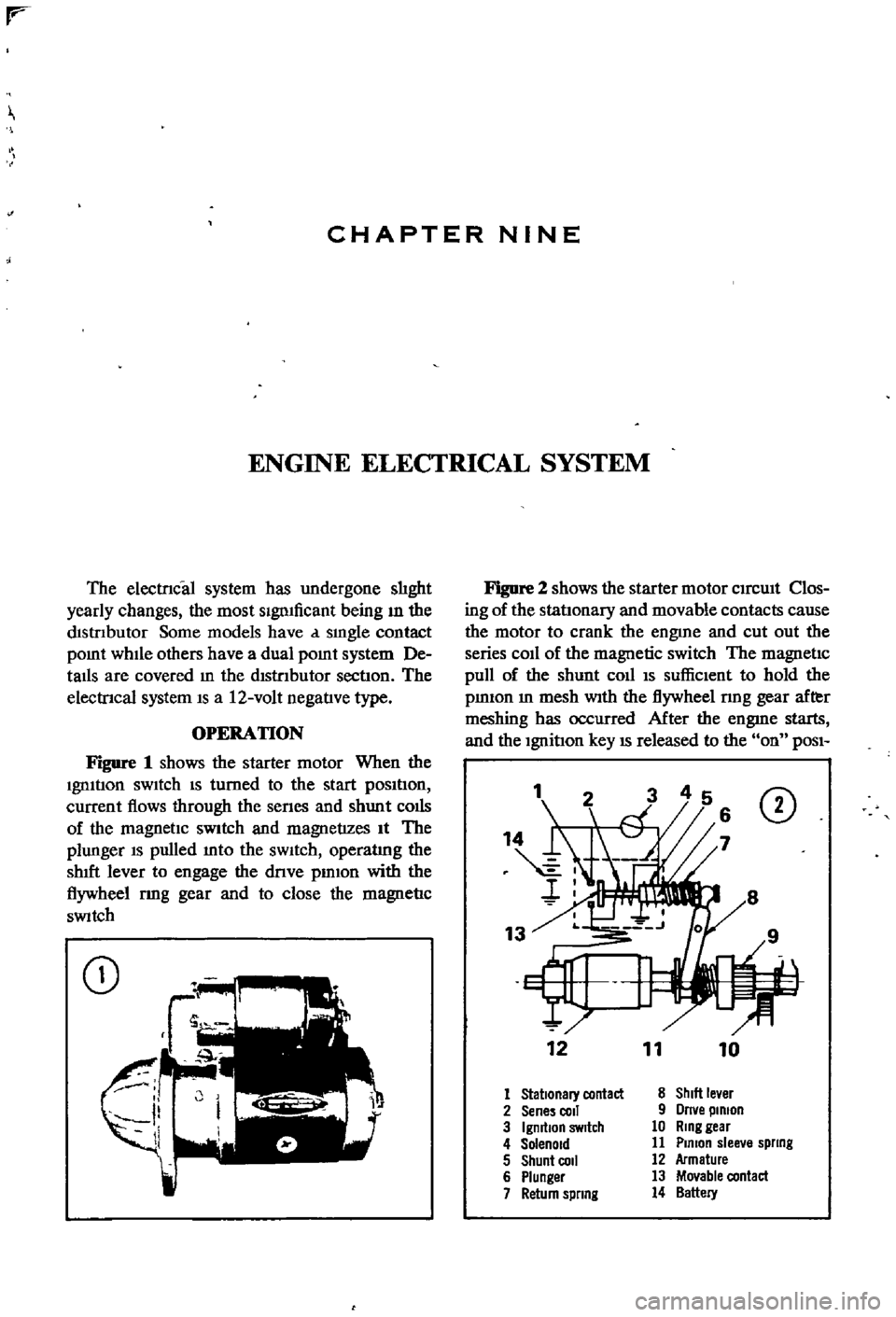

OPERATION

Figure

1

shows

the

starter

motor

When

the

Ignltlon

sWItch

IS

turned

to

the

start

pOSItIon

current

flows

through

the

senes

and

shunt

colis

of

the

magnetIc

SWitch

and

magnetizes

It

The

plunger

IS

pulled

mto

the

sWItch

operatlng

the

shIft

lever

to

engage

the

dnve

pmlon

with

the

flywheel

rmg

gear

and

to

close

the

magnetIc

SWitch

CD

Figure

2

shows

the

starter

motor

CIrcUIt

Clos

ing

of

the

statlonary

and

movable

contacts

cause

the

motor

to

crank

the

engme

and

cut

out

the

series

coIl

of

the

magnetic

switch

The

magnetic

pull

of

the

shunt

coll

IS

suffiCIent

to

hold

the

pmIOn

m

mesh

With

the

flywheel

nng

gear

after

meshing

has

occurred

After

the

engme

starts

and

the

Ignition

key

IS

released

to

the

on

POSI

1

CD

12

11

10

1

Stationary

contact

8

ShIlt

le

er

2

Sene

coli

9

Orne

pinion

3

IgmtlOn

SWitch

10

Ring

gear

4

Solenoid

11

Plmon

slee

e

spllng

5

Shunt

COil

12

Armature

6

Plunger

13

Movable

contact

7

Return

spllng

14

Battery

Page 100 of 252

ENGINE

ELECI

RlCAL

SYSTEM

9S

@

@

4

Test

the

COIls

for

shorts

by

unsoldermg

the

connectIons

of

each

coIl

and

repeatlng

the

test

given

m

step

3

If

a

defectIve

coil

IS

found

It

must

be

replaced

BRUSHES

AND

BRUSH

LEAD

WIRE

1

Check

condItIon

of

the

brush

contact

surface

and

general

wear

of

the

brush

If

the

brush

is

worn

to

under

02362

In

60mm

m

length

replace

It

Inspect

all

connectIons

carefully

for

looseness

or

cracks

Replace

or

reparr

as

re

qUIred

2

Check

the

connectIon

of

the

lead

clIp

and

WIre

3

Check

brush

holders

and

sprmg

clIps

for

damage

Replace

1f

they

will

not

hold

the

brushes

agaInst

the

commutator

properly

Clean

all

brushes

aIld

brush

holders

thoroughly

4

Check

brush

sprmg

tenSIon

WIth

a

spnng

scale

as

shown

m

Figure

14

The

reading

should

be

1

76

Ibs

0

8

kg

Replace

the

spnng

if

the

tenSIon

IS

under

1

54

Ibs

0

7

kg

@

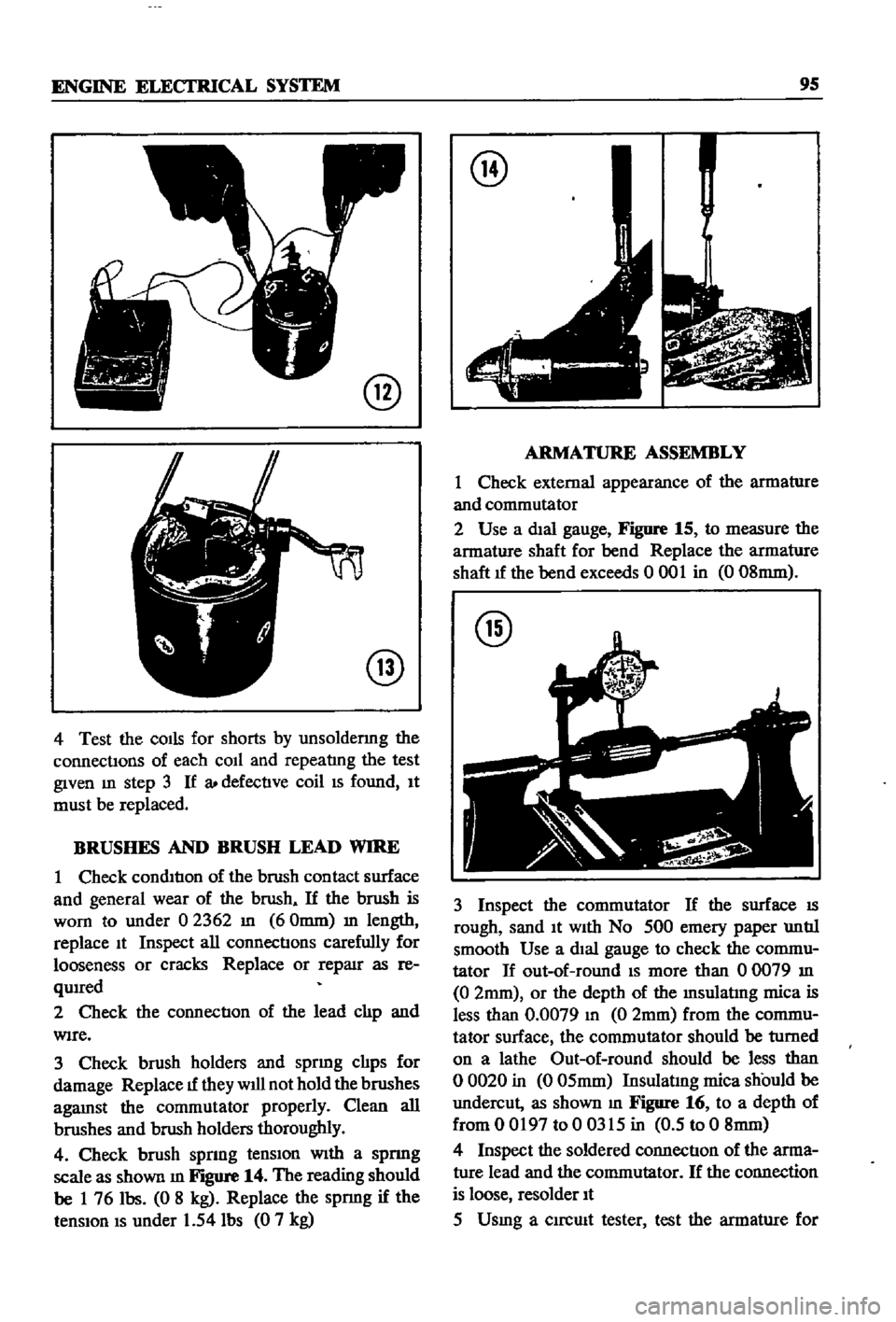

ARMATURE

ASSEMBLY

1

Check

external

appearance

of

the

armature

and

commutator

2

Use

a

dIal

gauge

Figure

15

to

measure

the

armature

shaft

for

bend

Replace

the

armature

shaft

1f

the

bend

exceeds

0

001

in

0

08mm

@

3

Inspect

the

commutator

If

the

surface

IS

rough

sand

It

With

No

500

emery

paper

untIl

smooth

Use

a

dIal

gauge

to

check

the

commu

tator

If

out

of

round

IS

more

than

00079

In

0

2mm

or

the

depth

of

the

Insulatlng

mica

is

less

than

0

0079

In

0

2mm

from

the

commu

tator

surface

the

commutator

should

be

turned

on

a

lathe

Out

of

round

should

be

less

than

o

0020

in

0

05mm

Insulatmg

mica

should

be

undercut

as

shown

m

Figure

16

to

a

depth

of

from

0

0197

to

0

0315

in

0

5

to

0

8mm

4

Inspect

the

soldered

connectIon

of

the

arma

ture

lead

and

the

commutator

If

the

connection

is

loose

resolder

It

5

Usmg

a

clrcmt

tester

test

the

armature

for

Page 102 of 252

ENGINE

ELECI

RlCAL

SYSTEM

97

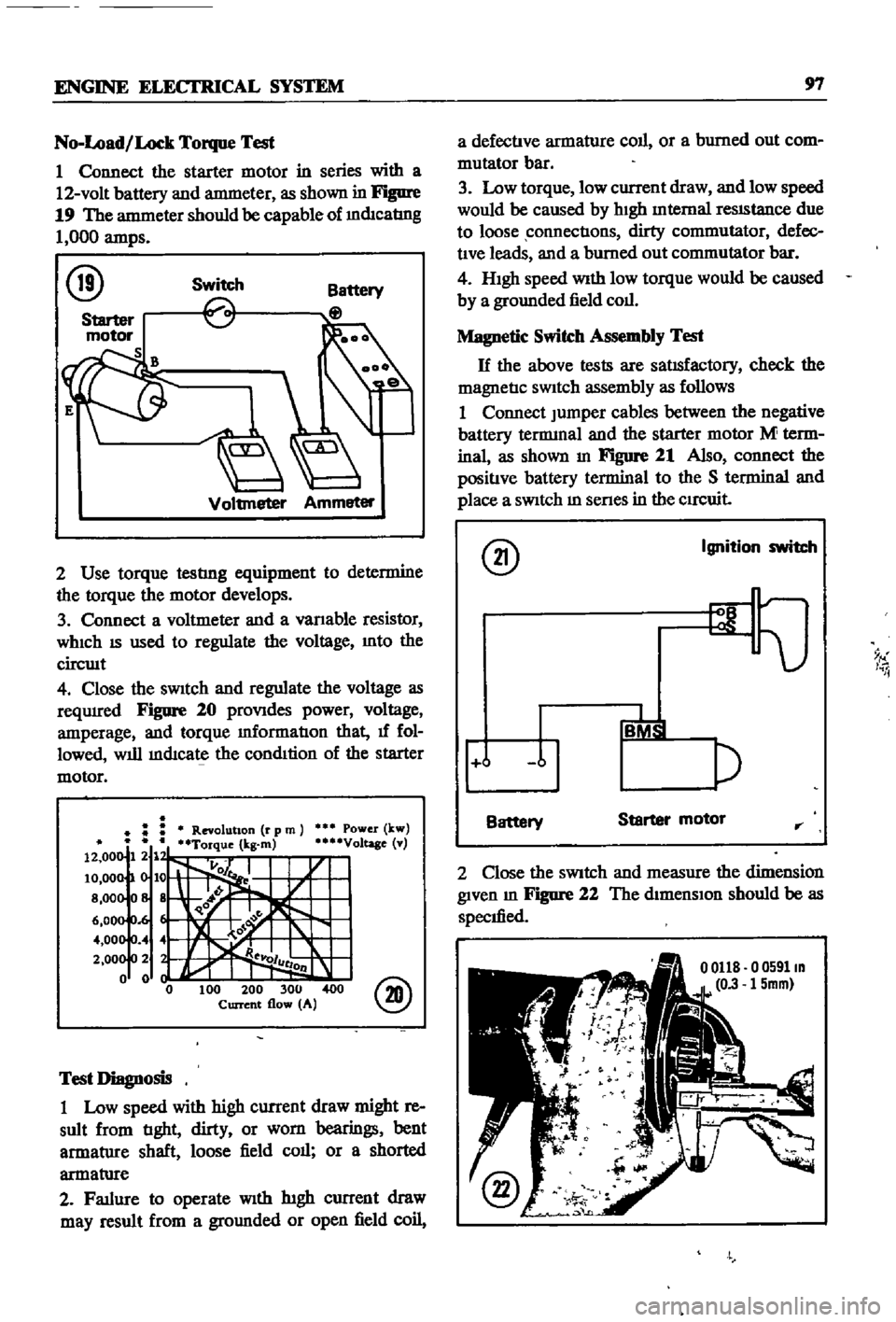

No

Load

Lock

Torque

Test

1

Connect

the

starter

motor

in

series

with

a

12

volt

battery

and

antmeter

as

shown

in

Figure

19

The

antmeter

should

be

capable

of

mdIcatIng

1

000

amps

@

Switch

Voltmeter

Ammeter

2

Use

torque

testlng

equipment

to

determine

the

torque

the

motor

develops

3

Connect

a

voltmeter

and

a

vanable

resistor

WhICh

IS

used

to

regulate

the

voltage

Into

the

circwt

4

Close

the

sWitch

and

regulate

the

voltage

as

reqUIred

Figure

20

proVIdes

power

voltage

amperage

and

torque

mformatIon

that

1f

fol

lowed

will

mdIcate

the

condItion

of

the

starter

motor

Power

kw

Voltage

v

@

Test

Diagnosis

1

Low

speed

with

high

current

draw

might

re

sult

from

tIght

dirty

or

worn

bearings

bent

armatlIre

shaft

loose

field

call

or

a

shorted

armatlIre

2

Fatlure

to

operate

With

htgh

current

draw

may

result

from

a

gromlded

or

open

field

coil

a

defectIve

armature

coll

or

a

burned

out

com

mutator

bar

3

Low

torque

low

current

draw

and

low

speed

would

be

caused

by

hIgh

Internal

reSIStance

due

to

loose

connectIons

dirty

commutator

defec

tIve

leads

and

a

burned

out

commutator

bar

4

HIgh

speed

With

low

torque

would

be

caused

by

a

grounded

field

coll

Magnetic

Switch

Assembly

Test

H

the

above

tests

are

satIsfactory

check

the

magnetIc

SWitch

assembly

as

follows

1

Connect

Jumper

cables

between

the

negative

battery

tennmal

and

the

starter

motor

M

term

inal

as

shown

In

Figure

21

Also

connect

the

positIve

battery

terminal

to

the

S

terminal

and

place

a

SWitch

m

senes

in

the

CIrCuit

@

Ignition

switch

9

I

i

j

Battery

Starter

motor

rr

2

Close

the

SWitch

and

measure

the

dimension

given

m

Figure

22

The

dimensIon

should

be

as

specIfied

o

0591m

15mm

Page 104 of 252

ENGINE

ELECfRlCAL

SYSTEM

99

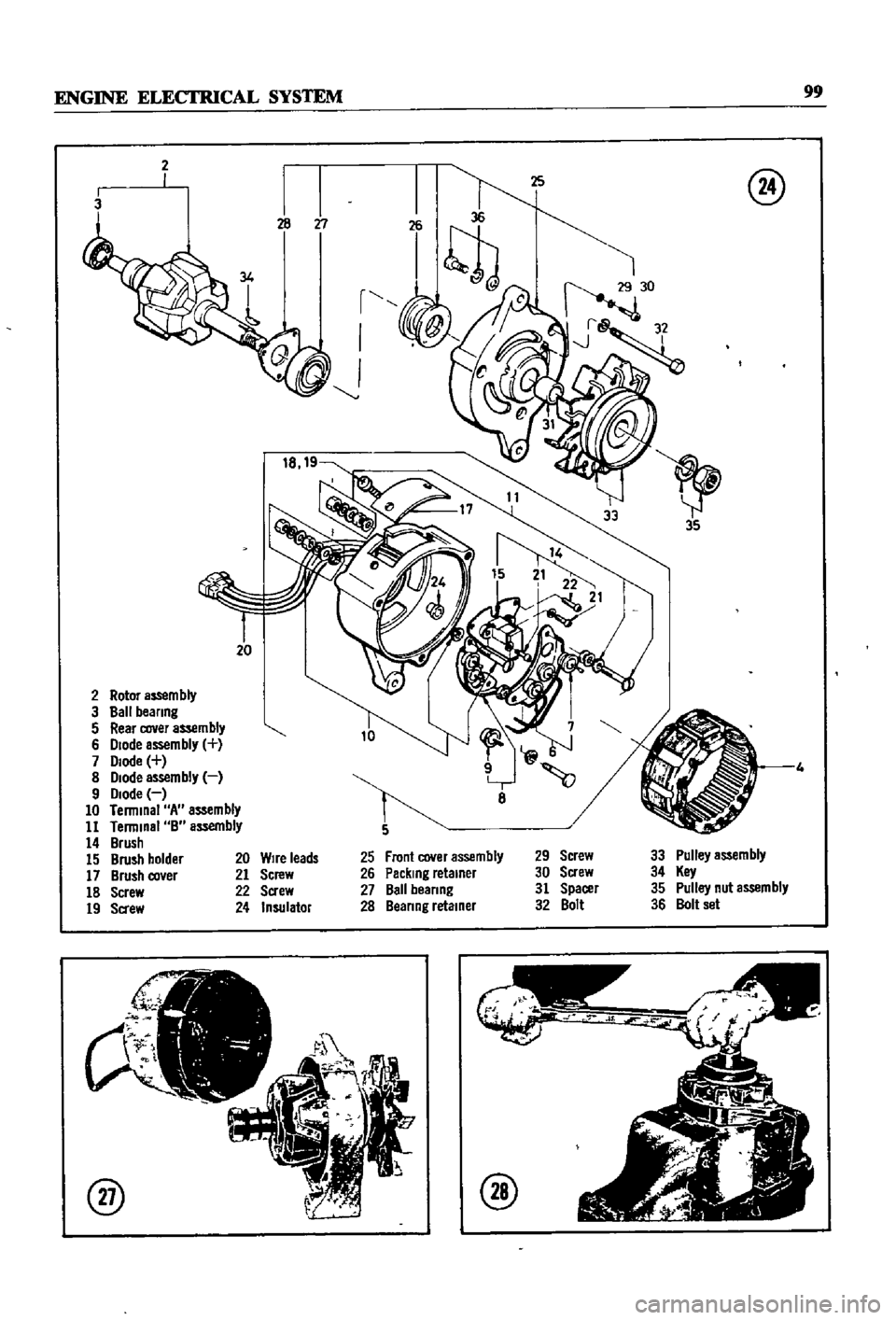

2

3

r

I

J

20

2

Rotor

aS5em

bly

3

Ball

beanng

5

Rear

cover

assembly

6

Diode

assembly

7

Diode

8

Diode

assembly

9

Diode

10

Terminal

A

assembly

11

Terminal

B

assembly

14

Brush

15

Brush

holder

17

Brush

co

er

18

Screw

19

Sa

ew

@

8

Front

cover

assembly

Packing

retainer

Ball

beanng

Beanng

retainer

29

Screw

30

Screw

31

Spacer

32

Bolt

33

Pulley

assembly

34

Key

35

Pulley

nut

assembly

36

Bolt

set

20

Wire

leads

21

Screw

22

Screw

24

Insulator

@

@